self-calibrating gear

A self-calibrating, gear technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem of not being able to adjust the meshing of gear pairs by itself, so as to prevent axial movement and ensure sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

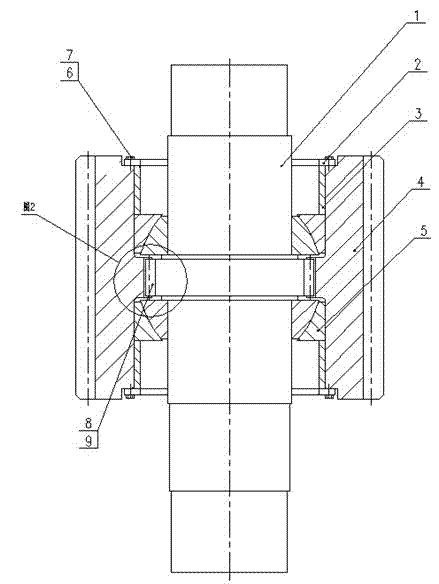

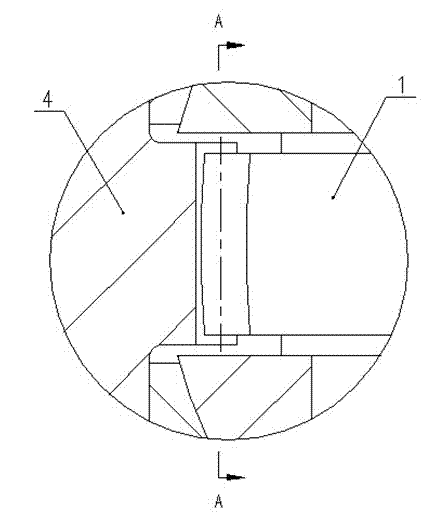

[0015] The accompanying drawings disclose the specific structures of the embodiments of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

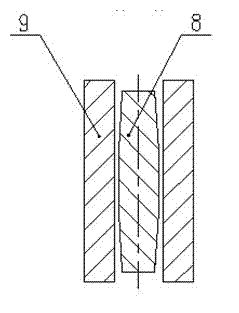

[0016] Depend on figure 1 It can be seen that the axis center of gear 4 is shaft 1, a section of protruding external spline is provided in shaft 1, and a section of protruding internal spline is provided in the assembly hole of gear 4. The length of the internal spline is the same as that of the external spline. Corresponding to the key; corresponding to the front and rear ends of the outer spline section and the inner spline, the joint bearing 5 is respectively provided, and the adjustment ring 3 and the pressure plate 2 are arranged in turn between the joint bearing 5 and the end face of the gear 4, and the pressure plate 2 is fixed on the gear 4 by bolts. end face. Shaft 1 and gear 4 are positioned by joint bearing 5 .

[0017] In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com