Brake device for support roller of coil stripping car

A technology of brake device and idler roller, which is applied in the direction of winding strips, transportation and packaging, and brake types, etc. It can solve the problems of unwinding of the belt tail, the failure of the brake device, and wear and tear, and solve the phenomenon of partial load , to avoid the effect of equipment failure and accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to better understand the structure, function and effect of the present invention, the following preferred embodiments are now described in detail in conjunction with the accompanying drawings. The same reference numerals designate the same or similar components.

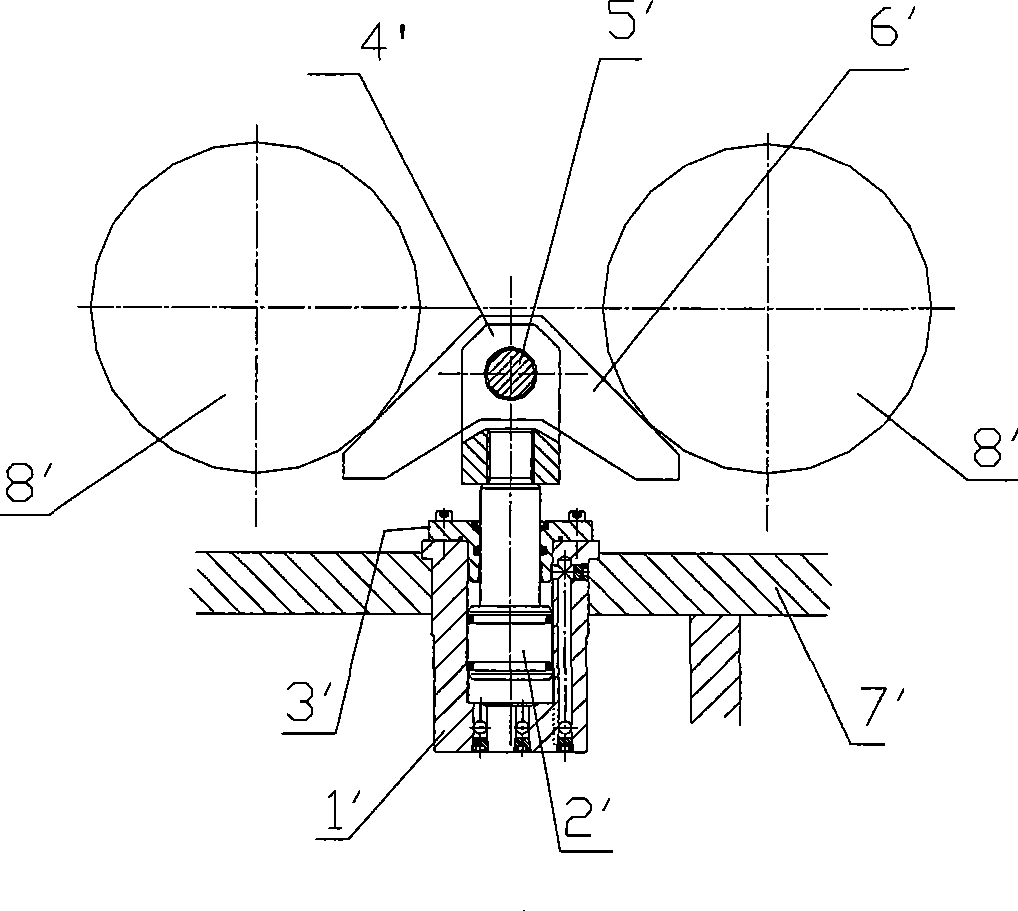

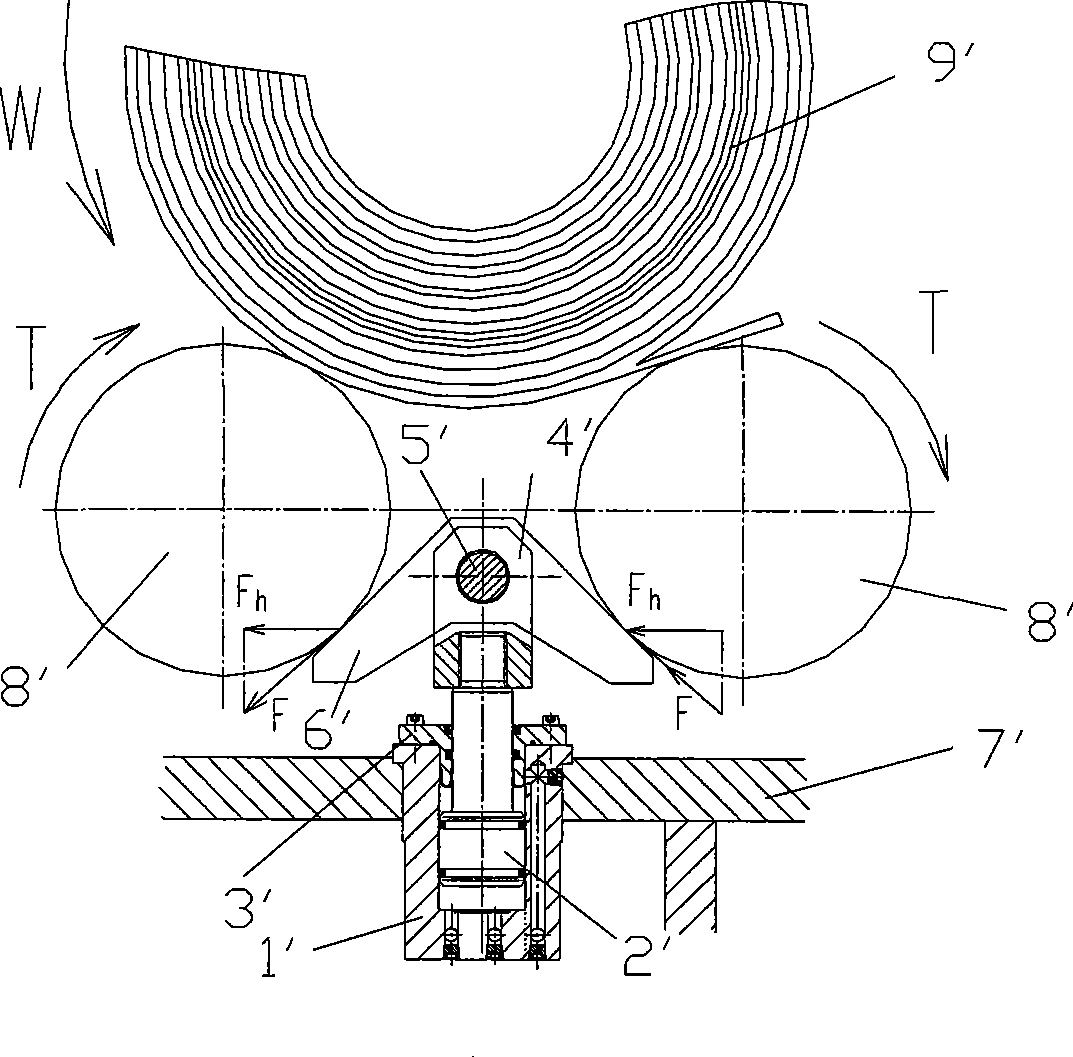

[0066] Figure 4 A top view of the assembly of the improved braking device according to the present invention is shown. The brake device mainly includes a hydraulic cylinder (not shown in the figure), a bracket 1, an ear seat 2, a brake arm 3 and a stop yoke 5, and the following details refer to Figure 5-7 Each component of this braking device is described in detail.

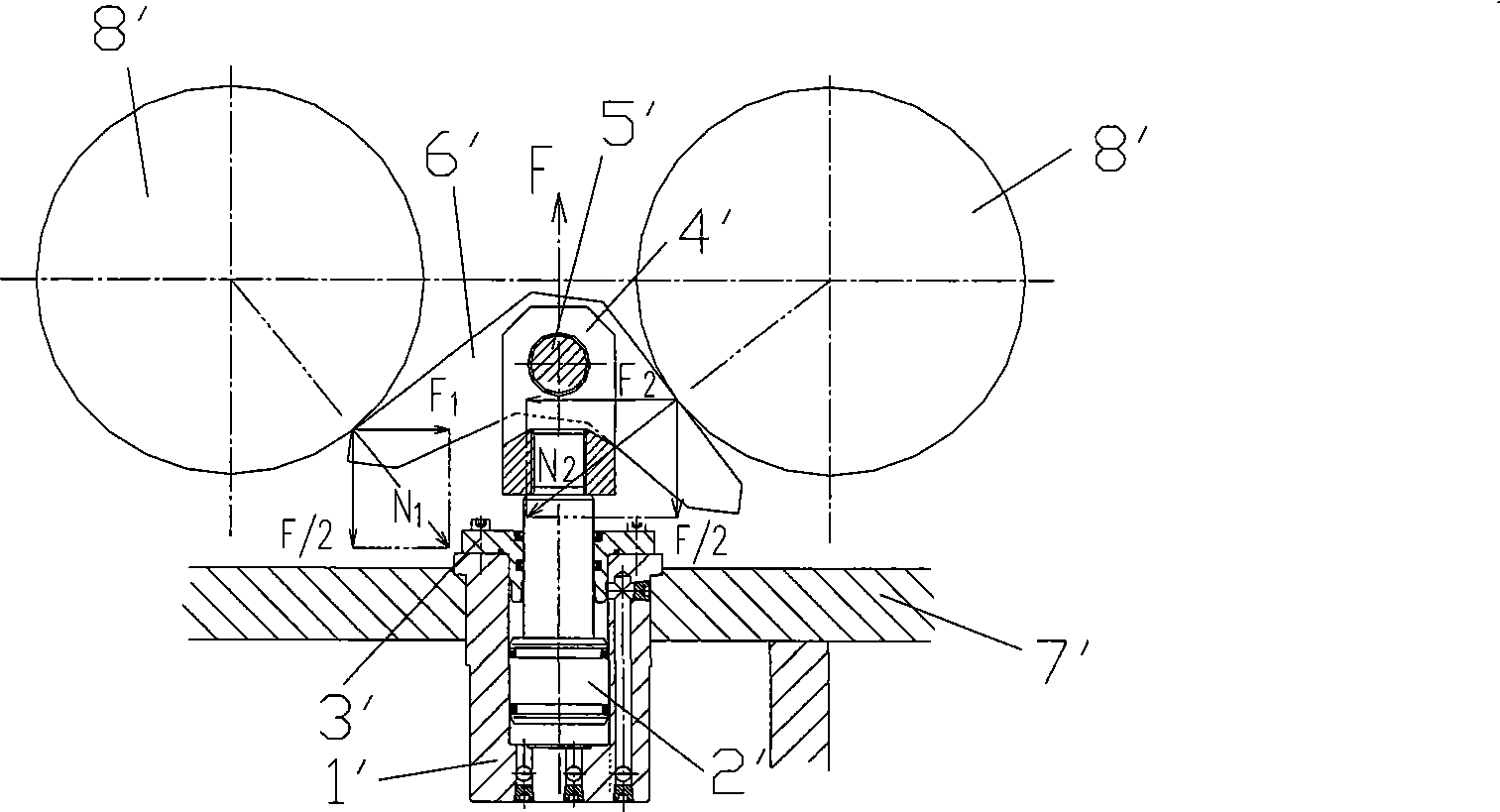

[0067] see first Figure 5 and Figure 6 , in this preferred brake device, the connecting shaft and the support in the adaptive floating system of the present invention are specifically a pair of trunnions 6 added on the hydraulic cylinder block 1' and a bushing 7 embedded in the inner hole. The ear seat 2, wherein the trunnion 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com