A zigzag tension pressure sensor

A pull-pressure sensor and sensor technology, applied in the sensor field, can solve the problems of increasing the sensor volume, complicated use and installation, and small application scope, and achieve the effects of improving compatibility and application scope, convenient processing, and less restrictions on use sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

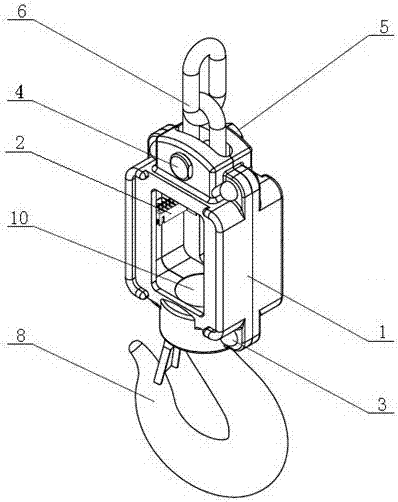

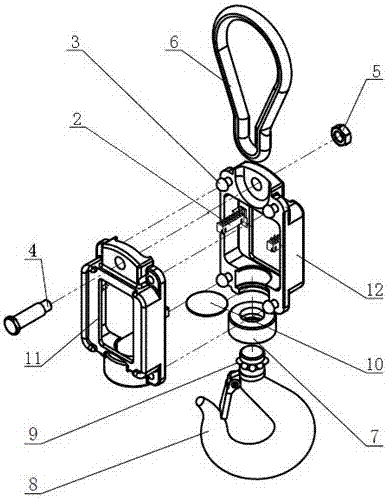

[0019] Embodiment 1: The main body structure of the sensor 1 remains unchanged, the upper connecting parts are the structure of the shaft pin 4 and the nut 5, and the structure of the shaft pin 4 and the nut 5 is also connected to the external member 6, which can be a chain or a shackle; the lower part is connected Parts are hook 8 structures.

Embodiment approach 2

[0020] Embodiment 2: The main body structure of the sensor 1 remains unchanged, and the upper and lower connecting parts are both the shaft pin 4 and the nut 5 structure, and the shaft pin 4 and the nut 5 structure are also connected to the external component 6, and the external component 6 can be a chain or a shackle .

Embodiment approach 3

[0021] Embodiment 3: The main structure of the sensor 1 remains unchanged, the upper connecting part is the structure of the hook 8; the lower connecting part is the structure of the shaft pin 4 and the nut 5, and the structure of the shaft pin 4 and the nut 5 is also connected to the external member 6, and the external member 6 Can be chain or shackle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com