Method for improving mechanical property of 45Cr-3Mo-B alloy

A technology of alloy mechanics and properties, applied in the field of improving the mechanical properties of 45Cr-3Mo-B alloy, can solve the problems of complex structure and no unified conclusion of strengthening mechanism, so as to improve the surface fatigue limit, prevent the phenomenon of partial load, and ensure the assembly The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

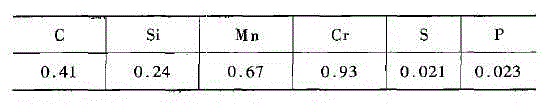

[0009] Table 145Cr-3Mo-B steel chemical composition (mass fraction) (%)

[0010]

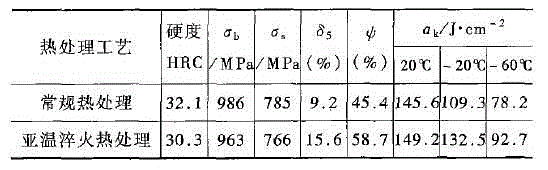

[0011] (2) Heat treatment process Divide the samples into two groups, one group is conventional heat treatment, its process is 850 ° C x 13 min oil quenching + 600 ° C * 2 h oil cooling; the other group is sub-temperature quenching heat treatment, its process is 850 ° C x 13 min oil Quenching+600℃xZh oil cooling+770℃x13min water quenching+600℃xZh water cooling. A quenching and tempering treatment (that is, pretreatment) is required before sub-temperature quenching, because sub-temperature quenching of steel has certain requirements on the original structure, and it is necessary to ensure that there are fine acicular ferrite precipitates with a certain orientation in order to improve the impact. tenacity.

[0012] (3) Hardness test The samples after conventional heat treatment and sub-temperature quenching heat treatment were made into samples, and the hardness test was carried out on a HR150...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com