Planetary drive reducer for tube mill and tube mill equipment

A planetary transmission and reducer technology, applied in mechanical equipment, transmission, gear transmission and other directions, can solve problems such as unfavorable energy saving, emission reduction, cost reduction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

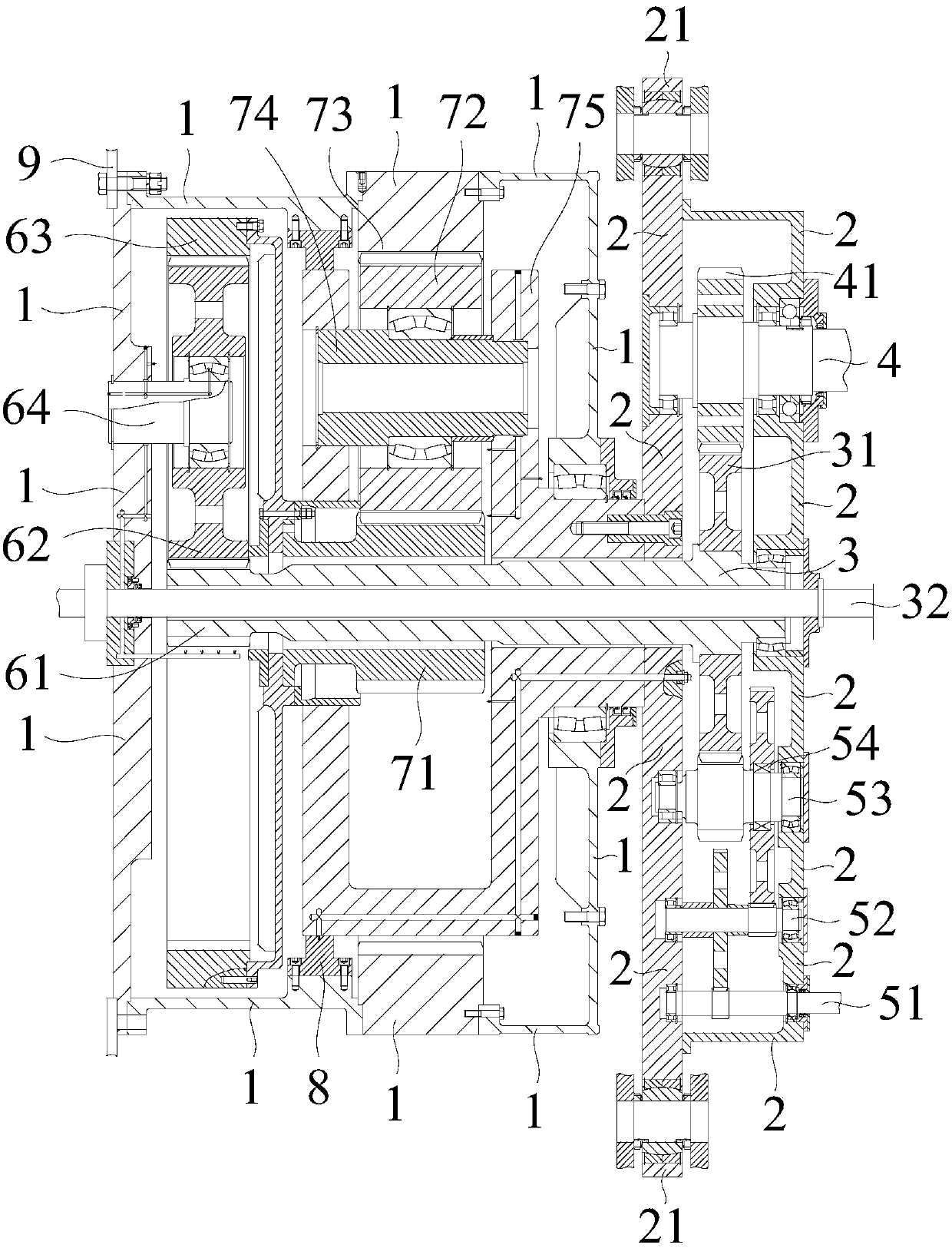

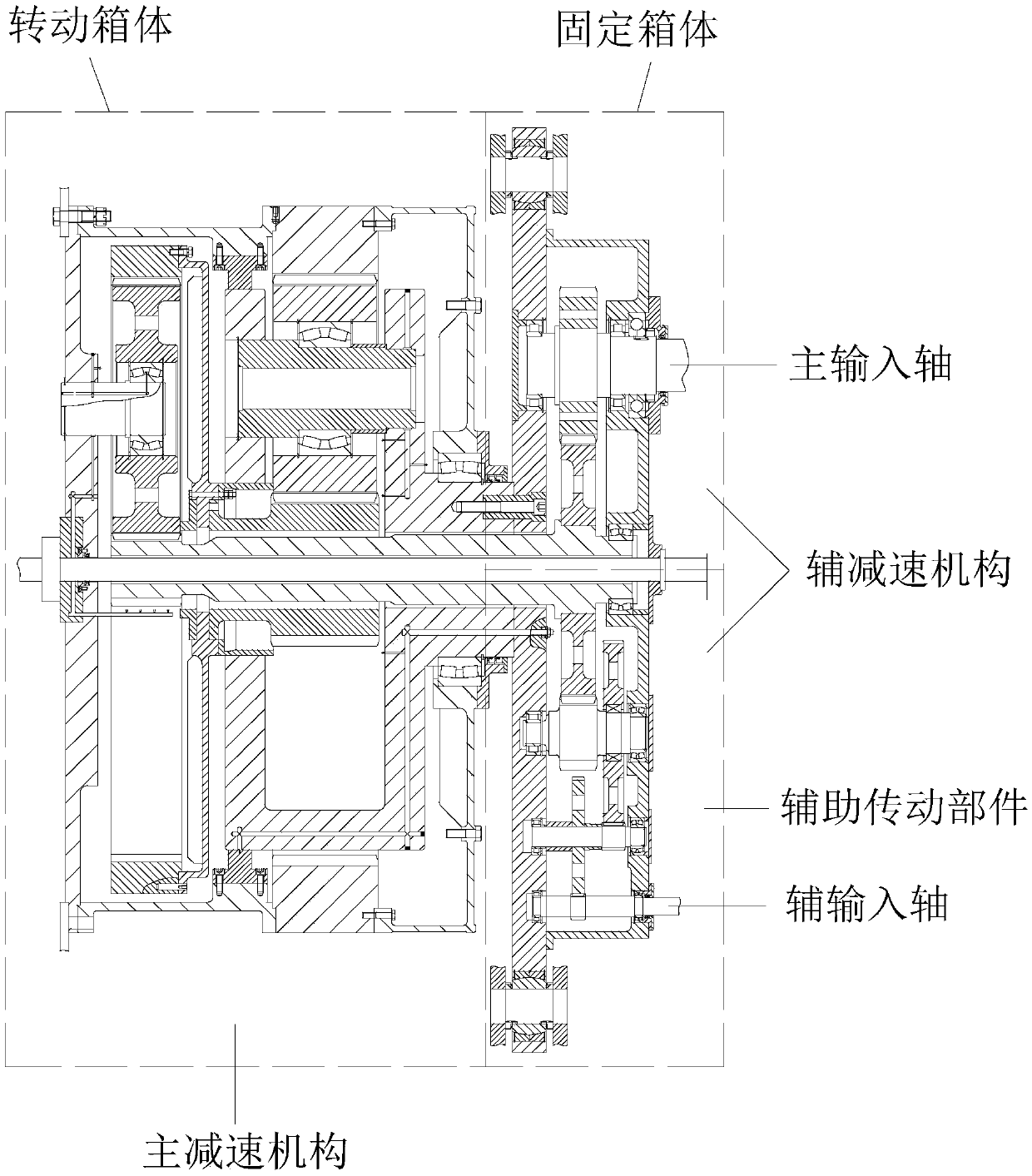

[0036] Such as Figure 2-3 As shown, a planetary transmission reducer for a tube mill according to the present invention includes a rotating box 1 and a fixed box 2 .

[0037] The fixed box 2 is provided with a central axis 3, and the central axis 3 extends out of the fixed box 2, and the rotating box 1 is connected to the extension of the central axis 3 and can rotate around it. Rotating box body 1 is provided with at least one stage of planetary transmission parts, and each stage of said planetary transmission parts includes a sun gear, a planetary gear, a planetary gear shaft, a planet carrier and an inner ring gear, and said sun gear in each stage of said planetary transmission parts The input and rotation of the wheel drive the inner ring gear to rotate and output, the inner ring gear of the first stage among the two adjacent planetary transmission parts is fixedly connected to the sun gear of the second stage, and the fixed box 2 is equipped with a The input shaft conne...

Embodiment 2

[0049] Such as Figure 2-4 As shown, a tube mill equipment according to the present invention includes a planetary transmission reducer for a tube mill as described in Embodiment 1.

[0050] The input shaft located in the fixed box 2 of the planetary transmission reducer 05 is connected to the motor 04, and the rotating box 1 is connected to the tube mill 01 through a flange 9 and bolts.

[0051] As a preference of this embodiment, the input shaft is connected to a universal joint, and the universal joint is connected to the motor 04 .

[0052] The main transmission power transmission route of the tube mill equipment is:

[0053] Main motor→universal joint→main input shaft 4→pinion gear 41→big gear 31→central shaft 3→primary sun gear 61→primary planetary gear 62→primary internal ring gear 63→secondary sun gear 71→two Stage planetary gear 72 → secondary ring gear 73 → rotating box 1 → tube mill 01.

[0054] The auxiliary transmission power transmission route of the tube mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com