Rail conveyor system

A conveyor and track technology, applied in the field of rail conveyor systems, can solve problems such as large rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

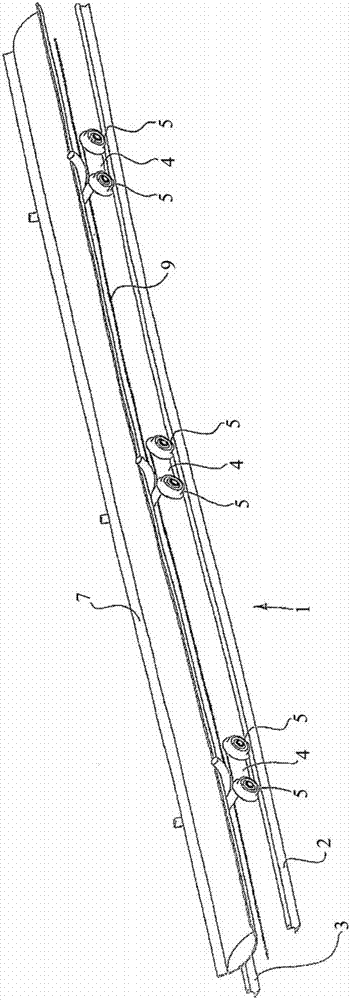

[0045] In a preferred form of the invention the rail conveyor system is formed by providing a track 1 which generally comprises two conventional rails 2 and 3 side by side. These rails may be similar to those used in conventional train tracks and may either be mounted on sleepers above ground as in conventional rail systems, or elevated or supported on rails as is known from typical belt conveyor systems. on the frame.

[0046] The system also includes a plurality of spaced apart carriages 4 running on wheels 5 supported by rails 2 and 3 .

[0047] exist figure 2 As can be seen more clearly in , the wheels generally have flanges, seen at 6, and engage the inner edges of rails 2 and 3 in a manner similar to conventional train systems.

[0048] The rail conveyor system according to the invention also comprises a continuous conveyor belt 7 supported by supports 4 and conveyed generally in suitably shaped yolks 8 mounted on each support.

[0049] In a preferred form of the inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com