An energy-saving and environment-friendly concrete mixer ship

An energy-saving, environment-friendly, concrete technology, used in mixing plants, mixing operation control, barges/barges, etc., can solve the problems of inability to achieve left-right cross-conveying, inability to produce continuously, and unfavorable environmental protection, achieving compact structure, avoiding pollution, reducing Effects of exhaust emissions and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

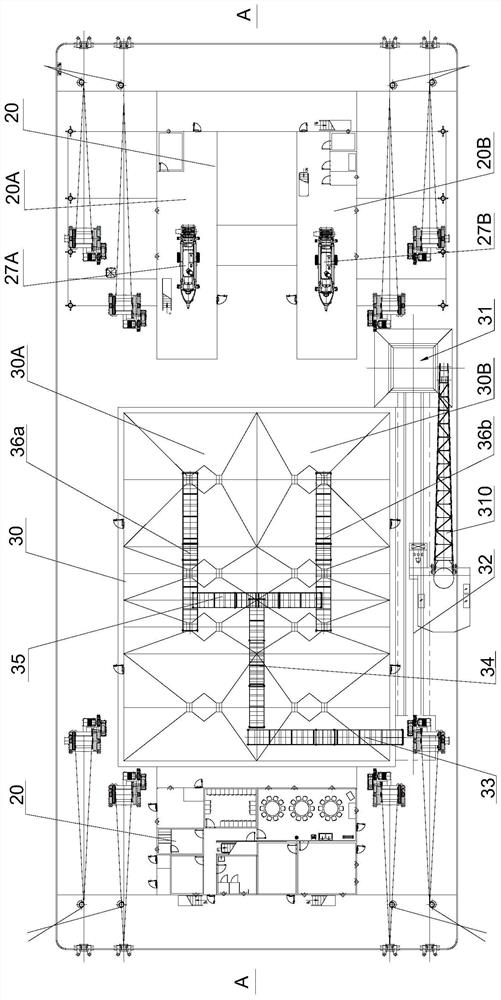

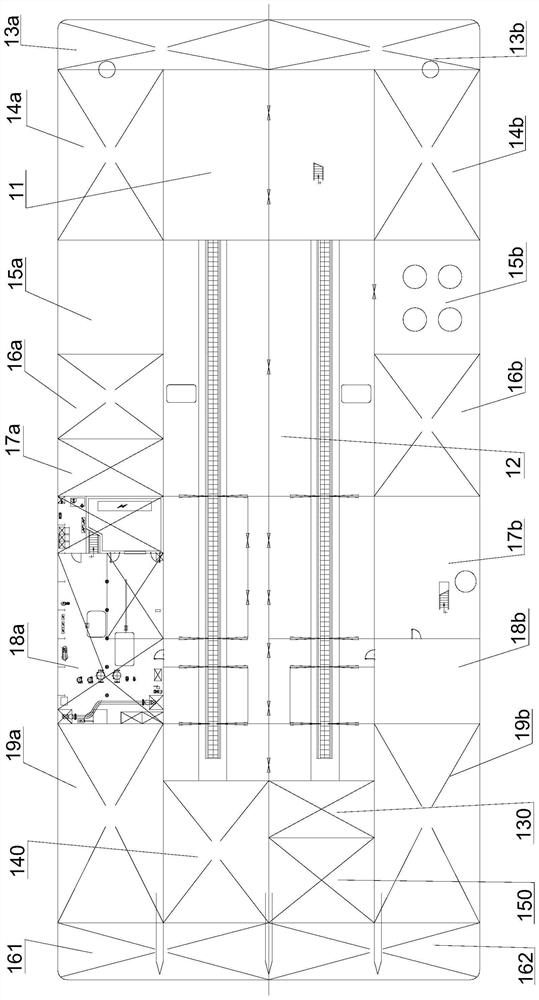

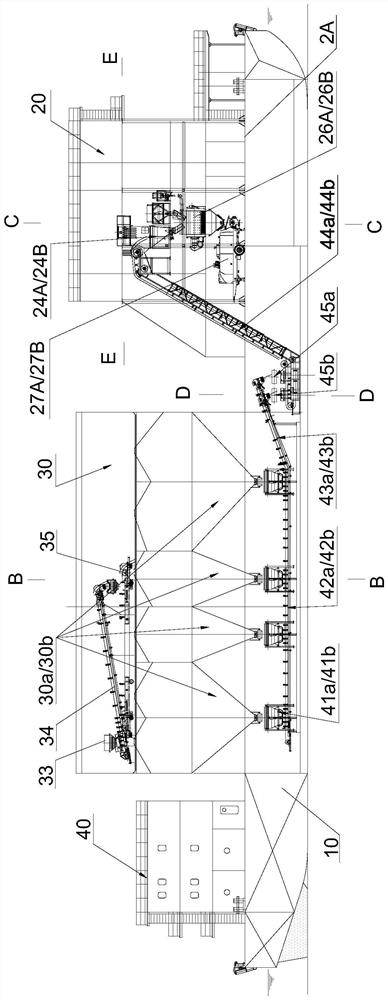

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

[0048] The aggregate feeding system includes a material receiving mechanism, a feeding mechanism and a material distribution mechanism; wherein,

[0049] The material receiving mechanism comprises a material receiving hopper 31, a feeding inclined belt conveyor 32 and a grab crane 310; the material receiving hopper 31 is located in the aggregate building

[0054] The aggregate batching system includes a left and right line batching mechanism and a transfer batching mechanism; wherein,

[0055] The left and right line batching mechanisms respectively include four left-line batching measuring hoppers 41a, four right-line batching measuring hoppers 41b,

[0063] The sewage tank 54 is arranged on the side of the vibrating screen 53 and is connected to the sewage outlet of the sewage processor 52 through a pipeline 59.

[0079] 5) The powder material tank includes three cement t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com