Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Clear border" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

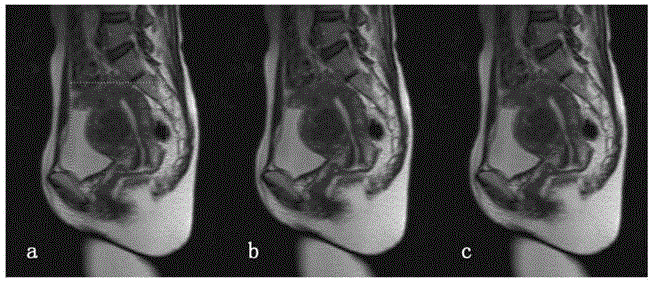

Construction method and device of three-dimensional model, image monitoring method and device

InactiveCN105078514APrecise registrationEnable mobilityImage analysisOrgan movement/changes detectionDimensional modelingComputer vision

Owner:CHONGQING HAIFU (HIFU) TECHNOLOGY CO LTD

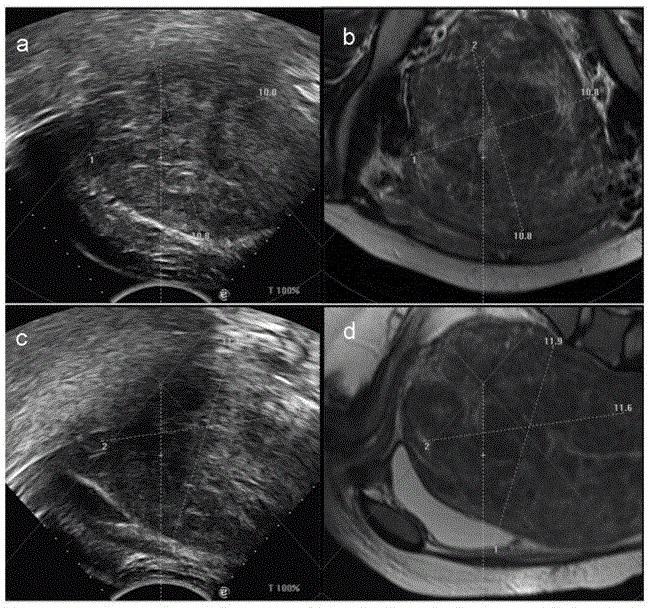

Frame correlation processing method and system in spatial compound imaging

ActiveCN101866480AAvoid Image Information ClutterAvoid confusionUltrasonic/sonic/infrasonic diagnosticsImage enhancementCompound imagingDeflection angle

The invention discloses a frame correlation processing method and a system in spatial compound imaging. The system comprises a same-angle frame correlation processor and a frame correlation coefficient calculator, wherein the same-angle frame correlation processor is used for receiving component images output by a B signal preprocessor, conducting frame correlation processing to the component images with the same deflection angle, and outputting results obtained after frame correlation processing to a spatial compound image processor; and the frame correlation coefficient calculator is used for calculating frame correlation coefficients during frame correlation processing according to the relevant parameters of a spatial compound imaging controller, and outputting results to the same-angle frame correlation processor. Aiming at the defects of a simple image processing method of using spatial compounding in combination with frame correlation, the frame correlation processing is put ahead of the spatial compounding, the same-angle frame correlation processing is adopted, the same-extent de-noising processing is conducted to different-angle information in advance before the spatial compounding and then the different-angle information is superimposed together, thereby avoiding image information disorder and not causing obvious boundaries in different areas of the images.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

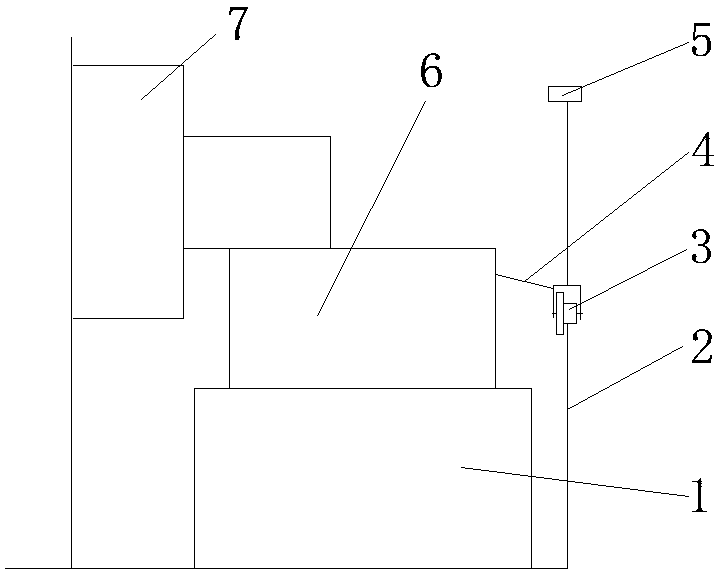

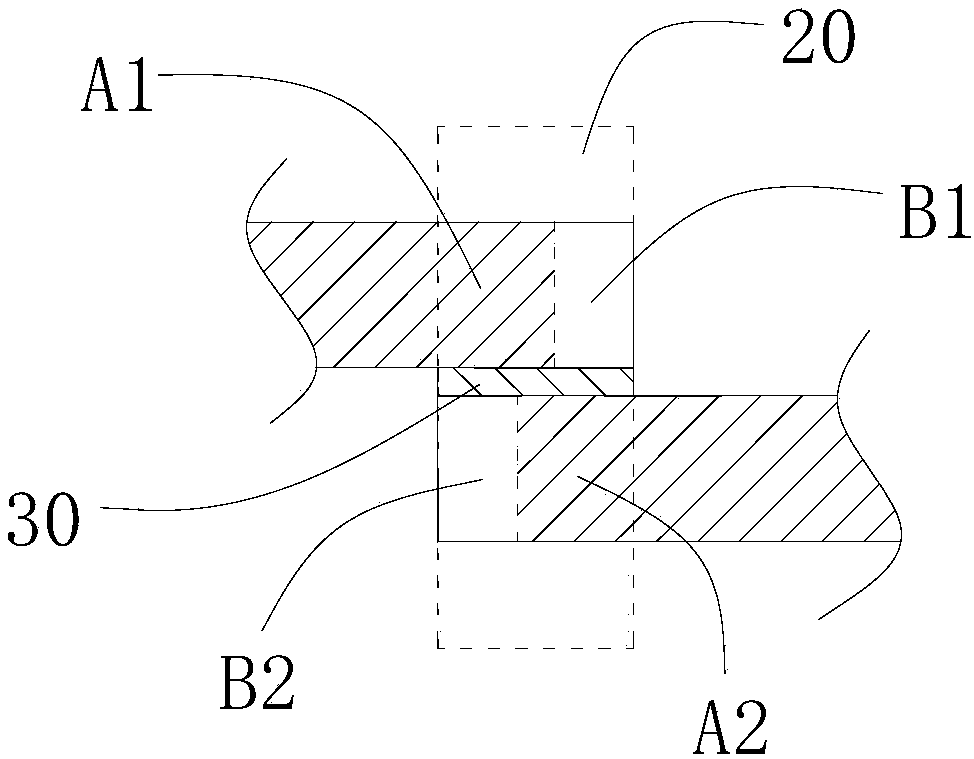

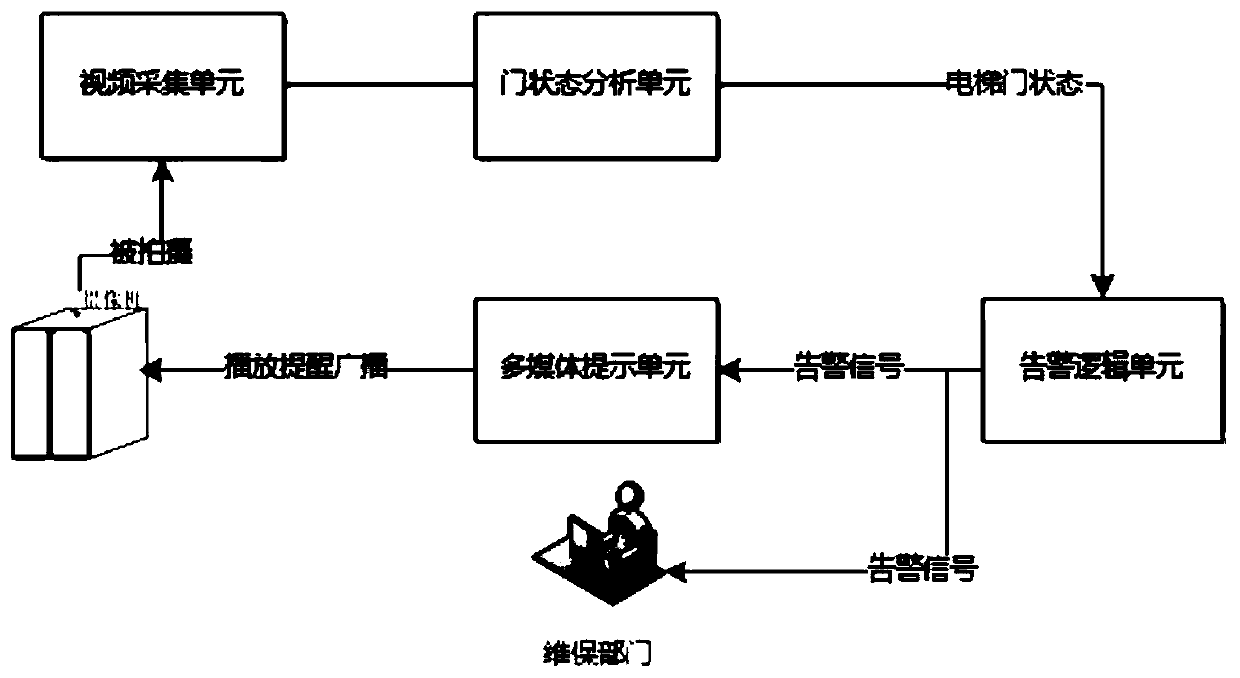

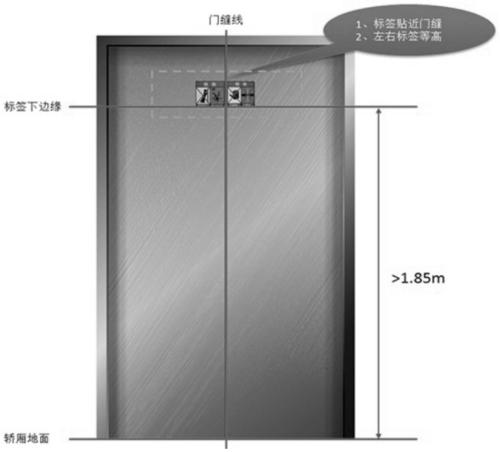

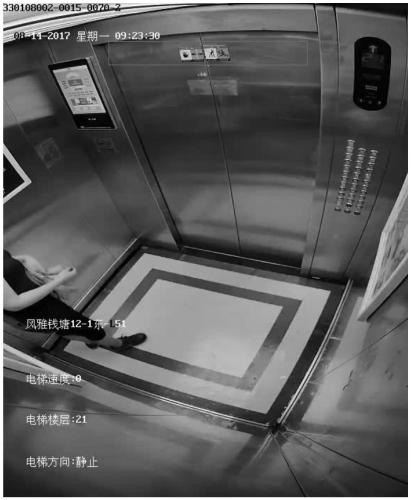

Detection system and method for elevator door shielding behavior based on video analysis

ActiveCN107915102AAvoid interferenceClear borderCharacter and pattern recognitionElevatorsSimulationReliability engineering

The invention provides a detection system for the elevator door shielding behavior based on video analysis. The detection system comprises a video collection unit, a door state analyzing unit, an alarm logistic unit and a multimedia prompting unit. The invention further provides a detection method for the elevator door shielding behavior based on video analysis, and the above system is adopted inthe detection method. The detection method includes the steps that a marker is stuck; information of the marker position on an elevator door is collected; the state of the elevator door is analyzed and judged; whether the door shielding behavior exists or not is judged; and a reminding broadcast is played. By means of the detection system and the detection method, an area collection manner is adopted, in addition, the set collecting area is calibrated in a tag manner so that the collecting boundary can be more obvious and is more accurate compared with the background, interference of the edgeof the elevator door and background shielding objects is avoided, and the detection accuracy is improved.

Owner:ZHEJIANG NEW ZAILING TECH CO LTD

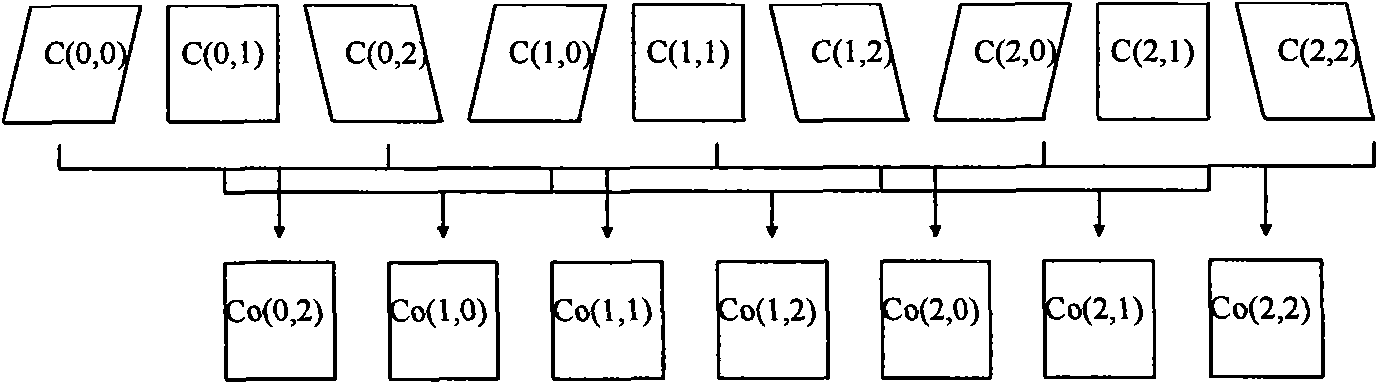

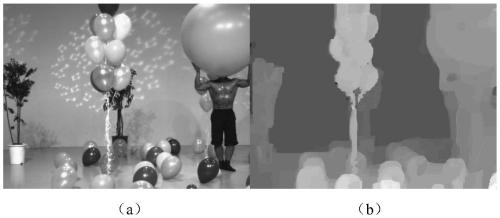

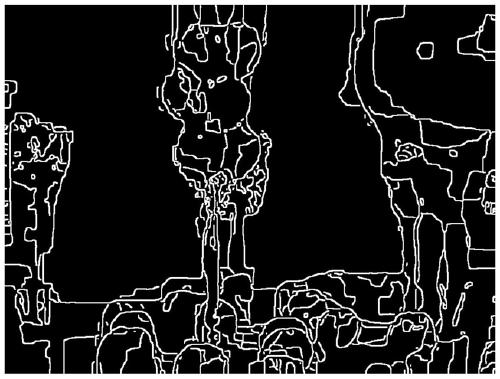

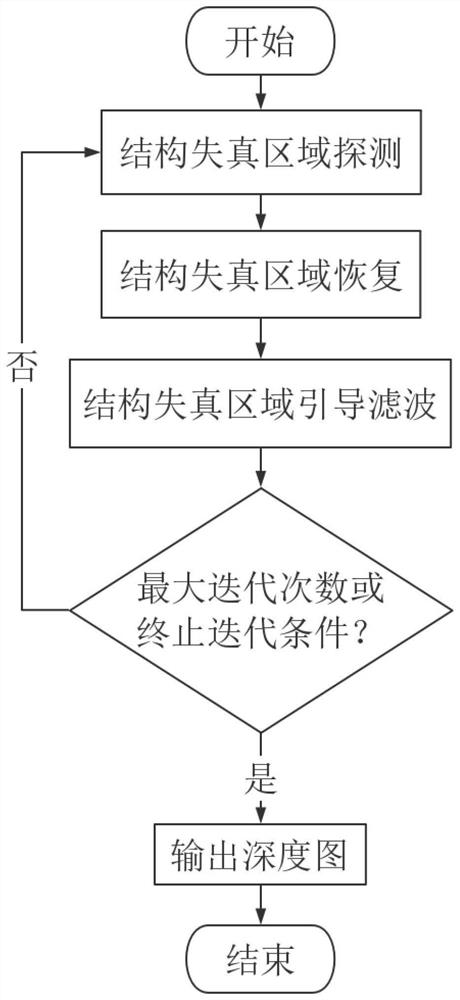

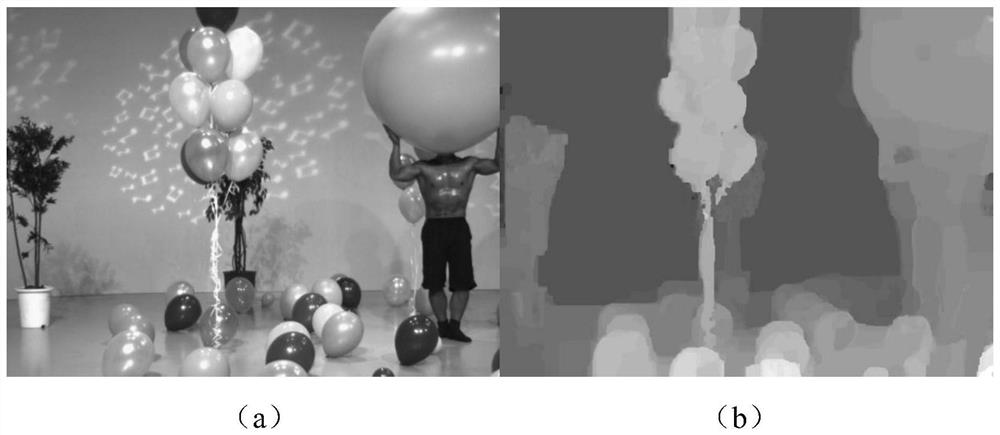

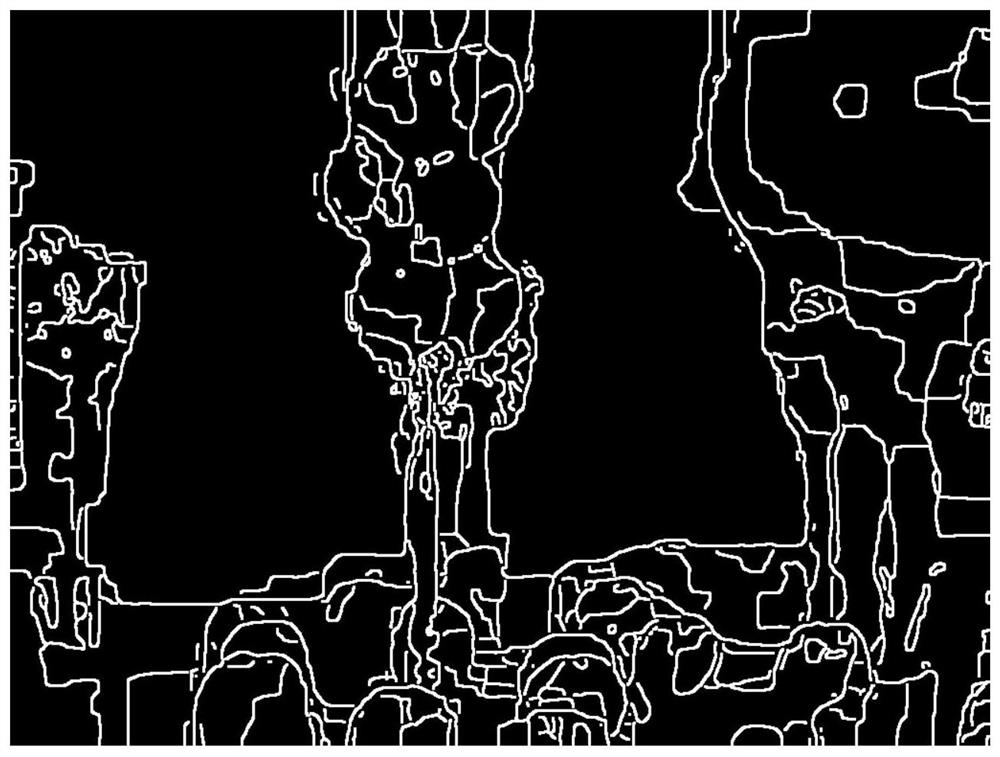

Iterative depth map structure restoration method for SSIM structural similarity based on RGB-D

The invention discloses an iterative depth map structure restoration method for SSIM structural similarity based on RGB-D. The method includes: firstly, detecting the edge of an input depth map; and expanding the edge, marking the expanded area as a potential structure distortion area; judging whether each pixel point in the potential structure distortion area is distorted or not; generating a structural distortion measurement index; and enabling distortion pixel points to construct a recovery weight by adopting a product of a color image Gaussian weight and a structural distortion measurementindex, carrying out guide recovery through weighted median filtering, then carrying out guide filtering on a distortion region, continuously carrying out iteration on a finished result image according to the steps until a set iteration termination condition is met, and outputting a depth image to finish calculation. According to the method, iterative detection and recovery are carried out on thestructure distortion area of the depth map, so that relatively accurate structure information is obtained, denoising and edge preserving are carried out on the undistorted area of the structure, and finally, the depth map with a clear structure and a smooth depth value can be obtained.

Owner:XI AN JIAOTONG UNIV

Irreversible thermo-sensitive type aquogel and preparation method thereof

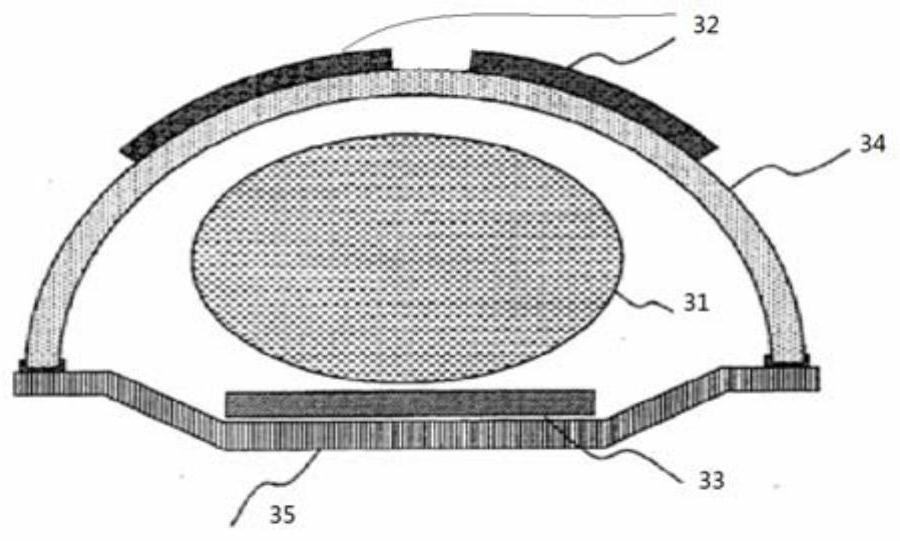

The invention provides irreversible thermo-sensitive type aquogel and a preparation method thereof and belongs to the technical field of aquogel. The irreversible thermo-sensitive type aquogel is nontoxic, wide in application range, long in storage time (over one year), stable in heat discoloration region, clear in boundary, strong in repeatability, simple in preparation process and suitable for large-scale production; and the denaturation temperature can be up to about 60-65 DEG C. The irreversible thermo-sensitive type aquogel provided by the invention contains the following components in percentage by weight: 2-10% of polyvinyl alcohol, 5-40% of temperature sensitive indicator, 10-67.5% of polyhydric alcohol antifreeze agent and 25-60% of water. The preparation method of the irreversible thermo-sensitive type aquogel provided by the invention comprises the steps of freezing and unfreezing to prepare the irreversible thermo-sensitive type aquogel. The irreversible thermo-sensitive type aquogel can be applied to the medical fields including thermal therapy and thermal ablation medical fields such as a focused ultrasound therapy technology and a neoplasms / radiotherapy.

Owner:CHONGQING HAIFU MEDICAL TECH CO LTD

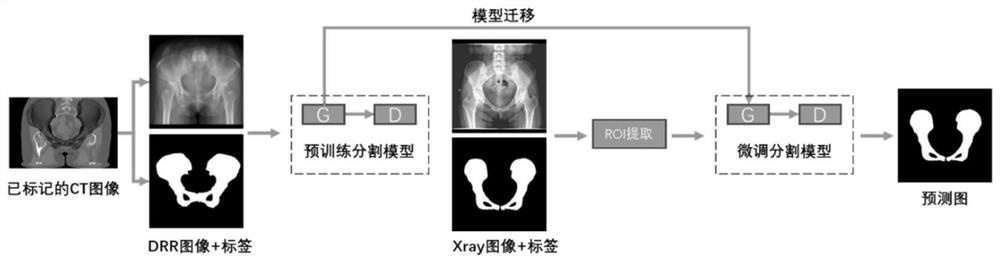

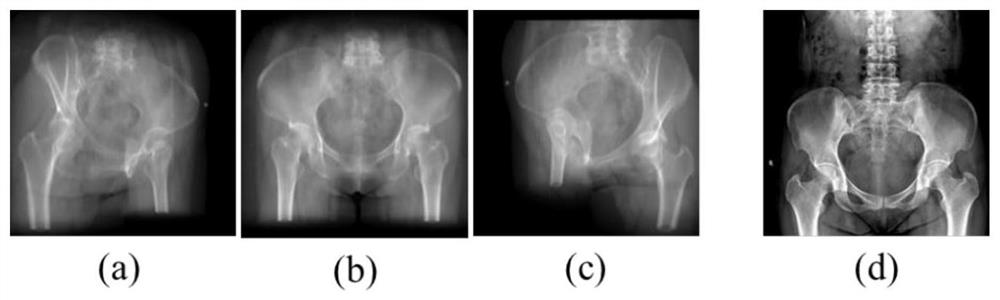

Hip joint segmentation model building method using small sample image training and application thereof

PendingCN112634283AClear borderSolve problemsImage enhancementImage analysisPattern recognitionData set

The invention discloses a hip joint segmentation model building method using small sample image training and application thereof, and belongs to the medical image processing field. The method comprises the following steps: projecting small sample CT data marked with a hip joint area from different angles through a digital reconstruction radiographic image method to obtain a lot of analog images with marks; forming a pre-training data set by the analog image and the hip joint area marked in the analog image; establishing a segmentation model for performing image segmentation on the input image to extract a hip joint area, and pre-training the segmentation model by using the pre-training data set; and constructing a training data set by using the small sample Xray image marked with the hip joint area, training the pre-trained segmentation model to finely adjust the segmentation model, and taking the segmentation model as the established hip joint segmentation model after the training is finished. The technical problem that an existing hip joint segmentation method is poor in segmentation result due to the fact that the existing hip joint segmentation method depends on a large amount of annotation data can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

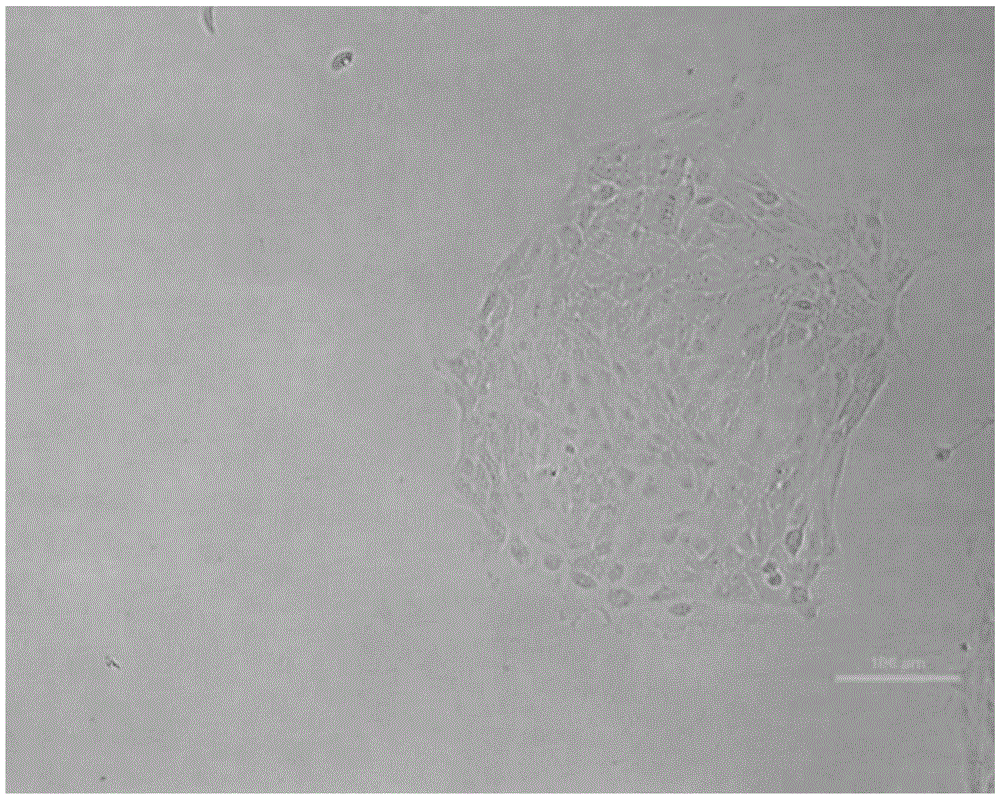

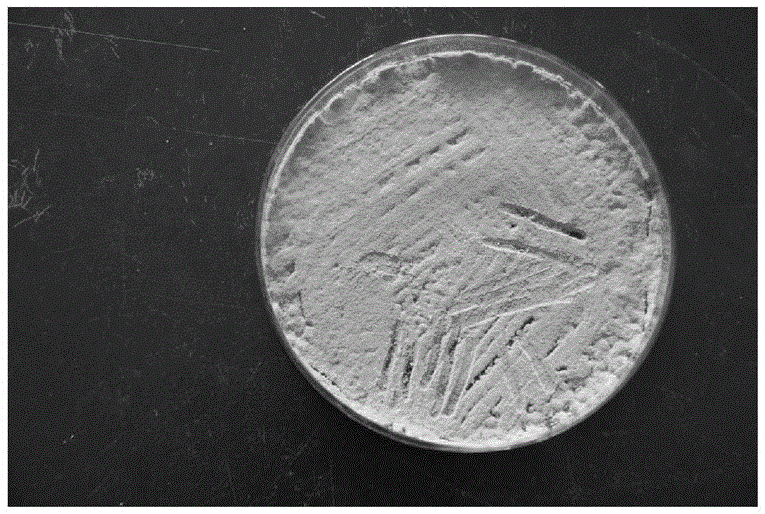

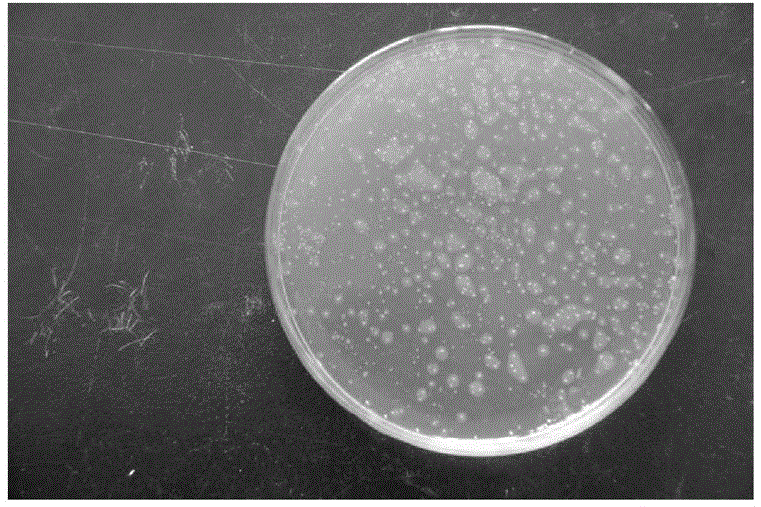

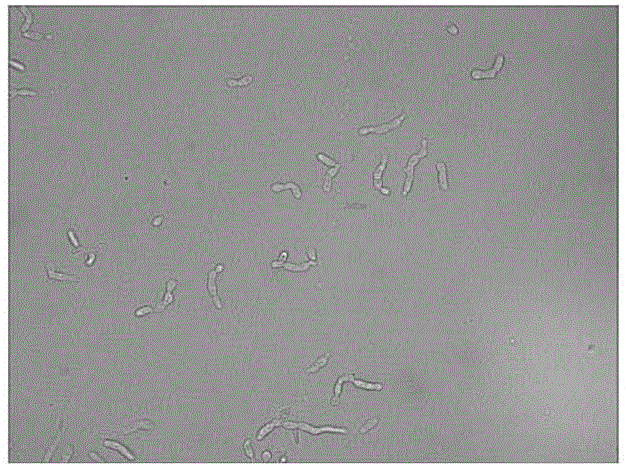

Immortalized piglet oral mucosa epithelial cell line and establishment method and application thereof

InactiveCN105483089AUniform shapeClear borderGenetically modified cellsEpidermal cells/skin cellsPrimary cellCulture mediums

The invention discloses an immortalized piglet oral mucosa epithelial cell line and an establishment method and application thereof. The establishment method comprises the following steps: carrying out primary culture of piglet oral mucosa epithelial cells; extracting and purifying eukaryotic expression plasmids pCI-neo-hTERT containing hTERT genes; replacing the culture medium of the cells 24 hours after the cells are transfected with the eukaryotic expression plasmids pCI-neo-hTERT; after 48 hours, adding a DMEM / F12 culture medium containing 500 mu g / ml of G418 for screening; marking positive clones under a high power lens, and transferring into a culture plate for culture; carrying out enlarged culture; screening for 1 month and not adding G418 into the culture medium any more, so that the cells obtained after culturing for over 50 generations are the immortalized cell line. The immortalized piglet oral mucosa epithelial primary cells are consistent and uniform in morphology.

Owner:张彦明

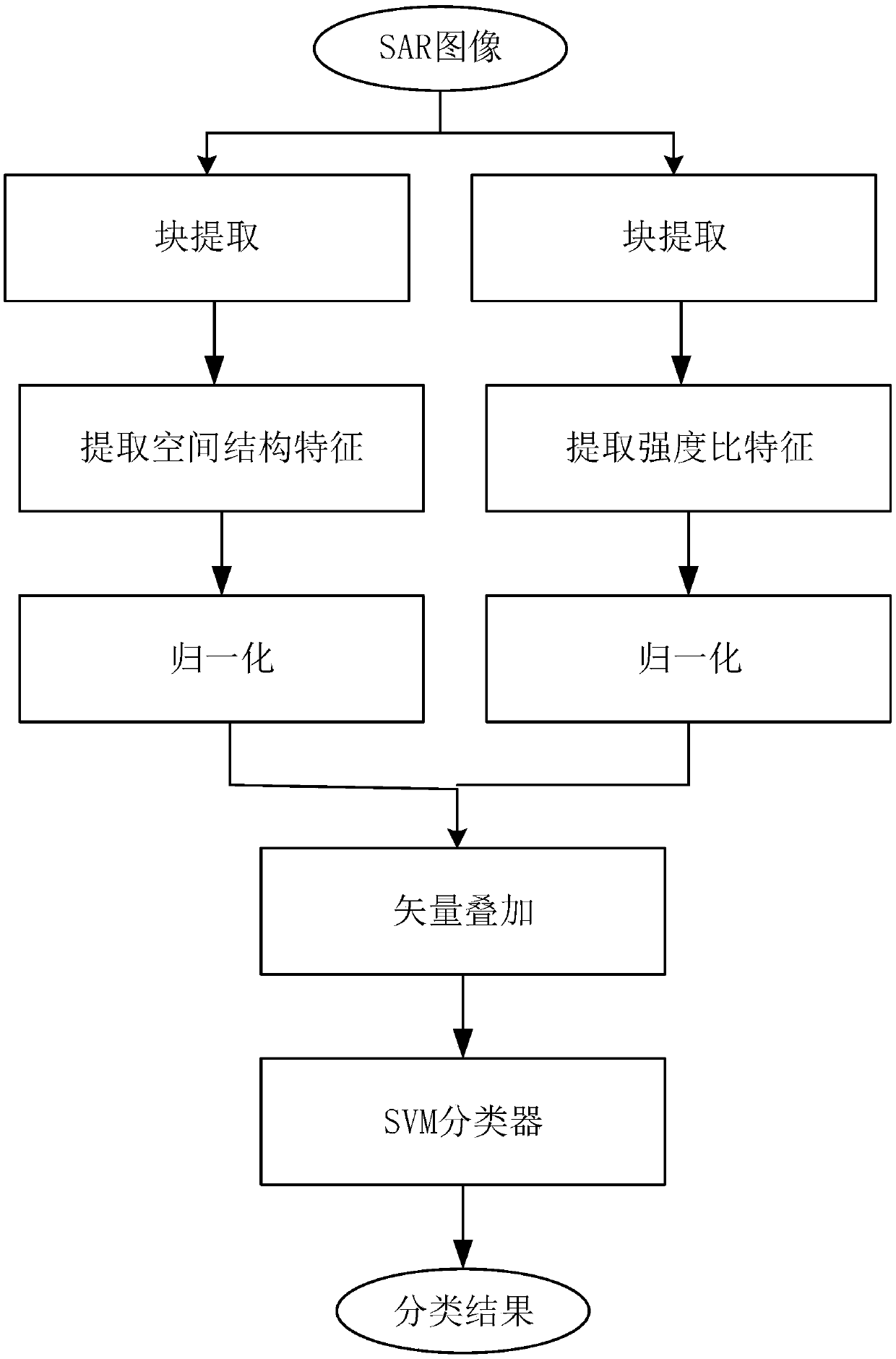

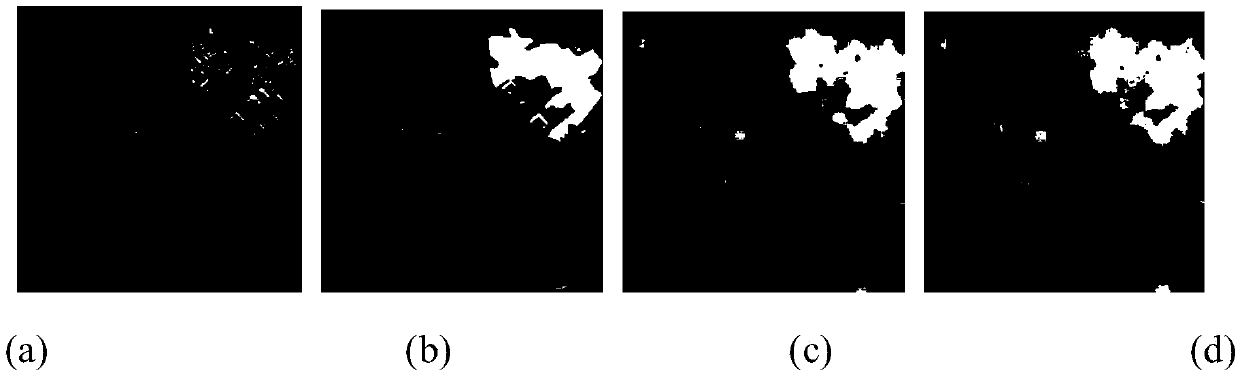

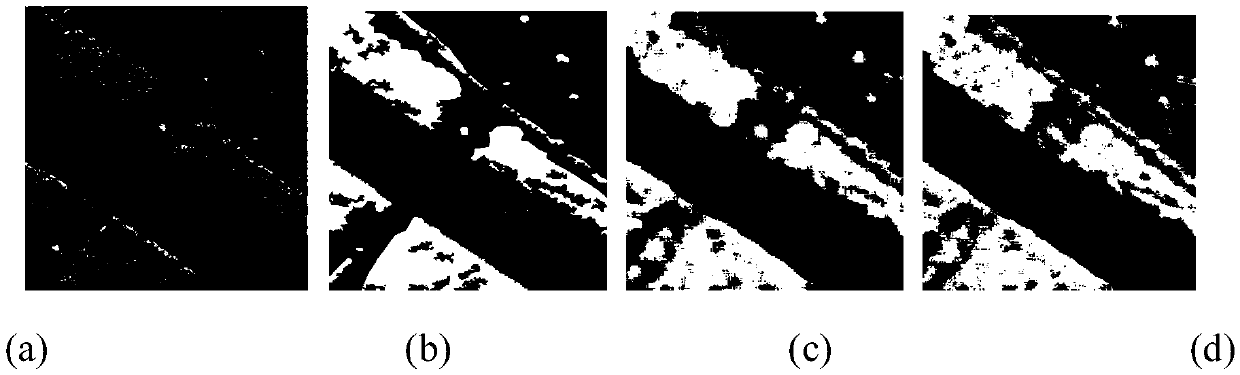

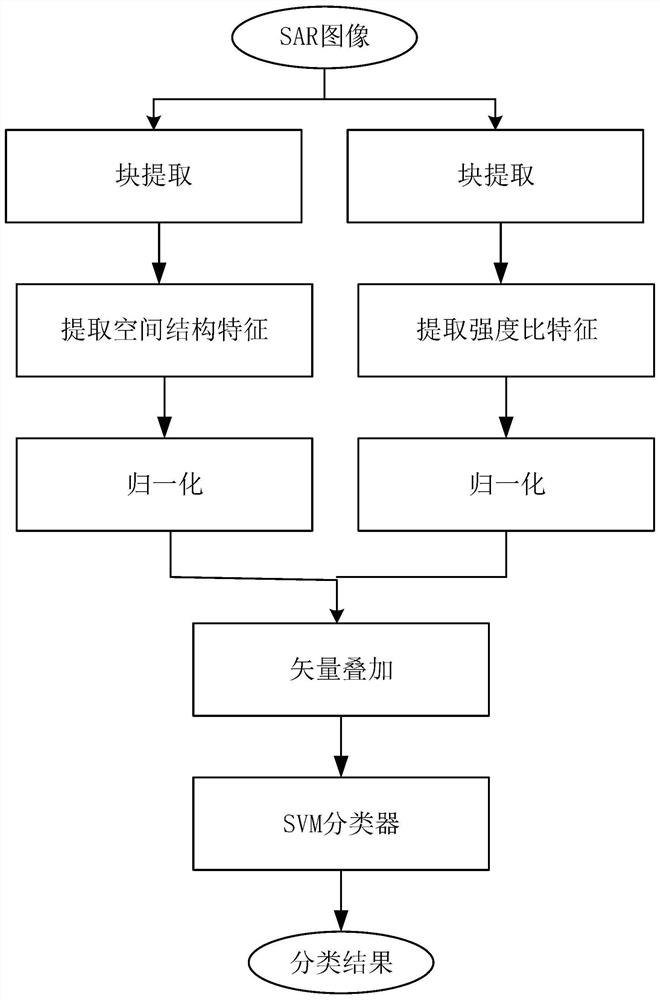

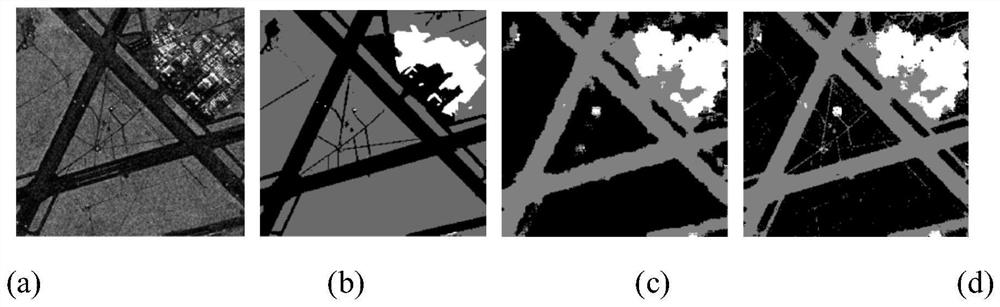

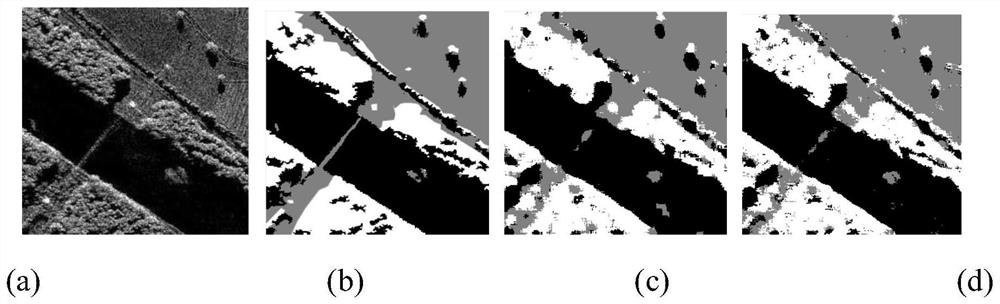

A high-resolution SAR image classification method based on intensity ratio and spatial structure feature extraction

ActiveCN109635789APreserve edge informationIntegrity guaranteedScene recognitionMirror reflectionSpatial structure

The invention discloses a high-resolution SAR (Synthetic Aperture Radar) image classification method based on intensity ratio and spatial structure feature extraction. The method comprises the following steps: performing mirror reflection on a classified SAR image around a boundary to perform boundary expansion; Carrying out block extraction on the extended SAR image; Calculating spatial structurecharacteristics of the block; Performing boundary expansion on the original SAR image again to extract blocks; Calculating an intensity ratio characteristic coefficient of the block; Carrying out vector superposition on the intensity ratio characteristics and the spatial structure information characteristics; Selecting a part of sample points and putting the sample points into an SVM classifier to train a model; And putting the whole image into the model to obtain a final prediction label image as a final classification result image. The method has the advantages that classification is finer,boundaries are more obvious, and region extraction features are easier to be classified, and can be used for SAR image classification and target recognition.

Owner:XIDIAN UNIV

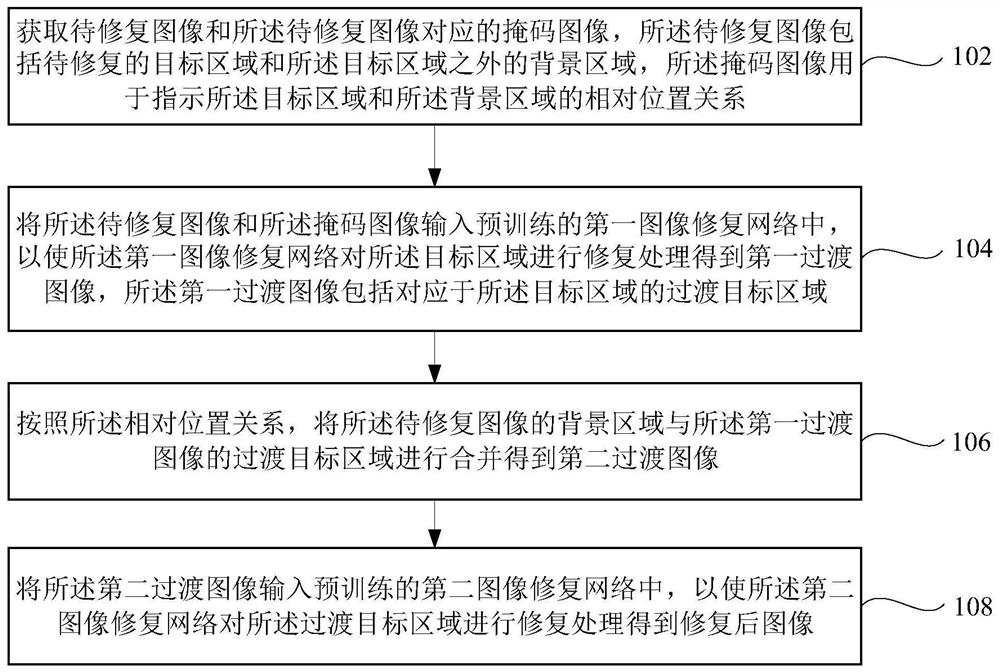

Image processing method and device, electronic equipment and storage medium

PendingCN112258404ARepair results are stableClear borderImage enhancementImage analysisImaging processingComputer graphics (images)

The invention relates to an image processing method and device, electronic equipment and a storage medium, and the method comprises the steps: obtaining a to-be-restored image and a mask image corresponding to the to-be-restored image, and the to-be-restored image comprises a background region and a to-be-restored target region; inputting the to-be-restored image and the mask image into a pre-trained first image restoration network to enable the first image restoration network to restore the target area to obtain a first transition image; according to the relative position relation, combiningthe background area of the image to be restored with the transition target area of the first transition image to obtain a second transition image; and inputting the second transition image into a pre-trained second image restoration network, so that the second image restoration network carries out restoration processing on the transition target area to obtain a restored image. According to the method, the restoration result of the missing area in the image is relatively stable, and the restoration area does not have an obvious boundary even under the condition that the background area of the image is complex, so that a relatively good restoration effect is achieved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Display assembly and electronic device

InactiveCN110764300AImprove signal transmittanceSmooth transitionTelevision system detailsColor television detailsComputer hardwareComputer graphics (images)

The embodiment of the invention provides a display assembly and an electronic device. The display assembly comprises a first display screen, a second display screen and a first driving mechanism, wherein the first display screen comprises a display layer and a backlight layer, the display layer comprises a first part and a second part, and an opening is formed in the backlight layer and is opposite to the first part; the first driving mechanism drives the second display screen to move; and when the second display screen is in a first state, the second display screen is opposite to the openingof the display layer and the first part, a user can see information displayed by the first display screen from the second part, and the user can see information displayed by the second display screenthrough the first part. When the second display screen is in a second state, the second display screen and the opening are arranged in a staggered mode, the inner side of the first part is not shielded by the second display screen and the backlight layer, signals can enter a sensor through the opening of the first part and the opening of the backlight layer, the sensor can transmit the signals through the opening and the first part, and the signal transmittance is greatly improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

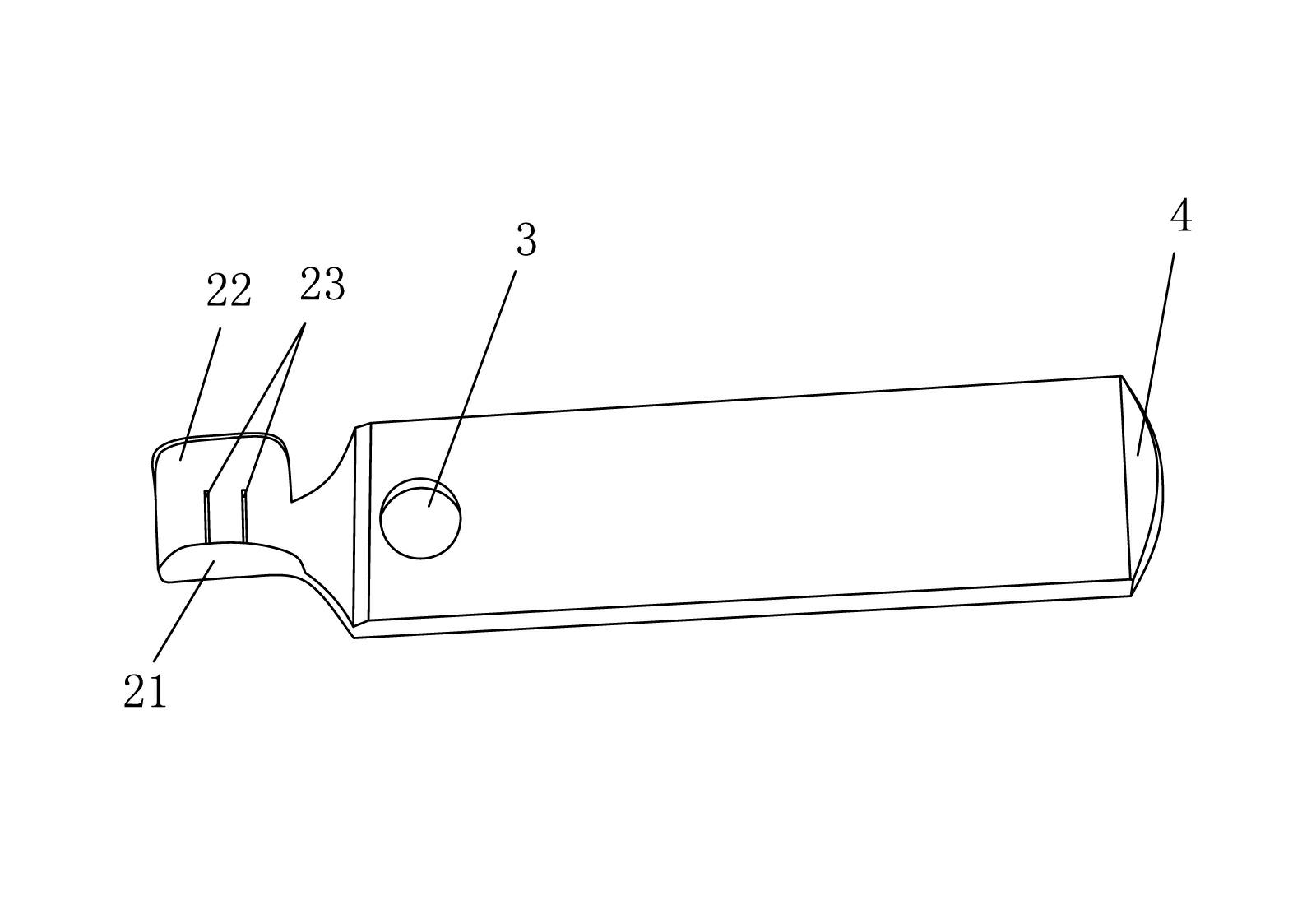

Manufacture technique for plugging sheet of attaching plug

The invention discloses a manufacture technique for a plugging sheet of an attaching plug, which comprises the steps as follows: long copper strips are formed; riveting trough positions are punched and flattened; left and right grooving cards and plugging sheet locating holes are punched and formed; anti-skid troughs are punched on the middle positions of the riveting troughs; meanwhile, inclinations are punched on the left and right grooving cards; then the left and right grooving cards are bent; meanwhile, forming treatment is implemented on the top ends of the long copper strips; then single plugging sheet is cut off; and finally the upper sides and the lower sides of the top end of the long copper strips are obliquely punched. In the technical method, metal materials do not need to be cut off, the utilization rate on the base materials for forming is high, and material wastes are reduced; meanwhile, the manufacture technique has more reasonable technique arrangement, and improves the production efficiency; moreover, the boundary effects of the products manufactured through the manufacture technique are ideal compared with the boundary effects of the products obtained through a commonly-used manufacture technique which manufactures a plurality of plugging sheets of an attaching plug in parallel.

Owner:苏辉

Light-cured resin and application thereof

The invention discloses a light-cured resin and application thereof. The light-cured resin is prepared from the following components in percentage by mass: 4.6 to 10.8 percent of ethyl methacrylate, 4.6 to 9.2 percent of ethyl acetate, 80 to 90 percent of polyurethane acrylate, and 0.1 to 0.6 percent of benzophenone-1. The light-cured resin provided by the invention is cheap in raw materials, convenient to acquire, easy to store, poisonless and harmless to a human body, good in permeability when dripping on fiber, rapid and controllable in film formation, firm, ductile, easy to cut into slices, high in success rate, clear and distinguishable in sliced fiber cross section, less in fiber extrusion, high in fiber dispersion degree, clear in boundary and middle cavity, obvious in characteristics, and easy to distinguish.

Owner:INSPECTION AND QUARANTINE TECHNOLOGY CENTER ZHONGSHAN ENTRY EXIT INSPECTION AND QUARANTINE

Coal mining machine video analyzing and controlling system

PendingCN107725050AClear borderFully automatedImage enhancementImage analysisMining engineeringControl system

The invention relates to a video analyzing system, in particular a coal mining machine video analyzing and controlling system. The coal mining machine video analyzing and controlling system comprisesa scraper conveyer, a coal mining machine, and a spill-plate. The system is characterized in that a track trolley is installed on the spill-plate; a coal recognition device is installed on the track trolley, and the track trolley is connected to the coal mining machine through a connection rod. The images collected by a camera are processed by image analyzing software to determine the boundary between a coal bed and rocks, the vertical movement of the coal mining roller of the coal mining machine is controlled to avoid the rocks in the digging working surface automatically; the coal mining machine can carry out digging automatically without human supervision; the safety of coal mines is improved, and the labor strength is reduced.

Owner:NINGXIA GUANGTIANXIA ELECTRONICS TECHNOLOGY CO LTD

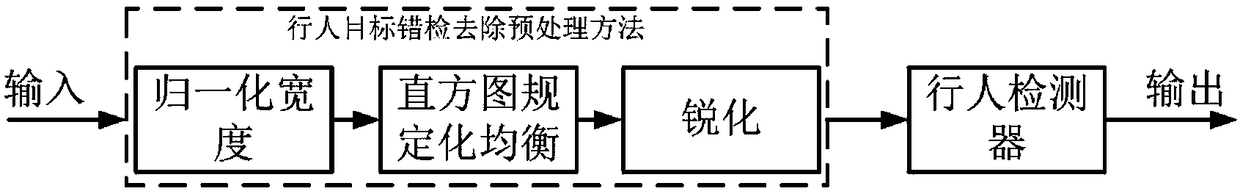

Pedestrian target false detection removal preprocessing method

ActiveCN108288041AReduce the number of targetsImprove detection accuracyCharacter and pattern recognitionPretreatment methodEqualization

The invention discloses a pedestrian target false detection removal preprocessing method, which belongs to the field of pedestrian detection preprocessing and is used for eliminating common false detection phenomena of pedestrian detection results in an image. According to the technical key points, the method comprises the steps of S1, performing normalized width processing; S2, performing histogram specification equalization processing; and S3, performing sharpening processing. The method has the effects that redundant pedestrian detection boxes appearing in a pedestrian detection process areremoved; the effectiveness of subsequent pedestrian tracking algorithm application is improved; and additional judgment and calculation consumption of a pedestrian detection system due to false detection of targets is avoided.

Owner:DALIAN NATIONALITIES UNIVERSITY

Blinn-Phong illumination enhancement algorithm based on gradient adaptation

The invention is directed to classical Binn-in direct volume rendering. The invention discloses a Phong illumination model, and provides a Blinn-based on a voxel gray value gradient. The invention discloses a Phong illumination enhancement algorithm. The method comprises the following steps of: firstly, calculating a gradient and a gradient module value of a gray value of each integrated element by using a central difference method, linearly mapping the gradient module value to a mirror surface index of the point, and then according to Binn-, calculating the gradient and the gradient module value according to a Binn-; the Phong illumination model calculates ambient light intensity, diffuse reflection light intensity, specular reflection light intensity and cumulative light intensity, thenlinearly maps the gradient modulus value of each pixel gray value to the opacity coefficient of the point, and finally gives the opacity coefficient to the cumulative light intensity to obtain the final color.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Display device

InactiveCN108594505ABorder bounds will not appearThere will be no obvious border boundariesNon-linear opticsDisplay deviceComputer science

The invention provides a display device. The display device comprises a plurality of display panels, wherein each display panel comprises a display area and a fringe area arranged on the periphery ofthe display area; every two adjacent display panels are overlapped to form an overlapped area, the fringe area of each display panel in each overlapped area is overlapped on the display area of the other display panel, the projection of the fringe area of each display panel on the other display panel is located on one side of the fringe area of the other display panel, and each fringe area is pervious to light, so that light can penetrate through the fringe area to irradiate the display area. Seamless display of display pictures of the overlapped display panel is realized.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Panel-type input device and electronic apparatus having the same

InactiveCN101446879AInhibit deteriorationReduce the inoperable areaDigital data processing detailsInput/output processes for data processingElectrical resistance and conductanceDisplay device

The present invention provides a panel-type input device having a resistive-type configuration, which can reduce an operation-impermissible area including a frame area and also can prevent a coordinate input precision from being degraded due to damage of a conductive coat. When a first electrode plate 16 is laid or superposed on a display device 52 and the panel-type input device is mounted on the display device 52, a second electrode plate 22 is exposed to perform an input operation by pressing the second electrode plate 22 with a pen or a finger, etc., in the outer peripheral portion of the input-permissible area 44 adjacent to a frame area 42. A second conductive coat 20 of the second electrode plate 22 is formed by using the conducting polymer. An electronic apparatus 50 and a casing 54 integrately comprise a frame attaching member 56 for attaching the panel-type input device 10 on the display device 52. The attaching member 56 is disposed on the outer surface 18b of the second substrate 18 of the second electrode plate 22 of the panel-type input device 10 at a location where the attaching member 56 does not overlap the input-permissible area 44.

Owner:FUJITSU COMPONENENT LTD

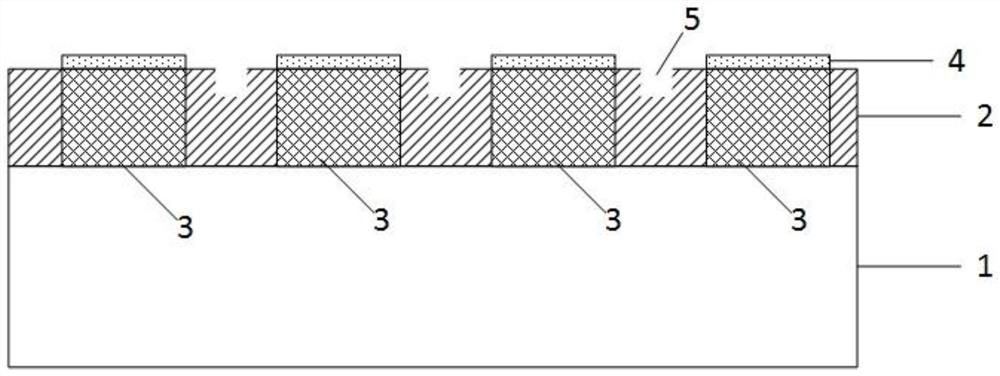

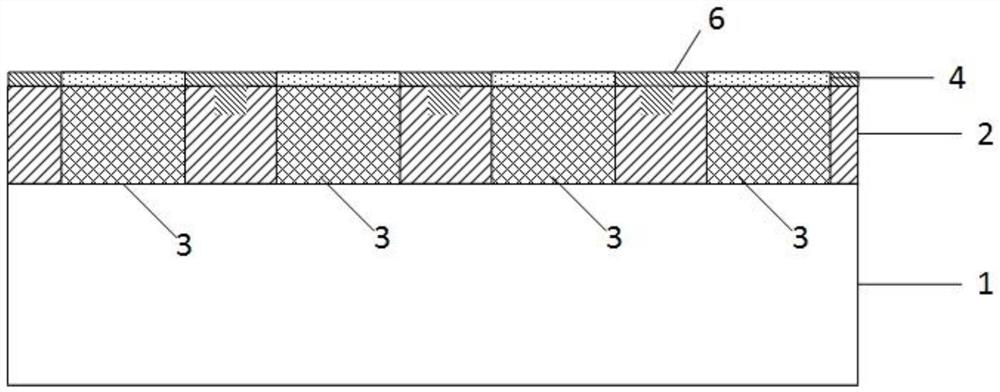

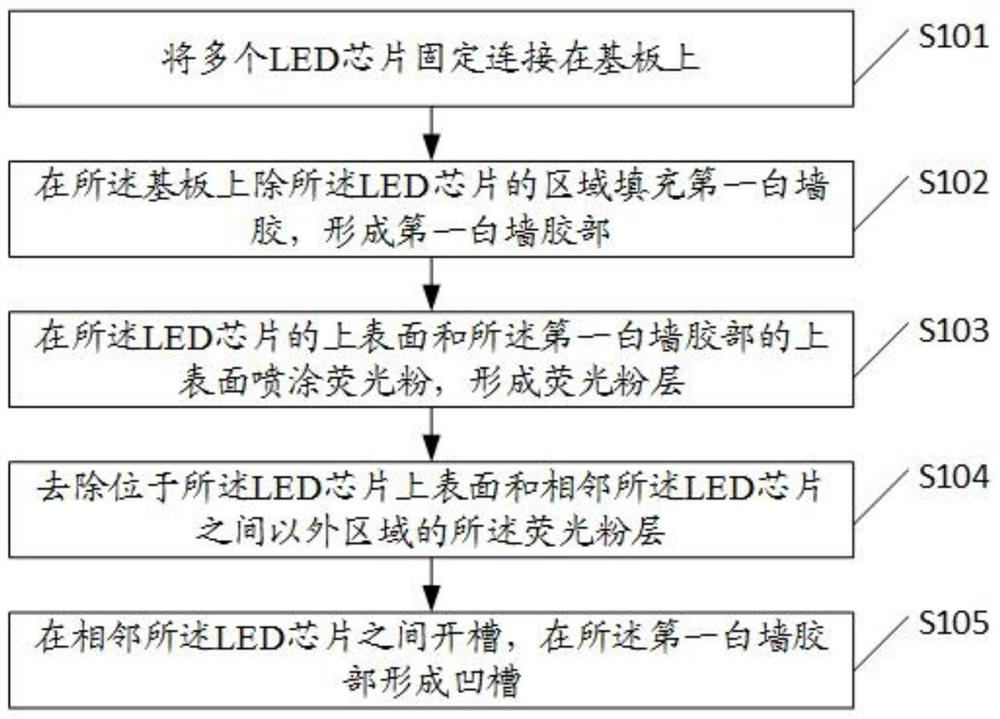

LED lamp and manufacturing method thereof

PendingCN113629176AImprove aestheticsPrevent spillageSolid-state devicesSemiconductor devicesLight spotFluorescence

The invention discloses an LED lamp. The LED lamp comprises a substrate; a plurality of LED chips which are arranged on the substrate and are electrically connected with the substrate; a fluorescent powder layer which is arranged on the upper surfaces of the LED chips; and a first white wall glue part which is arranged on the substrate and around the LED chips, and is provided with grooves distributed between the adjacent LED chips. The fluorescent powder layer is only arranged on the upper surfaces of the LED chips, so that invalid fluorescent powder areas are greatly reduced. The first white wall glue part is provided with the grooves between the adjacent LED chips, that is, there is no fluorescent powder layer between the adjacent LED chips, so that the boundaries of the light-emitting areas of the LED lamps are very obvious, and light spots are optimized. According to the LED lamp, the use of a fluorescent sheet patch is avoided, an adhesive and a steel mesh are not needed between the LED chips and the fluorescent powder layer, the manufacturing cost is reduced, the light emitting efficiency is improved, meanwhile, fluorescent glue is prevented from overflowing, and the attractiveness of the LED lamp is improved. The invention further provides a manufacturing method with the advantages.

Owner:NINGBO SUNPU OPTO SEMICON

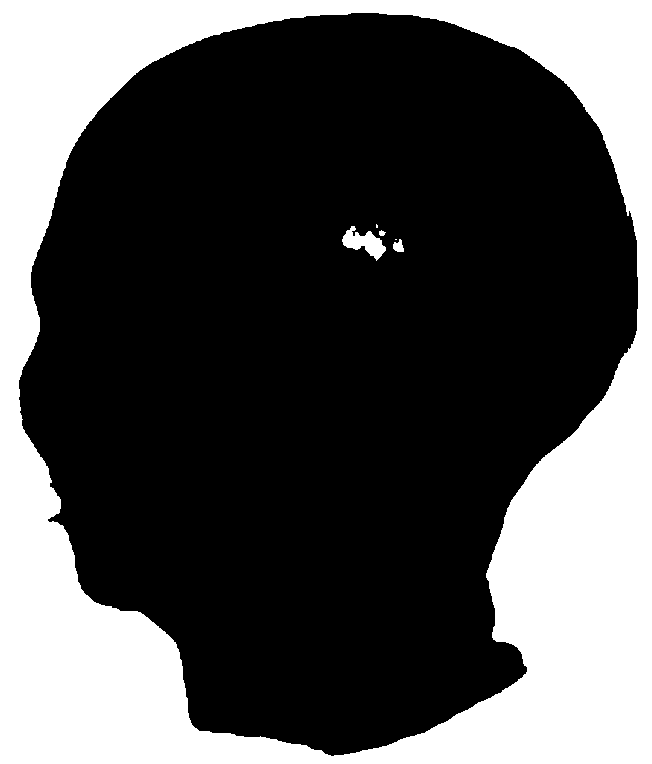

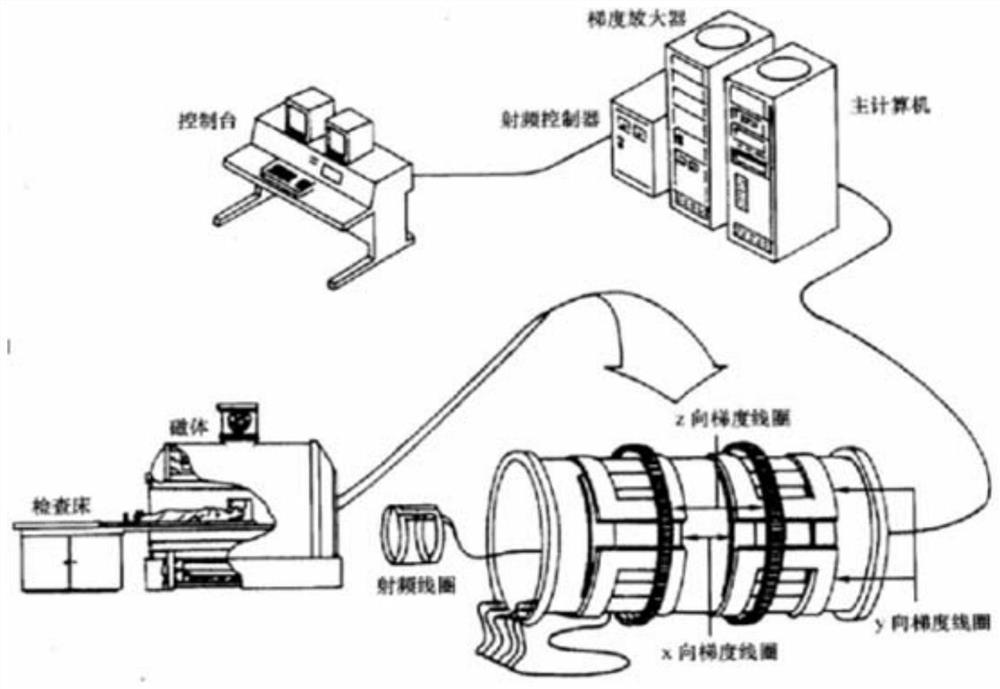

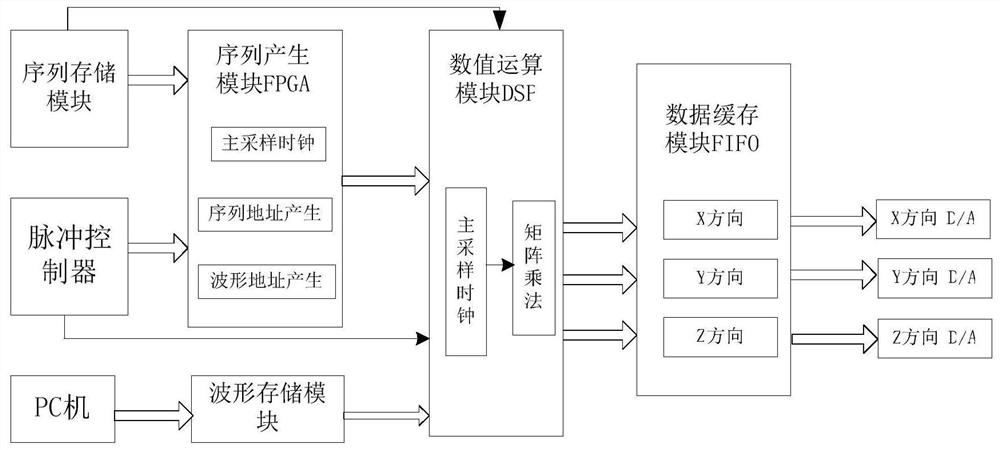

Brain MRI image segmentation method based on self-organizing mapping network for medical treatment and MRI equipment

InactiveCN111754523AClear borderImprove robustnessImage enhancementImage analysisImage segmentationBrain section

The invention relates to a brain MRI image segmentation method based on a self-organizing mapping network and MRI equipment. The method comprises the following steps: step (1), performing feature extraction on an input fused brain MRI image; (2), designing a multi-layer neural network according to the characteristics of the brain tumor image, and training the neural network by selecting a brain MRI image which is calibrated in advance; (3), sending the whole image to the trained network through each pixel, and for the feature vector of each pixel, generating a winning neuron on the first layeraccording to the minimum distance standard so as to specify a corresponding object by using the pixel; and step (4), during a merging process, in order to suppress wrong classification, requiring a merging clustering process to connect neurons belonging to normal classification after segmentation so as to segment a tumor region effectively and obtain a target image. The method can effectively jump out of local optimum, and is high in brain tumor MRI image segmentation precision and smooth in edge.

Owner:山东凯鑫宏业生物科技有限公司

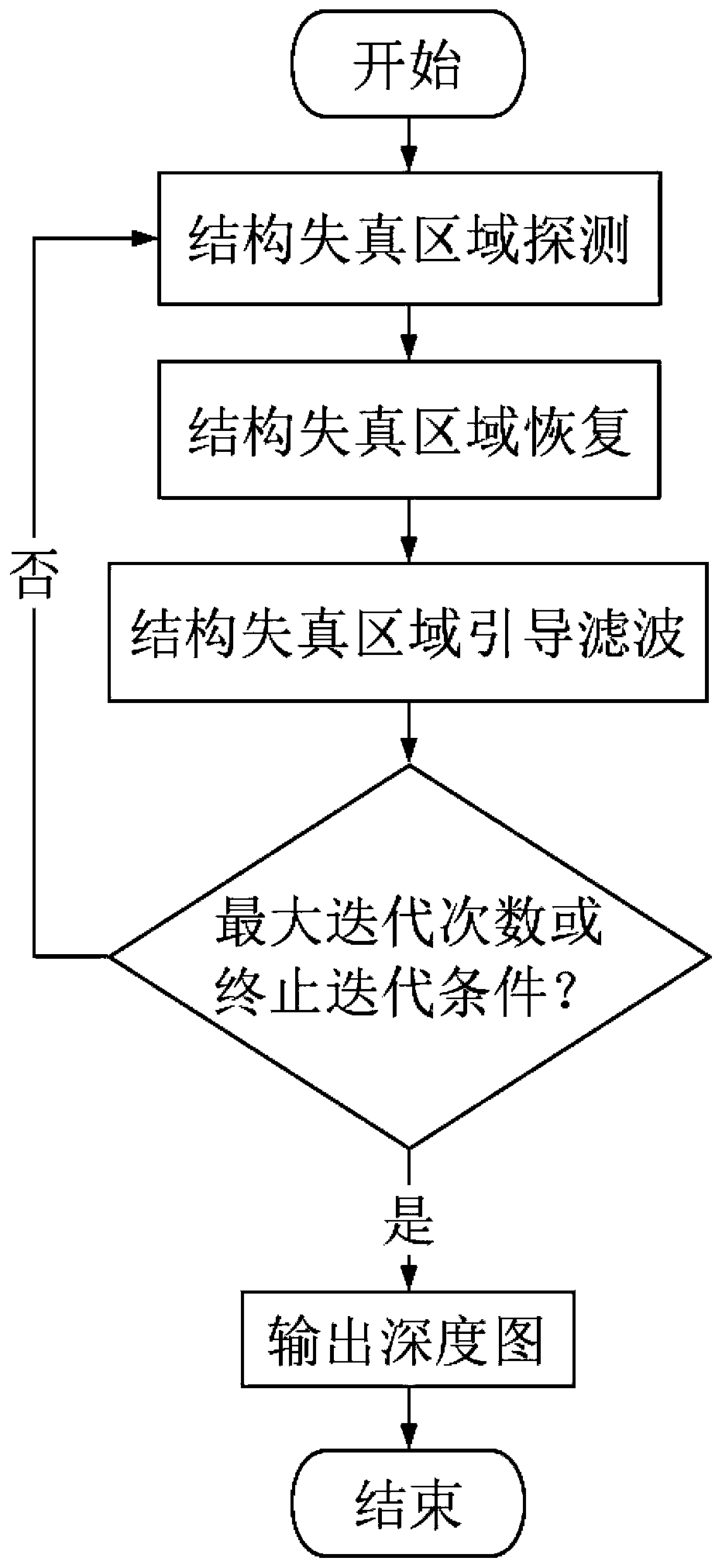

Iterative Depth Map Structure Restoration Method Based on RGB-D SSIM Structure Similarity

The invention discloses an iterative depth map structure restoration method based on RGB-D SSIM structure similarity. First, the edge of the input depth map is detected, and the edge is expanded, and the expanded area is marked as a potential structural distortion area, and then the Each pixel in the potential structural distortion area judges whether it is distorted, and generates a structural distortion metric index. The distorted pixel uses the product of the Gaussian weight of the color image and the structural distortion metric index to construct a restoration weight, and performs guided restoration through a weighted median filter, and then The distorted area is guided and filtered, and the completed result map continues to iterate according to the above steps until the set termination iteration condition is met, and the depth map is output to end the calculation. The present invention obtains more accurate structural information by iteratively detecting and recovering the structurally distorted area of the depth map, and at the same time denoises and preserves the edges of the structurally undistorted area, finally obtaining a depth map with a clear structure and smooth depth values .

Owner:XI AN JIAOTONG UNIV

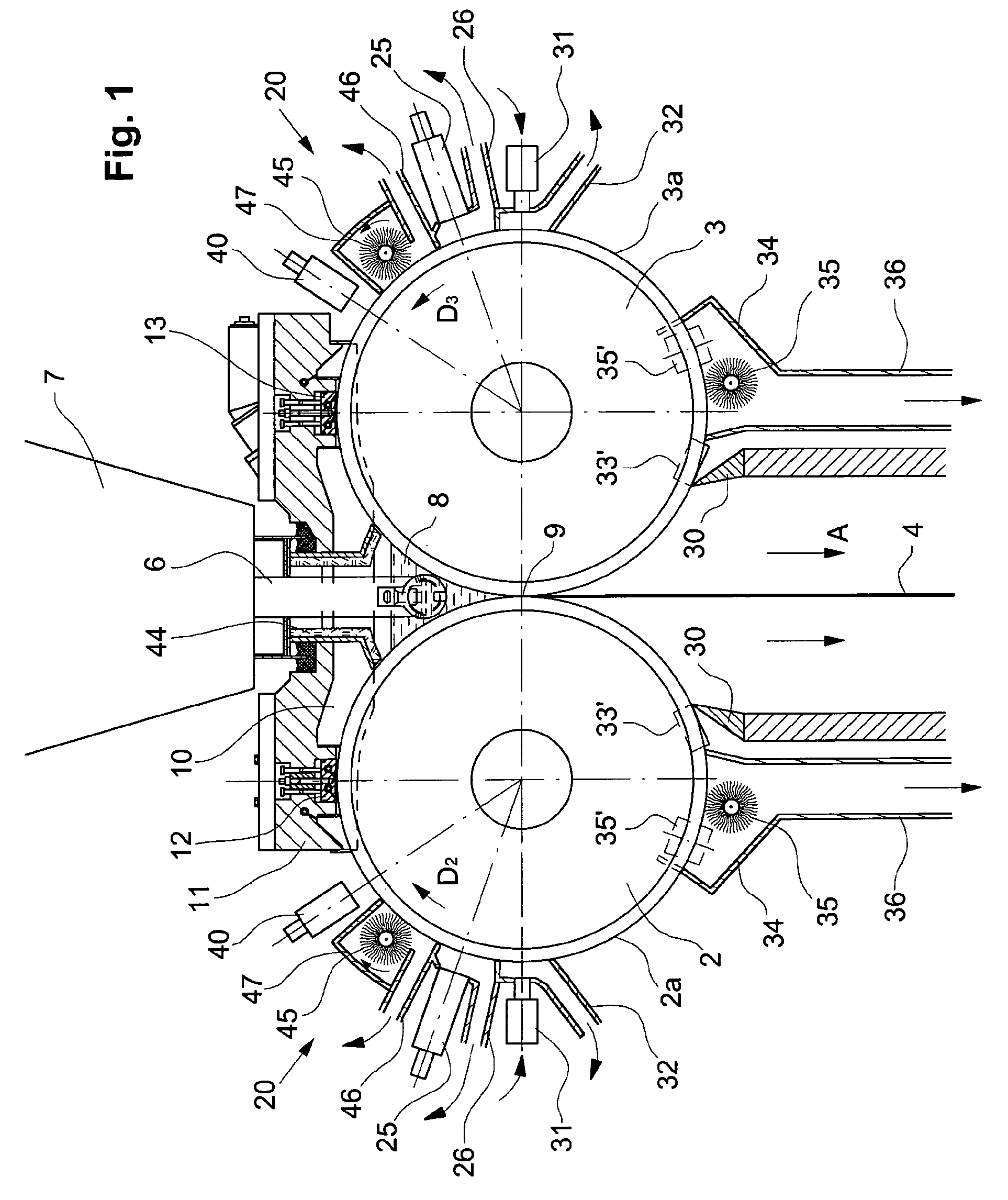

Apparatus for the continuous surface cleaning of rotationally movable casting rolls of a strip-casting machine

InactiveUS7874345B2Clear borderEliminate degradationCasting cleaning apparatusMoulding machinesSurface cleaningEngineering

An apparatus serves for the continuous surface cleaning of rotationally movable casting rolls (2, 3) of a strip-casting machine. A plurality of laser beam units (25) are arranged on the circumference of the respective casting roll (2, 3), which laser beam units (25) are arranged next to one another, are distributed over the casting-roll length and by means of which the casting-roll surface (2a, 3a) can be acted upon with one or more laser beams over the entire casting-roll length. Additional cleaning units (30, 31, 35, 45) for the mechanical cleaning of the casting-roll surface are advantageously connected ahead of and / or behind the laser beam units (25). This makes gap-free and regular surface cleaning of the casting rolls possible.

Owner:MAIN MANAGEMENT INSPIRATION AG

A laser method for fabricating strain sensors with different graphene patterns

InactiveCN106925885BQuality improvementExcellent quality graphene boundaries are excellentElectrical/magnetic solid deformation measurementLaser beam welding apparatusTransducerGalvanometer

Provided is a method for preparing a strain transducer with different graphene patterns through laser. The method comprises the following steps that firstly, a flexible transparent rubber substrate is prepared; secondly, a plurality of graphene materials grown through a chemical vapor deposition method are taken, transferred and spread on the flexible substrate prepared in the first step for standby use; thirdly, the graphene on the surface of the flexible transparent substrate forms patterned graphene; and fourthly, two parallel sides of the patterned graphene of the rectangular substrate are each brushed with a layer of silver glue, and the strain transducer is obtained through assembling. According to the method, the characteristic of ultrahigh energy of ultrashort pulse laser is utilized, cold processing for erosion of the graphene can be achieved, that is, carbon keys are directly broken off through laser energy, materials are removed without causing heating, and thus, graphene boundaries with great quality can be obtained; and any designable patterns can be scanned out through cooperation of focusing laser beams and high-speed motion of a galvanometer, and the method is flexible.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High-resolution SAR image classification method based on intensity ratio and spatial structure feature extraction

ActiveCN109635789BPreserve edge informationIntegrity guaranteedScene recognitionMirror reflectionSpatial structure

The invention discloses a high-resolution SAR image classification method based on intensity ratio and spatial structure feature extraction, which extends the boundary of the classified SAR image through mirror reflection around the boundary; performs block extraction on the expanded SAR image; calculates the block The spatial structure feature of the original SAR image is extended again to extract the block; the intensity ratio feature coefficient of the calculation block is calculated; the intensity ratio feature and the spatial structure information feature are vector superimposed; some sample points are selected and put into the SVM classifier to train the model; Put the whole image into the model, and get the final predicted label image as the final classification result image. The invention has the advantages of more detailed classification, more obvious boundaries and easier classification of region extraction features, and can be used for SAR image classification and target recognition.

Owner:XIDIAN UNIV

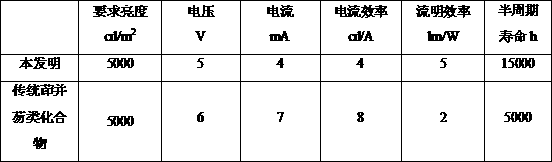

A kind of indenofluorene compound-graphene OLED photoelectric display material and preparation method

InactiveCN106876610BGood effectLower internal resistanceSolid-state devicesSemiconductor/solid-state device manufacturingPolystyreneGraphite

The invention provides an indenofluorene compound-graphene OLED photoelectric display material and a preparation method thereof. Graphene is obtained by carbonizing and graphitizing waste polystyrene containing benzene rings and its derivatives, and combining indene and fluorene in the Graphene is assembled, and the indenofluorene compound is assembled with the layer interface and ring boundary of graphene to form an indenofluorene compound-graphene OLED photoelectric display material. The method provided by the present invention overcomes the technical defects of poor film formation and short service life in the process of using indenofluorene compounds in the preparation of devices in the prior art, realizes the improvement of the glass transition temperature of indenofluorene compounds, and improves their dissolution The technical effect of high temperature resistance and uniform film formation, the prepared material has the characteristics of high brightness and long service life.

Owner:贵州乐洲科技有限公司

Method and system of beam injection to charged particle storage ring

The charged particle storage system includes: a storage ring circulating, by a perturbating device, charged particles injected from outside; a power source supplying an electric current to the perturbating device; and a charged particle beam generating device. The charged particle beam generating device includes a DC accelerator that generates a constant voltage to accelerate electrons and thereby generates a beam of the electrons. While a current having its current intensity changing in a sinusoidal wave is caused to flow through the perturbating device continuously for at least 10 μs by a power source, an electron beam output from the charged particle beam generating device is injected to the storage ring continuously for at least 10 μs. Thus, a current larger than that stored by the conventional resonance injection method can be stored in the storage ring, and an X-ray having higher intensity can be generated.

Owner:PHOTON PRODN LAB +1

A detection system and detection method for elevator blocking door behavior based on video analysis

ActiveCN107915102BAvoid interferenceClear borderCharacter and pattern recognitionElevatorsLogic cellSimulation

The invention provides a detection system for elevator door blocking behavior based on video analysis, which includes a video acquisition unit, a door state analysis unit, an alarm logic unit and a multimedia prompt unit. The present invention also provides a method for detecting elevator door blocking behavior based on video analysis using the above-mentioned system, including the steps of: pasting markers; collecting information on the location of the elevator door markers; analyzing and judging the state of the elevator door; judging whether there is a blocking door Behavior; play a reminder broadcast. The present invention adopts the method of area acquisition, and calibrates the set acquisition area in the form of a label, so that the boundary of acquisition is more obvious, and the comparison with the background is more accurate, thereby overcoming the interference of the edge of the elevator door and the background occluder, and improving detection accuracy.

Owner:ZHEJIANG NEW ZAILING TECH CO LTD

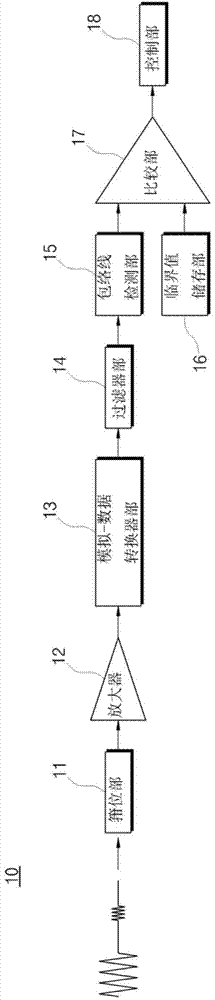

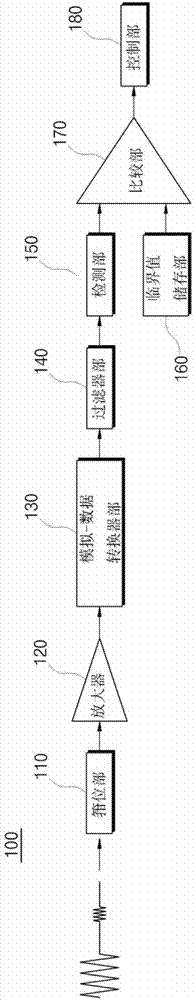

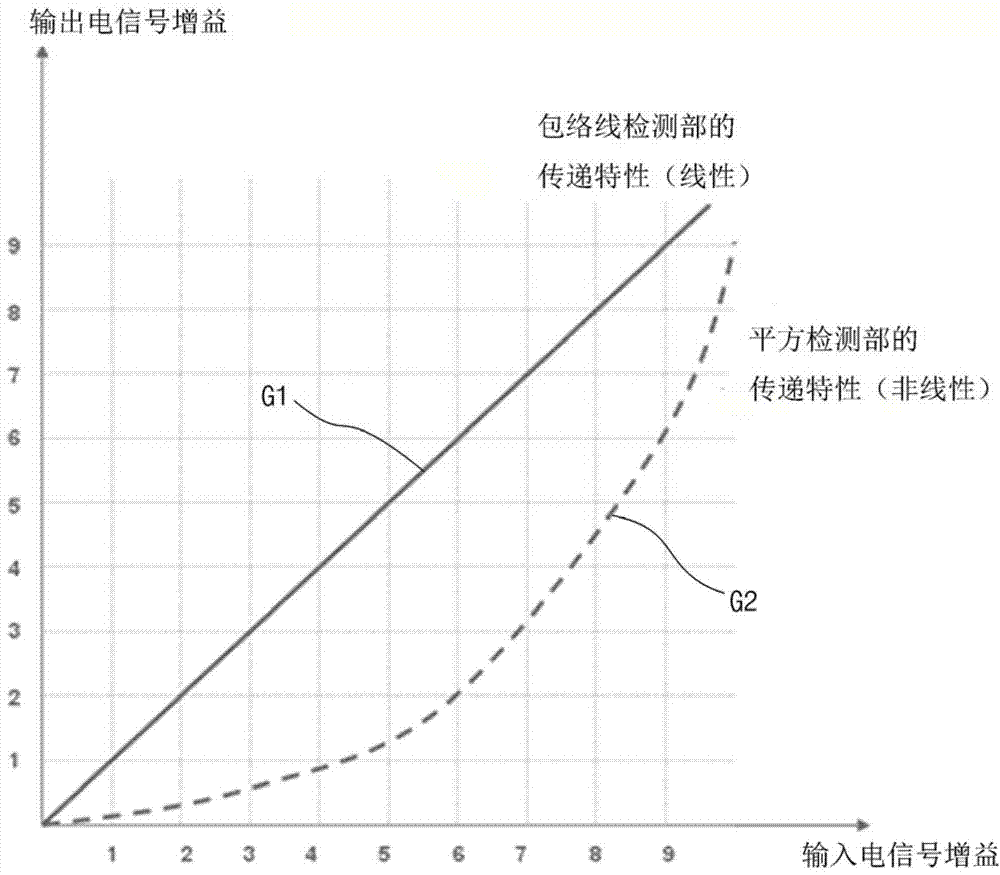

Receiving device and receiving method of parking assist system

ActiveCN103101493BImprove signal-to-noise ratioReduce manufacturing costElectric/fluid circuitAcoustic wave reradiationUltrasonic sensorSignal-to-noise ratio (imaging)

The invention provides a receiver and a method of a parking assistant system. The receiver device is characterized in that, a square detector is used to replace a current envelop line detector between an AD conversion part and a comparison part on a parking assistant system receiver using an ultrasonic sensor, so as to improve signal-to-noise ratio, thereby improving accuracy of the ultrasonic sensor detecting an object. The invention also provides a receiving method for the parking assistant system using the device, and the receiving method is characterized in that, storage medium of a predefined lookup table form is used to improve the signal-to-noise ratio.

Owner:HYUNDAI MOBIS CO LTD

Bilateral Filtering Algorithm Based on Homogeneous Region Segmentation

ActiveCN110163874BReduce in quantityReduce weight distributionImage enhancementImage analysisPattern recognitionImage segmentation

The bilateral filtering algorithm based on homogeneous region segmentation provided by the present invention first utilizes the spatial continuity of the physical characteristics of each pixel in the hyperspectral image to segment the hyperspectral image into several homogeneous regions with similar spectra, and then Each pixel in a homogeneous area is sequentially subjected to bilateral filtering, and finally an output image is obtained. Therefore, the number of non-structurally similar pixels in the bilateral filtering template corresponding to the pixel is greatly reduced, and the structural similarity of each pixel in the bilateral filtering template is relatively high, thereby greatly reducing the weight distribution of non-structurally similar pixels and reducing the non-structural similarity. The problem that pixels have a large negative impact on the output value of bilateral filtering, the boundary in the output image is more obvious, and the contrast is good.

Owner:BEIBU GULF UNIV

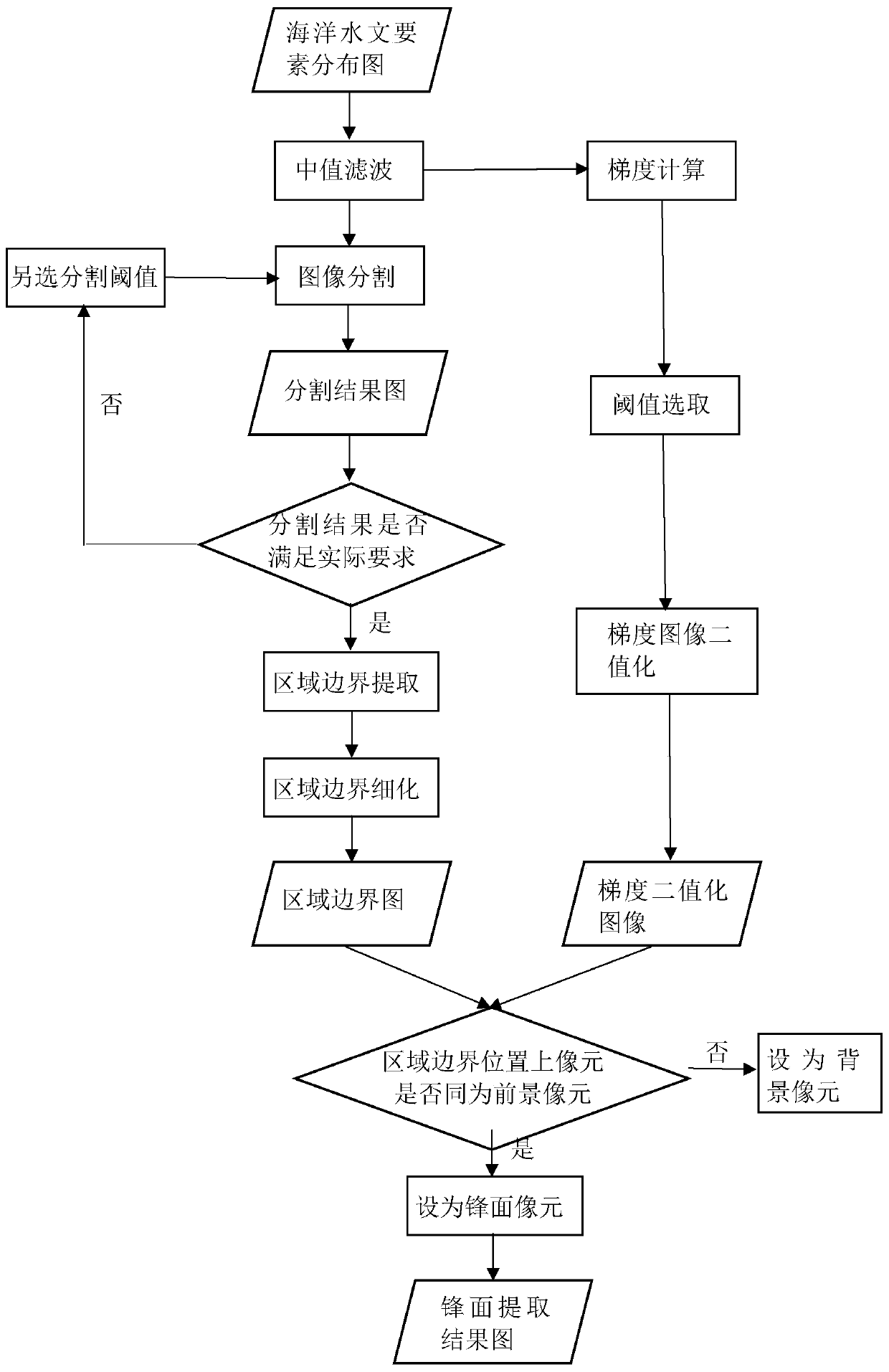

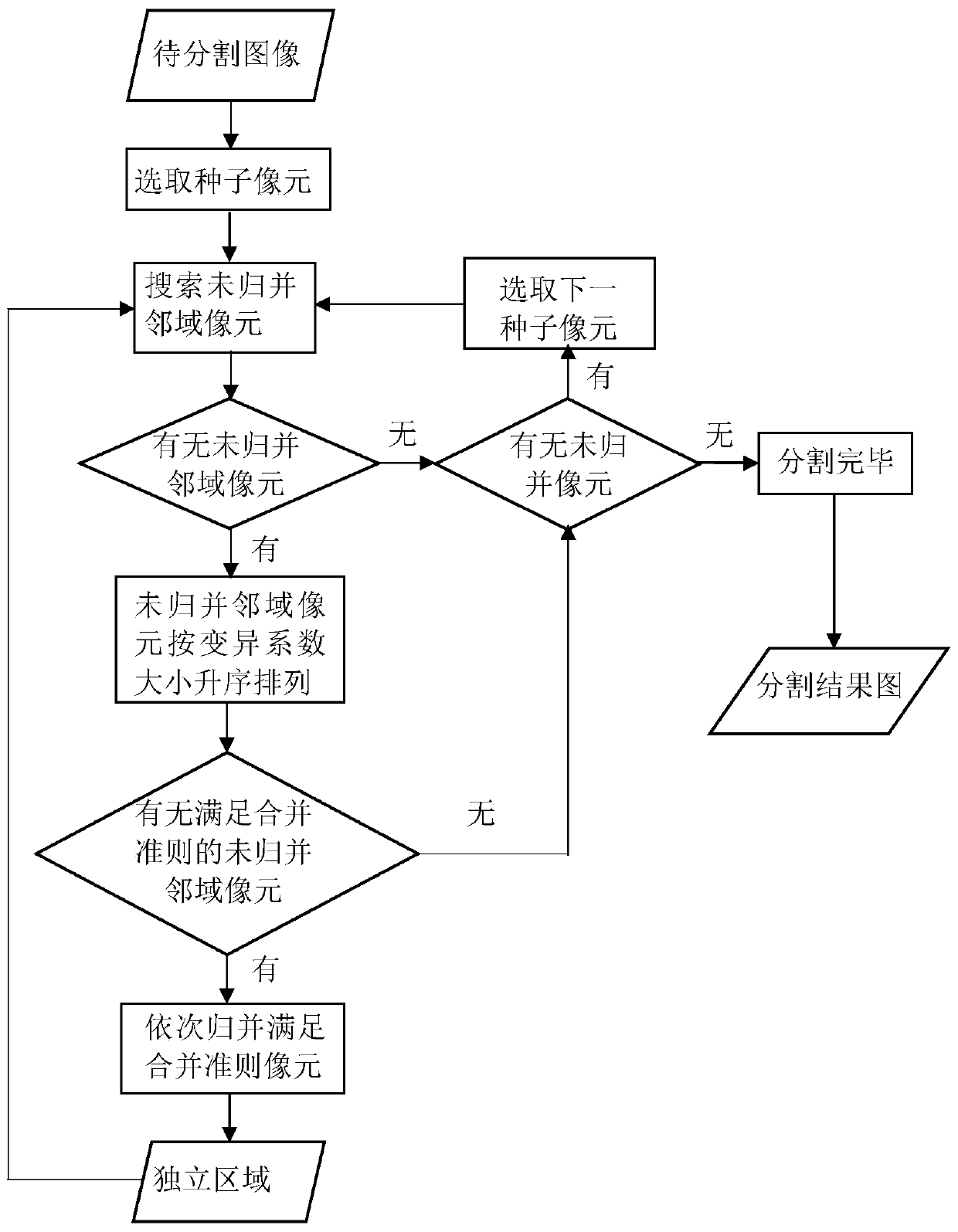

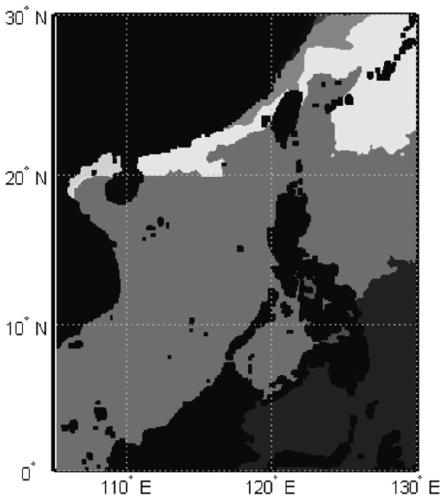

Ocean Front Extraction Method Based on Image Segmentation

ActiveCN107274420BReduce the impact of noiseImprove continuityImage enhancementImage analysisBoundary refinementStructure analysis

The invention relates to an image segmentation based ocean frontal surface extraction method. The method includes median filtering treatment on a marine hydrologic feature image; utilizing a section growth algorithm and using the magnitude of variable coefficients as a merging principle for performing image segmentation on the marine hydrologic feature image; performing area boundary detection and boundary refining treatment on the segmented image; performing gradient calculation on the marine hydrologic feature image and binarization processing on the gradient image; performing overlapping comparison on the area boundary image and the gradient binarization image and performing frontal surface pixel screening. According to the invention, shortcomings of a prior ocean frontal surface extraction method are overcome. A frontal surface extraction result is insusceptible to noise and is good in continuity and a smoother frontal surface central line can be acquired. The invention provides a basis for fishery production plan making, fishery forecast, marine organism habitat survey, ocean current structure analysis and the like related to ocean frontal surface distribution.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com