Energy-saving and environment-friendly concrete mixing ship

An energy-saving, environment-friendly, concrete technology, used in mixing plants, mixing operation control, barges/barges, etc., can solve the problems of inability to achieve left-right cross-conveying, inability to produce continuously, and unfavorable environmental protection, achieving compact structure, avoiding pollution, reducing Effects of exhaust emissions and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

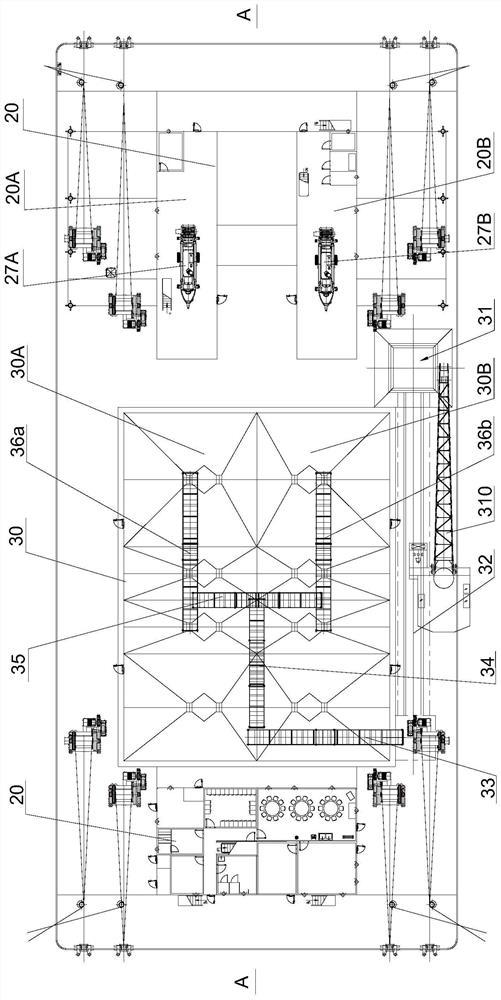

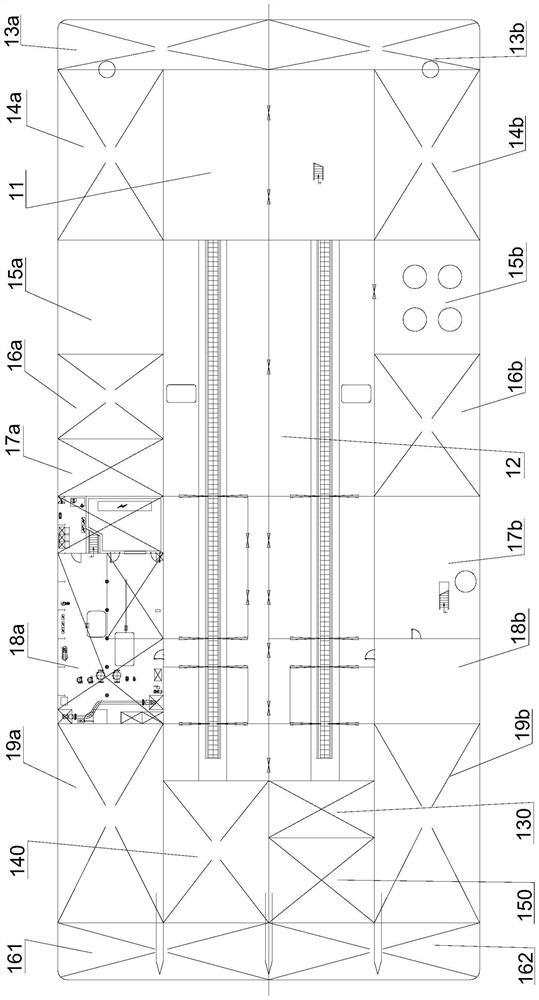

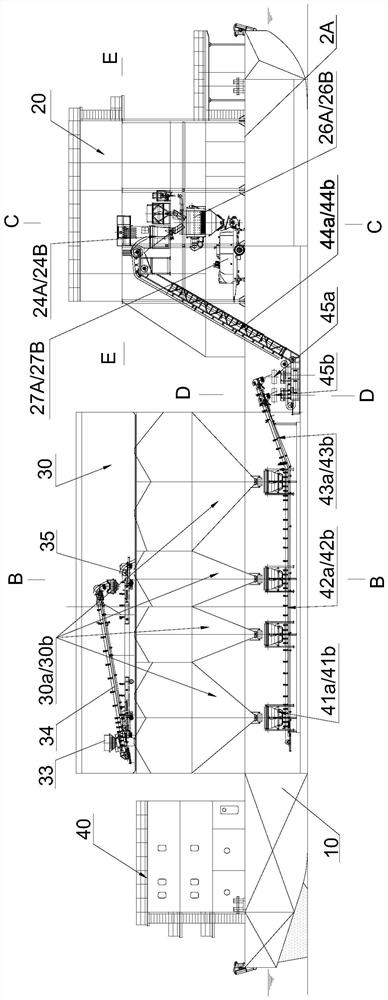

[0044] see Figure 1 to Figure 13 , the energy-saving and environment-friendly concrete mixing ship of the present invention comprises a hull 10, a concrete production system located in the middle of the hull and a living building 40 located at the rear of the hull; the concrete production system includes a mixing main building 20, an aggregate building 30, an aggregate feed Material system, aggregate batching system and waste concrete treatment system.

[0045] The lower part of the main deck of the hull 10 corresponds to the mixing main building 20 and is provided with a waste concrete treatment cabin 11. The rear part of the waste concrete treatment cabin 11 to the rear end of the aggregate building 30 is an aggregate delivery cabin 12; the front part of the waste concrete treatment cabin 11 There are left and right first ballast water tanks 13a, 13b, and the left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com