Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

369results about "Mine cars" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

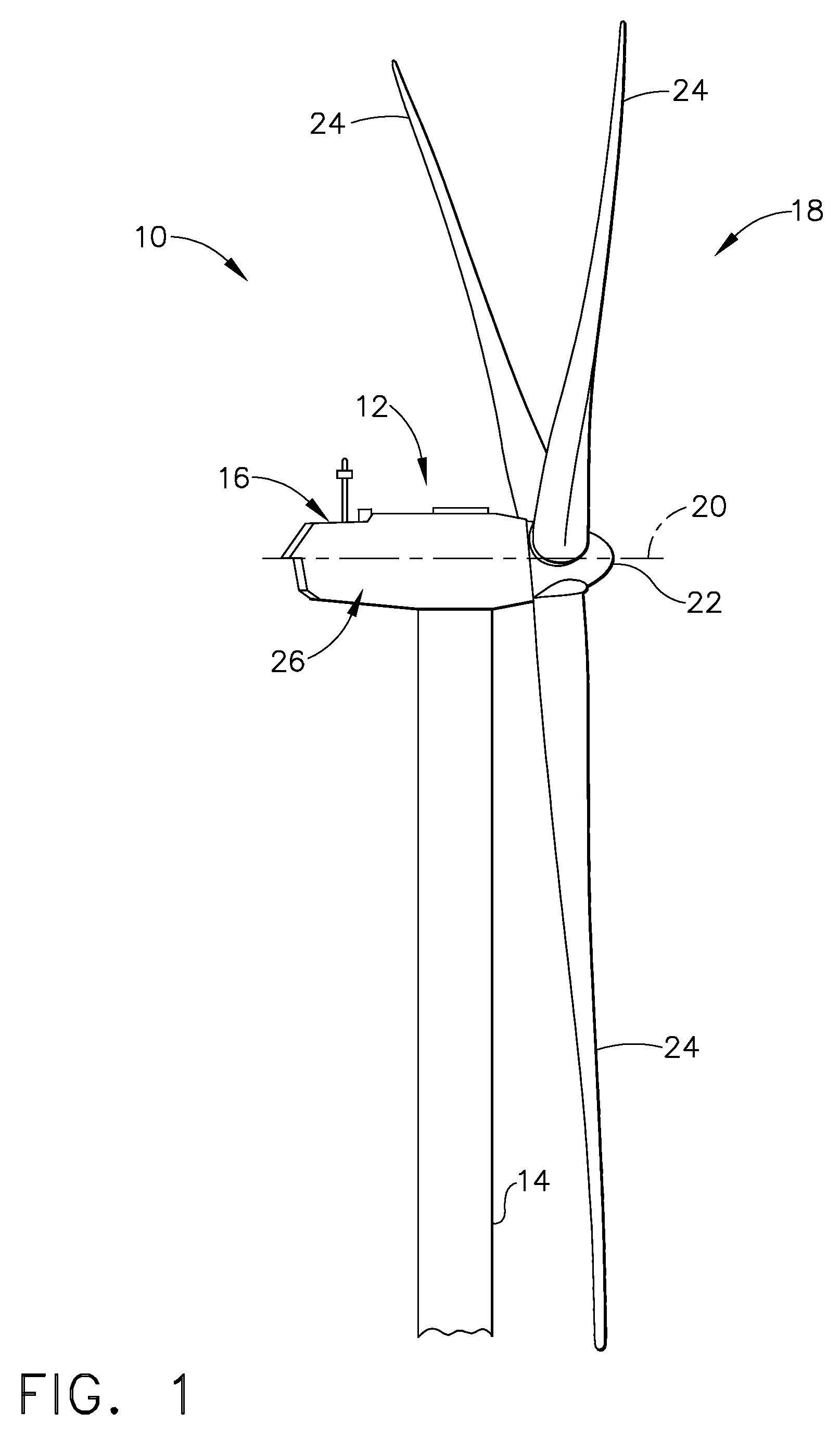

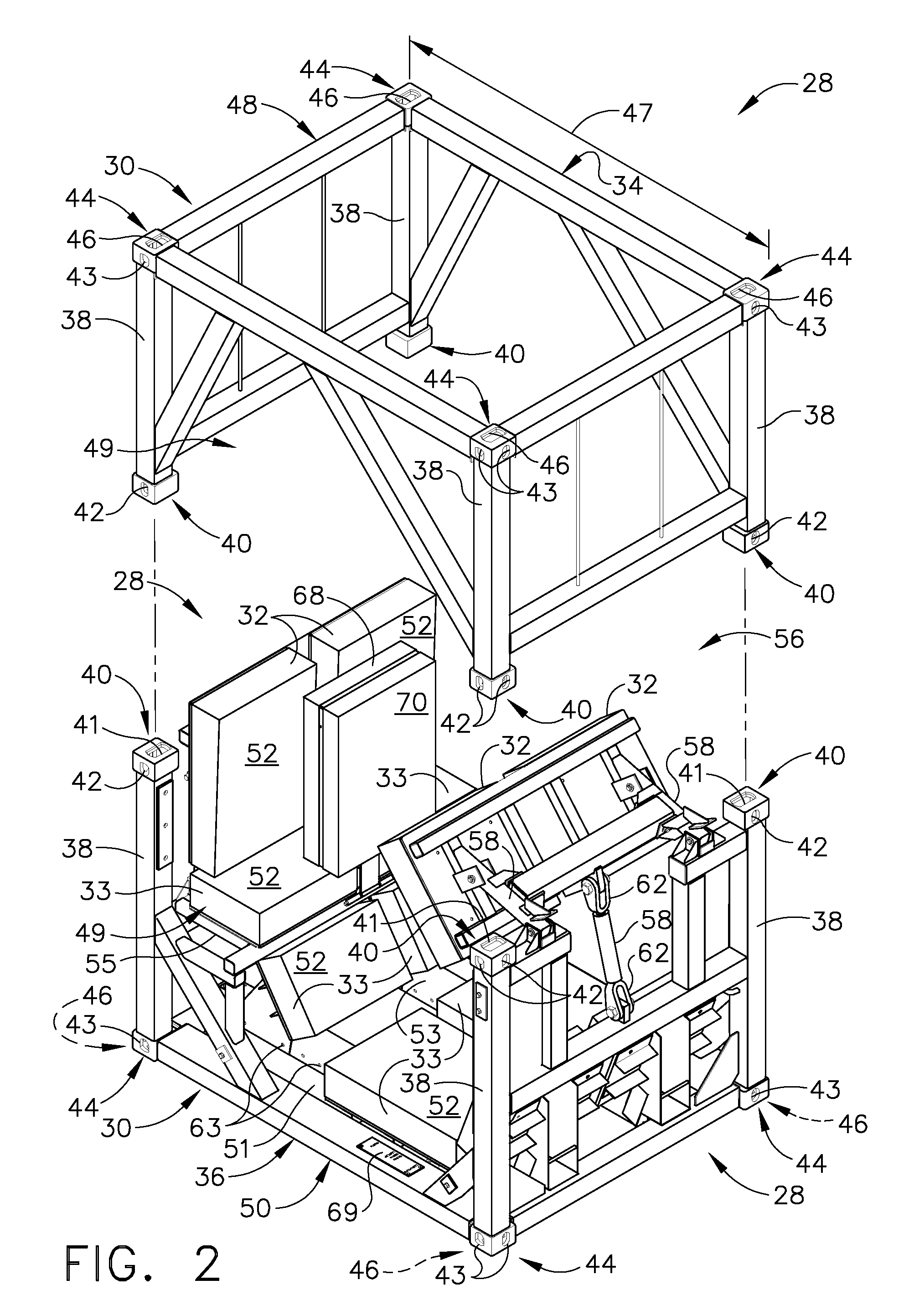

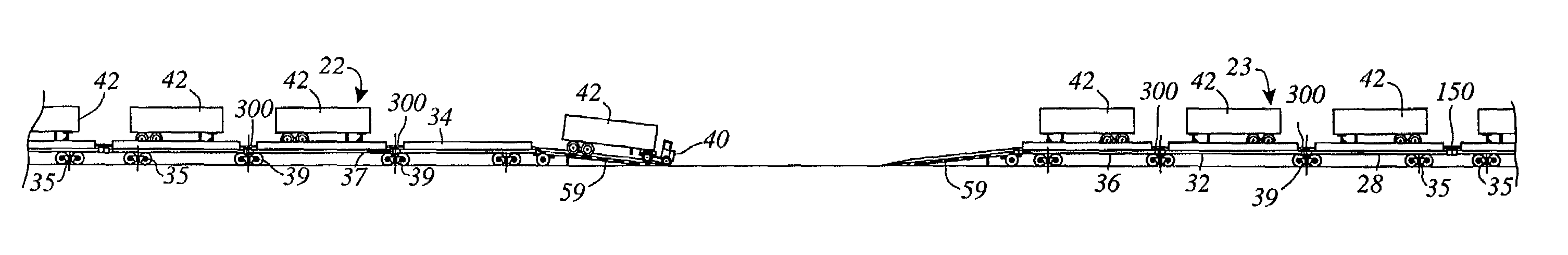

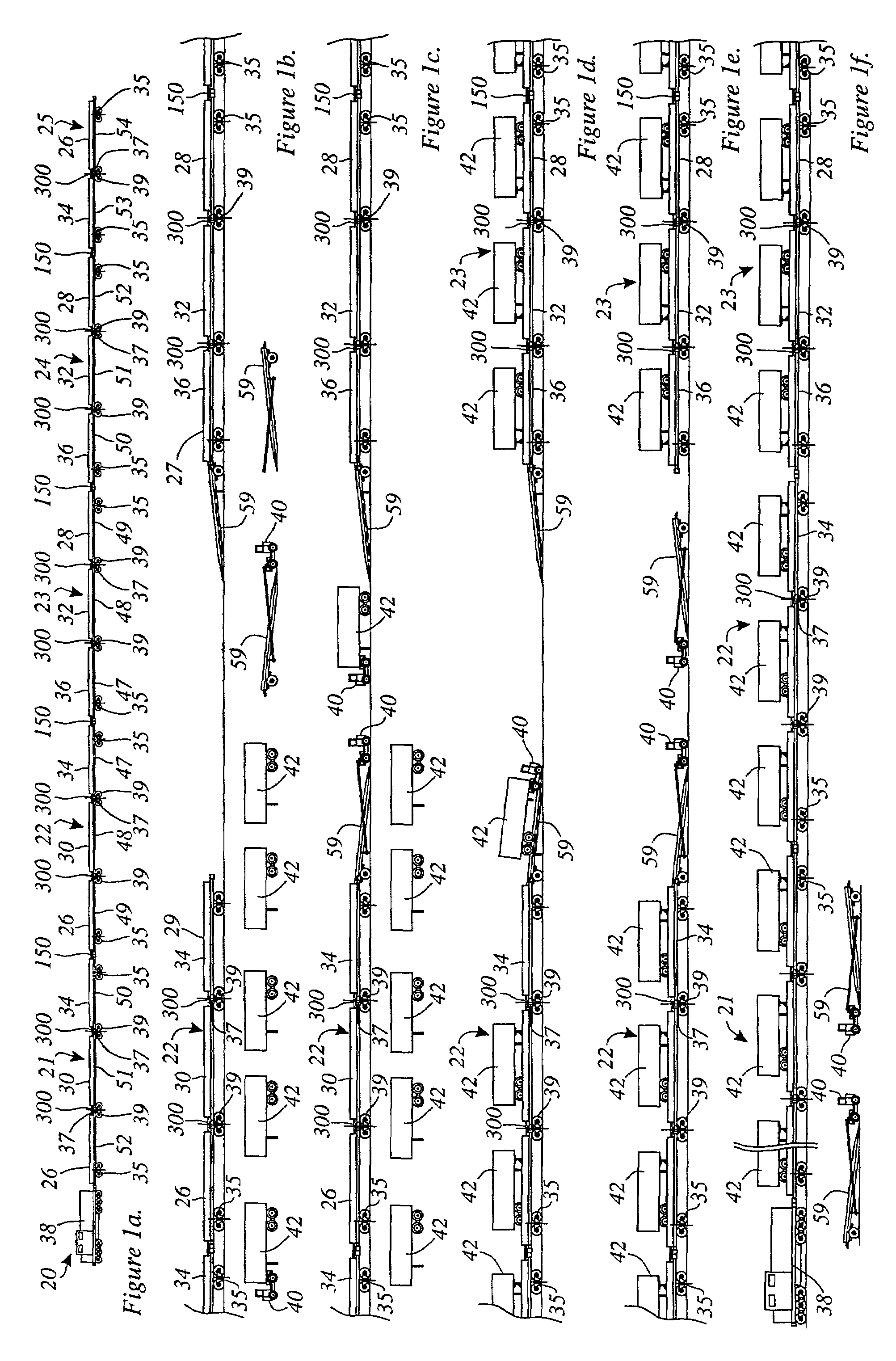

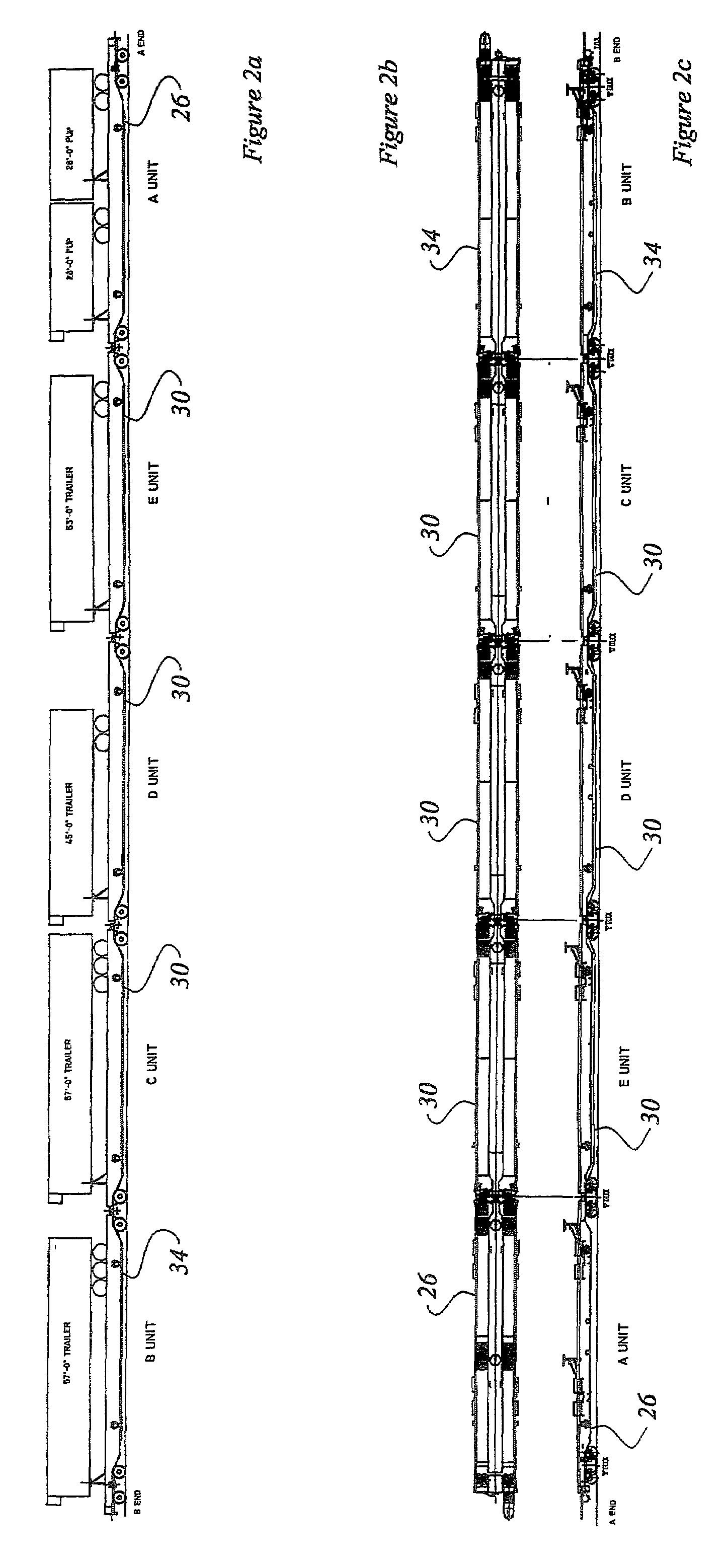

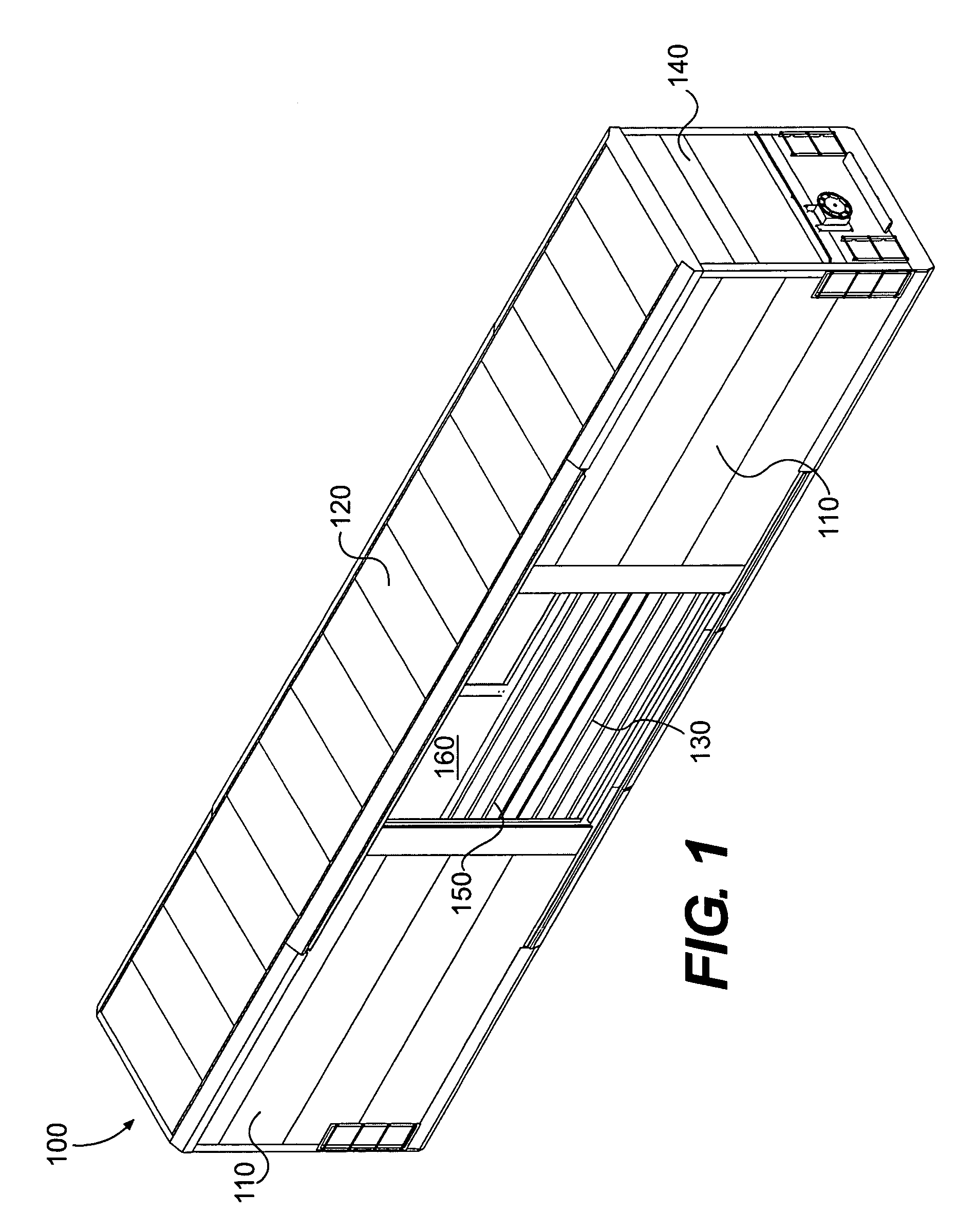

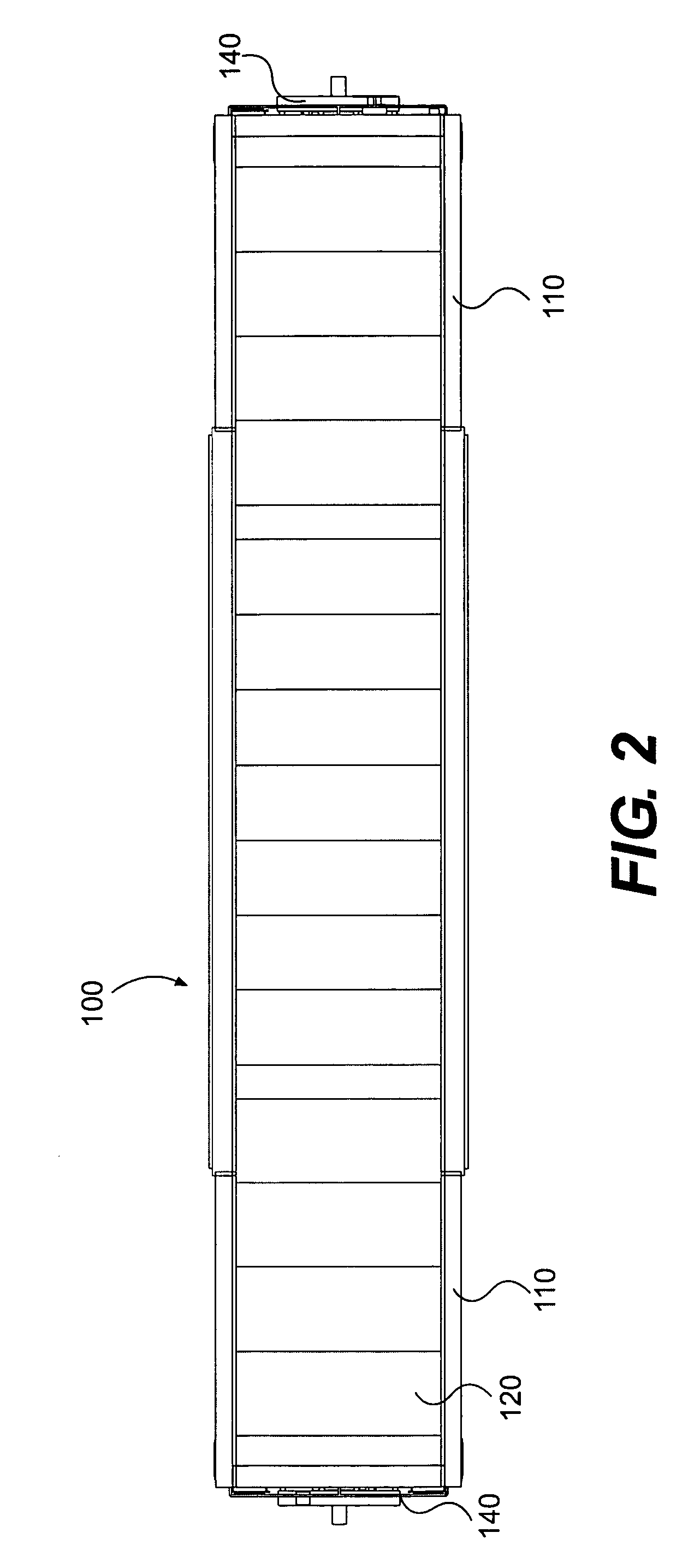

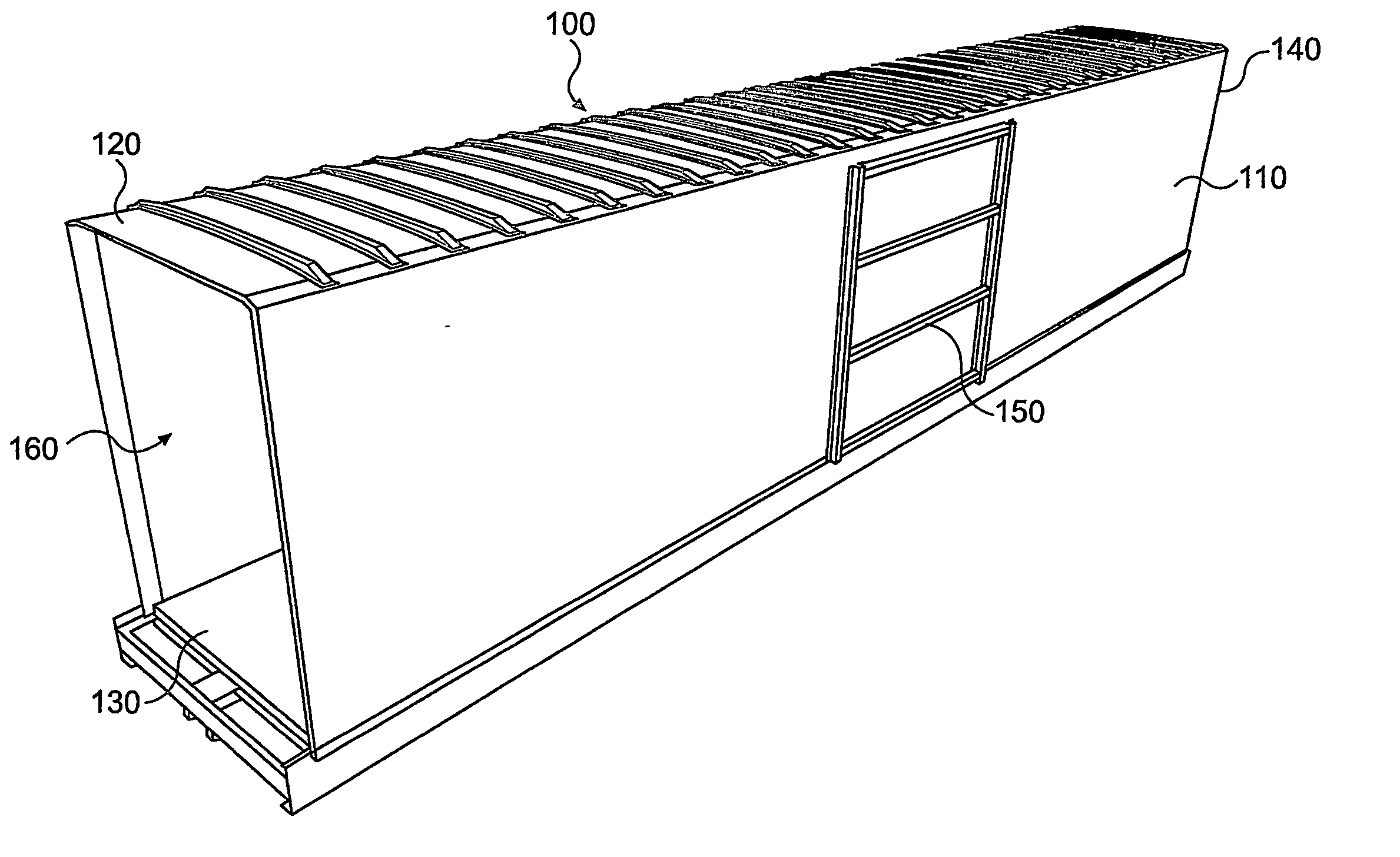

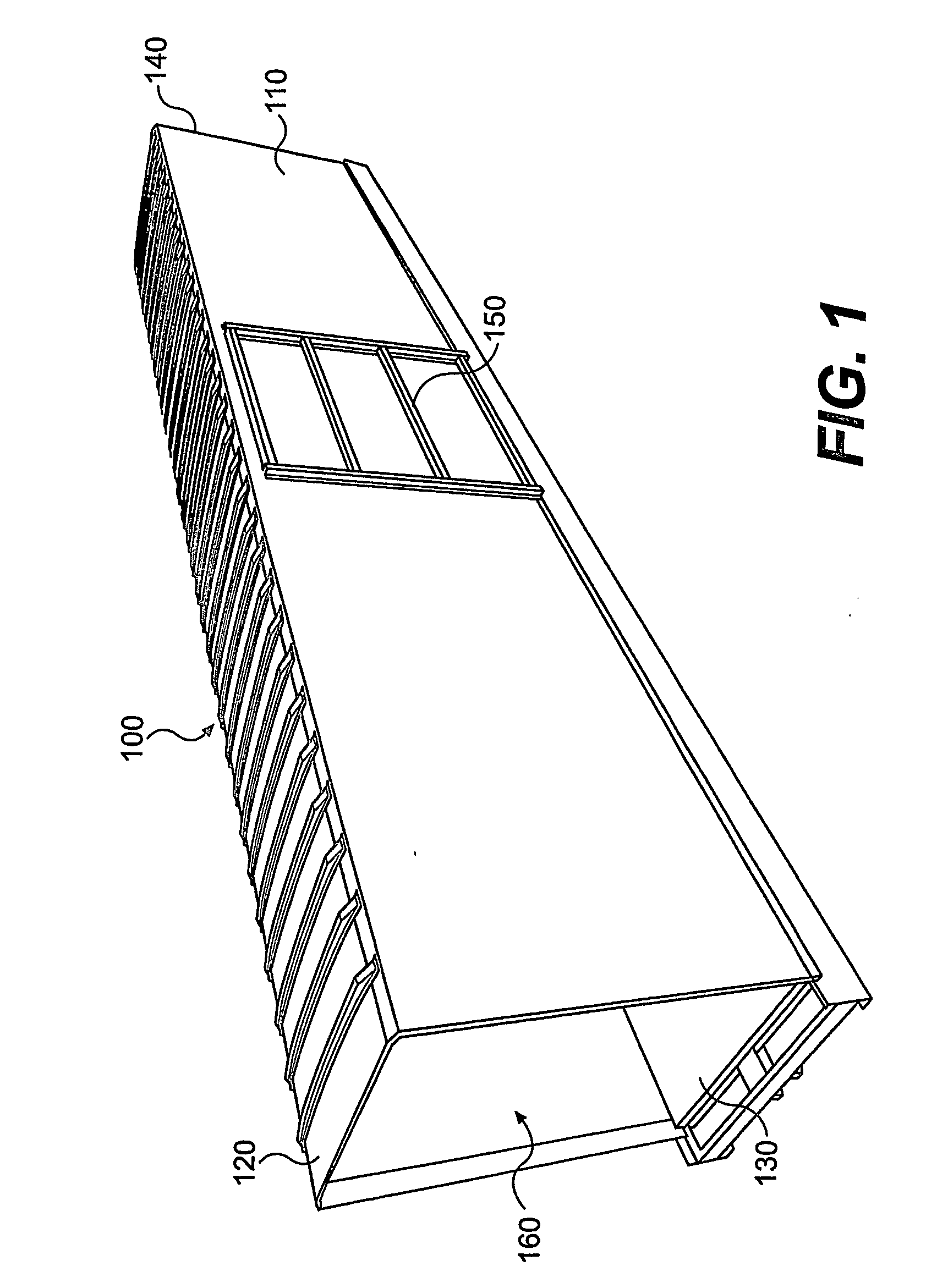

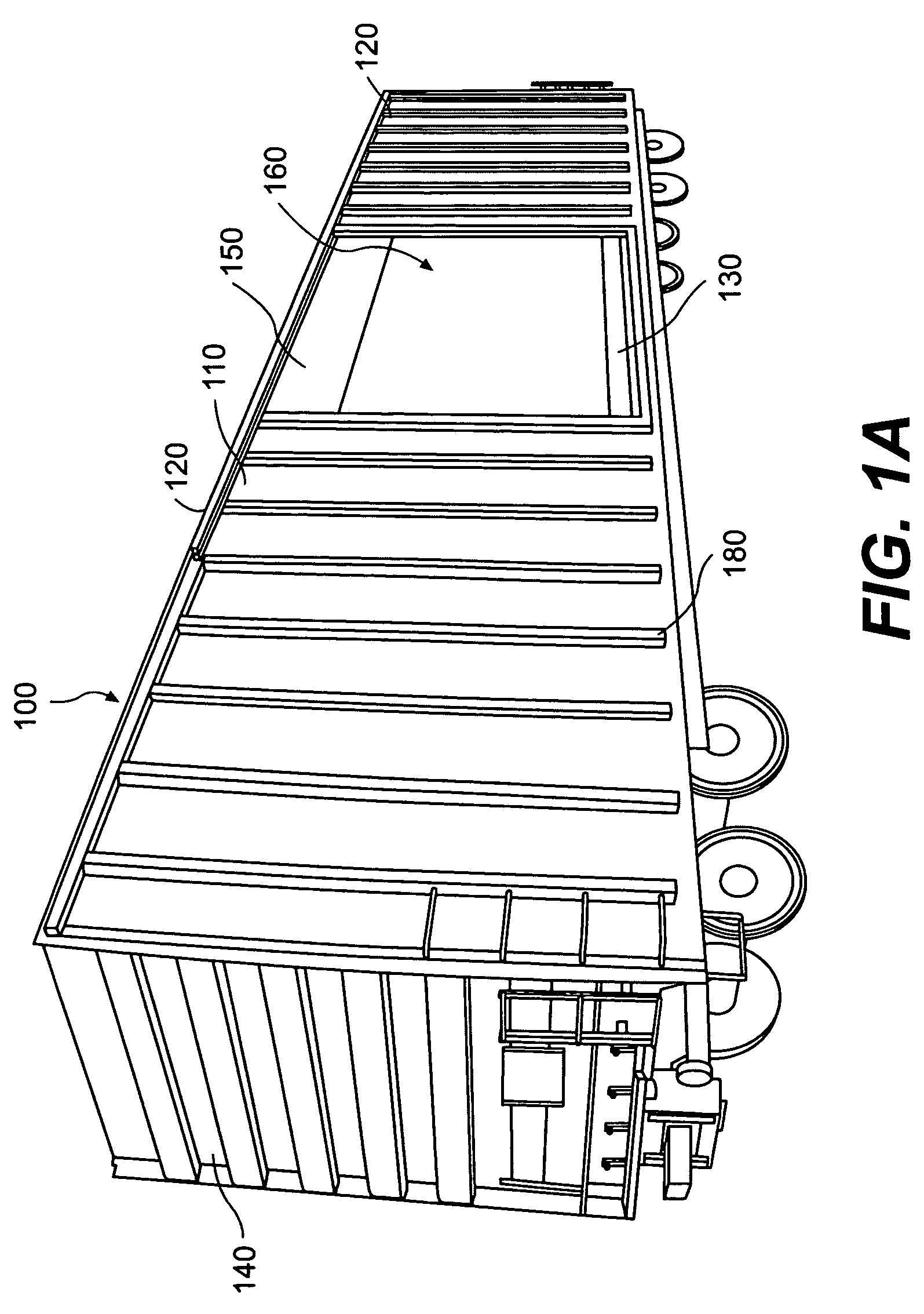

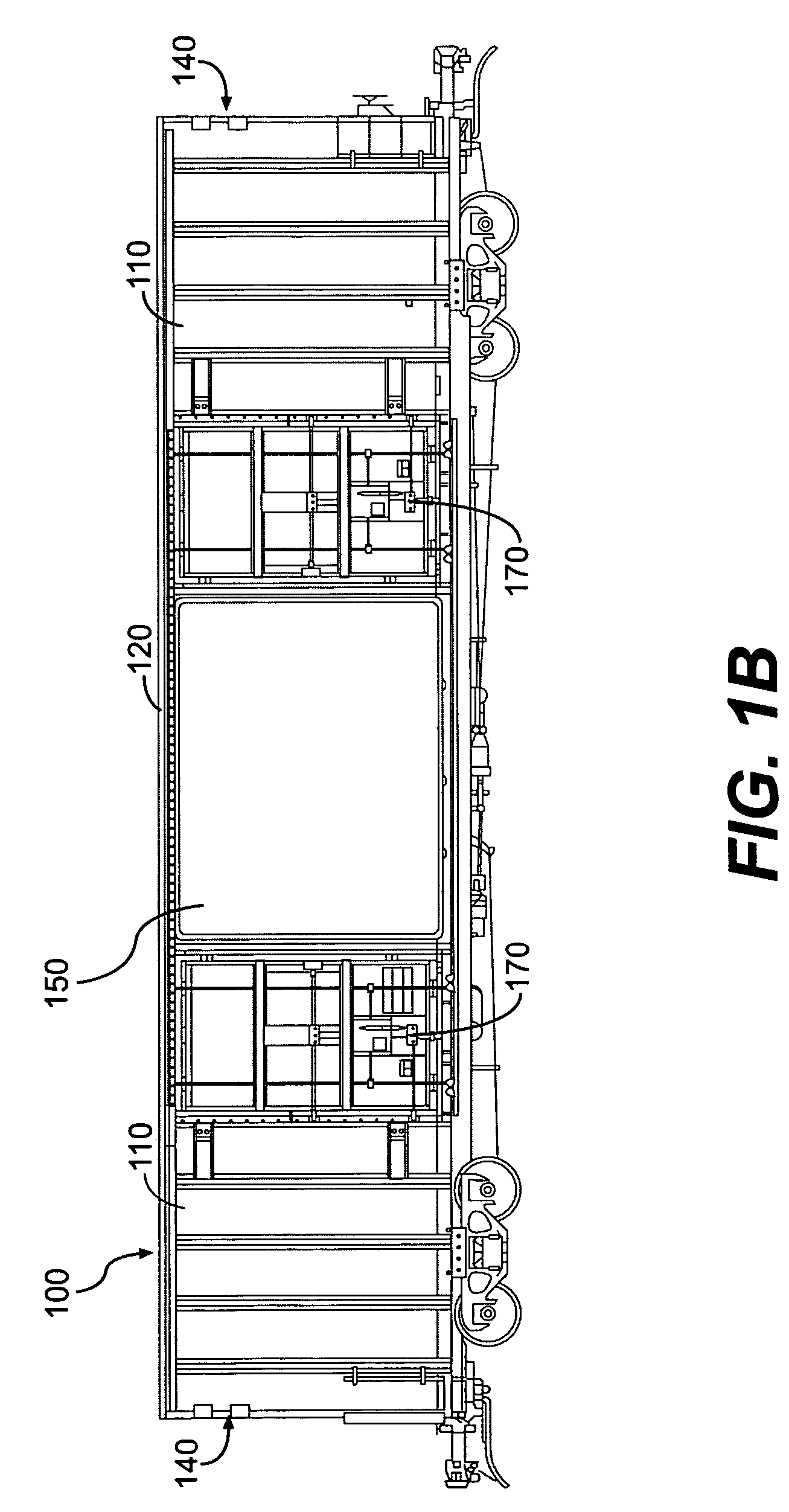

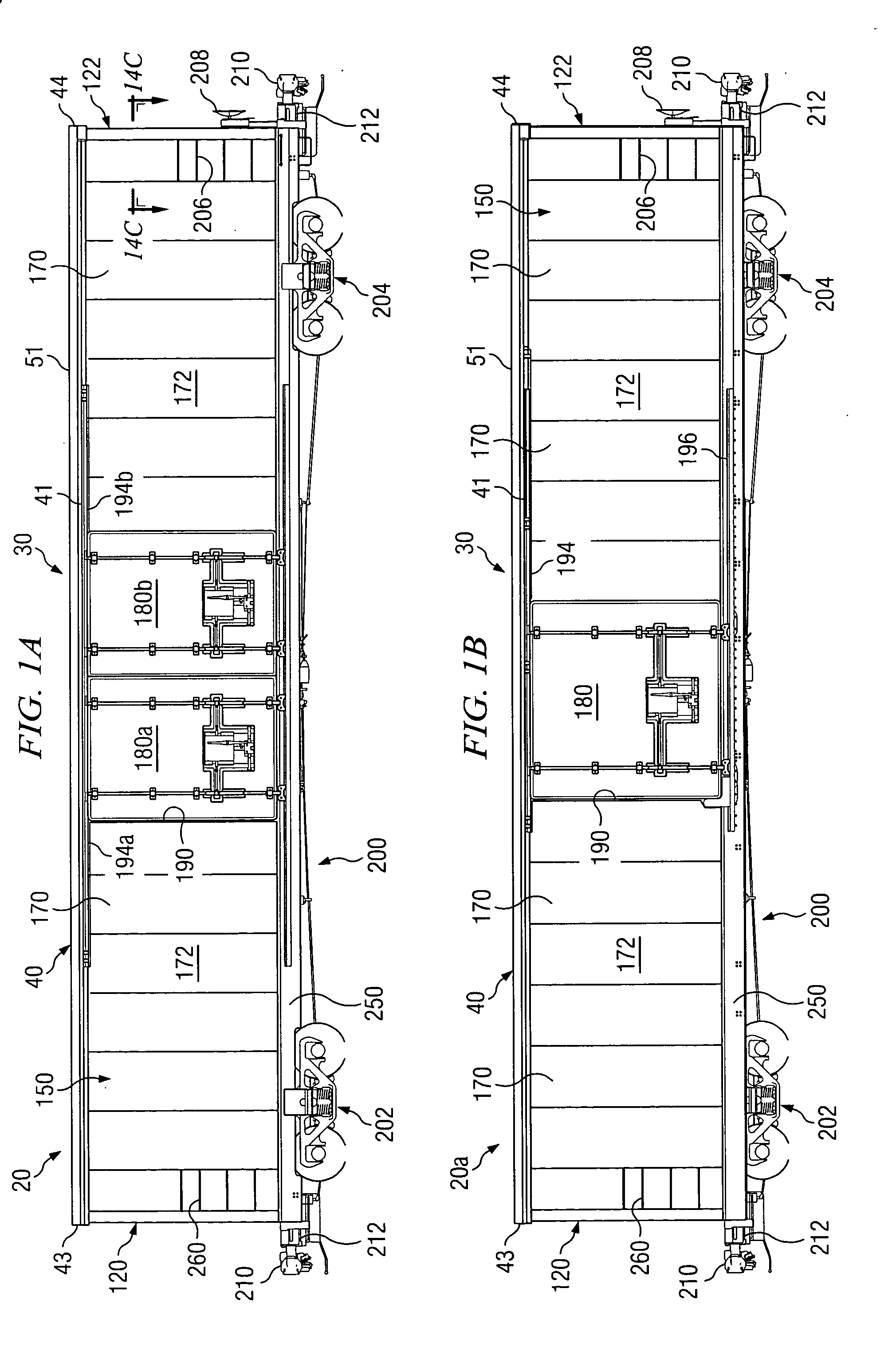

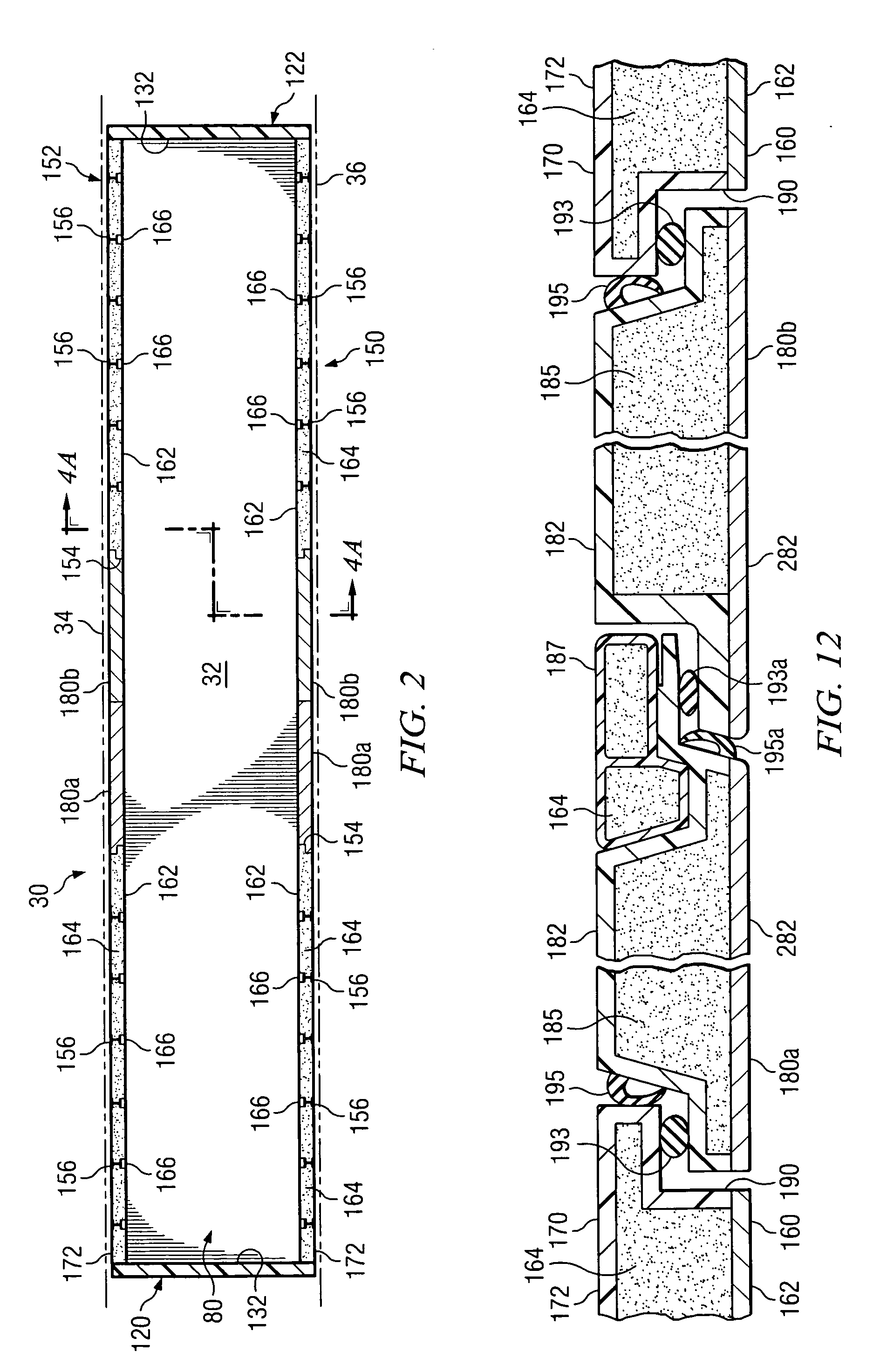

Methods and systems for transporting wind turbine components

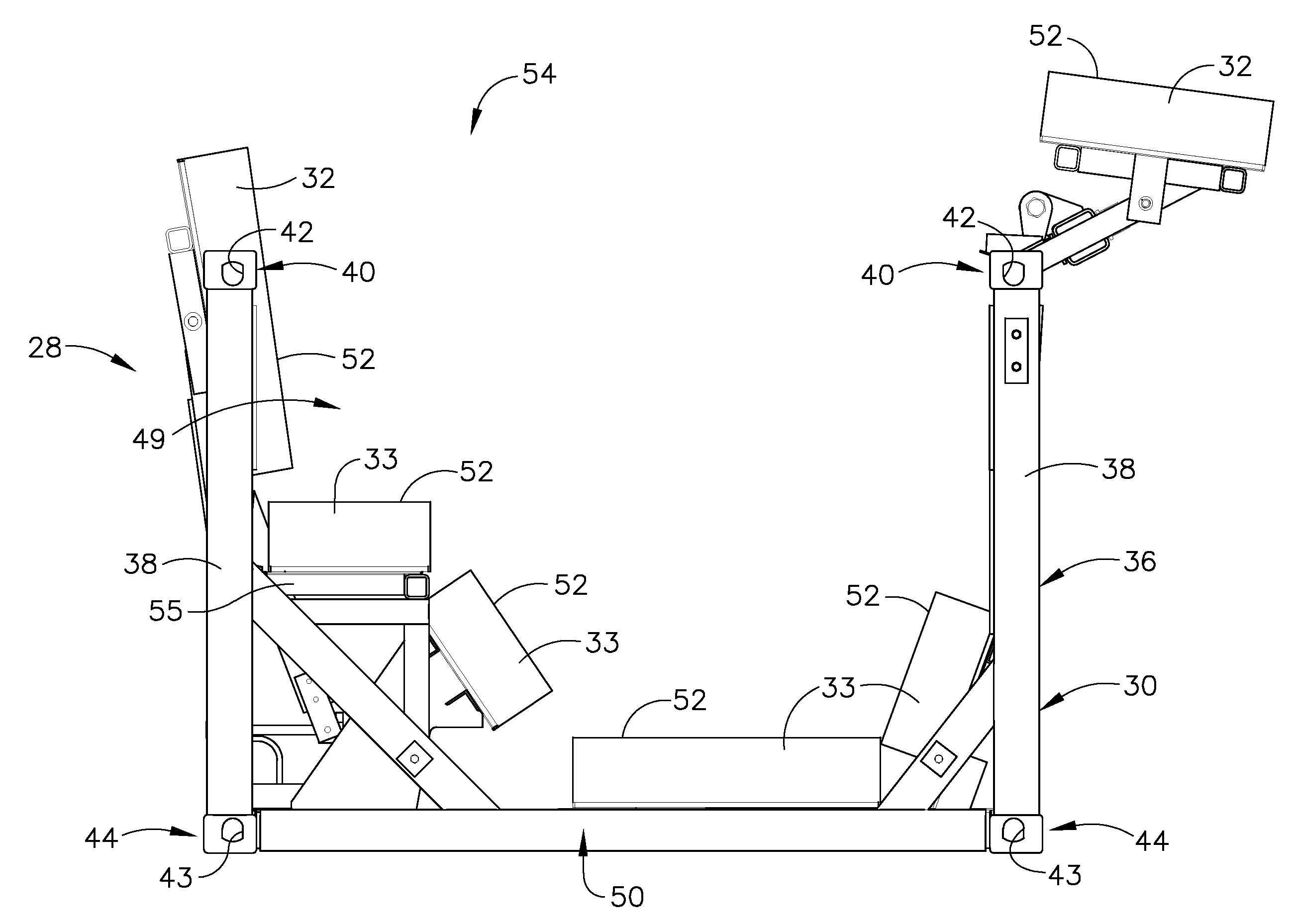

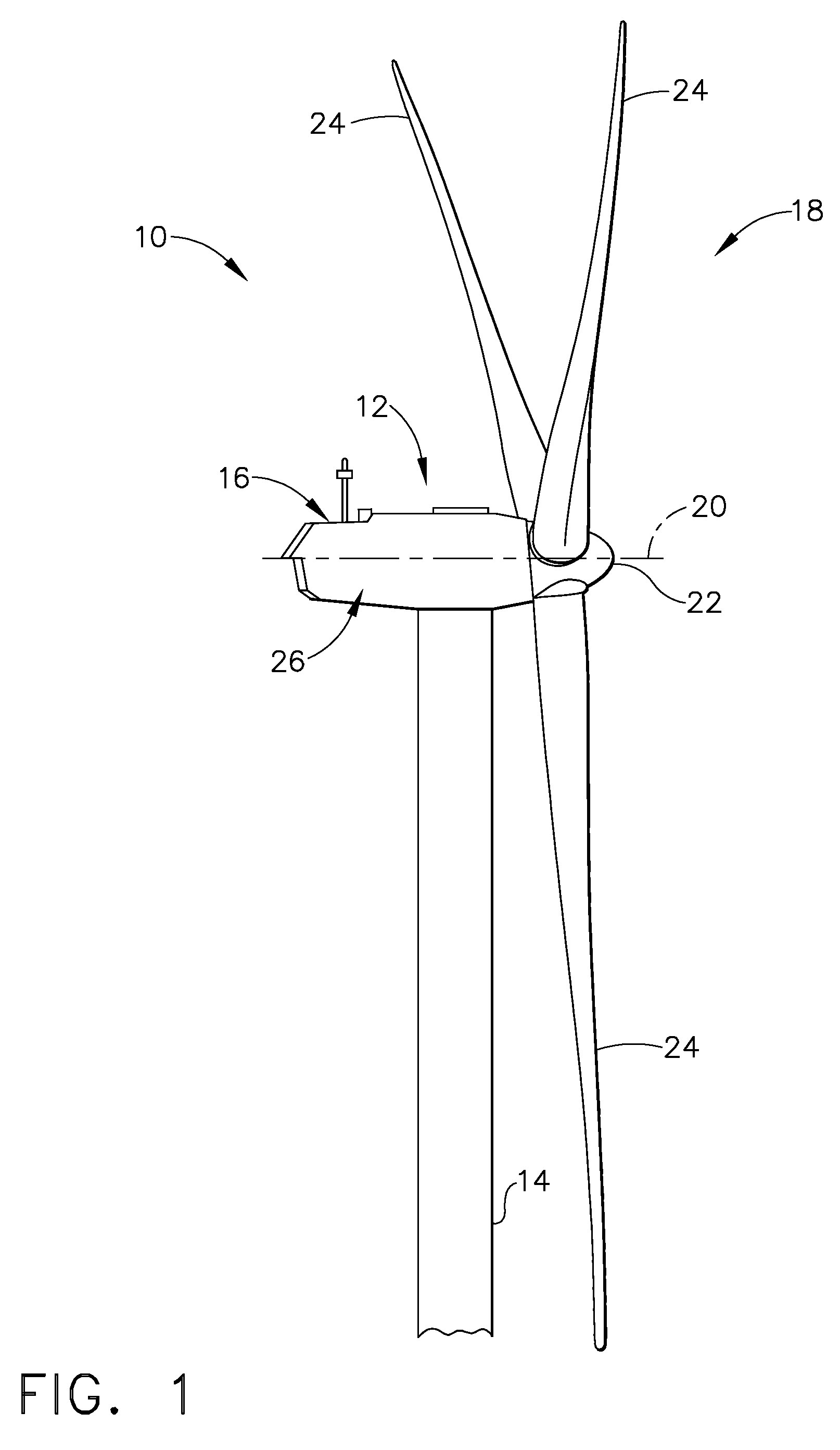

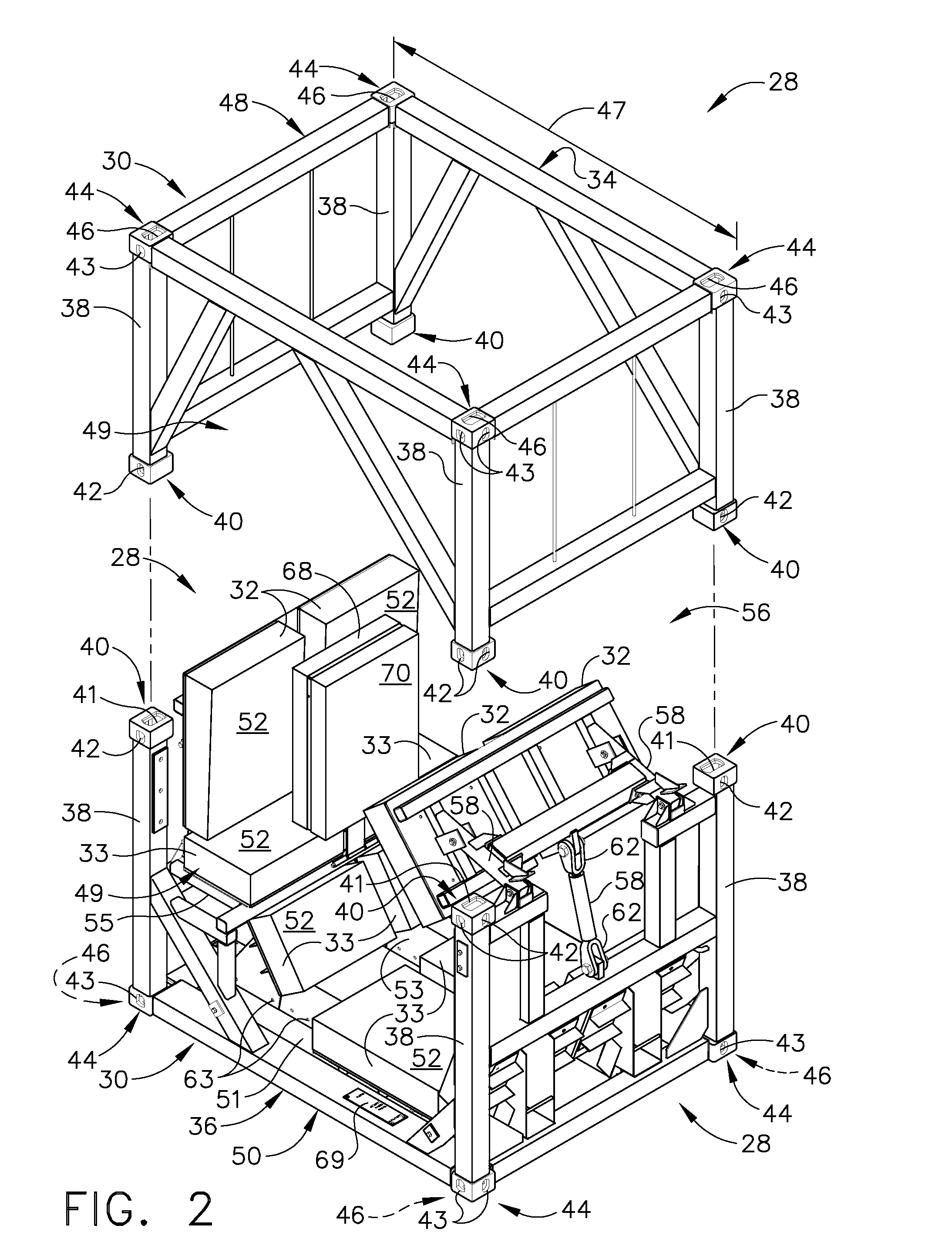

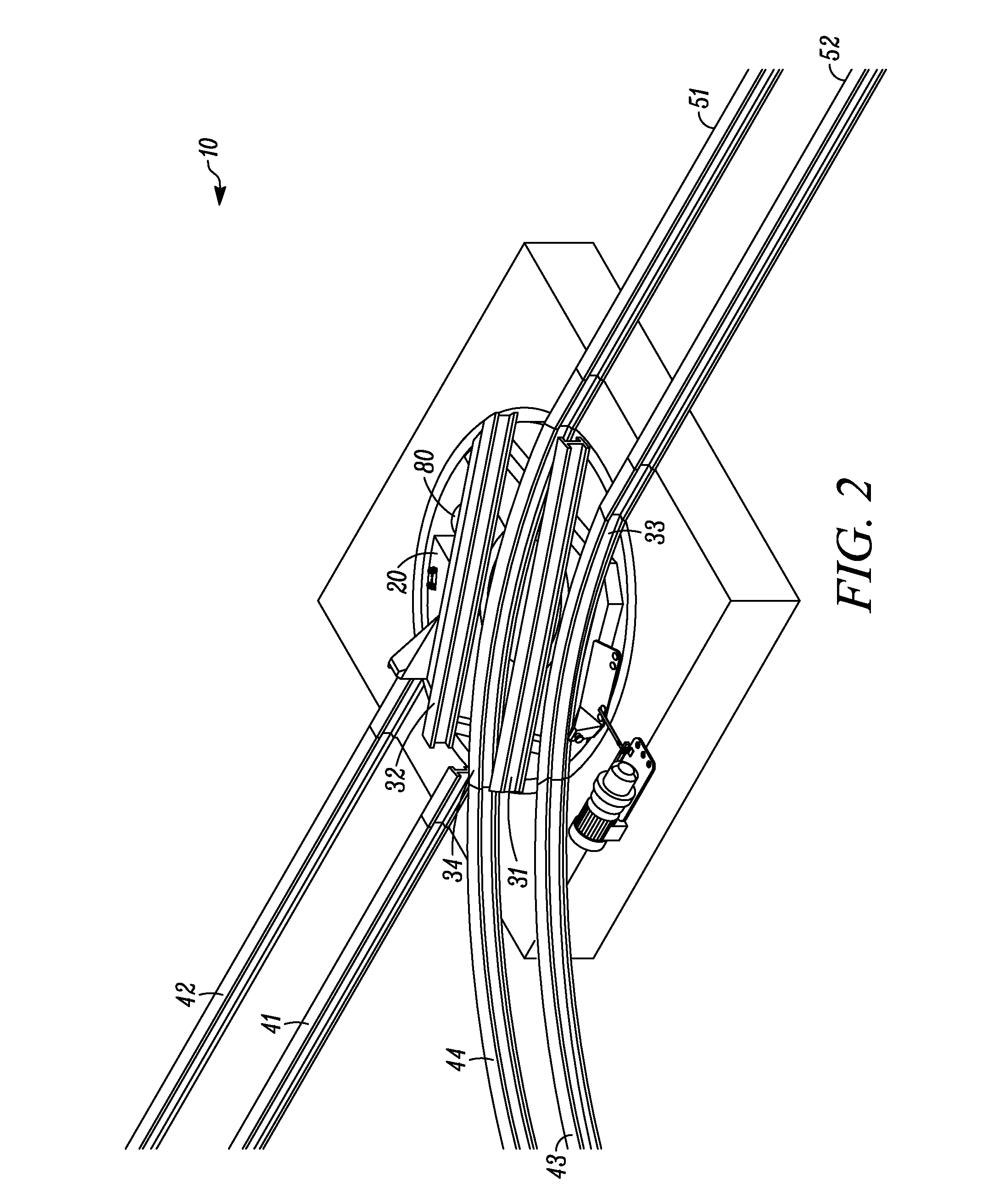

A mounting system includes a plurality of adjacent railcars including a first railcar that includes spaced first and second wheel assemblies each including at least one wheel pair. The mounting system also includes a first and second frames coupled to the first railcar. The first frame includes a space defined between at least two portions of the first frame and at least one cushion selectively positionable within the first frame space. The second frame includes a space defined between at least two portions of the second frame and at least one cushion selectively positionable within said second frame space. The first and second frames are spaced to facilitate at least one of partially containing and partially supporting the load. The first frame is substantially centered over at least one first wheel assembly wheel pair, and the second frame is substantially centered over at least one second wheel assembly wheel pair.

Owner:GENERAL ELECTRIC CO

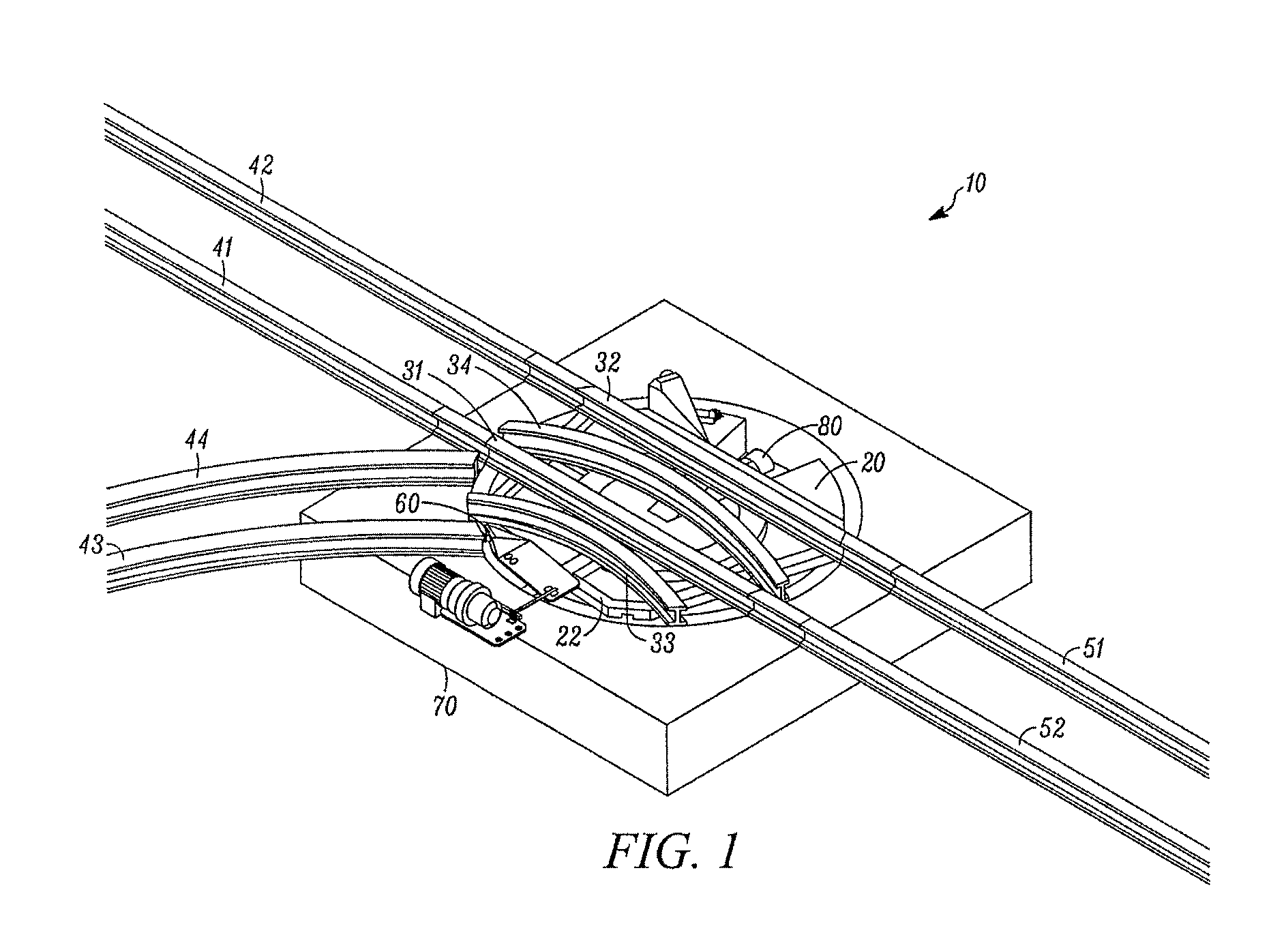

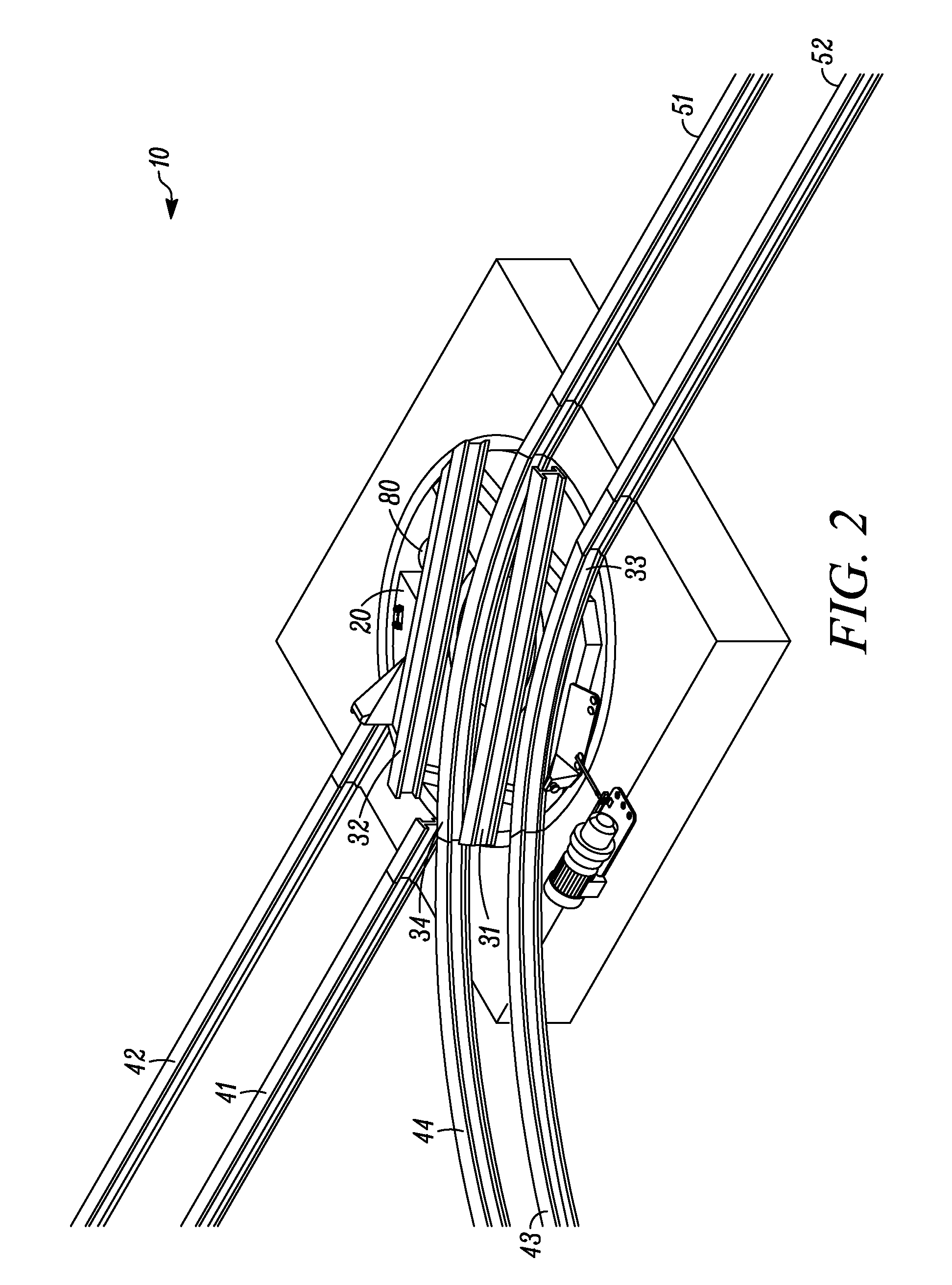

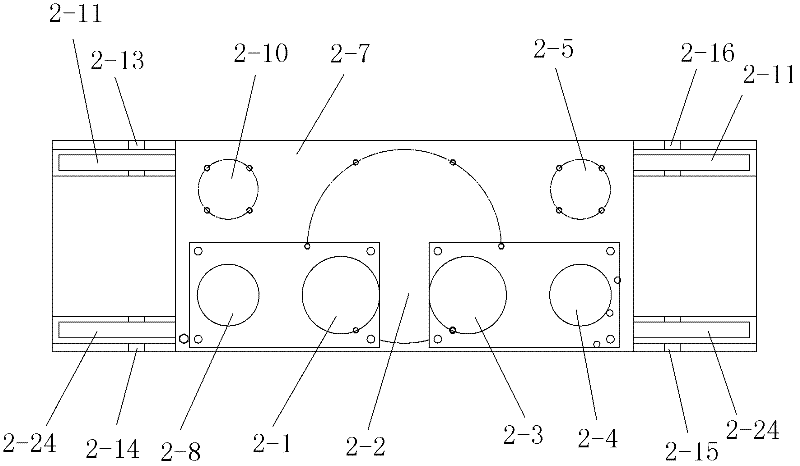

Switch for a powered pallet conveyor

ActiveUS20100147183A1Reduced space requirementsReduce wearRail switchesPoint operation from vehicleEngineeringPallet

In one embodiment of the present disclosure, a switch for a powered pallet conveyor is provided. The switch comprising (a) a turntable and (b) rail portions which are arranged upon the turntable and define at least a first travel pathway and a second travel pathway, whereby the first travel pathway is defined by straight rail portions and a second travel pathway is defined by curved rail portions, so that the central line of the first travel pathway and the departure lines of the second travel pathway respectively pass through the fulcrum of the turntable.

Owner:ROFA INDAL AUTOMATION

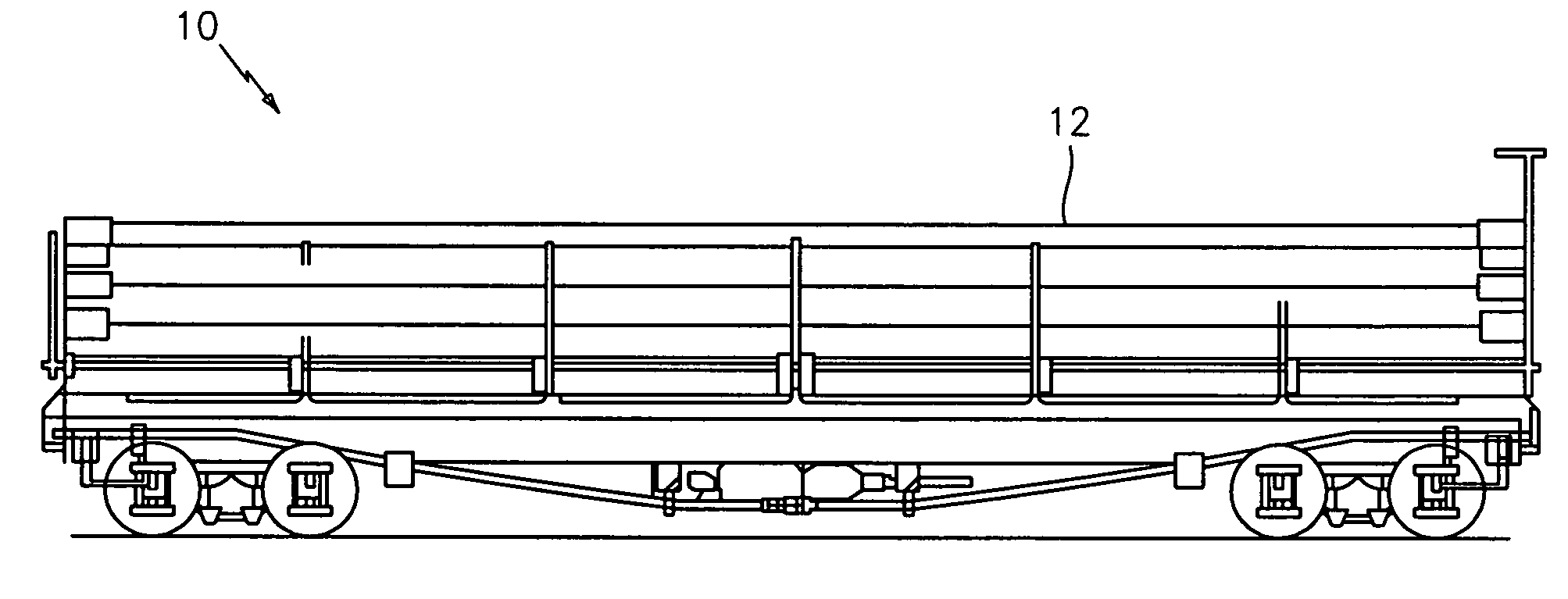

Rail road car and truck therefor

An autorack rail road car is provided with a truck that includes a pair of sideframes supported on wheel sets with bearing adapters positioned therebetween. The bearing adapters and the sideframes have associated parts or surfaces with curvatures configured to permit lateral swinging of the sideframes. A bolster is supported by the sideframes, and sets of laterally arranged dampers are provided therebetween to control the relationship between the sideframes and the bolster.

Owner:NATIONAL STEEL CAR

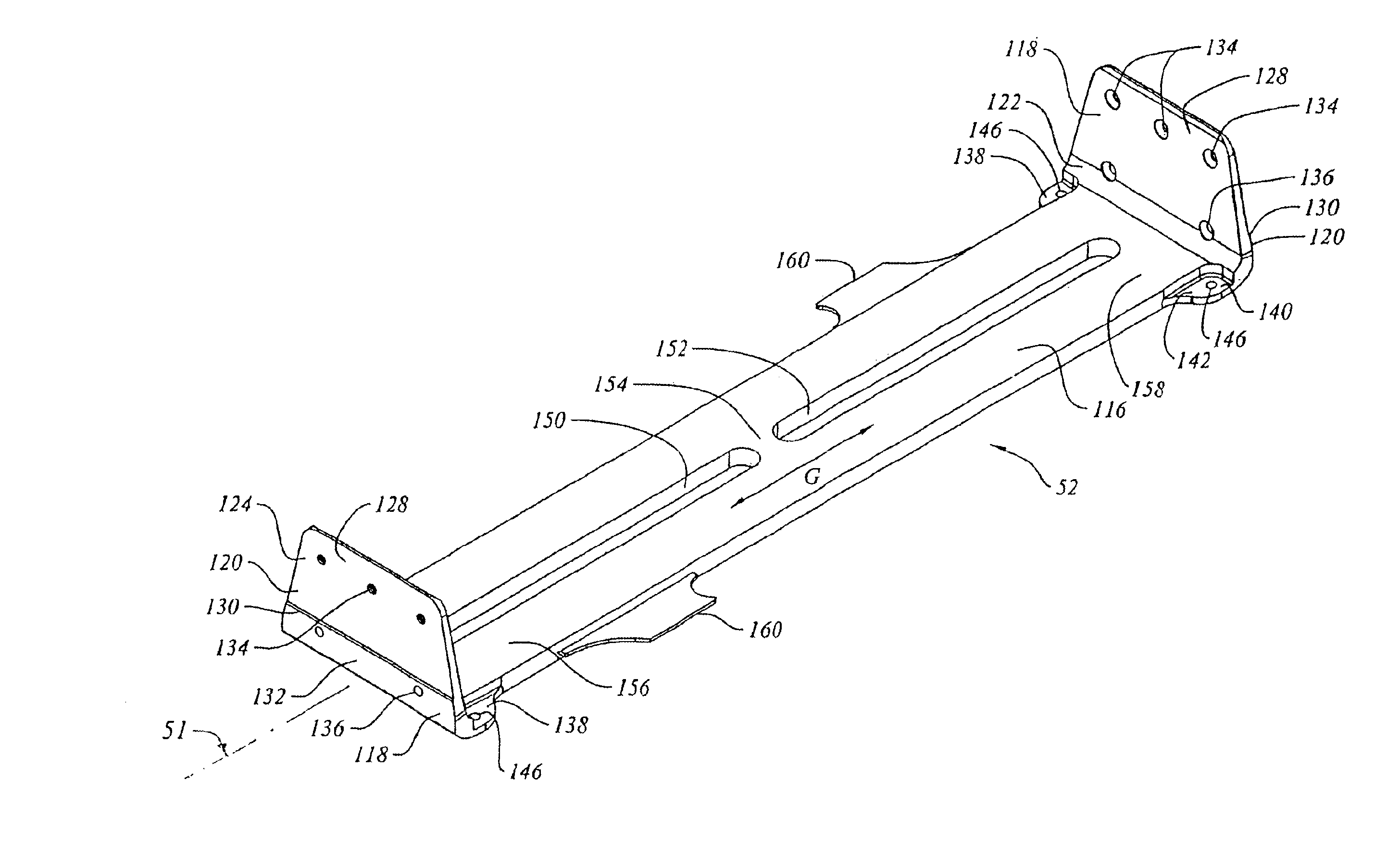

Methods and systems for transporting wind turbine components

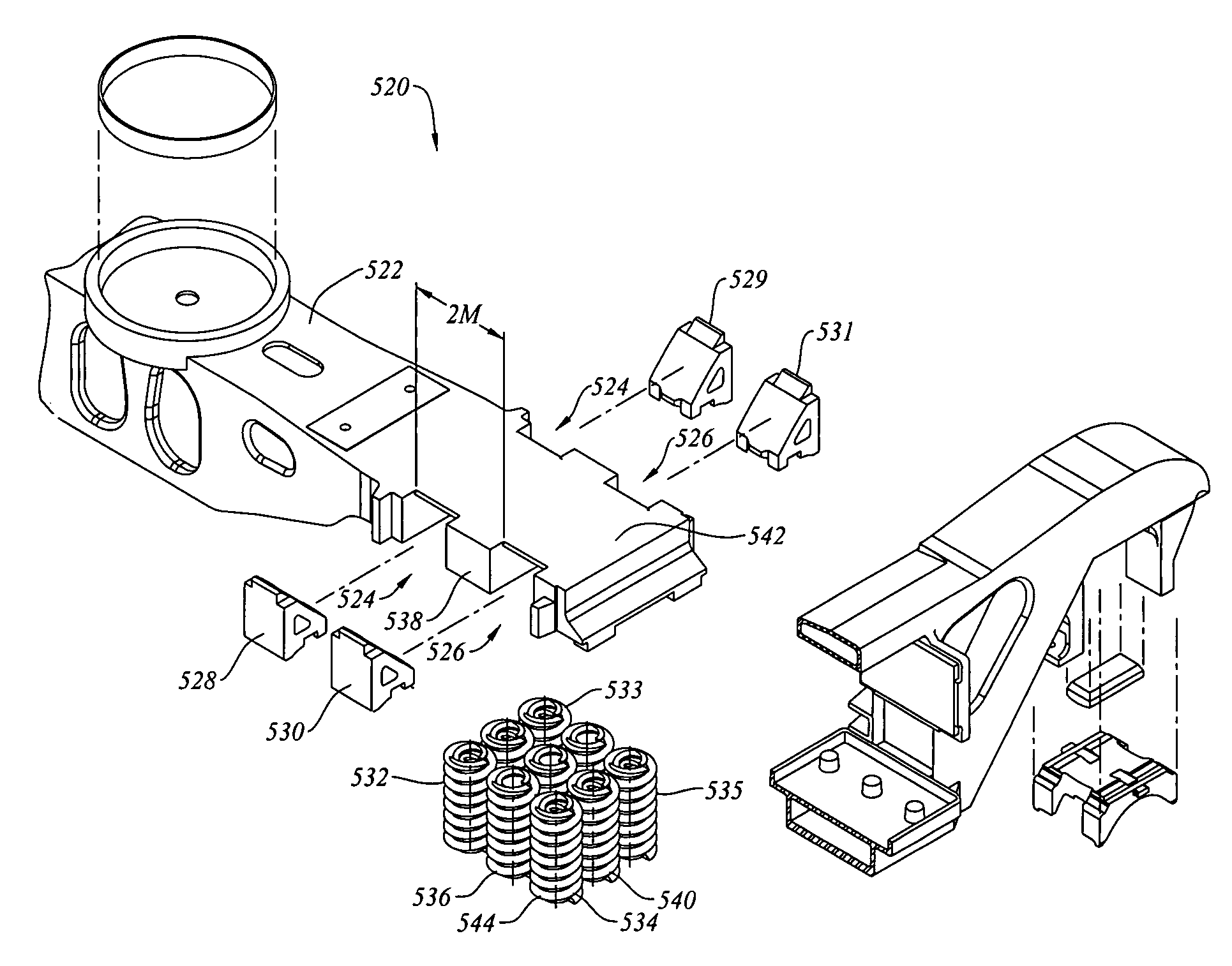

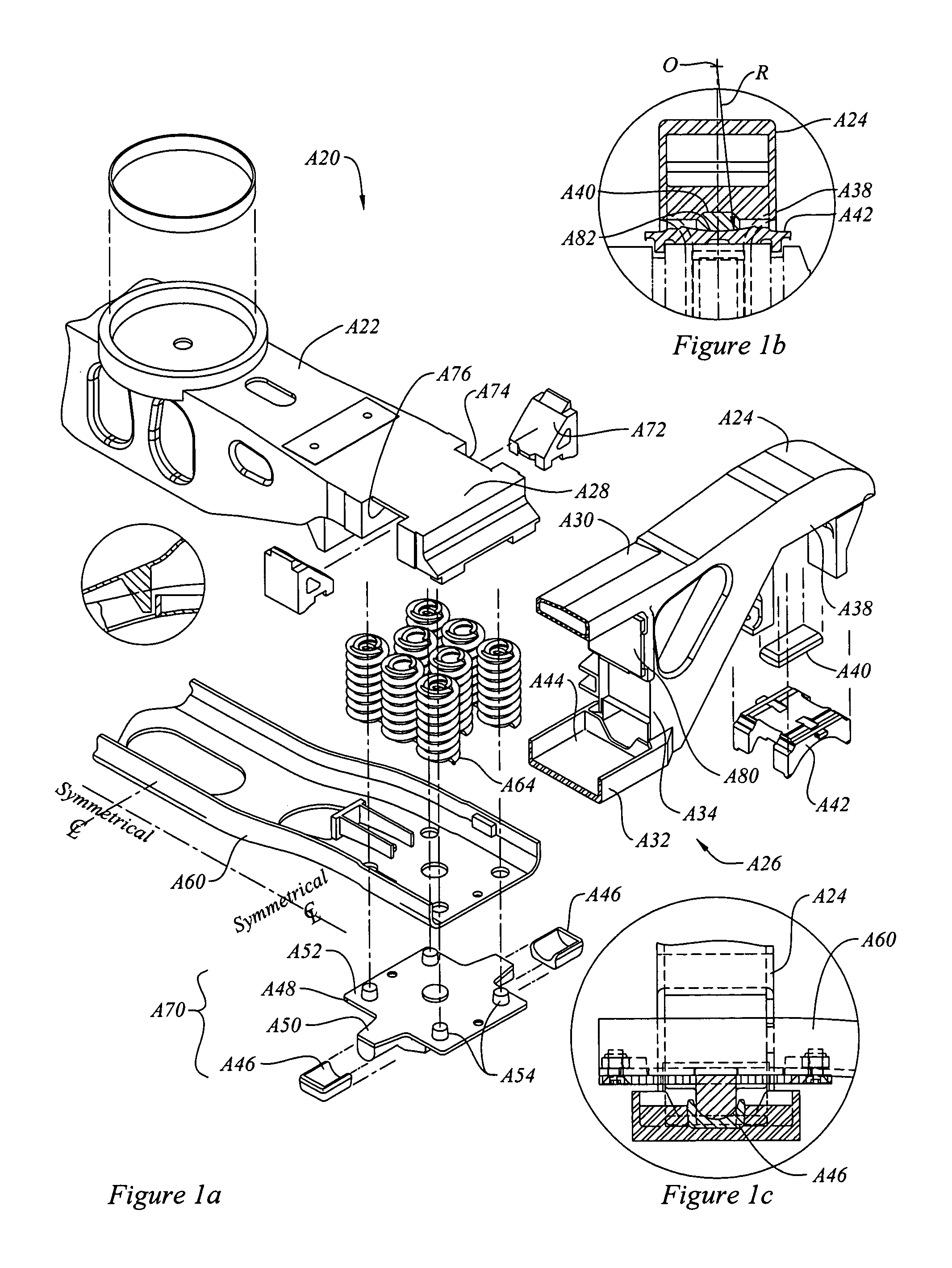

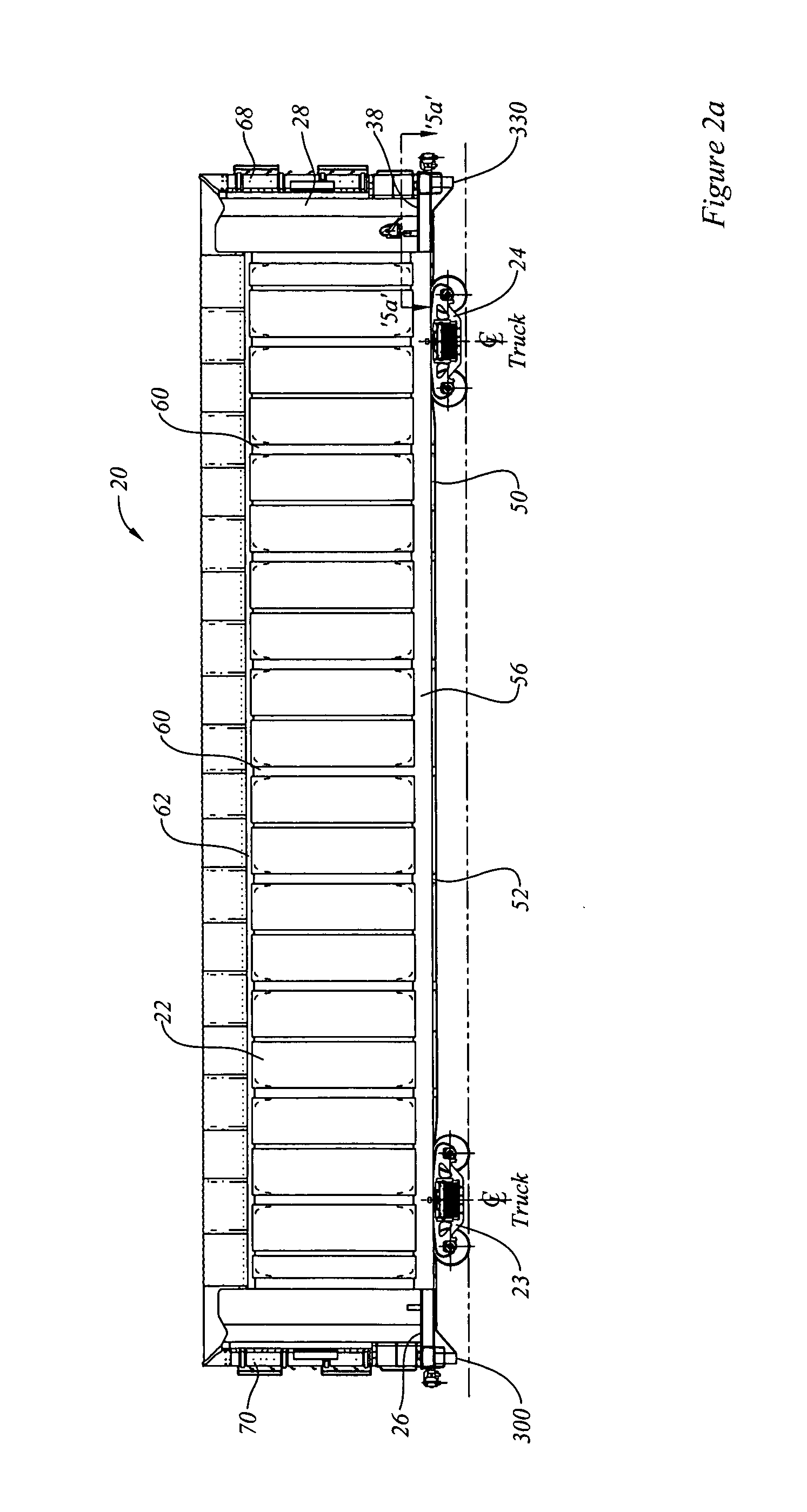

A mounting system includes a plurality of adjacent railcars including a first railcar that includes spaced first and second wheel assemblies each including at least one wheel pair. The mounting system also includes a first and second frames coupled to the first railcar. The first frame includes a space defined between at least two portions of the first frame and at least one cushion selectively positionable within the first frame space. The second frame includes a space defined between at least two portions of the second frame and at least one cushion selectively positionable within said second frame space. The first and second frames are spaced to facilitate at least one of partially containing and partially supporting the load. The first frame is substantially centered over at least one first wheel assembly wheel pair, and the second frame is substantially centered over at least one second wheel assembly wheel pair.

Owner:GENERAL ELECTRIC CO

Vehicle carrying rail road car and bridge plate therefor

Owner:NATIONAL STEEL CAR

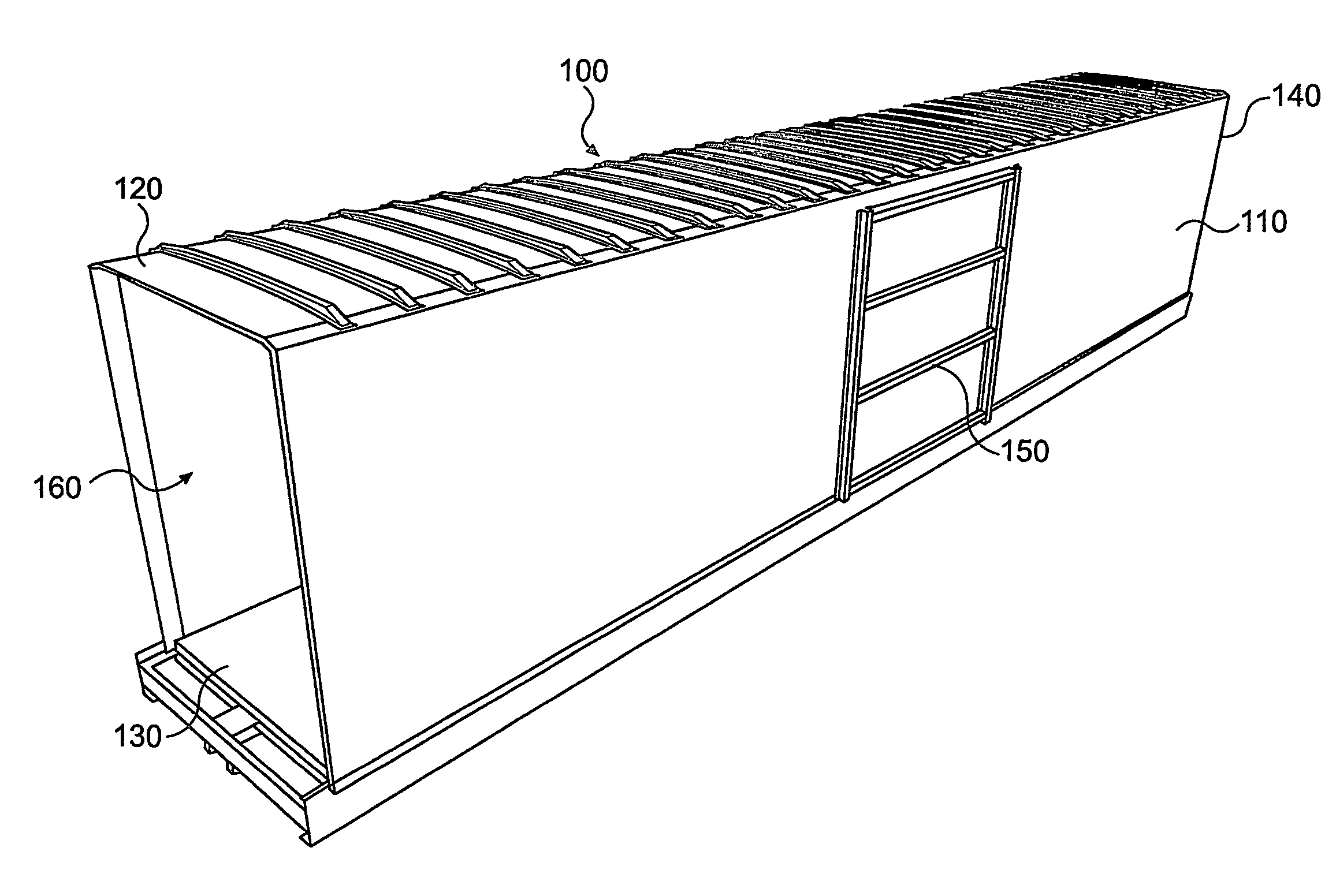

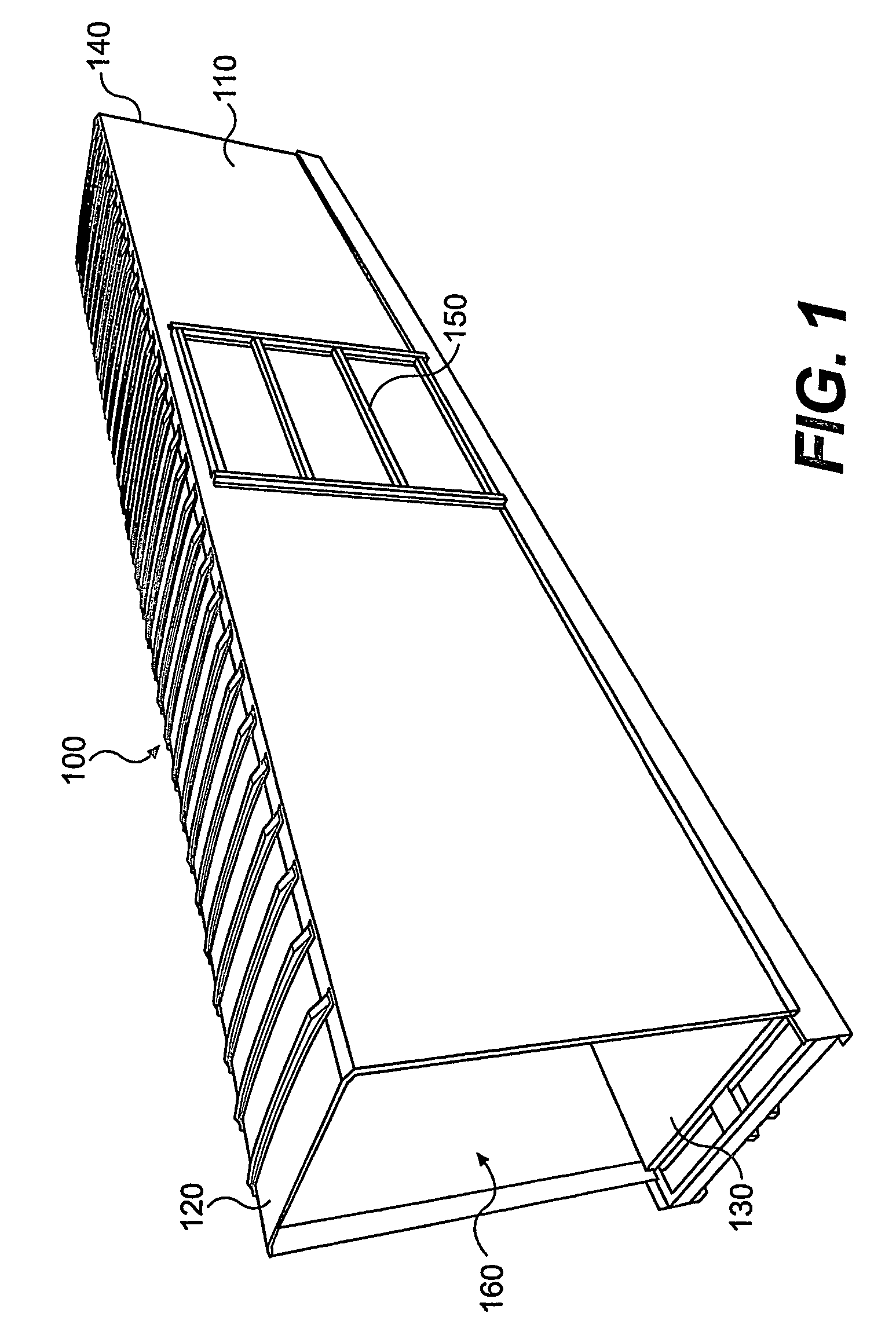

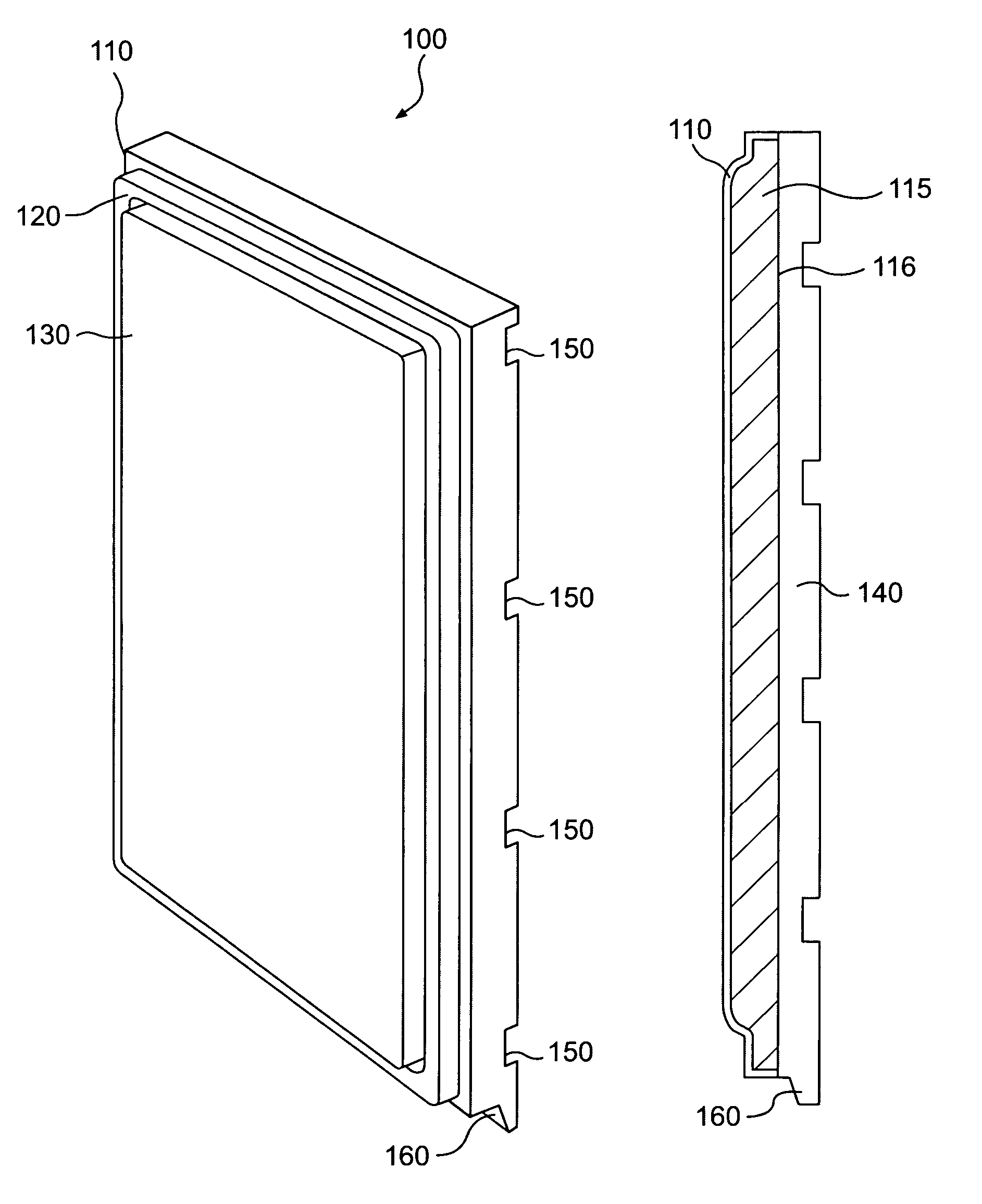

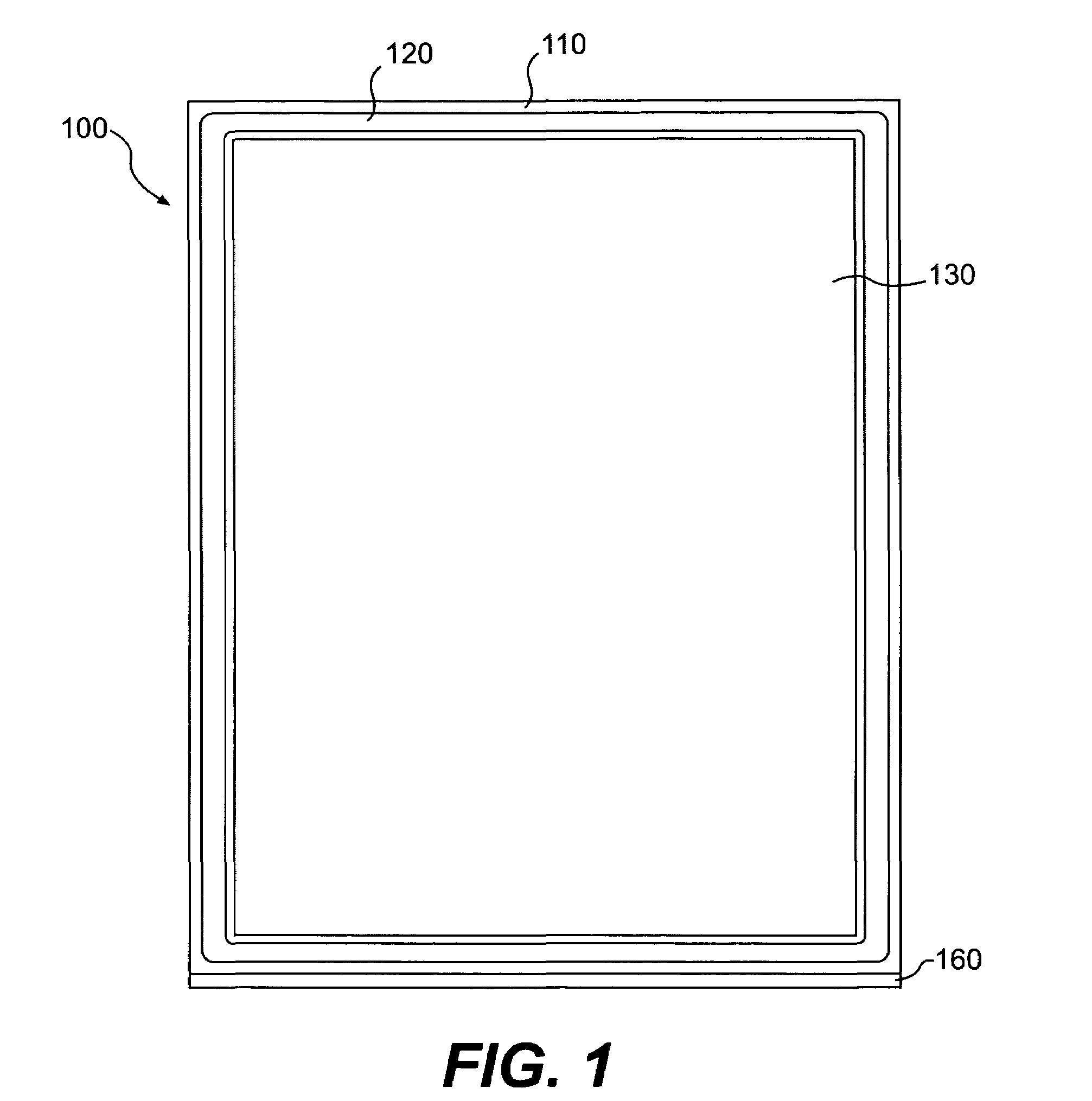

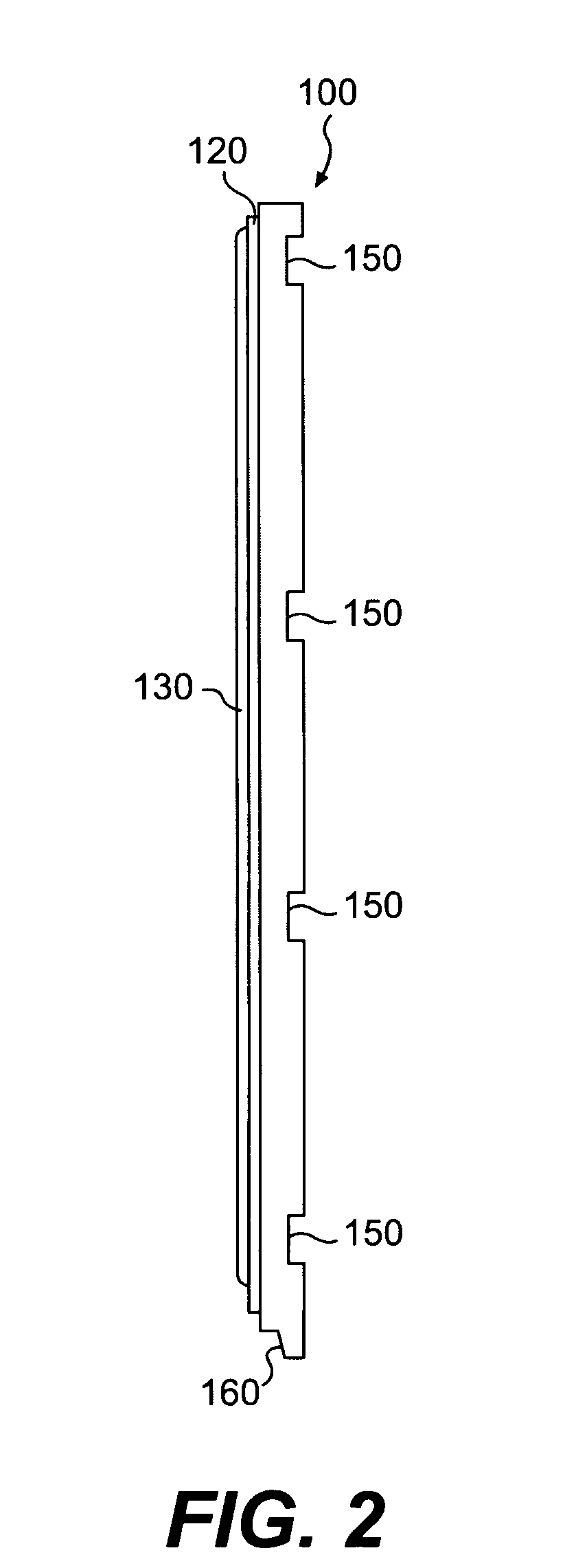

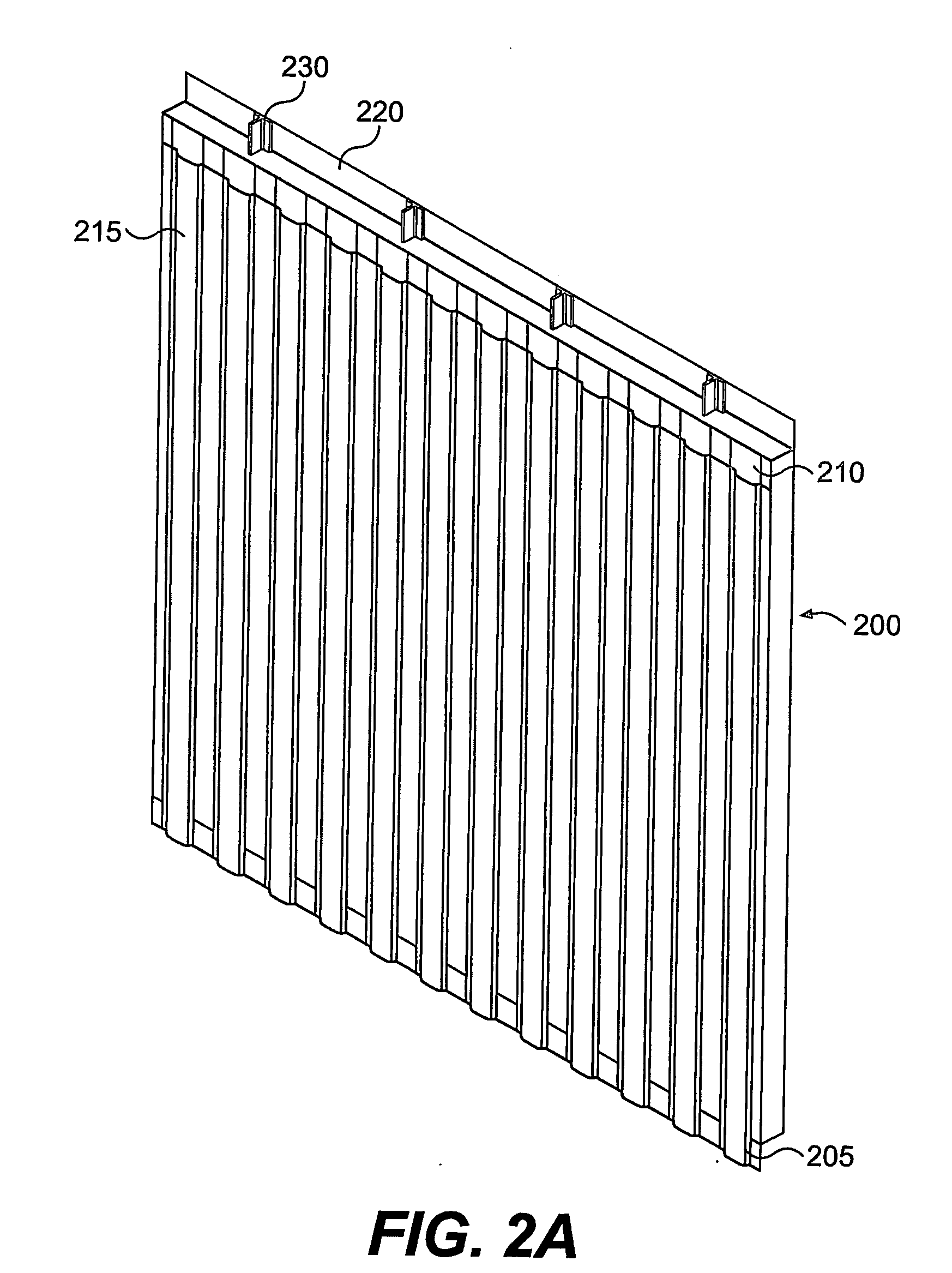

Insulated cargo containers

The present invention relates to an insulated cargo container that may have, in combination, an interior panel covering a layer of thermal insulation that has an air-impermeable layer thereon. The thermal insulation is attached to the exterior panel of the container, which may have structural supports on its interior surface. In one embodiment, the insulated cargo container is an insulated railroad boxcar.

Owner:MARTIN MARIETTA MATERIALS

Insulated cargo container doors

A method to insulate an existing door for an existing cargo container, such as a boxcar. In one implementation, the method includes attaching a liner to at least one surface of the door, incorporating an insulating layer, and attaching a gasket to the liner. A door retrofit by this method will have improved thermal efficiency.

Owner:MARTIN MARIETTA MATERIALS

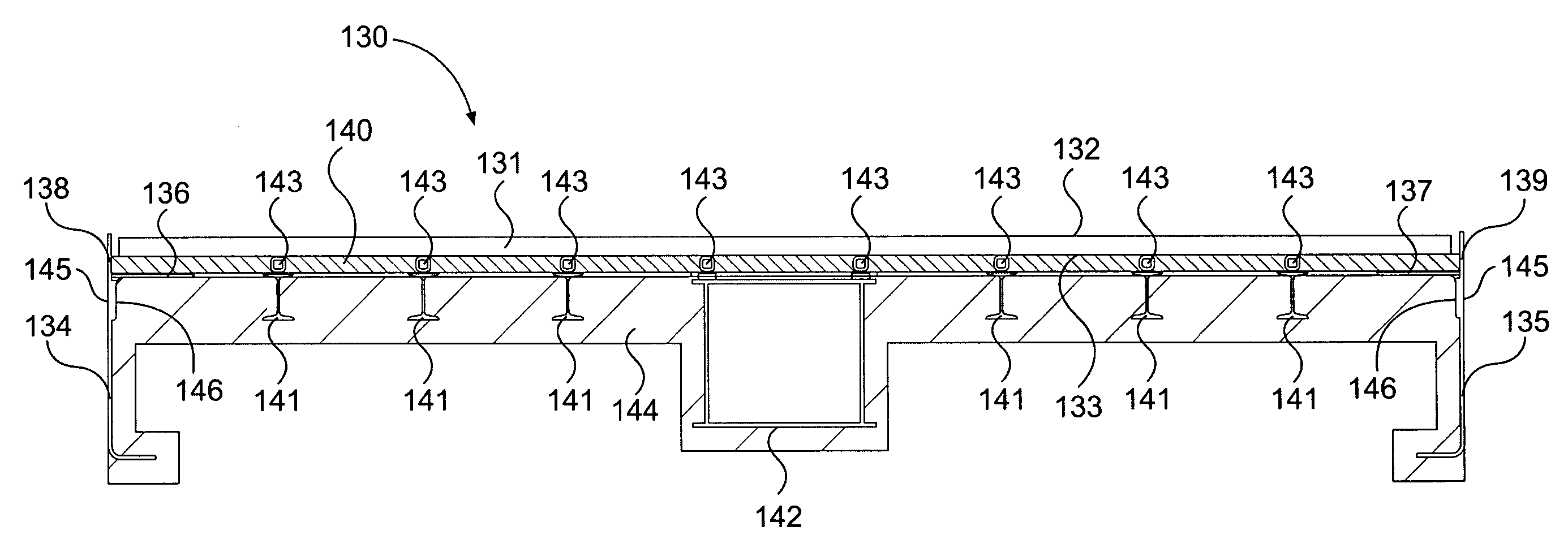

Cargo container with insulated floor

The present invention relates to an insulated cargo container with an insulated floor. The insulated floor includes insulating members and insulation layers in order to remove thermal shorts and increase the thermal efficiency of the cargo container.

Owner:MARTIN MARIETTA MATERIALS

Open-top rail car covers and open-top rail cars employing the same

An open-top rail car cover is defined by a frame having dimensions sufficient to fit an open-top freight car designed in accordance with the Association of American Railroads, a roof and a pair of end walls. A latch disposed about a side of the frame includes a first flange and a second flange that combine to define a means for receiving an engagement member of a rail car. Both the first and second flanges include a at least one first aperture and at least one second aperture designed to receive a means for securing the car cover to the rail car. The first and second apertures have dimensions sufficient to permit movement of the first and second flanges about the means for receiving.

Owner:MARTIN MARIETTA MATERIALS

Insulated cargo containers

The present invention relates to an insulated cargo container that may have, in combination, an interior panel covering a layer of thermal insulation that has an air-impermeable layer thereon. The thermal insulation is attached to the exterior panel of the container, which may have structural supports on its interior surface. In one embodiment, the insulated cargo container is an insulated railroad boxcar.

Owner:MARTIN MARIETTA MATERIALS

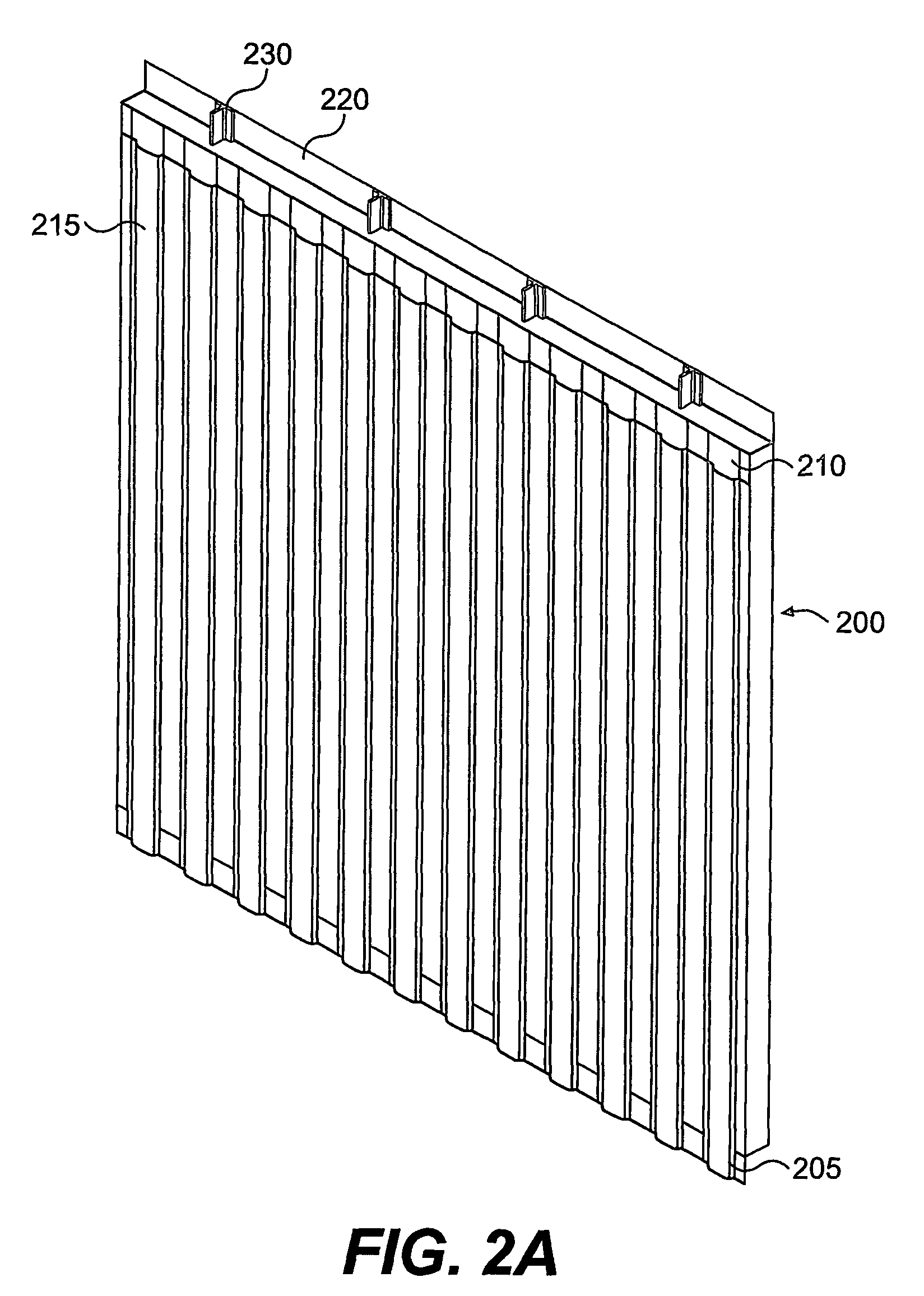

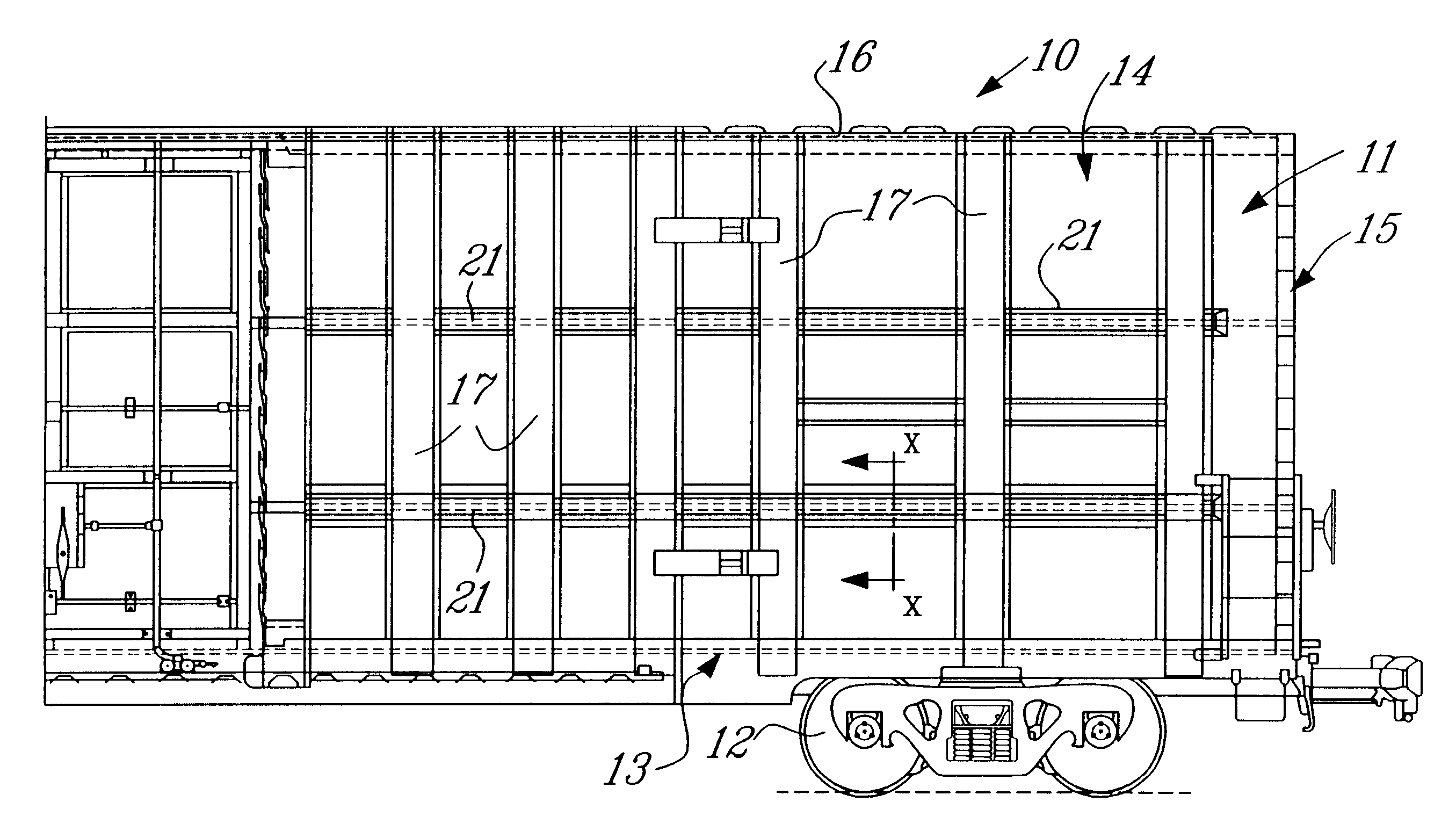

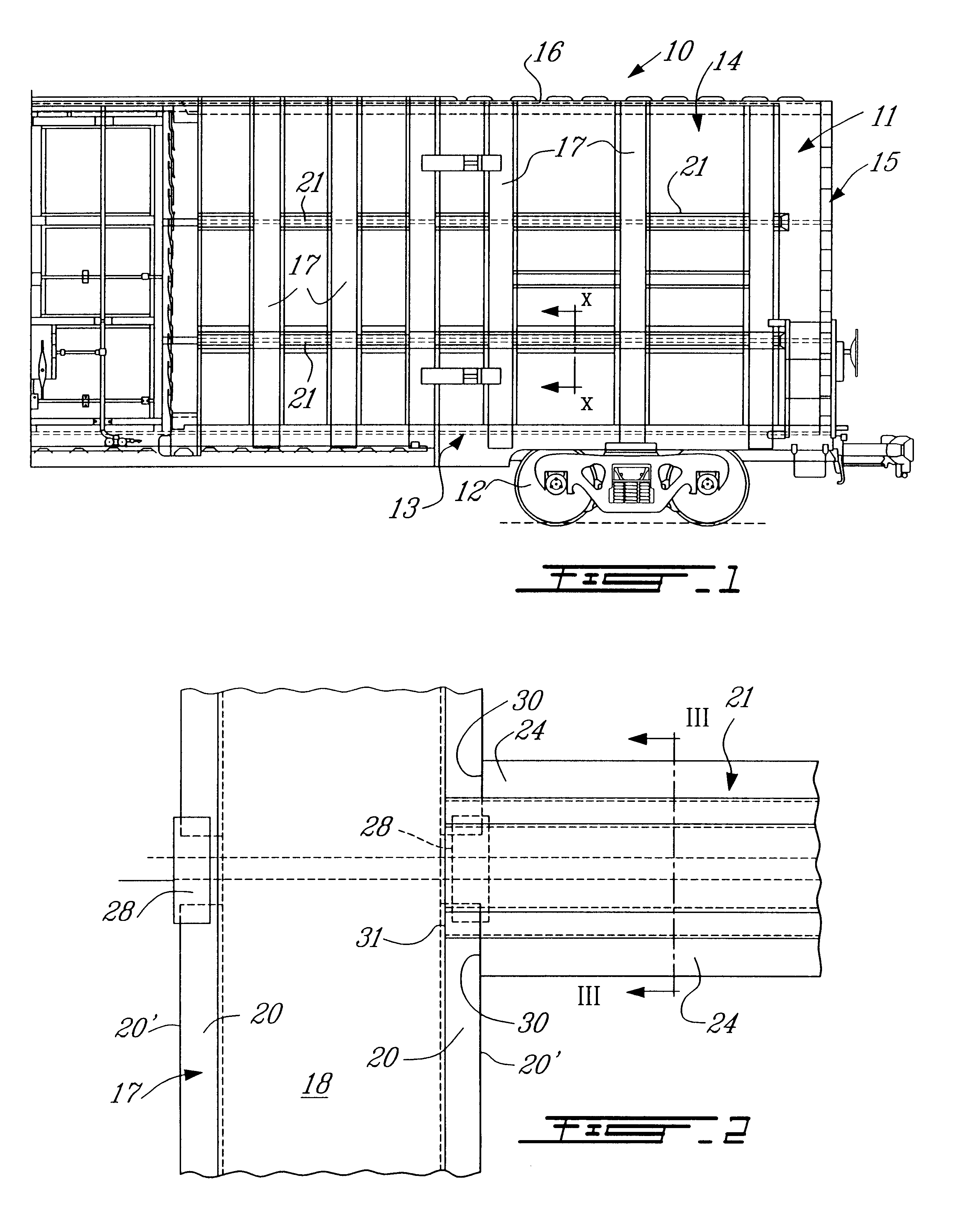

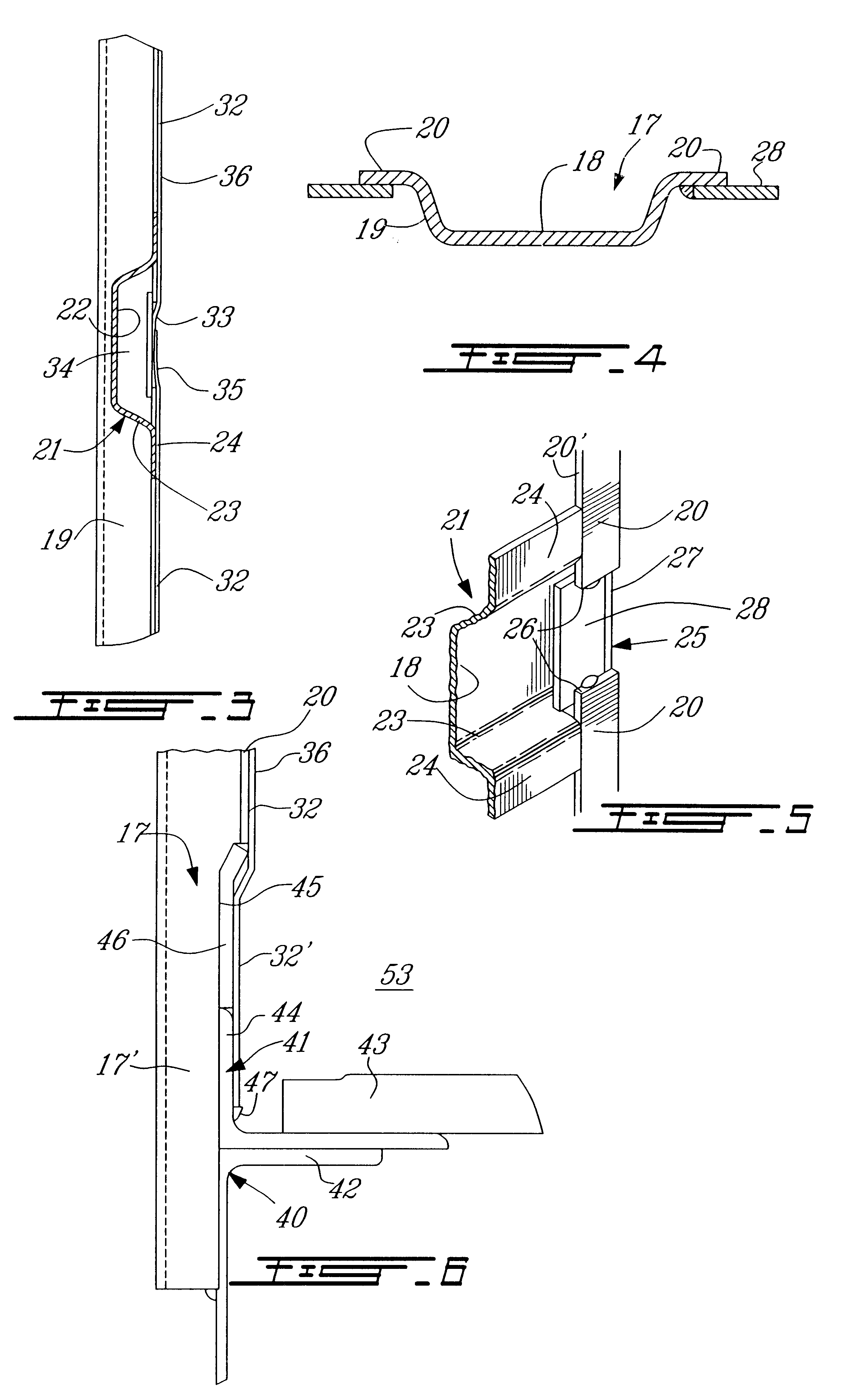

Railway box car structure

InactiveUS6422156B1Improved longitudinal side wall structureSimple designRailway roofsTank wagonsAirplaneFlange

An improved railway car body structure is described. One of the features of the box car is that the longitudinal side walls are formed by a plurality of spaced apart vertical side posts which are hat-shaped in cross-section and define a bottom wall portion, opposed side walls and opposed end flanges extending in a common plane. Horizontal structural stiffeners are secured between the vertical side posts. The stiffeners define a recessed wall portion aligned with a recessed formation formed in the opposed end flanges of the vertical side posts. Ferrous sheet members are secured to the side wall and also to the end frames by welds disposed in the recess wall portion of the stiffeners and recessed formation of the vertical posts to form flush, unobstructed, inner side and end walls of the railway car. A new roof structure is also described and incorporates improved skylight designs.

Owner:IEC HOLDEN INC

Insulated cargo containers

A method of insulating an existing cargo container, such as a boxcar. The method allows for the application of improved insulation materials to improve the R-Value of an existing boxcar without building a new boxcar. In one implementation, the method includes preparing multiple insulating panels comprising an insulating layer and an outer skin located on at least one face of the insulating layer and attaching the insulating panels on an exterior surface of the side walls, end walls, and roof of the boxcar. The method also includes installing closures on uncovered areas of the boxcar and applying foam insulation to the bottom surface of the boxcar.

Owner:MARTIN MARIETTA MATERIALS

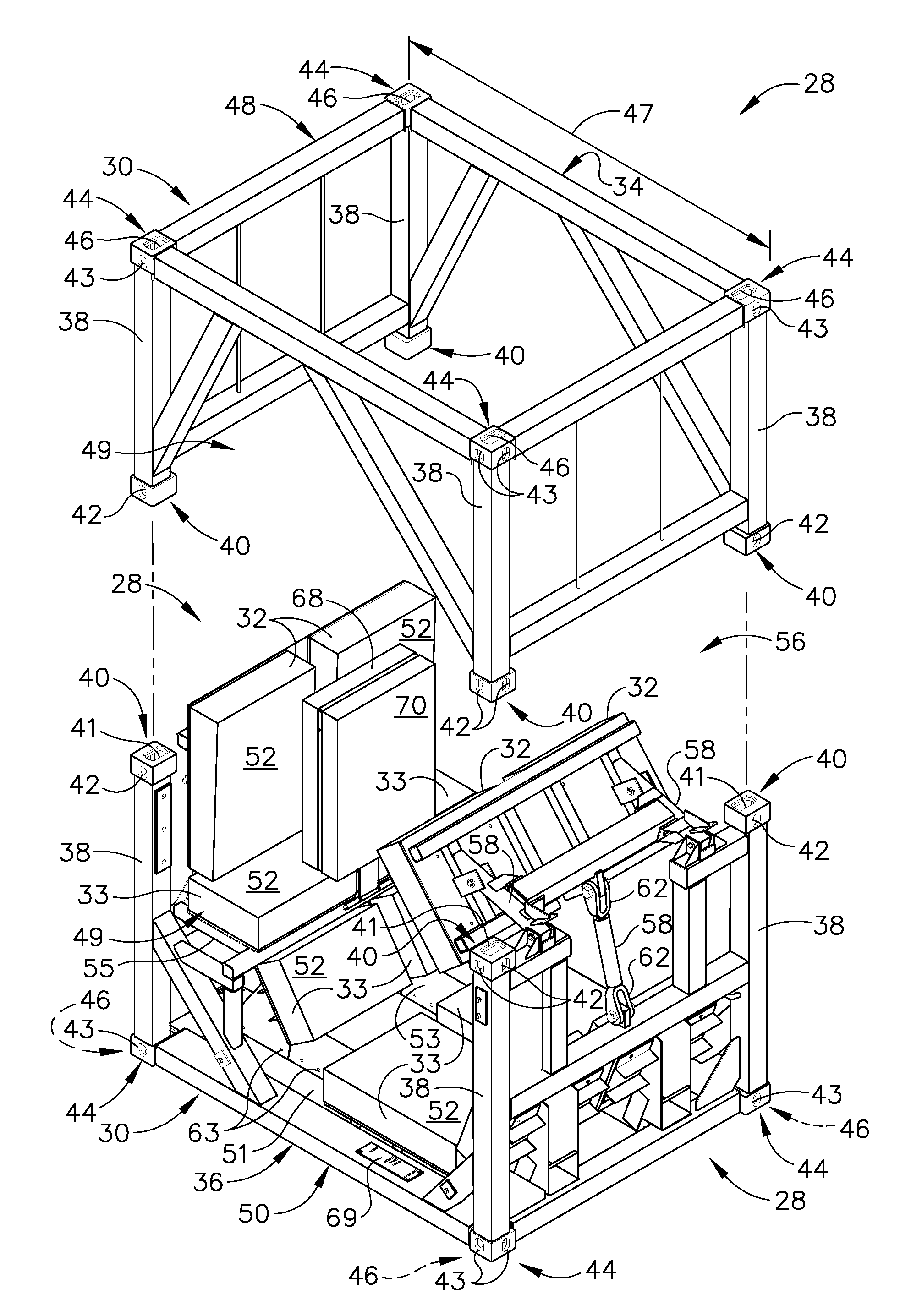

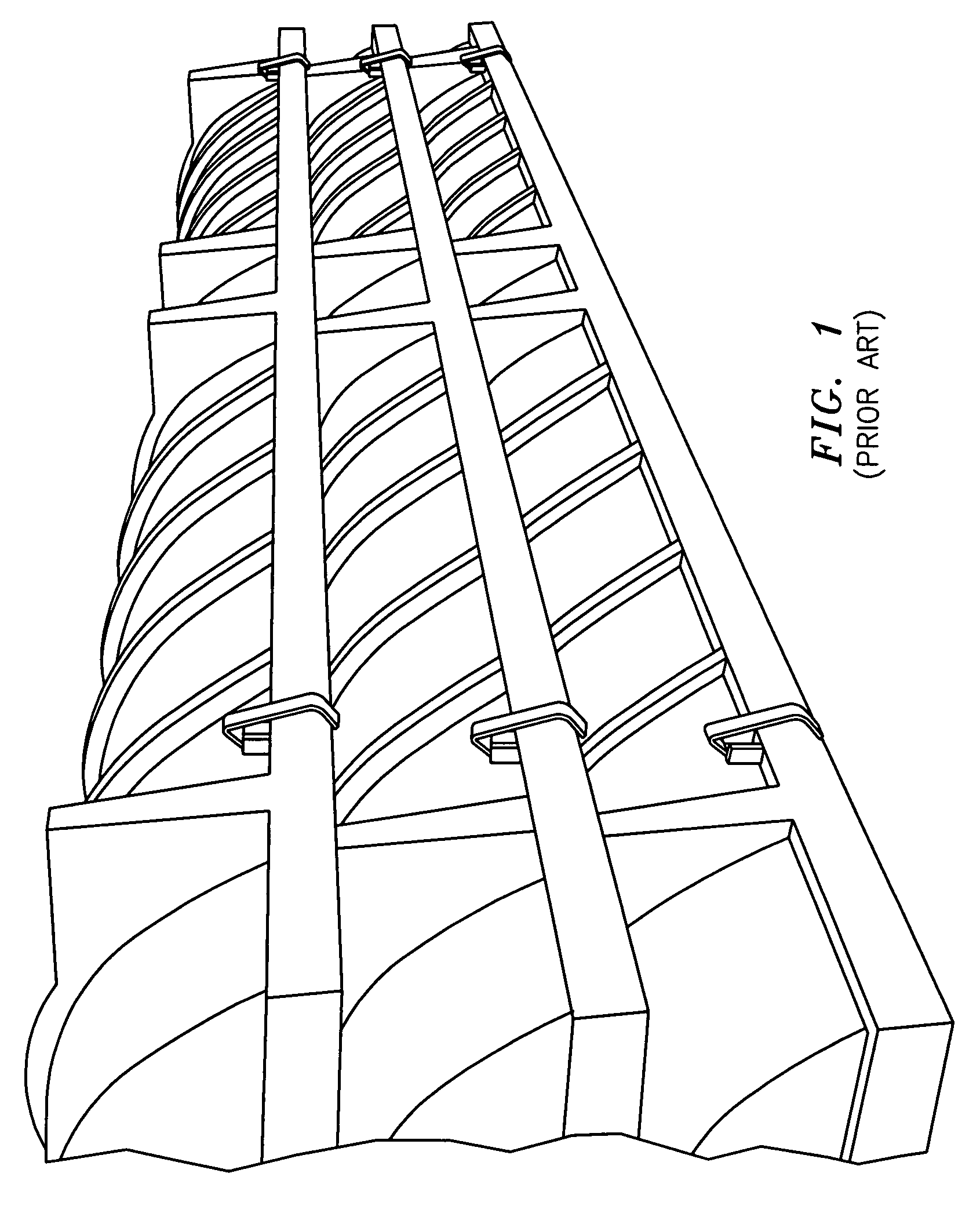

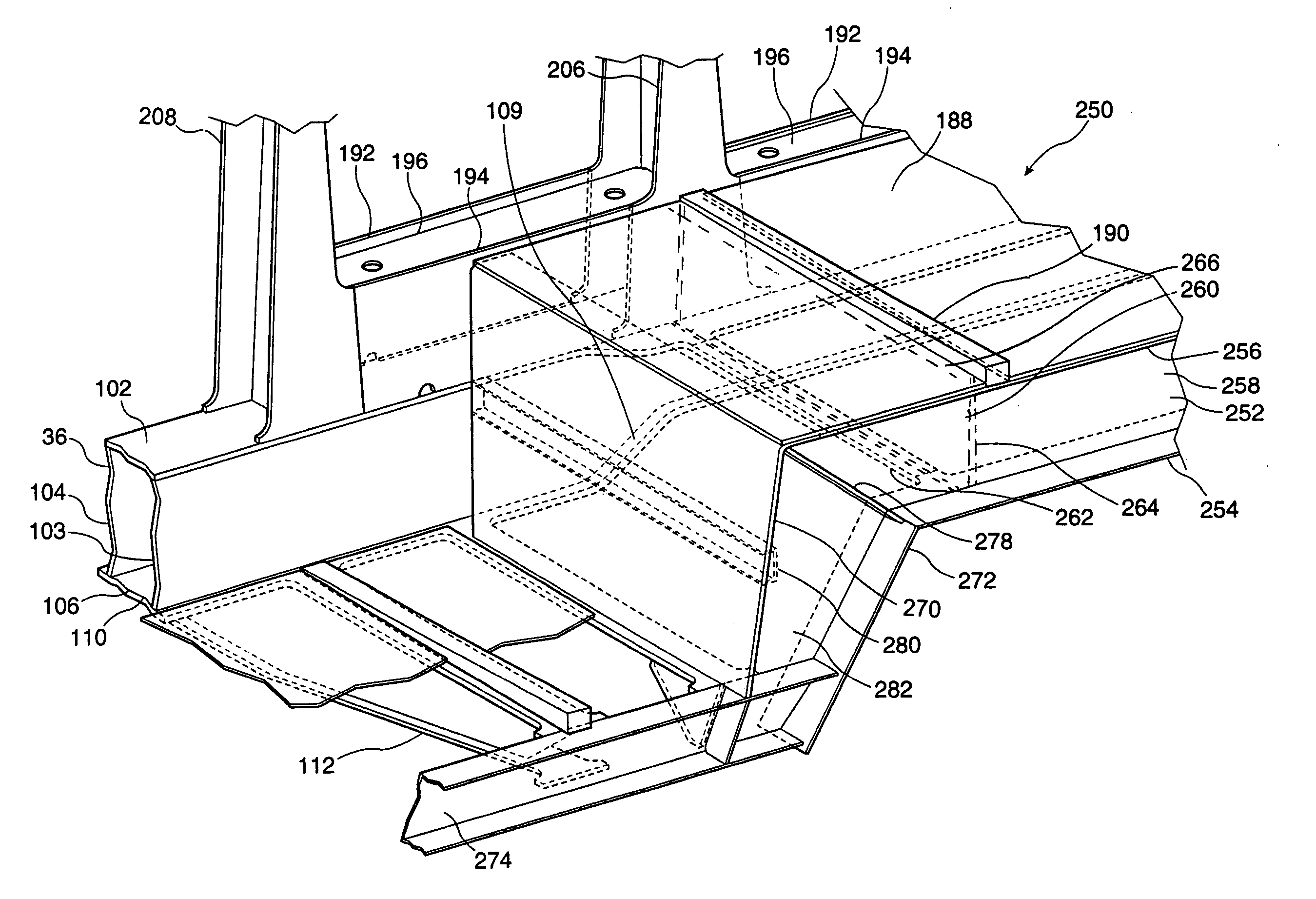

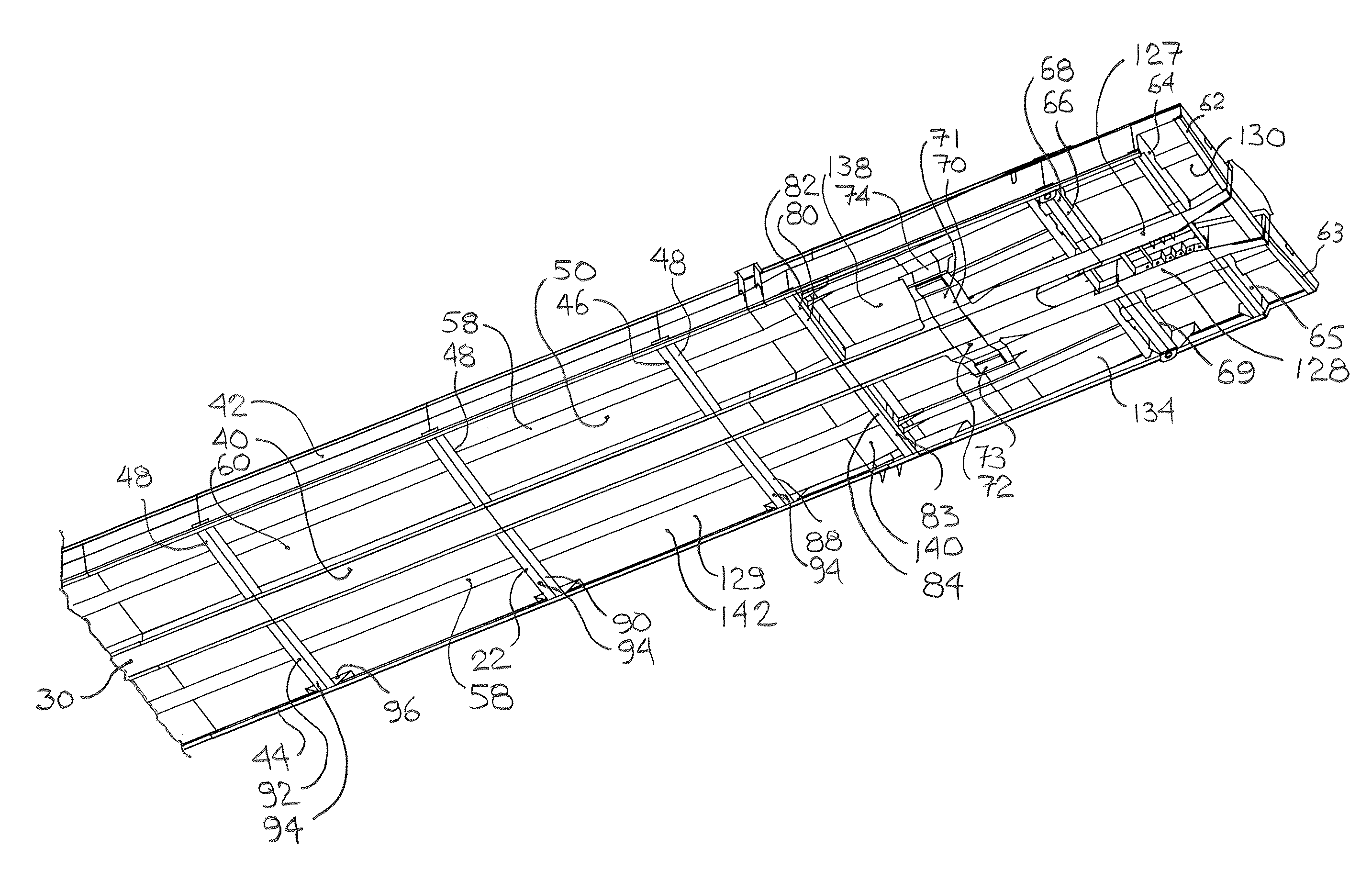

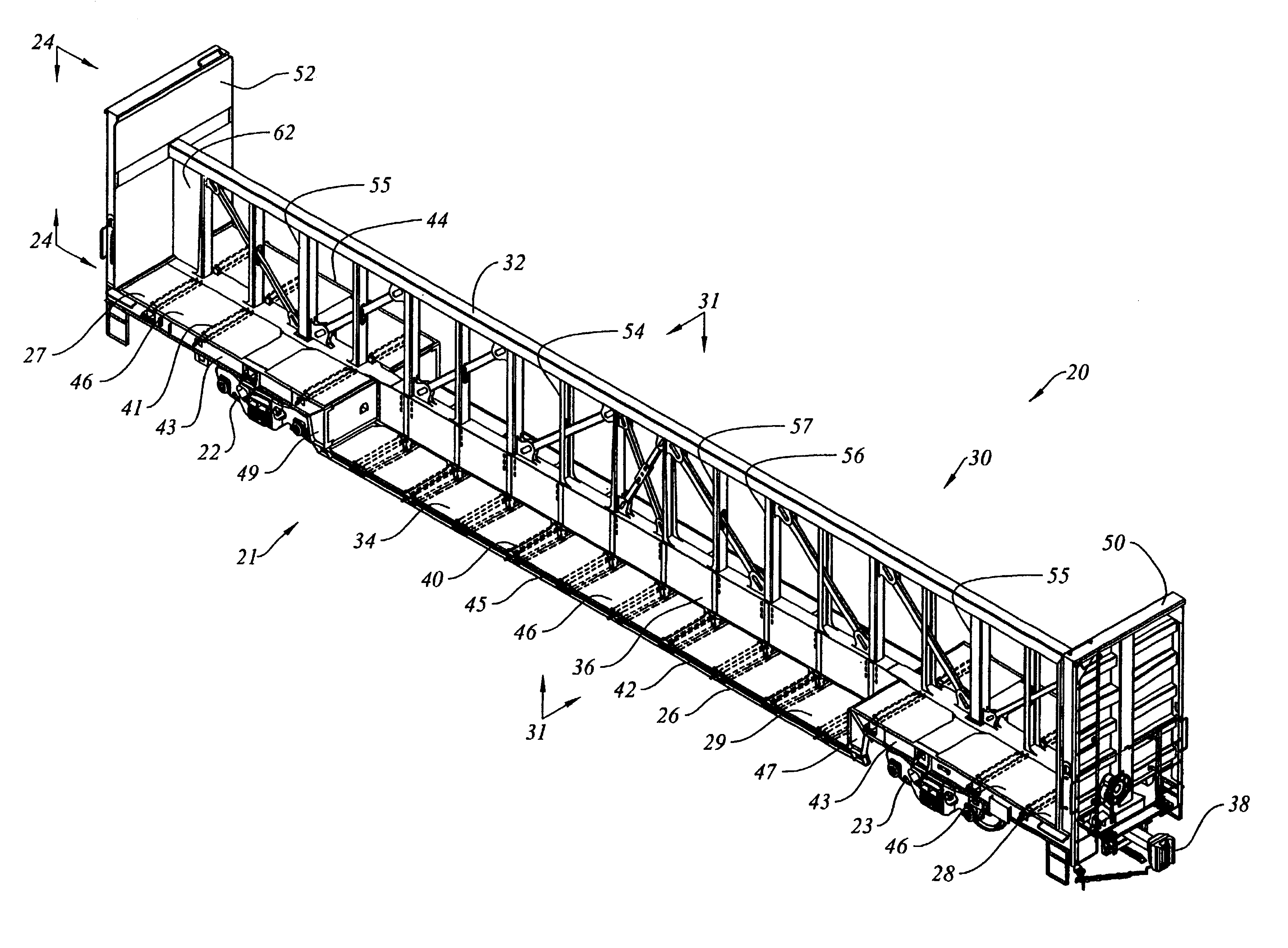

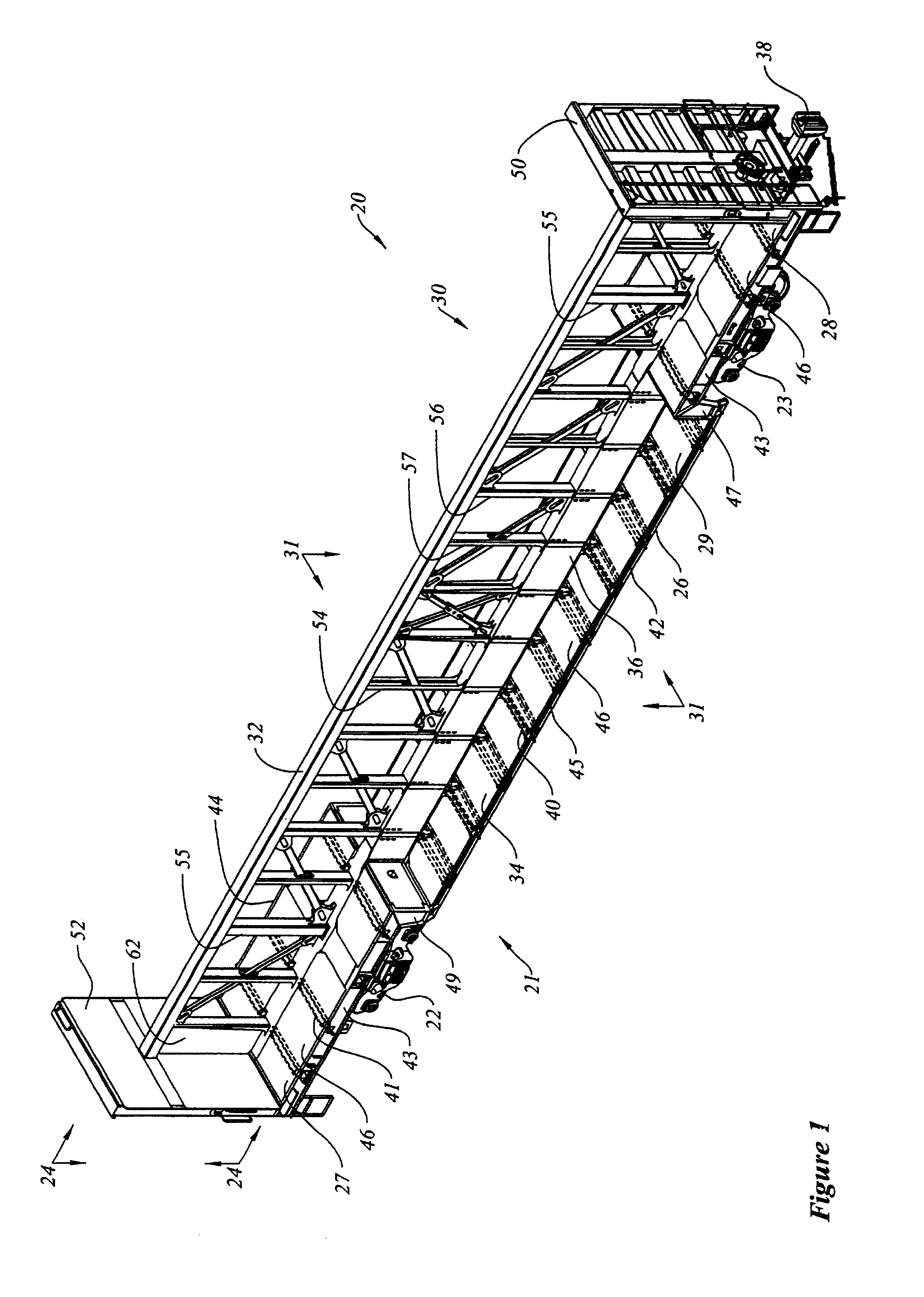

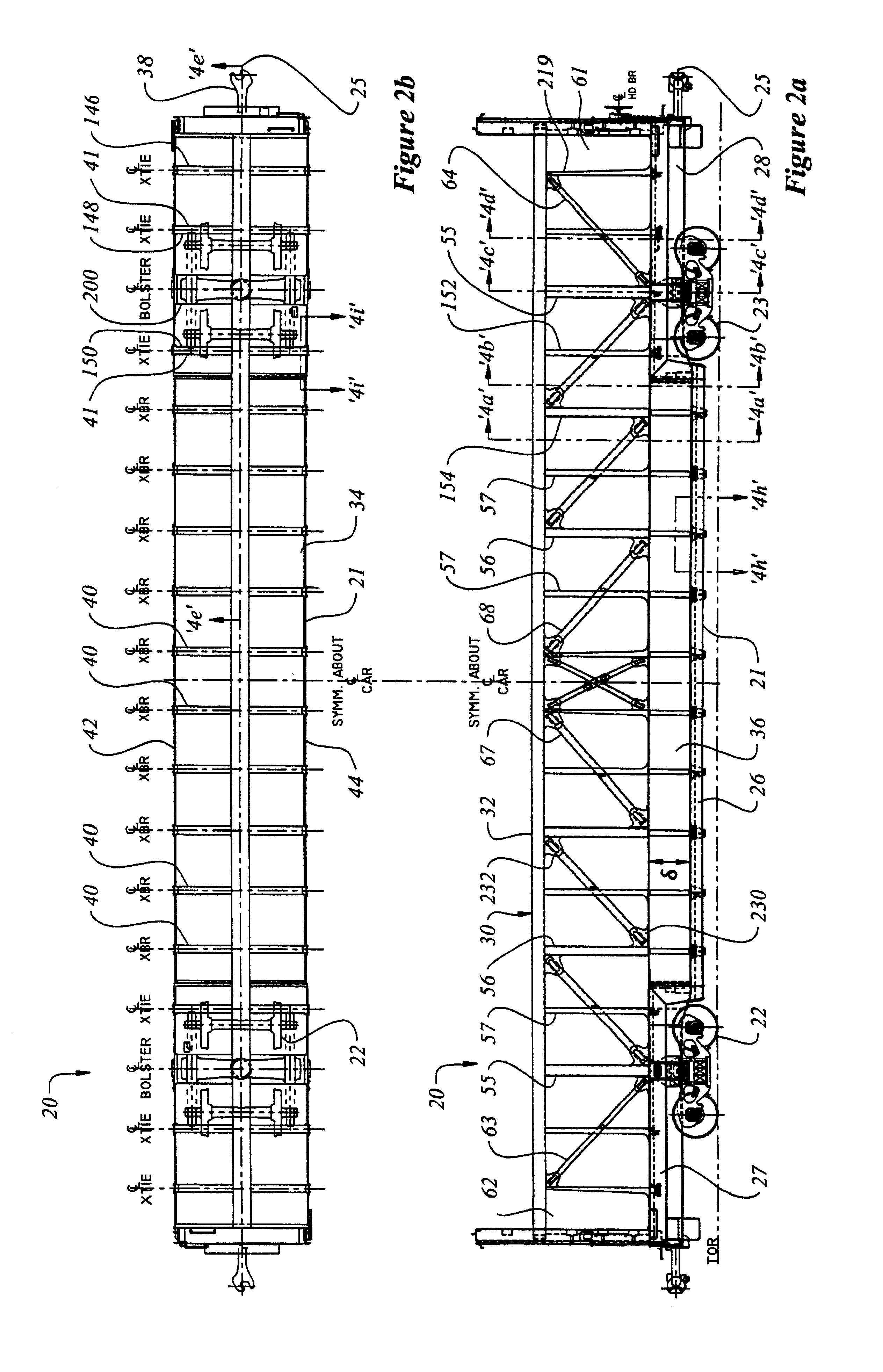

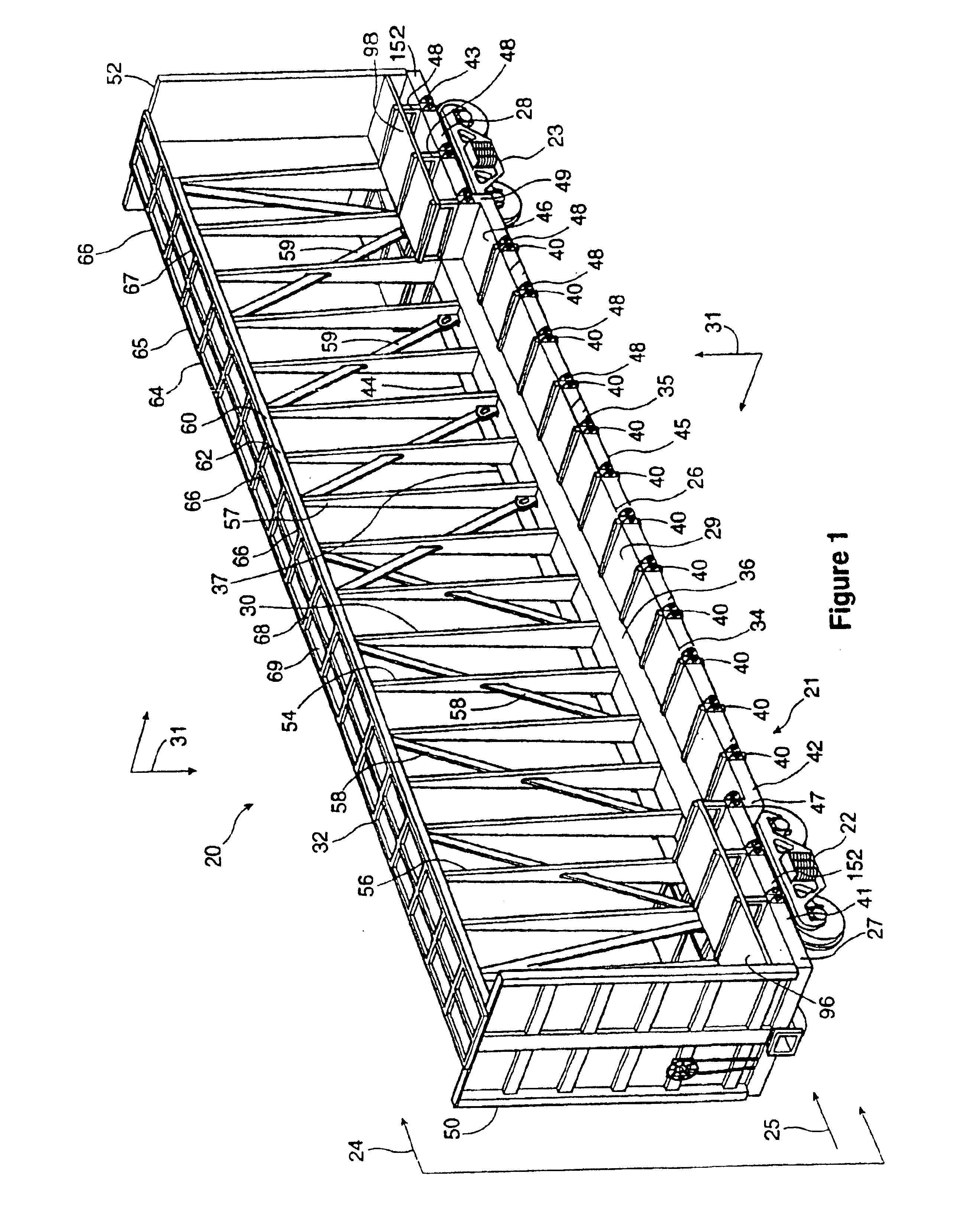

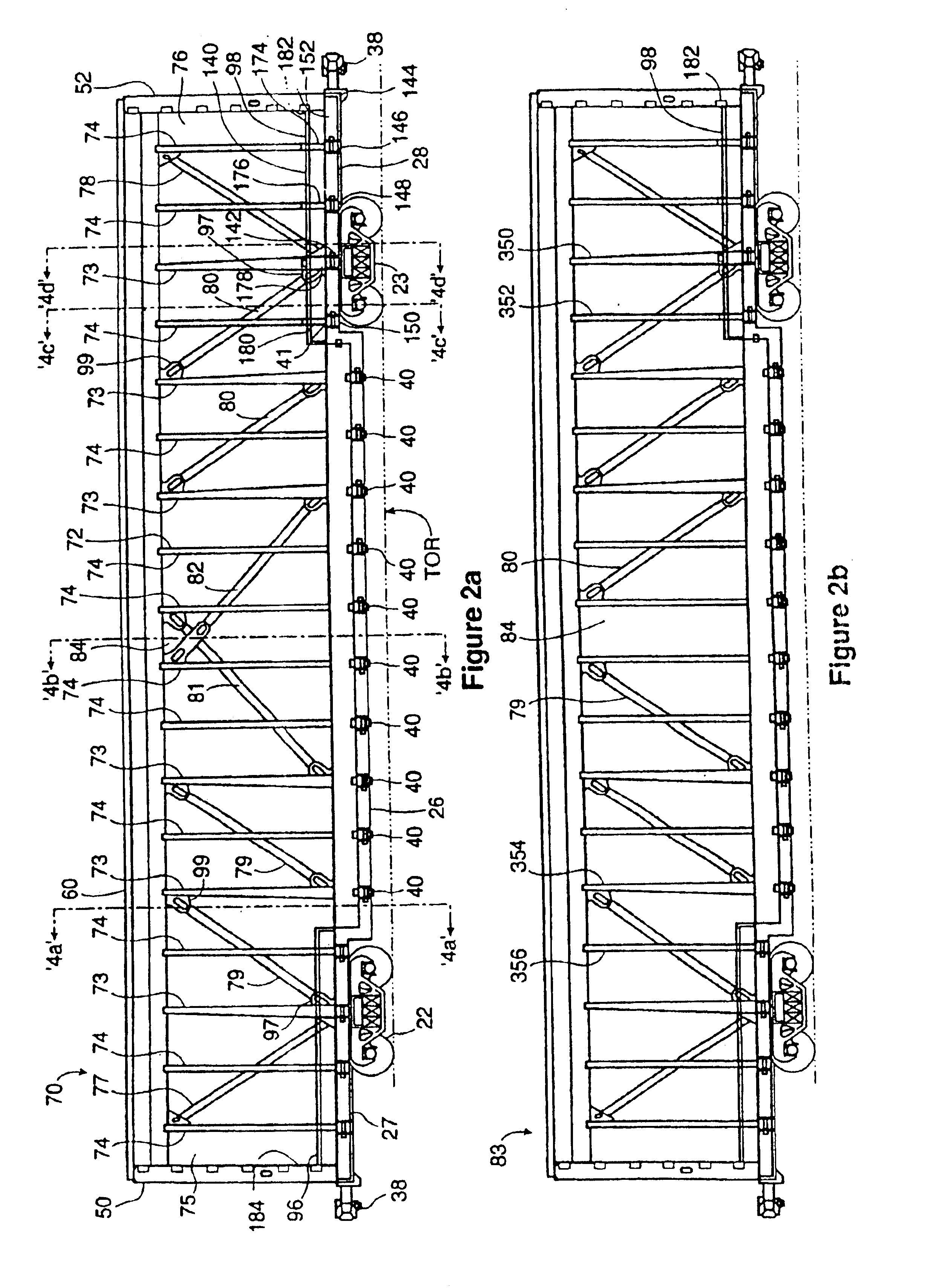

Dropped deck center beam rail road car

A center beam car has a main deck structure extending laterally from a main center sill, a laterally extending top truss structure, and a central vertically oriented web work structure for carrying vertical shear loads between the top truss and the center sill and decking. The center beam so formed defines bunks upon in which to carry cargo. The upper region of the web-work structure includes a deep upper beam structure that has downwardly extending skirts. The skirts provide an extended bearing area upon against which bundled loads can be secured. The skirts are inwardly reinforced to discourage deflection between adjacent upright members of the deep upper beam structure.

Owner:GREYPOINT CAPITAL INC

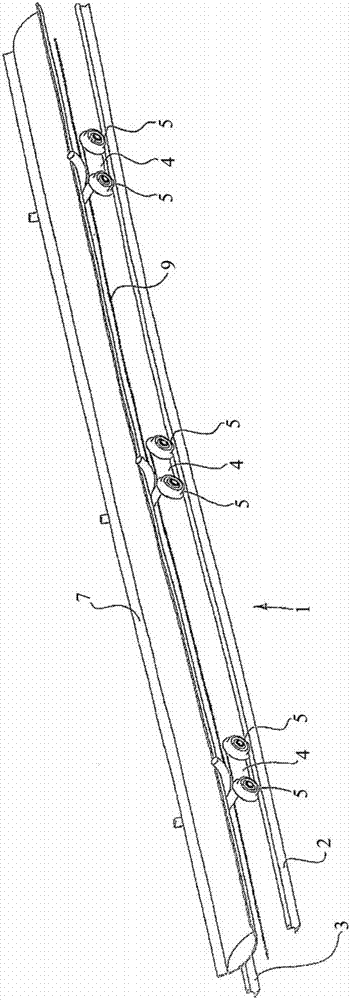

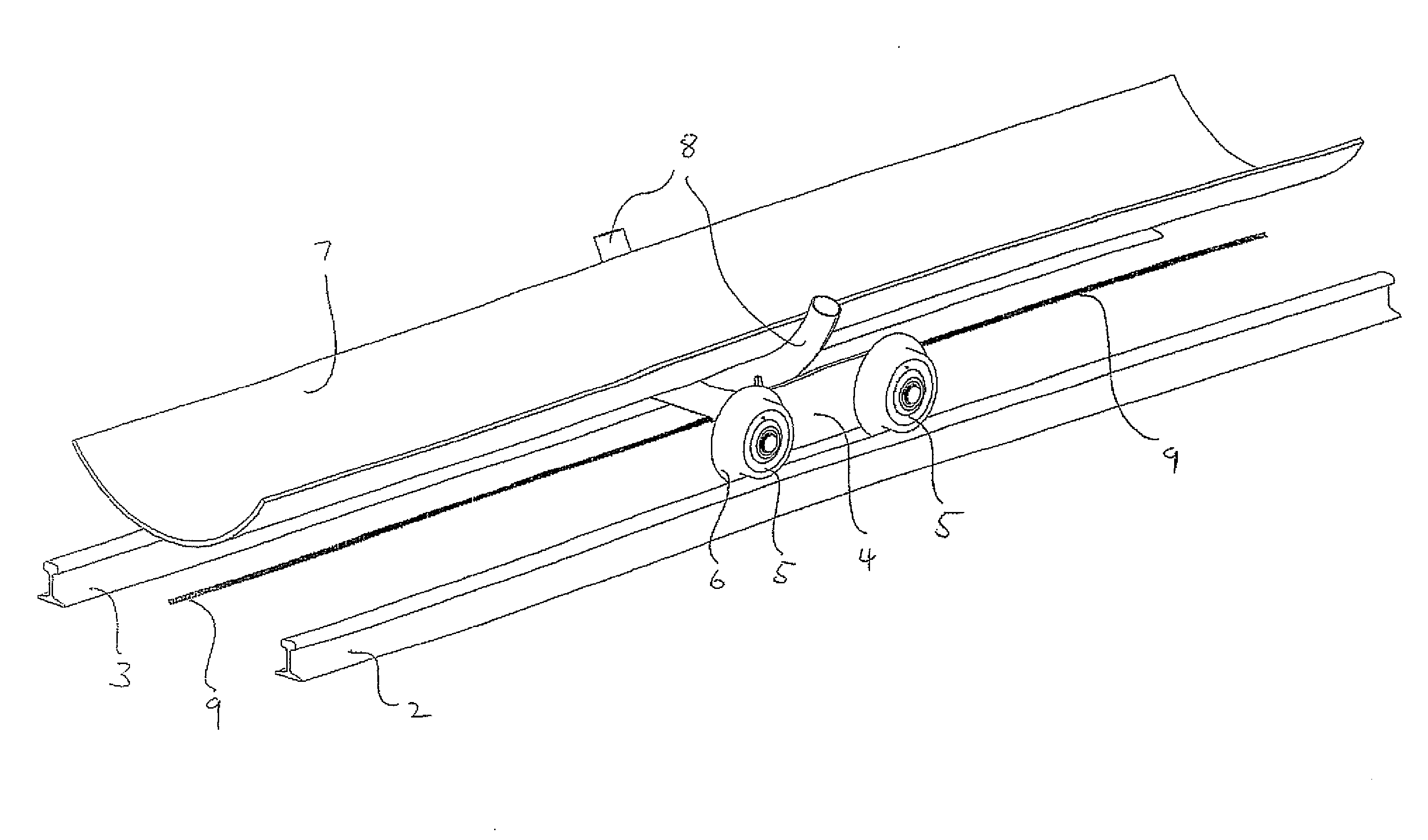

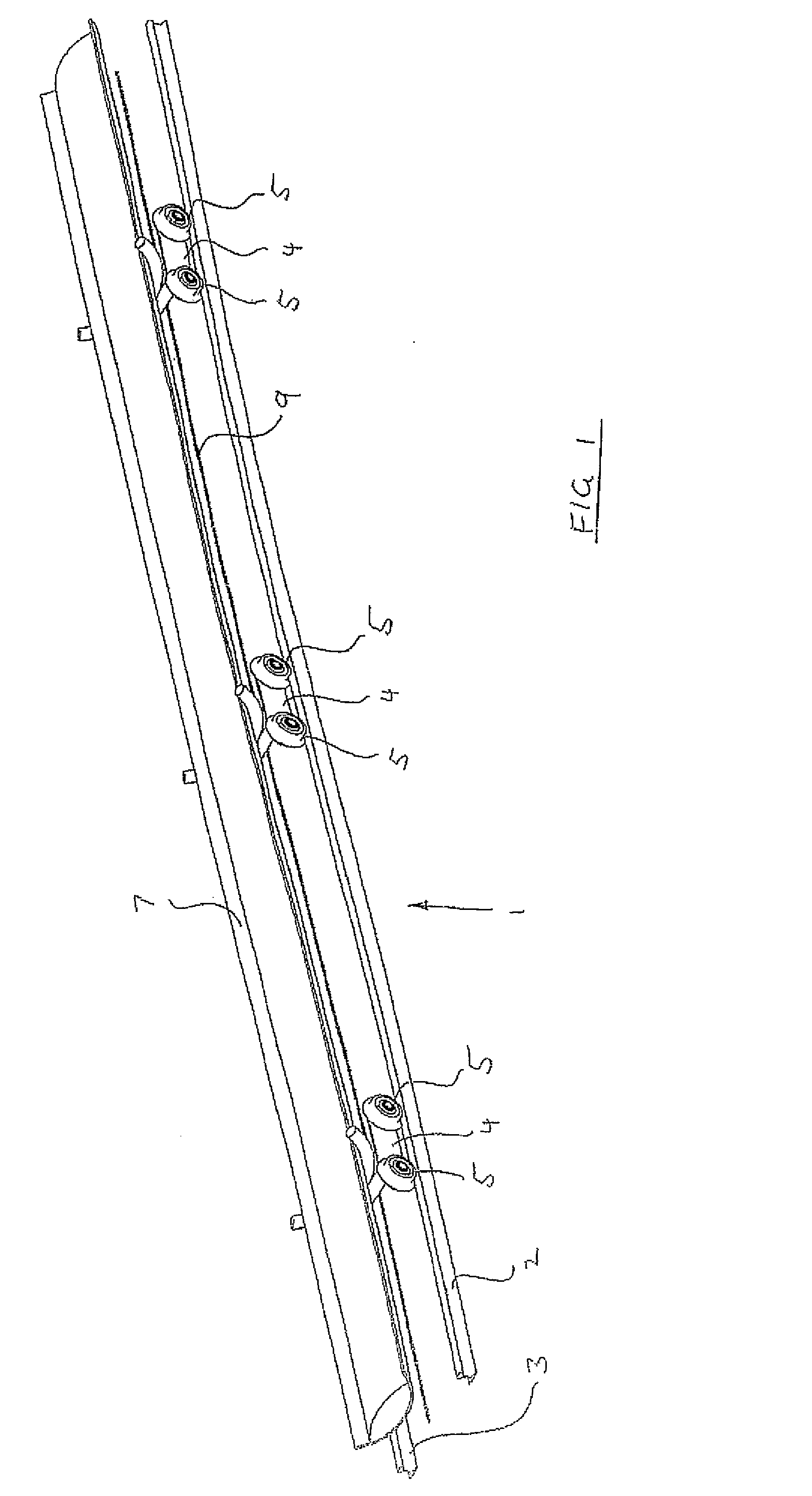

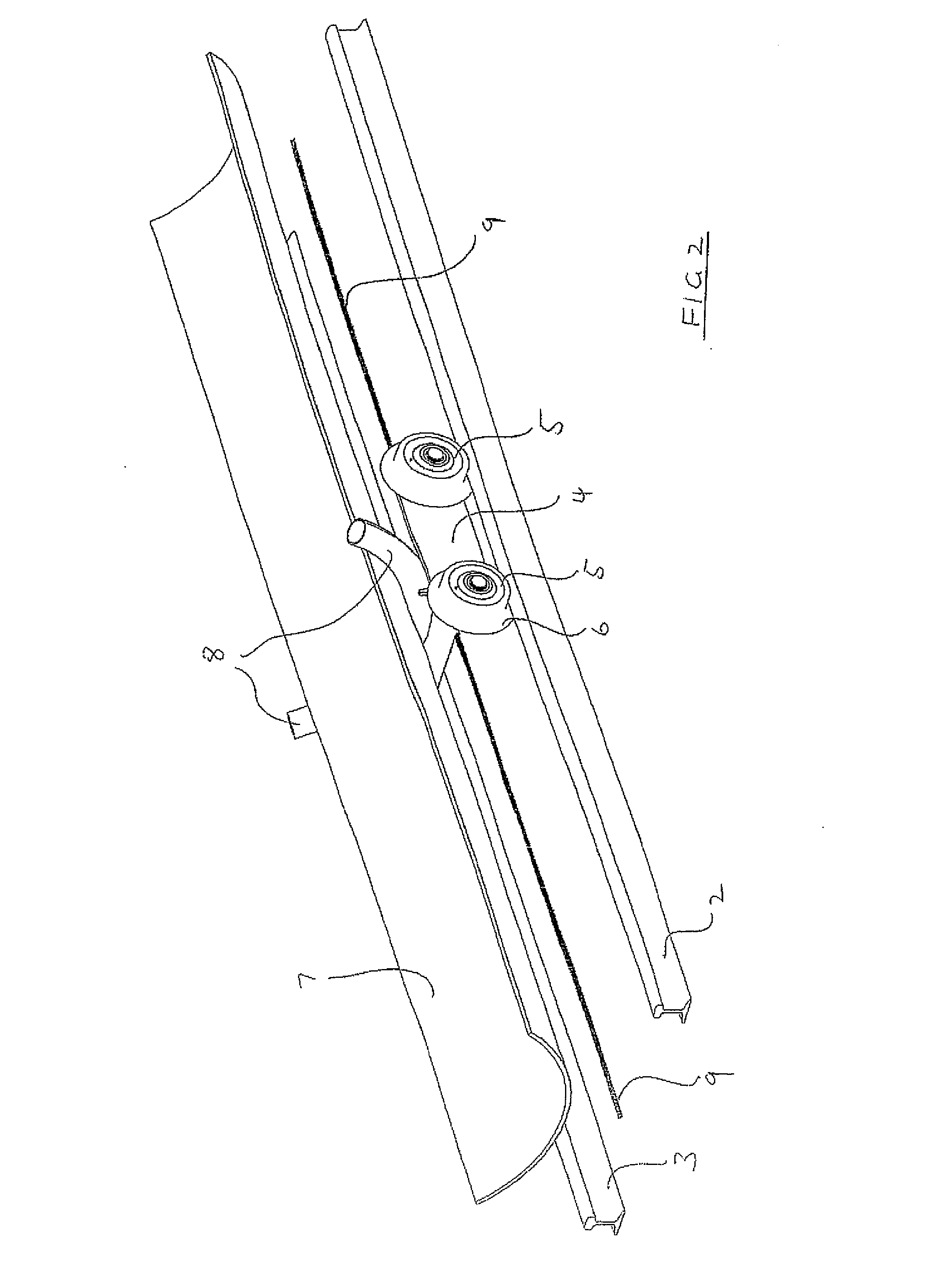

Rail conveyor system

A rail conveyor system combining the low friction attributes of railway transportation with the continuous bulk handling advantages of belt conveyors, uses a multiplicity of spaced carriages (4) running on steel wheels (5) on rail tracks (2, 3) to support a continuous carry belt (7). The system is driven by various means including a rope (9) extending between the carriages. Various other drive means including drive belt technology are also described along with loading and unloading stations and distributed drive stations.

Owner:NEWCASTE INNOVATION LTD

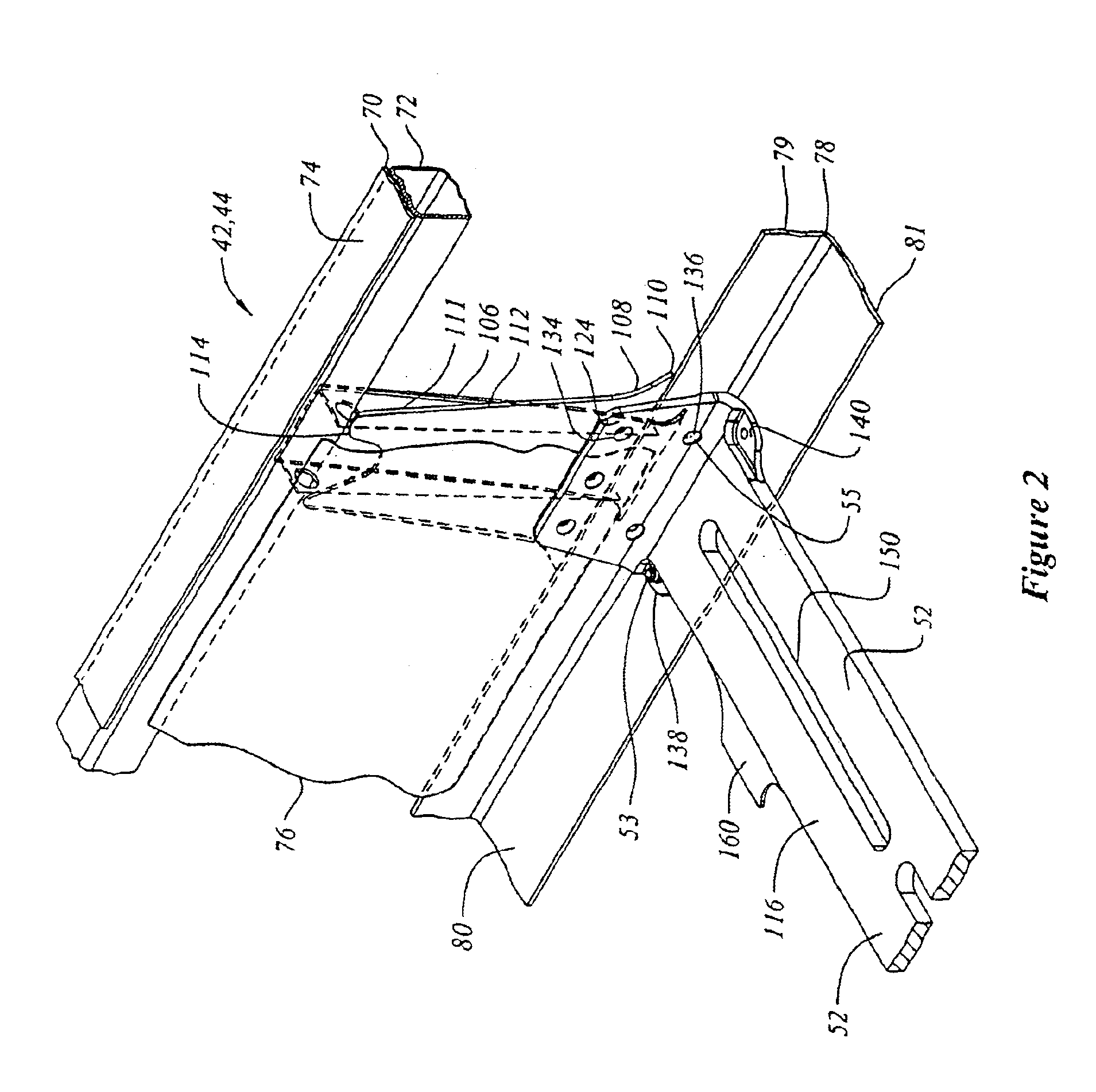

Well car with cross member and method

A well car for carrying shipping containers has a pair of end structures supported by rail car trucks, a pair of first and second spaced apart side beams extending between the end structures and a well defined therebetween. A container support cross member is mounted between the side sills in a position to support an end of a shipping container load carried within the well. The container support cross member may be a monolithic beam member with a attachment fitting formed at an end thereof. The attachment fitting is connectable to a side sill at a moment connection. The remaining end of the cross member is similarly configured and connected to the second side sill. Each end of the cross member has load bearing surface portions which may be used for supporting a corner of a shipping container. The moment connections permit a bending moment to be carried by the cross member between the first and second side sills.

Owner:NATIONAL STEEL CAR

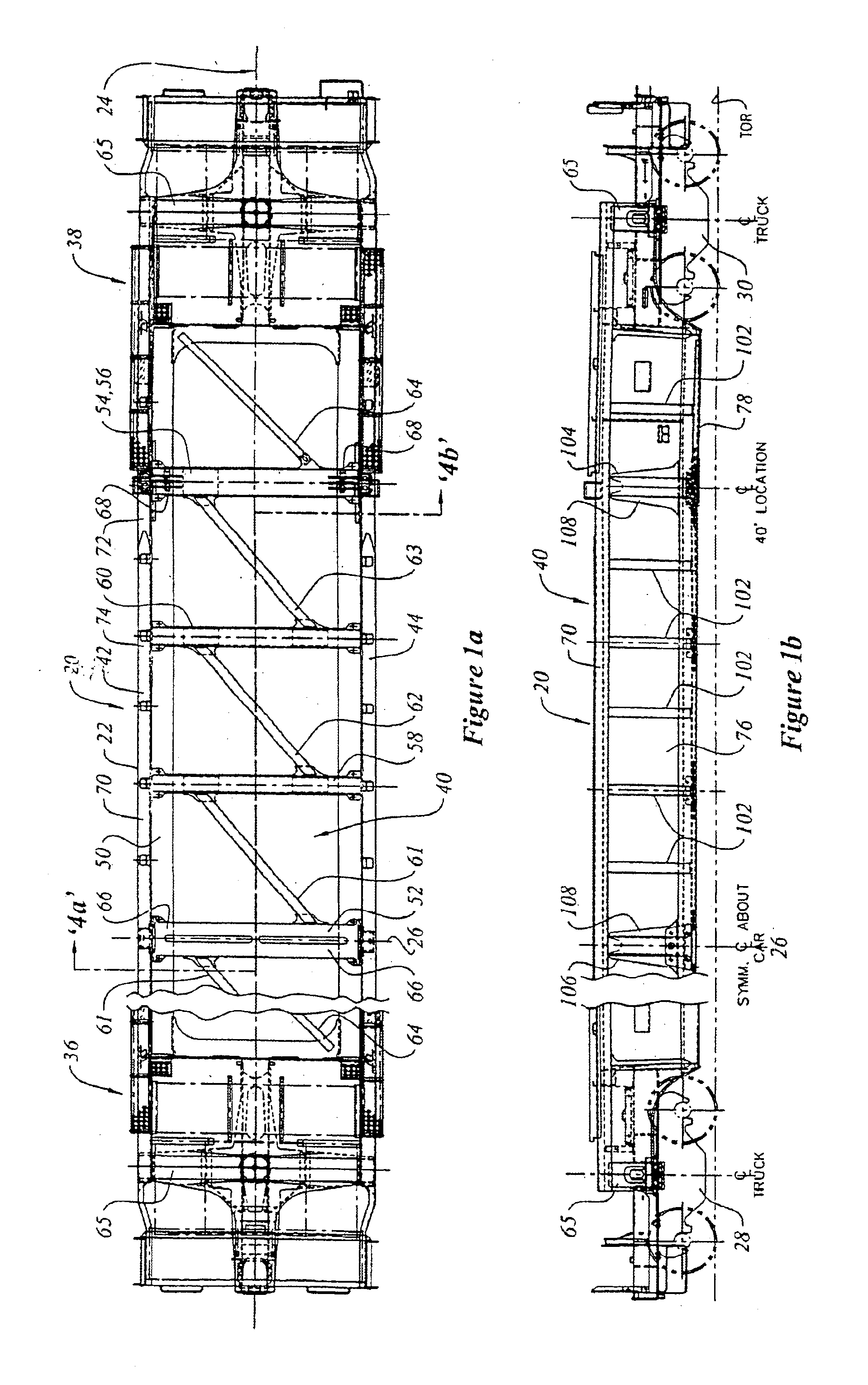

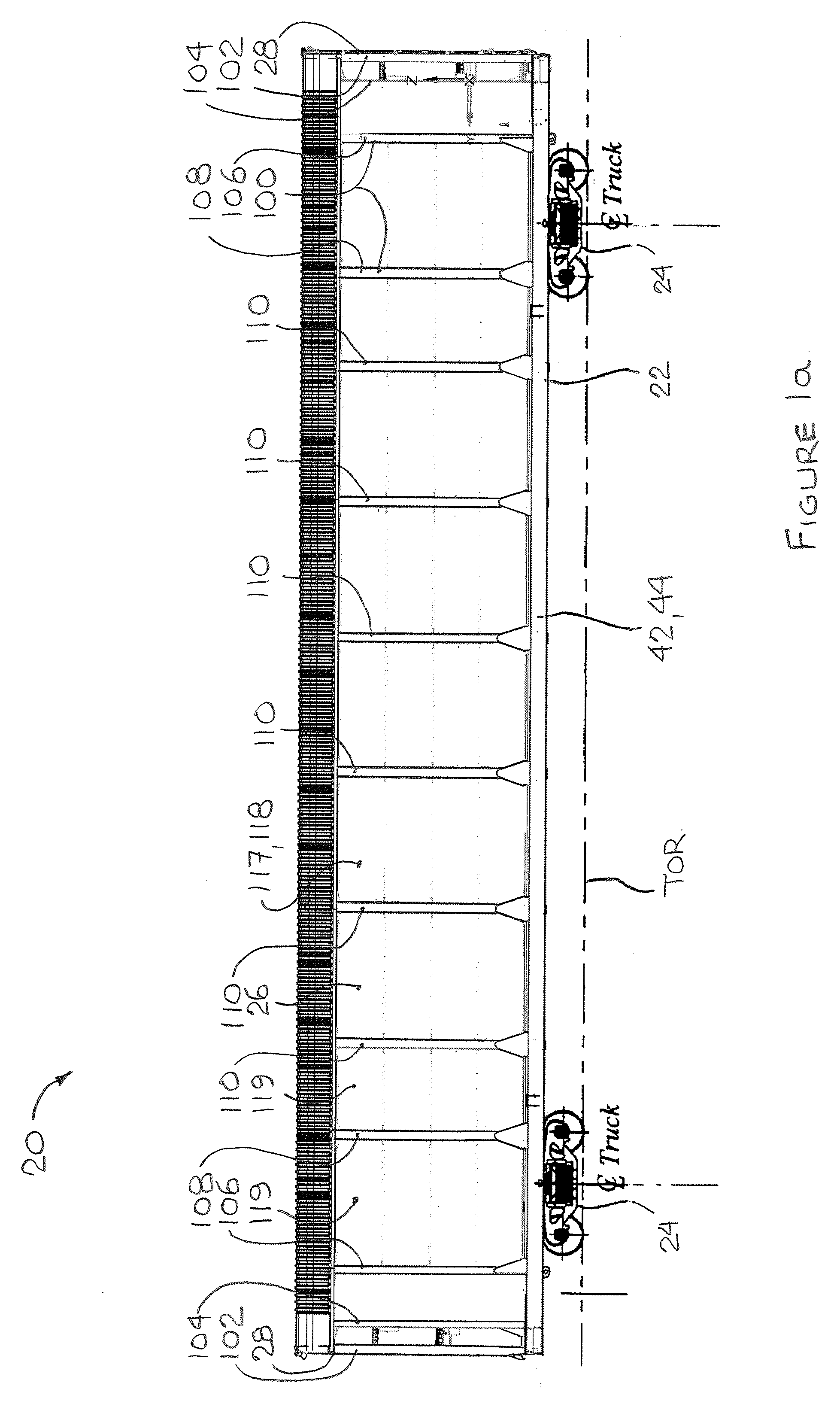

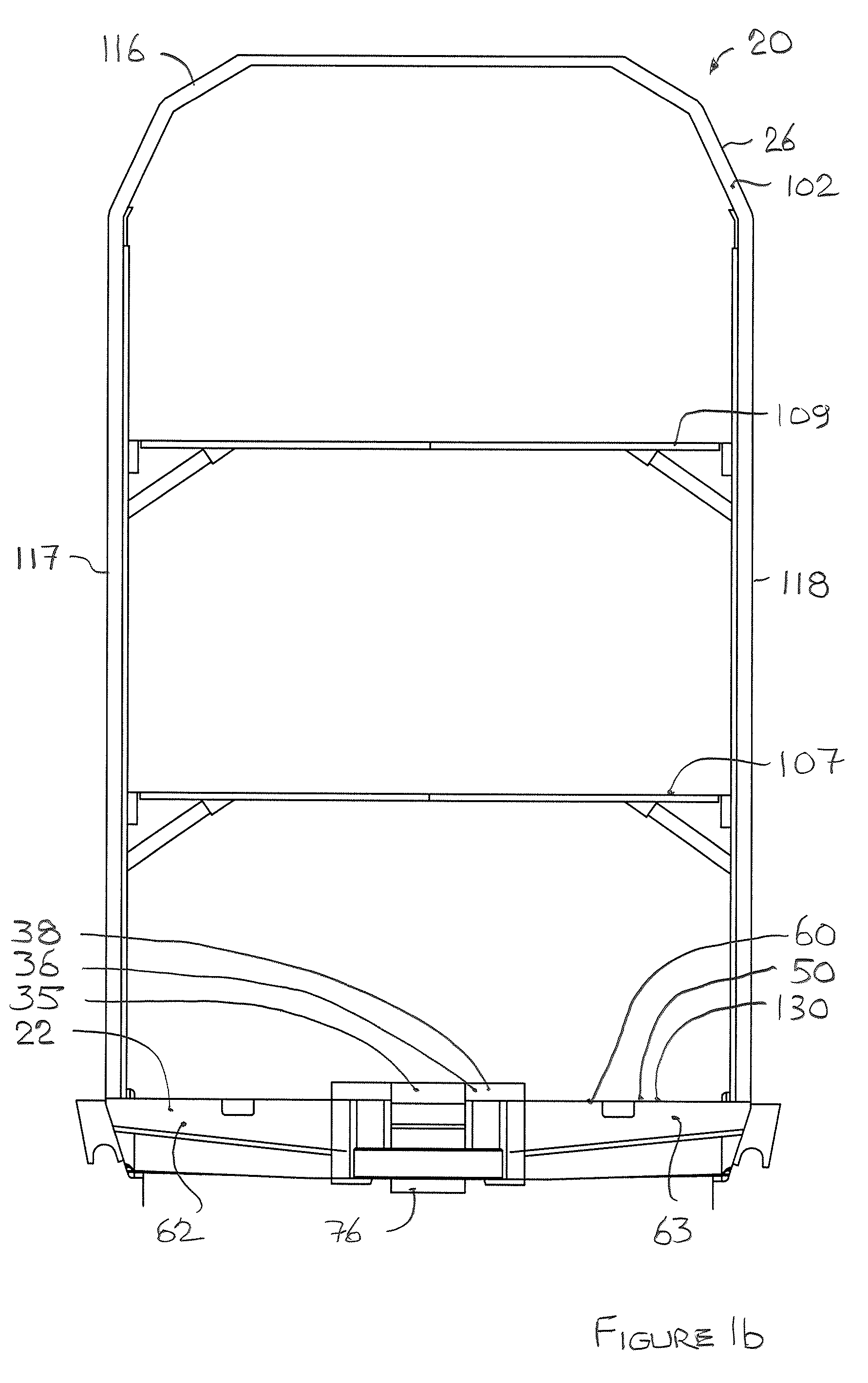

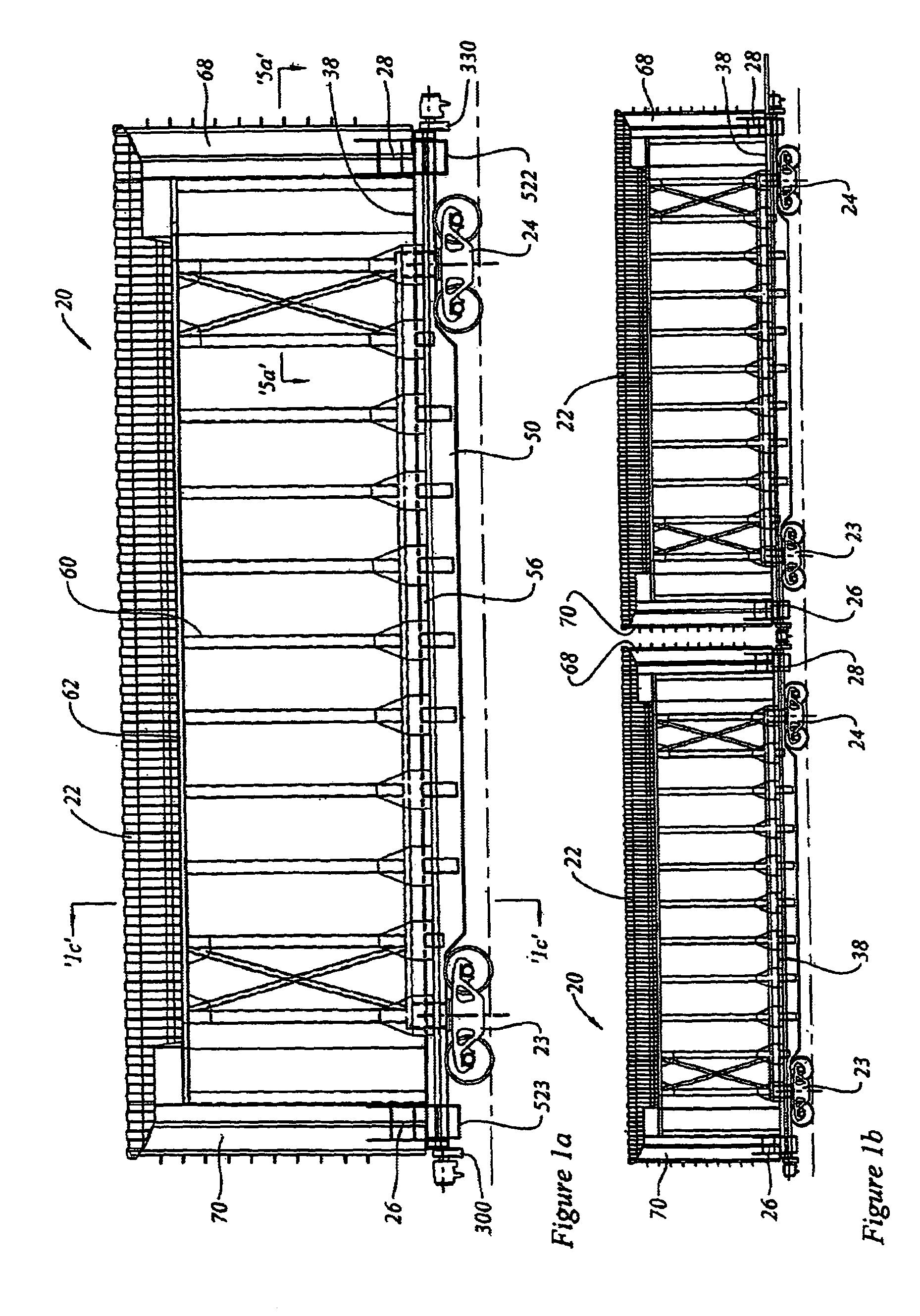

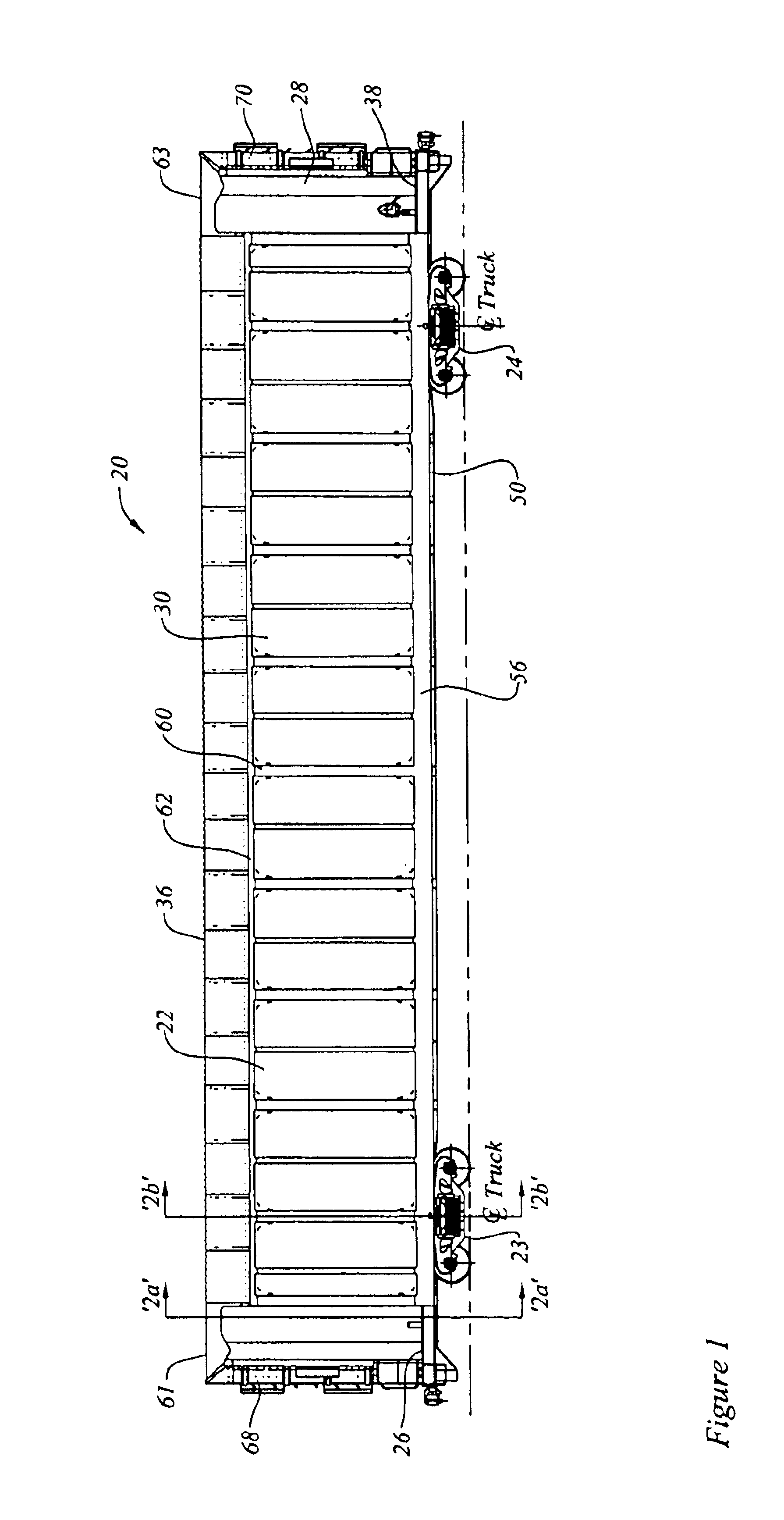

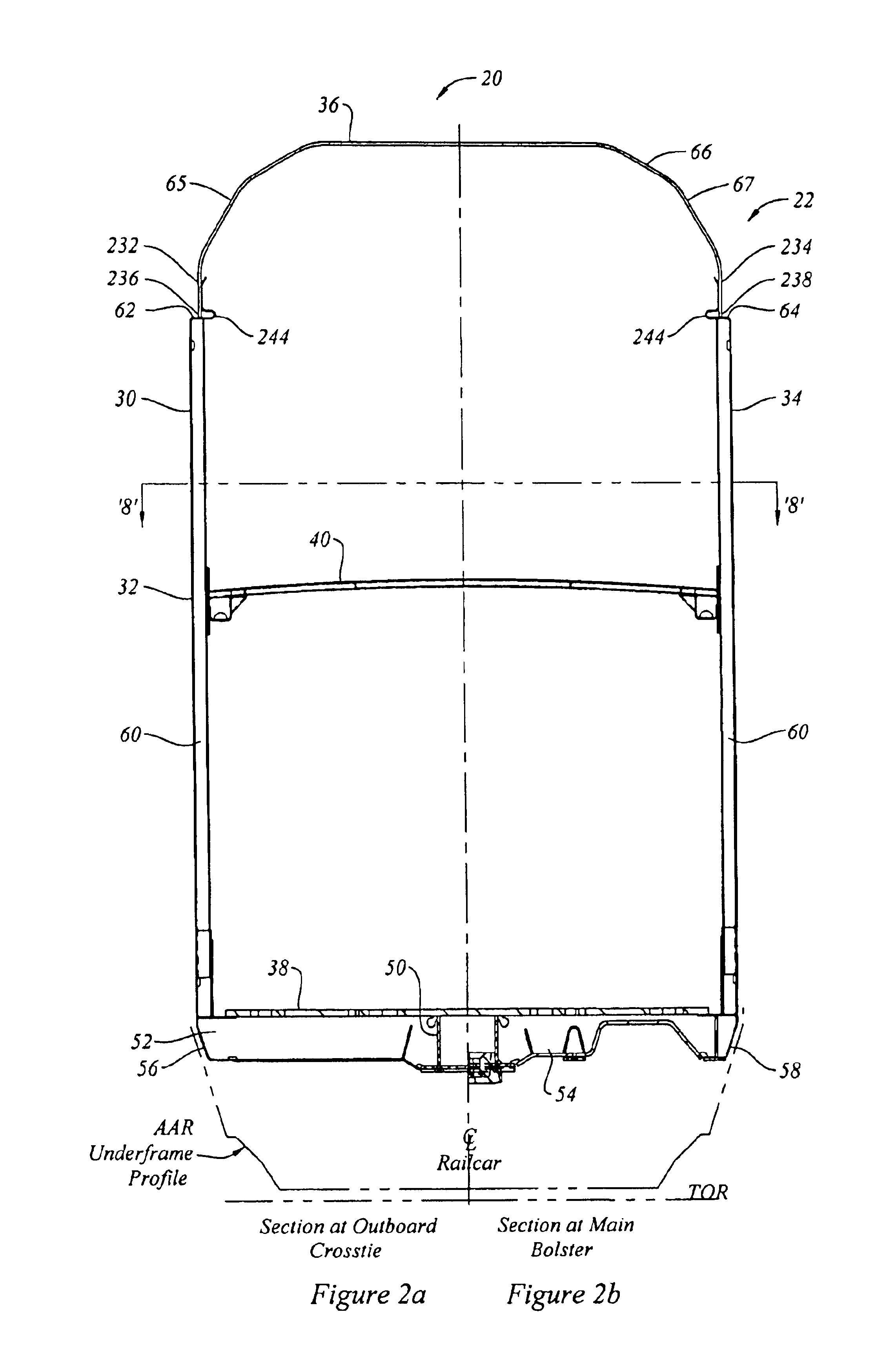

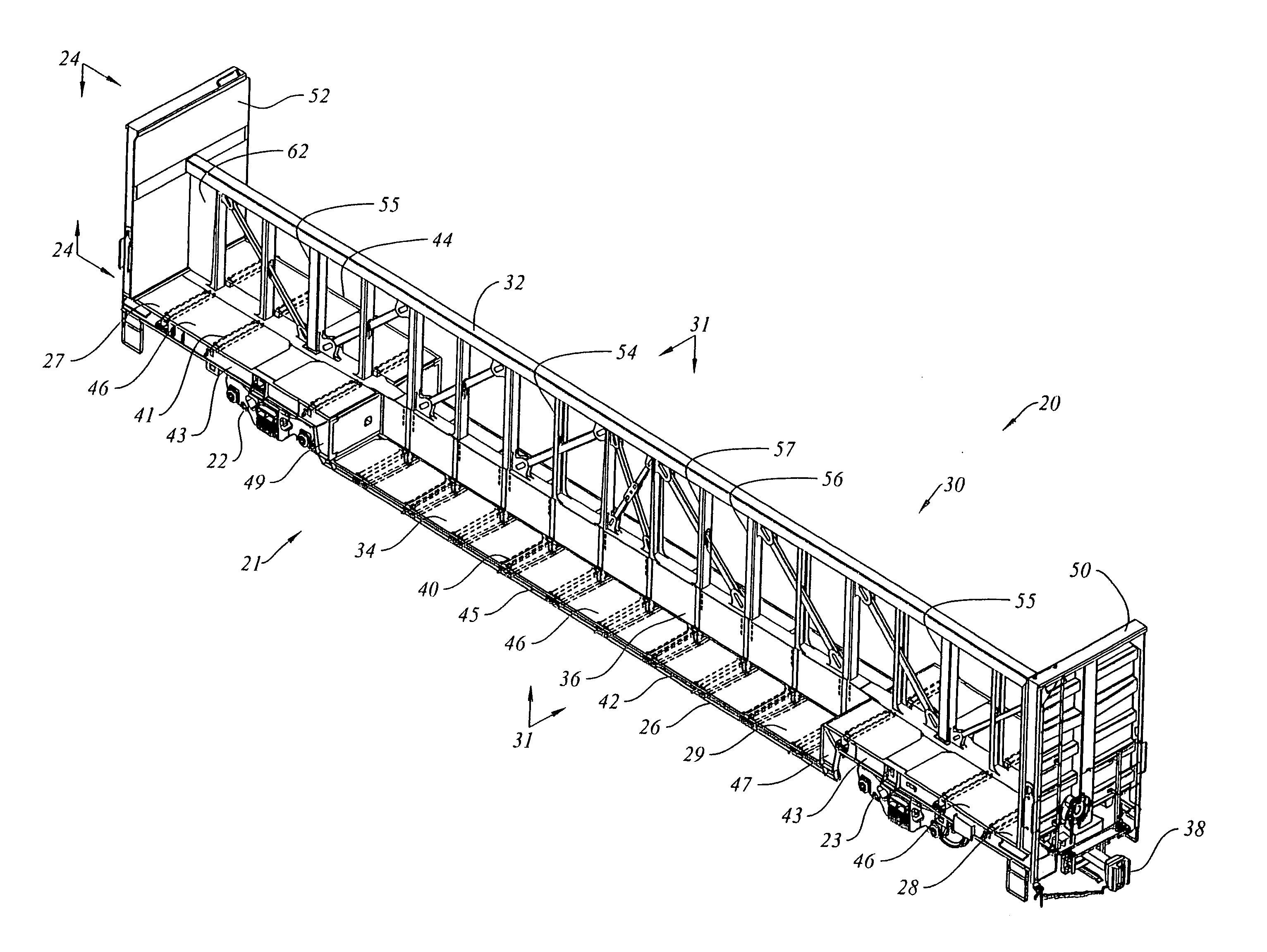

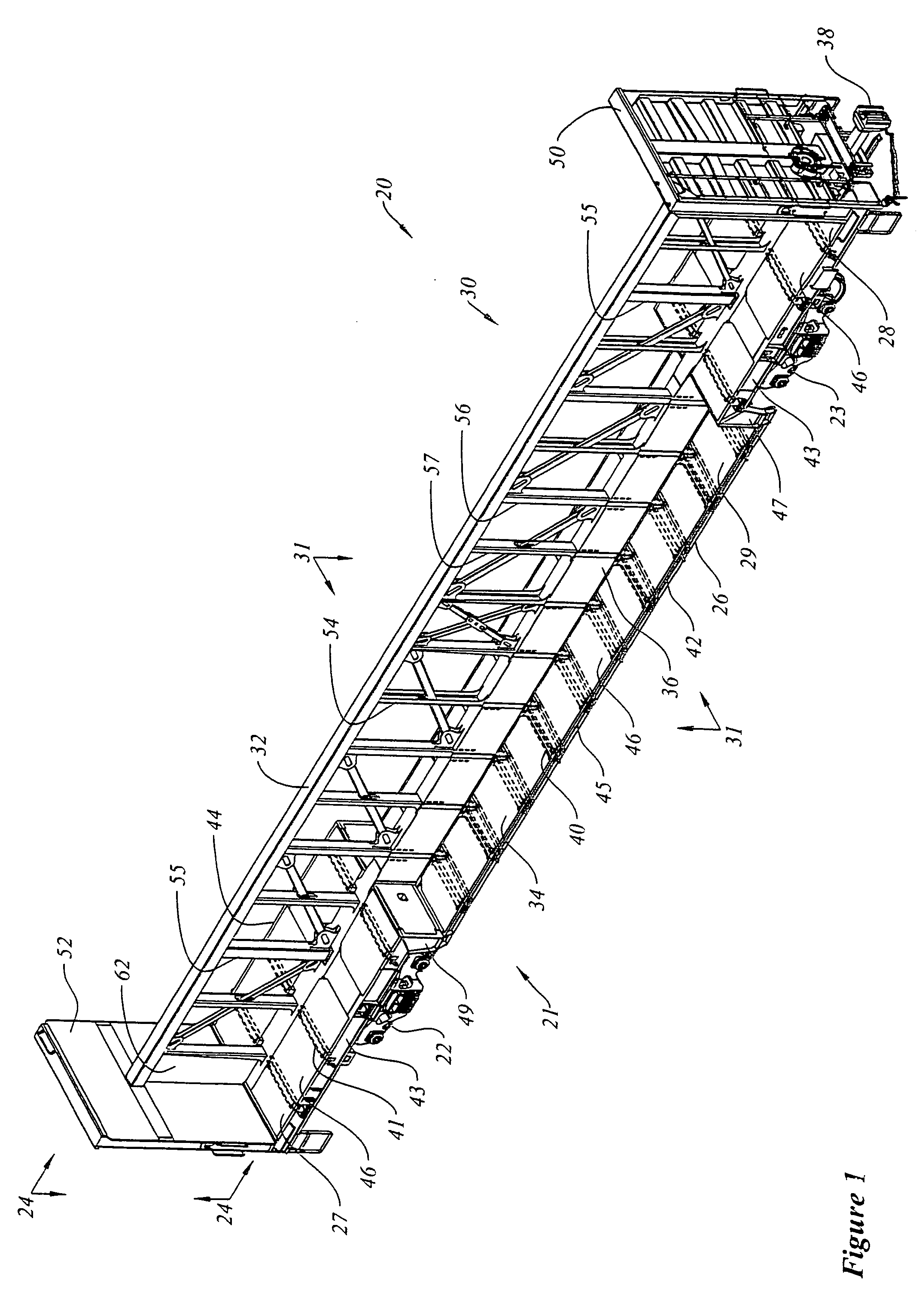

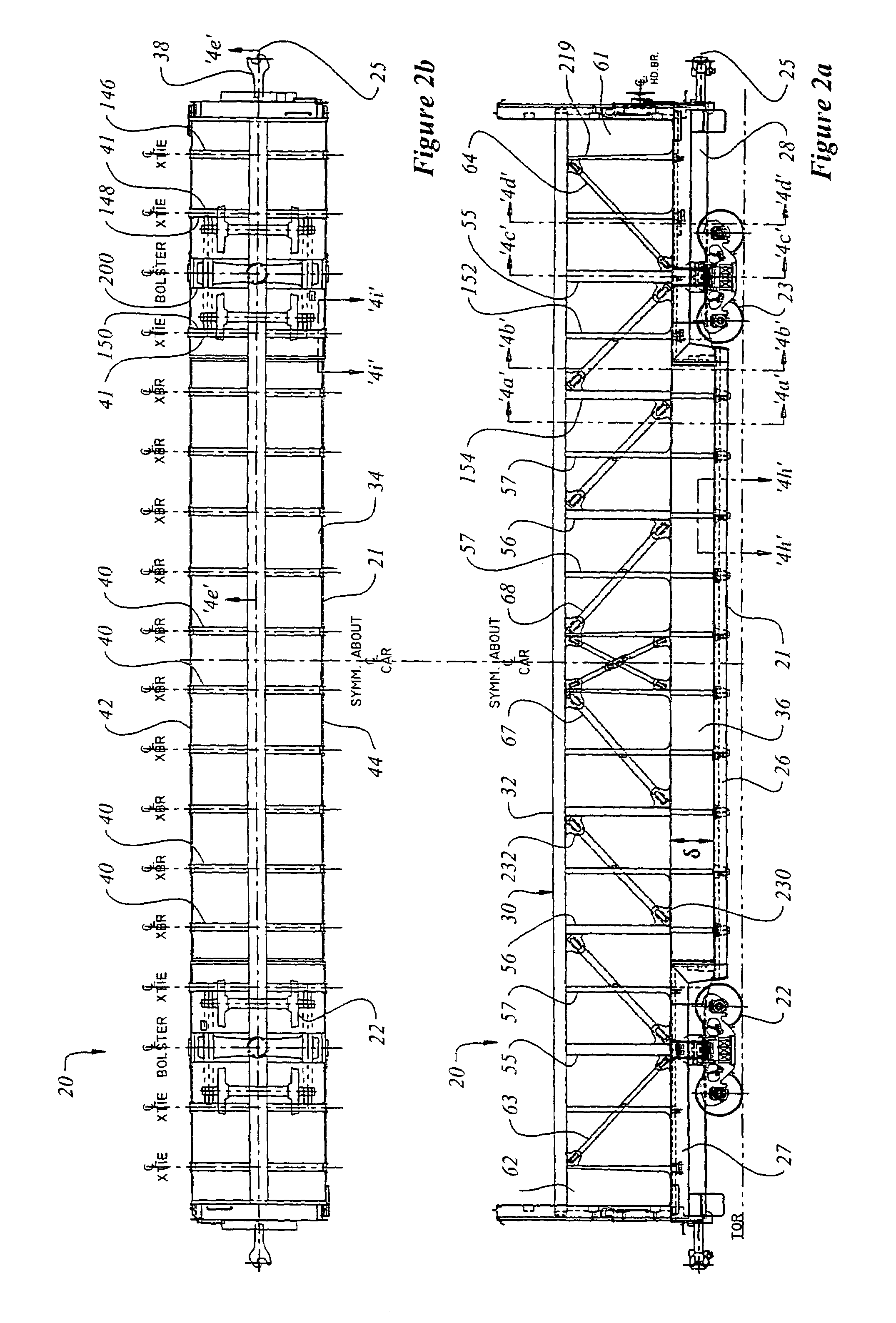

Autorack railroad car and underframe therefor

An autorack railroad car has an underframe that, in contrast to the prior art, has a straight-through center sill that is shallower, and of diminished geometry-based sectional properties generally, in the middle portion between the trucks than at the end portions at either the draft sills at the draft gear or at the truck centers. The bottom flange of the center sill is carried at a constant height from end to end, and is free of kinks in elevation. In the mid-span portion of the car, from truck center to truck center, the center sill is shallower in section than the side sills. The bottom flange of the center sill is carried at a height that corresponds to, or is higher than, the height of the lower flanges of the side sills, such that the cross-bearer arms are shallow, and the bottom flanges of the cross-bearer arms are substantially level.

Owner:NATIONAL STEEL CAR

Switch for a powered pallet conveyor

ActiveUS8051777B2Reduced space requirementsReduce wearRail switchesPoint operation from vehicleTrackwayEngineering

In one embodiment of the present disclosure, a switch for a powered pallet conveyor is provided. The switch comprising (a) a turntable and (b) rail portions which are arranged upon the turntable and define at least a first travel pathway and a second travel pathway, whereby the first travel pathway is defined by straight rail portions and a second travel pathway is defined by curved rail portions, so that the central line of the first travel pathway and the departure lines of the second travel pathway respectively pass through the fulcrum of the turntable.

Owner:ROFA INDAL AUTOMATION

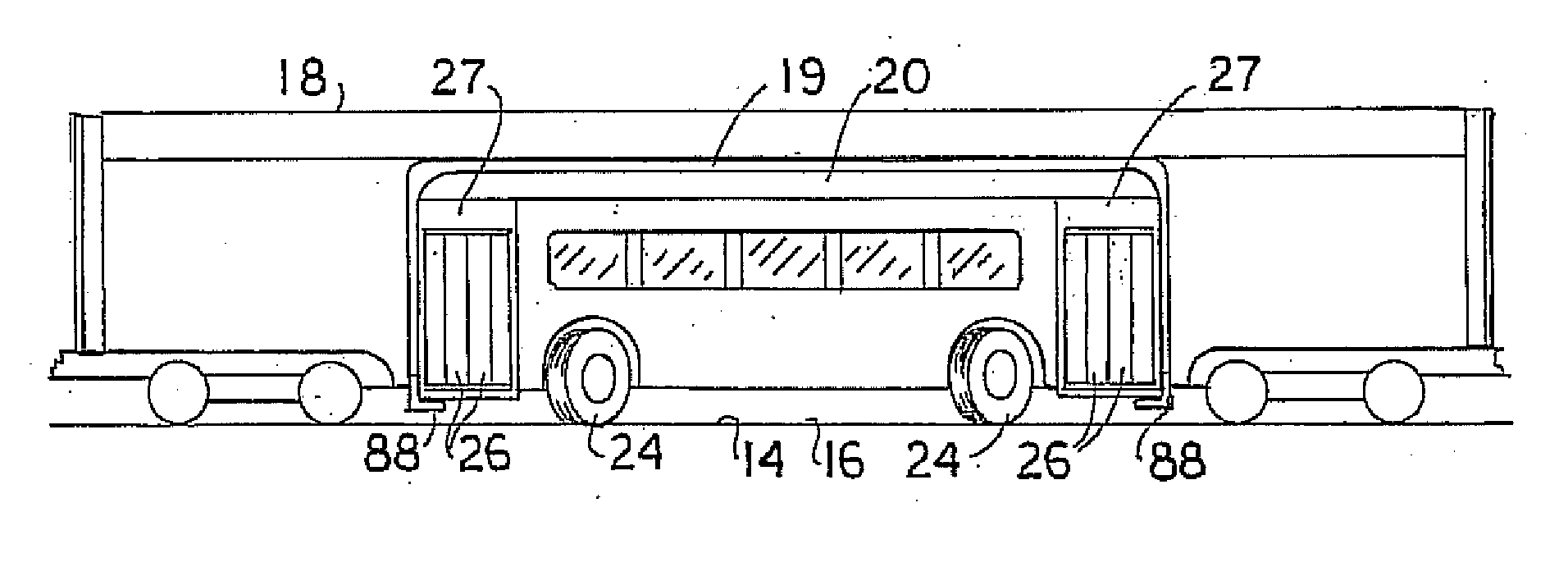

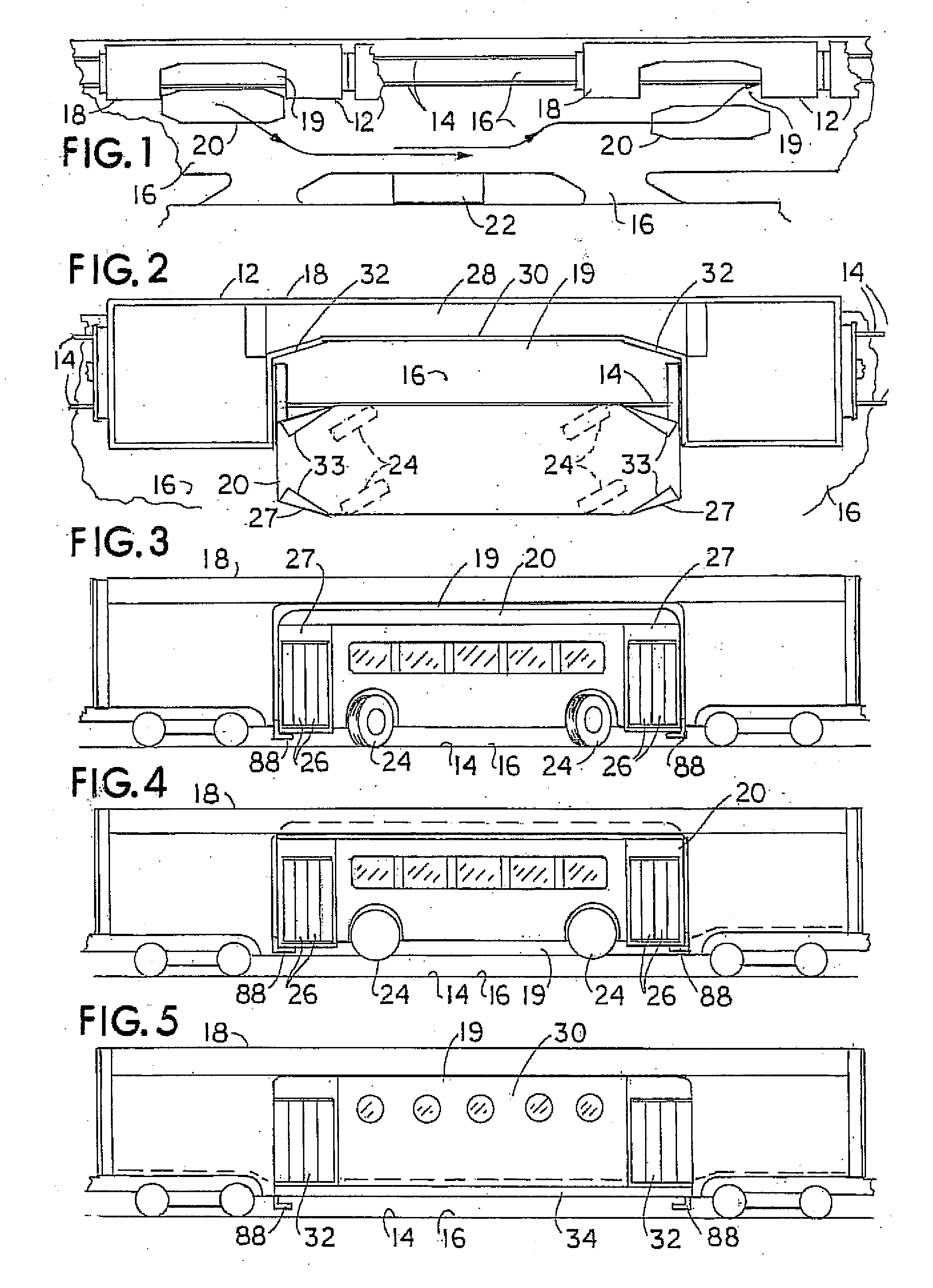

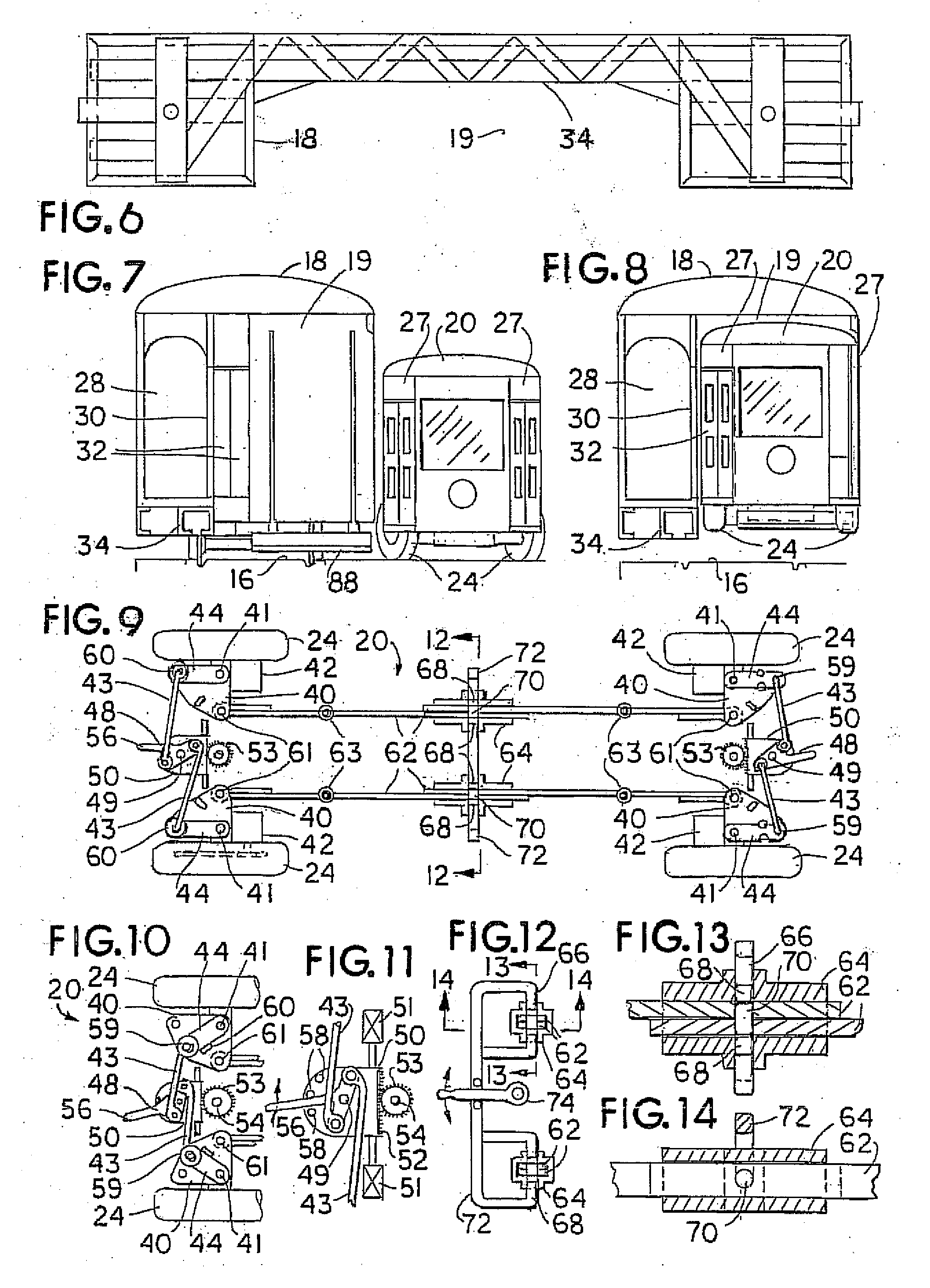

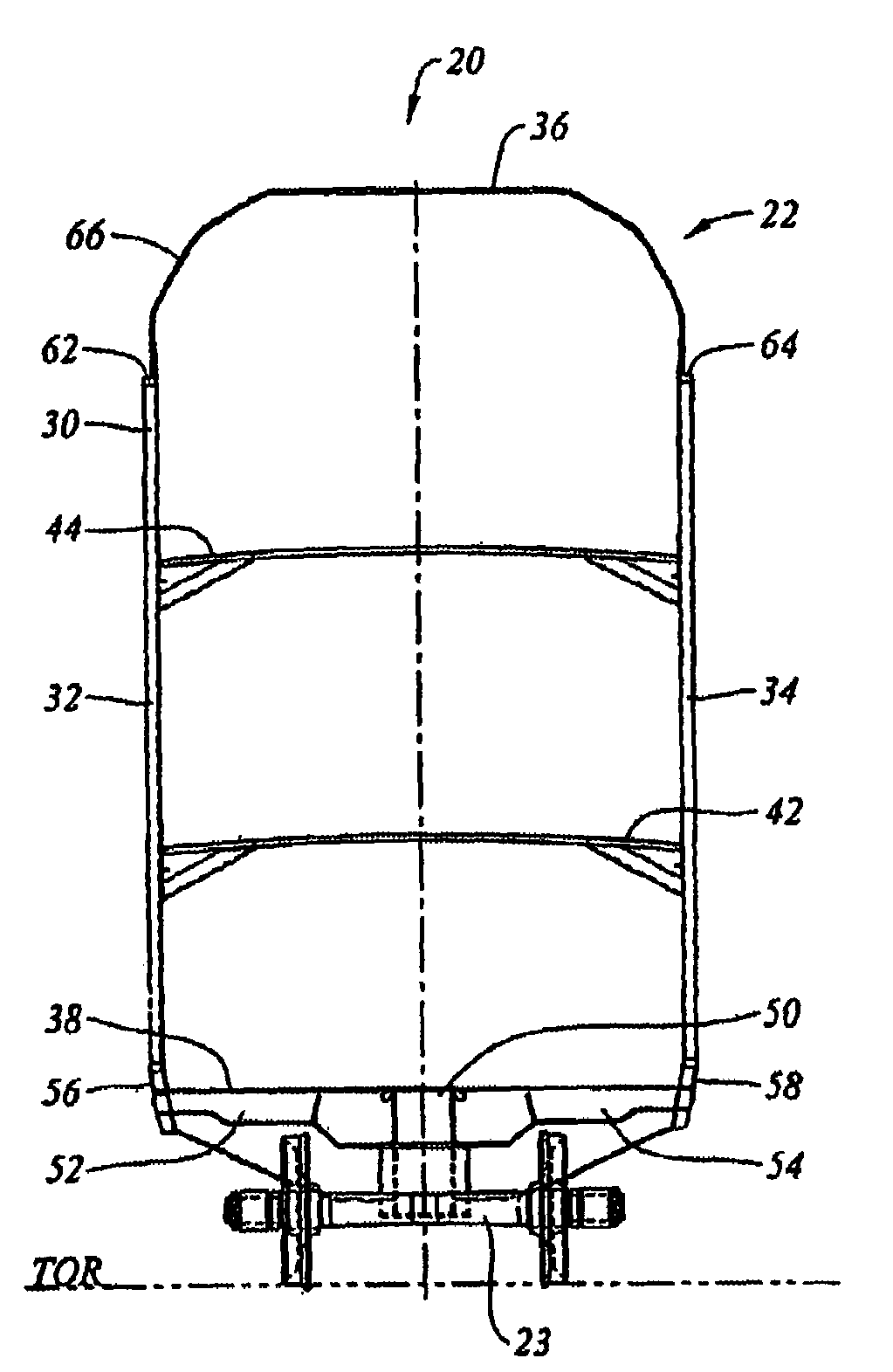

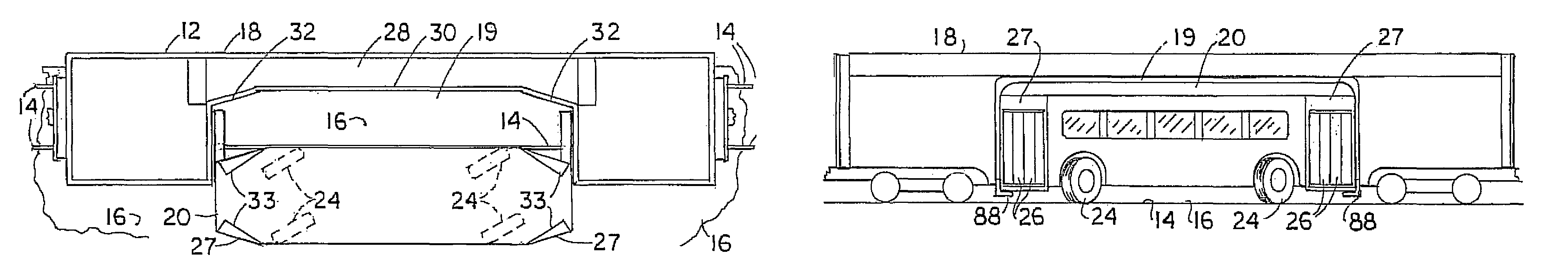

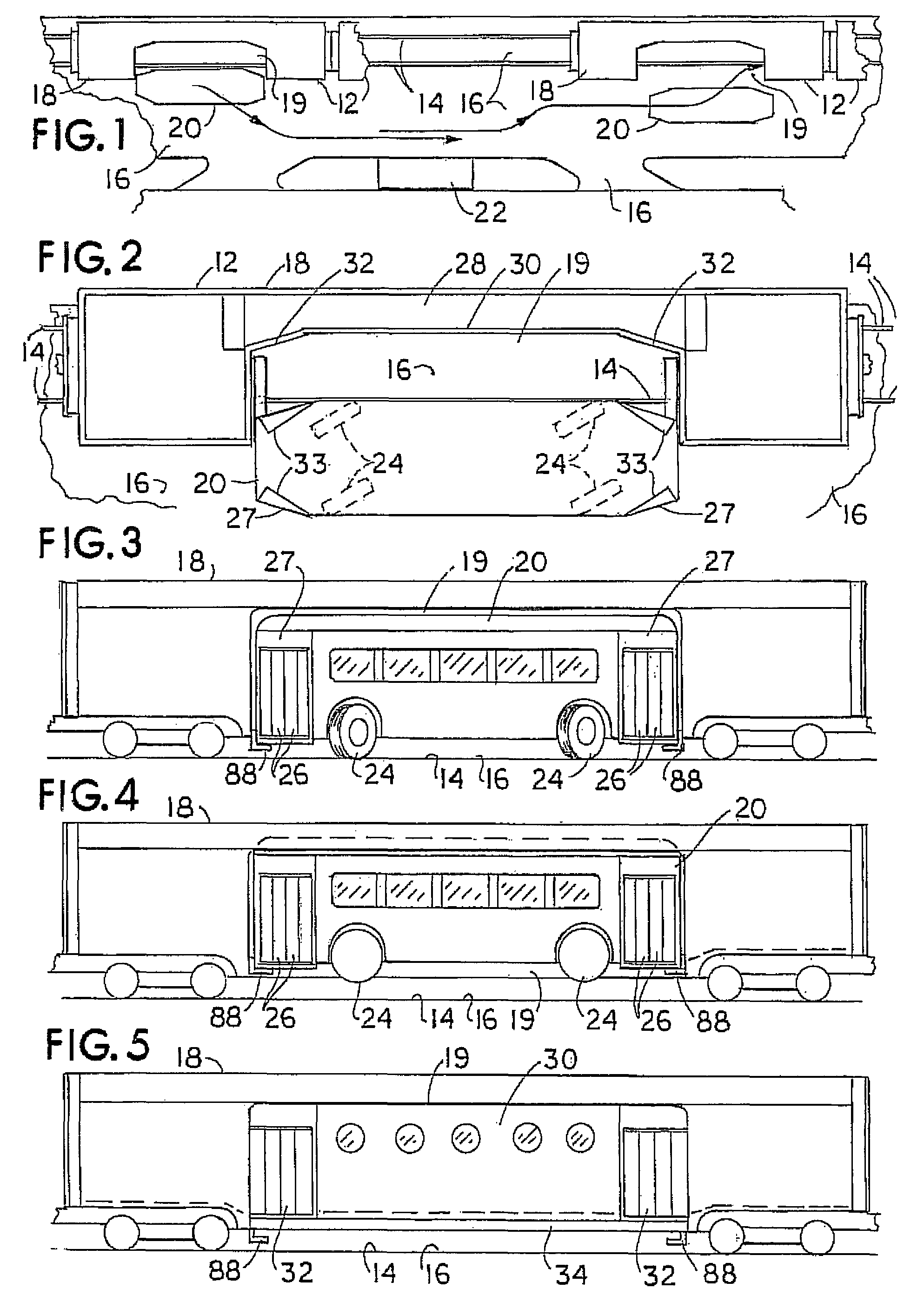

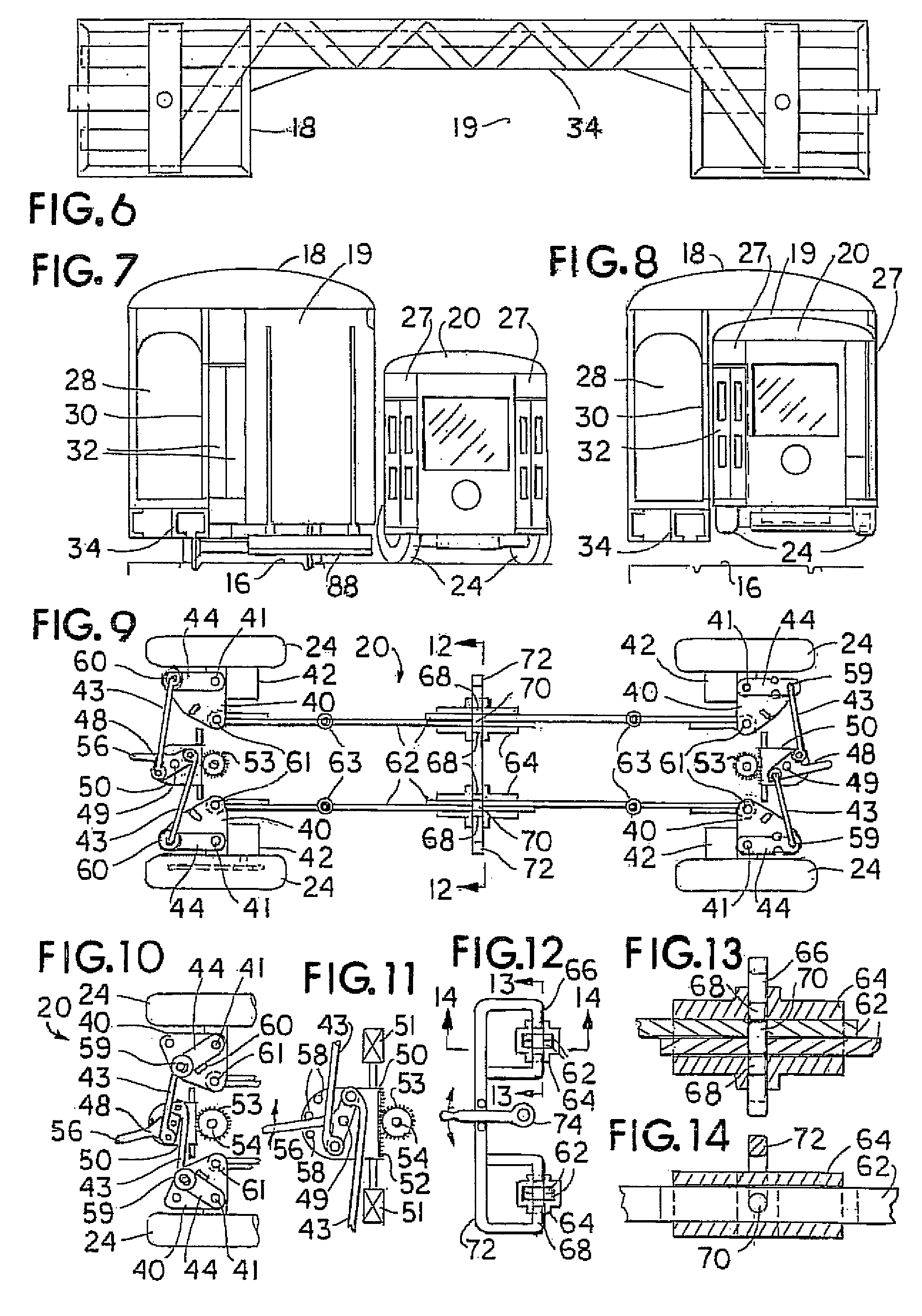

Under-way vehicle transfer

This invention is a guided transport vehicle with berth with open side and bottom for a roadway vehicle to be driven along side on a station driveway and obliquely steered into the berth and lifted for transport on the transport vehicle and lowered to another station driveway and obliquely steered out from the berth. The guided vehicle can be a railway car in a train on a track or guideway flush with station driveways for the transfer vehicle. The transfer vehicle can be a bus, truck, motor home, or platform for holding containers or vehicles. This transfer vehicle has all wheel parallel steering and can shift to front wheel steering and can have either end the front. End rollers guide the transfer vehicle parallelly in and out of the berth and end lifts raise the vehicle for travel on the train above the track. The vehicle is controlled to accelerate to train speed and aligned before all wheels are turned together at an oblique angle to enter the berth.

Owner:BARRY LEONARD D

Rail road car with reduced slack

A rail road car has a rail car body which includes a housing structure. The housing structure has a pair of sidewalls, a roof and at least one deck mounted to the sidewalls. An enclosed lading space is defined by the housing structure and there is at least one door for controlling access to the enclosed space. The rail road car is provided with short travel buff gear and a reduced slack, or slackless, coupler.

Owner:NATIONAL STEEL CAR

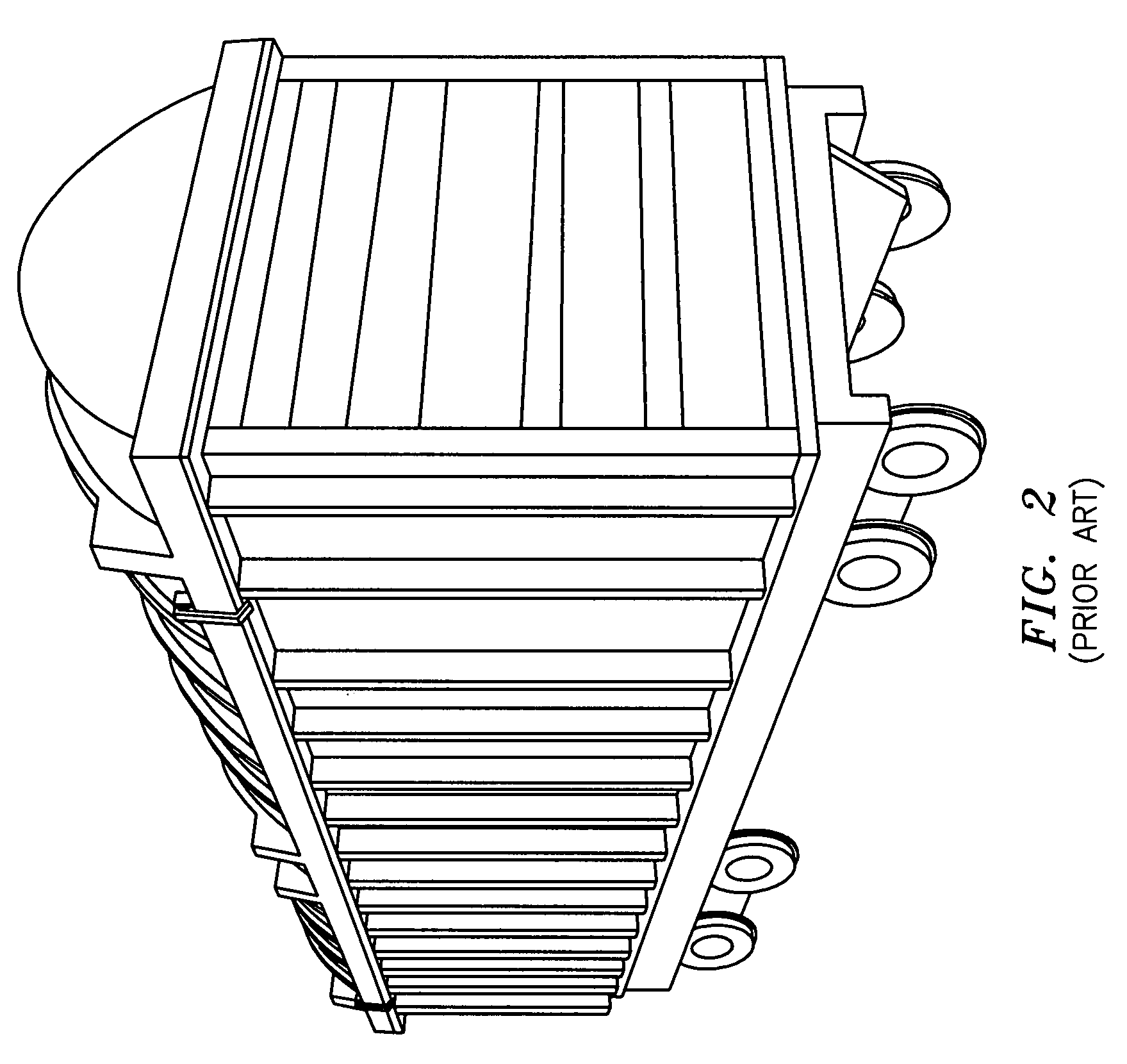

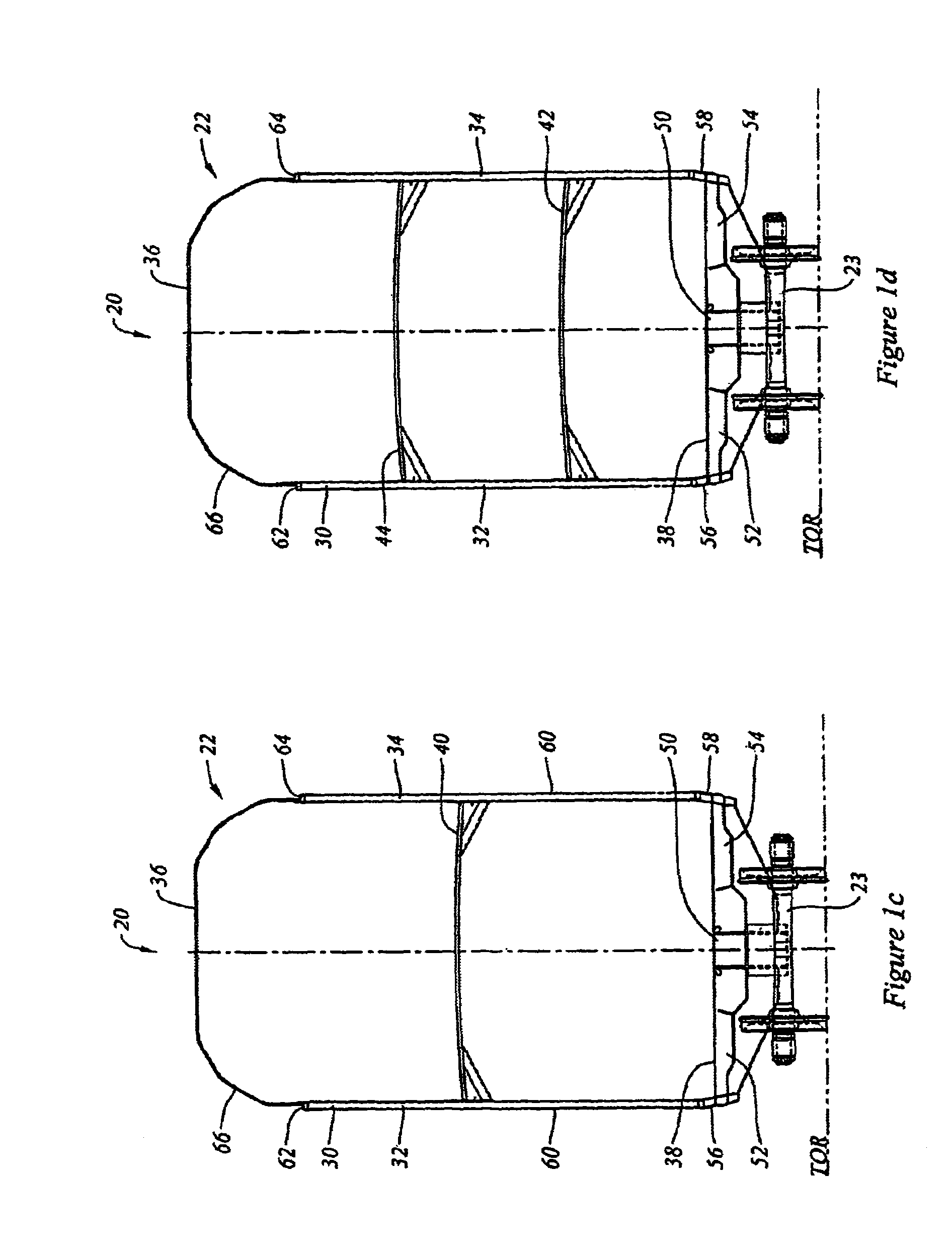

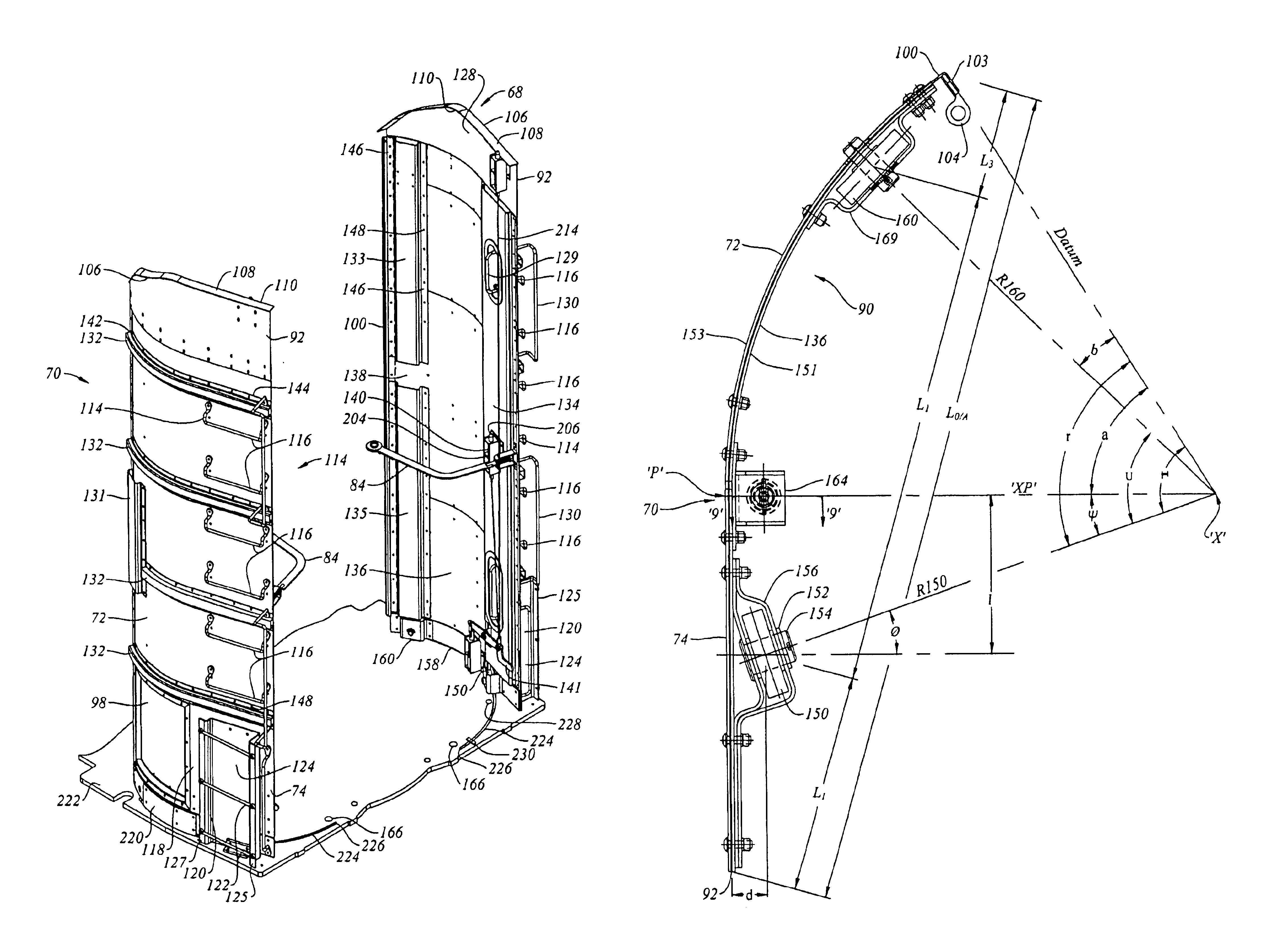

Auto rack car with end closure

An auto rack rail road car has a main deck and upper deck. It is provided with a door for controlling access thereto. The door is a radial arm door, and has a ladder mounted thereon by which personnel can ascend the second deck when the door is open. A second ladder is mounted to the first deck so that when the door is open the second ladder is positioned to co-operate with the first ladder. The arcuate path of the door is free from overhanging obstructions. The door also has internal and external weld-free stiffeners member for enhancing the rigidity thereof. A roller mounted to the door permits the door to be moved between open and closed positions. The door may further include a lock. A guide member protruding from the door co-operates with a groove in the main deck which slidingly guides the door as it moves between open and closed positions to control access to the car.

Owner:NATIONAL STEEL CAR

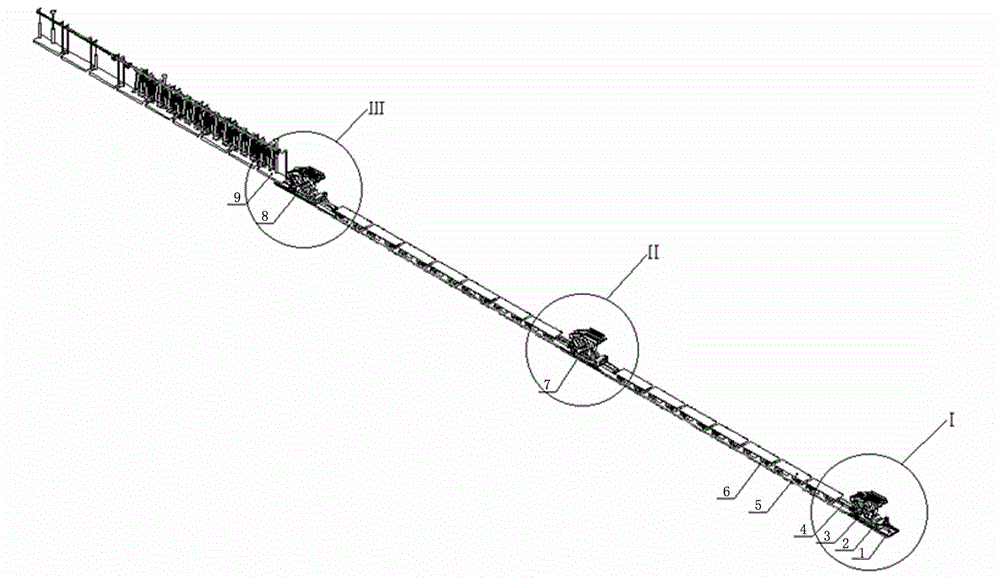

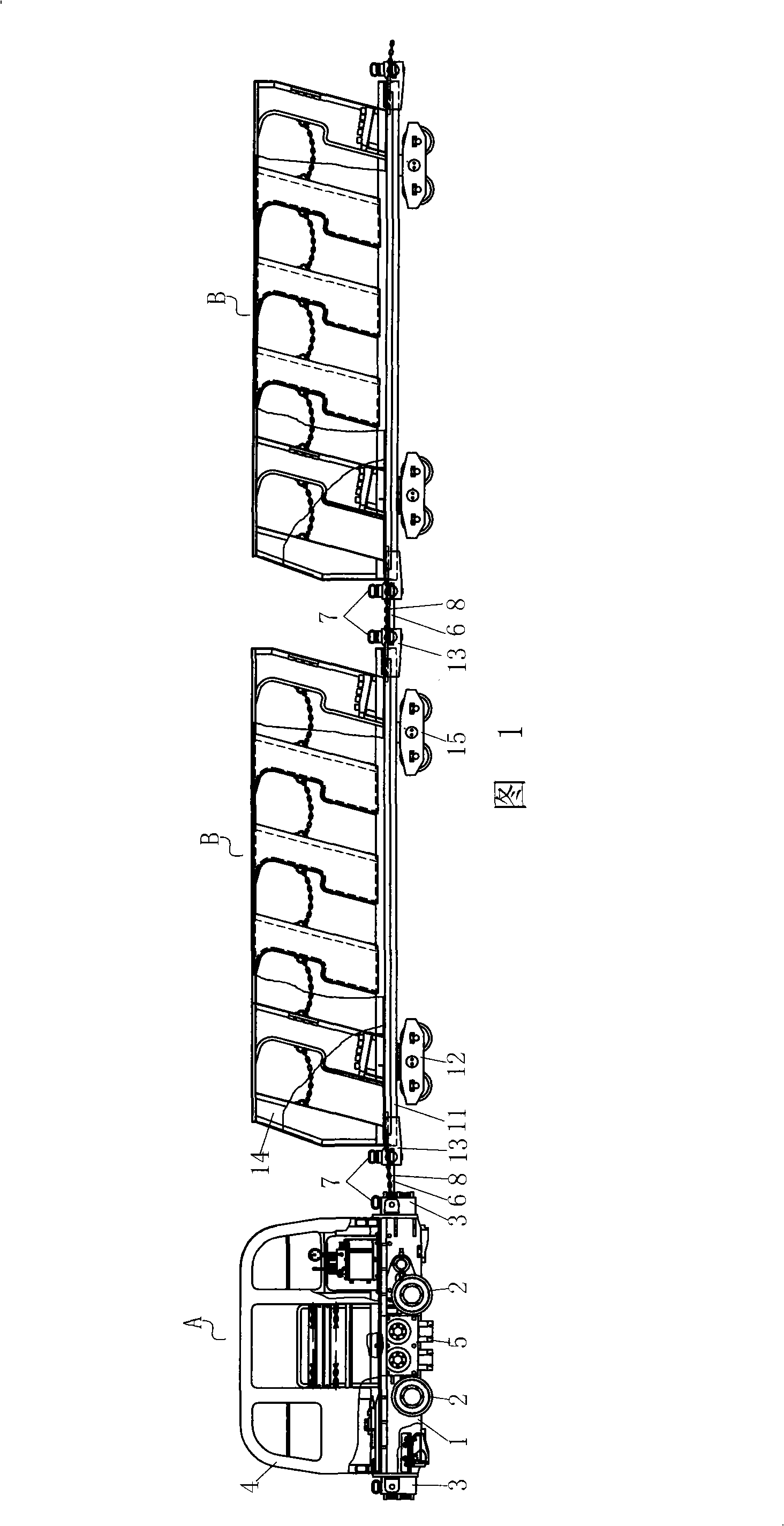

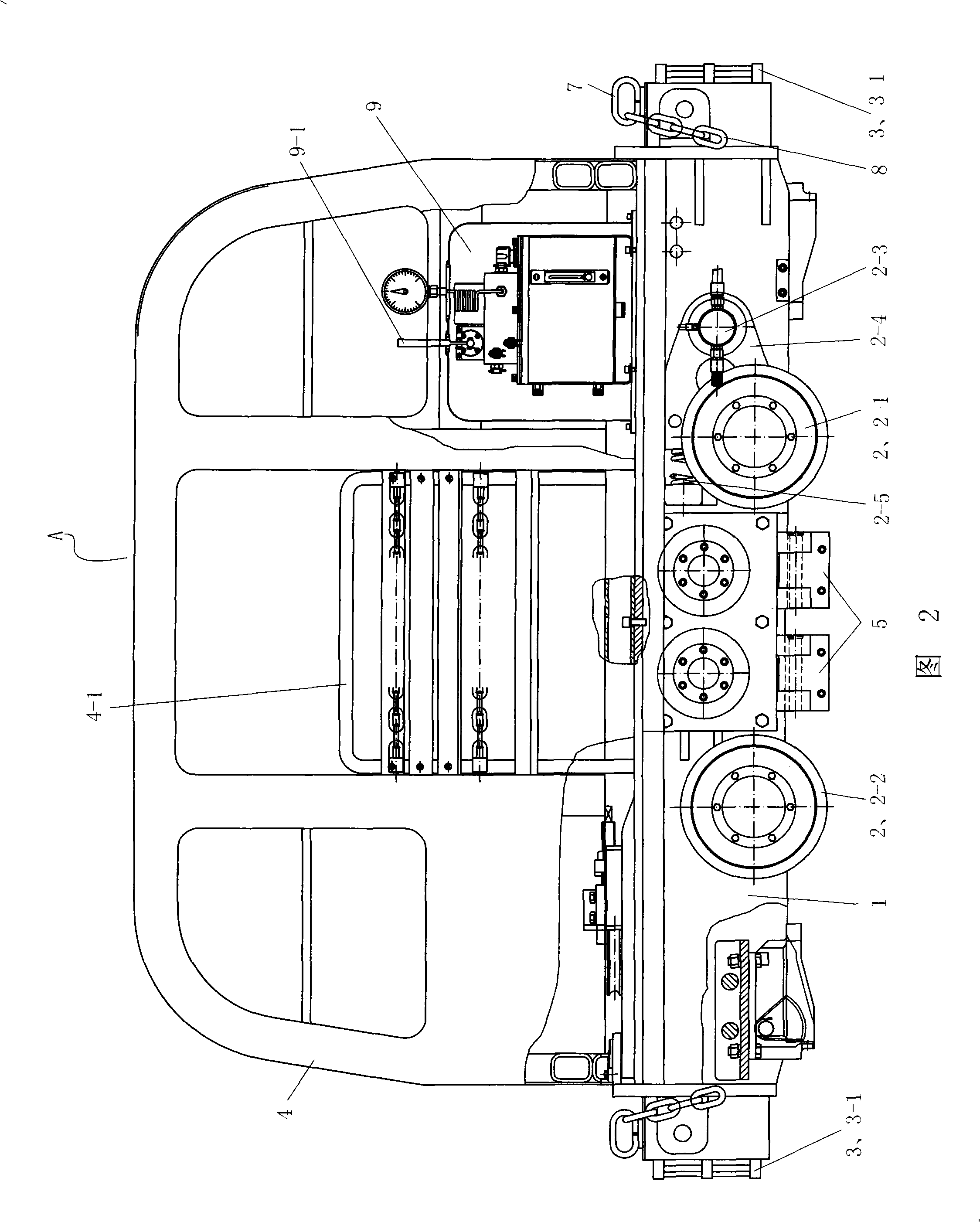

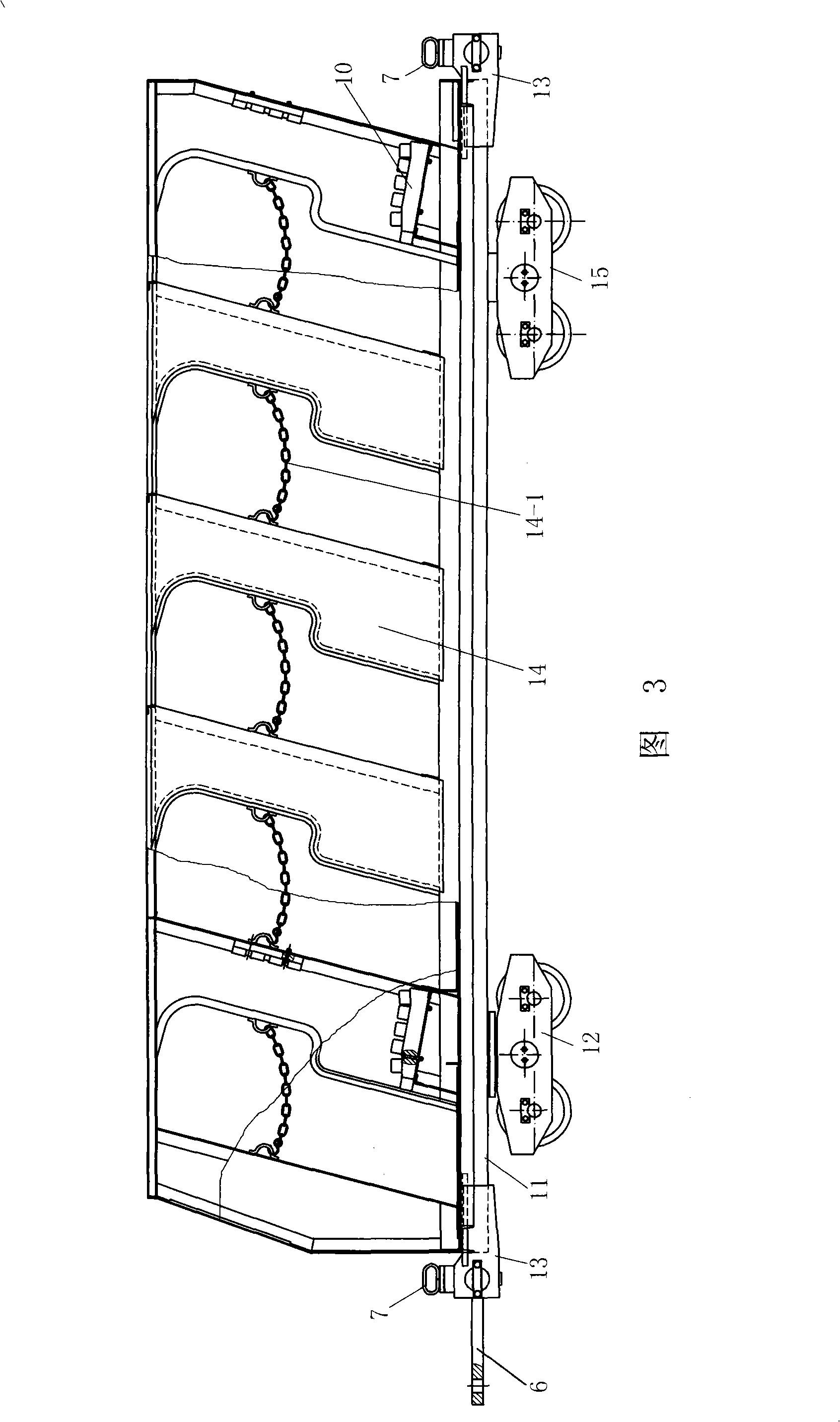

Big-gradient crossheading step-forward self-moving equipment train

ActiveCN104791003AIncrease frictionFully mechanized mining work is fastEarth drilling and miningUnderground transportManufacturing technologyEngineering

The invention belongs to the technical field of design and manufacturing of coal mine underground auxiliary transportation equipment in order to solve the transportation problem of a coal mine underground big-gradient crossheading roadway, and provides a big-gradient crossheading step-forward self-moving equipment train. The equipment train comprises a front anchoring, pulling and moving device, a middle anchoring, pulling and moving device, a rear anchoring, pulling and moving device, platform trolleys, advancing jacks and a pipe cable telescopic bearing system, wherein a front advancing jack is arranged at the front end of the front anchoring, pulling and moving device, the rear end of the front anchoring, pulling and moving device is connected with the platform trolleys through rear advancing jacks, the two ends of the middle anchoring, pulling and moving device are connected with the platform trolleys through the corresponding advancing jacks, the front end of the rear anchoring, pulling and moving device is connected with the platform trolleys through the corresponding advancing jacks, and the rear end of the rear anchoring, pulling and moving device is connected with the pipe cable telescopic bearing system through connecting rods. The train self-moving function, the walking deviation adjusting function, the pipe cable self-moving function and the like are highly integrated for the equipment train, and therefore the equipment train can step forward to move by itself when the gradient of the crossheading roadway is + / -25-degrees, slippage of equipment is effectively prevented, and it is guaranteed that the equipment train safely works in the big-gradient roadway.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

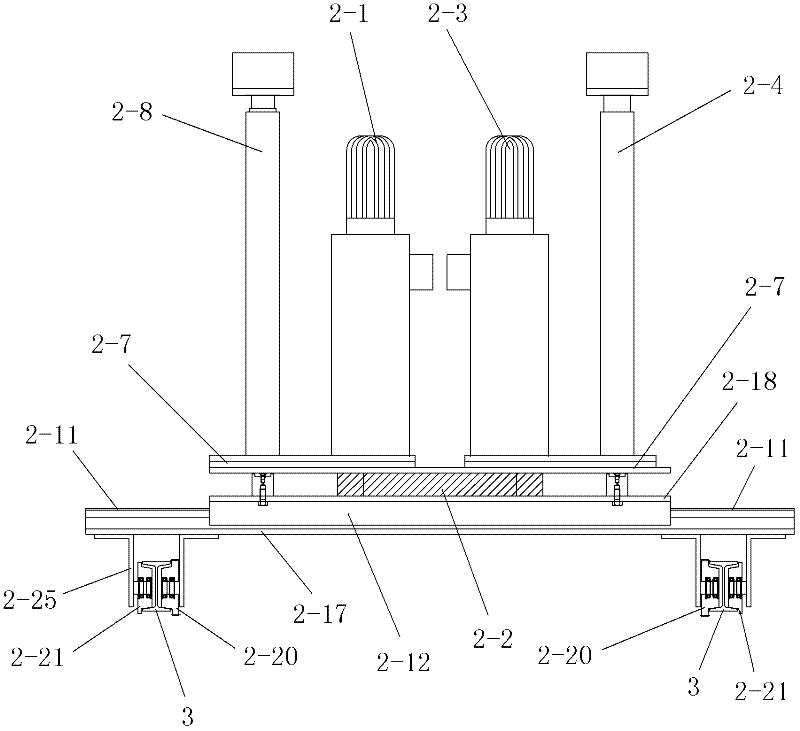

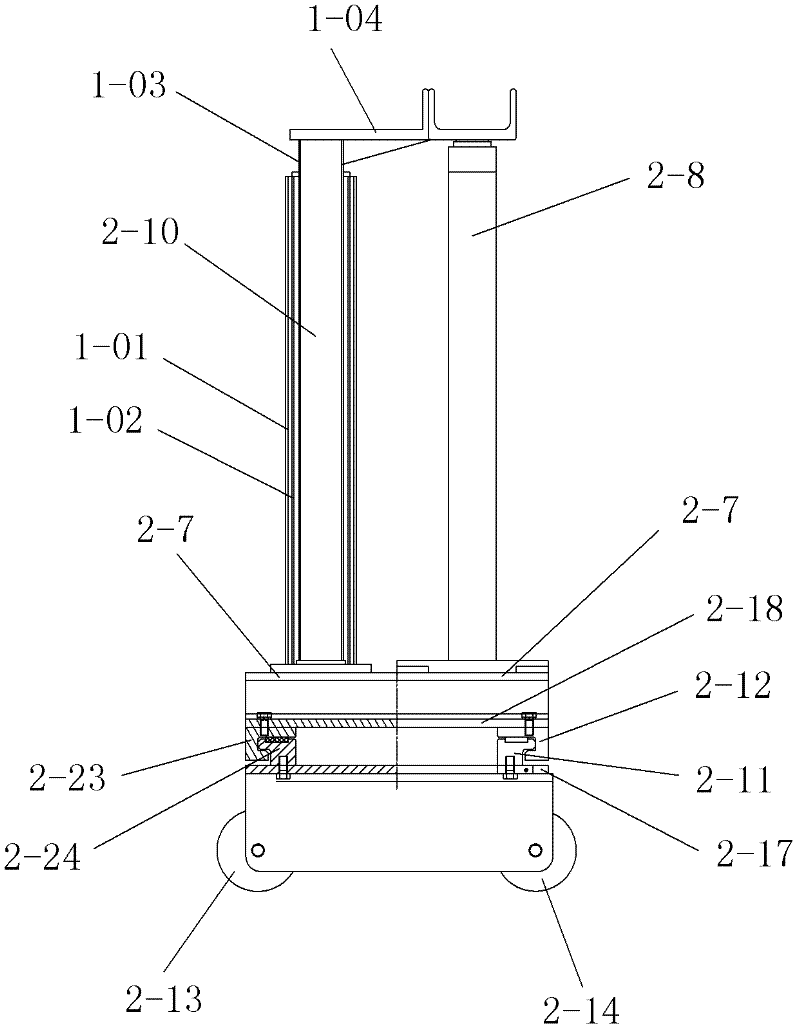

A transport mechanism for tunnel construction

ActiveCN102296986ASimple structureReasonable designEarth drilling and miningUnderground transportTunnel constructionAerospace engineering

The invention discloses a transport mechanism for tunnel construction, which comprises a travelling trolley, a lift mechanism and a lateral movement mechanism, the travelling trolley can move forward and back ward along a horizontal movement track, the lift mechanism can stably lift an article to be transported, the lateral movement mechanism can drive the lift mechanism to synchronously move to the left and the right, and is mounted on the travelling trolley, the lift mechanism is firmly mounted on the lateral movement mechanism, and the travelling trolley, the lateral movement mechanism andthe lift mechanism are a forward and backward alignment mechanism, a leftward and rightward alignment mechanism and an upward and downward alignment mechanism which can respectively align the articleto be transported in longitudinal, transverse and vertical directions. The transport mechanism has the advantages of simple structure, reasonable design, safe and reliable working performance and good use effect, is convenient to assemble and easy and convenient to operate, and can effectively solve a variety of practical problems in the movement and accurate positioning of hoisted articles in the process of tunnel construction, such as high working difficulty, low mounting efficiency, high labor intensity and long construction period.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Dropped deck center beam rail road car

A center beam car has a main deck structure extending laterally from a main center sill, a laterally extending top truss structure, and a central vertically oriented central beam structure. The center beam so formed defines bunks in which to carry cargo. The upper region of the web-work structure includes a top chord mounted to run between two end bulkheads. The deck has a central portion and end portions. The end portions of the deck are carried at a greater height than the center portion, the difference in height corresponding to the height of a bundle of lumber. The car has a center sill having a depth corresponding to the depth of the step in the deck. The end portion of the center sill has an internal plate defining a draft gear pocket upper wall. The medial portion of the center sill is narrower than the end portion, and of deep section, such that it has a high aspect ratio. Web separators are mounted in the medial portion of the center sill by a method that includes making part of the weld from outside the center sill through welding apertures. As the end deck is carried at a high level, the bolster is abnormally deep.

Owner:GREYPOINT CAPITAL INC

Fluctuate tunnel mancar for coal mine

ActiveCN101407222ASmooth rideAvoid the inconvenience of changing special switchesRail brake actuationBogiesBogieVehicle frame

The invention relates to an undulant alley man car for a coal mine, which comprises a braking vehicle and a man car. A stop head of the man car is provided with a movable connecting block which can change angle along with fluctuation of a track, a rotating pair is formed between each wheel frame of two steering frames of the man car and a steering main shaft, the two steering frames are connected with a car body through a horizontal rotating steering device and a three-dimensional rotating steering device respectively, so the undulant alley man car can adapt to small-diameter turning cover, and also can adapt to fluctuation change of the track. The man car is stable when the man car runs, and people in the car feel comfortable and safe.

Owner:CHANGZHOU DEV & MFR CENT

Rail conveyor system

A rail conveyor system combining the low friction attributes of railway transportation with the continuous bulk handling advantages of belt conveyors, uses a multiplicity of spaced carriages (4) running on steel wheels (5) on rail tracks (2, 3) to support a continuous carry belt (7). The system is driven by various means including a rope (9) extending between the carriages. Various other drive means including drive belt technology are also described along with loading and unloading stations and distributed drive stations.

Owner:NEWCASTE INNOVATION LTD

Under-way vehicle transfer

A guided transport vehicle has a berth with open side and bottom for a roadway vehicle to be driven along side on a station driveway and obliquely steered into the berth and lifted for transport on the transport vehicle and lowered to another station driveway and obliquely steered out from the berth. The guided vehicle can be a railway car in a train on a track or guideway flush with station driveways for the transfer vehicle. The transfer vehicle can be a bus, truck, motor home, or platform for holding containers or vehicles. This transfer vehicle has all wheel parallel steering and can shift to front wheel steering at either end. End rollers guide the transfer vehicle parallelly in and out of the berth, and end lifts raise the vehicle for travel on the train above the track. The vehicle is controlled to accelerate to train speed and aligned before all wheels are turned together at an oblique angle to enter the berth.

Owner:BARRY LEONARD D

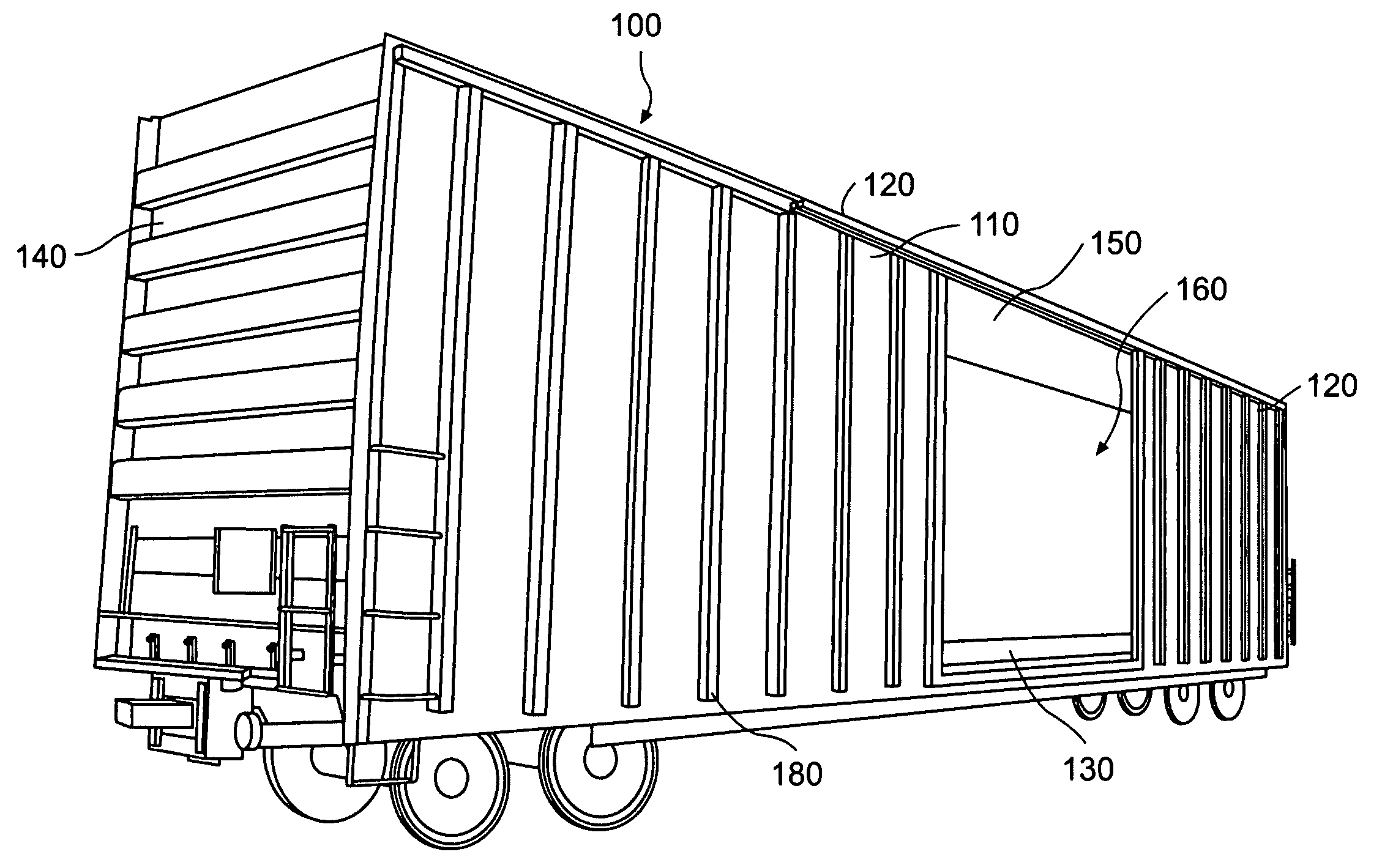

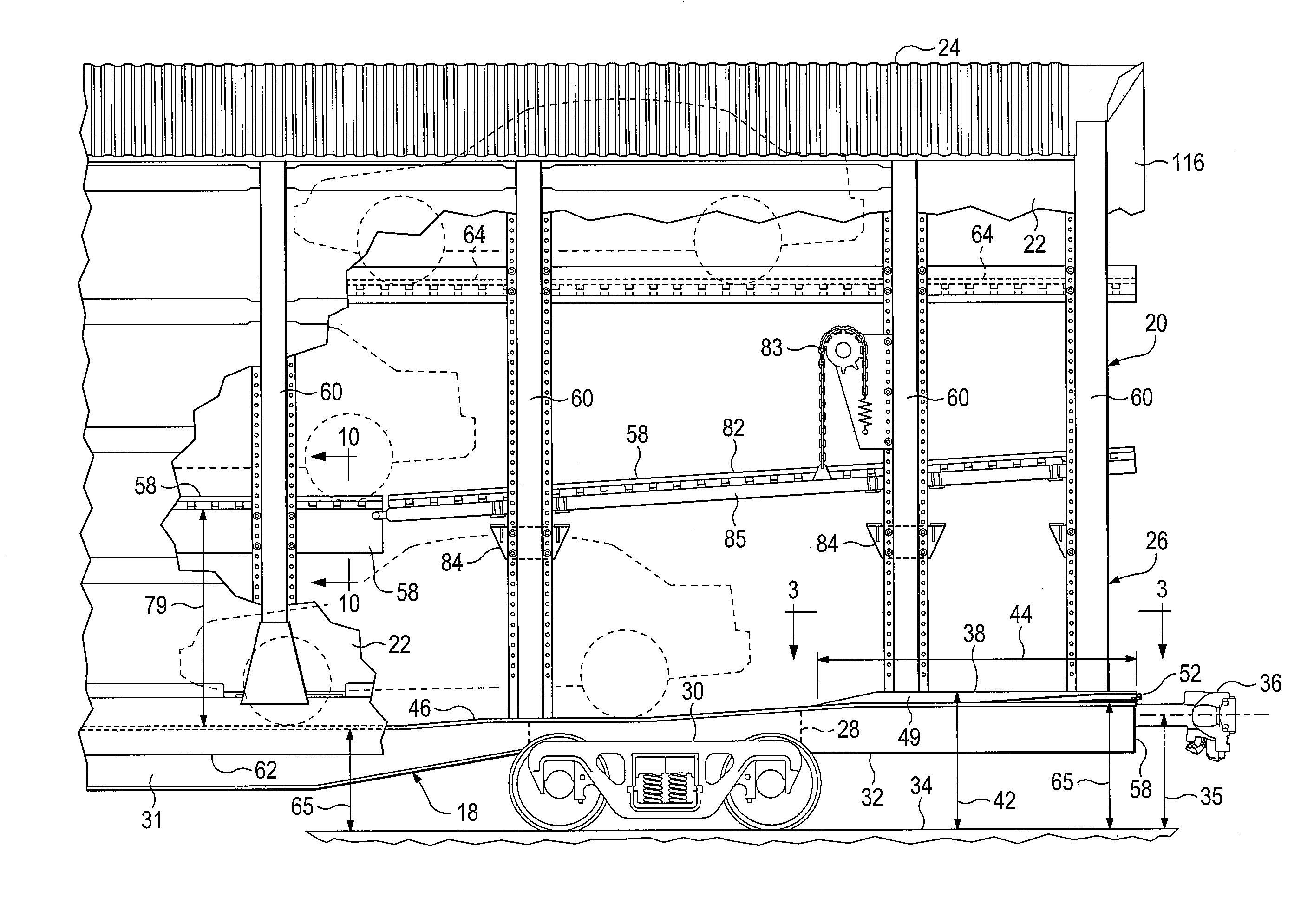

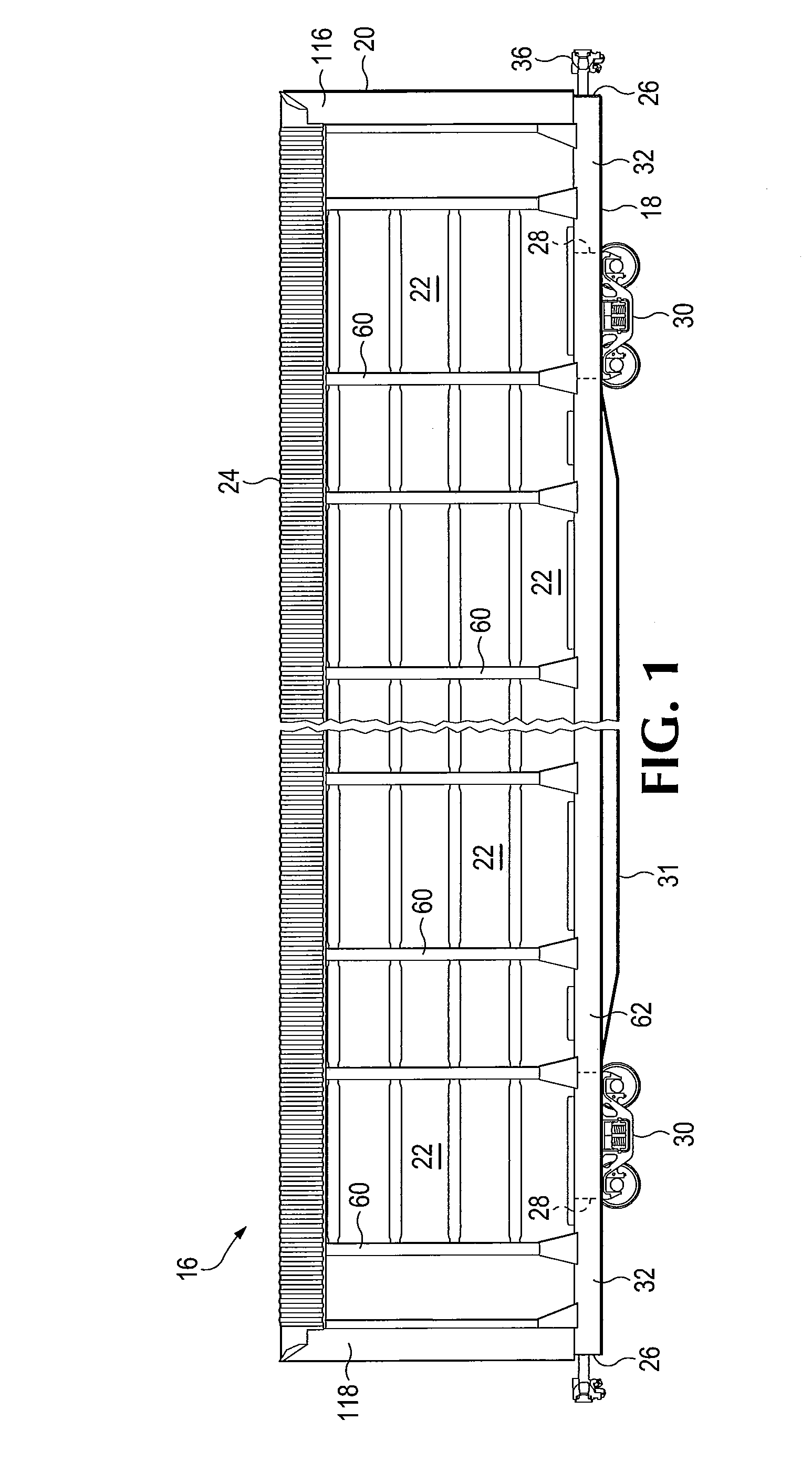

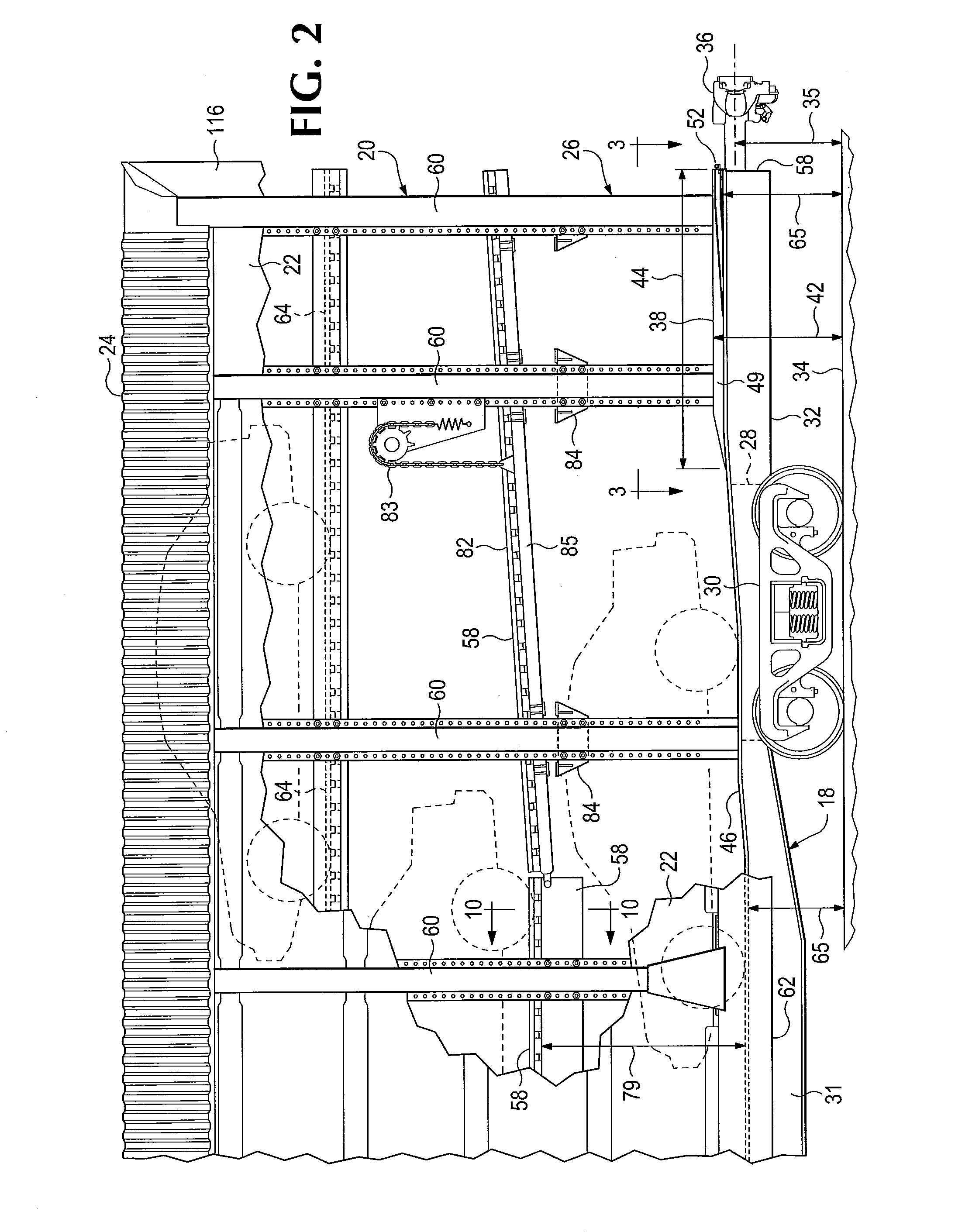

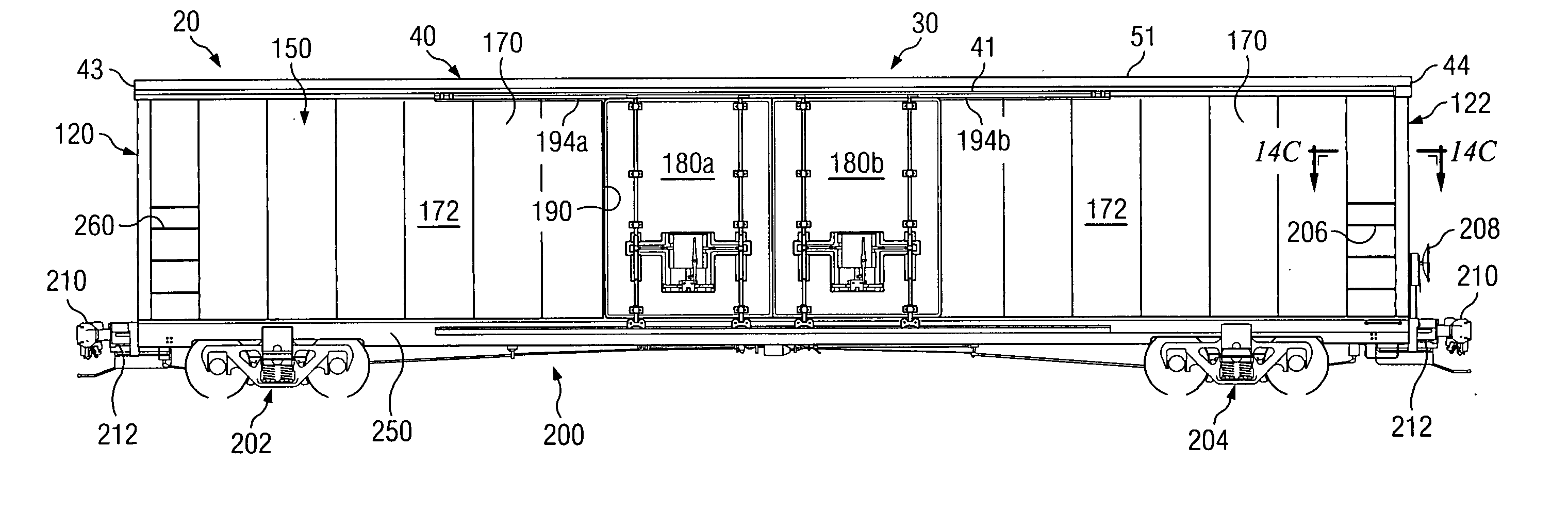

Railroad car for carrying motor vehicles

ActiveUS20140123872A1Ample vertical clearanceClearance can be providedTank wagonsWagons/vansMobile vehicleMotorized vehicle

A fully protective railroad freight car for carrying motor vehicles in a selected one of a bi-level or a tri-level configuration, with the lowest level including a depressed longitudinally central portion between body bolsters of the underbody, which may be a low-level flat car. A pair of vehicle-carrying decks are adjustable in height to provide for either one or two vehicle-carrying levels above the lowest level, while also providing at least a prescribed amount of vertical clearance above each vehicle-carrying deck. Ramps may be provided on the lowest level at an end of the car to provide a wheel-supporting surface having a prescribed minimum height. A roof structure is light in weight, and the car has an overall height not exceeding a prescribed limit for operation on most rail lines. The ends of the car are equipped with three-panel folding doors.

Owner:GUNDERSON

Dropped deck center beam rail road car

A center beam car has a main deck structure extending laterally from a main center sill, a laterally extending top truss structure, and a central vertically oriented central beam structure. The center beam so formed defines bunks upon in which to carry cargo. The upper region of the web-work structure includes a top chord mounted to run between two end bulkheads. The deck has a central portion and end portions. The end portions of the deck are carried at a greater height than the center portion, the difference in height corresponding to the height of a bundle of lumber. The car has a center sill having a depth corresponding to the depth of the step in the deck. The end portion of the center sill has an internal plate defining a draft gear pocket upper wall. The medial portion of the center sill is narrower than the end portion, and of deep section, such that it has a high aspect ratio. Web separators are mounted in the medial portion of the center sill by a method that includes making part of the weld from outside the center sill through welding apertures. As the end deck is carried at a high level, the bolster is abnormally deep.

Owner:NATIONAL STEEL CAR

Universal boxcar with exterior metal surfaces

ActiveUS20050087096A1Maximizing heightMaximizing widthRailway heating/coolingRefrigerated goods vehicleTemperature controlEngineering

Owner:TRINITY IND INC

Dropped deck center beam rail road car

A center beam car has a main deck structure extending laterally from a main center sill, a laterally extending top truss structure, and a central vertically oriented web work structure for carrying vertical shear loads between the top truss and the center sill and decking. The center beam so formed defines bunks upon in which to carry cargo. The upper region of the web-work structure includes a deep upper beam structure that has downwardly extending skirts. The skirts provide an extended bearing area upon against which bundled loads can be secured. The skirts are inwardly reinforced to discourage deflection between adjacent upright members of the deep upper beam structure.

Owner:NATIONAL STEEL CAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com