Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Avoid unbalanced load phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

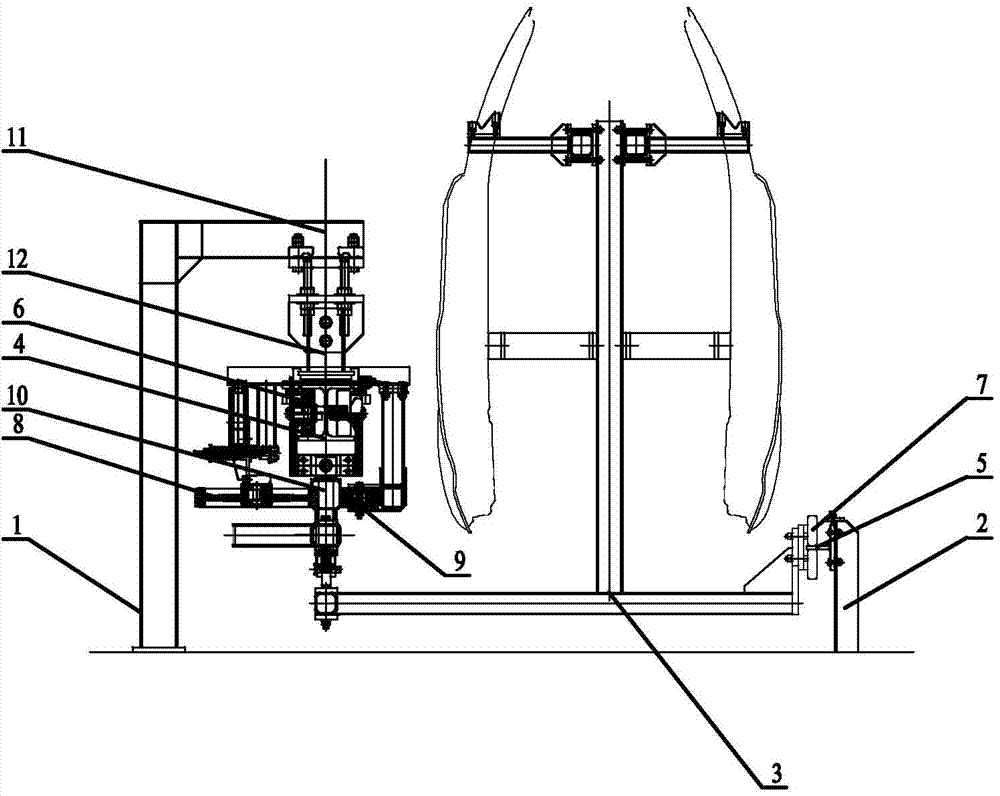

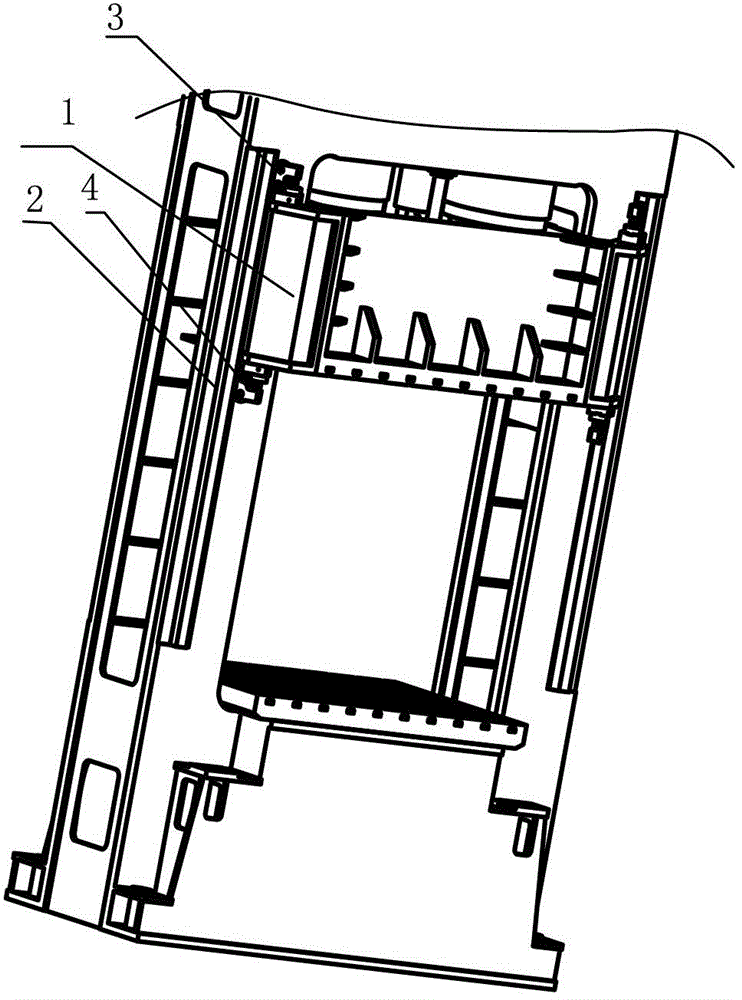

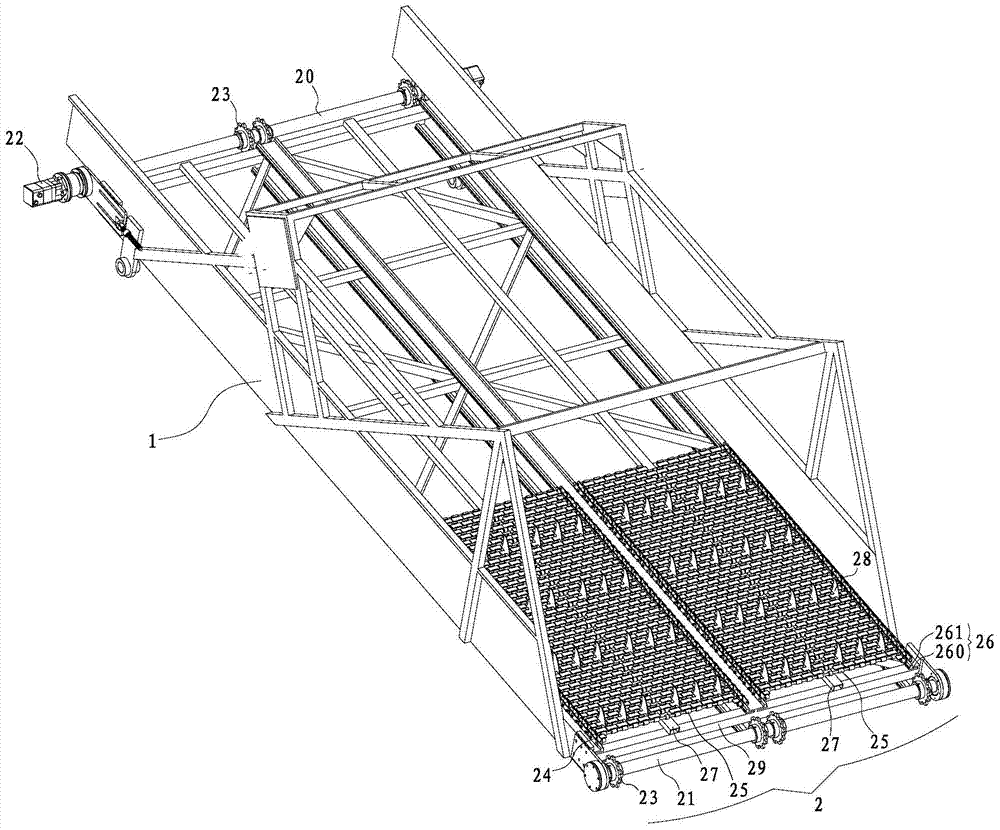

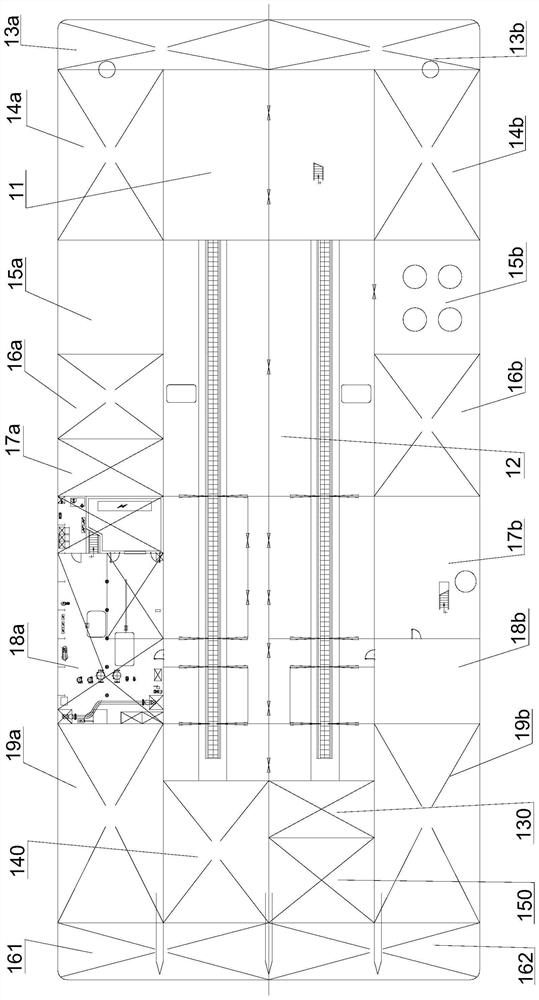

Conveying device suitable for collecting floating objects and water plants and front cabin collecting system

ActiveCN105501815AEasy to operateEasy to implementConveyorsWater cleaningDrive shaftCollection system

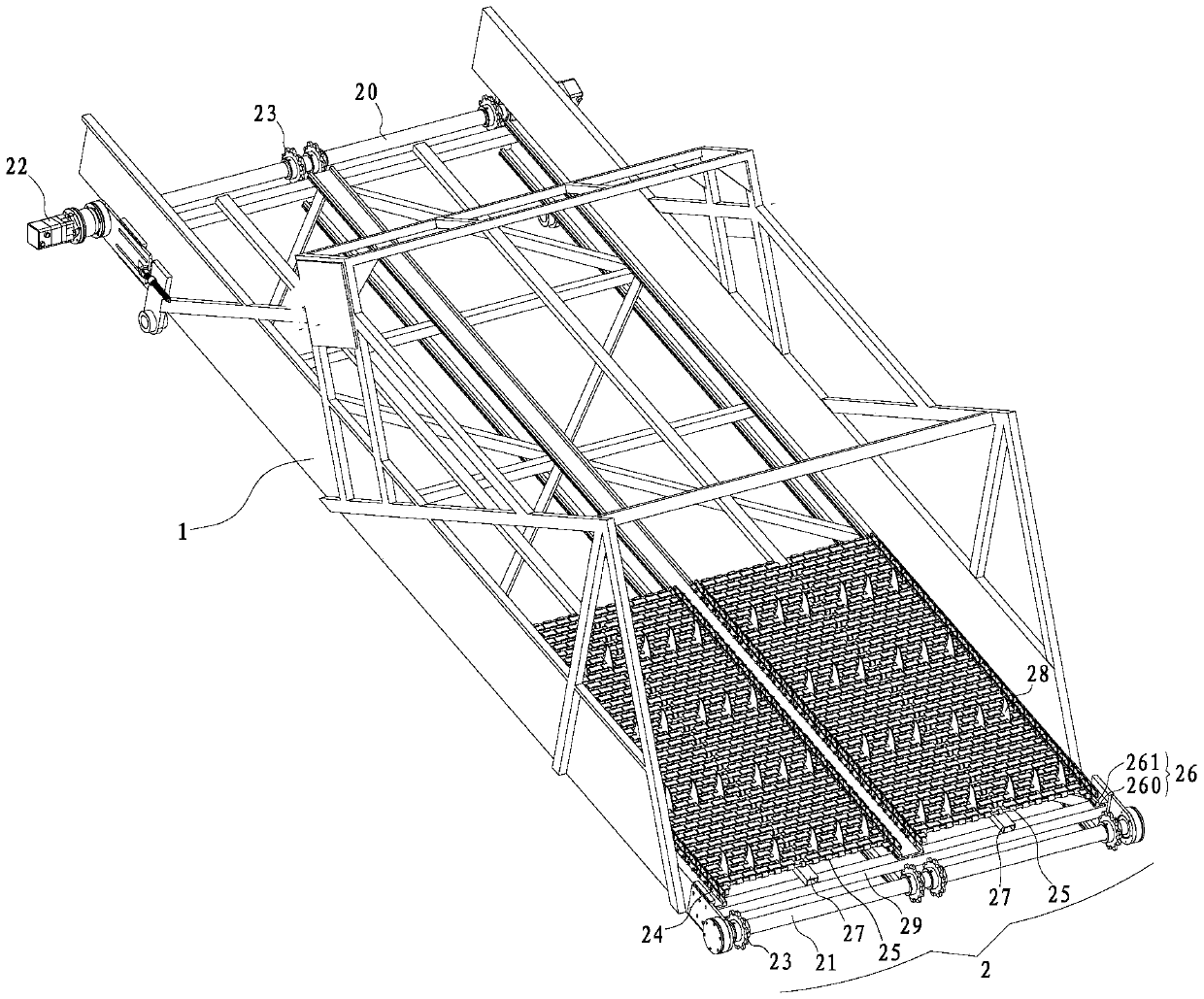

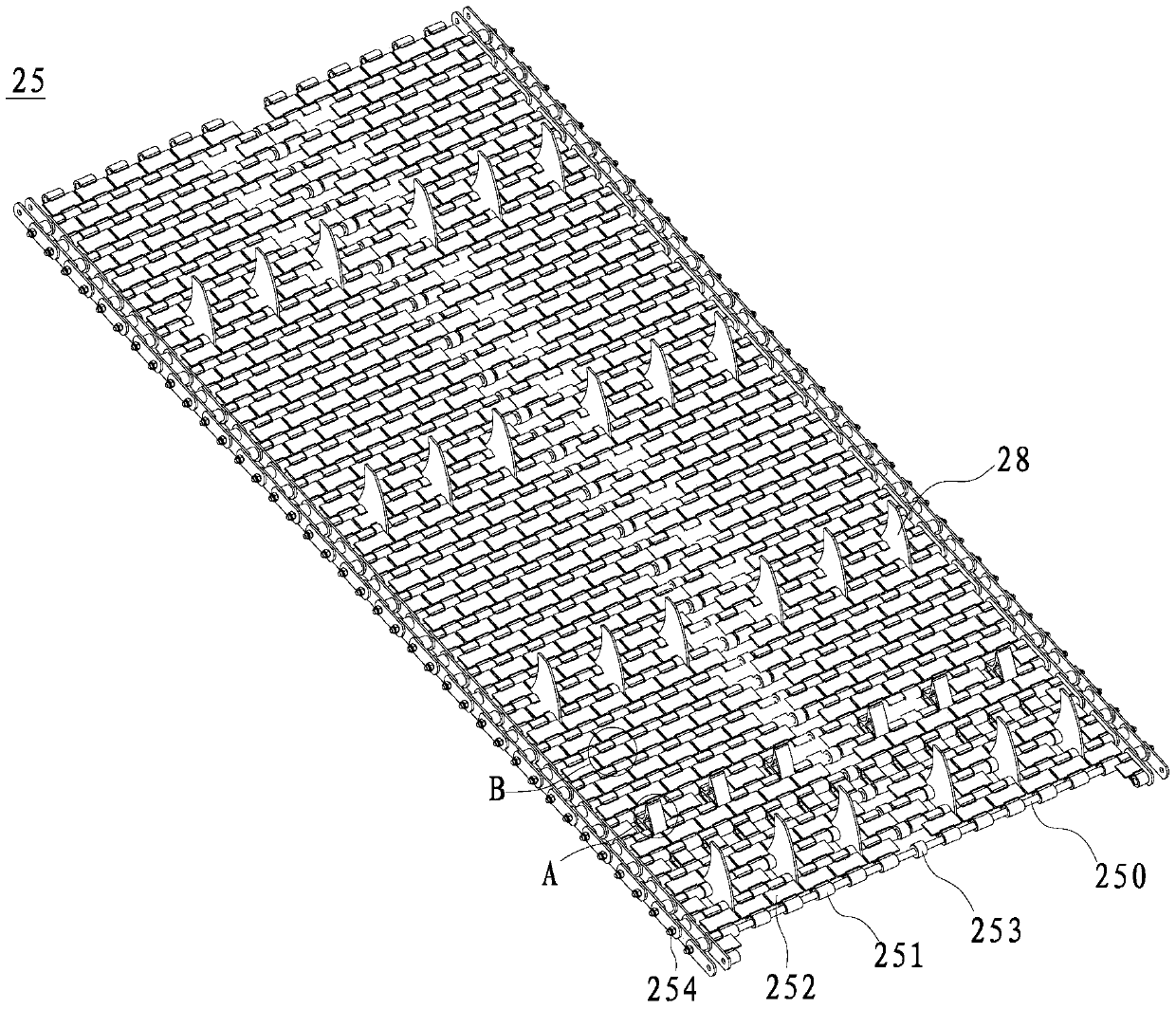

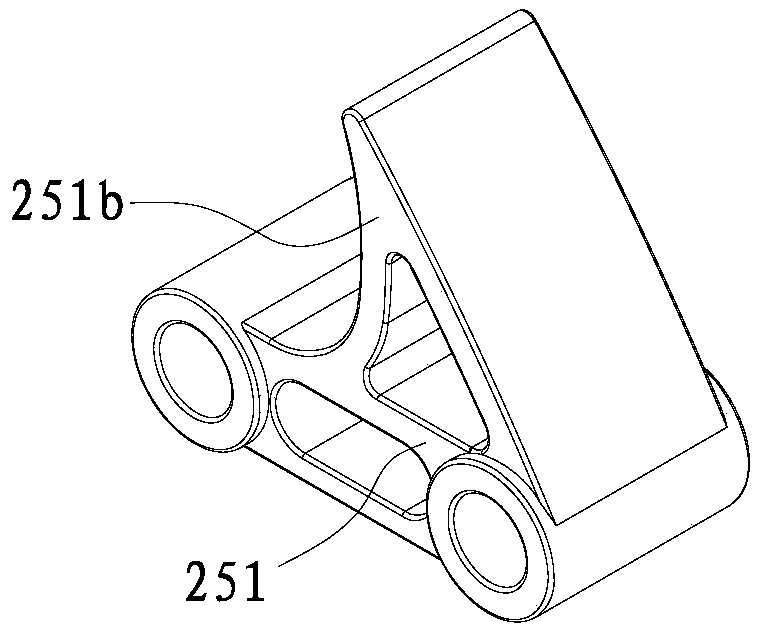

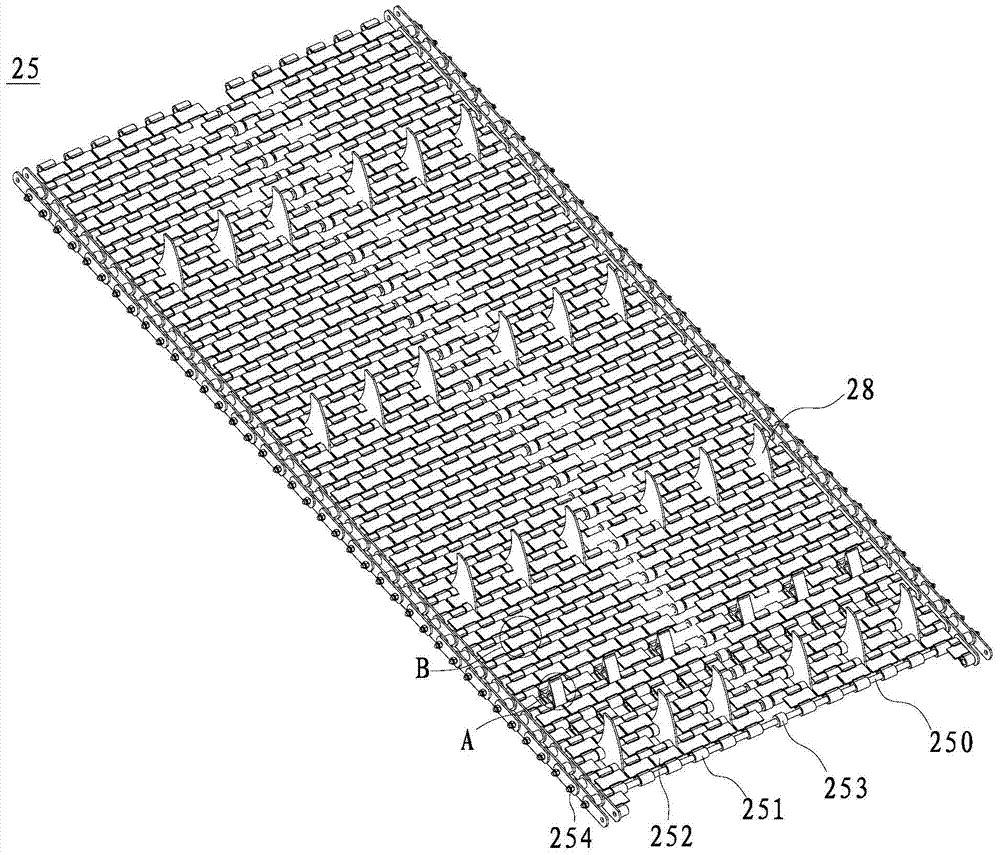

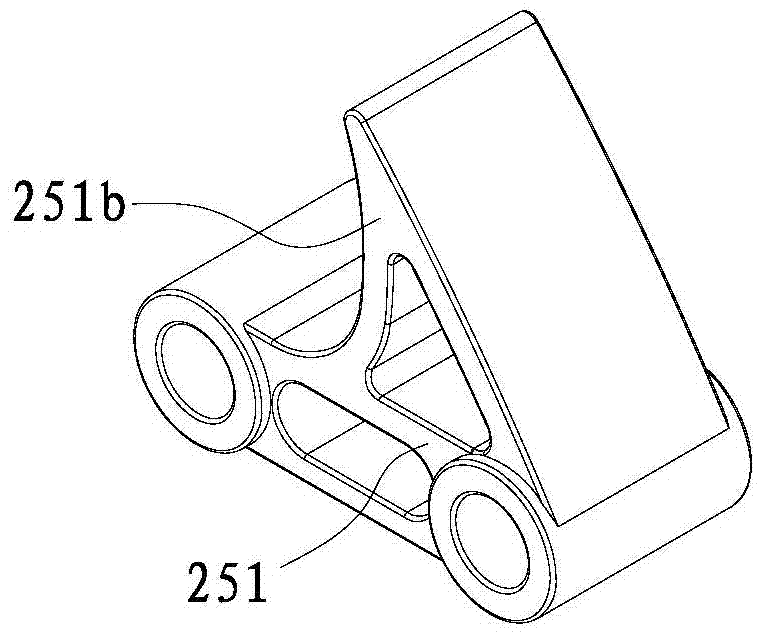

The invention relates to a conveying device suitable for collecting floating objects and water plants and a front cabin collecting system. The conveying device comprises a driving shaft, a transmission shaft, motors, chain wheels, transmission chains and conveyer belts, wherein the conveyer belts are row chain type conveyer belts; the transmission chains are hollow pin shaft chains. The conveying device further comprises supporting strips, supporting poles and steel hook sheets, wherein the supporting strips are positioned between the two chain wheels on the same side and are used for supporting the hollow pin shaft chains; the supporting poles are positioned in the row chain type conveyer belts and are used for supporting the row chain type conveyer belts; the steel hook sheets can be arranged on the row chain type conveyer belts in a detached manner; the supporting strips comprise supporting bodies which are arranged in the length direction of the hollow pin shaft chains, and convex strips arranged on the supporting bodies; rollers of the hollow pin shaft chains are erected on the convex strips. According to the conveying device and the front cabin collecting system disclosed by the invention, under the assistance of the supporting strips and the supporting poles, the stability of the conveying device is improved, the occurrence of an eccentric load phenomenon caused by too wide conveyer belts is avoided, and the service life of the conveying device is prolonged.

Owner:FEICHI ENVIRONMENTAL PROTECTION TECH INC CO LTD

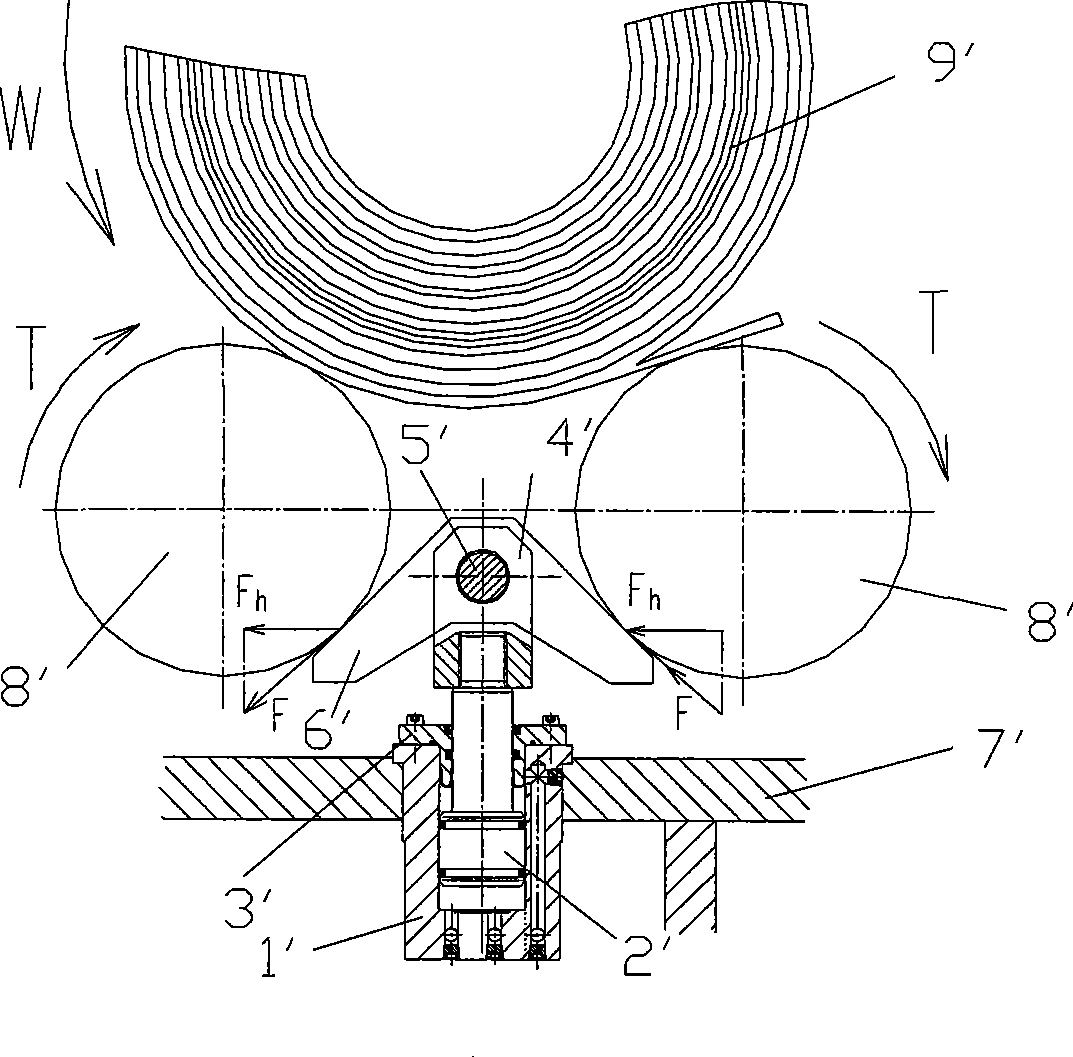

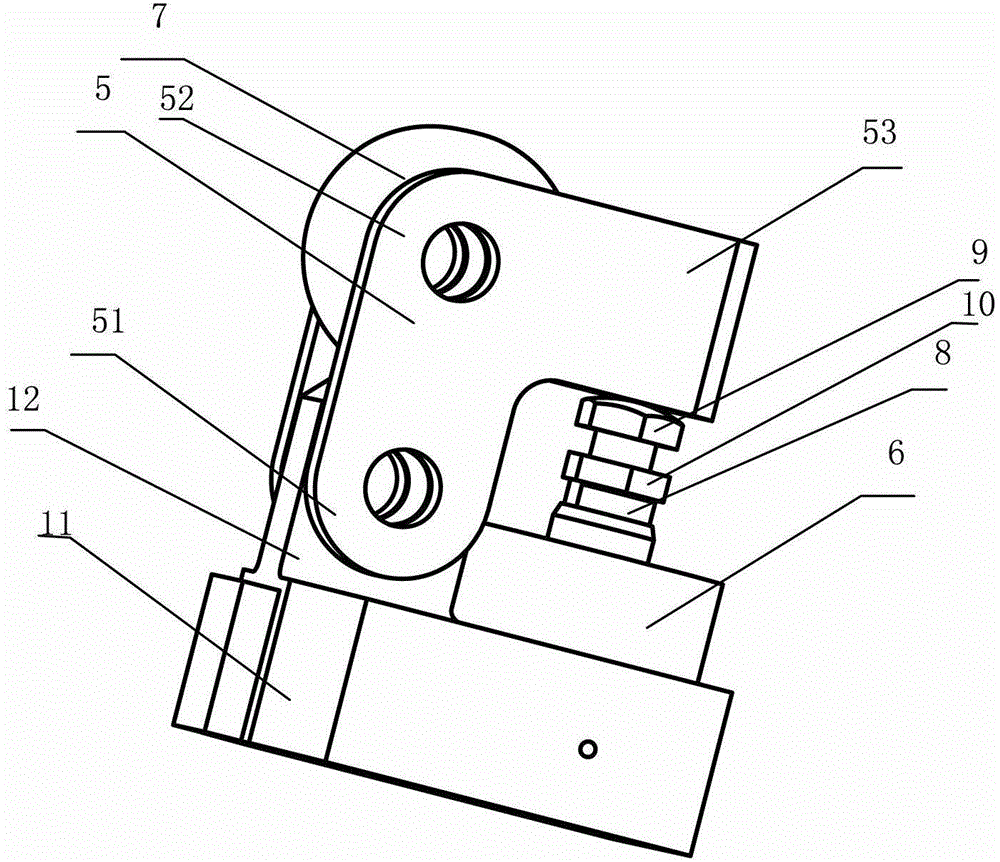

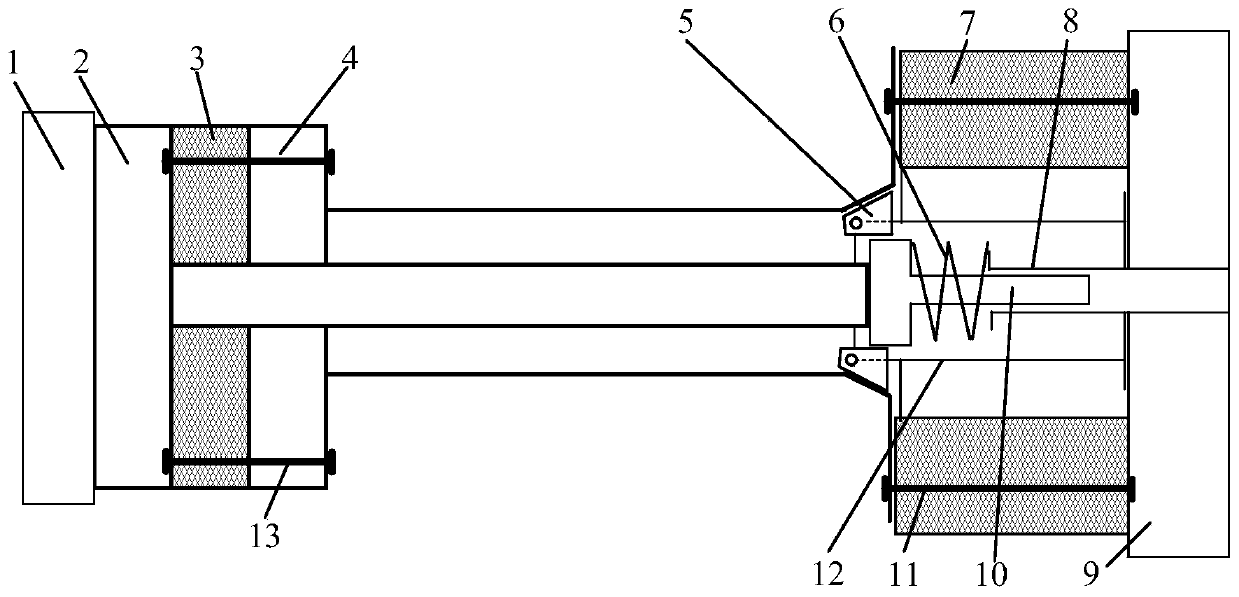

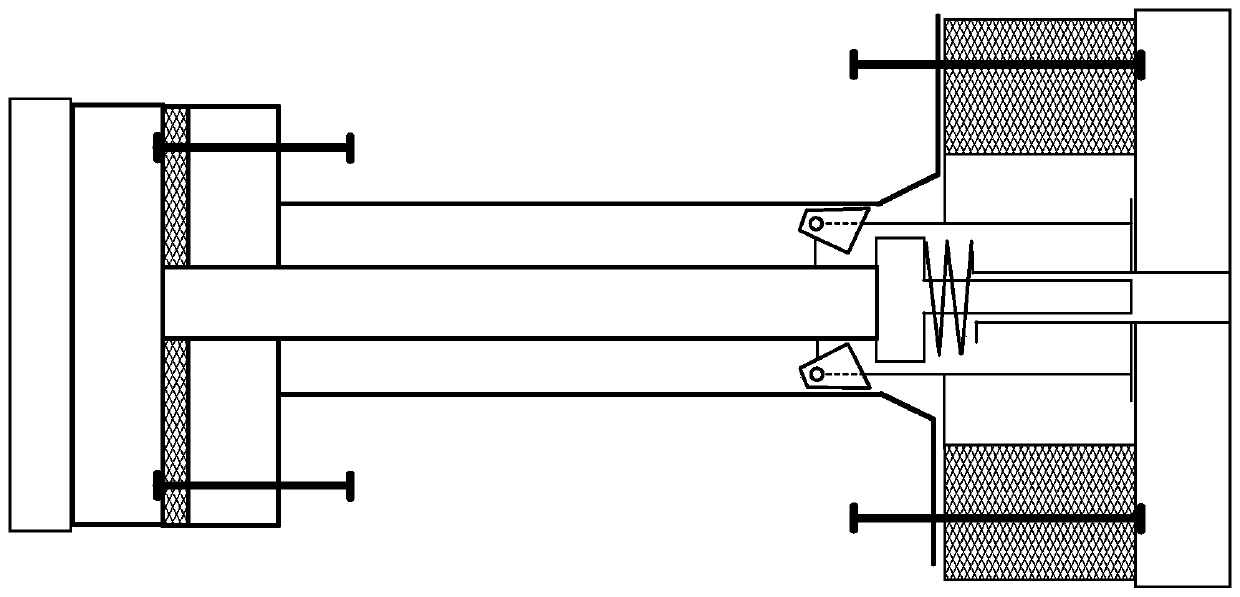

Brake device for support roller of coil stripping car

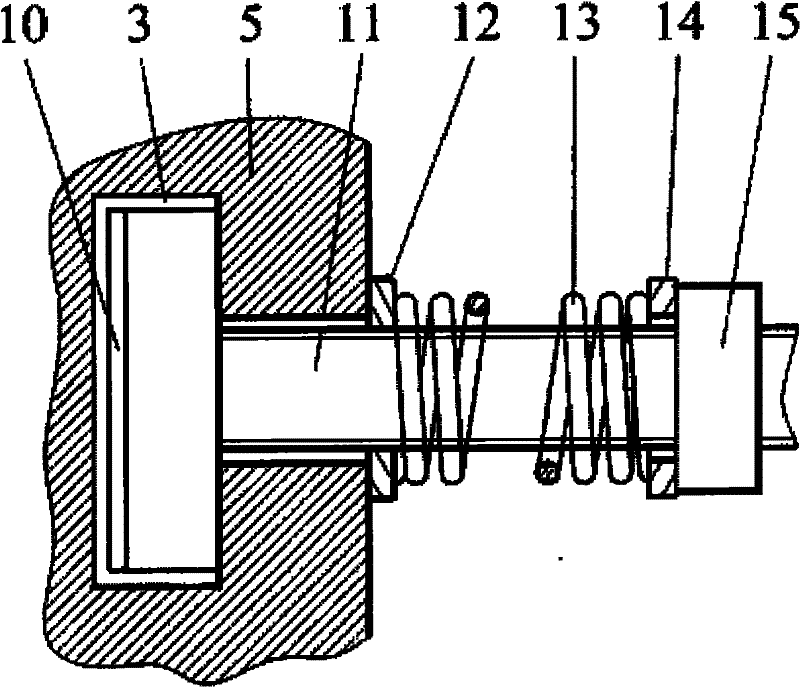

InactiveCN101397100AAvoid unbalanced load phenomenonAvoid failureDrum brakesWebs handlingHydraulic cylinderSelf adaptive

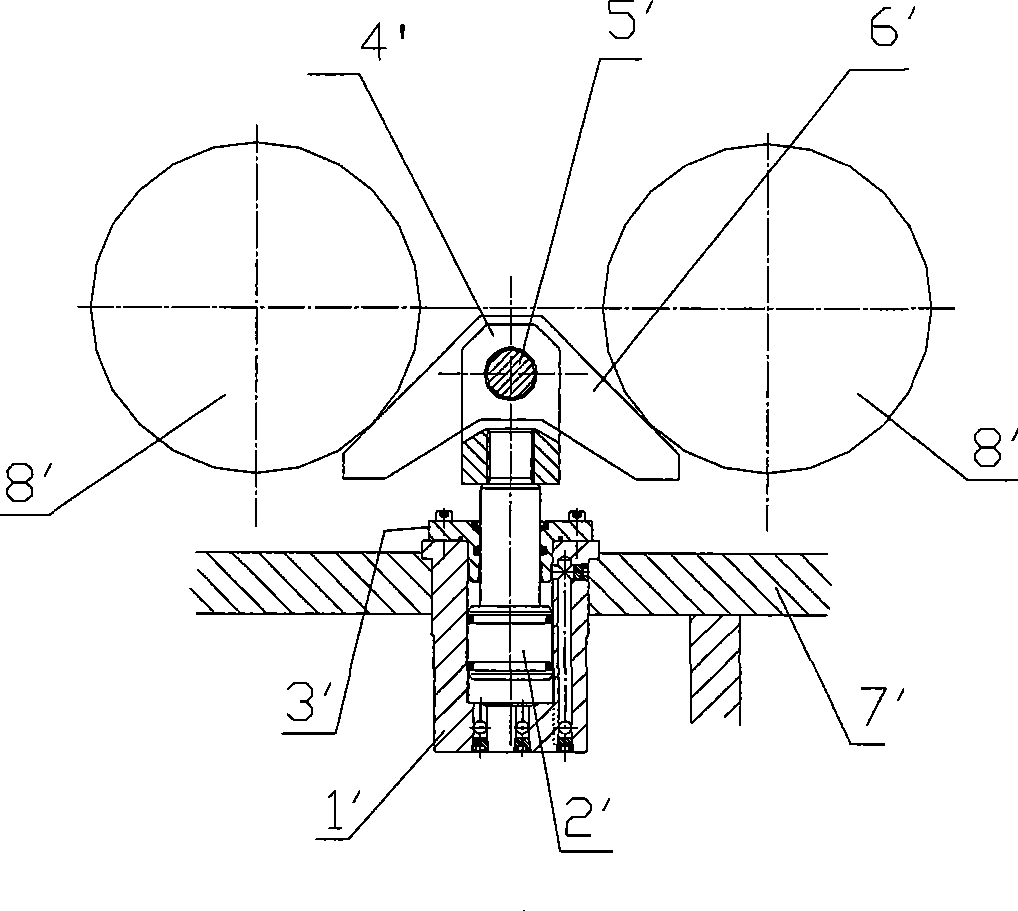

The invention provides a supporting roller brake device used for a coil stripping trolley, comprising a hydraulic cylinder, a fork head and a brake part; wherein, the brake part comprises an inclined wedge block and a pair of brake arms which are pivotally and rotatablely connected with the fork head; each brake arm is pivotally and rotatablely connected with a bracket which is fixed on the supporting frame of the trolley respectively; the supporting roller brake device also comprises a self-adaptive floating system which is arranged between the hydraulic cylinder and the supporting frame of the trolley and comprises a pair of connecting shafts and a pair of supporters; each connecting shaft is respectively connected with one side of the hydraulic cylinder; each supporter is respectively connected with the supporting frame of the trolley; the connecting shafts are pivotally and rotatablely connected in the holes arranged on the supporters correspondingly. According to corresponding mechanic principle, the invention reconstructs the whole assembly and local assembly of the supporting roller brake device system. The novel supporting roller brake device of the coiling stripping trolley effectively solves the offset load phenomenon of the piston rod of the hydraulic cylinder and avoids a series of equipment failure and accidents caused by the offset loads.

Owner:BAOSHAN IRON & STEEL CO LTD

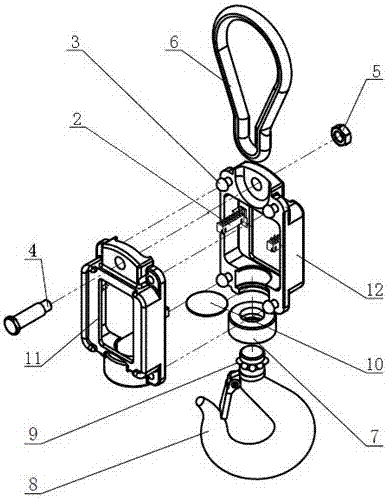

self-calibrating gear

InactiveCN102269225AGuaranteed SensitivityPrevent axial joltYielding couplingPortable liftingEngineeringSelf correction

The invention relates to a self-calibrating gear, including a gear, wherein: the shaft center of the gear is a shaft, a section of protruding external spline is arranged in the shaft, and a section of protruding internal spline is arranged in the gear assembly hole, the length of which is Corresponding to the external spline; the external spline is a convex arc along the axial direction, and its highest point is located at half of the external spline, and the axial arc of the internal spline is in line with the The convex arcs of the external splines match and mesh with each other; the front and rear ends of the external splines and internal splines are respectively provided with joint bearings, and an adjustment ring and a pressure plate are arranged between the joint bearing and the end face of the gear in turn, and the pressure plate passes through The bolt is fixed on the end face of the gear.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

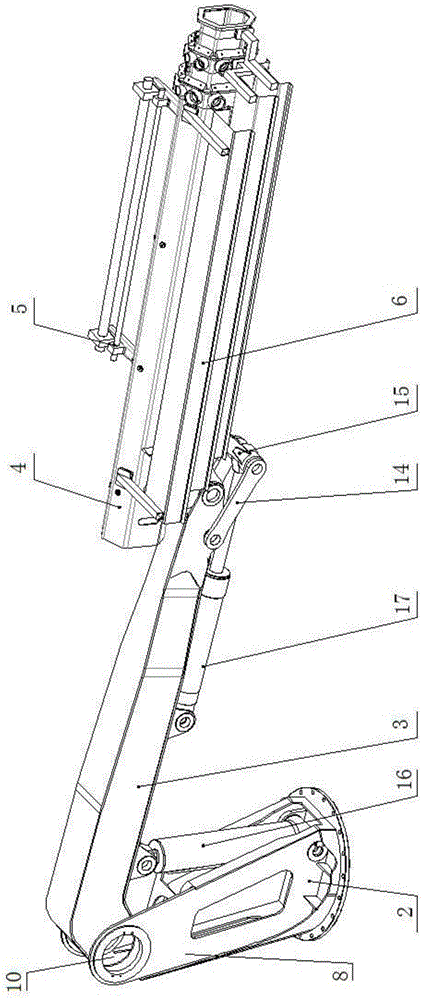

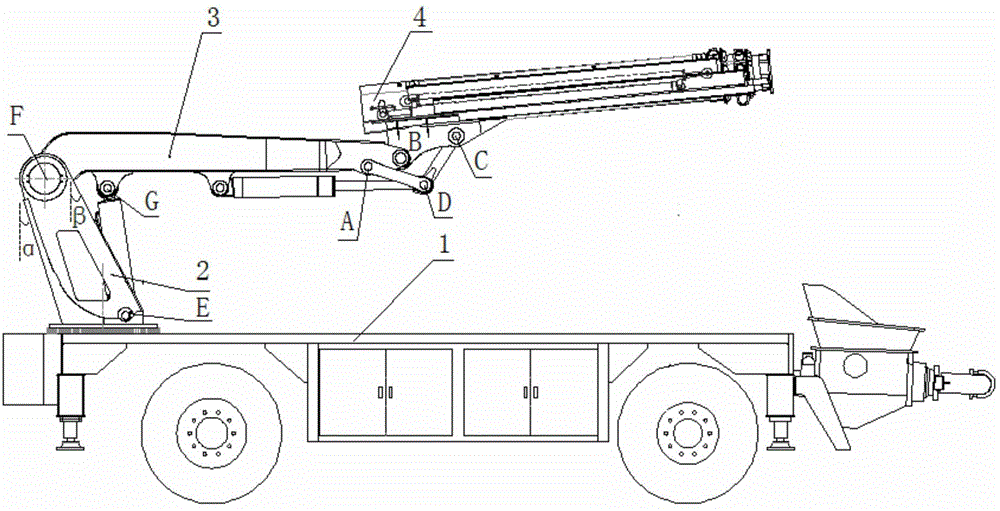

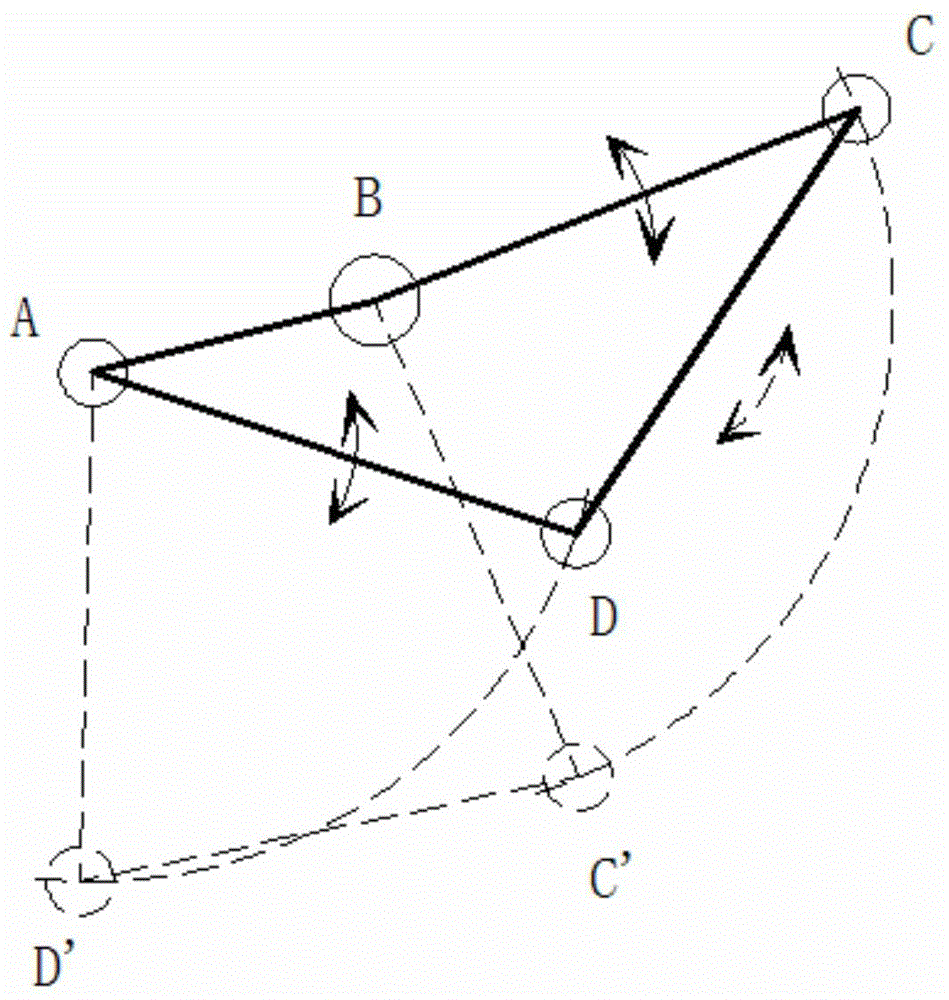

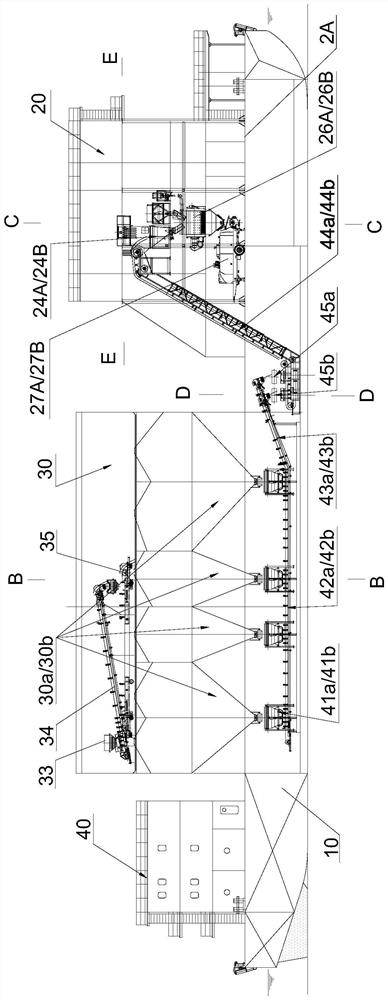

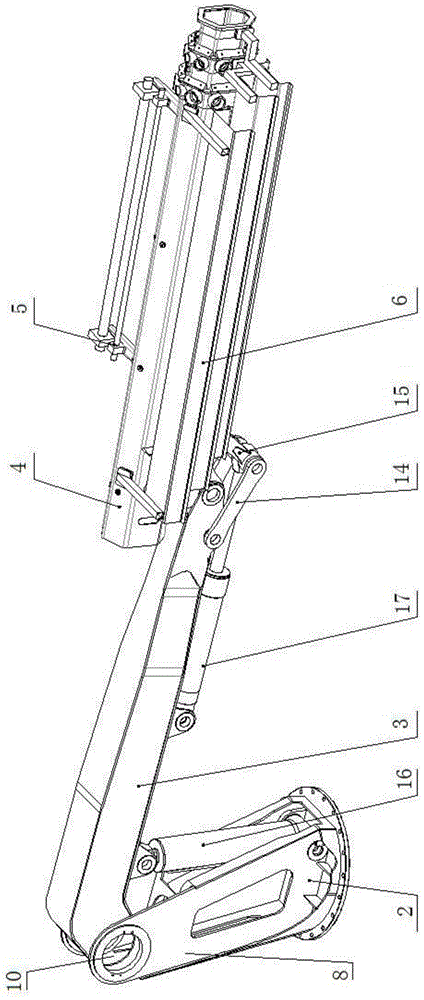

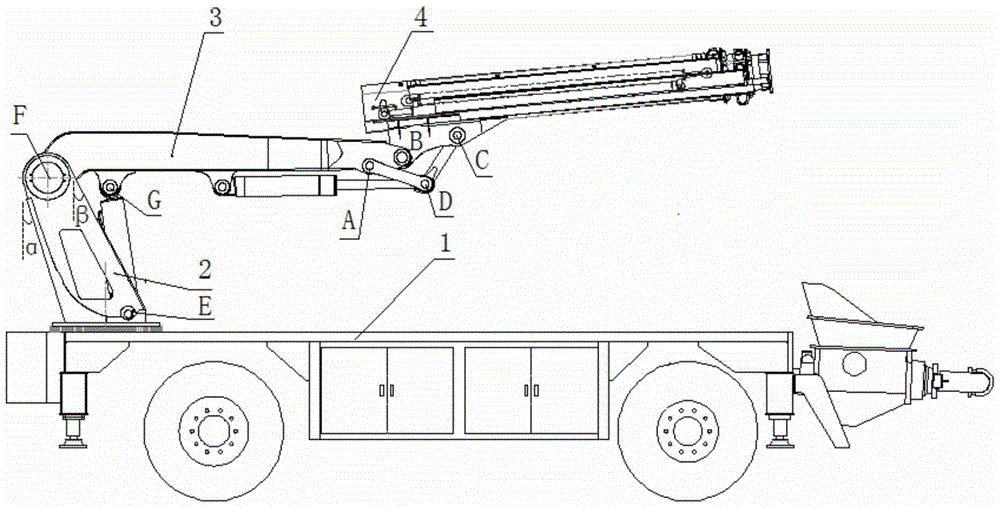

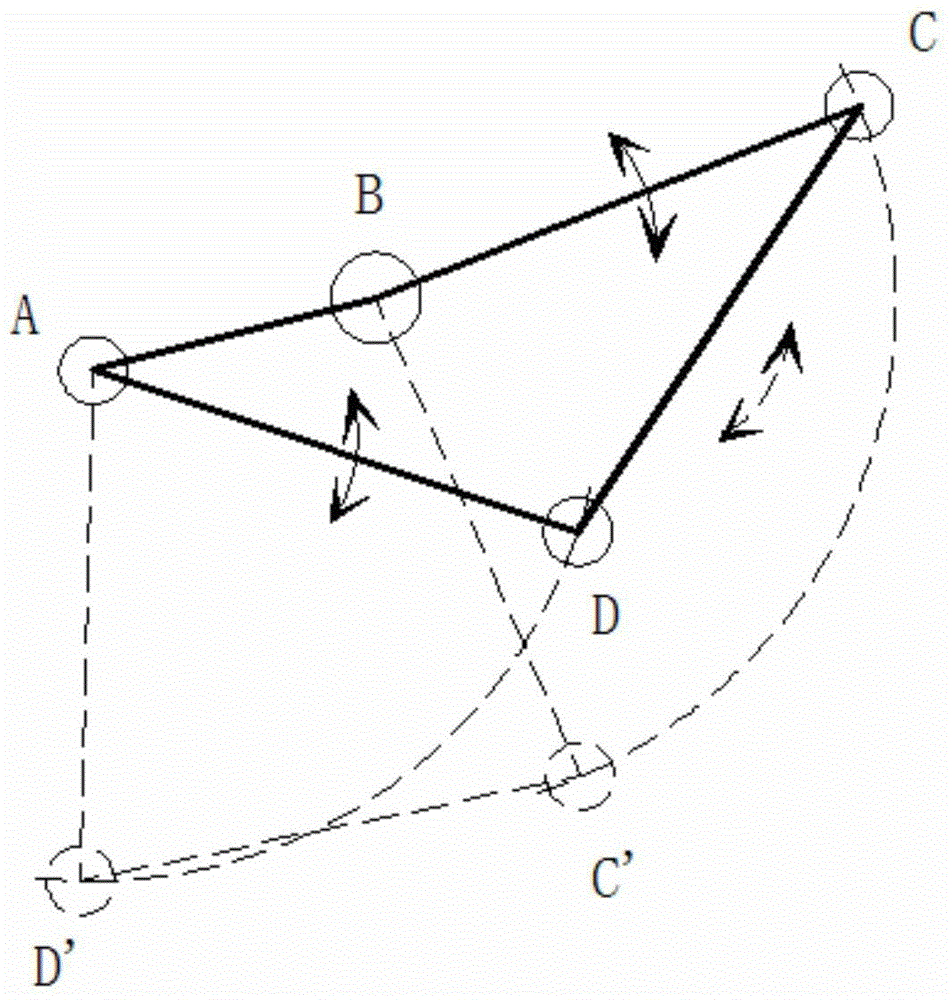

Boom system for wheel type wet sprayer

ActiveCN104594355APrevent deviationEnsure balanceUnderground chambersFoundation engineeringSprayerEngineering

The invention provides a boom system for a wheel type wet sprayer. The boom system for the wheel type wet sprayer comprises a rotary table arranged on a machine tool, and a boom device connected with the rotary table, wherein the rotary table is of a bilateral symmetry structure and comprises a rotary chassis, two vertical support plates and a horizontal support plate; a first through hole and a second through hole are respectively formed on the same height in the top parts of the vertical support plates; a third through hole is formed in the center of the horizontal support plate; the central points of the first through hole, the second through hole and the third through hole are located on the same vertical face; the tail end of a big arm and the rotary table are hinged at the first through hole and the second through hole; the front end of the big arm is hinged to the tail end of a small arm through two connecting rods; vertices of a quadrangle formed by one section of the front end of the big arm, one section of the tail end of the small arm and the two connecting rods are respectively located in a vertical face where the central axis of the big arm and the central axis of the small arm are jointly located. According to the boom system for the wheel type wet sprayer, the eccentric load phenomenon of all axle sleeves at hinged points is avoided, and the deformation of axle sleeve holes in the hinged points is controllable and uniform, so that the service life of a boom assembly and even the service life of the whole concrete wet spraying machine are improved.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

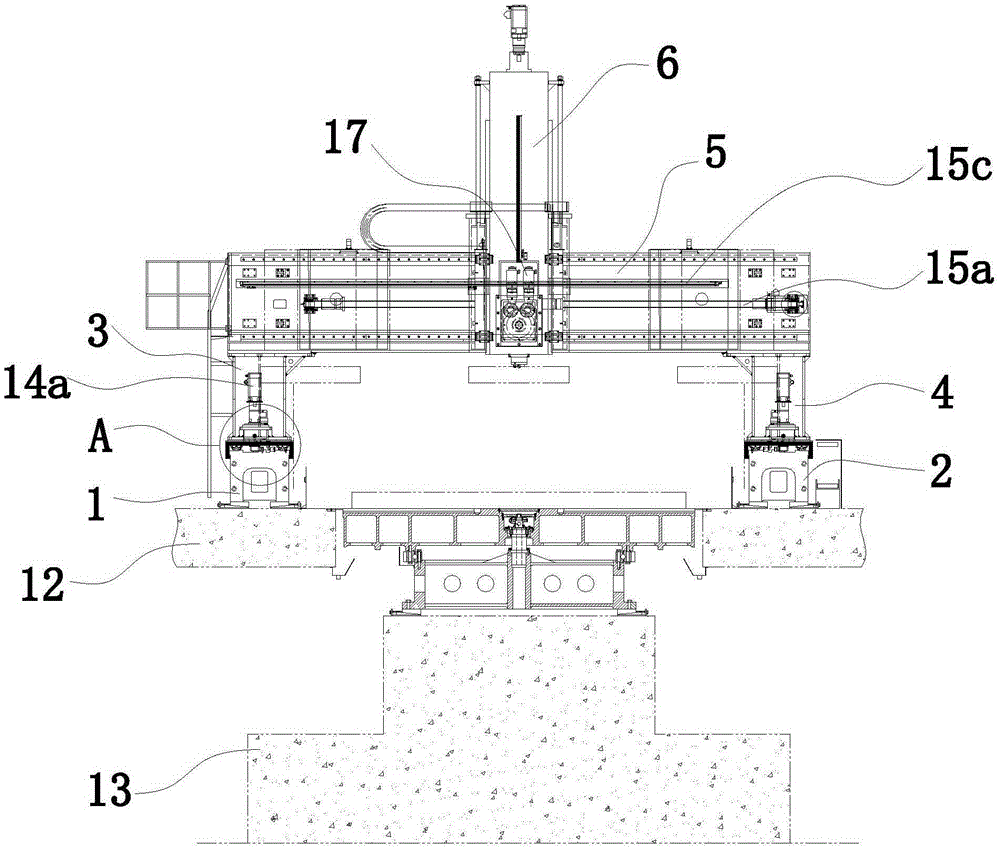

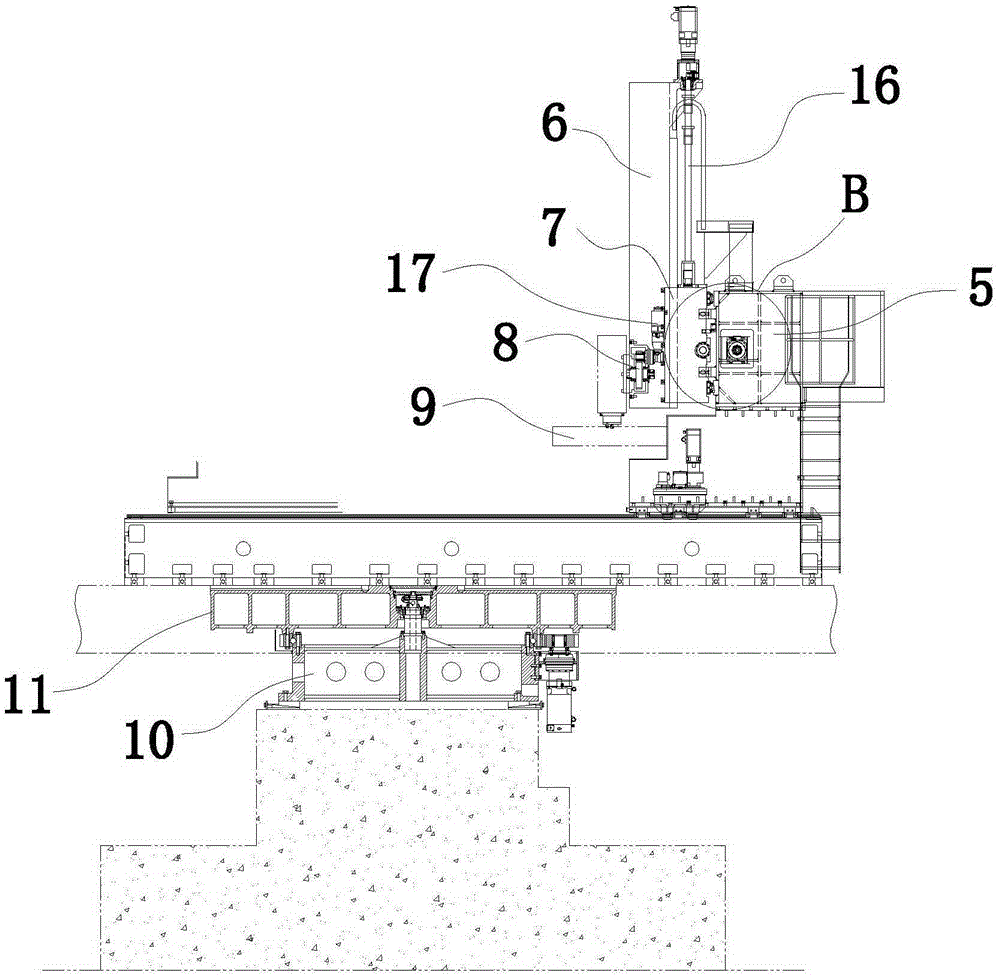

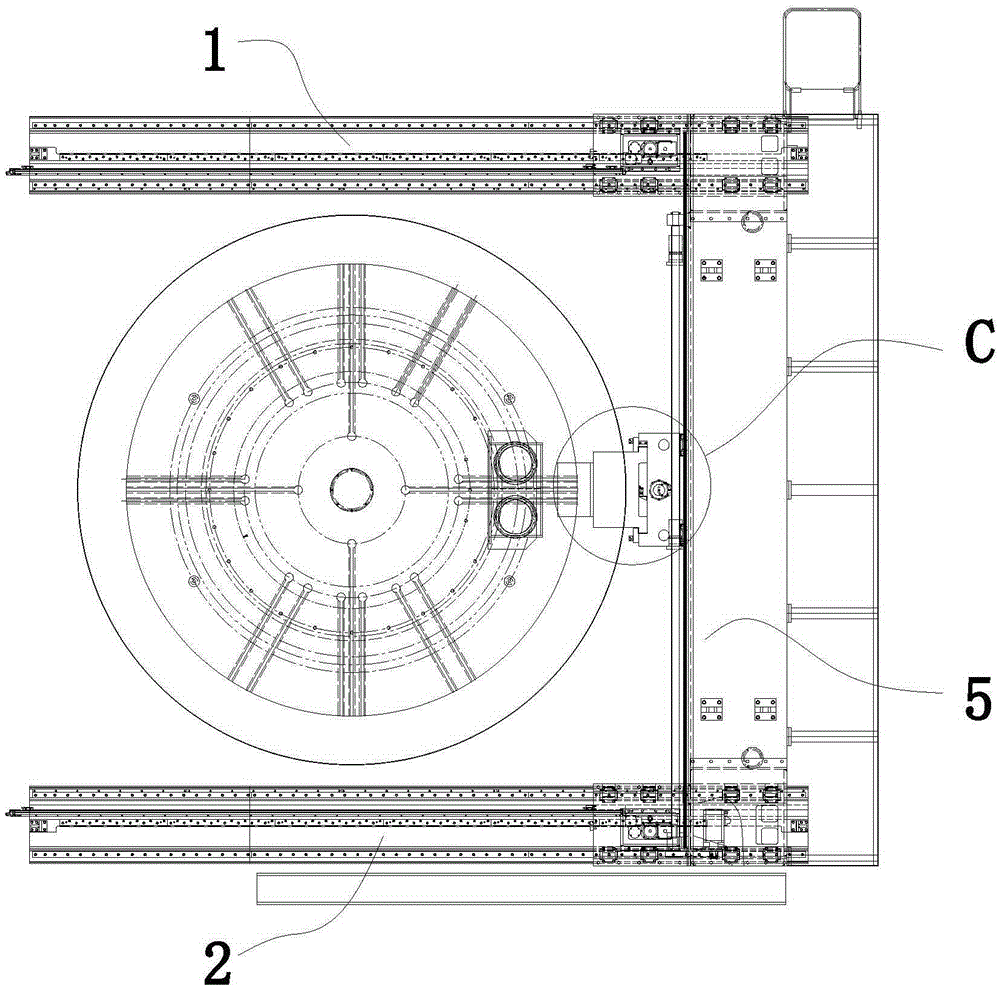

Gantry type five-axis linkage optical glass milling and grinding machine

InactiveCN105397919AAvoid influenceGuaranteed uptimeGrinding carriagesOptical surface grinding machinesEngineeringOptical glass

The invention relates to the field of optical glass milling and grinding equipment, in particular to a gantry type five-axis linkage optical glass milling and grinding machine which comprises a machine body, stand columns, a crossbeam, a rotary workbench, a machine body base and a workbench base. The first supporting column is connected with a first ram through an X-axis feeding mechanism, and the second supporting column is connected with a second ram through an X-axis feeding mechanism. A third ram is perpendicularly arranged on the crossbeam. The third ram is connected with the crossbeam through a Y-axis feeding mechanism. The Y-axis feeding mechanism is provided with a Y-direction sliding seat. The third ram is connected with the Y-direction sliding seat through a Z-axis feeding mechanism. A swinging head and an A-axis feeding mechanism for controlling the swinging head to swing are mounted on the third ram. A tool disc is mounted on the swinging head. The rotary workbench is provided with a C-axis feeding mechanism. The machine body is of a gantry type structure, the structure is simple, maintaining and debugging are convenient, and rigidity and reliability are high; one-time clamping of a workpiece can be achieved, the machine has multiple purposes, and the machining quality and production efficiency of the workpiece are improved.

Owner:芜湖戎征达伺服驱动技术有限公司

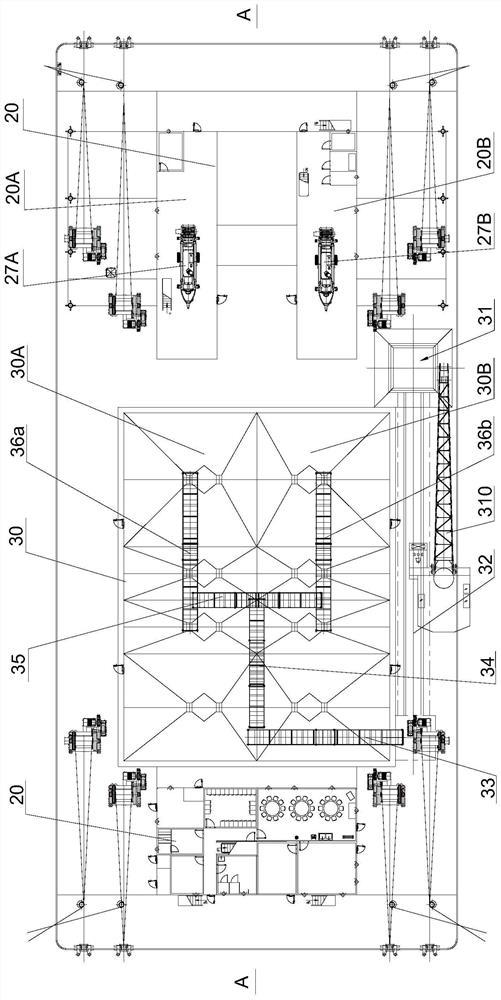

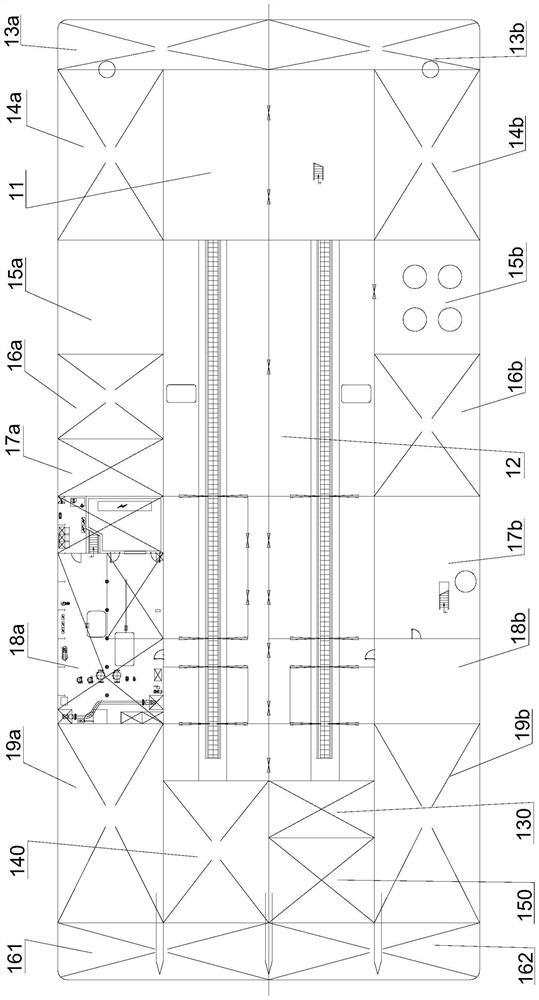

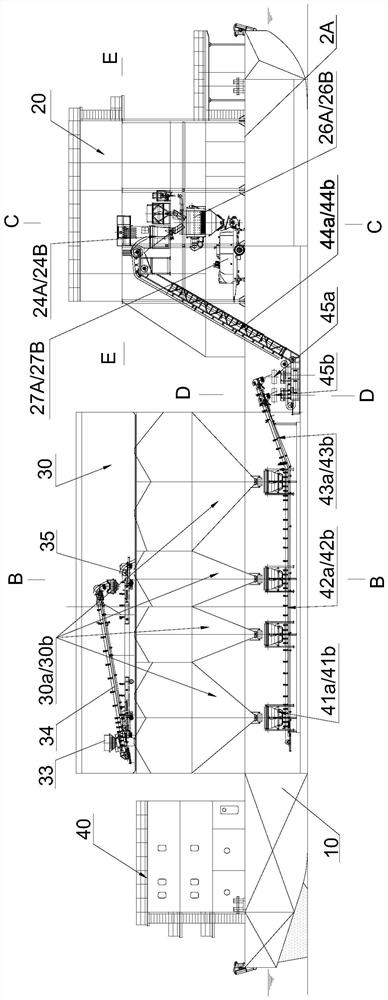

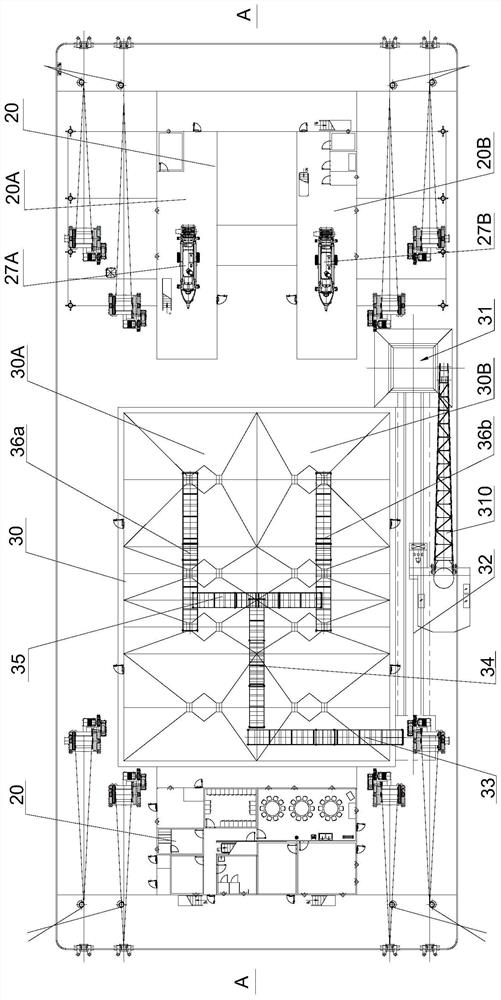

Energy-saving and environment-friendly concrete mixing ship

ActiveCN113290707ACompact structureReasonable layoutSolid waste managementPretreatment controlDust controlArchitectural engineering

The invention discloses an energy-saving and environment-friendly concrete mixing ship. The ship comprises a ship body, a concrete production system and a living building; the concrete production system comprises a stirring main building, an aggregate building, an aggregate feeding system, an aggregate batching system and a waste concrete treatment system; the stirring main building comprises a left-line stirring chamber and a right-line stirring chamber, and a left-line aggregate transition middle storage cabin and a right-line aggregate transition middle storage cabin are arranged between a dust removal deck and a weighing deck which correspond to the left-line stirring chamber and the right-line stirring chamber; a left-line stirring main machine and a right-line stirring main machine are arranged on the stirring deck corresponding to the left-line stirring chamber and the right-line stirring chamber; the aggregate building comprises a left-line aggregate chamber and a right-line aggregate chamber which are symmetrically arranged along the central axis of the ship body; the aggregate feeding system comprises a material receiving mechanism, a material conveying mechanism and a material distributing mechanism; the aggregate batching system comprises a left-line batching mechanism, a right-line batching mechanism and a transfer batching mechanism; the waste concrete treatment system comprises two flushing pipelines, a sewage chute, a sewage treatment device, a vibrating screen, a sewage tank, a filter press and a filter pressing clear water tank. The working environment can be improved, the aggregate of the left-line aggregate bin and the right-line aggregate bin can be consumed in a balanced mode, and continuous concrete production is achieved.

Owner:CCCC THIRD HARBOR ENG +2

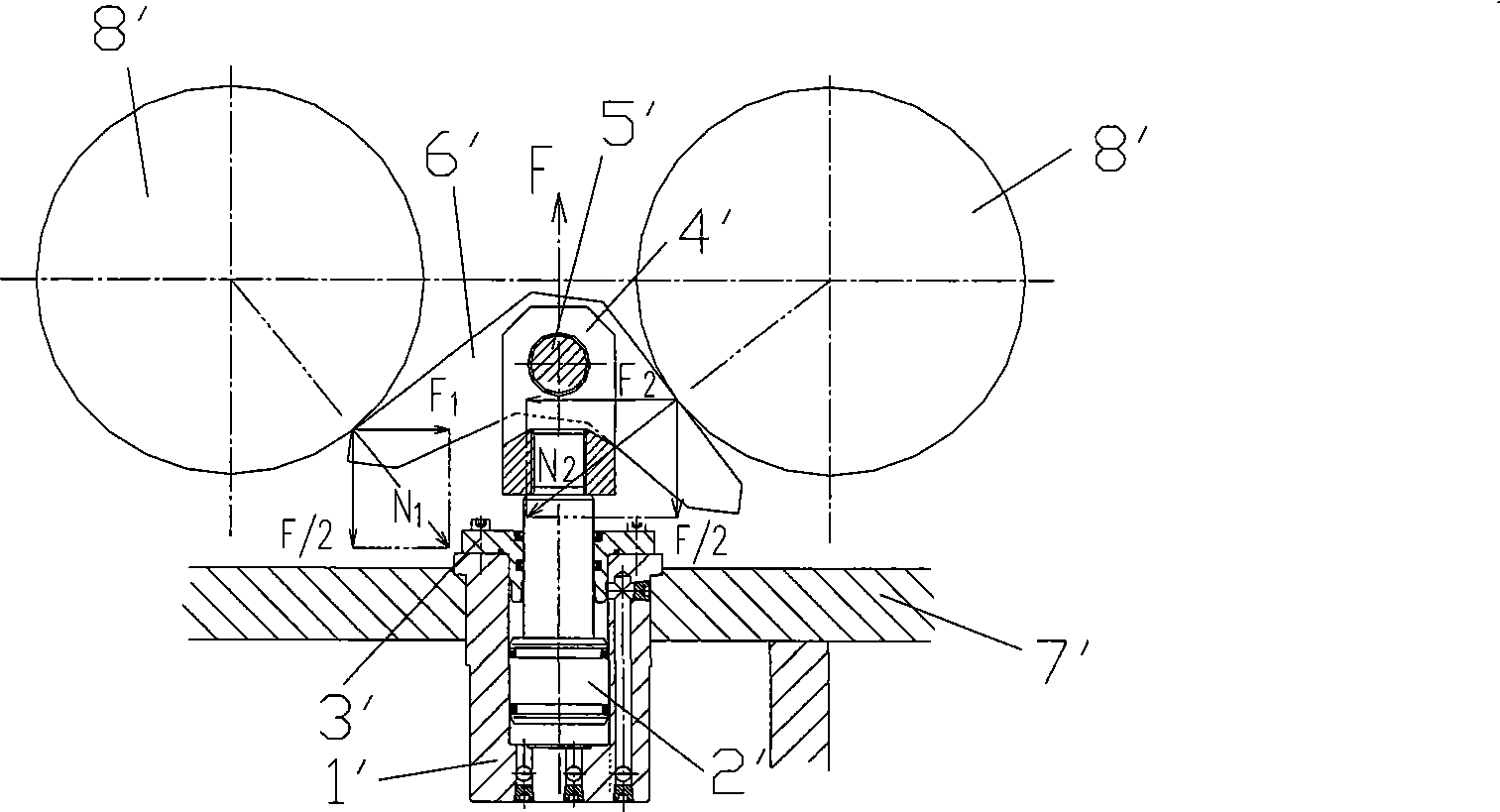

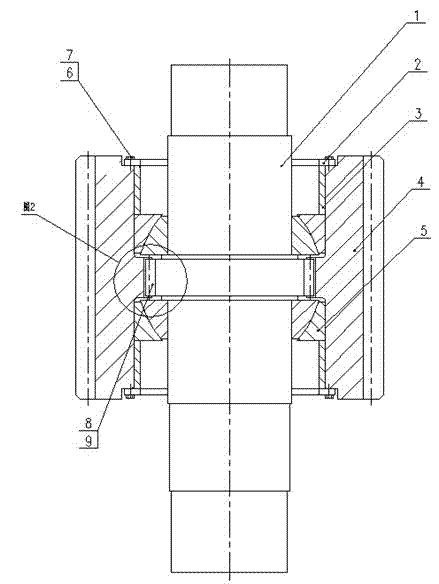

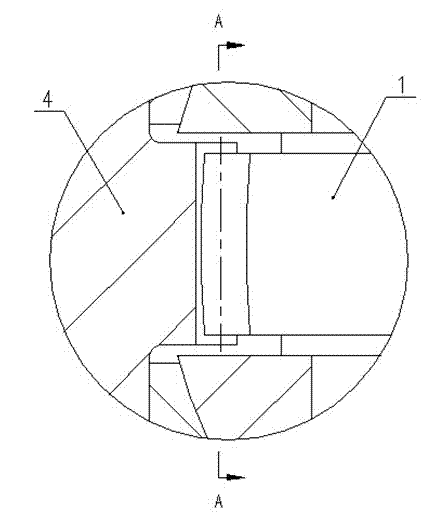

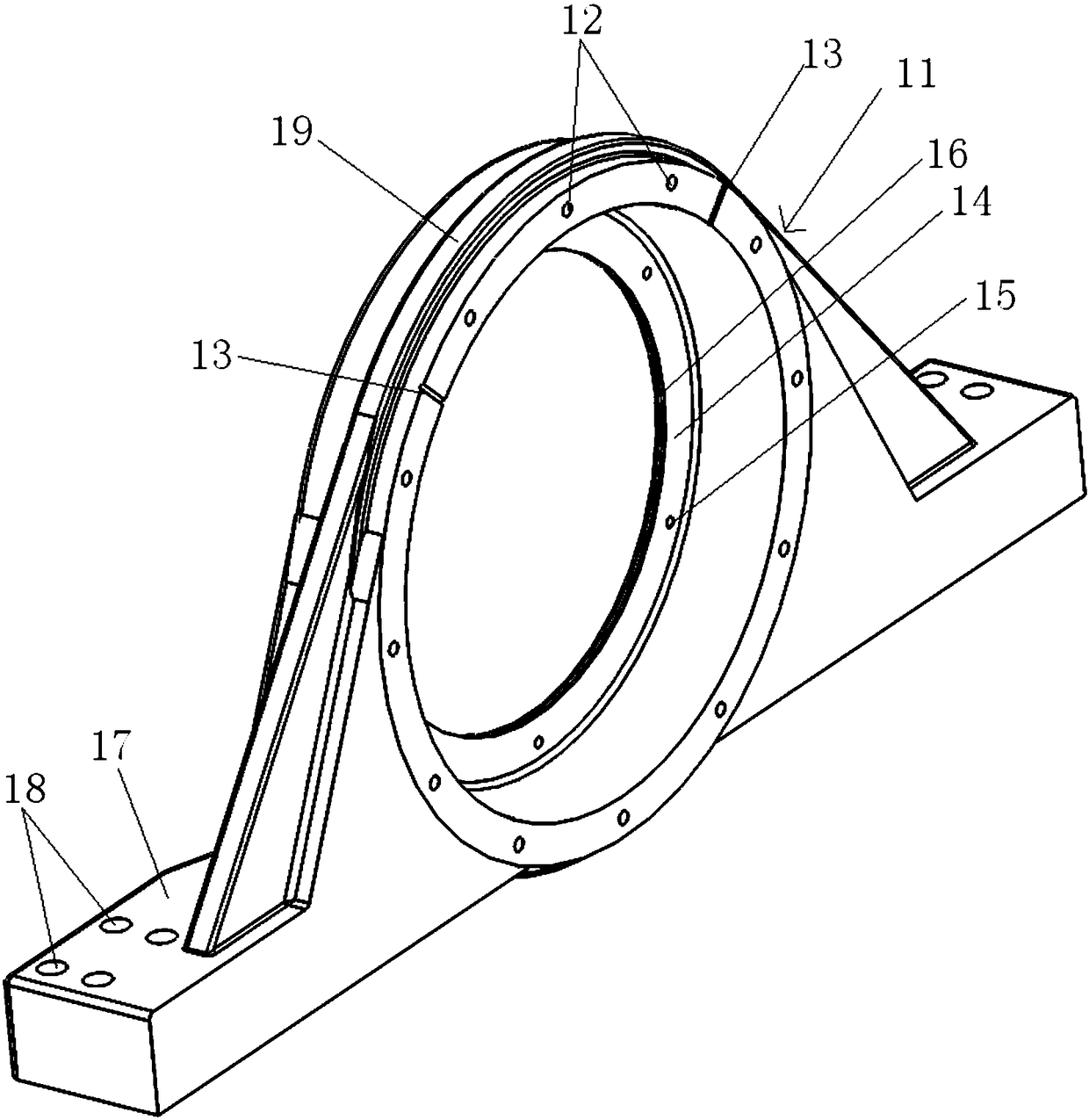

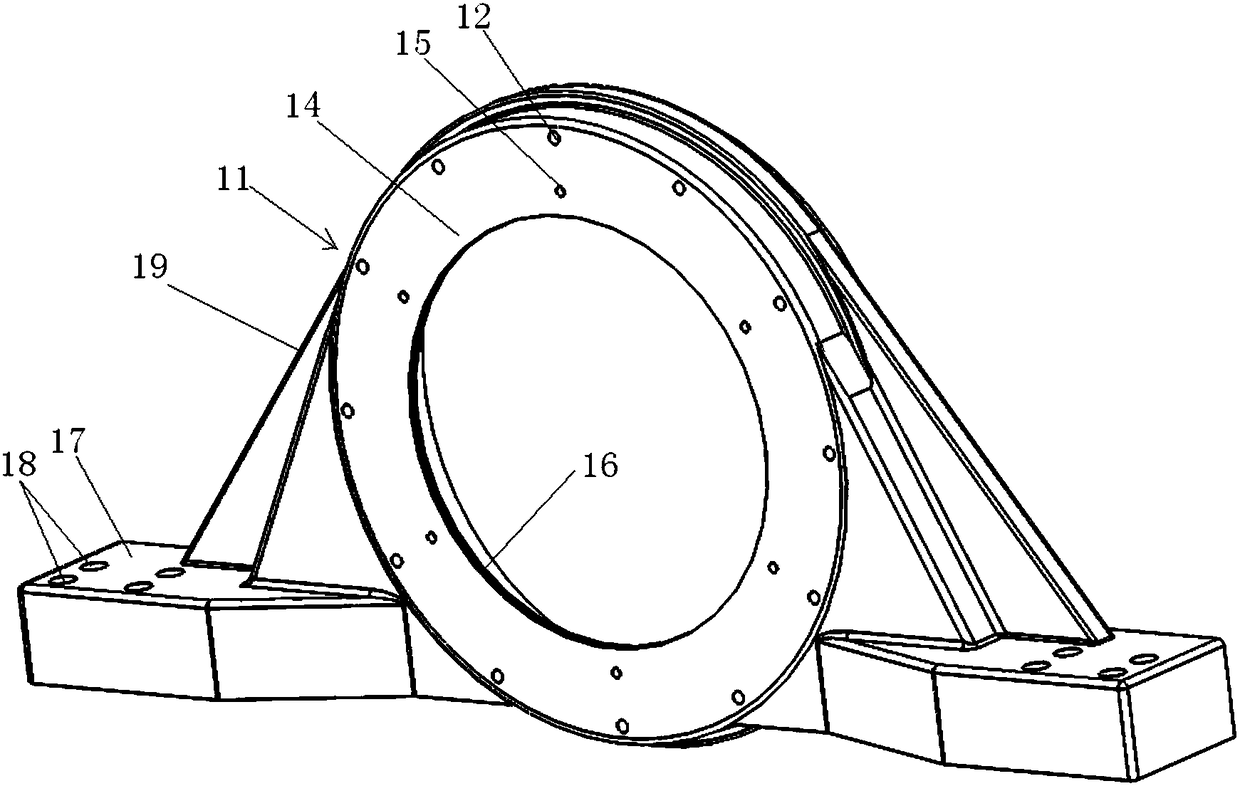

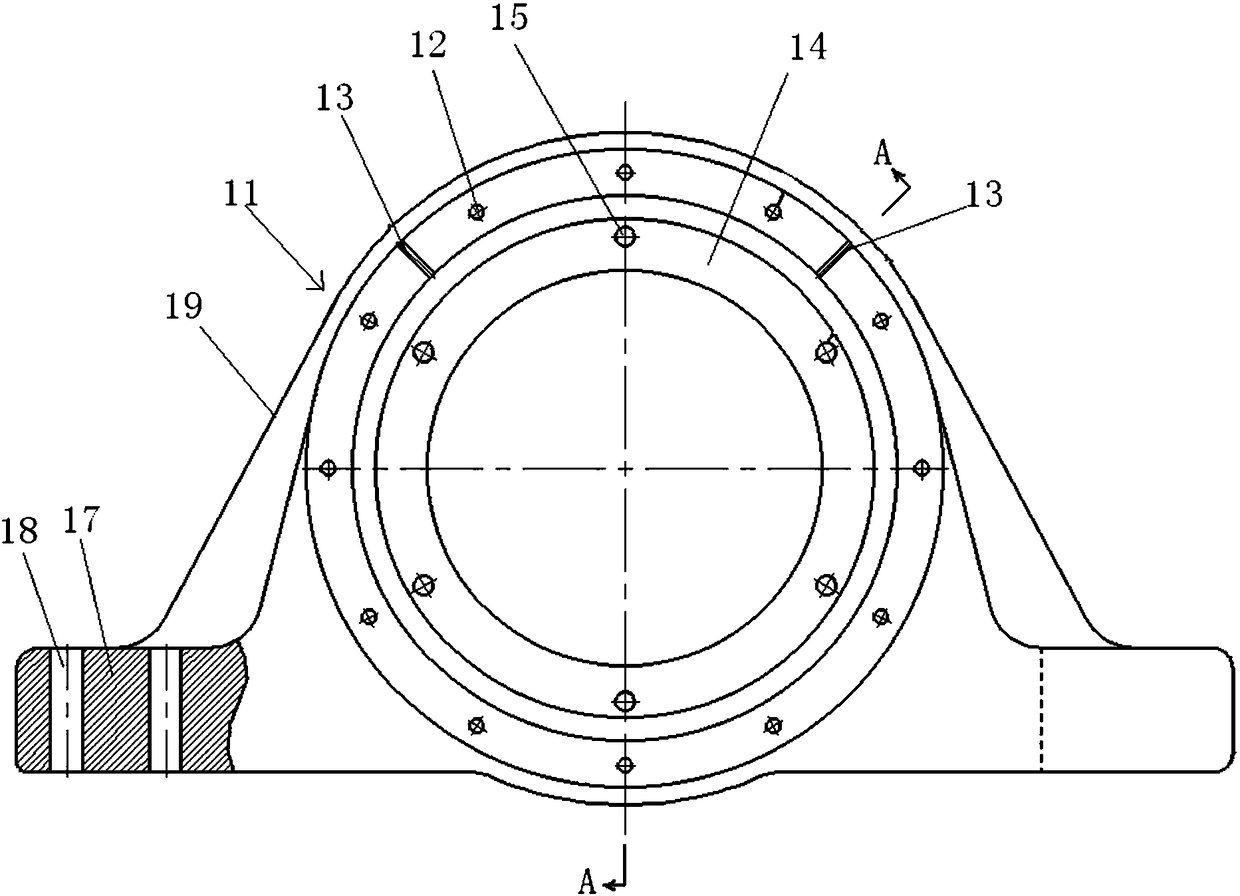

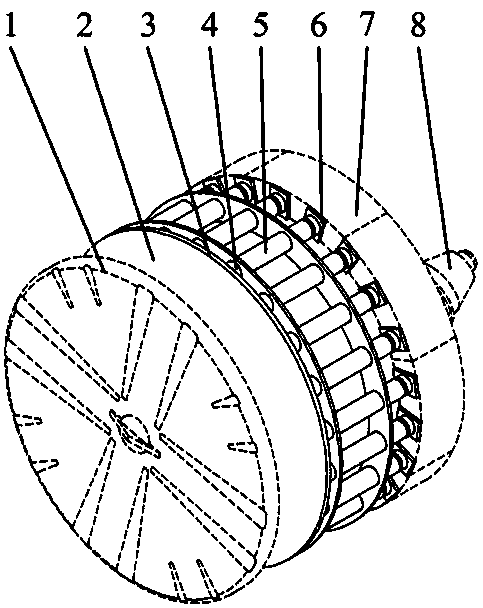

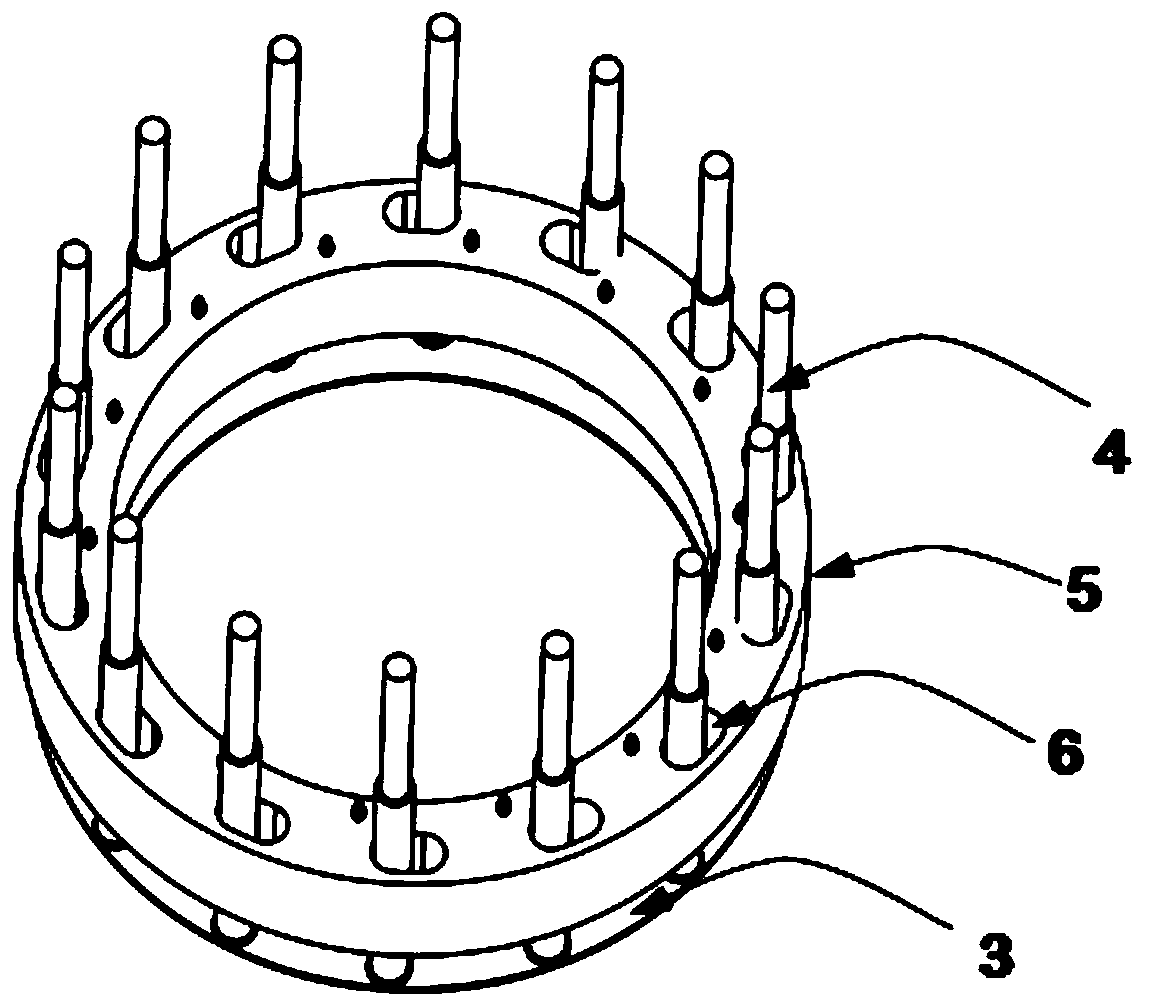

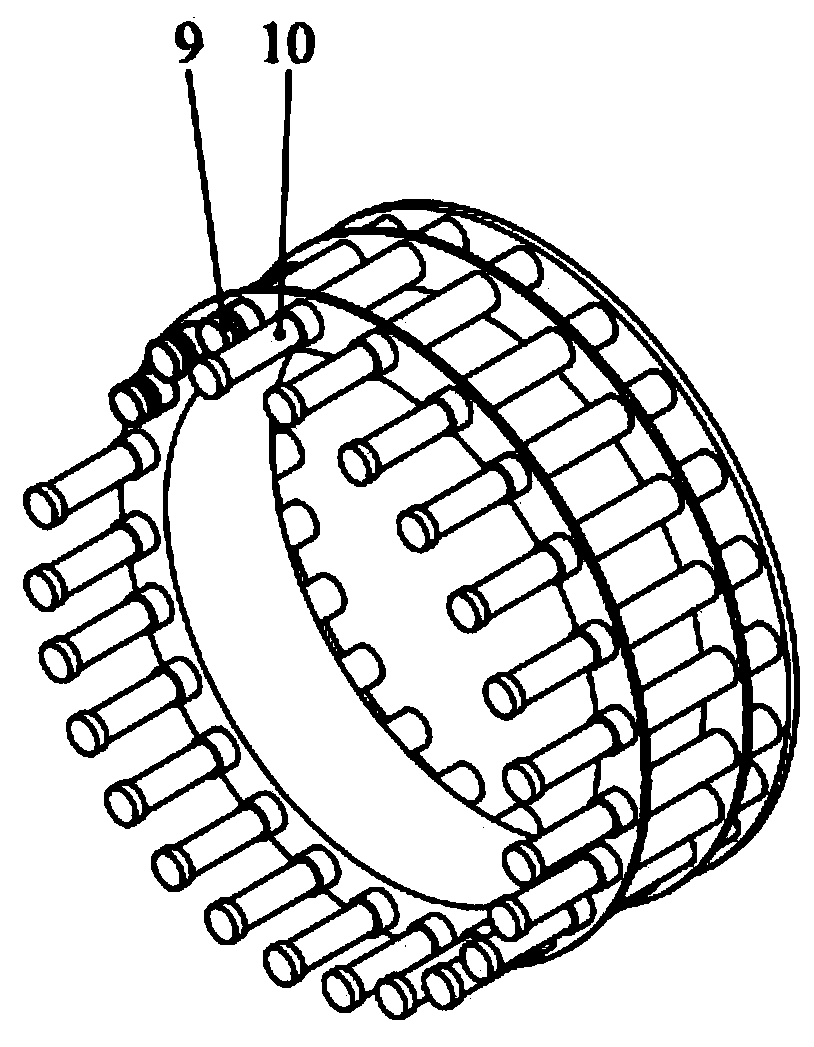

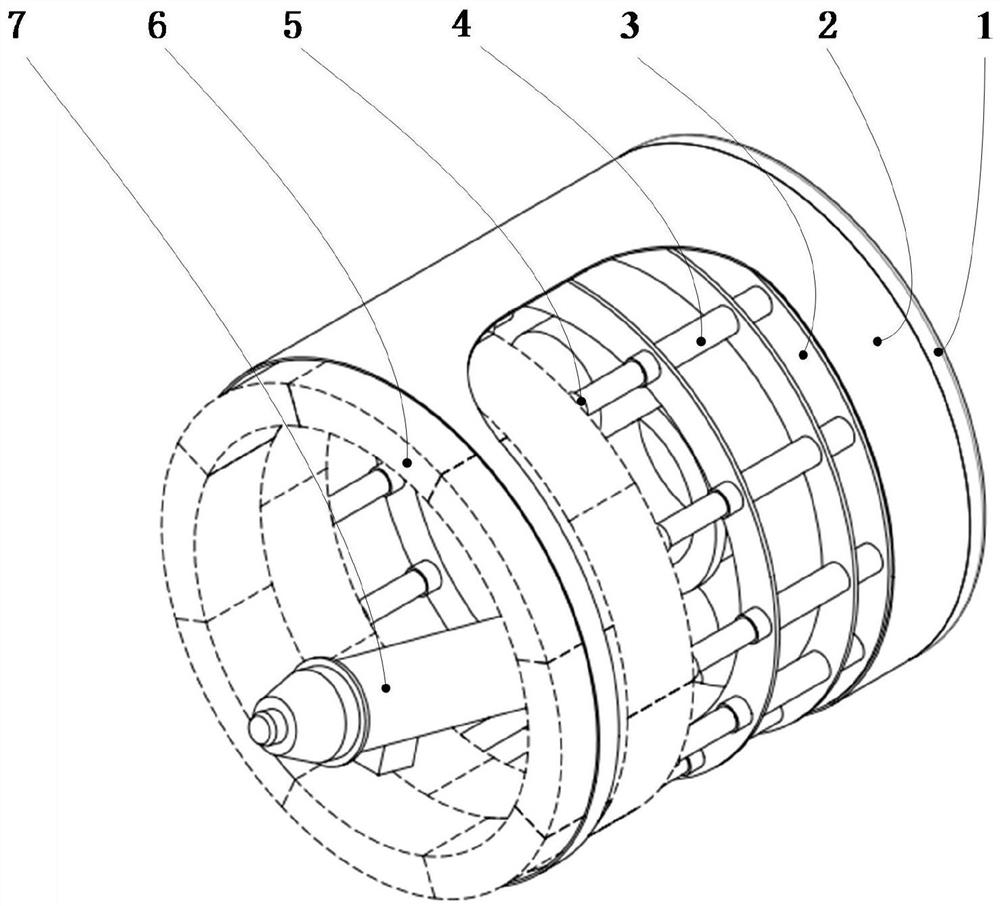

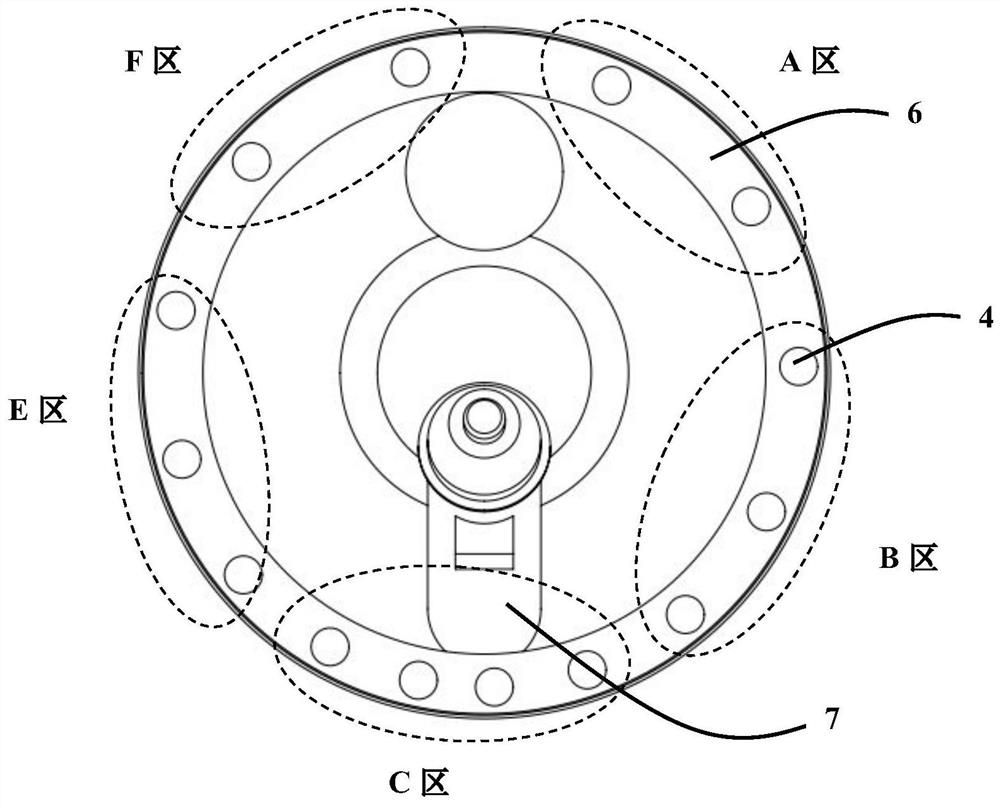

Modular centering bearing device

PendingCN108266456ARealize the centering functionEasy to useRoller bearingsBearing unit rigid supportModular designModularity

The invention discloses a modular centering bearing device, which comprises a division bearing box and a conical roller bearing arranged in the division bearing box, wherein the outer surface of the outer ring of the conical roller bearing and the radial surface of the inside of the bearing box are in gap matching by using a spherical surface structure. The conical roller bearing is a double-row conical roller bearing. The division bearing box comprises two bearing box units in symmetrical arrangement; the two bearing box units are connected through screw bolts; a radial oil injection hole isformed in the bearing box unit; an oil groove communicating with the oil injection hole is formed in the middle of the outer surface of the outer ring of the conical roller bearing along the circumference; a plurality of oil inlet holes are formed in the bottom of the oil groove. The advantages of the conventional centering roller bearing and the conical roller bearing are merged; the prestress caused by assembly errors in the assembly can be effectively avoided; the unbalance loading phenomenon can also be avoided. The modular design is used; the processing is convenient; the assembly is facilitated; the device is suitable for being used as thrust bearings capable of bearing radial loads and axial loads.

Owner:GUODIAN UNITED POWER TECH

Four-corner leveling device of novel rapid hydraulic machine

The invention relates to the technical field of hydraulic machine devices, in particular to a four-corner leveling device of a novel rapid hydraulic machine. The four-corner leveling device comprises an oil cylinder, a piston rod, a piston and a flange. Leveling cylinders are arranged below the piston and fixedly installed on the four corners of the lower end of a hydraulic machine body. Displacement sensors are arranged at the bottom portions of the leveling cylinders and connected with a control assembly. By the adoption of the structure, when sliding block assemblies of the hydraulic machine move downwards to be combined with a die, adjustable threaded rods on the four corners of the sliding block assemblies make contact with the four leveling cylinders, workpieces to be pressed are prevented from unbalance loading, it is guaranteed that the thickness of the pressed workpieces is uniform and the same, pressed product scrap is avoided, product quality is effectively improved, and production cost is reduced.

Owner:JIANGSU SHENXIANG ELECTROMECHANICAL +1

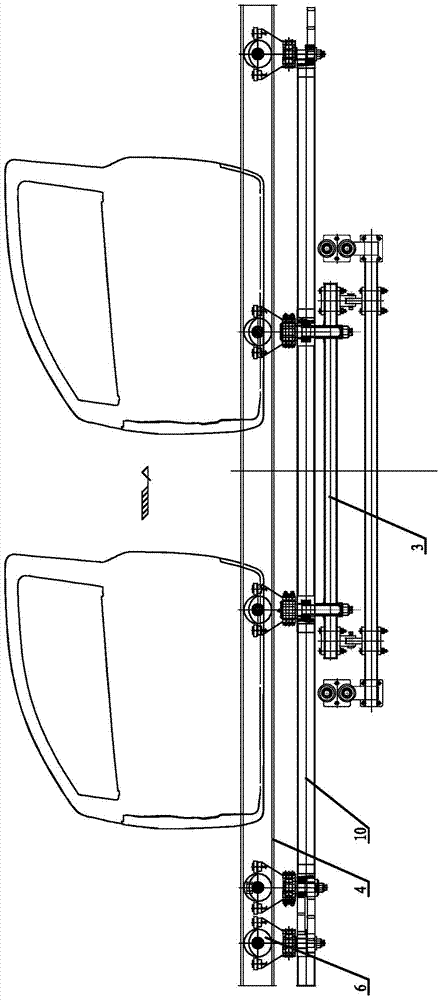

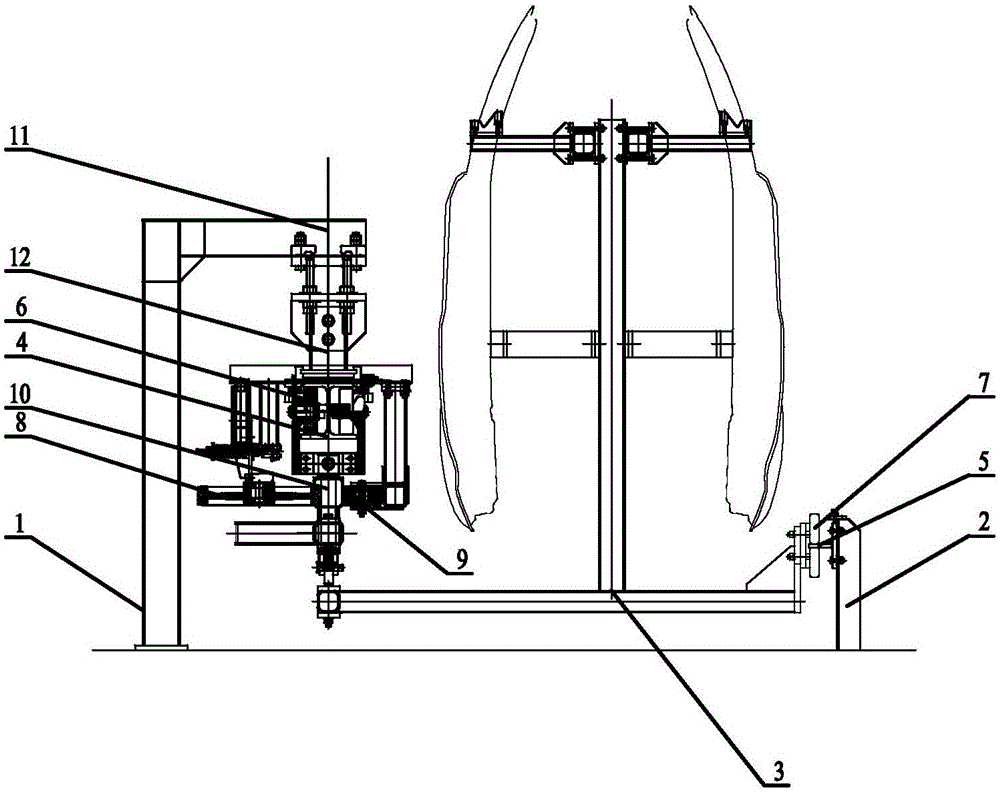

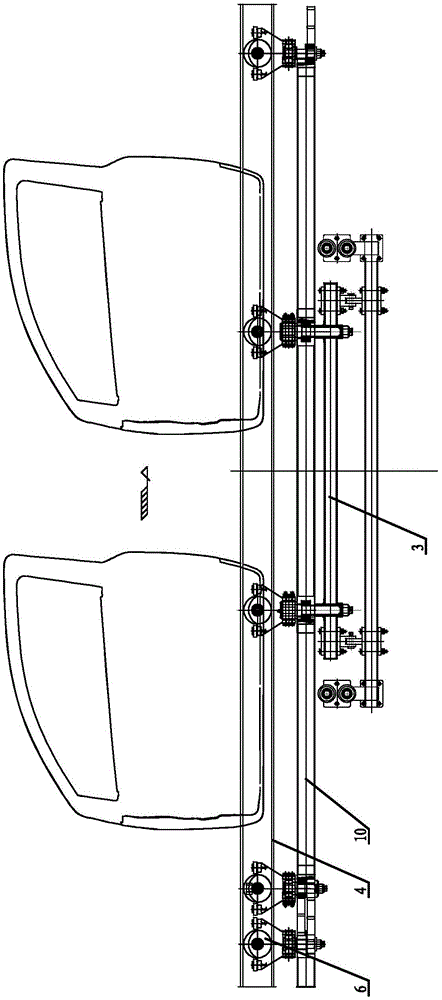

Suspension type ground friction conveying line

ActiveCN103523482ALower installation heightAvoid unbalanced load phenomenonMechanical conveyorsEngineering

The invention relates to a suspension type ground friction conveying line. An auxiliary track installing support is fixedly installed on the outer side of a main track installing column, a main track is fixed on the main track installing column and suspended above plant area ground, a straightening track is fixed on the auxiliary track installing support, walking wheels are arranged in the main track, every two adjacent walking wheels are connected through a connecting rod, a straightening wheel is arranged in the straightening track, the walking wheels and the straightening wheel are installed on a workpiece support, a driving friction wheel and a driven friction wheel are installed on the main track installing column, and the connecting rod is located between the driving friction wheel and the driven friction wheel. According to the suspension type ground friction conveying line, the total installing height is reduced, the problem that paint is sprayed on a conveying line body at a paint spraying station is avoided, maintenance and safety are enhanced, and an auxiliary walking track is installed additionally simultaneously to avoid an eccentric load.

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

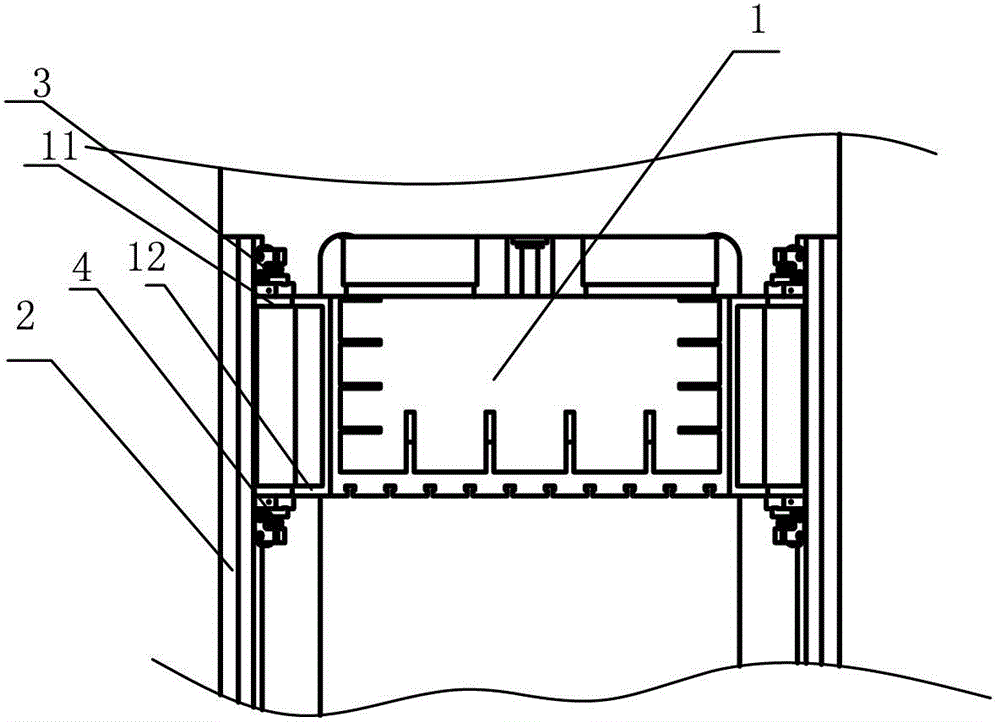

Guide device for slide beam of hydraulic machine

ActiveCN103358576BAvoid unbalanced load phenomenonWorks smoothly up and downPress ramHydraulic cylinderCoupling

The invention discloses a guide device for a slide beam of a hydraulic machine. An upper guide assembly is mounted on the upper end surface of the slide beam; a lower guide assembly is mounted on the lower end surface of the slide beam; the upper guide assembly comprises an L-shaped bracket, a hydraulic cylinder and a roller wheel; one free end of the L-shaped bracket is a coupling end; the roller wheel is coupled to the corner of the L-shaped bracket; a piston rod of a hydraulic cylinder is contacted with another free end of the L-shaped bracket. When the piston rod of the hydraulic cylinder extends out of the hydraulic cylinder, the L-shaped bracket deflects by taking the coupling end as a center, and the roller wheel on the L-shaped bracket is contacted with a guide column. The guide device has the advantages that the roller wheel acts on the column surface of the guide column under the action of the piston rod of the hydraulic cylinder when the slide beam moves up and down; as the roller wheel is in rolling friction with the surface of the guide column, the unbalanced load phenomenon caused when the slide beam moves up and down is avoided and the slide beam can very stably move up and down under the circumstance that the moving speed is more than 800 mm / s.

Owner:NINGBO HENGWEILI HYDRAULIC EQUIP

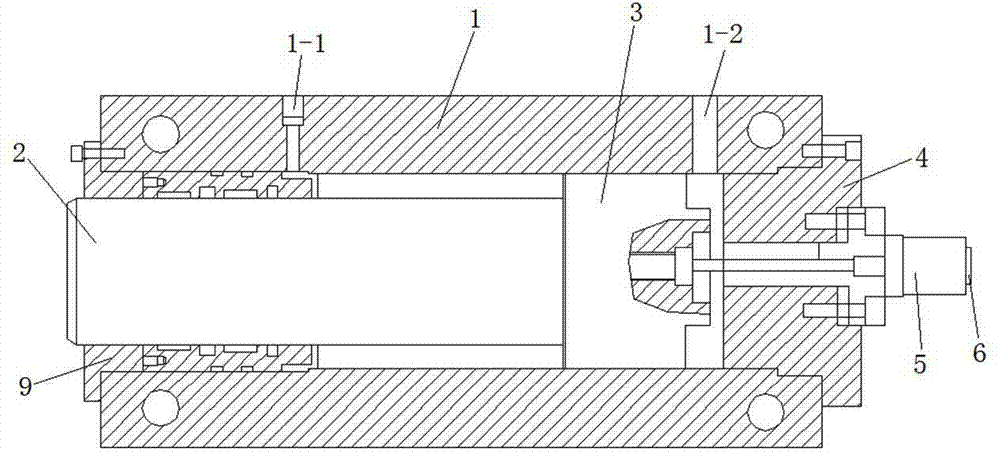

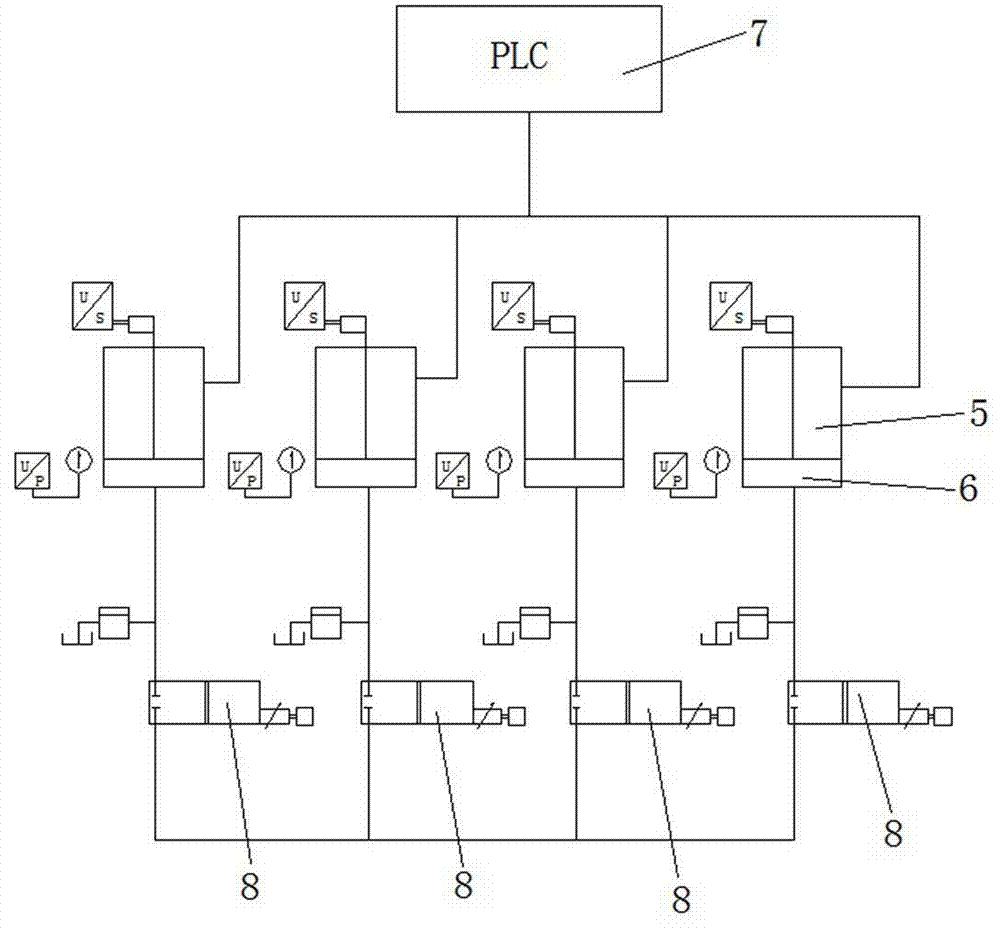

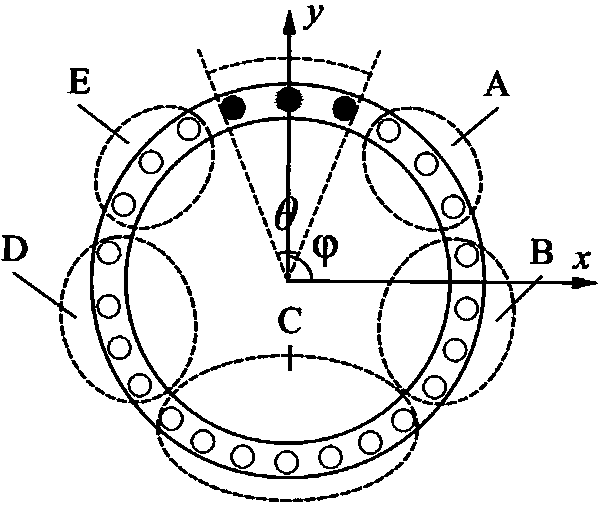

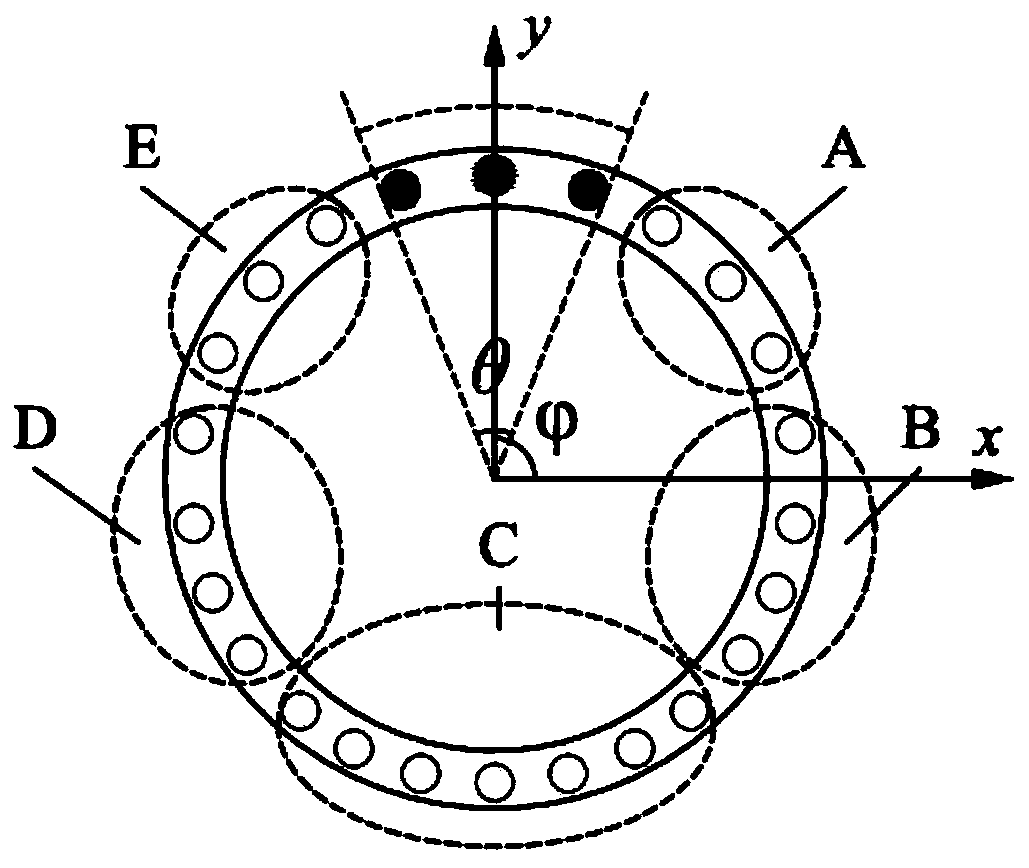

A shield propulsion system control method for anti-offset load

ActiveCN109026041BIncrease the scope of geological applicationImproved thrust transfer characteristicsTunnelsHydraulic cylinderClassical mechanics

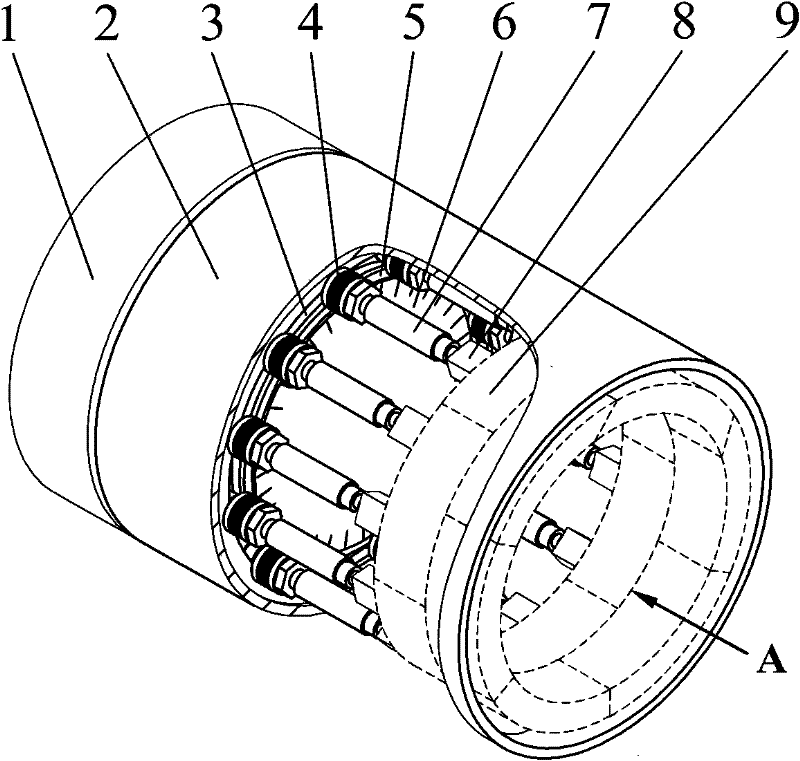

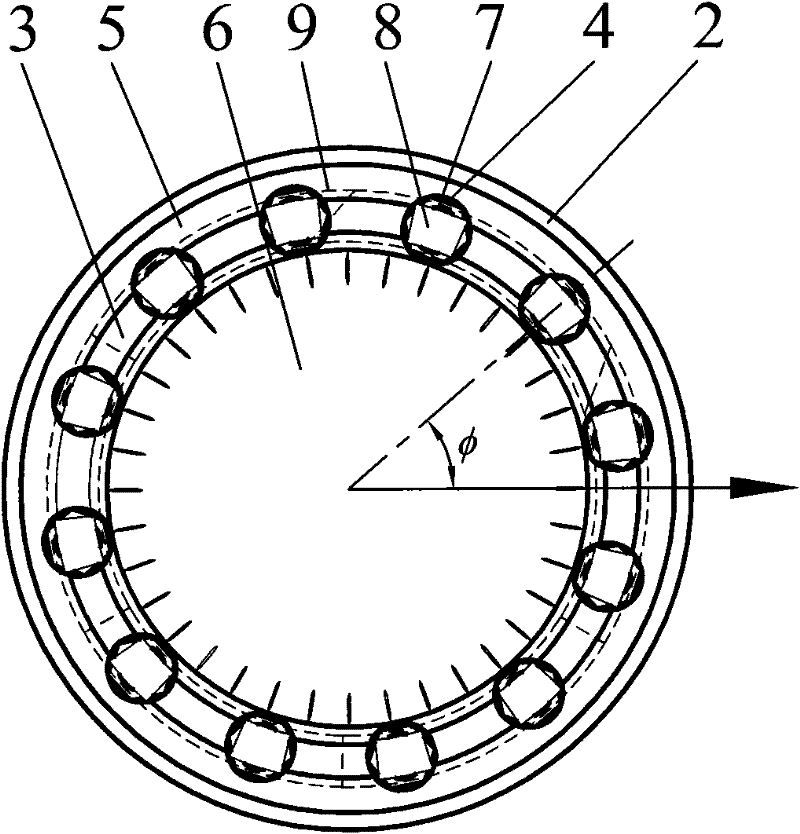

The invention discloses a shield propulsion system control method for eccentric load prevention, wherein the method belongs to the field of tunnel engineering technology. On the system according to the invention, a circular separator plate is fixedly connected with a shield body. Rock and soil which are cut by a cutterhead are conveyed out through a spiral conveyor. The right end of a hydraulic jack abuts against a pipe plate through a supporting boot. Furthermore the whole shield is pushed to perform frontward propulsion through a reaction force on a pipe plate. All hydraulic cylinders in thepropulsion system are uniformed arranged. According to the shield propulsion system control method, a radian theta and an azimuth phi are calculated according to geomechanics parameters in shield propulsion, thereby starting or stopping the hydraulic cylinder sets which are annularly, equidistantly and continuously arranged in the propulsion system. The control method according to the invention can adjust distribution of the hydraulic cylinders in real time, thereby setting an eccentric load problem in shield propulsion.

Owner:HUNAN UNIV OF SCI & TECH

Conveying device and front cabin collection system for flotsam and weed collection

ActiveCN105501815BImprove stabilityExtended service lifeConveyorsWater cleaningCollection systemDrive shaft

The invention relates to a conveying device suitable for collecting floating objects and water plants and a front cabin collecting system. The conveying device comprises a driving shaft, a transmission shaft, motors, chain wheels, transmission chains and conveyer belts, wherein the conveyer belts are row chain type conveyer belts; the transmission chains are hollow pin shaft chains. The conveying device further comprises supporting strips, supporting poles and steel hook sheets, wherein the supporting strips are positioned between the two chain wheels on the same side and are used for supporting the hollow pin shaft chains; the supporting poles are positioned in the row chain type conveyer belts and are used for supporting the row chain type conveyer belts; the steel hook sheets can be arranged on the row chain type conveyer belts in a detached manner; the supporting strips comprise supporting bodies which are arranged in the length direction of the hollow pin shaft chains, and convex strips arranged on the supporting bodies; rollers of the hollow pin shaft chains are erected on the convex strips. According to the conveying device and the front cabin collecting system disclosed by the invention, under the assistance of the supporting strips and the supporting poles, the stability of the conveying device is improved, the occurrence of an eccentric load phenomenon caused by too wide conveyer belts is avoided, and the service life of the conveying device is prolonged.

Owner:FEICHI ENVIRONMENTAL PROTECTION TECH INC CO LTD

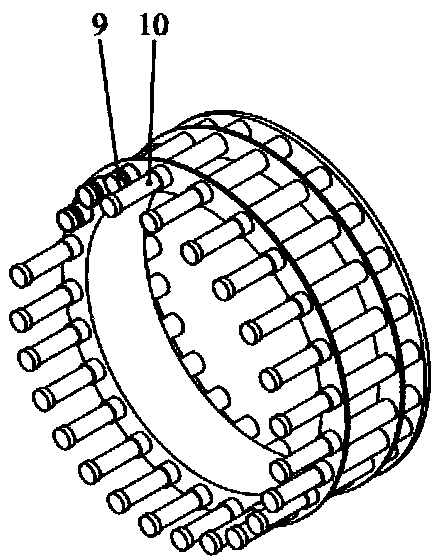

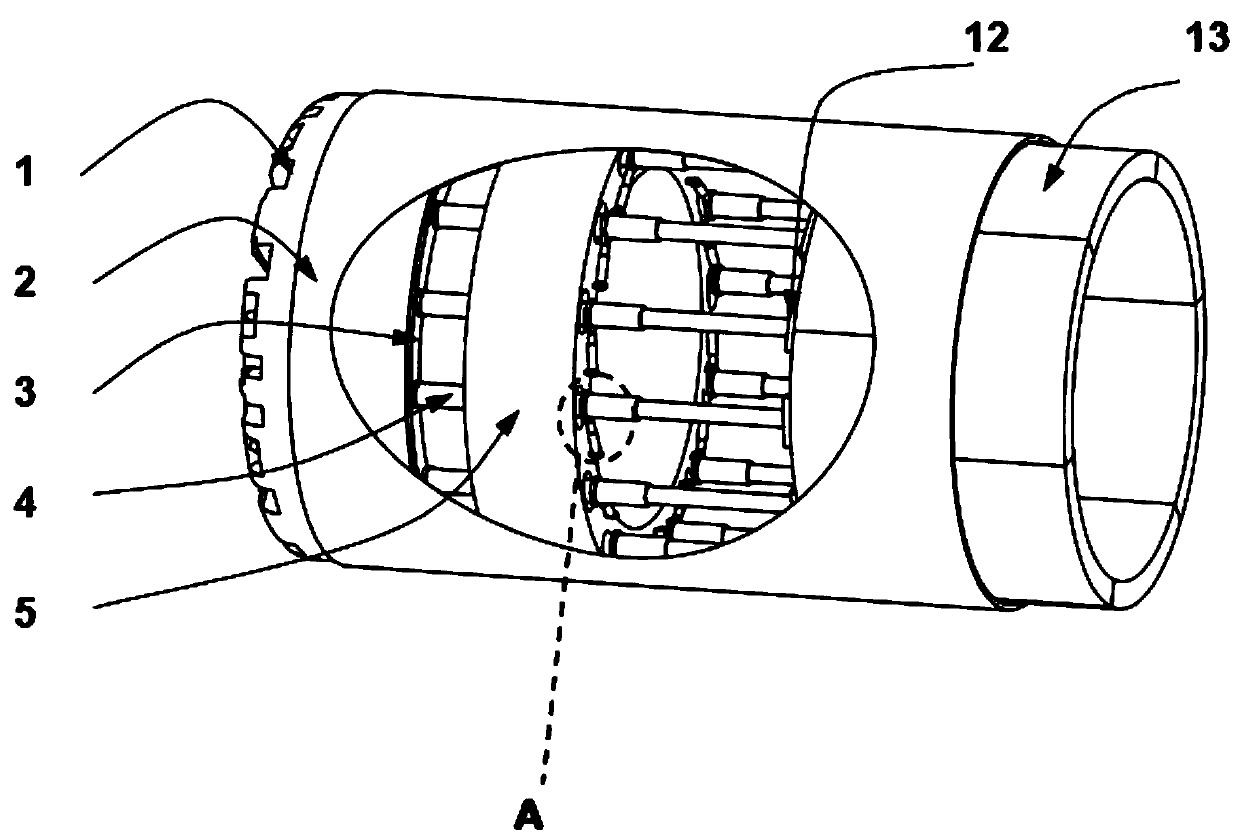

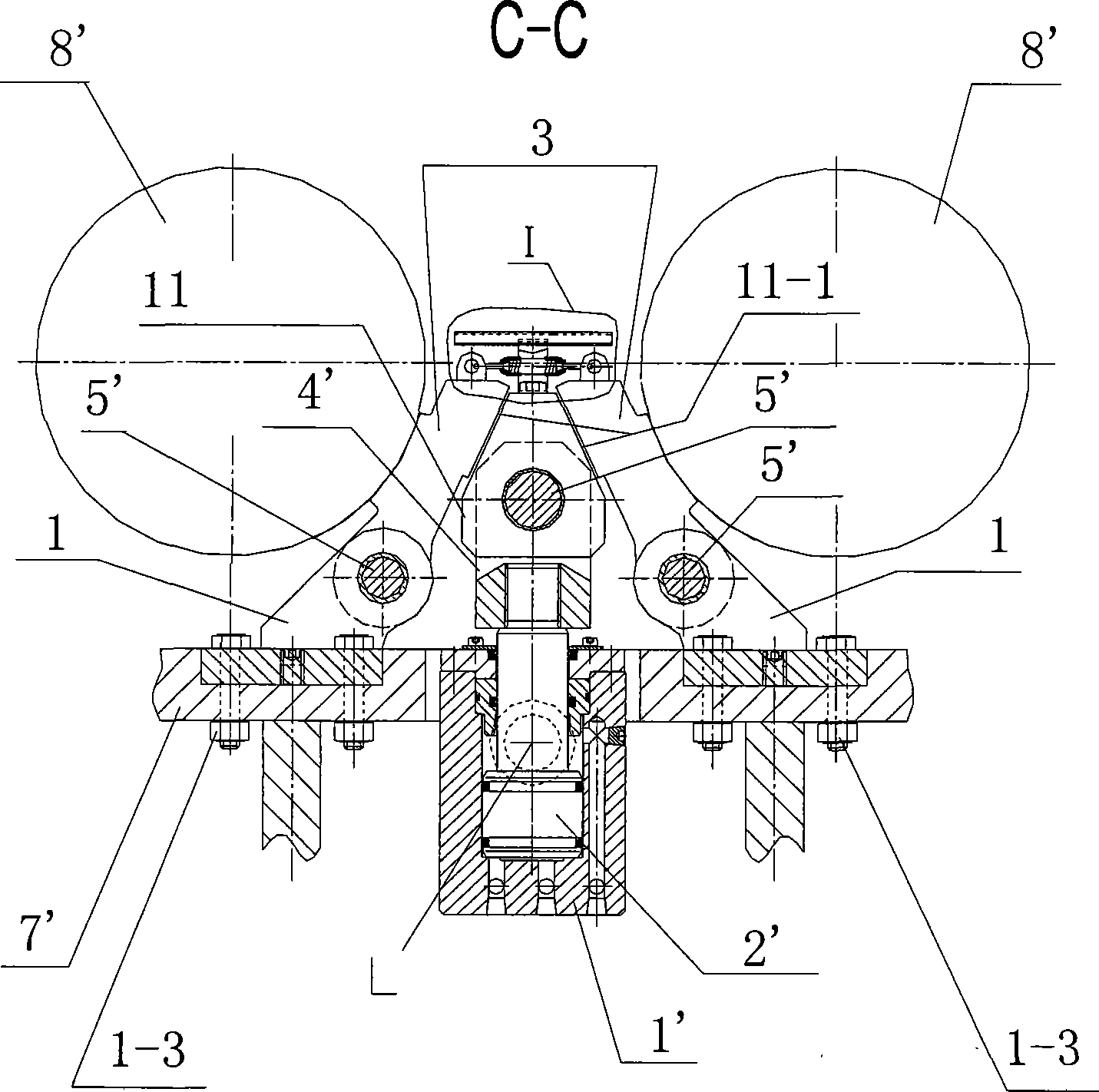

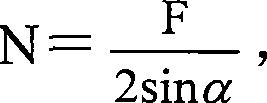

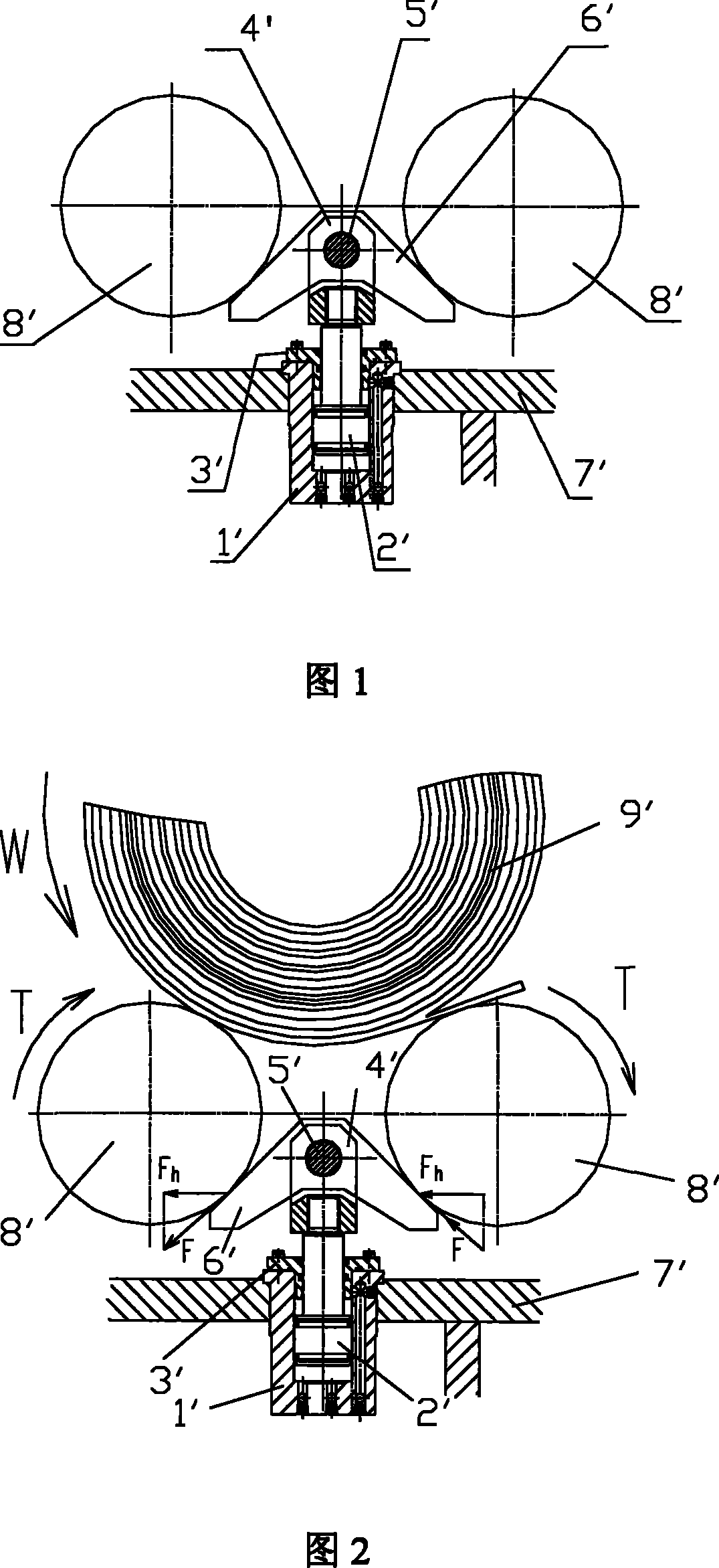

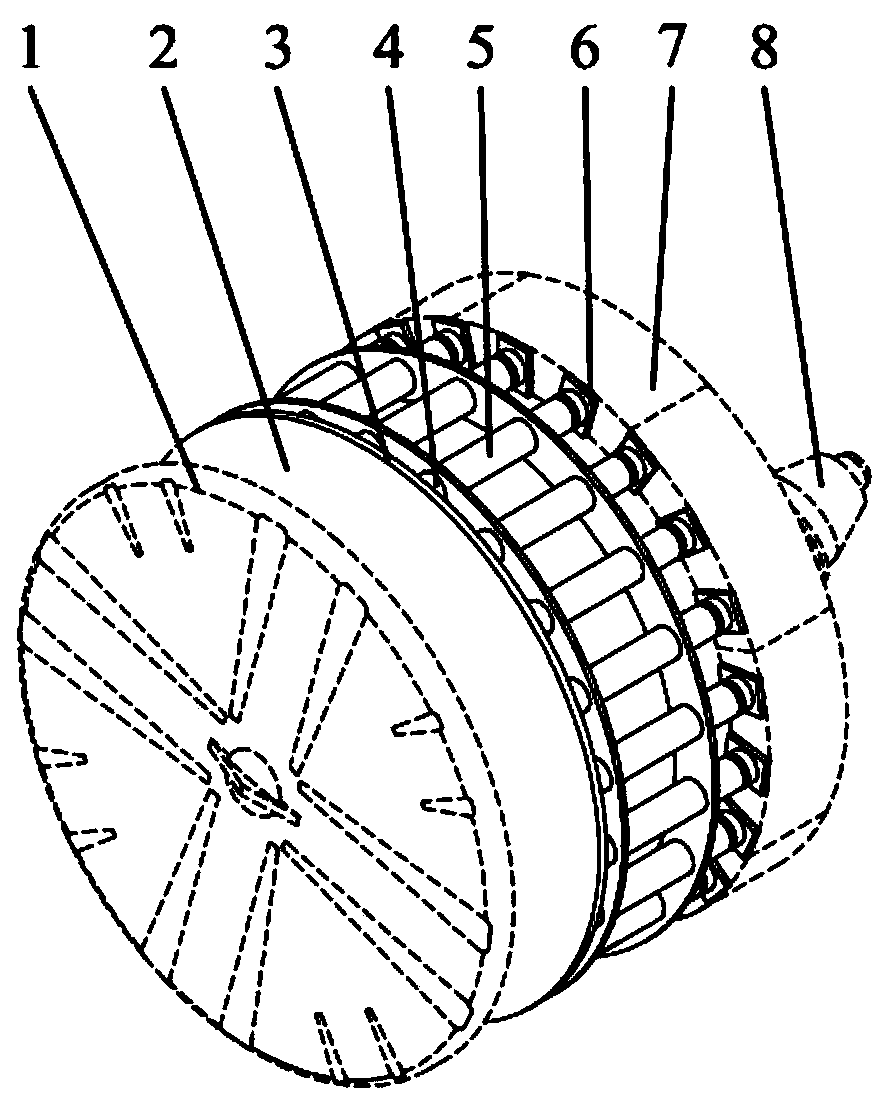

Adjustable propulsion mechanism for soil pressure balance type shield

InactiveCN101649743BAvoid unbalanced load phenomenonIncrease the scope of geological applicationTunnelsJackscrewEngineering

The invention discloses an adjustable propulsion mechanism for a soil pressure balance type shield, which belongs to the technical field of tunnel engineering. A middle junction fixedly connected with propulsion jacks are arranged on a circular T-shaped chute of a chute barrier plate; a circular disk of the middle junction is arranged in the T-shaped chute; a pressure piece, a spring and a loading piece of the middle junction are sequentially sleeved on a cylinder of a top body and pressed on the chute barrier plate by adjusting nuts; a pressure resistant hard rubber block is fixedly connected with the circular disk of the top body; the chute barrier plate is fixedly connected with a dial and a shield and one end of the propulsion jack is supported on a supporting barrier acted on a pipe piece. Because the middle junction is connected with the chute barrier plate in a sliding mode, the distance between the propulsion jacks is adjustable and the distribution of the propulsion jacks canbe optimized according to the concrete working geologic parameter of the shield and the deadweight of the shield, thereby overcoming the unbalance loading phenomenon of the shield due to special geologic conditions, or the deadweight or reversal loads. The adjustable propulsion mechanism is suitable for a soil pressure balance type shield.

Owner:TSINGHUA UNIV

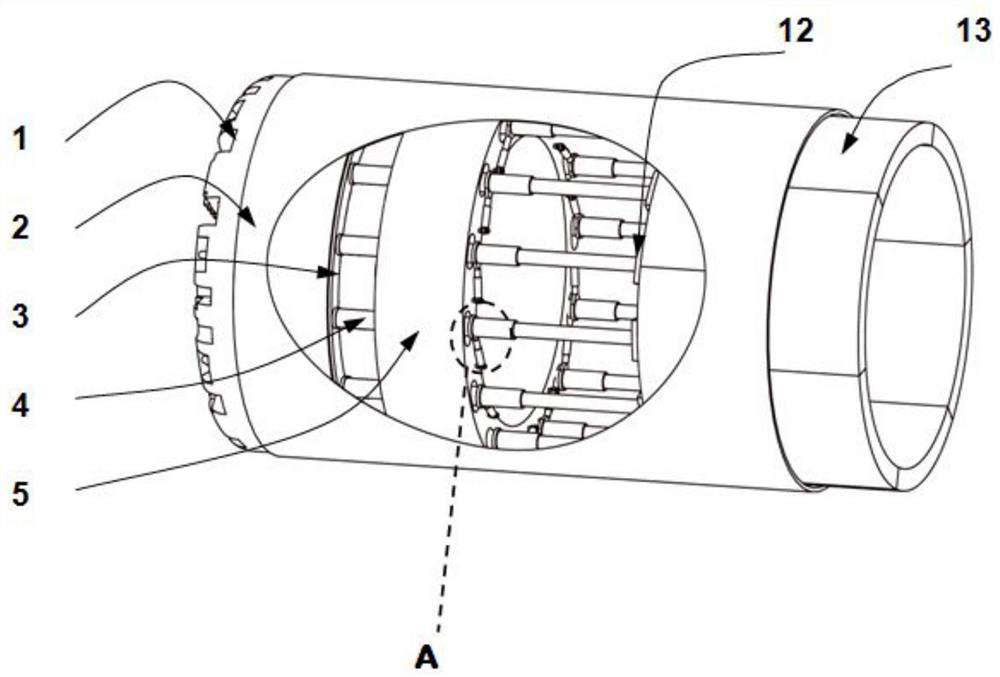

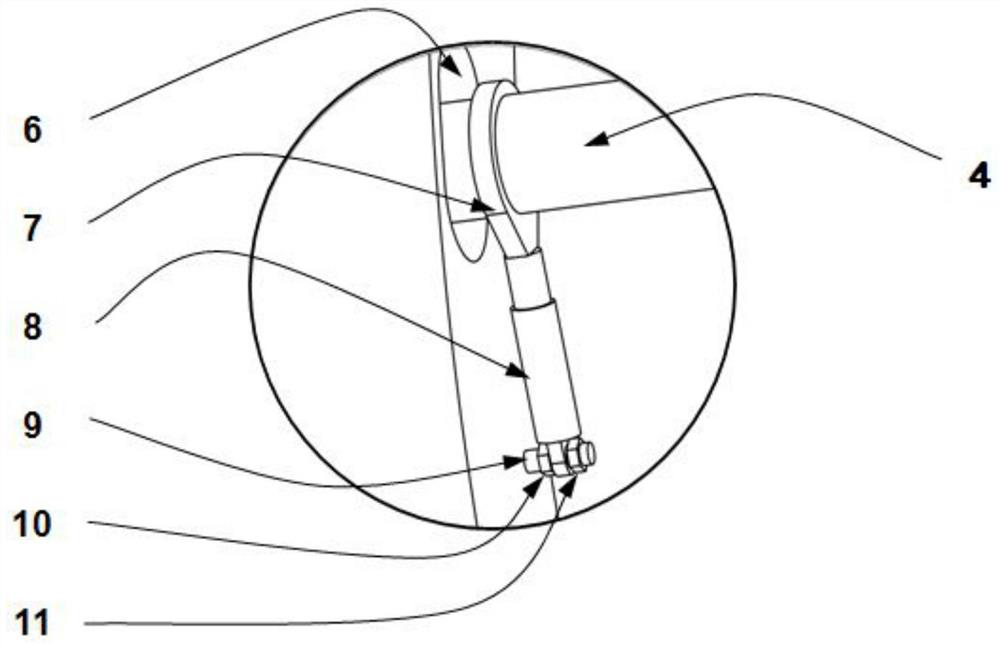

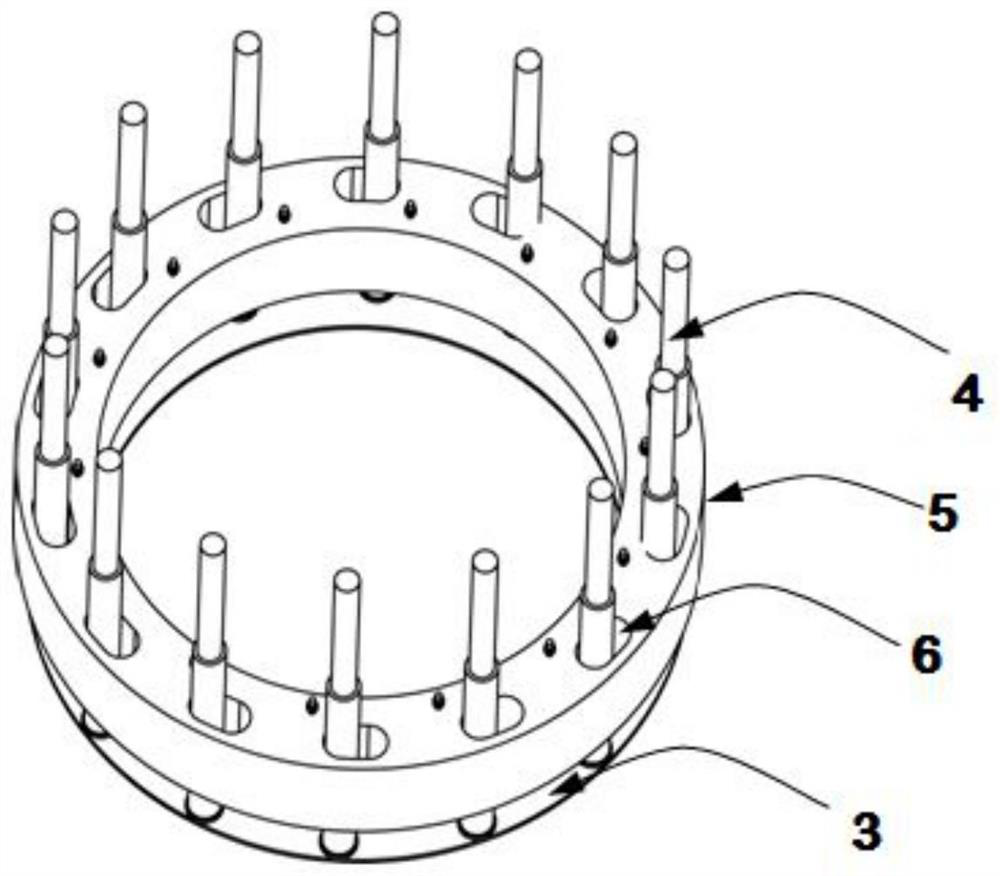

Hydraulic cylinder arrangement control mechanism for shield tunneling machine

ActiveCN109826638AAvoid unbalanced load phenomenonIncrease the scope of geological applicationTunnelsHydraulic cylinderPush and pull

The invention discloses a hydraulic cylinder arrangement control mechanism for a shielding tunneling machine. The hydraulic cylinder arrangement control mechanism comprises a shield body, a partitionplate, hydraulic cylinders, a supporting frame and a push-and-pull device; the supporting frame is arranged inside the shield body and fixedly connected with the shield body, the partition plate is arranged in the shield body, multiple groove holes are formed in the supporting frame in the extension direction of the axis of the shield body, and formed in the supporting frame around the axis of theshield body, the hydraulic cylinders penetrate through the groove holes, one ends of the hydraulic cylinders are backed on the side face of the partition plate, and the other ends of the hydraulic cylinders are jacked on duct pieces through support boots; the hydraulic cylinders are arranged around the axis of the shield body, one end of the push-and-pull device is hinged to hydraulic cylinder bodies, the other end of the push-and-pull device is hinged to the supporting frame, and the push-and-pull device is used for rotating the hydraulic cylinders around the axis of the shield body for adjustment. By means of the hydraulic cylinder arrangement control mechanism for the shielding tunneling machine, when a shield propelling system tunnels a compound stratum, the positions of the hydrauliccylinders can be changed at the right time, layout optimization is achieved, and thus the shield tunneling efficiency is improved.

Owner:HUNAN UNIV OF SCI & TECH

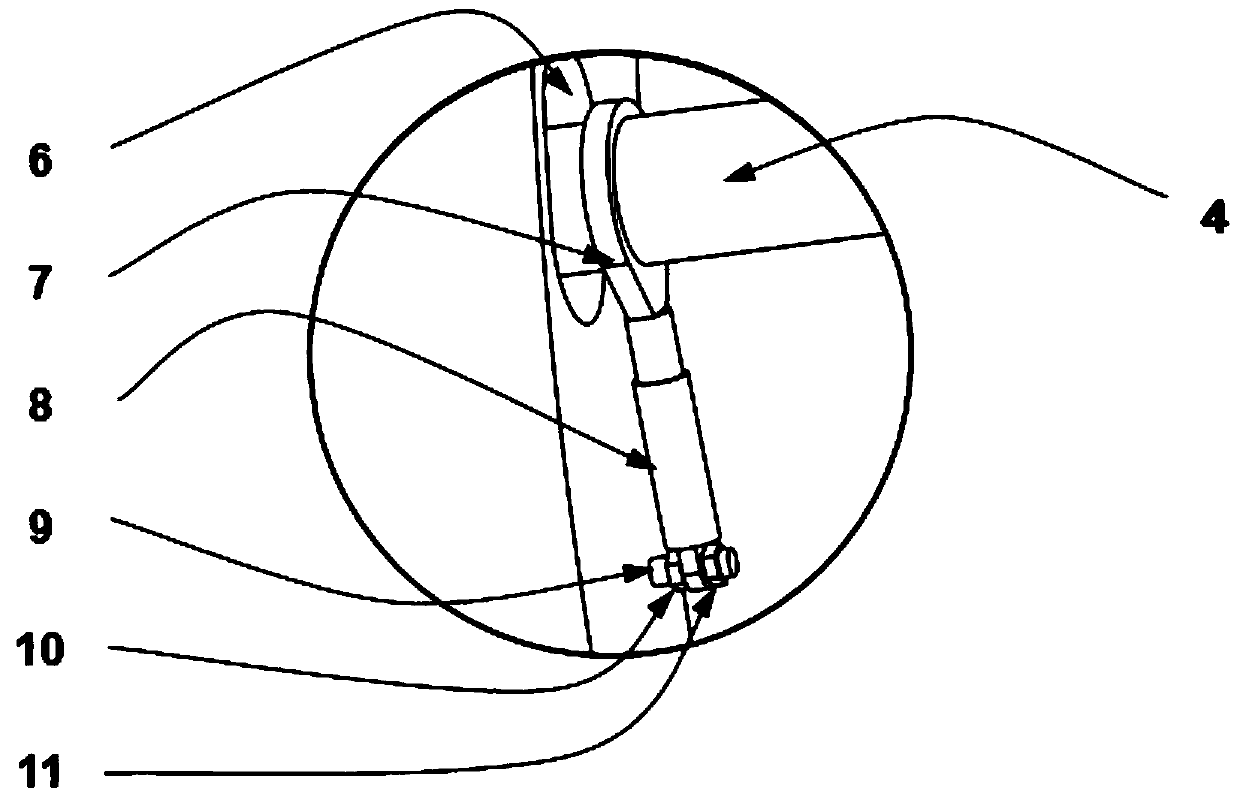

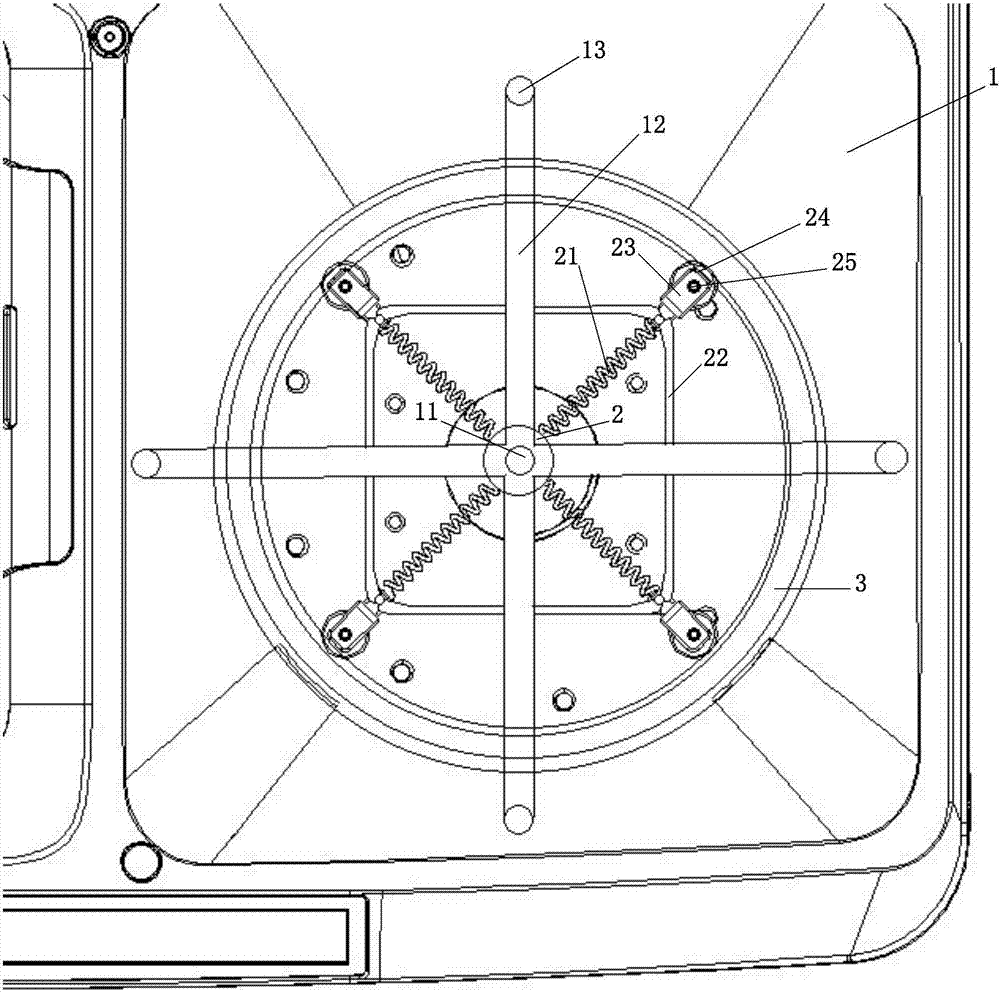

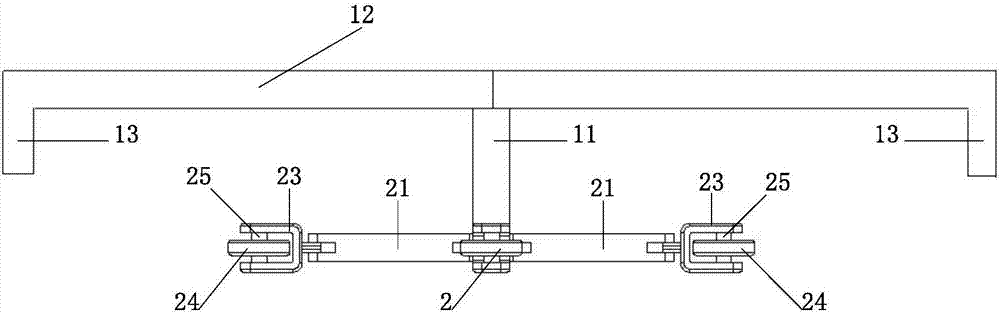

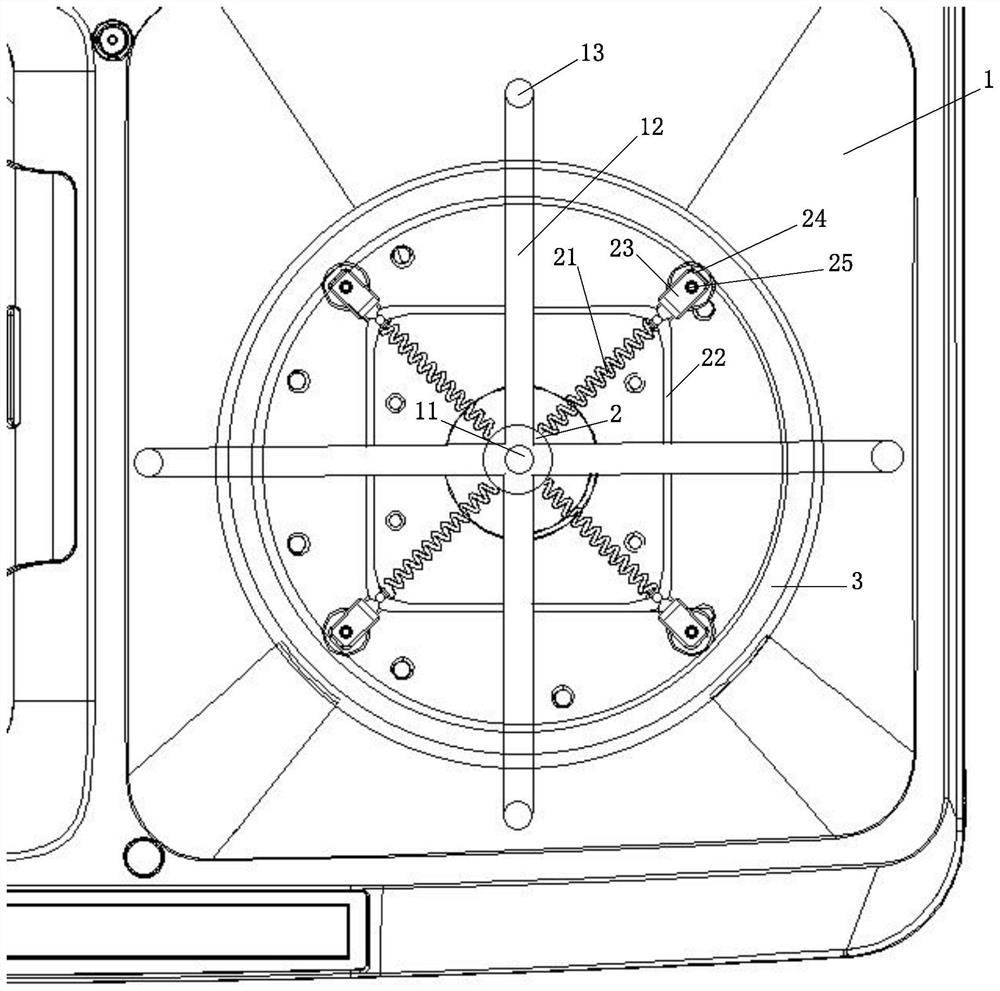

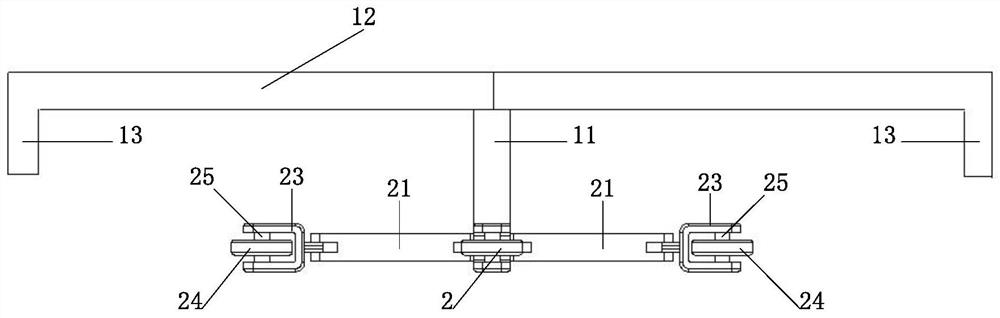

Anti-unbalance-loading device for drum and washing machine

ActiveCN107190471AAvoid unbalanced load phenomenonOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention relates to an anti-unbalance-loading device, and particularly provides an anti-unbalance-loading device for a drum. The anti-unbalance-loading device aims at solving the problems that the anti-unbalance-loading effect of an existing anti-unbalance-loading device for a drum is poor, and the drum is extremely easy to wear. The anti-unbalance-loading device for the drum comprises a fixing assembly capable of being fixed on a shell and a flexible unbalance-loading absorbing assembly. The fixing assembly comprises a supporting part located in an opening area of the drum, and the flexible unbalance-loading absorbing assembly comprises at least two elastic pieces capable of rotating relative to the supporting part or the drum wall; meanwhile, one end of each elastic piece is connected to the supporting part, and the other end of each elastic piece is connected to the drum wall of the drum. The fixing assembly can provide the stable supporting effect for the anti-unbalance-loading device, and when the drum rotates, the flexible unbalance-loading absorbing assembly can adjust swinging generated by the drum in time, rotating of the drum can be in the balance state as quickly as possible under the adjustment effect, and therefore occurrence of the unbalance-loading phenomenon is effectively prevented.

Owner:HEFEI HAIER WASHING MACHINE +1

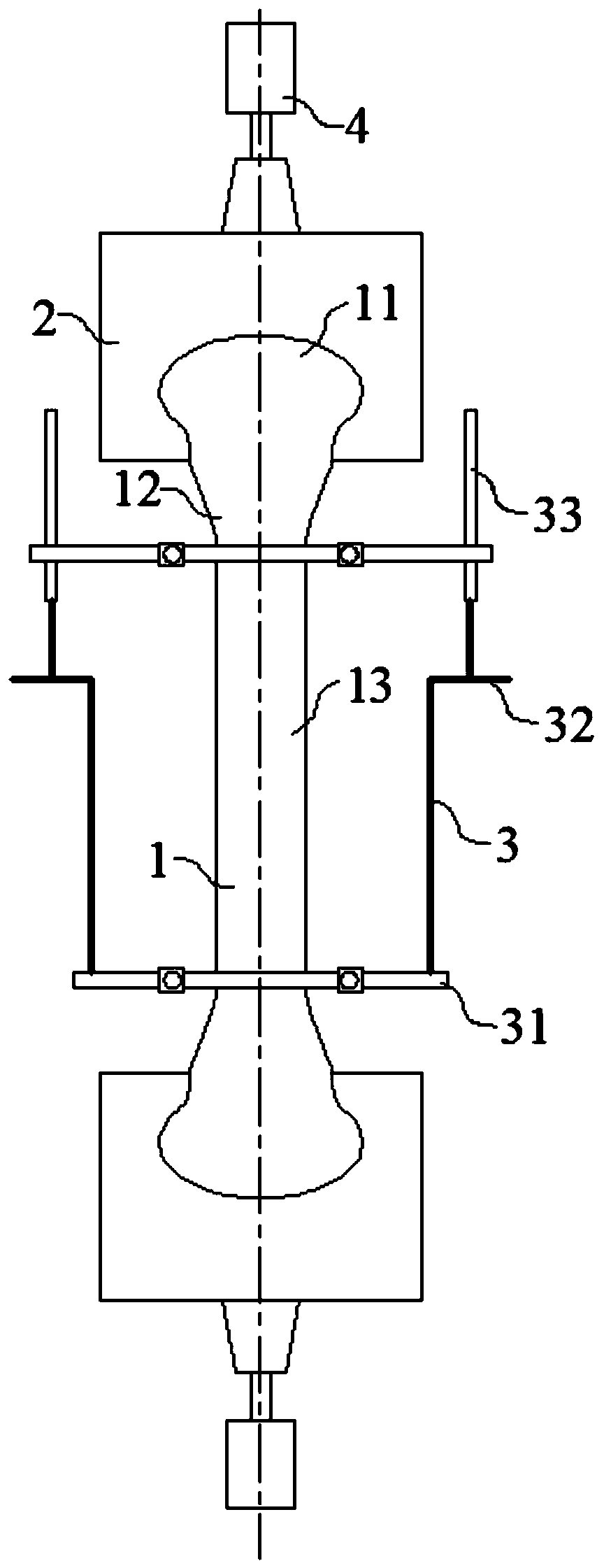

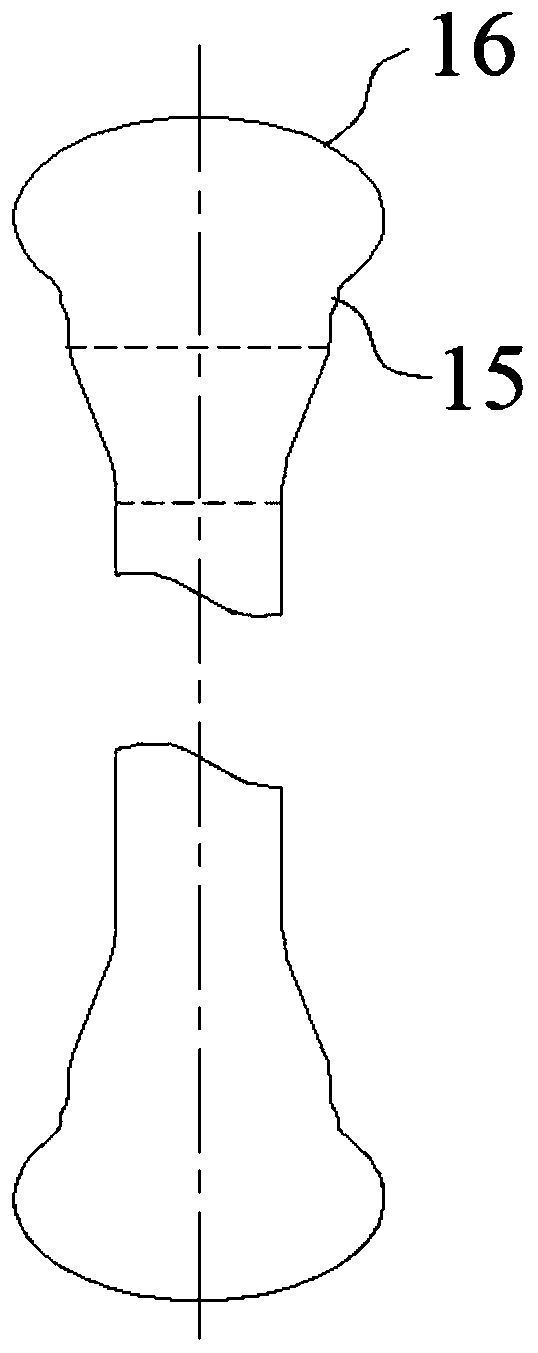

Fiber-reinforced concrete uniaxial tensile performance test specimen and its test method

ActiveCN109459310BGood contact fitLess prone to stress concentrationMaterial strength using tensile/compressive forcesStress concentrationTest segment

The invention provides a test piece for testing the uniaxial tensile property of fiber reinforced concrete and a test method thereof. The test piece is bone-shaped, and comprises clamping sections attwo ends, a middle test section and a force transmitting section, wherein the clamping sections are in a streamline form. The test method comprises test piece forming, demoulding, tensile test preparation and experimental data recording, wherein the test piece is poured in a molding cavity defined by two side plates, two end part clamping molds and a bottom forming template, during demoulding, thetest piece is taken down together with the clamping molds, and the clamping molds are connected with the testing equipment. According to the testing method provided by the invention, the clamping molds and the test piece integrally formed, the test piece and a clamping fixture are good in contact embedding degree, a stress concentration phenomenon is not easy to occur, force transmission is uniform, and the test piece can be directly installed on test equipment to be quickly and effectively tested; the test piece is bone-shaped, the sections thereof are in smooth transition, uniform stress and force transmission are achieved, fracture at a position outside the test section is reduced, and the test success rate is high.

Owner:HAINAN UNIV

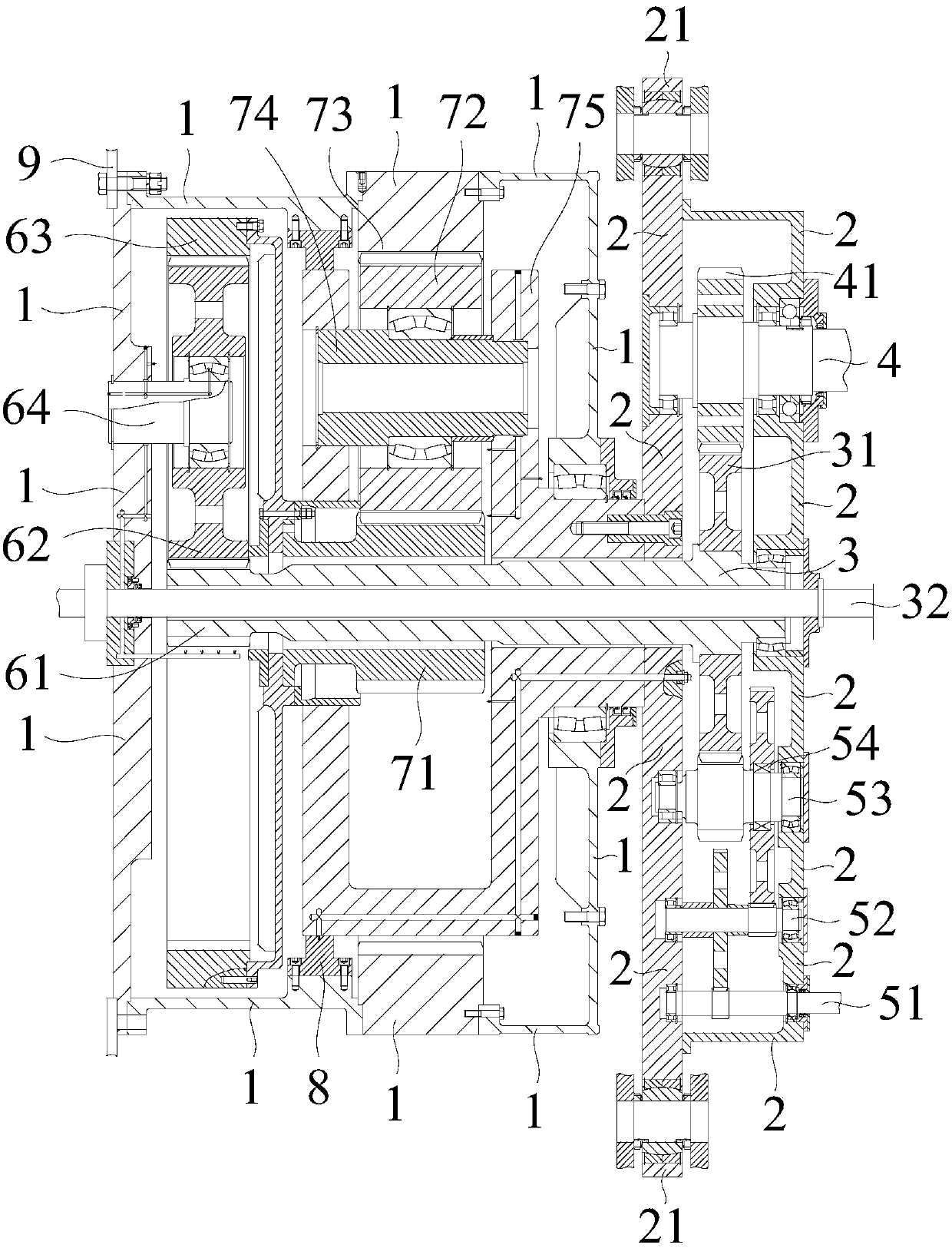

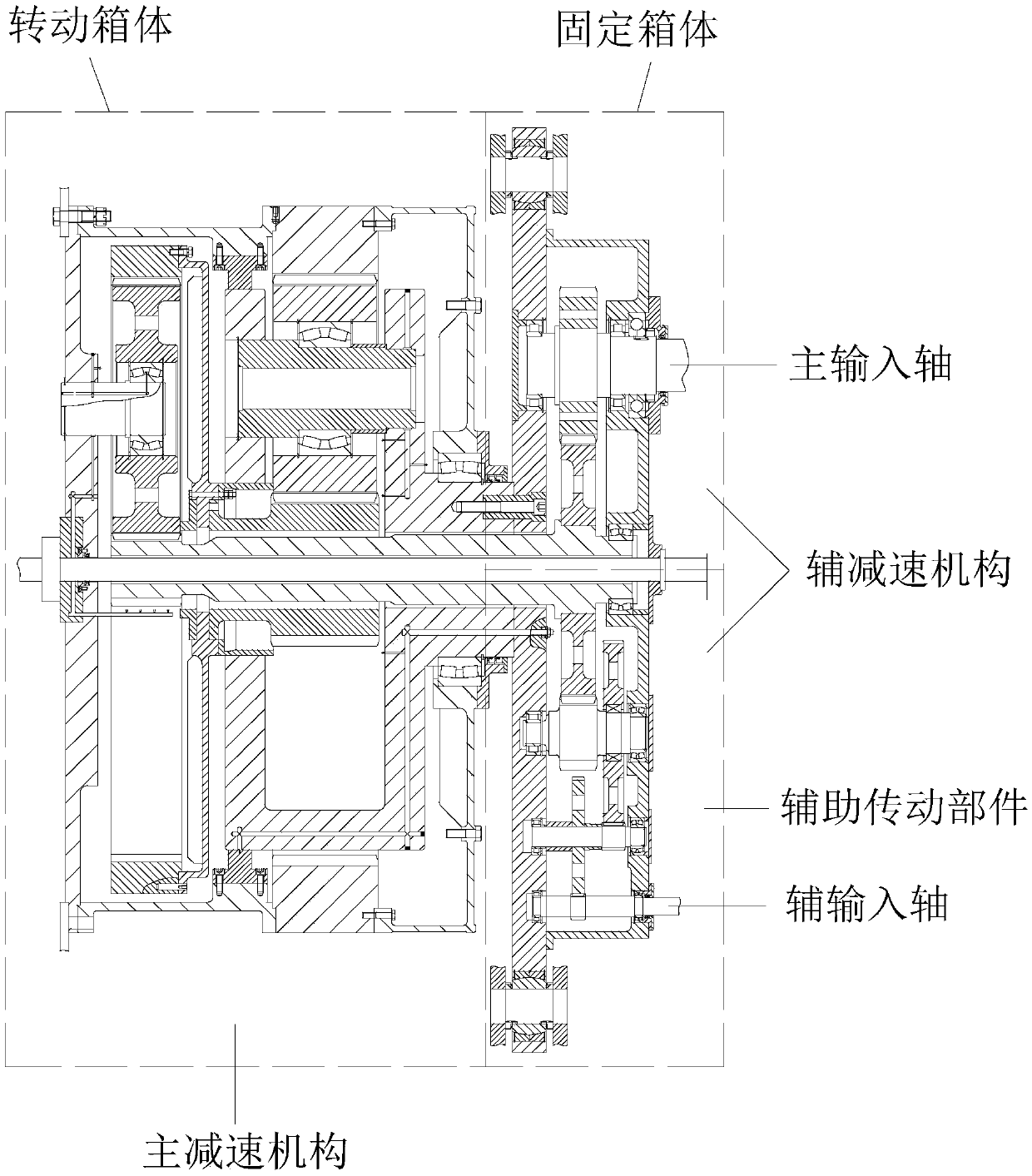

Planetary drive reducer for tube mill and tube mill equipment

ActiveCN106051067BSimple structureExtended service lifeToothed gearingsGear lubrication/coolingReducerTransmission properties

The invention discloses a planetary transmission reducer for a tube mill. The planetary transmission reducer comprises a rotating box and a fixed box, wherein a central shaft is arranged inside the fixed box; planetary transmission parts are arranged inside the rotating box; sun gears in the planetary transmission parts input force and rotate to drive inner gear rings to rotate and output force; and the rotating box is connected with the tube mill. Through the application of the reducer, planetary gear transmission is utilized, so that compared with a conventional parallel shaft reducer, the planetary transmission reducer has the advantages that the transmission ratio is increased, the transmission efficiency is improved, under the same output requirement, the sizes of the planetary transmission reducer and a matched motor are smaller, and the weights are lighter; a planet carrier relative mounting base is fixedly arranged, and after the sun gears input force, the planetary transmission parts transmit the force to drive the last stage inner gear ring fixedly connected with the rotating box to rotate; and the structure has flexible transmission property, the conventional eccentric load phenomenon can be effectively overcome, the impact vibration is reduced, the output is more stable, the service life is prolonged, the structure is simple, the manufacturing and transportation are convenient, the cost is low, and the popularization is facilitated.

Owner:成都名辰传动设备有限公司

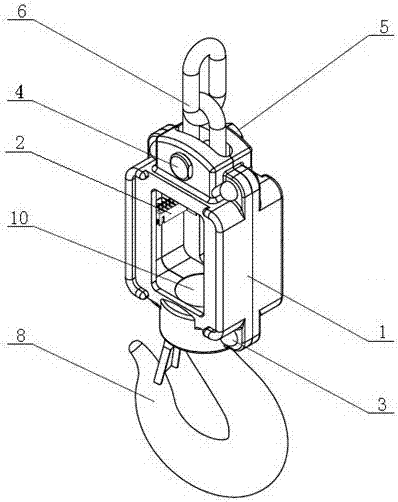

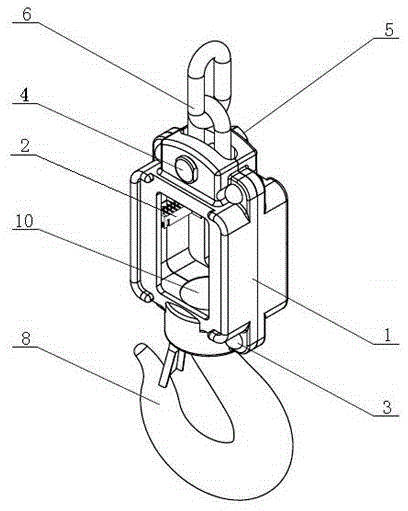

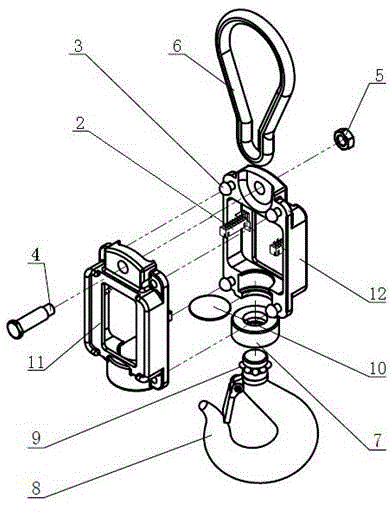

A zigzag tension pressure sensor

ActiveCN104697675BReduce volumeImprove compatibilityForce measurement by elastic gauge deformationEngineeringStrain gauge

A mouth-shaped pull-pressure sensor comprises a sensor body and strain gauges. The middle of the sensor body is hollowed to be mouth-shaped, the strain gauges are arranged on two sides of the inside of the sensor body, and the sensor body can be integrally formed and can also be formed by combining two sensor bodies. The mouth-shaped pull-pressure sensor is simple in structure, convenient to machine, accurate in measurement and high in deflection resistance, eccentric load is overcome, the structure of the sensor can serve as a portion of a shell, the strain gauges and other accessories inside the sensor are effectively protected, space is saved, the size of the sensor is reduced, the sensor body is provided with a structure connected with the outside, materials are saved, cost is reduced, using places are less limited, and compatibility and the applicable range of the sensor are expanded.

Owner:HANGZHOU XINJIAN ELECTRONICS

Brake device for support roller of coil stripping car

InactiveCN101397100BAvoid unbalanced load phenomenonAvoid failureDrum brakesWebs handlingHydraulic cylinderEngineering

The invention provides a supporting roller brake device used for a coil stripping trolley, comprising a hydraulic cylinder, a fork head and a brake part; wherein, the brake part comprises an inclined wedge block and a pair of brake arms which are pivotally and rotatablely connected with the fork head; each brake arm is pivotally and rotatablely connected with a bracket which is fixed on the supporting frame of the trolley respectively; the supporting roller brake device also comprises a self-adaptive floating system which is arranged between the hydraulic cylinder and the supporting frame of the trolley and comprises a pair of connecting shafts and a pair of supporters; each connecting shaft is respectively connected with one side of the hydraulic cylinder; each supporter is respectively connected with the supporting frame of the trolley; the connecting shafts are pivotally and rotatablely connected in the holes arranged on the supporters correspondingly. According to corresponding mechanic principle, the invention reconstructs the whole assembly and local assembly of the supporting roller brake device system. The novel supporting roller brake device of the coiling stripping trolley effectively solves the offset load phenomenon of the piston rod of the hydraulic cylinder and avoids a series of equipment failure and accidents caused by the offset loads.

Owner:BAOSHAN IRON & STEEL CO LTD

A propulsion system for automatic distribution of shield anti-eccentric load

ActiveCN109026042BIncrease the scope of geological applicationAvoid unbalanced load phenomenonTunnelsHydraulic cylinderClassical mechanics

The invention discloses an automatic-assigned propulsion system used for shield deviated-load resisting. A circular round baffle plate is fixedly connected with a shield body, rocks and soil cut by acutter plate are delivered by a spiral delivering machine, a duct piece is jacked by the right end of a hydraulic lifting jack through a supporting boot, the whole shield is pushed to excavate forwards through the counter force on the duct piece, all hydraulic cylinders in the propulsion system are uniformly distributed. According to the shield deviated-load resisting propulsion system, data is collected through pressure sensors distributed on the exterior of the shield machine, the arc angle theta and azimuthal angle of the propulsion system are computed by a hydraulic control system to control the starting or stopping of a hydraulic cylinder group which is circularly, equidistantly and consecutively arranged in the propulsion system. By means of the method, the distribution of the hydraulic cylinders can be timely adjusted to solve the deviated-load problem of shield excavating.

Owner:HUNAN UNIV OF SCI & TECH

A secondary buffer unlocking device for passive protection of high-speed trains

ActiveCN109532924BIncrease specific energy absorptionOverall small sizeRailway wheel guards/bumpersAluminum honeycombMechanical engineering

The invention provides a high-speed train passive protection secondary buffer unlocking device. The end of a car coupler push rod of the device is fixedly connected with a first train, a car coupler push frame is of a hollow structure and is axially inserted with the car coupler push rod, a first-stage buffer aluminum honeycomb structure sleeves the periphery of the car coupler push rod, the first-stage buffer aluminum honeycomb structure is located between the car coupler push rod and the two ends of the car coupler push frame, a plurality of first pull rods penetrate through the ends of thecar coupler push frame and the first-stage buffer aluminum honeycomb structure to be fixed with the end of the car coupler push rod, and a plurality of second pull rods penetrate through the tail endof the car coupler push frame and a second-stage buffer aluminum honeycomb structure to be fixed with the side face of a second train; a guide part is arranged in the axial direction of the second-stage buffer aluminum honeycomb structure, an unlocking rod is inserted into a guide piece, and the four inclined blocks are hinged to the front end of an inclined block hinge barrel and are matched withthe inner inclined surface of the tail end of the car coupler push frame. The defect of an existing high-speed train energy absorption buffering technology is overcome, ordered dissipation of kineticenergy of the trains is realized, it is guaranteed that unbalance loading is not generated in the buffer process of the trains, and good dynamic stability is achieved.

Owner:SHENZHEN CANSINGA TECH CO LTD

An energy-saving and environment-friendly concrete mixer ship

ActiveCN113290707BCompact structureReasonable layoutSolid waste managementPretreatment controlDust controlTreatment system

The invention discloses an energy-saving and environment-friendly concrete mixing ship, which comprises a hull, a concrete production system and a living building; the concrete production system comprises a main mixing building, an aggregate building, an aggregate feeding system, an aggregate batching system and a waste concrete treatment system; The main mixing building includes left and right line mixing rooms, and there is a left and right line aggregate transition storage tank between the dust removal deck corresponding to the left and right line mixing rooms and the weighing deck; the mixing deck corresponding to the left and right line mixing rooms Install the left and right line mixing main engines; the aggregate building includes the left and right line aggregate rooms arranged symmetrically along the central axis of the hull; the aggregate feeding system includes a material receiving mechanism, a feeding mechanism and a material distribution mechanism; the aggregate batching system includes the left , Right line batching mechanism and transfer batching mechanism; waste concrete treatment system includes two flushing pipelines, sewage chute, sewage processor, vibrating screen, sewage tank, filter press and filter press clear water tank. The invention can improve the working environment, and can also balance the consumption of aggregates in the left and right line aggregate cabins, so as to realize continuous production of concrete.

Owner:CCCC THIRD HARBOR ENG +2

Anti-eccentric load device for drum and washing machine

ActiveCN107190471BAvoid unbalanced load phenomenonOther washing machinesTextiles and paperLaundry washing machineEngineering

The invention relates to an anti-eccentric load device, in particular to an anti-eccentric load device for a drum. The invention aims to solve the problem that the anti-eccentric load effect of the existing anti-eccentric load device for the drum is not good, and the drum is easily worn. The anti-eccentric load device for the rotating drum of the present invention includes a fixing component capable of being fixed on the casing and a flexible eccentric load absorbing component. The fixing assembly includes a support part located in the opening area of the drum, and the flexible offset load absorbing assembly includes at least two elastic parts that can rotate relative to the support part or the wall of the drum, and at the same time, one end of each elastic part is connected to the support The other end is connected to the wall of the drum. The fixing assembly can provide stable support for the anti-eccentric load device. When the drum rotates, the flexible eccentric load absorbing assembly can adjust the swing of the drum in time, so that the rotation of the drum can be adjusted Under the action, it reaches the equilibrium state as soon as possible, thus effectively preventing the occurrence of partial load phenomenon.

Owner:HEFEI HAIER WASHING MACHINE +1

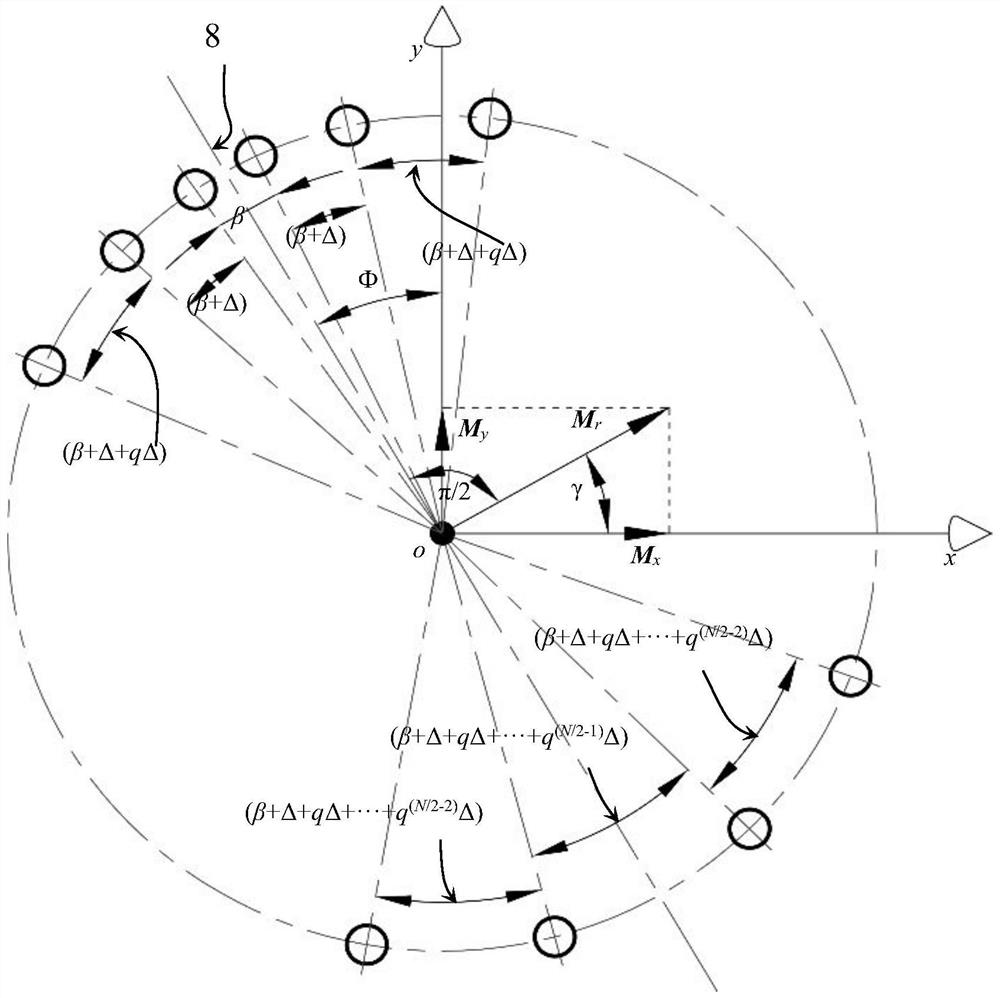

A Geometric Series Layout Method for Shield Propulsion System

ActiveCN109578000BAvoid unbalanced load phenomenonIncrease the scope of geological applicationTunnelsHydraulic cylinderClassical mechanics

Owner:HUNAN UNIV OF SCI & TECH

A hydraulic cylinder arrangement control mechanism for shield machine

ActiveCN109826638BAvoid unbalanced load phenomenonIncrease the scope of geological applicationTunnelsHydraulic cylinderClassical mechanics

The invention discloses a hydraulic cylinder arrangement control mechanism for a shielding tunneling machine. The hydraulic cylinder arrangement control mechanism comprises a shield body, a partitionplate, hydraulic cylinders, a supporting frame and a push-and-pull device; the supporting frame is arranged inside the shield body and fixedly connected with the shield body, the partition plate is arranged in the shield body, multiple groove holes are formed in the supporting frame in the extension direction of the axis of the shield body, and formed in the supporting frame around the axis of theshield body, the hydraulic cylinders penetrate through the groove holes, one ends of the hydraulic cylinders are backed on the side face of the partition plate, and the other ends of the hydraulic cylinders are jacked on duct pieces through support boots; the hydraulic cylinders are arranged around the axis of the shield body, one end of the push-and-pull device is hinged to hydraulic cylinder bodies, the other end of the push-and-pull device is hinged to the supporting frame, and the push-and-pull device is used for rotating the hydraulic cylinders around the axis of the shield body for adjustment. By means of the hydraulic cylinder arrangement control mechanism for the shielding tunneling machine, when a shield propelling system tunnels a compound stratum, the positions of the hydrauliccylinders can be changed at the right time, layout optimization is achieved, and thus the shield tunneling efficiency is improved.

Owner:HUNAN UNIV OF SCI & TECH

Mouth-shaped pull-pressure sensor

ActiveCN104697675AReduce volumeImprove compatibilityForce measurement by elastic gauge deformationEngineeringStrain gauge

A mouth-shaped pull-pressure sensor comprises a sensor body and strain gauges. The middle of the sensor body is hollowed to be mouth-shaped, the strain gauges are arranged on two sides of the inside of the sensor body, and the sensor body can be integrally formed and can also be formed by combining two sensor bodies. The mouth-shaped pull-pressure sensor is simple in structure, convenient to machine, accurate in measurement and high in deflection resistance, eccentric load is overcome, the structure of the sensor can serve as a portion of a shell, the strain gauges and other accessories inside the sensor are effectively protected, space is saved, the size of the sensor is reduced, the sensor body is provided with a structure connected with the outside, materials are saved, cost is reduced, using places are less limited, and compatibility and the applicable range of the sensor are expanded.

Owner:HANGZHOU XINJIAN ELECTRONICS

Suspended ground friction conveyor line

ActiveCN103523482BLower installation heightAvoid unbalanced load phenomenonMechanical conveyorsEngineeringMechanical engineering

The invention relates to a suspension type ground friction conveying line. An auxiliary track installing support is fixedly installed on the outer side of a main track installing column, a main track is fixed on the main track installing column and suspended above plant area ground, a straightening track is fixed on the auxiliary track installing support, walking wheels are arranged in the main track, every two adjacent walking wheels are connected through a connecting rod, a straightening wheel is arranged in the straightening track, the walking wheels and the straightening wheel are installed on a workpiece support, a driving friction wheel and a driven friction wheel are installed on the main track installing column, and the connecting rod is located between the driving friction wheel and the driven friction wheel. According to the suspension type ground friction conveying line, the total installing height is reduced, the problem that paint is sprayed on a conveying line body at a paint spraying station is avoided, maintenance and safety are enhanced, and an auxiliary walking track is installed additionally simultaneously to avoid an eccentric load.

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

A boom system for a wheeled wet spraying machine

ActiveCN104594355BPrevent deviationEnsure balanceUnderground chambersFoundation engineeringSprayerEngineering

The invention provides a boom system for a wheel type wet sprayer. The boom system for the wheel type wet sprayer comprises a rotary table arranged on a machine tool, and a boom device connected with the rotary table, wherein the rotary table is of a bilateral symmetry structure and comprises a rotary chassis, two vertical support plates and a horizontal support plate; a first through hole and a second through hole are respectively formed on the same height in the top parts of the vertical support plates; a third through hole is formed in the center of the horizontal support plate; the central points of the first through hole, the second through hole and the third through hole are located on the same vertical face; the tail end of a big arm and the rotary table are hinged at the first through hole and the second through hole; the front end of the big arm is hinged to the tail end of a small arm through two connecting rods; vertices of a quadrangle formed by one section of the front end of the big arm, one section of the tail end of the small arm and the two connecting rods are respectively located in a vertical face where the central axis of the big arm and the central axis of the small arm are jointly located. According to the boom system for the wheel type wet sprayer, the eccentric load phenomenon of all axle sleeves at hinged points is avoided, and the deformation of axle sleeve holes in the hinged points is controllable and uniform, so that the service life of a boom assembly and even the service life of the whole concrete wet spraying machine are improved.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

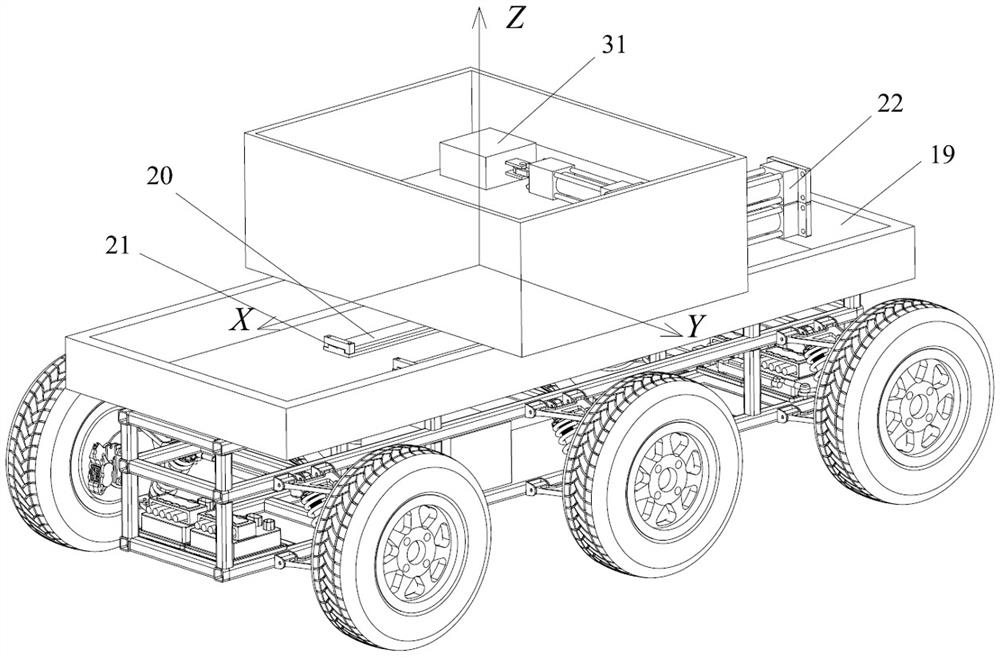

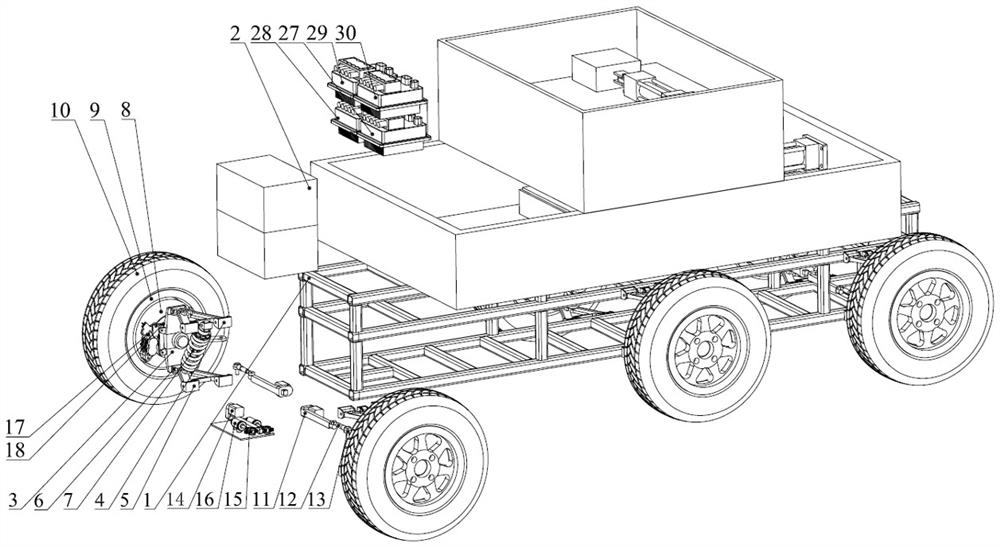

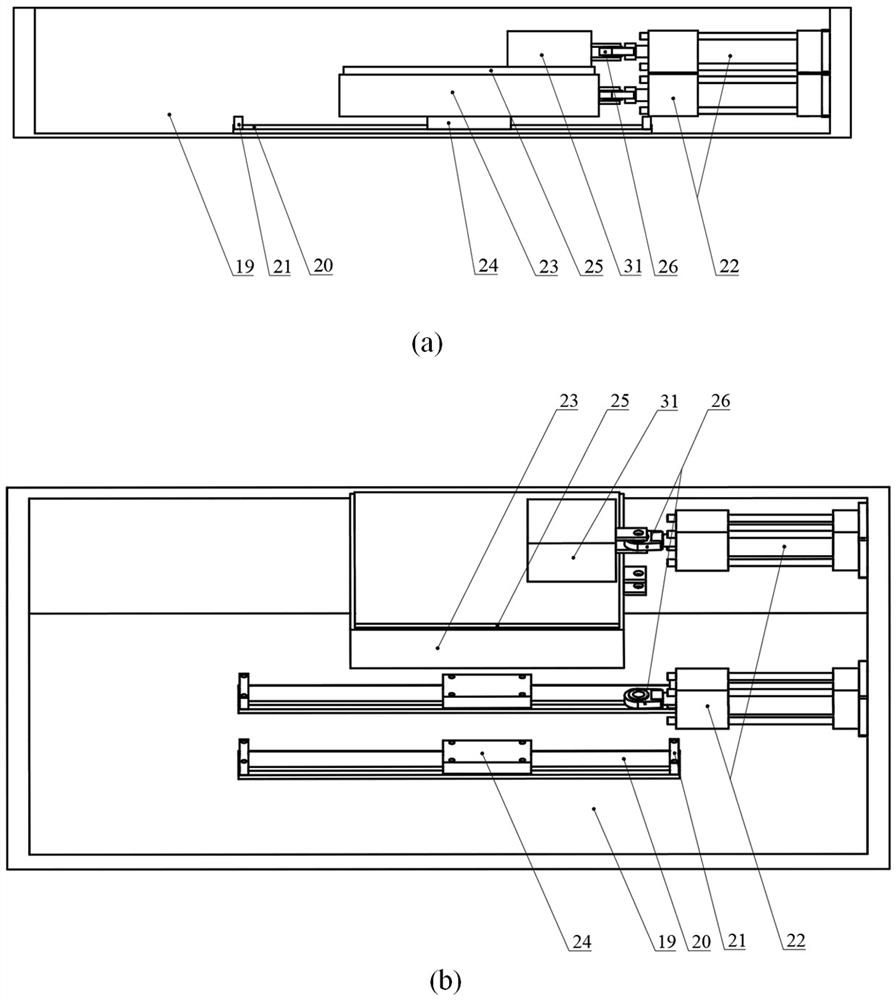

Multi-axle vehicle experiment bench capable of realizing dynamic load simulation and working method thereof

PendingCN114636569AAdd varietyIncrease authenticityVehicle testingSustainable transportationVehicle dynamicsData acquisition

The invention relates to a multi-axle vehicle experiment bench capable of realizing dynamic load simulation and a working method thereof. The multi-axle vehicle experiment bench comprises a chassis, a data acquisition system, a whole vehicle controller and a dynamic load adjusting device, the chassis controls the movement state and posture change of the whole vehicle through the suspension system, the steering system, the braking system and the driving system; the dynamic load adjusting device is installed on the chassis and comprises an upper layer load adjusting mechanism and a lower layer load adjusting mechanism which drive balancing weights on the load adjusting mechanisms to move in the transverse direction and the longitudinal direction respectively. The data acquisition system comprises a wheel corner sensor, a vehicle speed sensor, a yaw velocity sensor, a whole vehicle transverse acceleration sensor and a whole vehicle longitudinal acceleration sensor; the whole vehicle controller controls the dynamic load adjusting device to work according to set simulation working conditions and collected whole vehicle dynamic parameters, and changes of dynamic loads between all axles and left and right wheels are adjusted in real time. The experiment bench can truly and reliably simulate the dynamic load, the engineering application range of the experiment bench is expanded, and the simulation range of the experiment bench to the load change of the whole vehicle is expanded.

Owner:FUZHOU UNIV

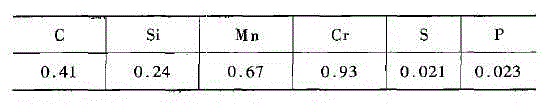

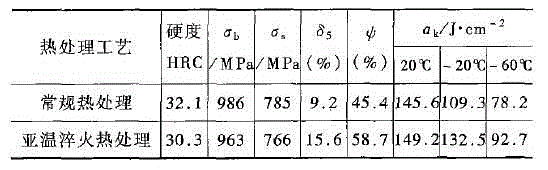

Method for improving mechanical property of 45Cr-3Mo-B alloy

The invention discloses a method for improving the mechanical property of 45Cr-3Mo-B alloy. The method is characterized by comprising the steps that the 45Cr-3Mo-B alloy is prepared from, by mass, 0.41 part of C, 0.24 part of Si, 0.67 part of Mn, 0.93 part of Cr, 0.021 part of S, 0.023 part of P and the balance Fe; steel is prepared by the raw materials through a conventional method and then processed through subcritical quenching heat treating; the technology comprises the steps that oil quenching is performed at the temperature of 750 DEG C-850 DEG C for 13 min; oil cooling is performed at the temperature of 550 DEG C-600 DEG C for 2 h; water quenching is performed at the temperature of 700 DEG C-770 DEG C for 13 min; water cooling is performed at the temperature of 560 DEG C-600 DEG C for 2 h.

Owner:罗伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com