Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Avoid unmanageable problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Network management system, management method and equipment

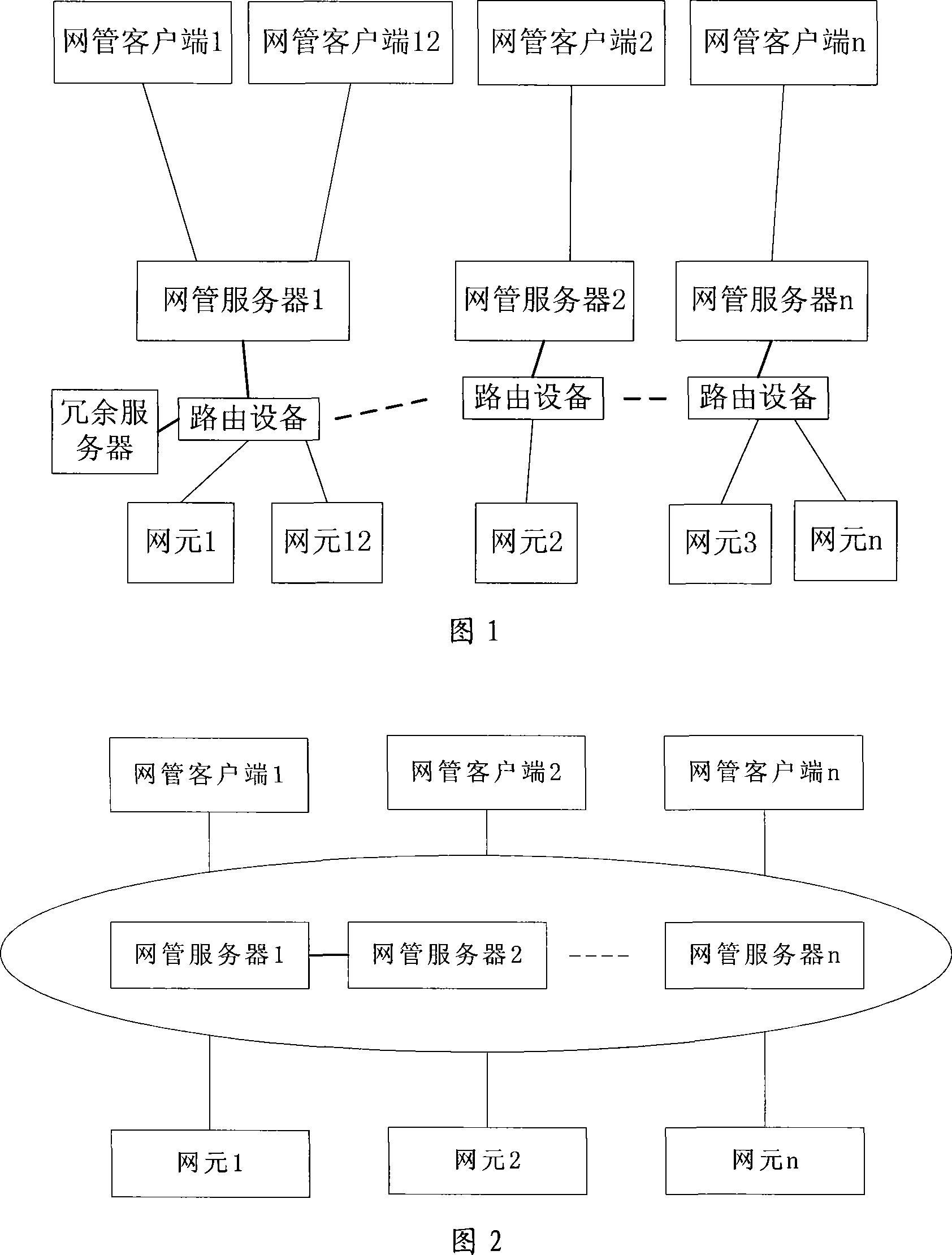

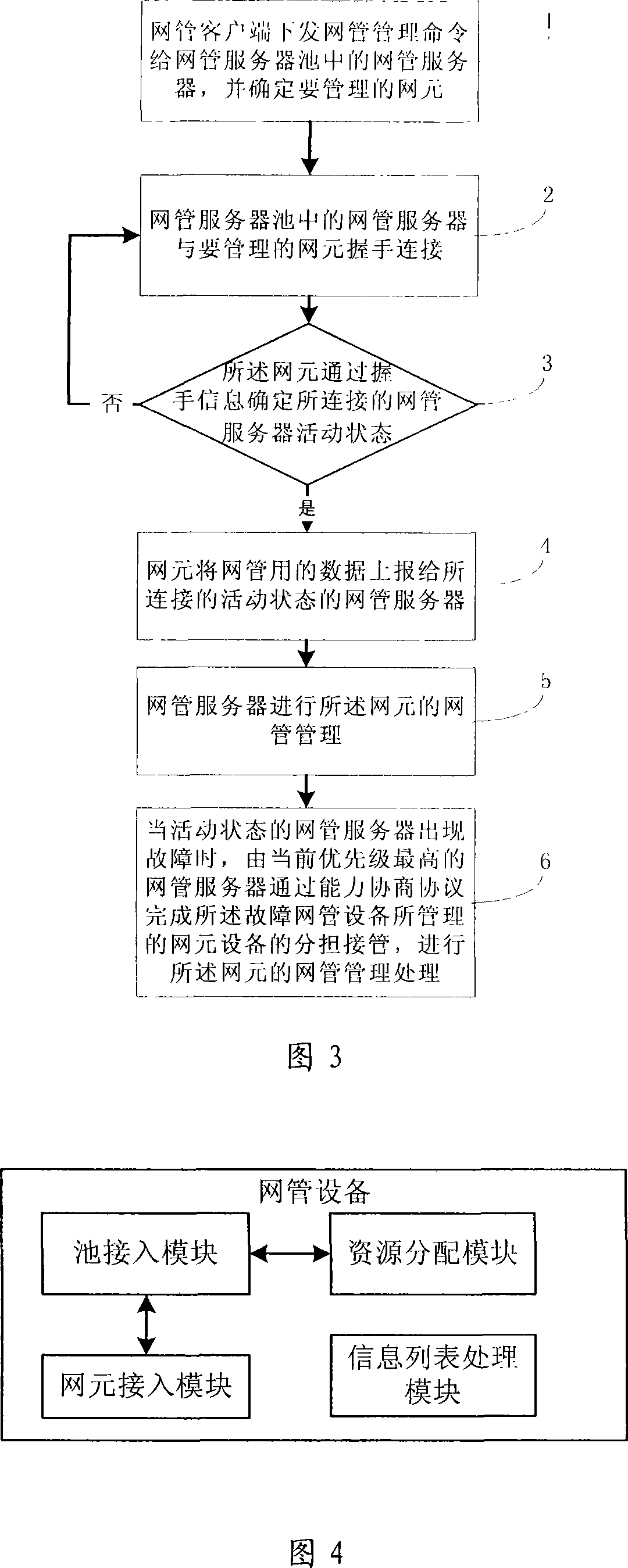

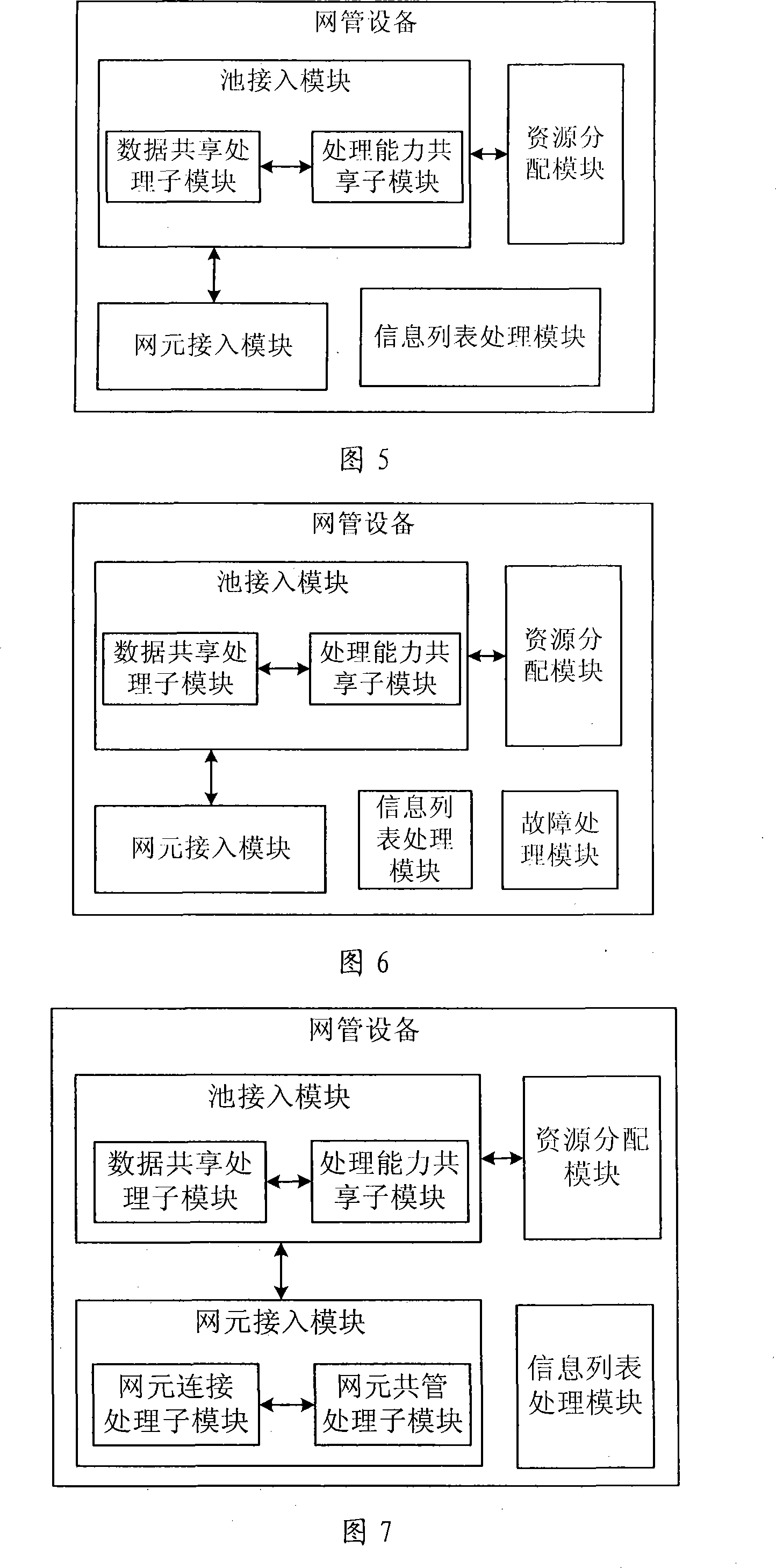

ActiveCN101183984AAvoid unmanageable problemsData switching networksNetwork managementShared resource

A network management system, management method and equipment. The system includes: a network management device pool, which is formed by connecting at least two network management devices, and each connected network management device communicates with each other to share resources and business processing capabilities for network management management and disaster recovery processing; a network management client device is connected to all The network management equipment pool is connected and communicated with at least one network management equipment in the network management equipment pool, and the network management equipment connected to the network management equipment pool performs network management management on the network element equipment connected to the network management equipment pool. In the embodiment of the present invention, network management equipment is connected into a network management equipment pool as a network management system, so that the network management system can manage multiple networks; when some network management equipment fails, it can be switched to other network management equipment in the network management equipment pool. The device takes over the network management management processing of the corresponding network element equipment, avoiding the problem that the corresponding network element equipment cannot be managed due to the failure of a certain network management equipment in the traditional network management system.

Owner:HUAWEI TECH CO LTD

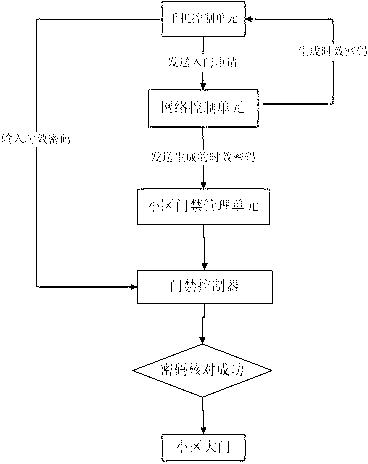

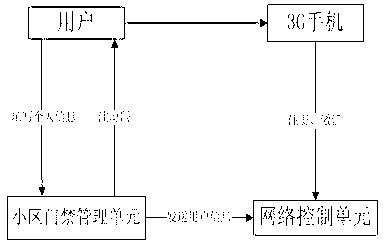

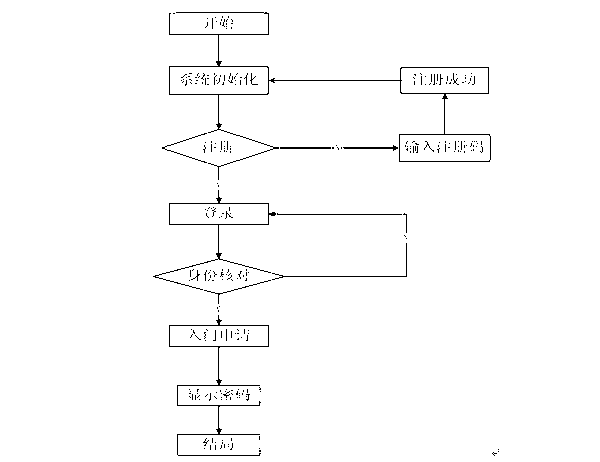

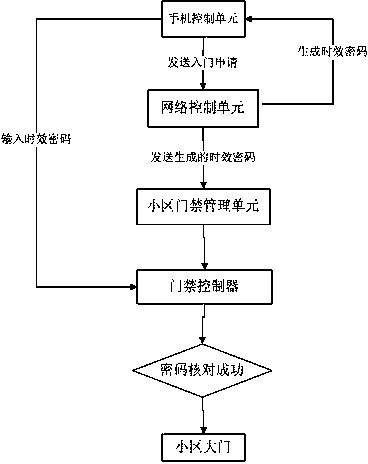

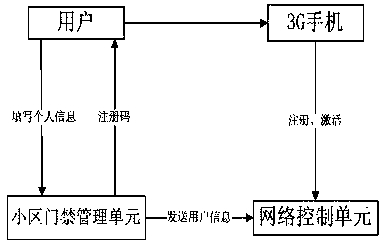

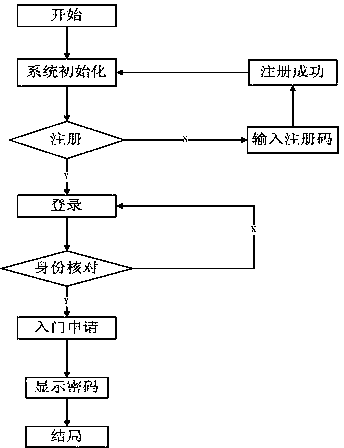

Community intelligent entrance guard control method as well as device thereof based on mobile phone 3G (third generation) network

InactiveCN103295304AImprove securityRealize the combination of man and machineIndividual entry/exit registersStaff managementMobile phone

The invention discloses a community intelligent entrance guard control method based on a mobile phone 3G (third generation) network. The community intelligent entrance guard control method based on a mobile phone 3G network is characterized in that an entrance guard control device mainly comprises a mobile phone control unit, a community entrance guard management unit and a network control unit; the mobile phone control unit is used for user registration, entrance application, mobile phone binding and entrance password display; the network control unit is used for user identity checking, password saving as well as transmission; the community entrance guard management unit is used for checking the password input by users, opens a gate automatically after successful checking, can generate user access records, can manage people conveniently, is safe, reliable, convenient and feasible, and can achieve scientific management of community entrance guard.

Owner:NORTHEAST DIANLI UNIVERSITY

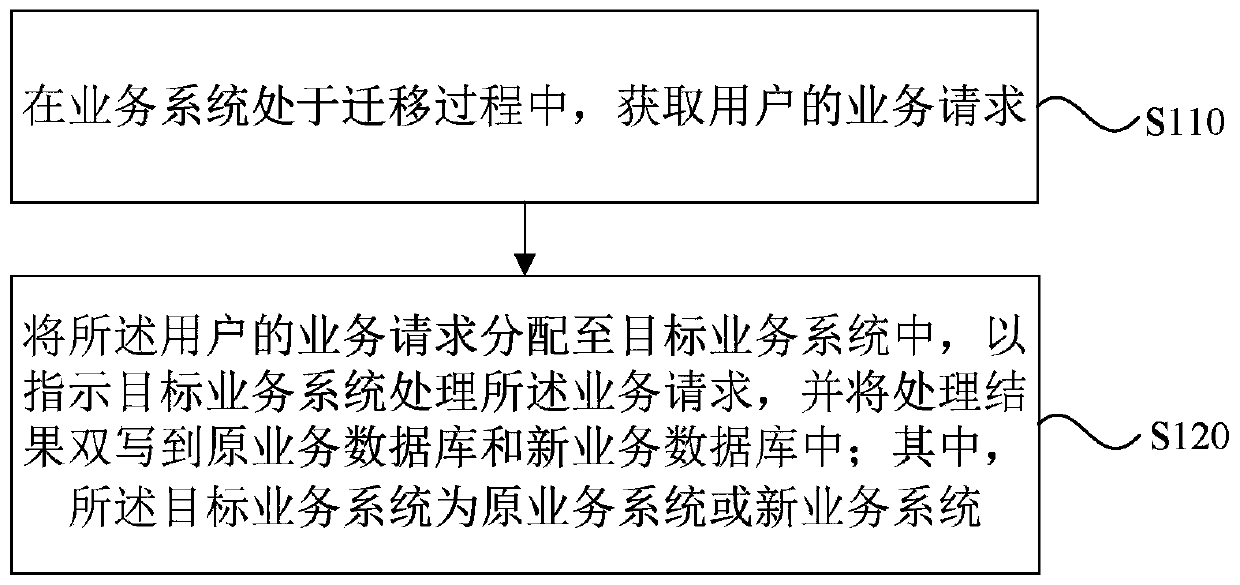

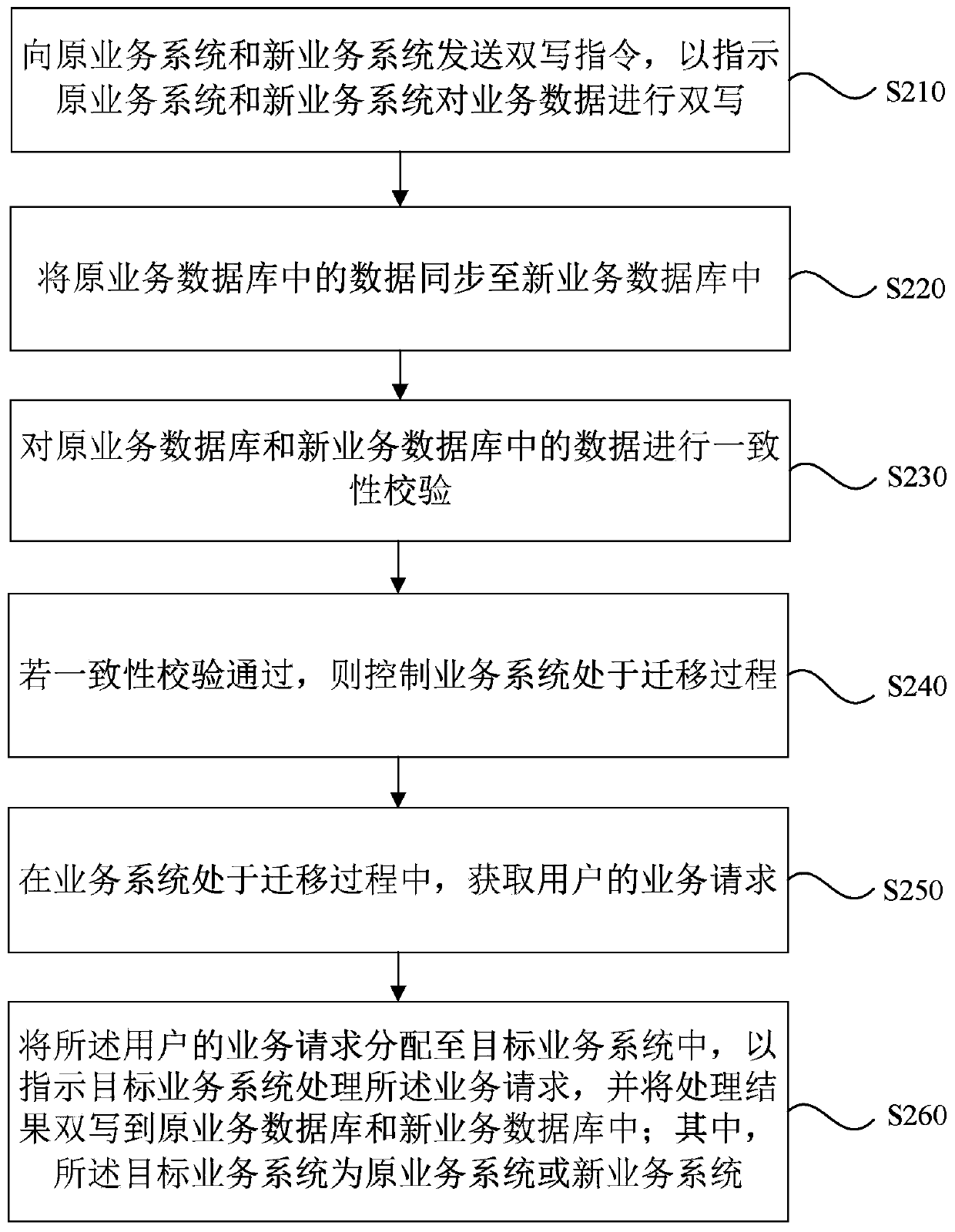

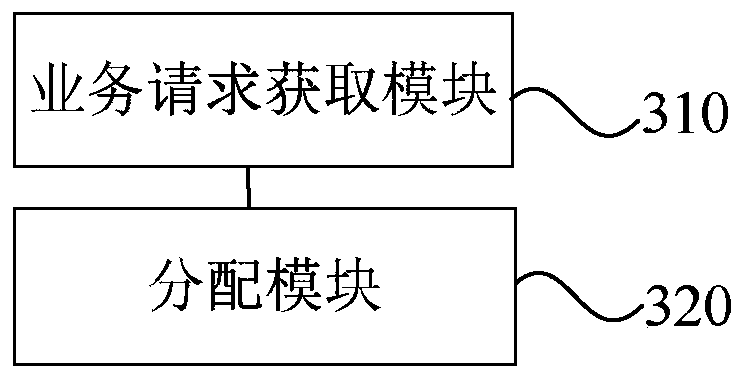

Service system processing method, device and equipment, and storage medium

InactiveCN110471688AAvoid unmanageable problemsUpdate stableDatabase updatingDatabase distribution/replicationOperating systemRequest distribution

The embodiment of the invention discloses a service system processing method and device, equipment and a storage medium. The method comprises the steps of obtaining a service request of a user when aservice system is in a migration process; allocating the service request of the user to a target service system so as to indicate the target service system to process the service request, and doubly writing a processing result into an original service database and a new service database; wherein the target service system is an original service system or a new service system. According to the embodiment of the invention, the service request is distributed to the original service system or the new service system; therefore, the original service system and the new service system process the service request at the same time, and the target service system is instructed to write the processing result to the original service database and the new service database, so that the data in the two databases are kept consistent, and stable updating is realized under the condition of ensuring normal operation of the systems.

Owner:SHENZHEN LANBEI TECH CO LTD

Microcapsule nematicide

InactiveCN105660627ASolve the shortcomings of unstable efficacy of photodecompositionImprove the effect of prevention and controlBiocideNematocidesAvermectinPreservative

The invention discloses a microcapsule nematicide, which is composed of the following components by mass: 20-30% of fosthiazate, 0.1-2% of avermectin, 1-5% of an encystation agent, 1-10% of a surfactant, 1-10% of a solvent, 1-2% of a thickening agent, 0.01-1% of a defoaming agent, 0.01-1% of a preservative, and the balance water. The microcapsule nematicide involved in the invention has the advantages of high efficiency, broad spectrum, and simple production process.

Owner:PLANT PROTECTION RES INST OF GUANGDONG ACADEMY OF AGRI SCI +1

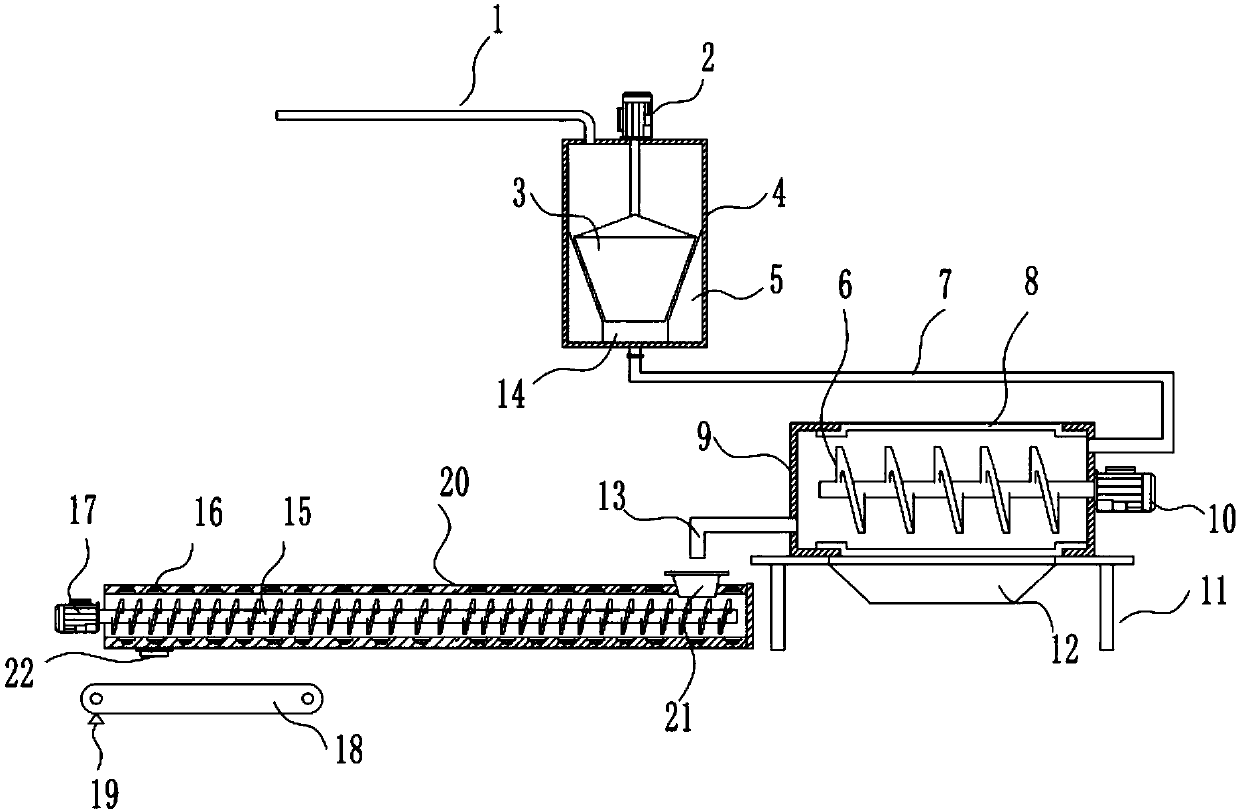

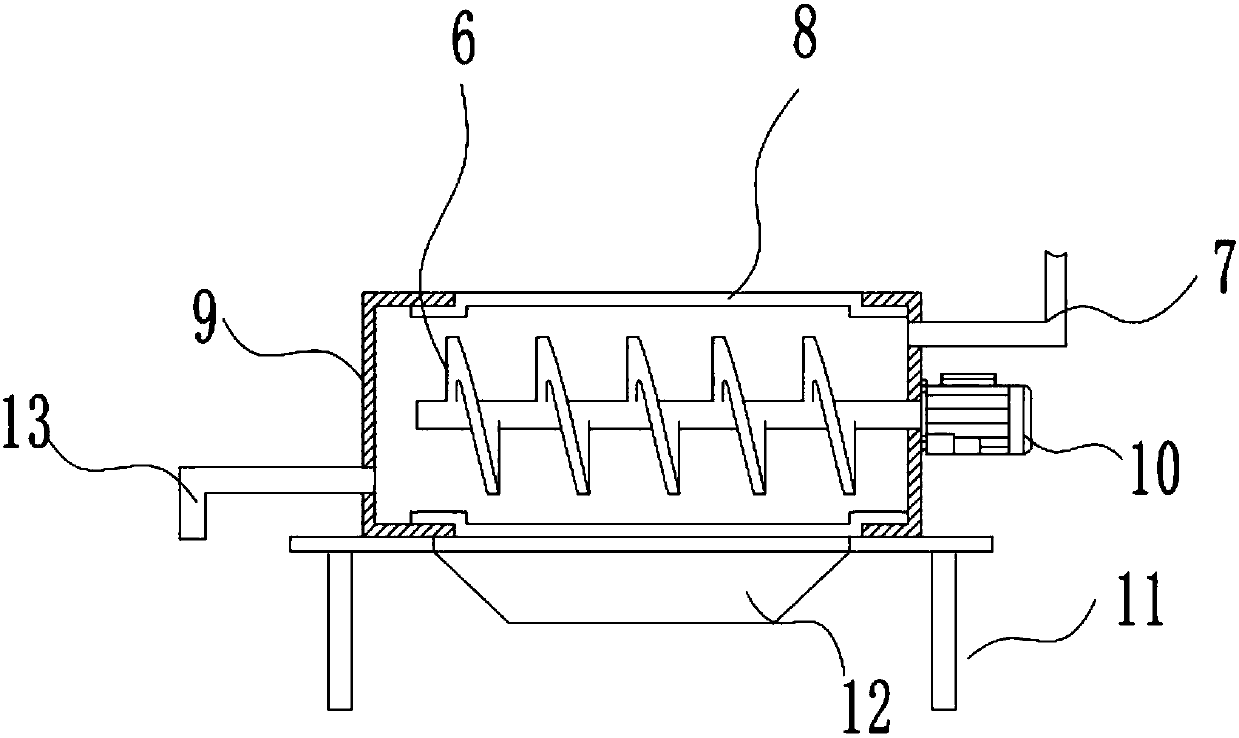

High-quality ceramic stone machining system

InactiveCN107913778AImprove product qualityImprove processing efficiencyMagnetic separationGrain treatmentsScrapContinuous production

The invention discloses a high-quality ceramic stone machining system. The high-quality ceramic stone machining system comprises a slurry inlet pipe, a grinding mechanism for grinding slurry, a filtering mechanism for filtering the slurry, a drying mechanism for drying ceramic stone particles, and an iron removal mechanism for removing iron in the ceramic stone particles. The high-quality ceramicstone machining system has the beneficial effects that the slurry can be subjected to adsorbing impurity removal after being dried and formed, iron scraps in the slurry are reduced, and the problem that due to the fact that impurity removal is carried out before an overall process, the iron scraps mixed in the work process cannot be treated is avoided; the product quality is improved, a continuousproduction mode of grinding, filtering and screening, drying and iron removing can be formed, and machining efficiency is greatly improved; and the overall structure is simple, and very good market generalization performance is achieved.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

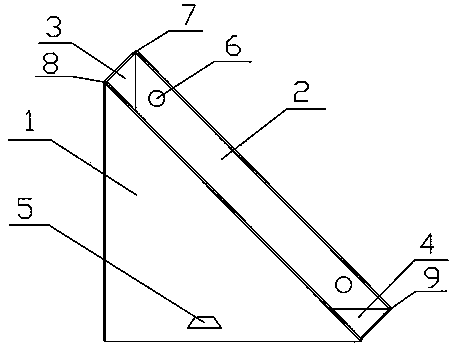

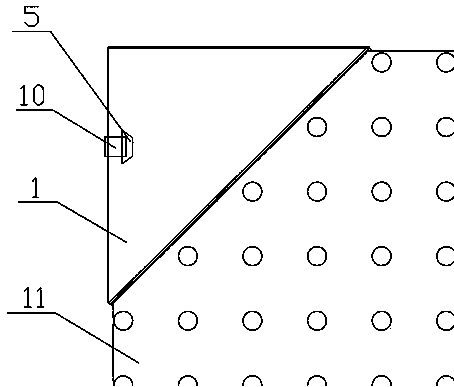

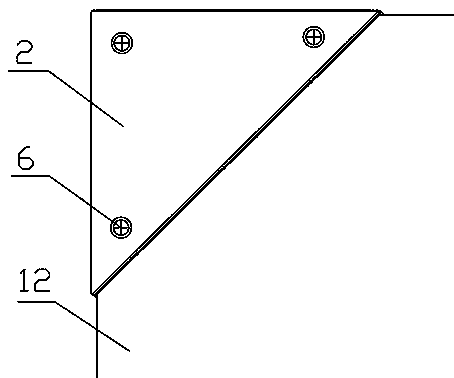

Corner protection device for LED display screen

InactiveCN103474002AAvoid discardingAvoid unmanageable problemsCasings/cabinets/drawers detailsIdentification meansRight triangleLED display

The invention discloses a corner protection device for an LED display screen. The corner protection device comprises a first side surface, a second side surface, a third side surface and a fourth side surface; each of the first side surface and the second side surface is in the shape of an isosceles right triangle and comprises a first right-angle side and a second right-angle side; both the third side surface and the fourth side surface are rectangular and respectively comprise first long sides and second long sides; the first right-angle side of the first side surface is movably connected with the first long side of the third side surface; the first right-angle side of the second side surface is movably connected with the second long side of the third side surface; the second right-angle side of the second side surface is movably connected with the first long side of the fourth side surface. The corner protection device has the advantages that the corner protection device is arranged on a screen body of the LED display screen, and is simple in installation and convenient to use, a corner of the ultra-thin leased LED display screen can be protected from being damaged in real time, and accordingly the corner protection device has excellent practical value.

Owner:WUXI TONGMING TECH

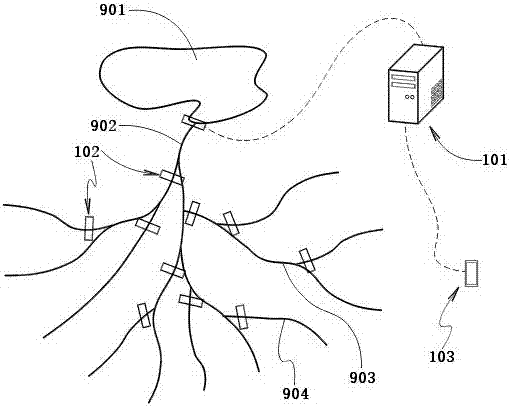

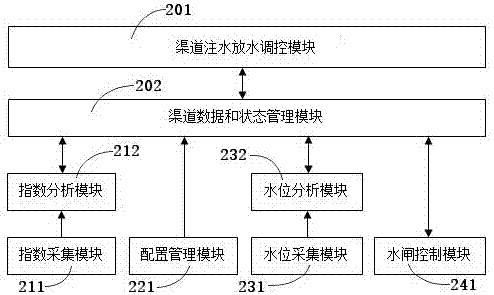

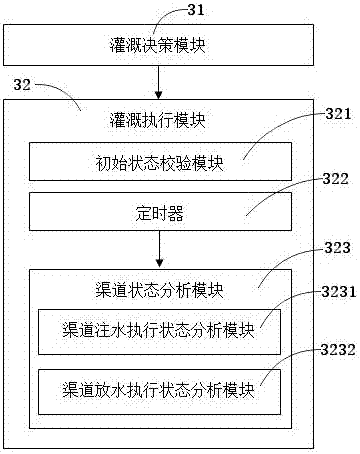

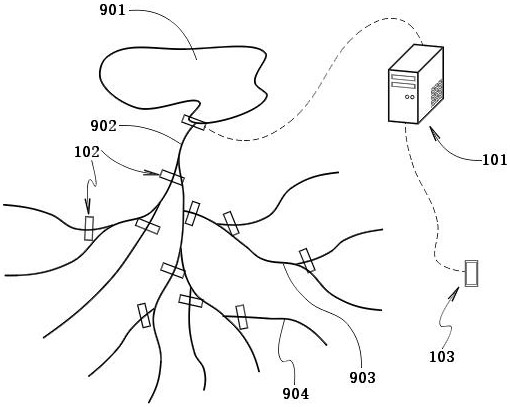

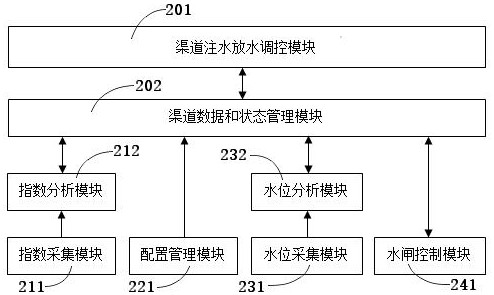

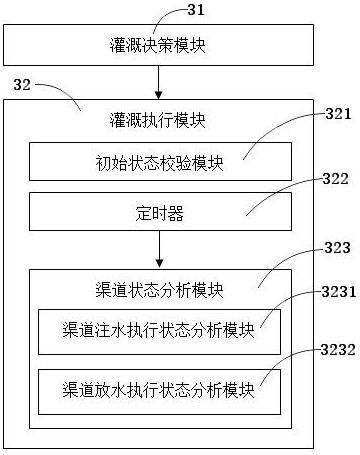

Irrigation control system and irrigation control method based on open channels

ActiveCN107223544AEnsure safetyAvoid unmanageable problemsClimate change adaptationWatering devicesStream gaugeWater discharge

The invention discloses an irrigation control system and irrigation control method based on open channels. The irrigation control system comprises a management module, an index acquisition module, an index analysis module, a water level acquisition module, a water level analysis module and a channel water-injection water-discharge regulation and control module. The channel water-injection water-discharge regulation and control module traverses each main channel and each branch channel from top to bottom in a breadth-first manner by means of a stepping control method, and carries out water-injection and water-discharge control on each main channel and each branch channel in dependence on the channel data and the sluice state of the main channel and the branch channel until the water-discharge amount of all the farmland channels satisfies the water demand of the farmland sides corresponding to the farmland channels. By employing a mode of calculating the water storage amount by a water level gauge, the problem that the flow velocity and flow of the open channel are difficult to control is avoided.

Owner:JIANGSU COCON TECH

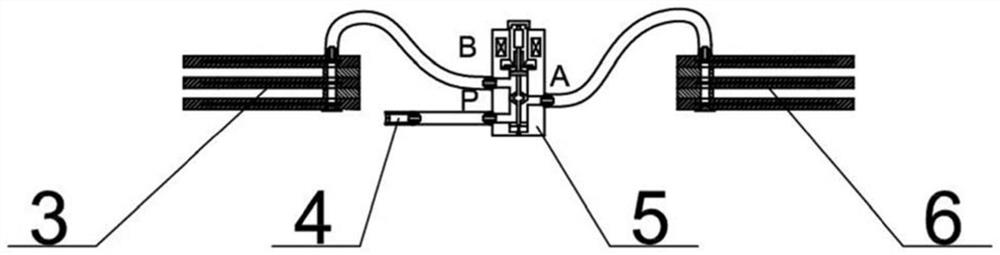

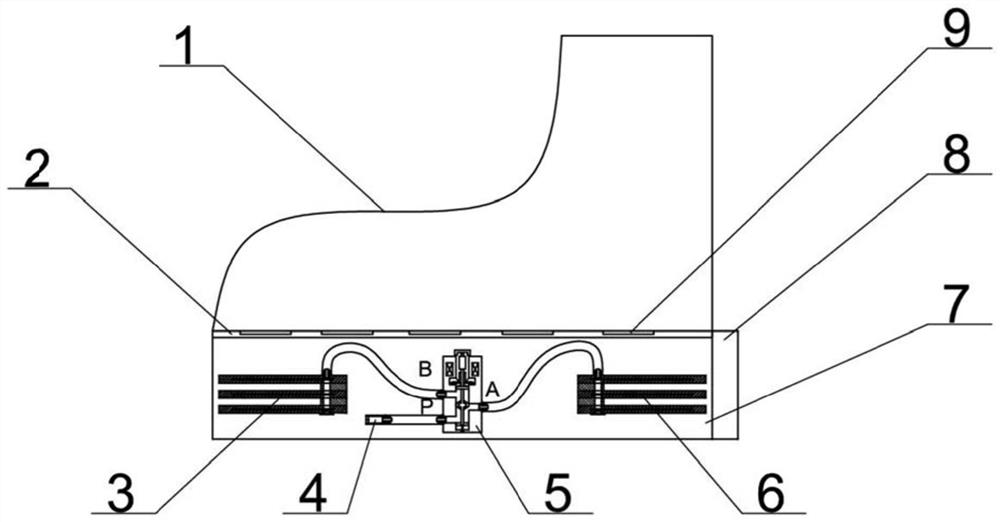

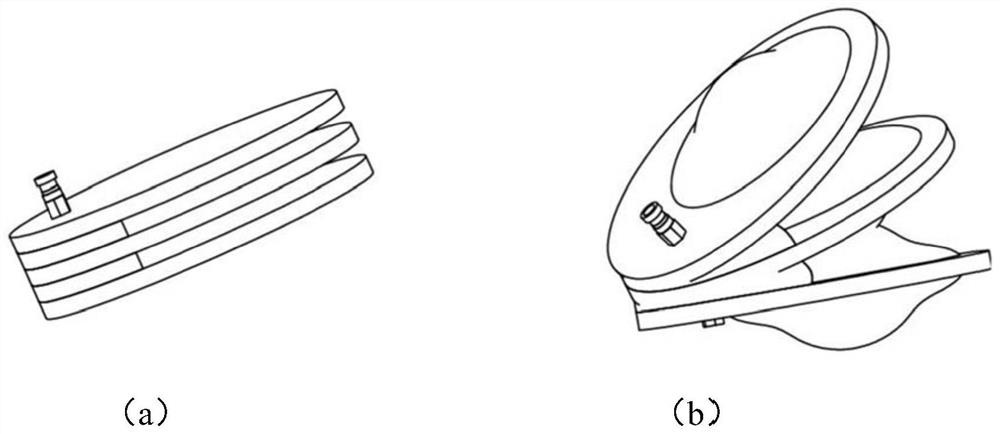

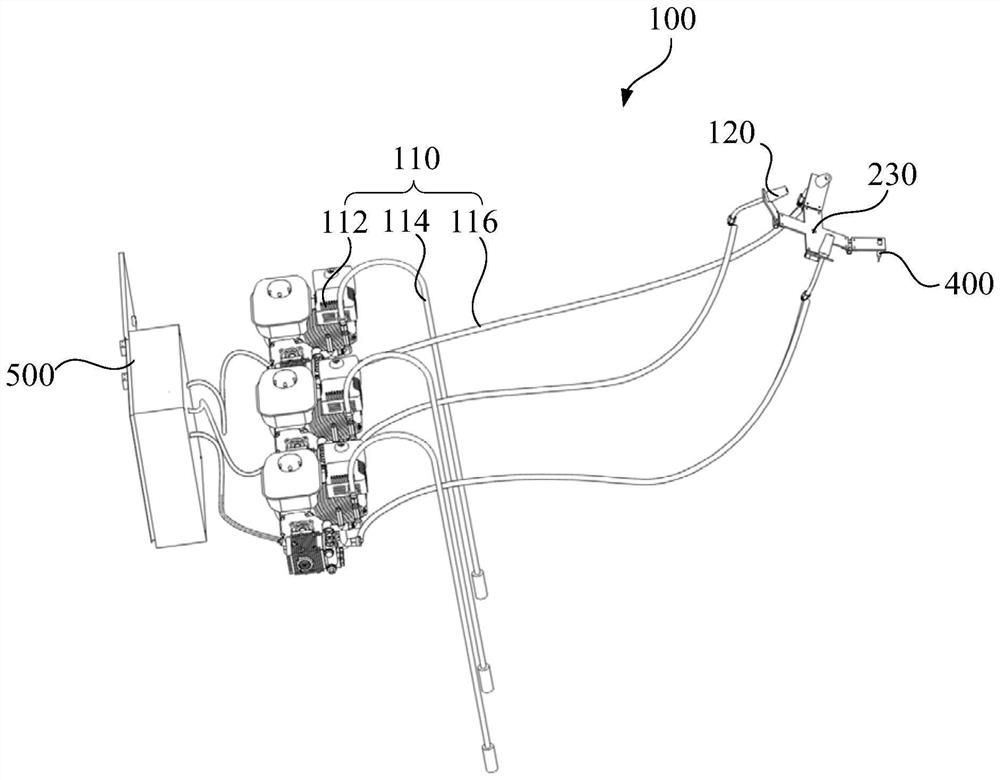

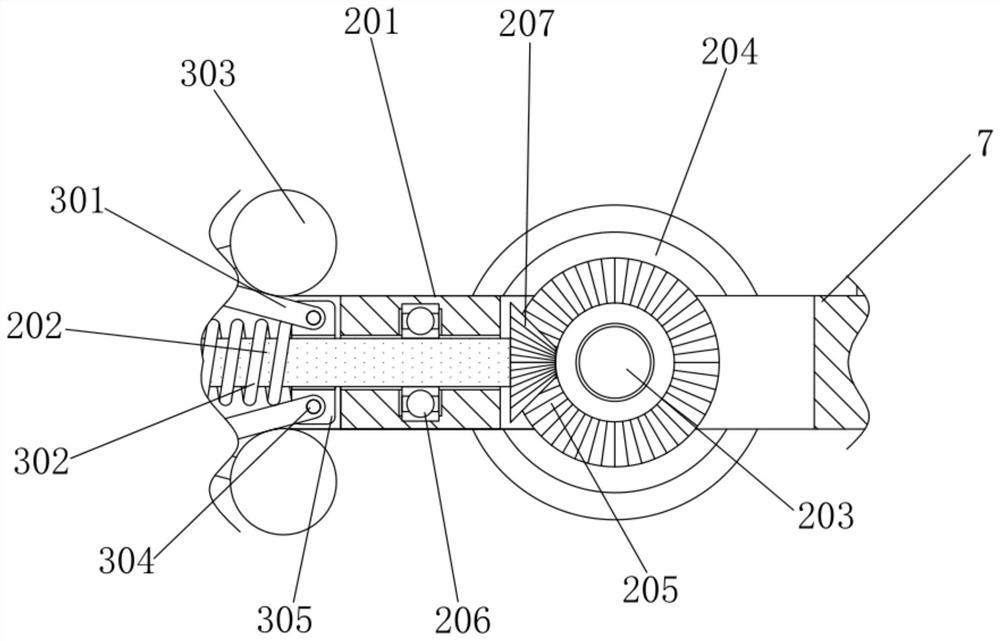

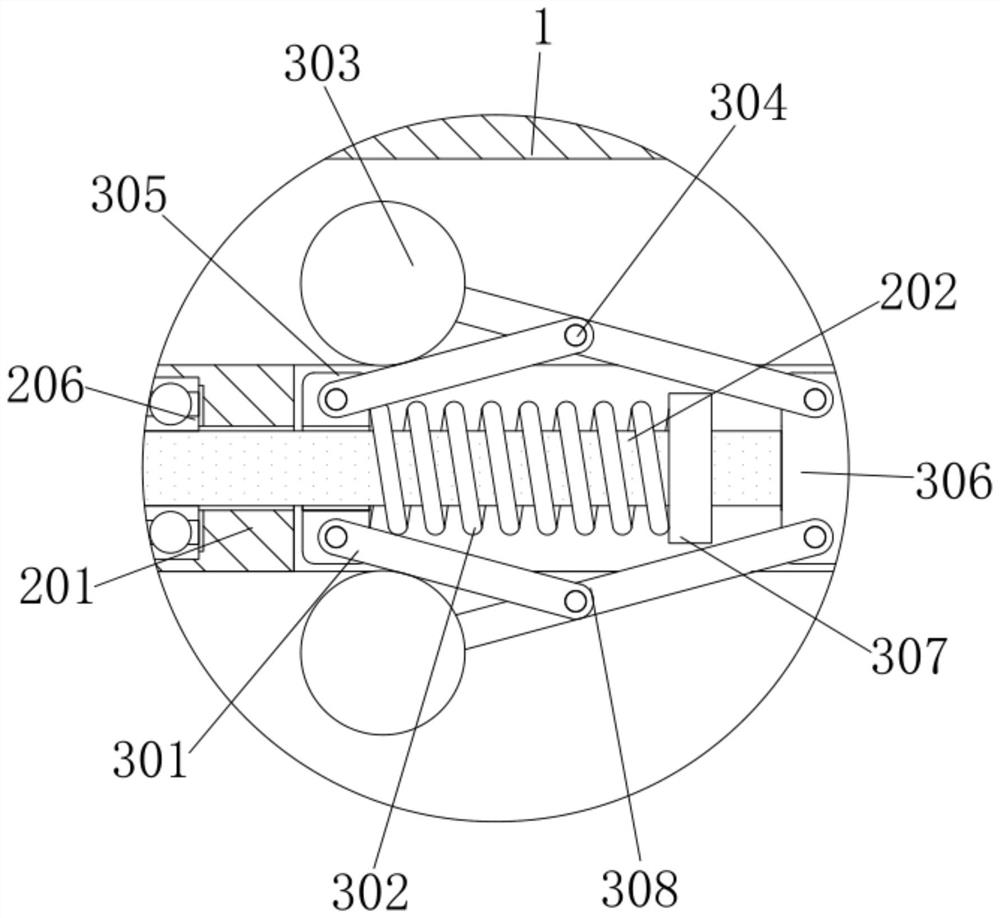

Power-assisted mechanism and power-assisted shoes

The invention discloses a power-assisted mechanism and a power-assisted shoe. The power-assisted mechanism comprises a front sole pneumatic muscle located at the front sole part, a heel pneumatic muscle, a non-return inflation inlet and a two-position three-way electromagnetic valve, wherein the heel pneumatic muscle is located at the heel part; the non-return inflation inlet is further included; a port B of the two-position three-way electromagnetic valve is connected with the front sole pneumatic muscle, a port A of the two-position three-way electromagnetic valve is connected with the rear heel pneumatic muscle, a port P of the two-position three-way electromagnetic valve is connected with the non-return inflation port, and the two-position three-way electromagnetic valve is configured as follows: in a ready inflation state, the port P is communicated with the port A, and the port B is not communicated with the port A; in a heel landing state, the port P is not communicated with the port A, and the port B is communicated with the port A; in a tiptoe landing state, the port P is not communicated with the port A, and the port B is not communicated with the port A; in a heel off-ground state, the port P is not communicated with the port A, and the port B is communicated with the port A; and when the tiptoe is off the ground, the port P is not communicated with the port A, and the port B is not communicated with the port A. The power-assisted shoe comprises a sole and a power assisting mechanism, wherein the power assisting mechanism is arranged in the shoe sole, and the power assisting mechanism is the power assisting mechanism.

Owner:杭州昆泰机器人有限公司

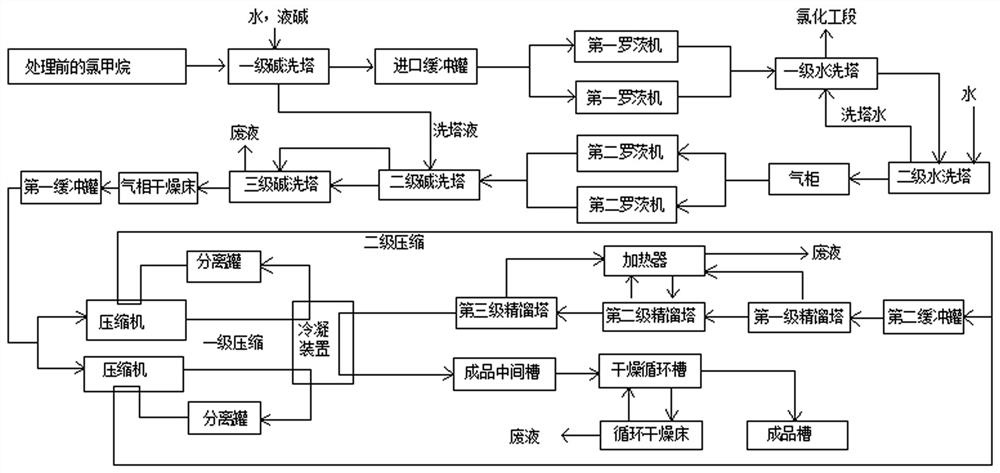

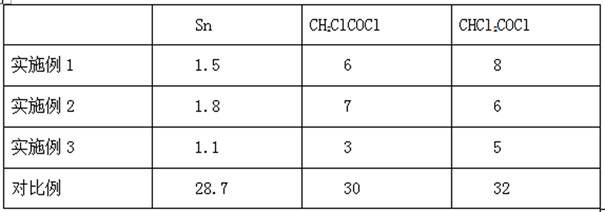

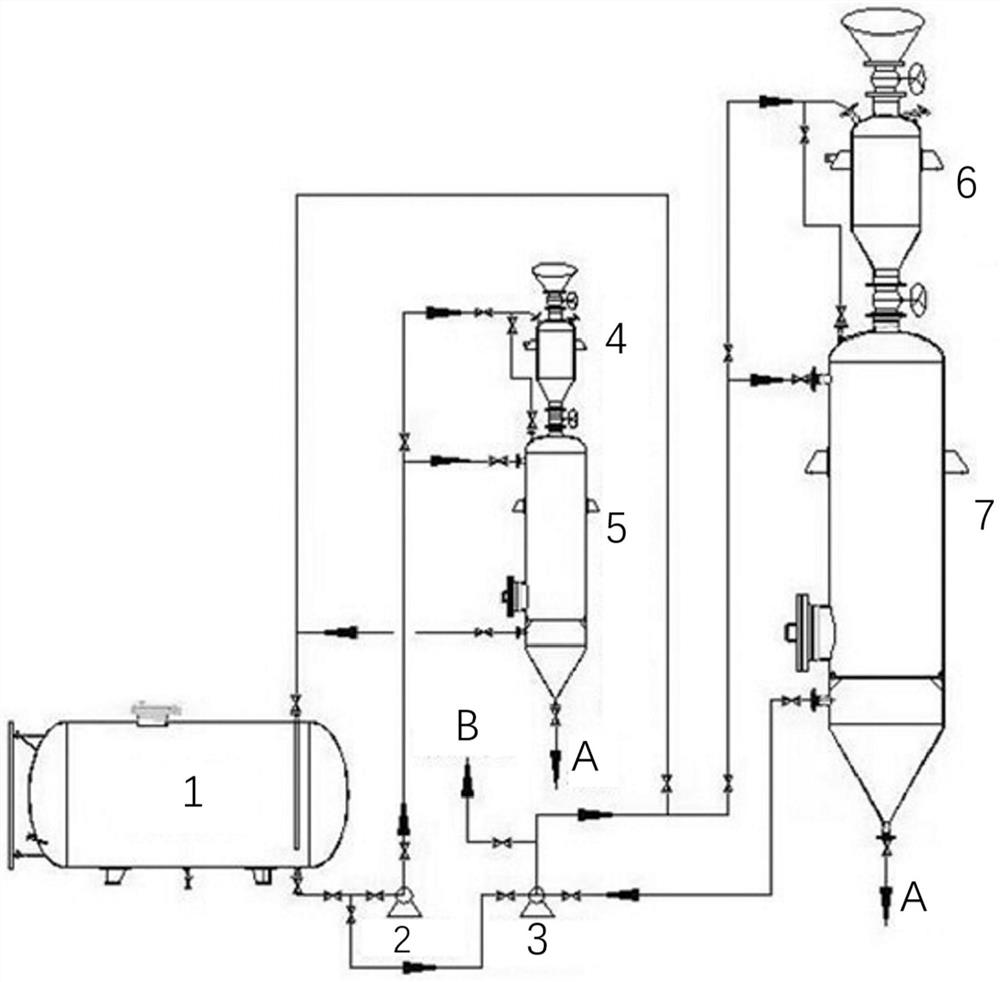

Method for recovering byproduct chloromethane in maltol production process

PendingCN112573995AAvoid unmanageable problemsHalogenated hydrocarbon separation/purificationChemistryProcess engineering

The invention relates to a method for recovering byproduct chloromethane in a maltol production process. The method comprises the following steps: pumping low-pressure gaseous chloromethane from a first roots machine at an inlet of a gasometer, introducing the low-pressure gaseous chloromethane into the gasometer after passing through first-stage alkali wash, first-stage water wash, second-stage water wash and a gas-phase drying bed, performing pressurizing by a roots machine at an outlet of the gasometer, and introducing the process gas into second-stage alkali washing and third-stage alkaliwashing, and a gas-phase drying bed; and carrying out two-stage compression and three-stage rectification on the preliminarily dried gaseous chloromethane by a compressor to remove impurities step bystep, condensing the overheated gaseous chloromethane into a liquid state, and finally carrying out circulating drying to obtain the finished chloromethane. According to the method, a large number ofhigh-boiling-point and low-boiling-point impurities mixed in chloromethane generated by chlorination reaction can be removed, and a qualified chloromethane product is produced.

Owner:ANHUI JINGHE IND

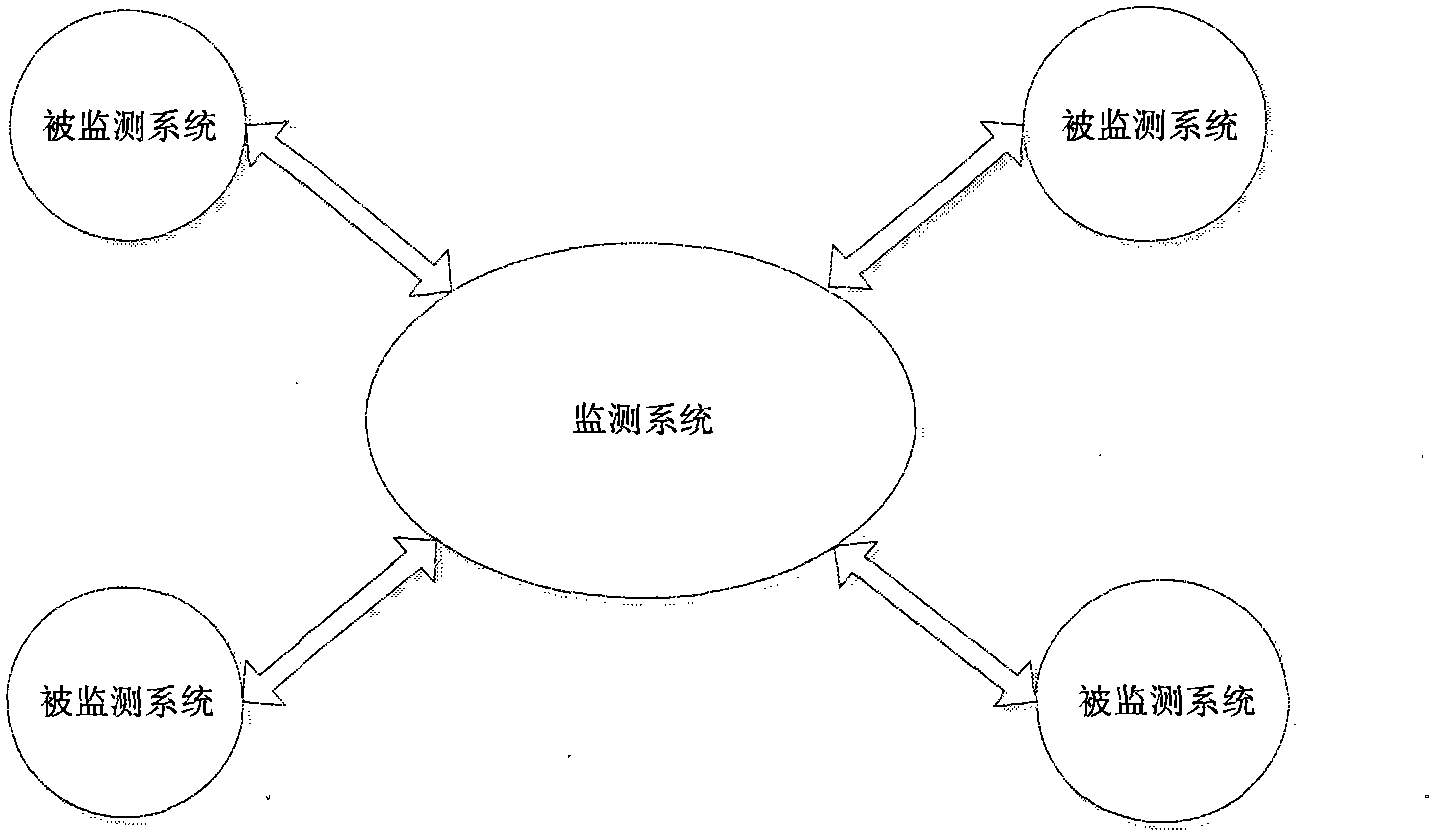

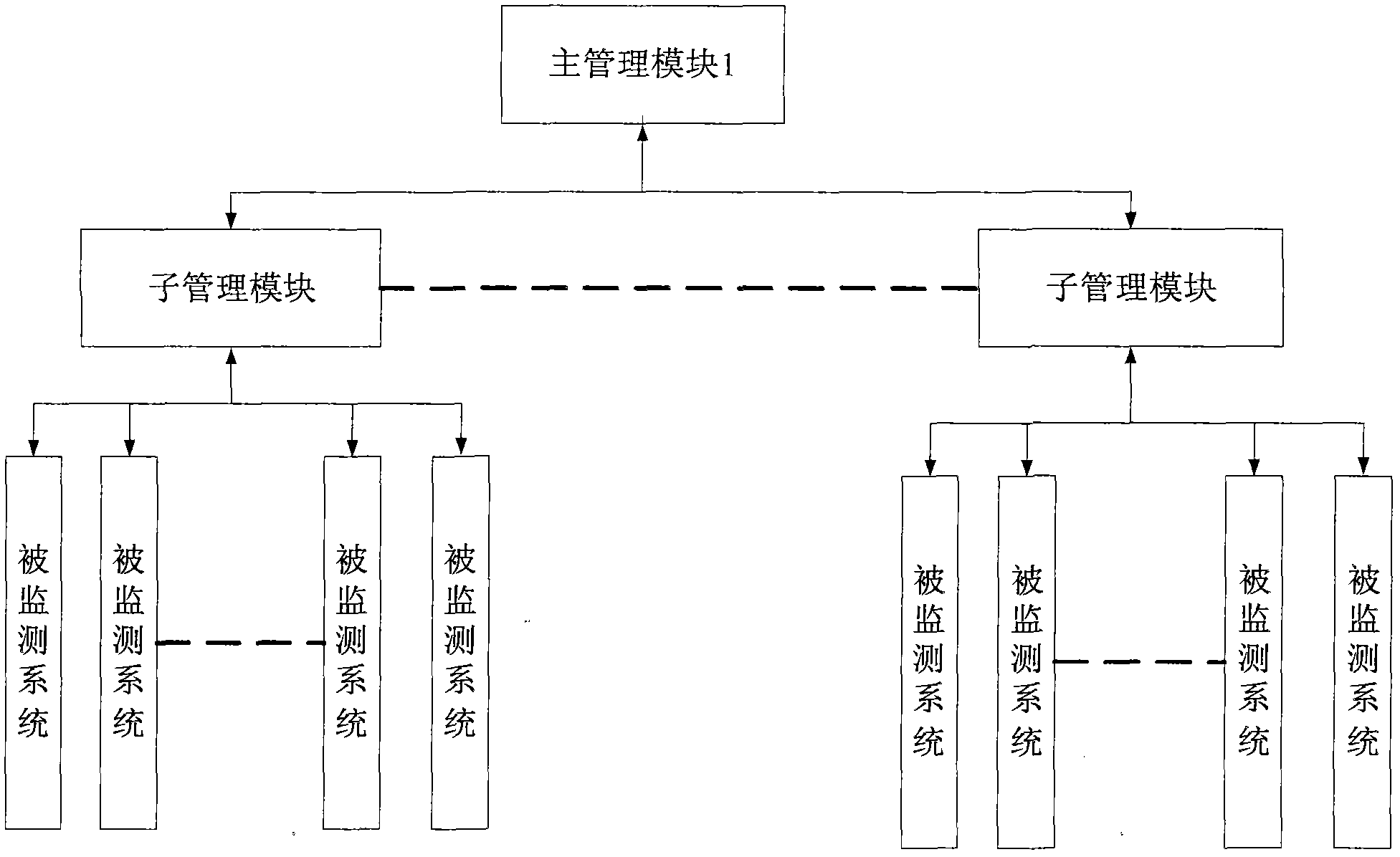

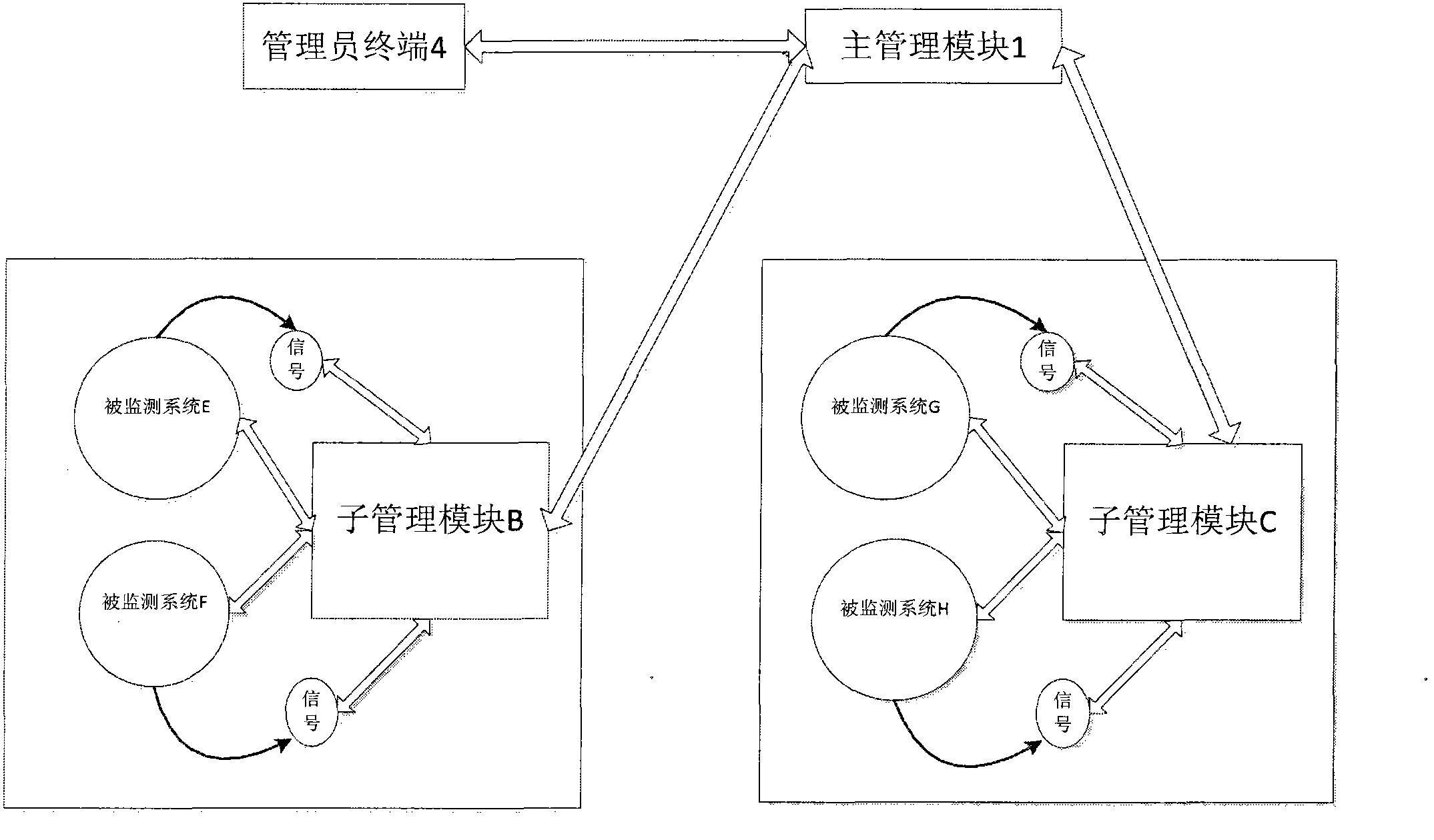

Monitoring device and method

InactiveCN104301167ASolve the problem of service paralysisAvoid unmanageable problemsData switching networksManagement systemWhole systems

The invention relates to a monitoring device and a method. The device comprises a main management module, multiple sub management modules and a manager terminal. When one monitored system has abnormity, the corresponding sub management system corresponding to the abnormal monitored system takes control and processing actions without any manual auxiliary operation. The main management module makes determination, employs corresponding motion modes for the dependent monitored system and notifies the dependent monitored system to take corresponding motions through the corresponding sub management module. After the abnormal system recovers, the whole system functions recover through steps above gradually. A user can communicate with the main management module through a management interface and can send a special instruction to the monitored system. Through the method and the device, a problem that the whole dependent system is abnormal or even collapses because of abnormity of one system can be effectively settled.

Owner:FOUNDER BROADBAND NETWORK SERVICE

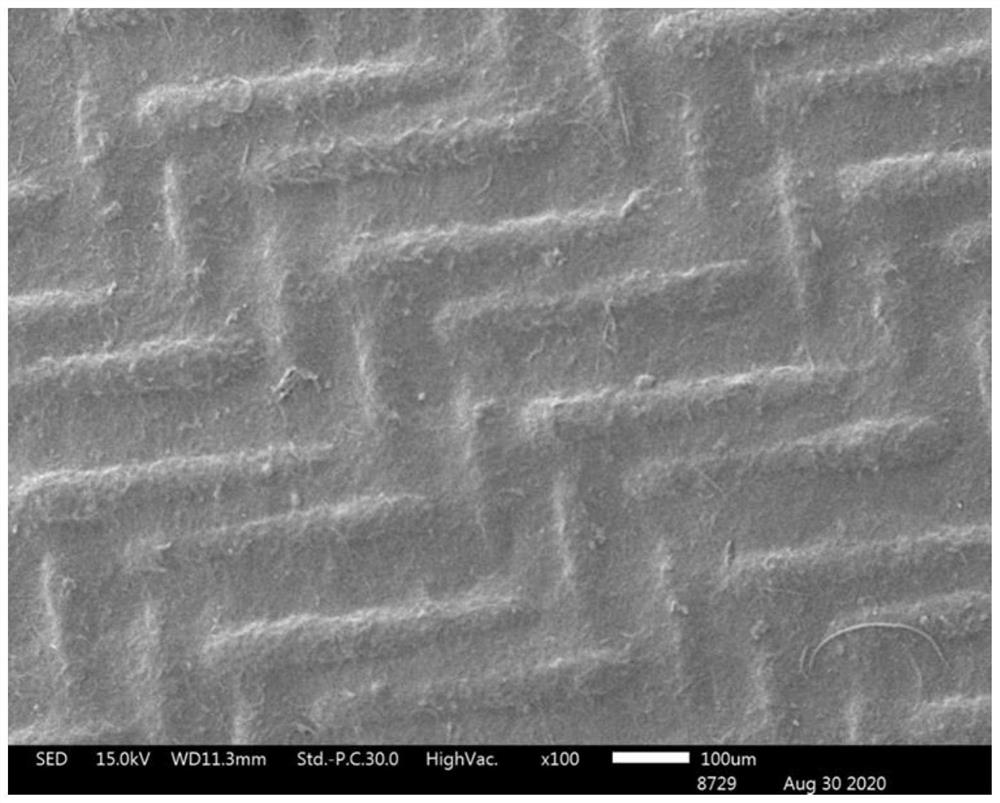

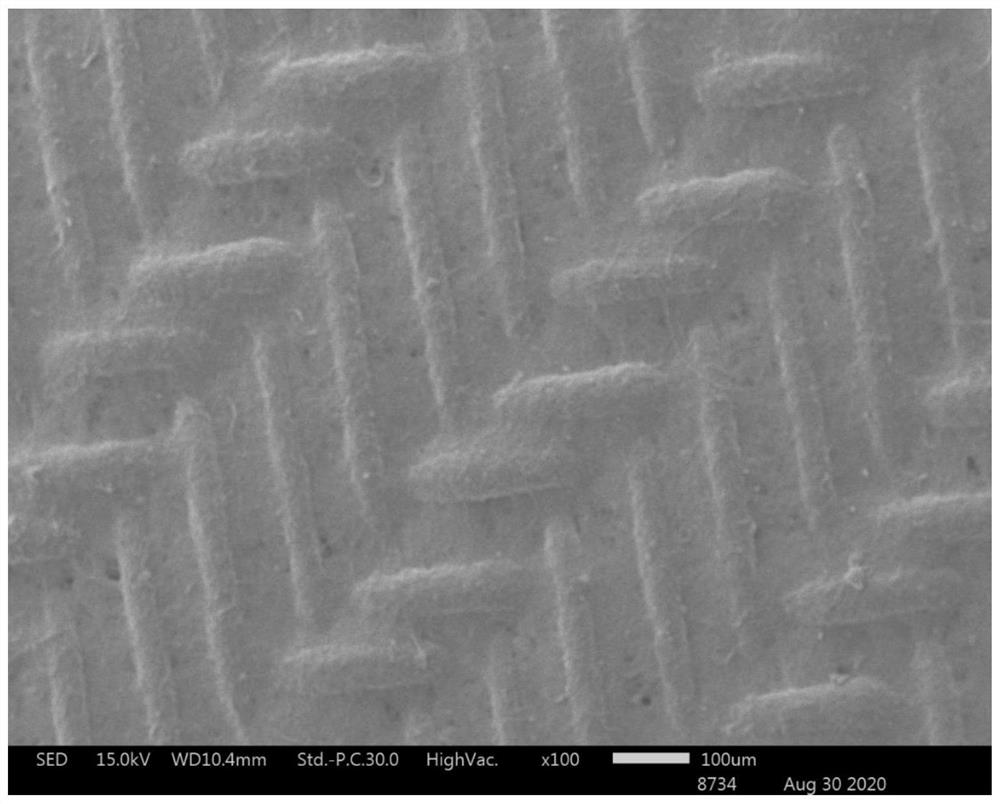

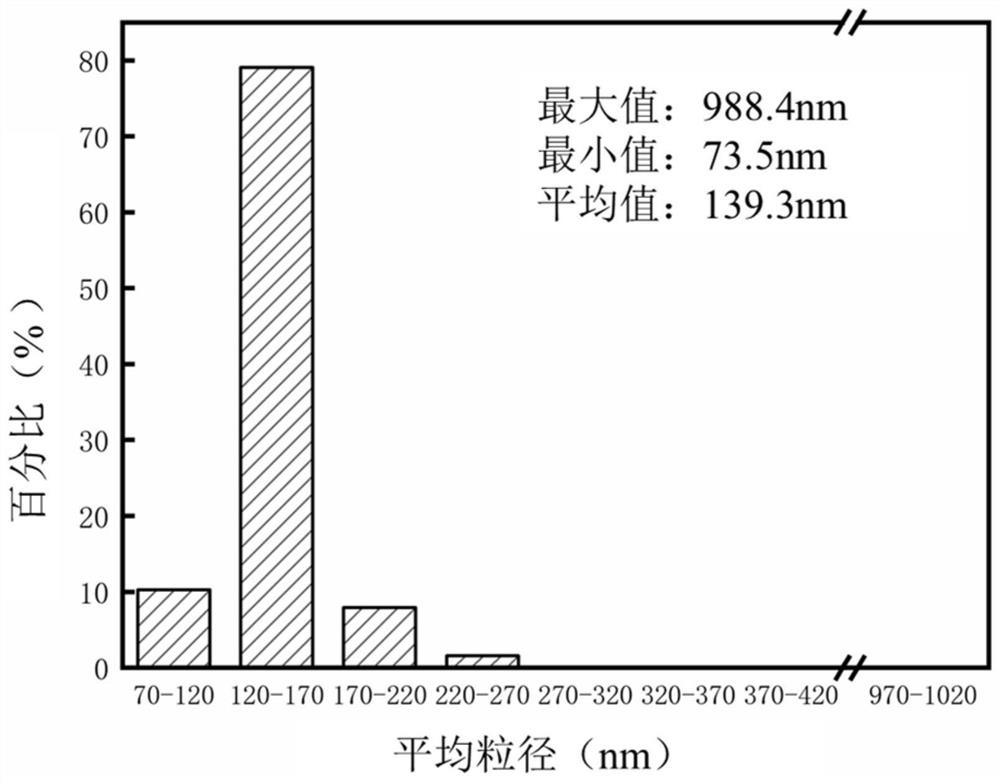

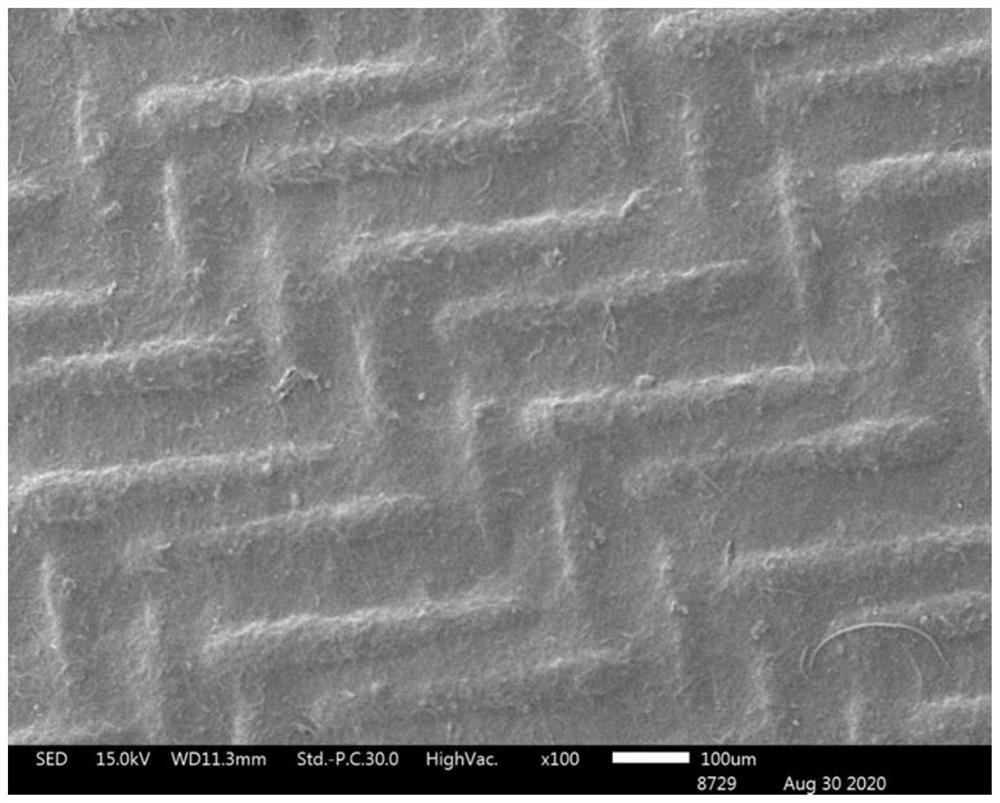

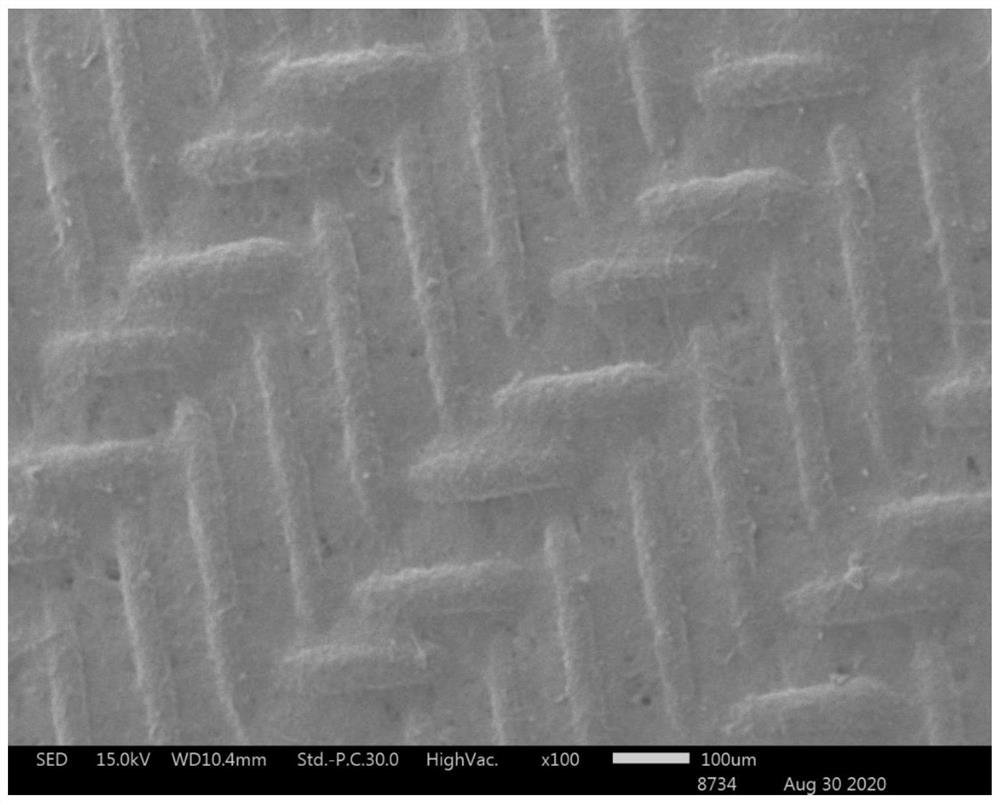

High-permeability anti-fouling nanofiber separation membrane material and preparation method and application thereof

ActiveCN113144913AExtended service lifeIncrease permeable areaMembranesSemi-permeable membranesPhysical chemistryNanofiber

The invention provides a high-permeability anti-fouling nanofiber separation membrane material and a preparation method and application thereof. According to the preparation method, a woven fabric with periodic textures on the surface serves as a base material, a hydrophilic polymer nanofiber coating is loaded on the surface of the woven fabric through a wet non-woven technology, meanwhile the woven fabric and the polymer nanofiber coating are tightly attached through a chemical cross-linking agent, and the high-permeability anti-fouling nanofiber separation membrane material is obtained. Through the mode, the prepared separation membrane material has a small-aperture compact structure and a surface texture structure at the same time, and the permeability and the pollution resistance of the membrane material are synergistically improved. The preparation method of the separation membrane material is simple, convenient and easy to implement, the controllability is high, the preparation efficiency can be improved, large-scale preparation is easy, and the prepared separation membrane material can be applied to the field of ultrafiltration and microfiltration of tangential flow liquid and has high practical application value.

Owner:WUHAN TEXTILE UNIV

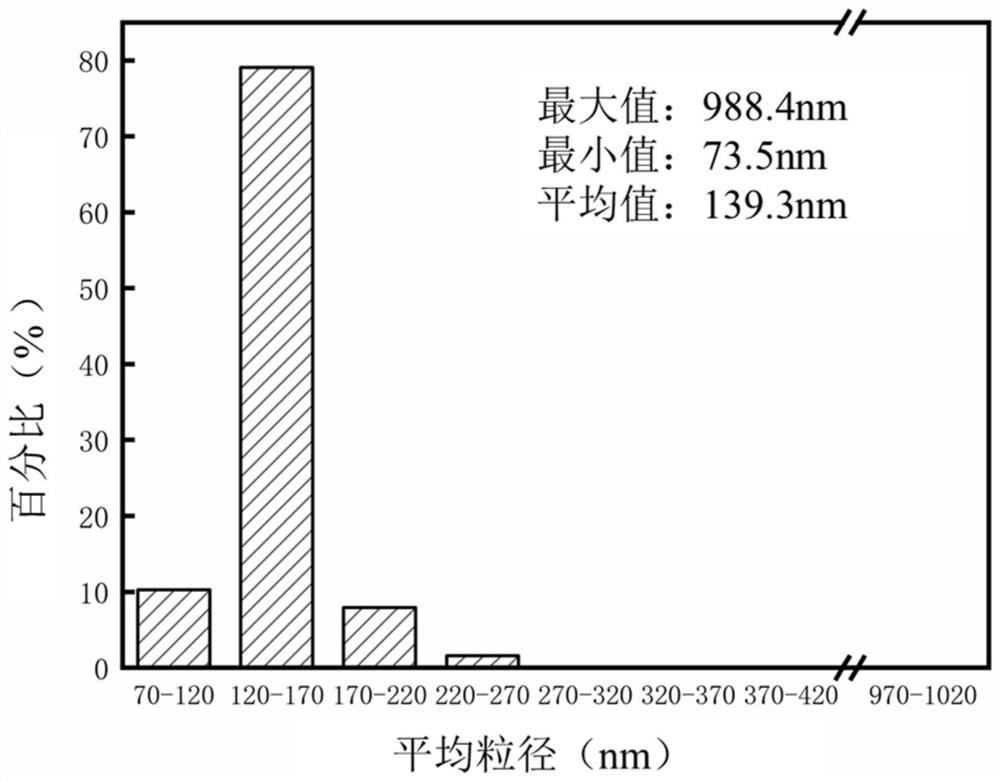

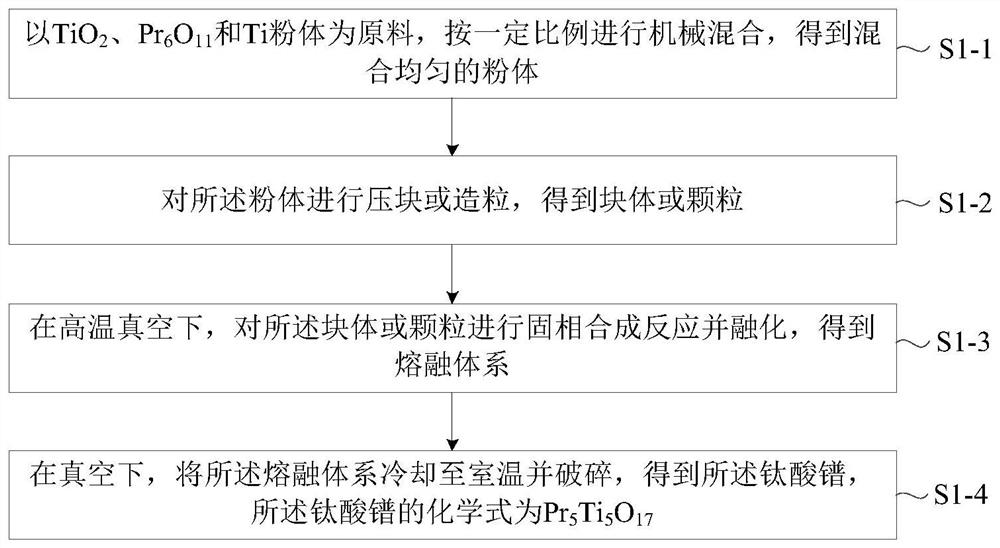

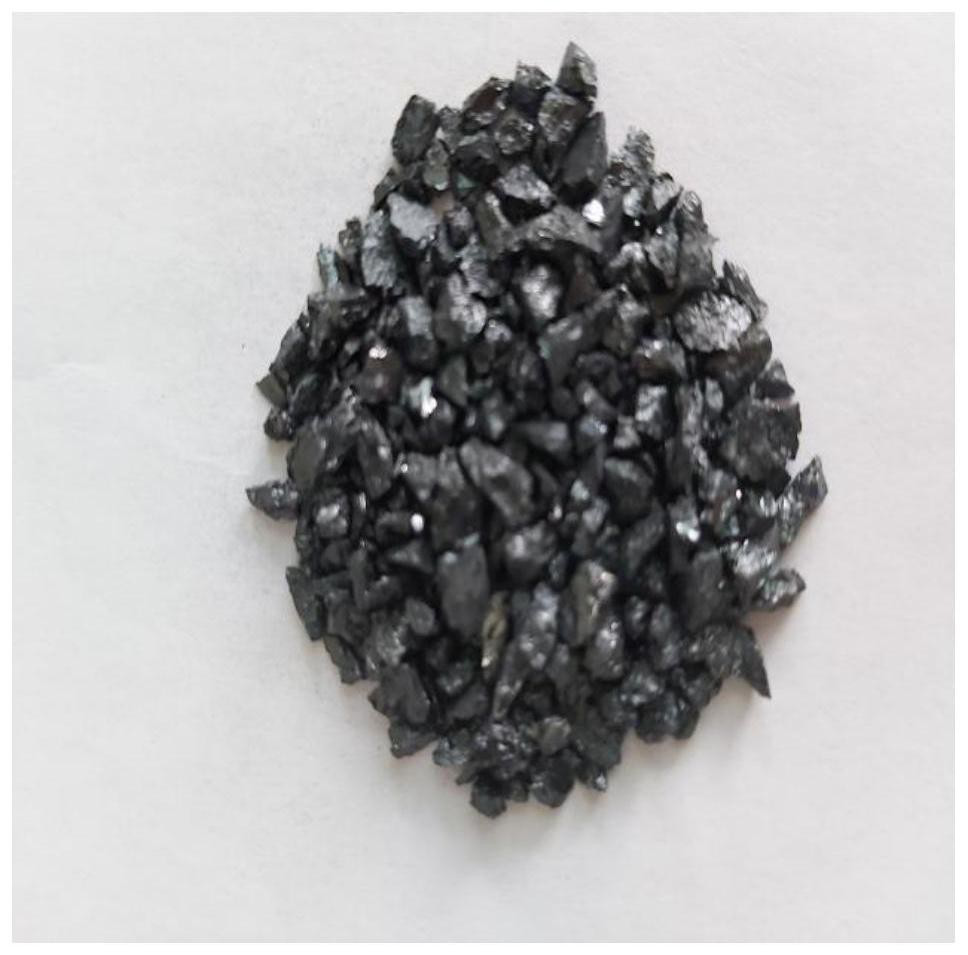

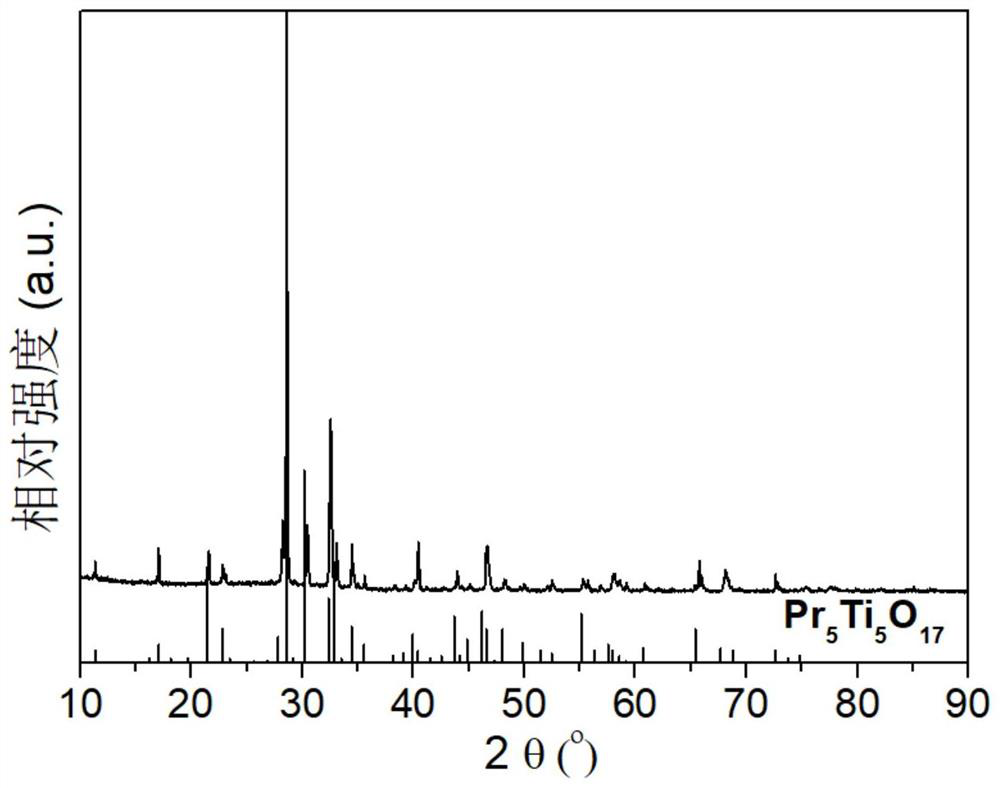

Pre-melted high-refractive-index optical coating material as well as preparation method and application thereof

ActiveCN113200566AFix stability issuesSolving Consistency IssuesVacuum evaporation coatingSputtering coatingRefractive indexOptical thin film

The invention provides a pre-melted high-refractive-index optical coating material as well as a preparation method and application thereof, and belongs to the field of optical thin film materials. The high-refractive-index optical coating material is praseodymium titanate, and the chemical formula of the high-refractive-index optical coating material is Pr5Ti5O17. In addition, the praseodymium titanate is prepared by taking TiO2, Pr6O11 and Ti powder as raw materials through a solid-phase synthesis reaction. The praseodymium titanate prepared by the preparation method provided by the invention keeps stable chemical composition in the evaporation process, can form a very flat evaporation surface during pre-melting, and is beneficial to process control in the coating process. Moreover, an optical film layer plated by adopting the praseodymium titanate disclosed by the invention has relatively high transmittance from a near ultraviolet band to a near infrared band, and meanwhile, the film layer is compact, firm and stable in chemical property, and can be used as a high-quality high-refractive-index material to be applied to optical film system design and batch film plating production.

Owner:有研资源环境技术研究院(北京)有限公司

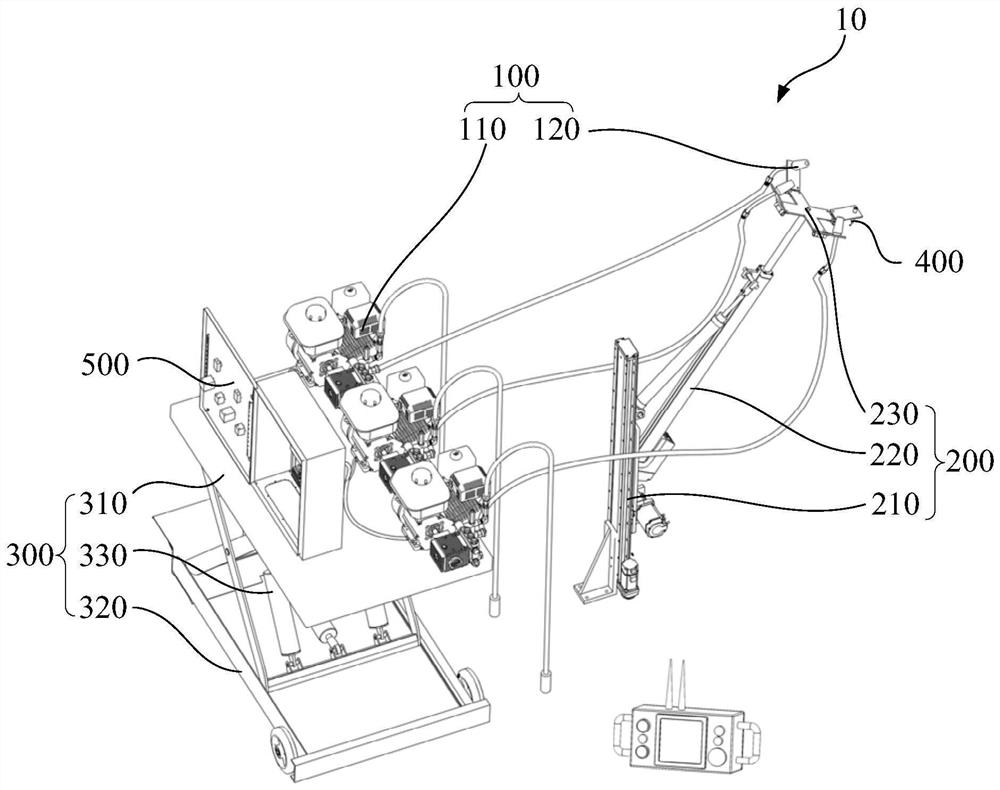

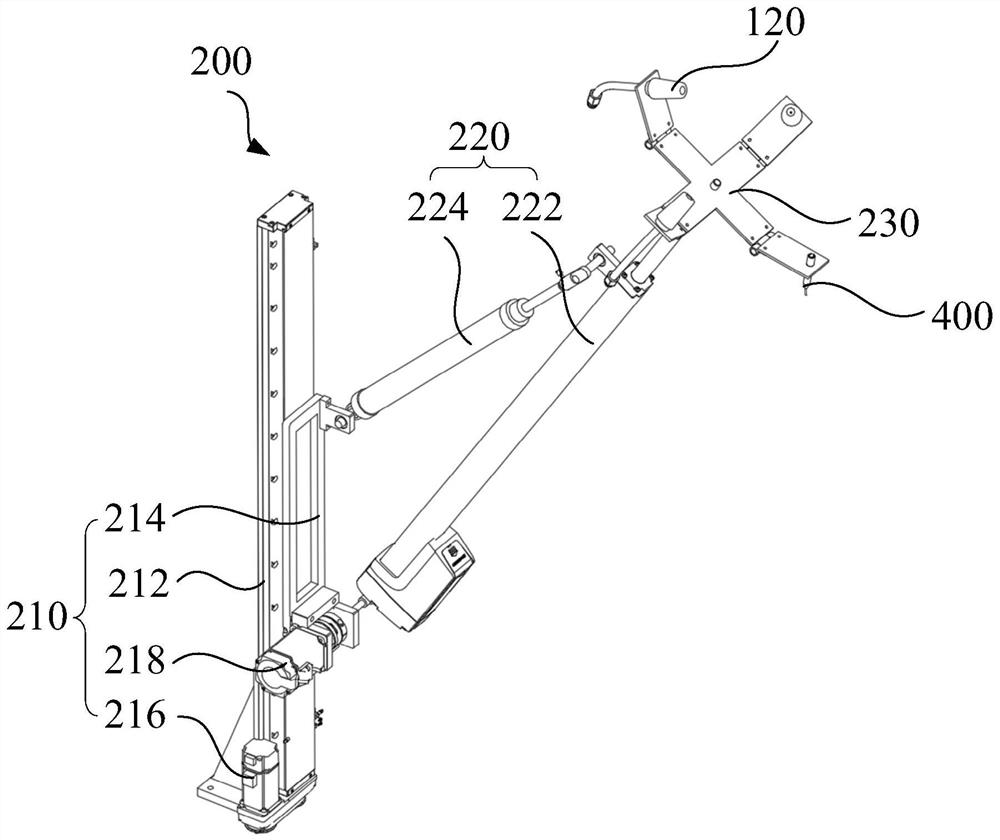

Insulator cleaning machine and insulator cleaning method

ActiveCN114074087AEasy to cleanImprove job stabilityCleaning using liquidsControl engineeringMechanical engineering

The invention discloses an insulator cleaning machine and an insulator cleaning method. The insulator cleaning machine comprises a waterway adjusting device, a positioning mechanism and a lifting mechanism; the waterway adjusting device comprises a water supply assembly and a spray head; the water supply assembly is used for supplying water to the spray head; the spray head is connected to the positioning mechanism which is used for adjusting the position and orientation of the spray head; the water supply assembly is connected to the lifting mechanism used for adjusting the height of the water supply assembly; the water supply assembly is connected to the lifting mechanism; and the spray head is connected to the positioning mechanism. The water supply assembly is adjusted to the approximate height around an insulator to be cleaned through the lifting mechanism, then the positioning mechanism independently controls the spray head to move; and due to the fact that the spray head is simple in structure, the positioning operation of the positioning mechanism on the spray head is accurate, efficient, high in flexibility and convenient to operate, and the problem that the spray head is difficult to control due to the redundant structure of the waterway adjusting device is avoided. According to the insulator cleaning method, the cleaning of the insulator is realized by independently moving the spray head, and the cleaning effect is good.

Owner:DALI BUREAU OF ULTRA HIGH VOLTAGE TRANSMISSION CO CHINA SOUTHERN POWER GRID CO LTD

Fluorapatite purification method and method for preparing fluorohydroxyapatite bioceramic thereof

InactiveCN109909058AReduce manufacturing costSimple processWet separationPurification methodsFluorohydroxyapatite

The invention discloses a fluorapatite purification method and a method for preparing a fluorohydroxyapatite bioceramic, and belongs to the technical field of mineral processing. The fluorapatite purification method comprises the following steps that the fluorapatite ore is ground, stirred and slurried, adjusted to pH value, added with an inhibitor and a collector, and inflated for rough selectionto obtain a coarsely selected concentrate and a coarsely selected tailings; the coarsely selected concentrate is slurried, adjusted to pH value, and added with the inhibitor for selection to obtain afluoroapatite concentrate and a selected tailings; and the fluoroapatite concentrate is added with water and slurried and then added with phosphoric acid leaching, solid-liquid separation is carriedout, and the purified fluoroapatite is obtained after drying. The purified fluoroapatite is added with water and stirred to remove the agent, concentrated nitric acid is added to dissolve, NaOH is added to carry out hydroxy reaction, and after calcination and crystallization, the fluorohydroxyapatite bioceramic is obtained. The method obtains the synthesized fluorohydroxyapatite which is used as ahuman body hard tissue substitute material, and the method has the characteristics of being low in production cost, simple in process, easy to operate and the like.

Owner:NORTHEASTERN UNIV

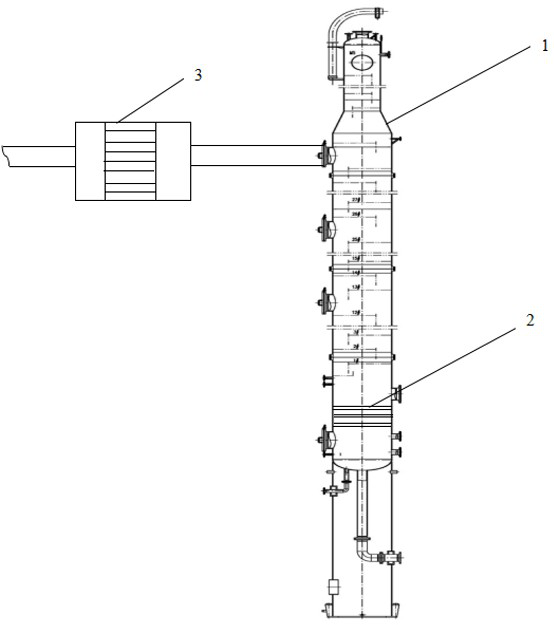

Method for reducing tin content of titanium tetrachloride

PendingCN112758977ALow costEquipment installation is simpleTitanium tetrachlorideStannic chlorideTitanium tetrachlorideMolecular sieve

The invention relates to a method for reducing the tin content of titanium tetrachloride, which comprises the following steps: adding an aluminum wire mesh in the middle of a distillation tower, controlling the tower top temperature of the distillation tower at 136-155 DEG C, feeding titanium tetrachloride into the distillation tower, collecting a mixture of tin tetrachloride and titanium tetrachloride at the tower top of the distillation tower because the boiling point of tin tetrachloride is lower than that of titanium tetrachloride, and collecting titanium tetrachloride at the tower bottom of the distillation tower, wherein the reflux ratio is reduced in the rectification process. The method has the advantages that the cost is low, a honeycomb zeolite molecular sieve is applied, excessive equipment capital investment is not needed, and equipment is easy to install and manufacture.

Owner:仙桃市中星电子材料有限公司

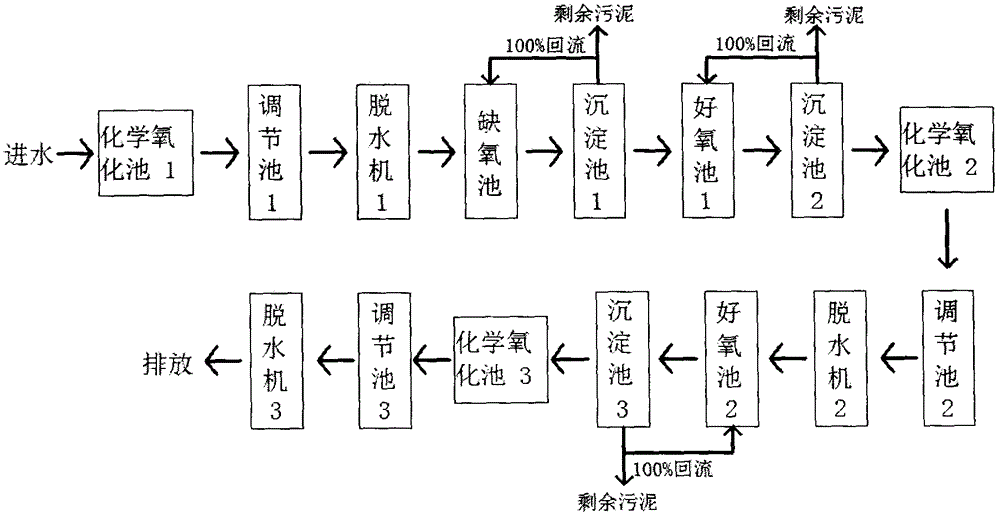

A kind of treatment method of recycled polyester production wastewater

ActiveCN104692594BReduce processing costsReduce energy consumptionMultistage water/sewage treatmentNature of treatment waterPolyesterChemical treatment

The invention relates to a treatment method for wastewater produced by recycled polyester. In the present invention, the recycled polyester production waste water enters the first chemical oxidation pool, and enters the first neutralization adjustment pool after chemical oxidation, the pH is adjusted to 6.5, dehydrated by the first centrifugal dehydrator, and passed through the anoxic pool-the first sedimentation tank-the second The first aerobic tank-the second sedimentation tank performs the first biochemical treatment, the second chemical oxidation tank performs chemical treatment, adjusts pH=4, removes part of COD, enters the second neutralization adjustment tank, adjusts the pH to 7.5, and passes through the second Centrifugal dehydrator dehydration, the second biochemical treatment through the second aerobic tank-the third sedimentation tank, enter the third chemical oxidation tank for chemical treatment, adjust pH = 4, enter the third neutralization adjustment tank, adjust the pH to 6 , and discharge after dehydration by the third centrifugal dehydrator. The invention overcomes the defects of high energy consumption and extremely high cost. The invention is friendly, and compared with the distillation method, the waste water treatment cost is low, the energy consumption is low, the COD removal rate is improved, and the problem that the dangerous mother liquor cannot be treated caused by the distillation method is avoided.

Owner:YANGZHOU UNIV

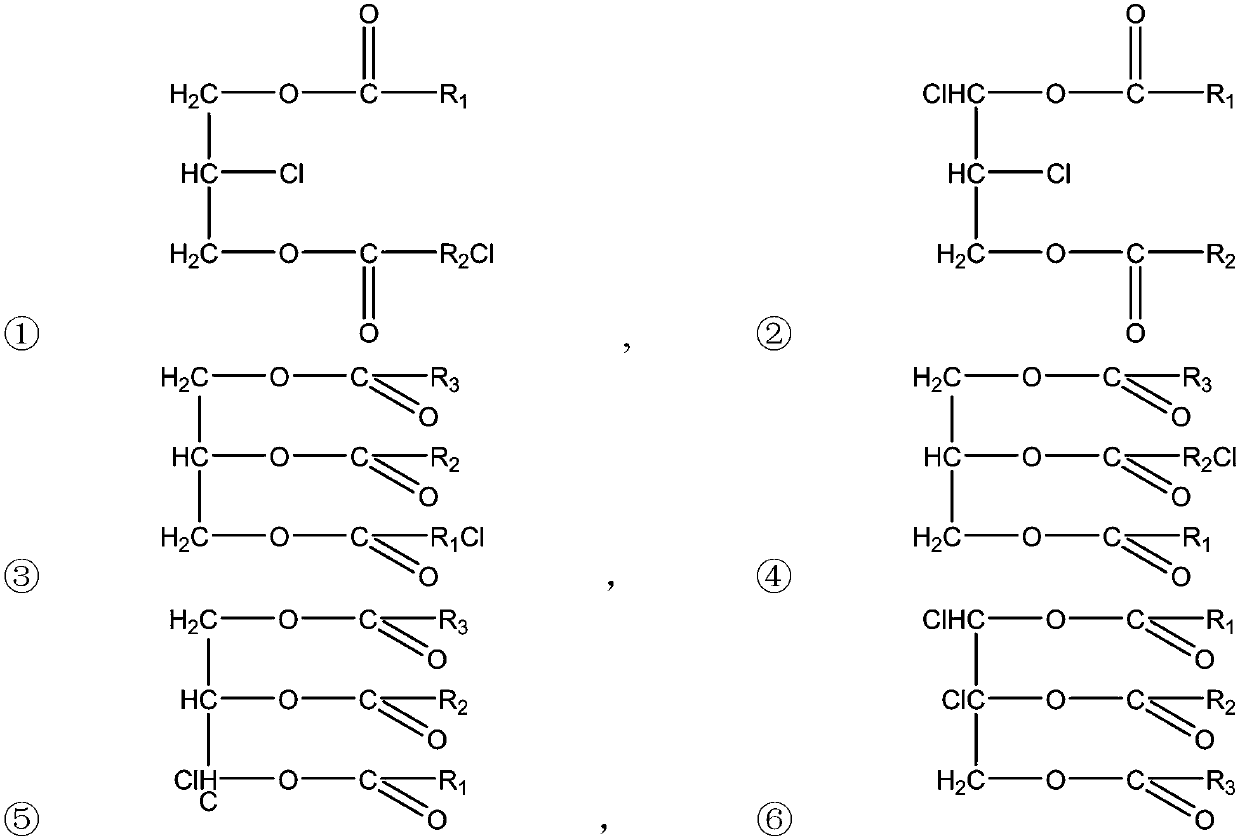

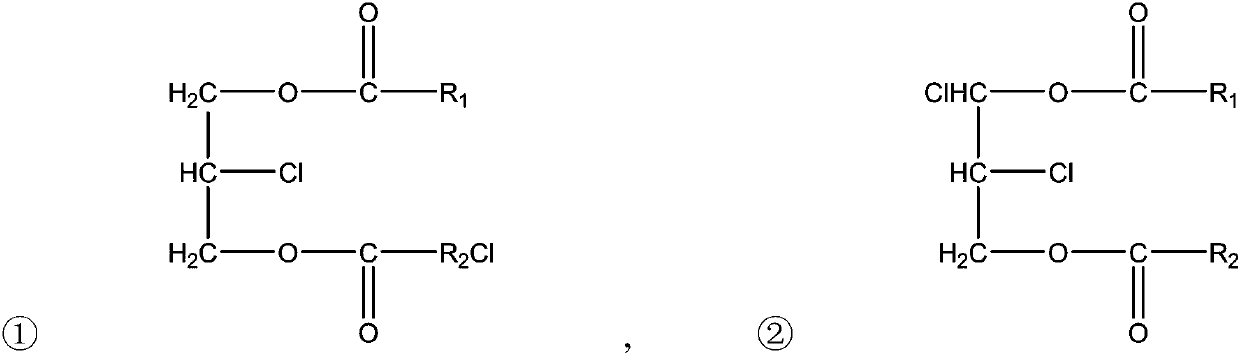

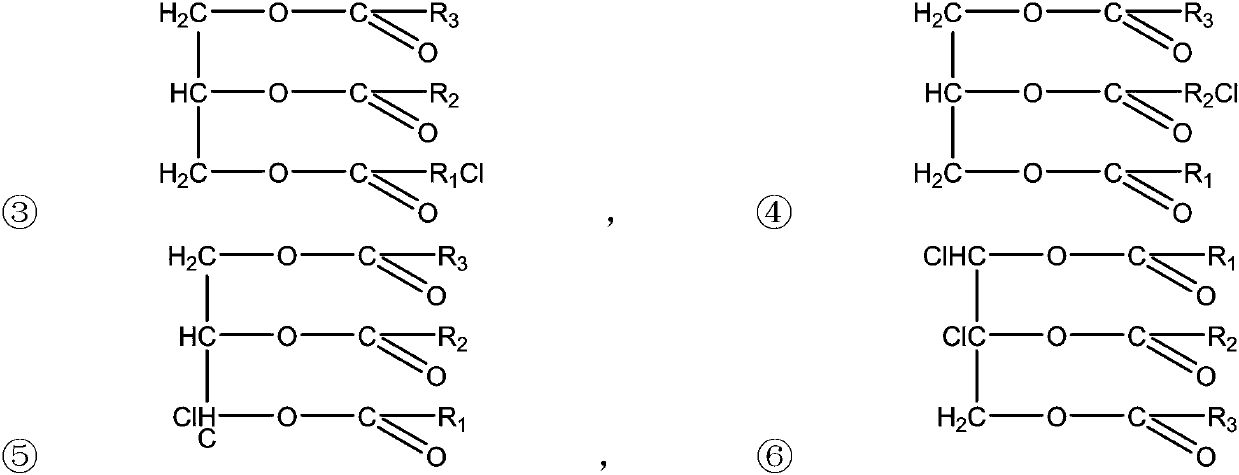

Composite plasticizer taking chlorinated glycerol ester as main body as well as preparation method and application thereof

InactiveCN107778878AIncrease added valueIncrease the chlor-alkali industry chainBenzoic acidBiodiesel

The invention relates to a composite plasticizer taking chlorinated glycerol ester as a main body. The composite plasticizer comprises: a combination of any three or more of formula (1) to formula (6), wherein R1, R2 and R3 represent H, and C1-C5 alkyl or phenyl respectively; 3 weight percent of a stabilizer, 0.5 weight percent of a surfactant and 5-10 weight percent of a viscosity reducer. The invention also provides a preparation method of the composite plasticizer, and the preparation method comprises reacting a biodiesel byproduct namely crude glycerol, alkyl acid or benzoic acid, a water-carrying agent, and an esterification catalyst, and other steps. The plasticizing efficiency of the composite plasticizer provided by the invention can be equivalent to that of dioctyl phthalate (DOP); moreover, the biodiesel byproduct namely crude glycerol is fully utilized, and direct high-value utilization with a high transformation rate of the crude glycerol and the problem that a large numberof byproducts cannot be treated are fundamentally solved at the same time; on the other hand, chlorine can also be utilized to increase the chlorine-alkali industry chain and increase economic benefits; the preparation process of the composite plasticizer is simple and reliable, and a produced plasticizer product is stable in chemical property and good in product processing property, avoids potential dangers at the same time, and is safe and environment-friendly.

Owner:SHANDONG YANHAI CONSTR RESOURCES

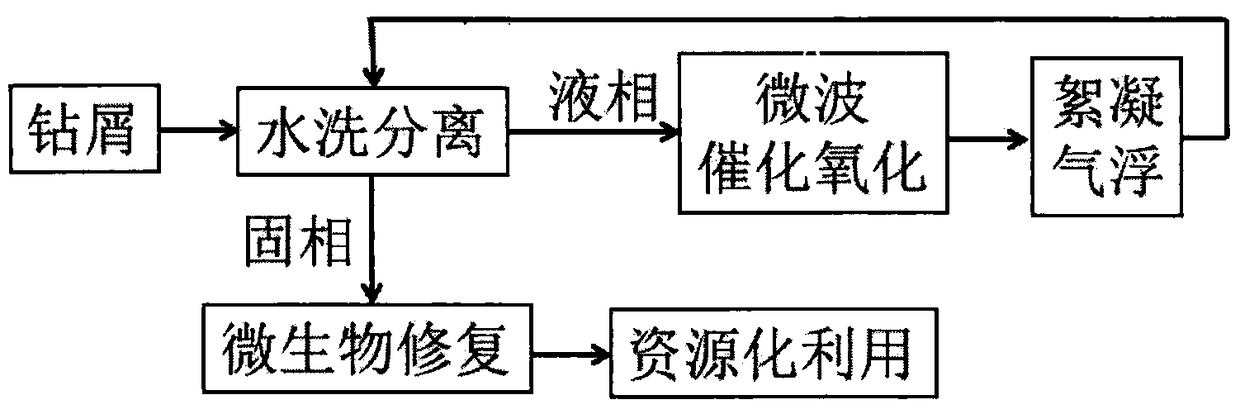

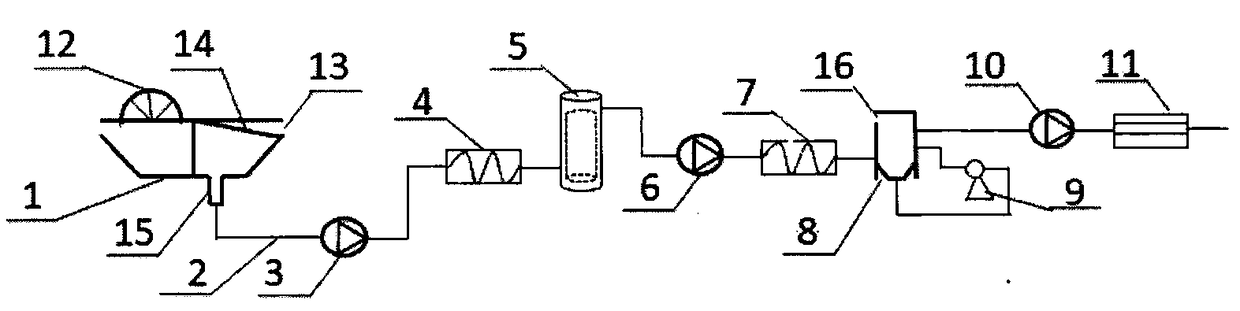

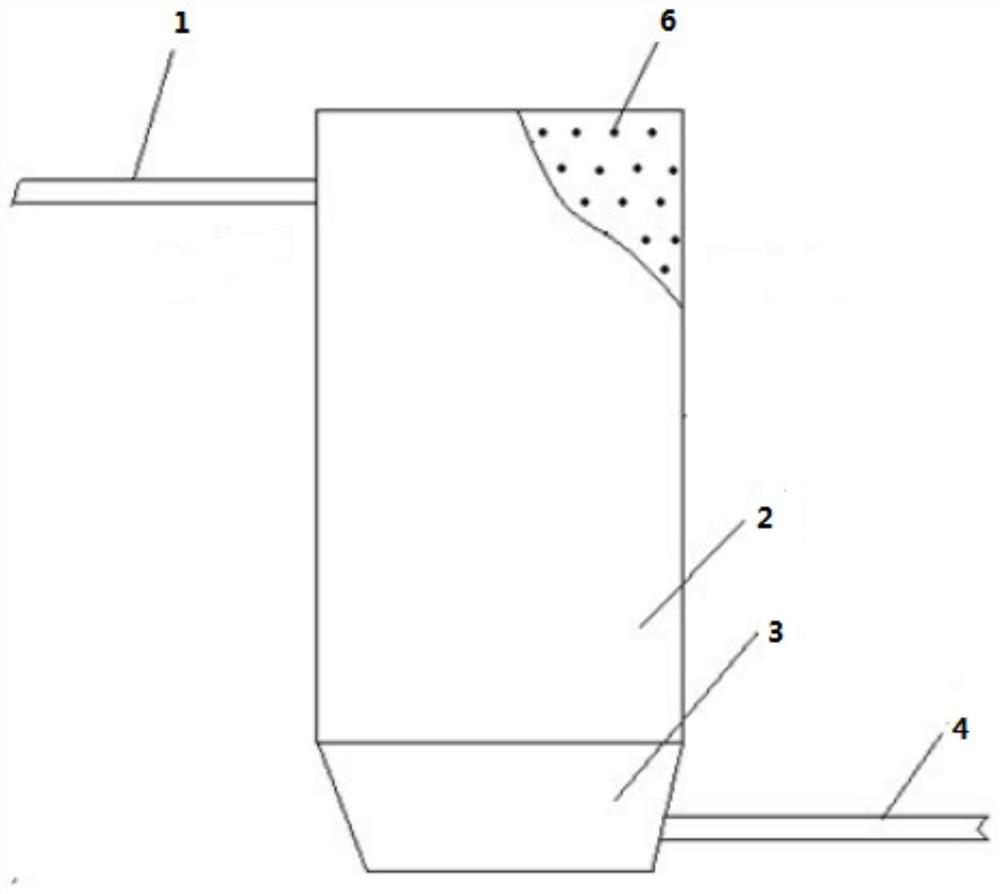

Treatment method of drilling waste

ActiveCN109025868AAvoid unmanageable problemsIncrease concentrationFlushingResource utilizationCatalytic oxidation

The invention relates to a treatment method of drilling waste. A treatment device involved in the method is composed of a water washing separator, an impeller, a rock debris discharge opening, a vibrating screen, a water outlet, a pipeline, a first water pump, a first dosing mixer, a microwave reactor, a second water pump, a second dosing mixer, an air floating device, an air floating device slagdischarging port, an air dissolving pump, a third water pump and a magnetizer, wherein rock debris separated from the vibrating screen is washed with water by the water washing separator, the water-washed solid-phase rock debris is subjected to microbial remediation treatment, a small quantity of residual harmful pollutants are further removed, the pollutant content is lower than a specified limitvalue, and then resource reutilization is realized; water-washed liquid-phase sewage is subjected to microwave catalytic oxidation, flocculation and air floatation separation to serve as cleaning water for recycling. The method has the advantages of being simple in process, thorough in pollutant removal, capable of realizing resource utilization, low in treatment cost and the like, and large-scale application can be carried out on a drilling site of an oil and gas field.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

Rare earth doping metal halogenide photostimulable phosphor phase separation glass and preparation thereof

InactiveCN101328020AAvoid unmanageable problemsSimple preparation stepsLuminous intensityInterference factor

The invention provides a rare earth-doped metal halide photostimulated luminescence phase separation glass and a method for preparing the same characterized in that the mol percentage composition of the glass is as follows: AlF3 25-40%, BaF2 5-63%, BaCl2 1-15%, BaBr2 1-15%, YF3 10-20%, EuF3 0.1-1%. The rare earth-doped metal halide photostimulated luminescence phase separation glass is obtained by melting for 10-45 minutes in a high-frequency current furnace under the chlorine or inert atmosphere protection at 800-1000 DEG C and heat-treating for 0.5-4 hours around the phase separation temperature after cooling. The method of the invention solves the problem that the powder morphology is not easy to control during the agglomeration and milling processes of photostimulated luminescence powder synthesis using solid phase method and liquid phase method, simplifies the preparation steps of the radiation image storage materials of photostimulated liminescence glass, while eliminates the external interference factors during the preparation process, increases the luminous intensity of the rare earth ion in the glass, has advantage of rapid heating and cooling and reduces the volatilization of the halogen component.

Owner:KUNMING UNIV OF SCI & TECH

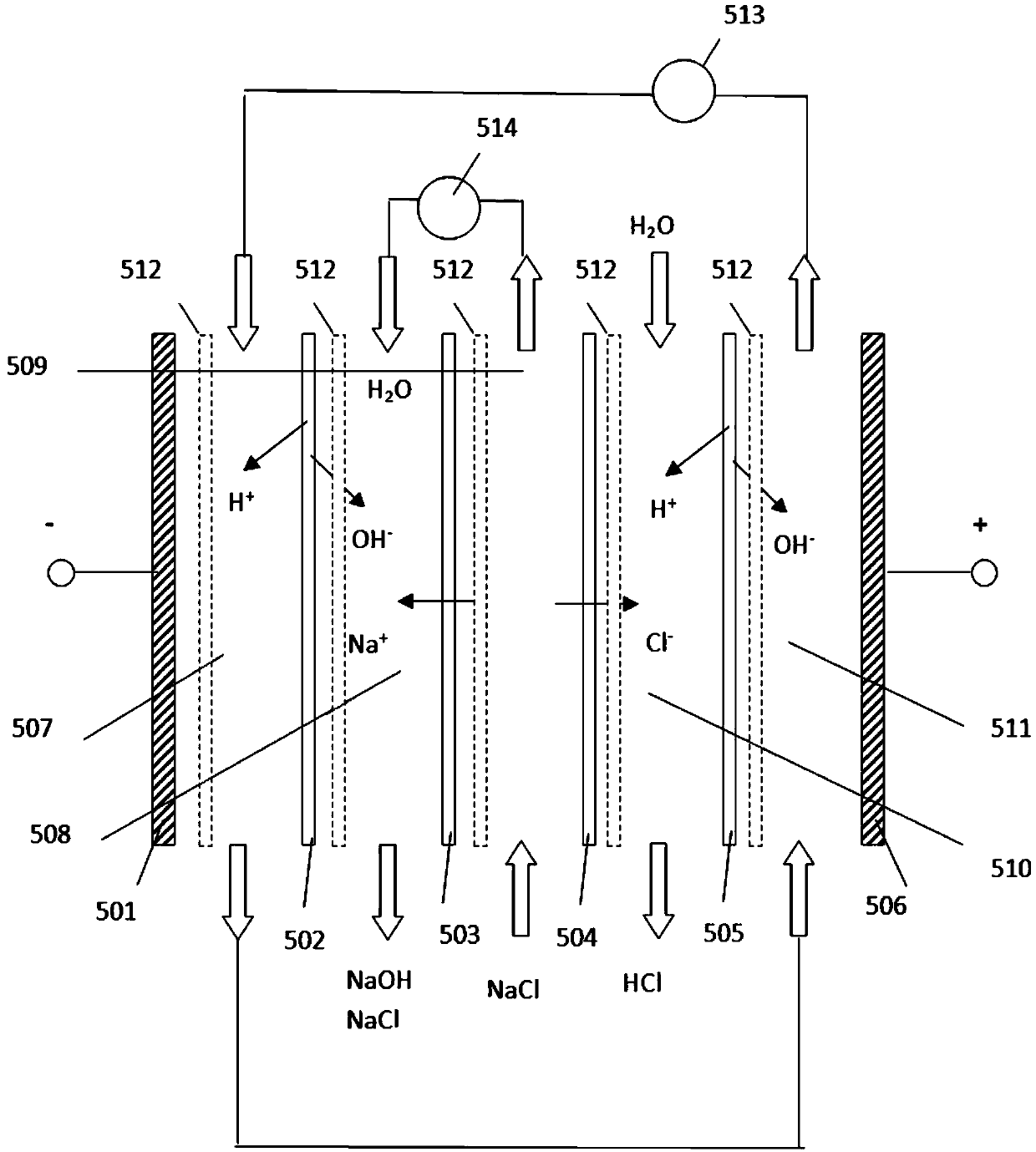

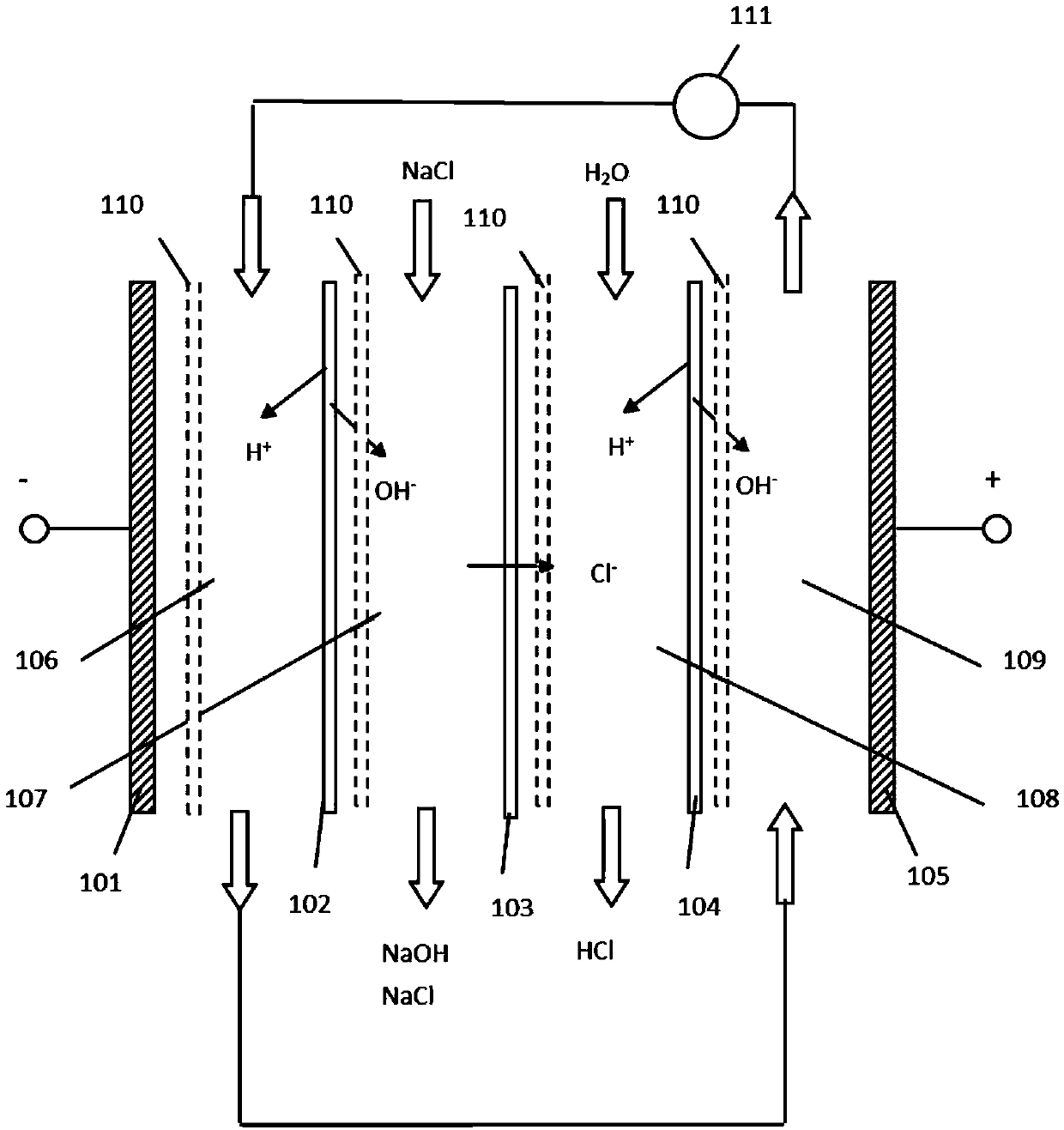

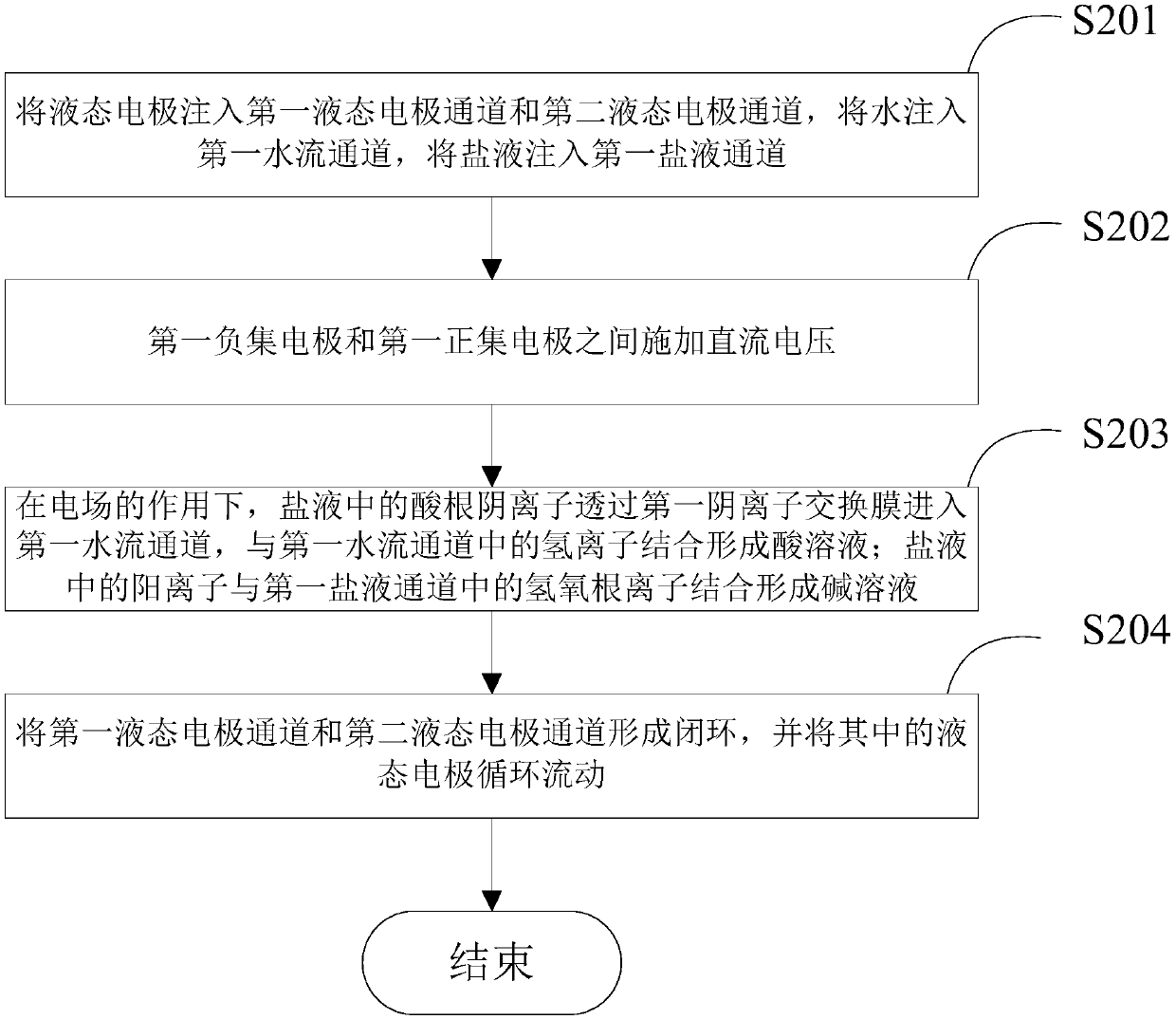

Device, method and system for converting salts into acids and alkalis

PendingCN110228836AAvoid unmanageable problemsWater/sewage treatment bu osmosis/dialysisWater/sewage treatment apparatusPipe fittingElectrical polarity

The invention provides a device, method and system for converting salts into acids and alkalis. Water having a certain salt concentration flows through a treatment module composed of ion exchange membranes, an electrode, an isolation material, a fixing piece and corresponding pipe fittings, so that salt ions in the water migrate towards different polarity directions by virtue of the action of a direct-current electric field, and are separately recombined to form acids and alkalis in different flow paths by virtue of blocking and penetrating effects of various ion exchange membranes, so that acid liquor and alkali liquor can be obtained at the outlet of the module. The acid liquor and alkali liquor can be directly applied to industrial production or furthermore concentrated and utilized.

Owner:SHANGHAI ANJIANG ENVIRONMENTAL PROTECTION TECH PARTNERSHIP (LLP)

Smart access control method and device for community based on mobile phone 3G network

InactiveCN103295304BAvoid unmanageable problemsImprove securityIndividual entry/exit registersManagement unitPassword

The invention discloses a community intelligent entrance guard control method based on a mobile phone 3G (third generation) network. The community intelligent entrance guard control method based on a mobile phone 3G network is characterized in that an entrance guard control device mainly comprises a mobile phone control unit, a community entrance guard management unit and a network control unit; the mobile phone control unit is used for user registration, entrance application, mobile phone binding and entrance password display; the network control unit is used for user identity checking, password saving as well as transmission; the community entrance guard management unit is used for checking the password input by users, opens a gate automatically after successful checking, can generate user access records, can manage people conveniently, is safe, reliable, convenient and feasible, and can achieve scientific management of community entrance guard.

Owner:NORTHEAST DIANLI UNIVERSITY

A kind of irrigation control system and irrigation control method based on open channel

ActiveCN107223544BEnsure safetyAvoid unmanageable problemsClimate change adaptationWatering devicesStream gaugeStream flow

The invention discloses an irrigation control system and an irrigation control method based on an open channel. The system is configured with a management module, an index acquisition module, an index analysis module, a water level acquisition module, a water level analysis module and a channel water injection and discharge control module. The channel water injection and discharge control module adopts a step-by-step control method, traverses each main channel and branch channel from top to bottom in a breadth-first manner, and controls water injection and discharge for each main channel and branch channel according to its channel data and sluice status. Until the amount of water released to all farmland channels meets the requirements of the corresponding water demand on the farmland side. The present invention avoids the problem that the flow rate and flow rate of the open channel are difficult to control by calculating the water storage capacity through the water level gauge.

Owner:JIANGSU COCON TECH

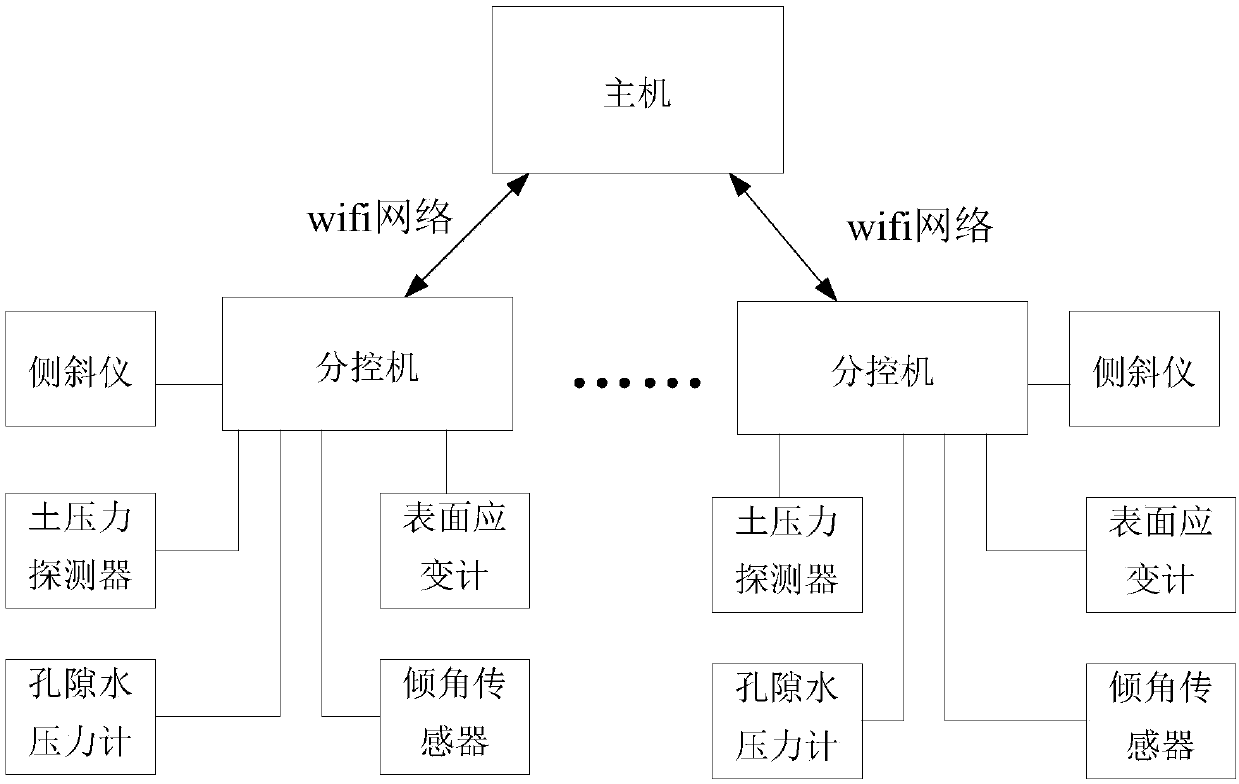

Multifunctional data acquisition system suitable for geotechnical monitoring

InactiveCN107862846AAvoid confusionAvoid unmanageable problemsElectric signal transmission systemsEarth material testingData acquisitionEngineering

The invention discloses a multifunctional data acquisition system suitable for geotechnical monitoring, which includes a host computer and a plurality of detection sensor groups, and several sub-controllers are arranged between the host computer and the plurality of detection sensor groups, one sub-controller and one detection sensor Multiple sensors in the sensor group are connected through RS485 cables, and all sub-controllers are connected with the host computer through wireless network. The invention solves the problems of high installation cost, chaotic detection lines and cumbersome construction of the existing detection system.

Owner:成都行泽科技有限公司

Device and method for removing moisture in liquid chloromethane through multi-stage drying

ActiveCN114177653AHigh purityAvoid unmanageable problemsNon-miscible liquid separationEnvironmental engineeringChloromethane

The invention discloses a device for removing moisture in liquid chloromethane through multi-stage drying, which is characterized in that a bottom outlet of a chloromethane storage tank is respectively connected with upper inlets of a first-stage circulating drying bed and a second-stage circulating drying bed through pipelines, and a lower outlet of the first-stage circulating drying bed is connected to the chloromethane storage tank through a pipeline; and a lower outlet of the secondary circulating drying bed is connected to an upper inlet of the secondary circulating drying bed through a pipeline and a pump. The invention further discloses a method for removing moisture in liquid chloromethane through multi-stage drying. The product produced by the method and the equipment is good in quality, and no waste is generated.

Owner:ANHUI JINHE IND CO LTD

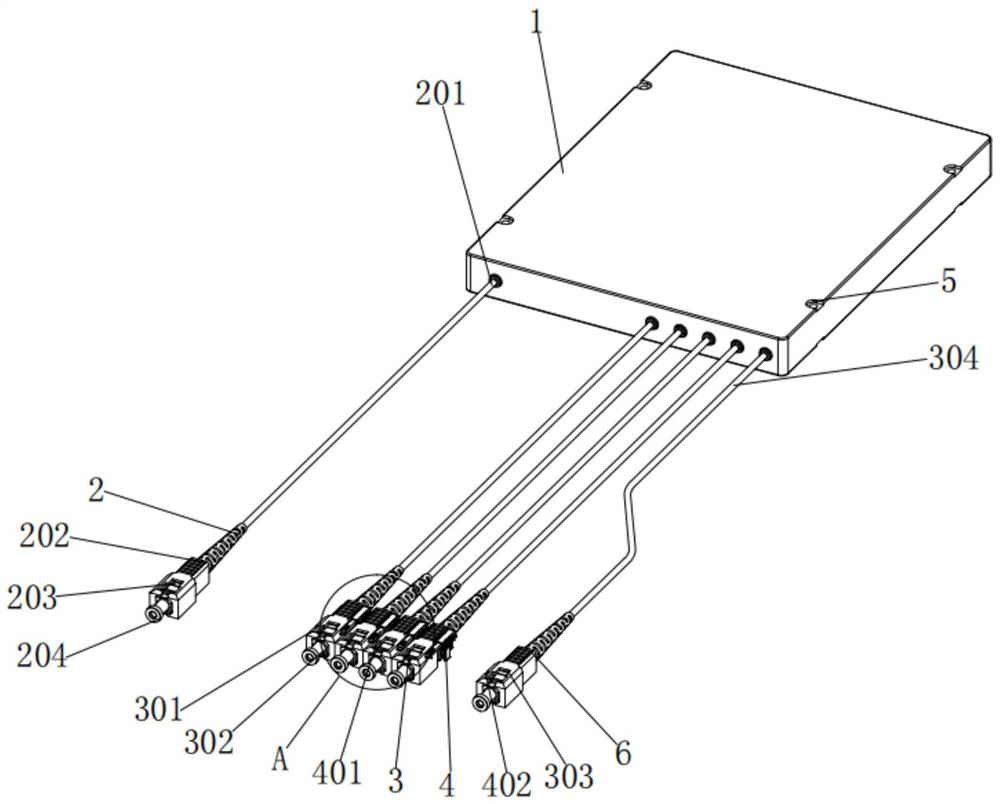

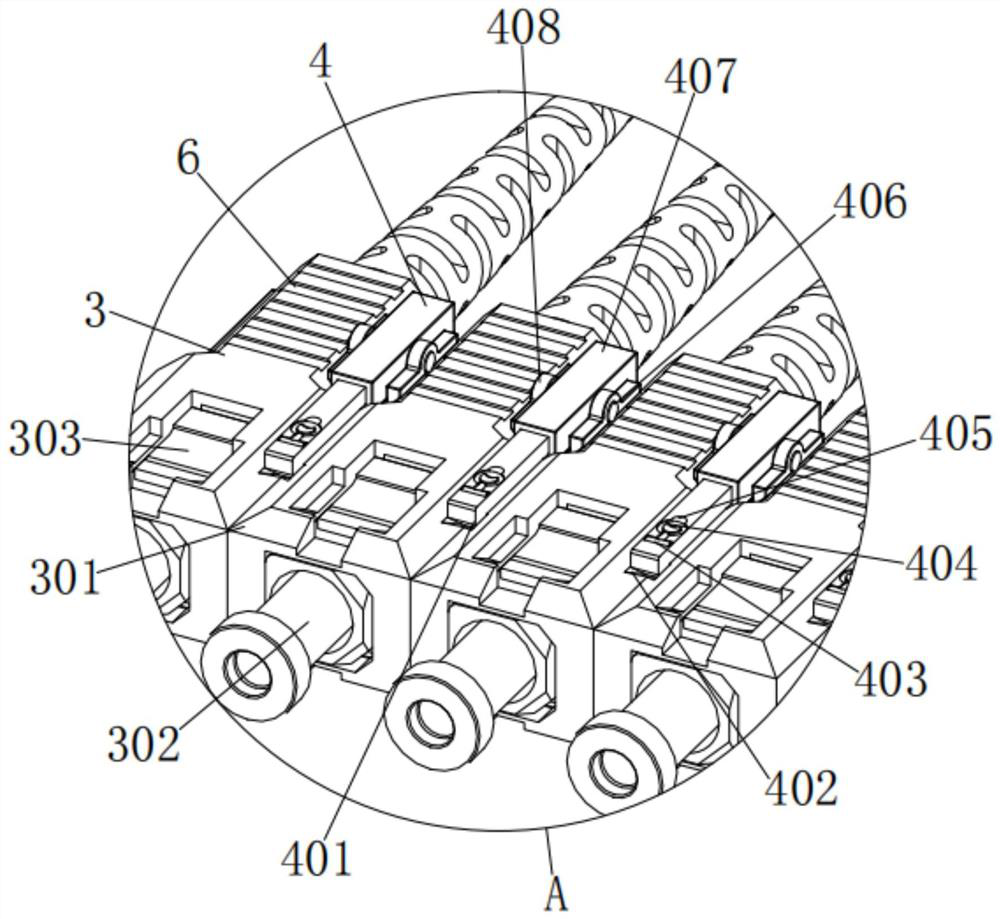

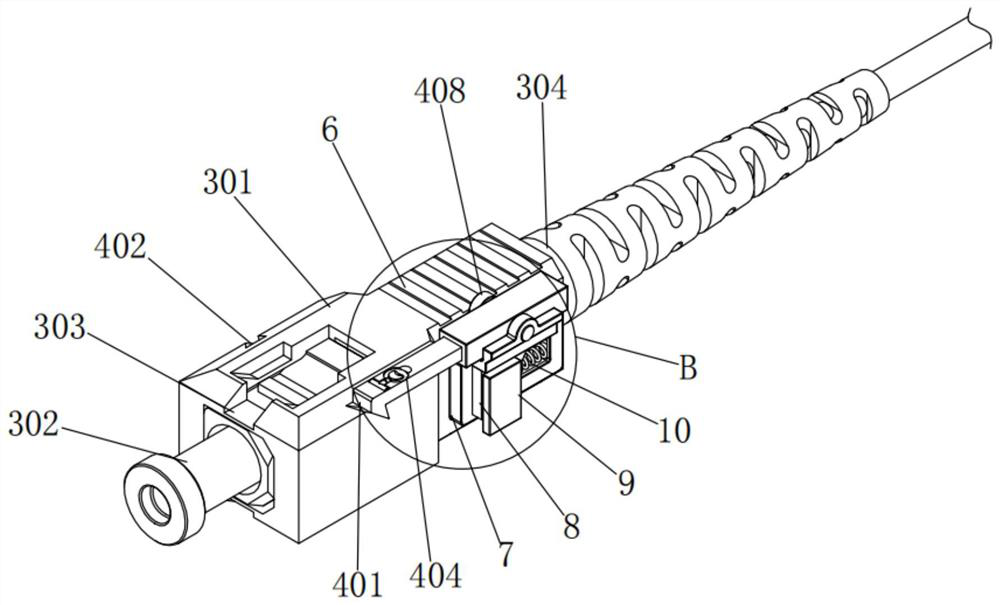

Communication module micro-connection structure of optical fiber splitter and use method

PendingCN113589460AAvoid unmanageable problemsAvoid mobile demand problemsCoupling light guidesFibre mechanical structuresMechanical engineeringOptical fiber

A communication module micro-connection structure of an optical fiber splitter disclosed by the present invention comprises an optical fiber splitter and installation holes, the installation holes are processed in the interiors of the front and rear sides of the left and right ends of the optical fiber splitter, and a main line assembly and a branching assembly are installed on the two sides of the front end of the optical fiber splitter respectively; second springs are arranged on the upper side and the lower side of the right portion of a second sliding block correspondingly, and the two sides of the second springs are fixedly connected with the second sliding block and a right side plate correspondingly. According to the communication module micro-connection structure of the optical fiber splitter and the use method thereof, through cooperation among the branch cable shells, a left side plate, a first sliding blocks and the branch cable connectors, after the branch cable shells are assembled, the first sliding blocks can abut against the inner wall of the adjacent left side plate to achieve synchronous movement of the multiple branch cable shells, and when respective installation is needed, respective installation with the optical fiber jacks can be realized without assembling, so that the problem that the existing branch cable cannot be assembled or separated for integral installation or sequential installation is solved.

Owner:山西常泽科技有限公司

House viewing guidance method and system

PendingCN112348712AImprove viewing efficiencyImprove viewing experienceCustomer communicationsComputer graphics (images)Operations research

The embodiment of the invention provides a house viewing guidance method and system, and the method and system can display the to-do list of a to-be-viewed house resource through the house viewing guidance information, can enable a user to view a house more comprehensively according to the guidance of the to-do list, and avoid the problems of repeated house viewing and low house viewing efficiencycaused by the fact that the user cannot see or cannot see the house completely. According to the embodiment of the invention, the house resource material corresponding to the to-do list of the to-be-viewed house resource is acquired, and the house viewing guidance record corresponding to the to-be-viewed house resource is generated according to the house resource material, so that the user can autonomously collect the house resource material, and the problem of unremembering is avoided. Moreover, the to-do list and the to-be-seen house resource in the embodiment of the invention correspond toeach other, so that the user can easily determine the house resource to which the house resource material belongs, and the problem that the house resource information cannot correspond to the house resource only by memorizing and recording the house resource information is avoided. The house viewing experience of the user can be greatly improved, the house viewing efficiency of the user is improved, and the transaction volume of house resource transaction is improved.

Owner:BEIKE TECH CO LTD

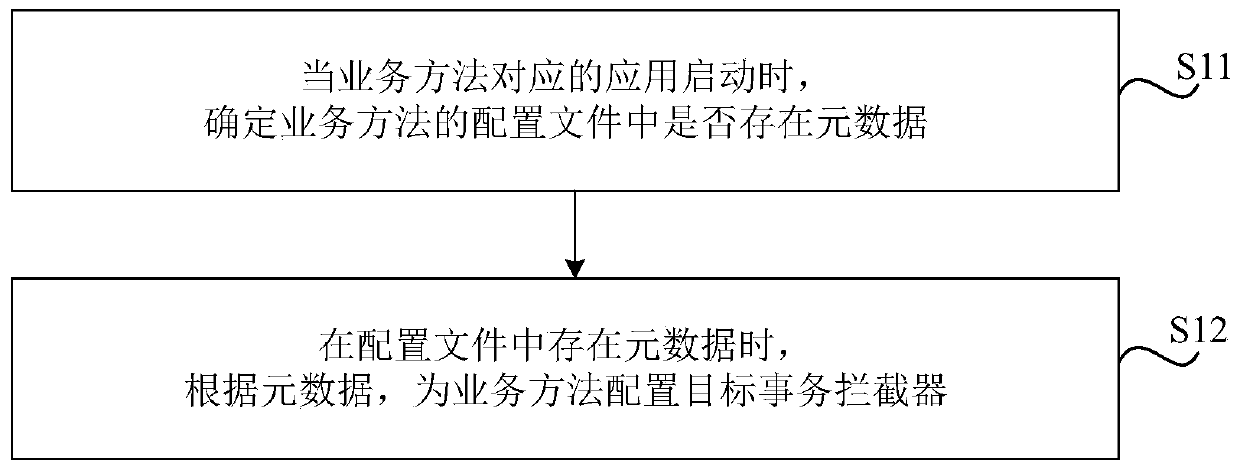

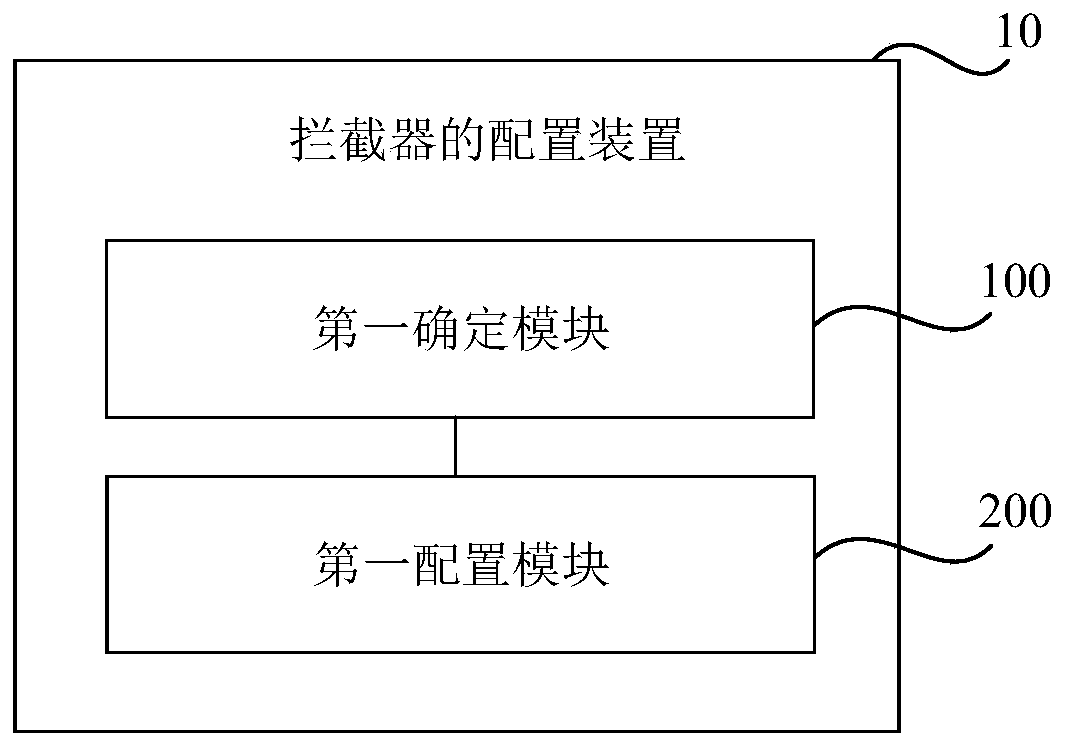

Interceptor configuration method and device, storage medium and electronic equipment

PendingCN109947415AGuaranteed normal processingAvoid unmanageable problemsProgram loading/initiatingCreation/generation of source codeDatabaseMetadata

The invention relates to an interceptor configuration method and device, a storage medium and electronic equipment. The method comprises the steps that when an application corresponding to a businessmethod is started, whether metadata exists in a configuration file of the business method or not is determined, the metadata is generated when the business method is established and indicates the corresponding relation between the business method and target transaction interceptors, and the number of the target transaction interceptors is one; And when the metadata exists in the configuration file, the target transaction interceptor is configured for the business method according to the metadata. Therefore, through the technical scheme, the problem that the transaction cannot be processed dueto the fact that the business method executes the processing logics of the transaction interceptors can be effectively avoided, normal processing of the business method is further guaranteed, the userequirement of a user is met, and the use experience of the user is improved.

Owner:NEUSOFT CORP +1

An online plugging method for an acid plant

ActiveCN113102917BAvoid unmanageable problemsImpact resistantWelding/cutting auxillary devicesAuxillary welding devicesInsulation layerAgricultural engineering

Owner:SGIS SONGSHAN CO LTD

Underground new energy locomotive for mine

ActiveCN111645710AAchieve extrusionAvoid unmanageable problemsRailway device loading/unloadingMine carsMining engineeringBall (bearing)

The invention discloses an underground new energy locomotive for a mine. The locomotive comprises an ore bucket body and a bottom plate, the bottom plate is placed below the ore bucket body, transmission assemblies are installed on the left side and the right side of the interior of the bottom plate, each transmission assembly comprises a base plate, a first rotating shaft, a fourth rotating shaft, a roller, a first bevel gear, a first bearing and a second bevel gear, and the front side and the rear side of each base plate are fixedly connected with the bottom plate. The underground new energylocomotive for a mine is scientific and reasonable in structure, safe and convenient in use, an ore bucket, ore, a first rotating shaft, a fourth rotating shaft, a roller, a spring, a sleeve plate, abaffle and a vertical plate, a first inclined rod, a second inclined rod and a ball body are arranged in cooperation, a force can drive the sleeve plate to move inwards to extrude the spring, and meanwhile, the elastic force of the spring can counteract the displacement of the sleeve plate caused by centrifugal force generated by overspeed due to the fact that the original spring is in an extruded state, so that the problems that the speed is too high and speed limiting treatment cannot be performed due to specific positions such as downhill of equipment are solved.

Owner:深圳市力鼎鹏智能科技有限公司

High permeability and antifouling nanofiber separation membrane material, preparation method and application thereof

ActiveCN113144913BExtended service lifeIncrease permeable areaMembranesSemi-permeable membranesPolymer scienceNanofiber

The invention provides a high-permeability anti-fouling nanofiber separation membrane material and a preparation method and application thereof. The preparation method uses a woven fabric with periodic texture on the surface as a base material, uses a wet non-woven technology to load a hydrophilic polymer nanofiber coating on the surface of the woven fabric, and uses a chemical cross-linking agent to make the woven fabric The fabric is closely attached to the polymer nanofiber coating to obtain a high permeability and antifouling nanofiber separation membrane material. Through the above method, the present invention enables the prepared separation membrane material to have a small pore size dense structure and a surface texture structure at the same time, so as to achieve synergistic improvement of the permeability and antifouling properties of the membrane material. In addition, the preparation method of the separation membrane material is simple and easy to operate, has strong controllability, can improve the preparation efficiency, and is easy to prepare on a large scale. High practical application value.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com