Suspension type ground friction conveying line

A hanging, conveying line technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of eccentric load, easy to stain the conveying line with paint, and inconvenient maintenance and repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples.

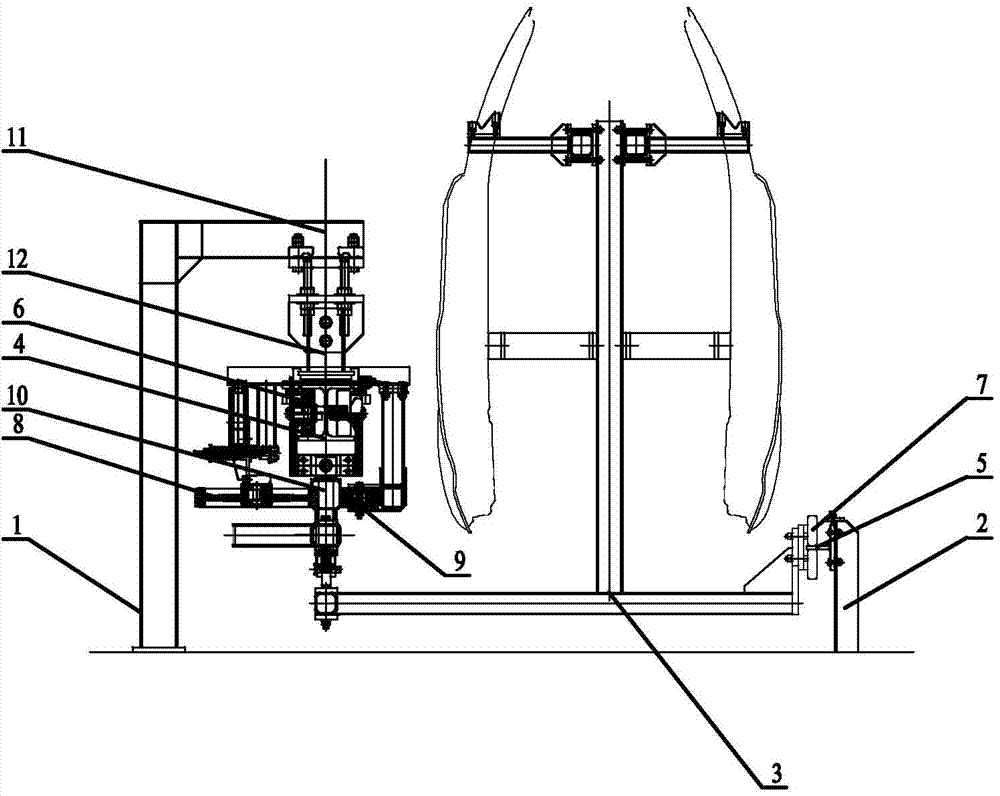

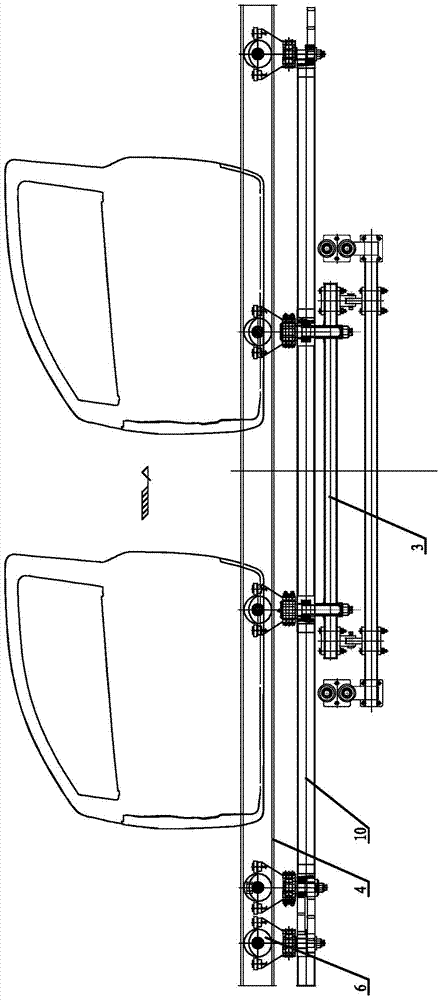

[0018] The suspended ground friction conveying line includes a main track installation column 1, an auxiliary track installation bracket 2 and a workpiece support 3, and the auxiliary track installation bracket 2 is fixedly installed on the outside of the main track installation column 1 and fixed on the main track installation column 1. There is a main track 4, the main track 4 is suspended above the ground of the factory area, a righting track 5 is fixed on the auxiliary track mounting bracket 2, and a walking wheel 6 is arranged in the main track 4, and two adjacent walking wheels 6 are connected by a connecting The rods 10 are connected to each other, and a centering wheel 7 is provided in the centering track 5, and the traveling wheel 6 and the centering wheel 7 are installed on the workpiece support 3, and the driving friction wheel 8 and the driven friction wheel 9 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com