Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Avoid insufficient traffic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for generating video cover, electronic equipment and computer readable storage medium

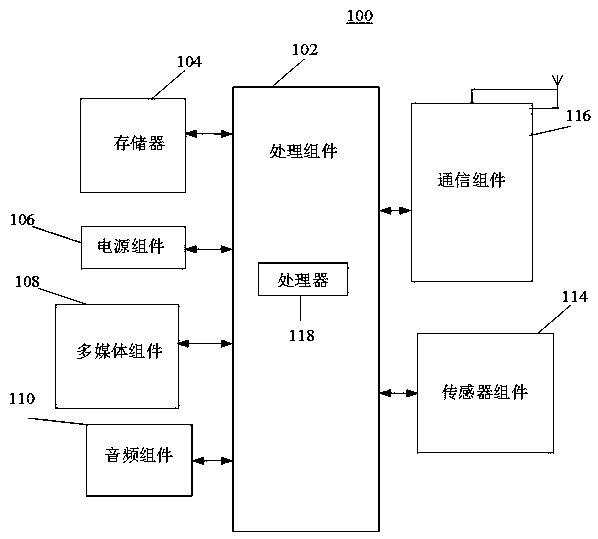

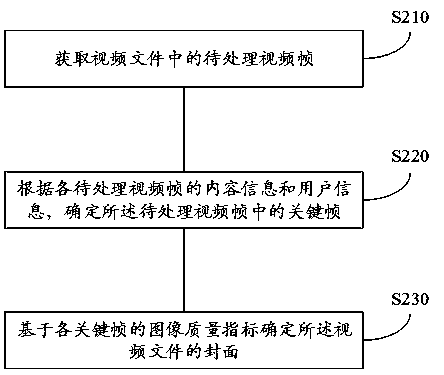

InactiveCN109996091AAttract attentionImprove experienceSelective content distributionImaging qualityComputer science

The invention discloses a method and device for generating a video cover, electronic equipment and a computer readable storage medium. The method for generating the video cover comprises the steps ofobtaining a to-be-processed video frame in a video file; according to the content information and the user information of each to-be-processed video frame, determining a key frame in the to-be-processed video frame; and determining the cover of the video file based on the image quality index of each key frame. According to the technical scheme provided by the embodiment of the invention, the coverwhich is high in relevancy with the video content, conforms to user preferences and is good in quality can be automatically generated for the video.

Owner:苏州八叉树智能科技有限公司

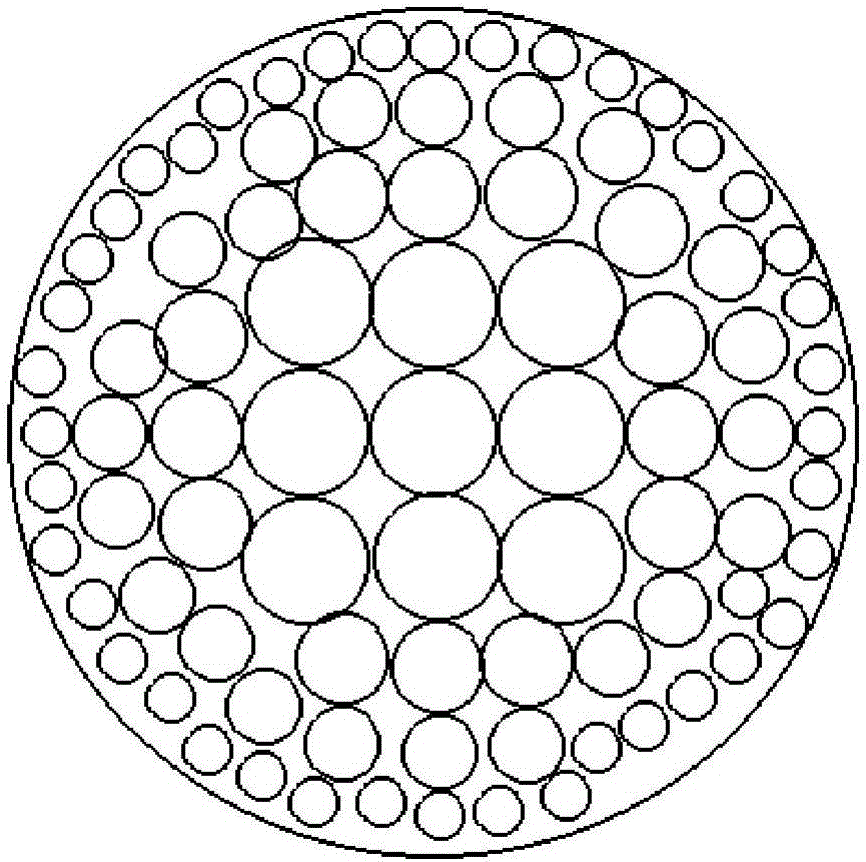

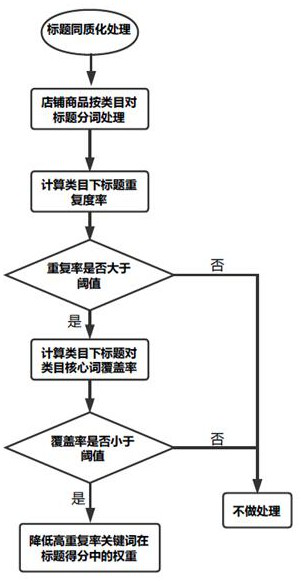

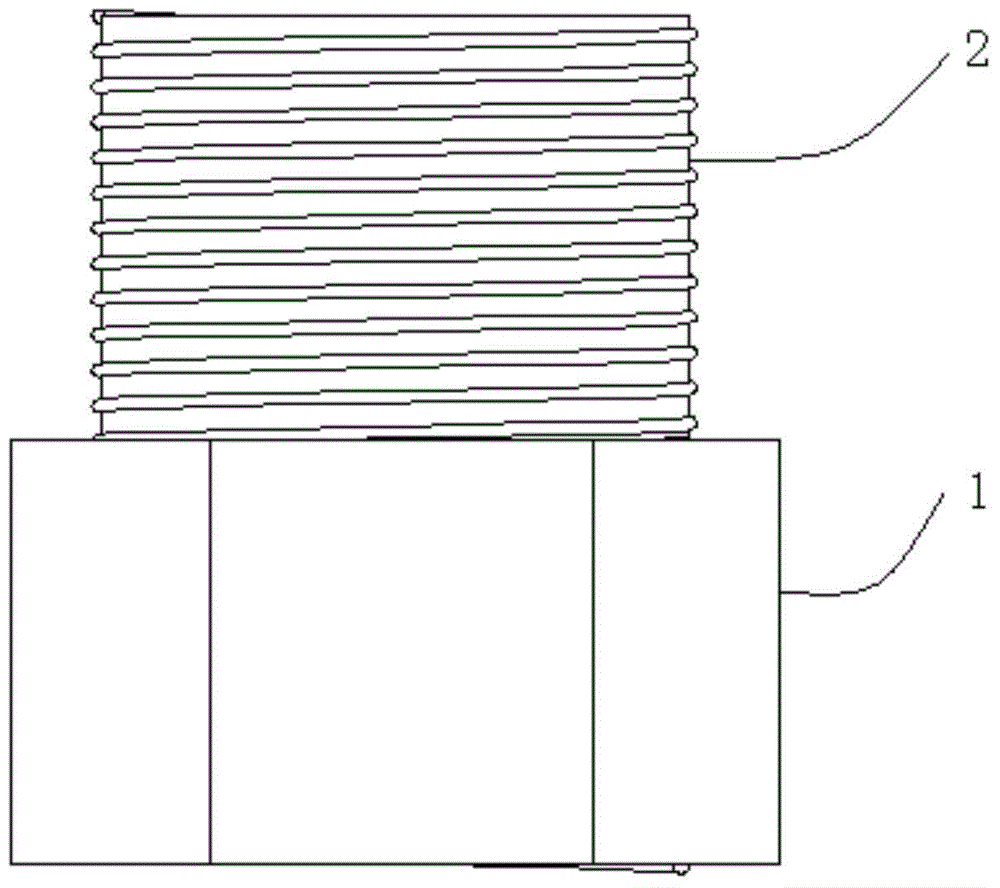

Glass tube bundle and porous medium composite structure solar absorber

InactiveCN106440418AEfficient Transmission ConversionIncrease the areaSolar heating energyHeat transfer optimizationPorous mediumSolar absorber

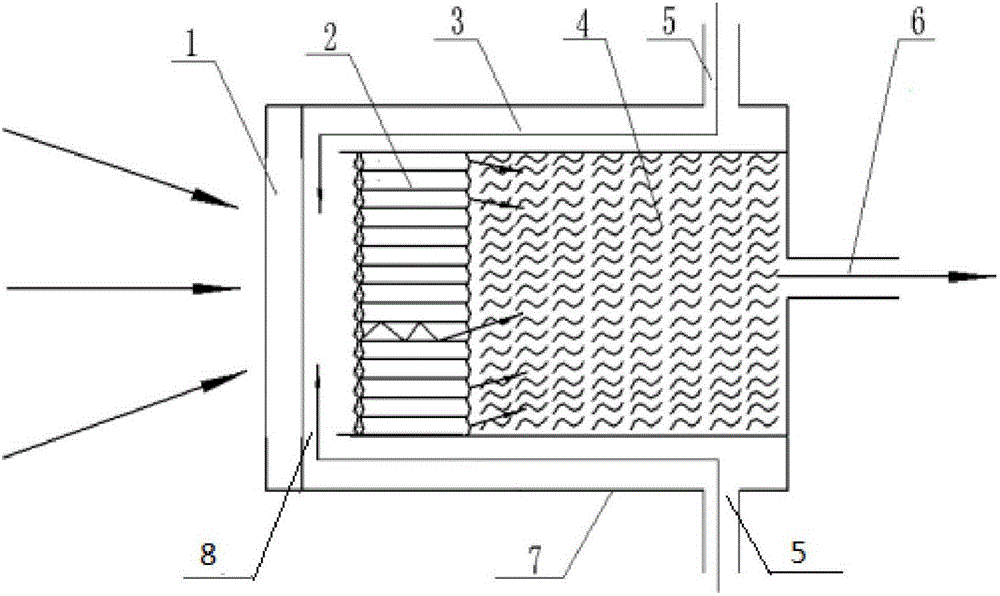

The invention discloses a glass tube bundle and porous medium composite structure solar absorber which comprises a solar absorber shell, wherein a quartz glass window is formed in one end of the solar absorber shell, and a medium outlet is formed in the other end of the solar absorber shell; the solar absorber shell and the quartz glass window are connected into a whole, and a cavity is formed between the solar absorber shell and the quartz glass window; glass tube bundles and porous media are sequentially arranged inside the cavity along the solar incident direction; a preheating channel is formed among the solar absorber shell, the glass tube bundles and the porous media; a first medium inlet is formed in one end of the preheating channel; and after preheated in the preheating channel, the media converge sunlight at the second medium inlet so as to enter the glass tube bundles. Because the glass tube bundles are small in solar absorption and small in external radiation energy, the thermal efficiency of the system is improved. Meanwhile, the incident sunlight is transmitted to the porous medium by the glass tube bundles, so that medium distribution is matched with sunlight flow density, while the porous medium is mainly capable of converting solar radiation energy into internal energy of working media; and therefore, the problem that the existing porous medium solar absorber is low in thermal efficiency and reliability is effectively solved.

Owner:FUJIAN UNIV OF TECH

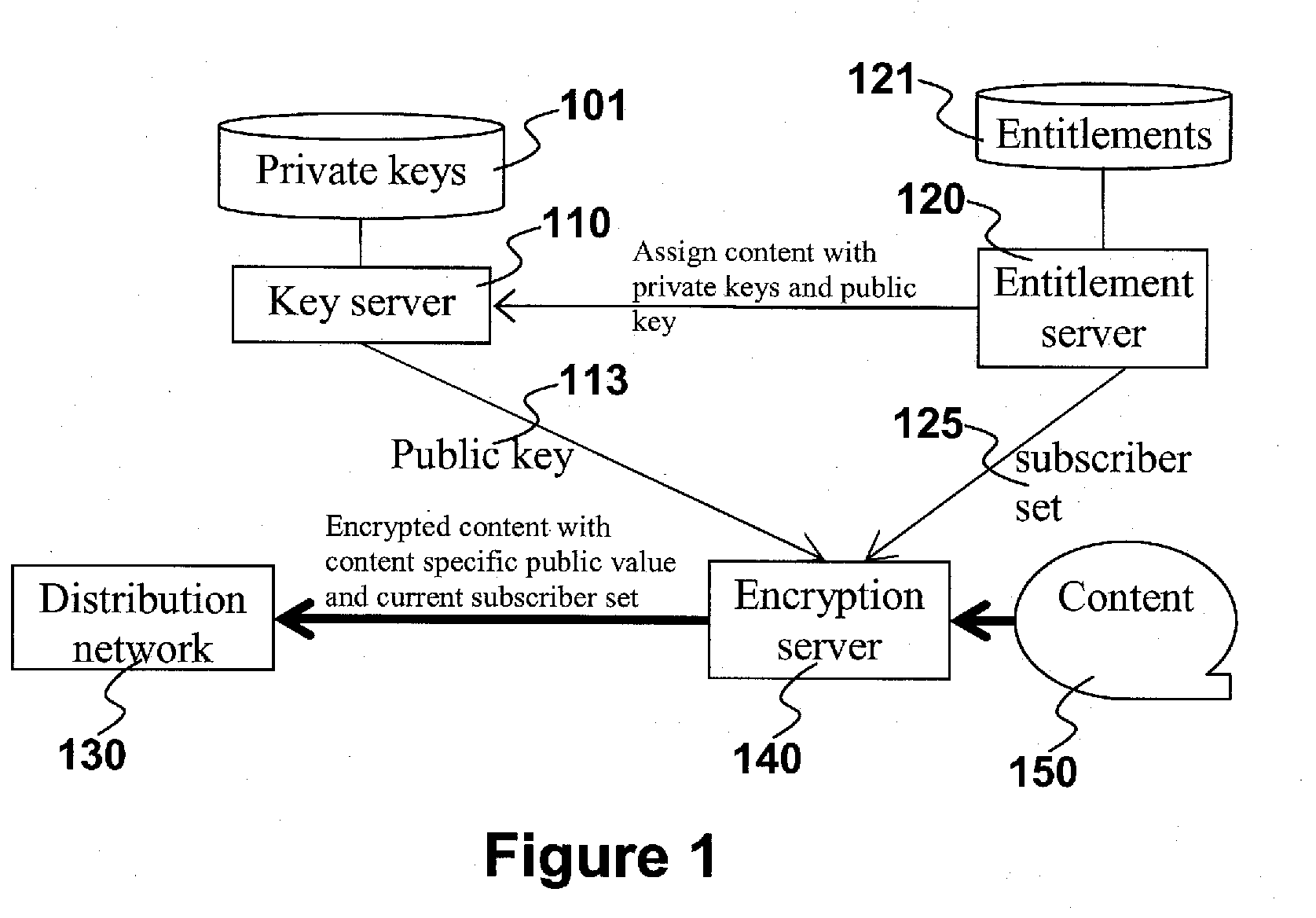

System and Method for Content Distribution with Broadcast Encryption

ActiveUS20100228972A1Save computation timeEffective encryptionUser identity/authority verificationComputer security arrangementsContent distributionKey distribution

The claimed invention relates to system and method for providing encrypted content via a distribution network 630 with efficient key distribution and distribution network assignment. The claimed invention assigns users to content-specific distribution network in which the content is broadcast. This makes the content access much more efficient by conducting the authorization at the time of joining the content-specific distribution network and providing the content to entitled users through broadcasting. The claimed invention provides additional security by removing a user from the content-specific distribution network when his entitlement is no longer valid.

Owner:HONG KONG APPLIED SCI & TECH RES INST

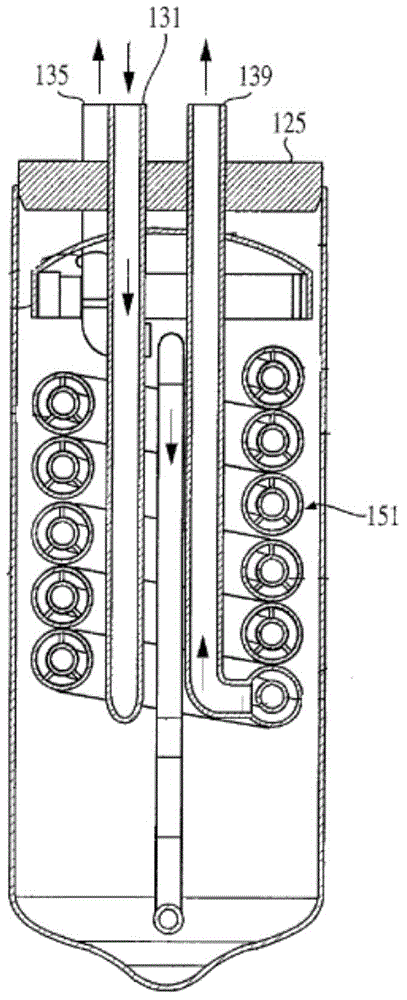

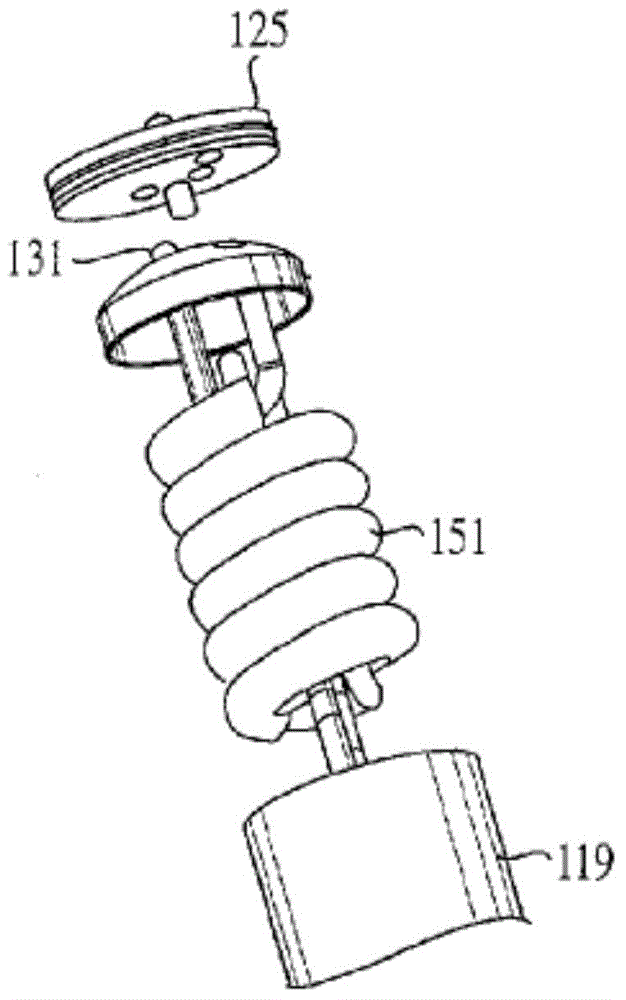

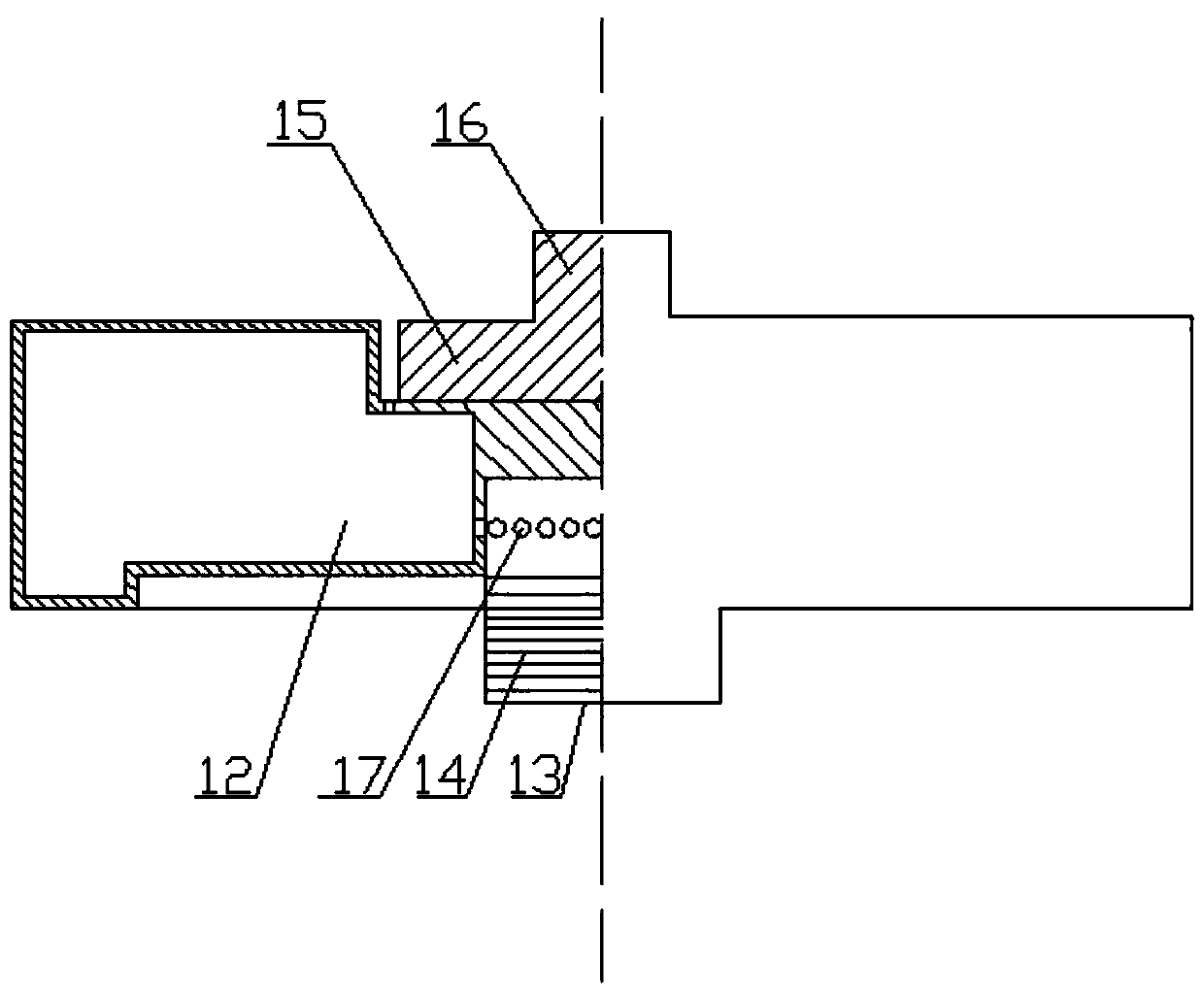

Carbon dioxide air-conditioning system and gas-liquid separator thereof

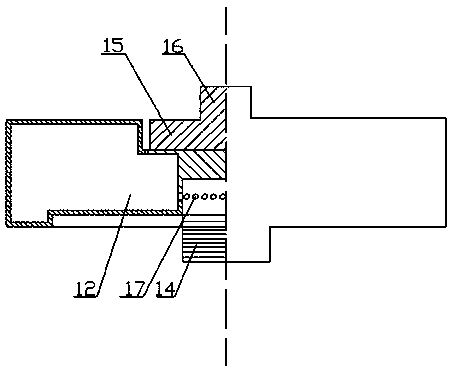

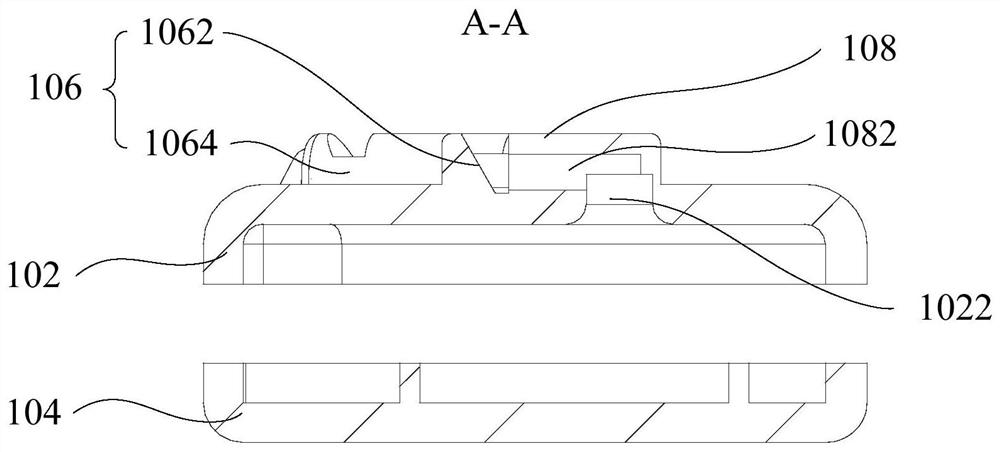

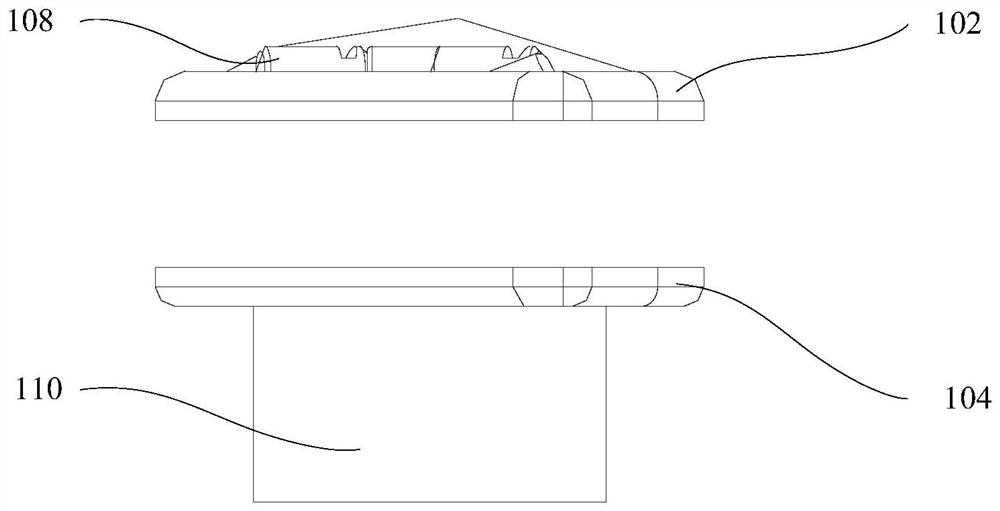

InactiveCN105805990ANo leakageAvoid insufficient trafficCompression machinesRefrigeration componentsVapor–liquid separatorEngineering

The invention provides a carbon dioxide air-conditioning system and a gas-liquid separator thereof. The gas-liquid separator is provided with a low-temperature low-pressure pipeline and a high-temperature high-pressure pipeline, wherein the low-temperature low-pressure pipeline communicates with a compressor, and heat exchange is conducted between the high-temperature high-pressure pipeline and the low-temperature low-pressure pipeline. Both the low-temperature low-pressure pipeline and the high-temperature high-pressure pipeline are arranged independently. The high-temperature high-pressure pipeline is arranged spirally. The low-temperature low-pressure pipeline is inserted in a cylinder cavity formed by the spiral high-temperature high-pressure pipeline. As the high-temperature high-pressure pipeline and the low-temperature low-pressure pipeline of the gas-liquid separator are arranged independently, the gas-liquid separator can be technologically and easily obtained, the structure is simple, and the phenomenon of pipeline leakage is avoided; in addition, compared with the prior art, the space of the spiral cylinder cavity is utilized by the low-temperature low-pressure pipeline, so that under the conditions of the same spiral radius and the same spiral pipeline radius, the flow of a high-temperature high-pressure refrigerant is larger; and moreover, a low-temperature low-pressure refrigerant in the whole inner cavity can also participate in heat exchange, and thus a better heat exchange effect can be achieved.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

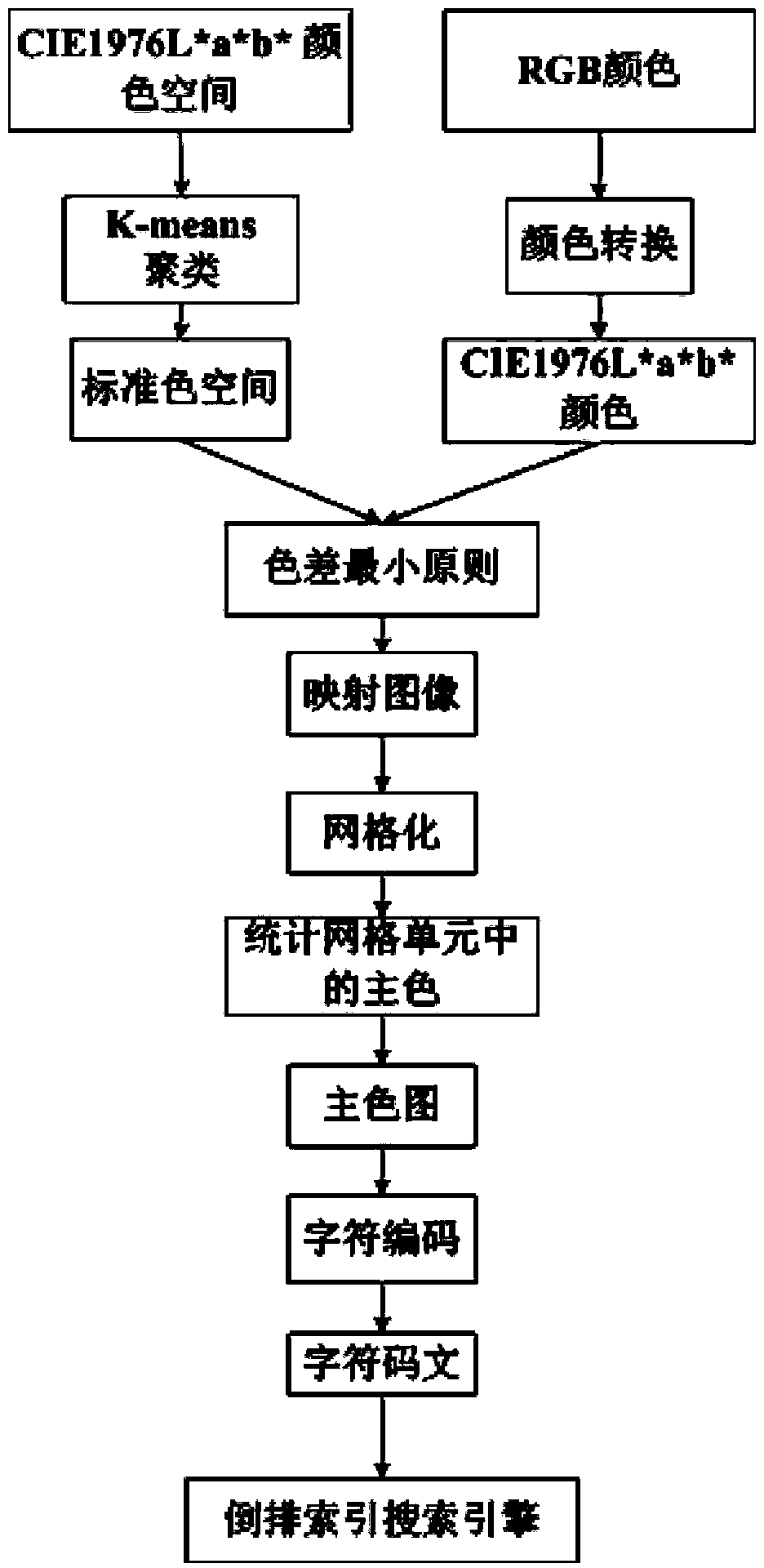

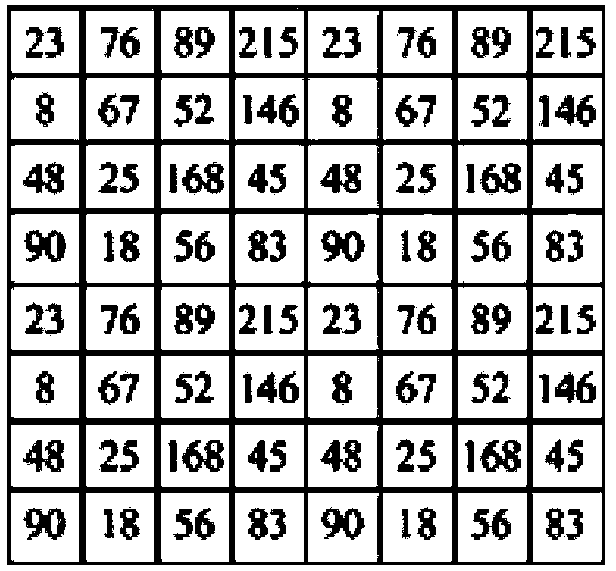

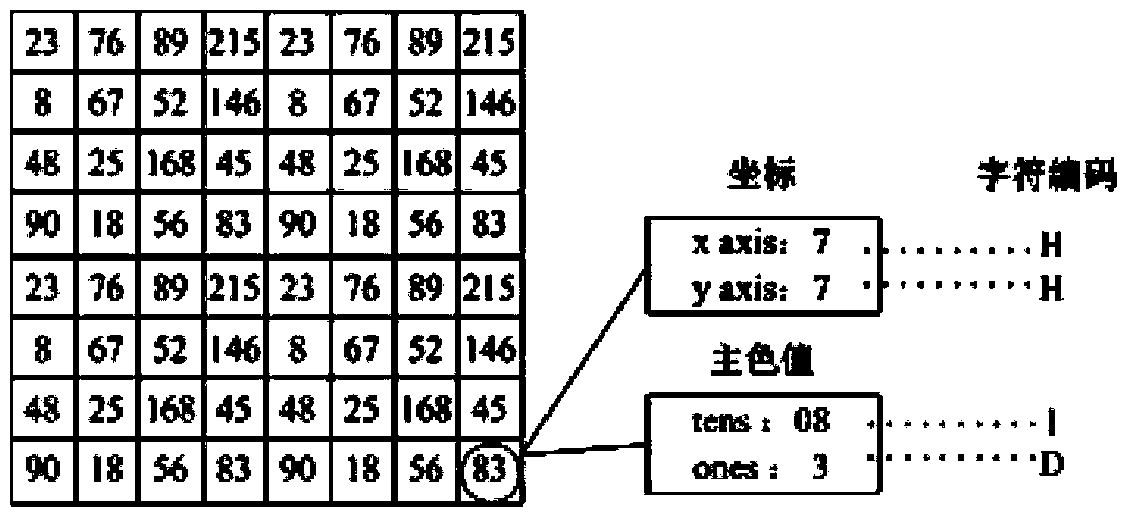

Mass image searching system based on color features and inverted indexes

InactiveCN103593458ASolve the problem of fast and efficient retrievalEfficient retrievalSpecial data processing applicationsPattern recognitionGrid cell

The invention provides a mass image searching system based on color features and inverted indexes. The mass image searching system is used in the following steps that firstly, a CIE1976L*a*b*c (Lab for short) color space with good uniformity is selected, K-means clustering is conducted on the space, and n types of colors are obtained; secondly, image pixels to be searched for are mapped according to the principle that color differences are minimum, and dimensionality reduced images are obtained; thirdly, the images obtained in the second step are divided into grids, main colors in grid units are obtained and used as representative colors, and each image is composed of a plurality of representative colors; fourthly, user-defined coding is conducted on the representative colors obtained in the third step, a piece of class text composed of a plurality of character codes is obtained finally, the class text is uploaded to an inverted index server, index building of mass images is completed, and therefore an image searching function can be completed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

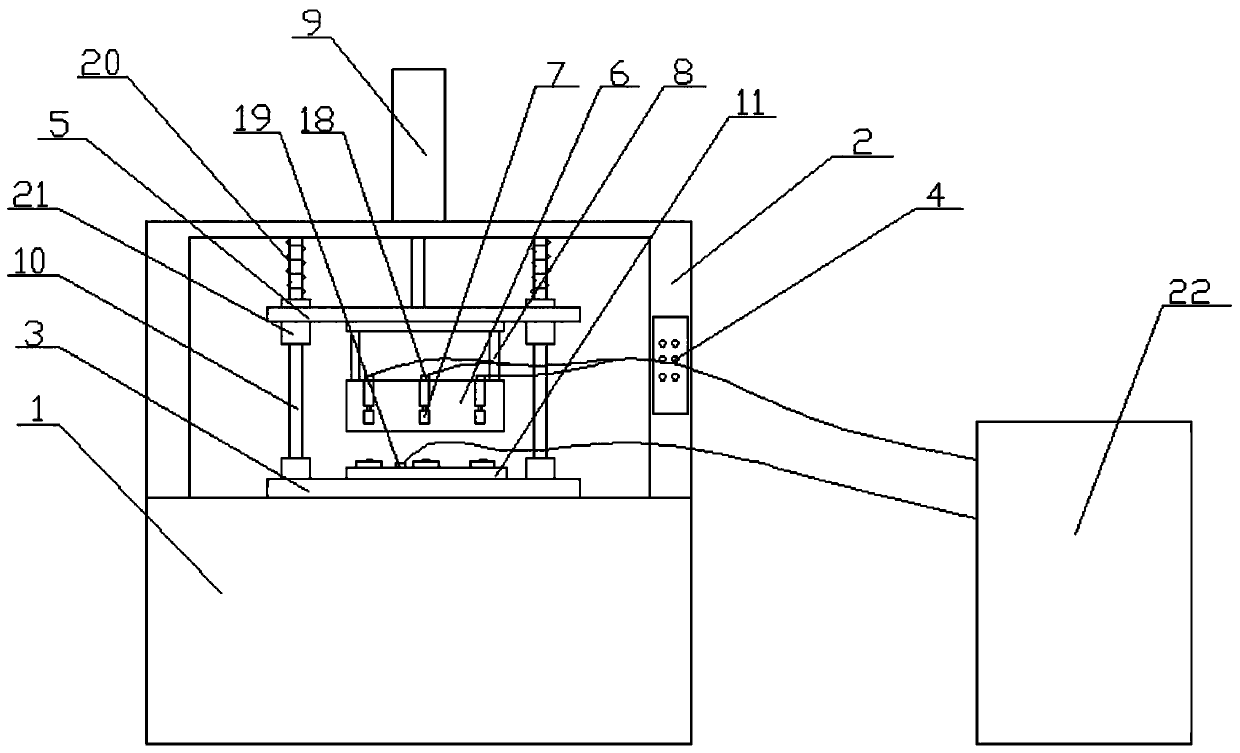

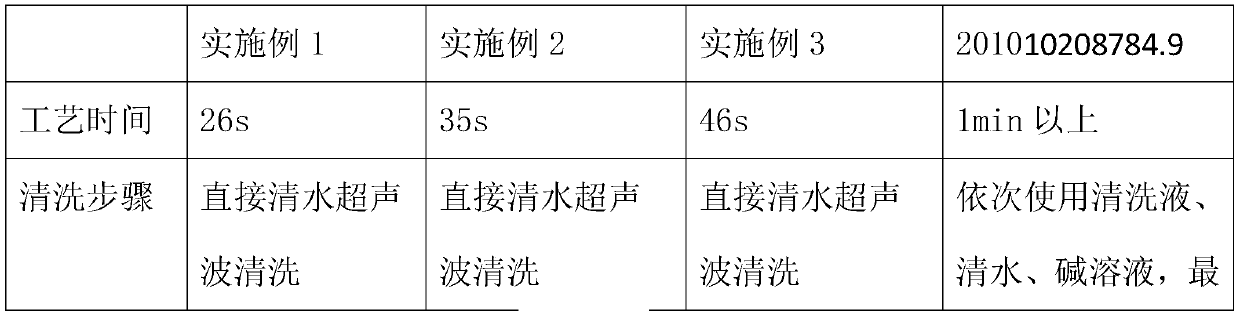

Gear burr removing technology

ActiveCN108746898AJet speedGood deburring effectElectrochemical machining apparatusTraffic volumeCorrosion

The invention relates to a gear burr removing technology. The technology comprises the following specific steps that 1, a burr removing device is constructed; 2, a gear is placed; 3, conducting and discharging are carried out; 4, an electrolyte is sprayed; 5, the gear is washed ultrasonically; 6, antirust treatment is carried out; and 7, the gear is naturally dried in air and delivered from storage. The technology has the following advantages that an anode terminal and a cathode terminal are utilized for conducting and discharging, the electrolyte is sprayed to the gear fast from bottom to top, the spraying speed is high, the electrolyte is sprayed in a centralized manner, and the burr removing effect is achieved; meanwhile, the burr removing effect is remarkable, the risk that the gear isbroken down is avoided, time for burr removing is short, and efficiency is high; the concentration of sodium nitrate is low, harm to the human body is avoided, corrosion to the surface of the gear isavoided, and meanwhile, the good burr removing effect can be ensured; and as the electrolyte spraying speed is high and the flow amount is large, the complex washing step in the later period is omitted, the gear only needs to be washed with clear water, the gear is washed ultrasonically, and thus greasy dirt on the surface of the gear can be decomposed and emulsified.

Owner:NANTONG ZHONGLV GEAR CO LTD

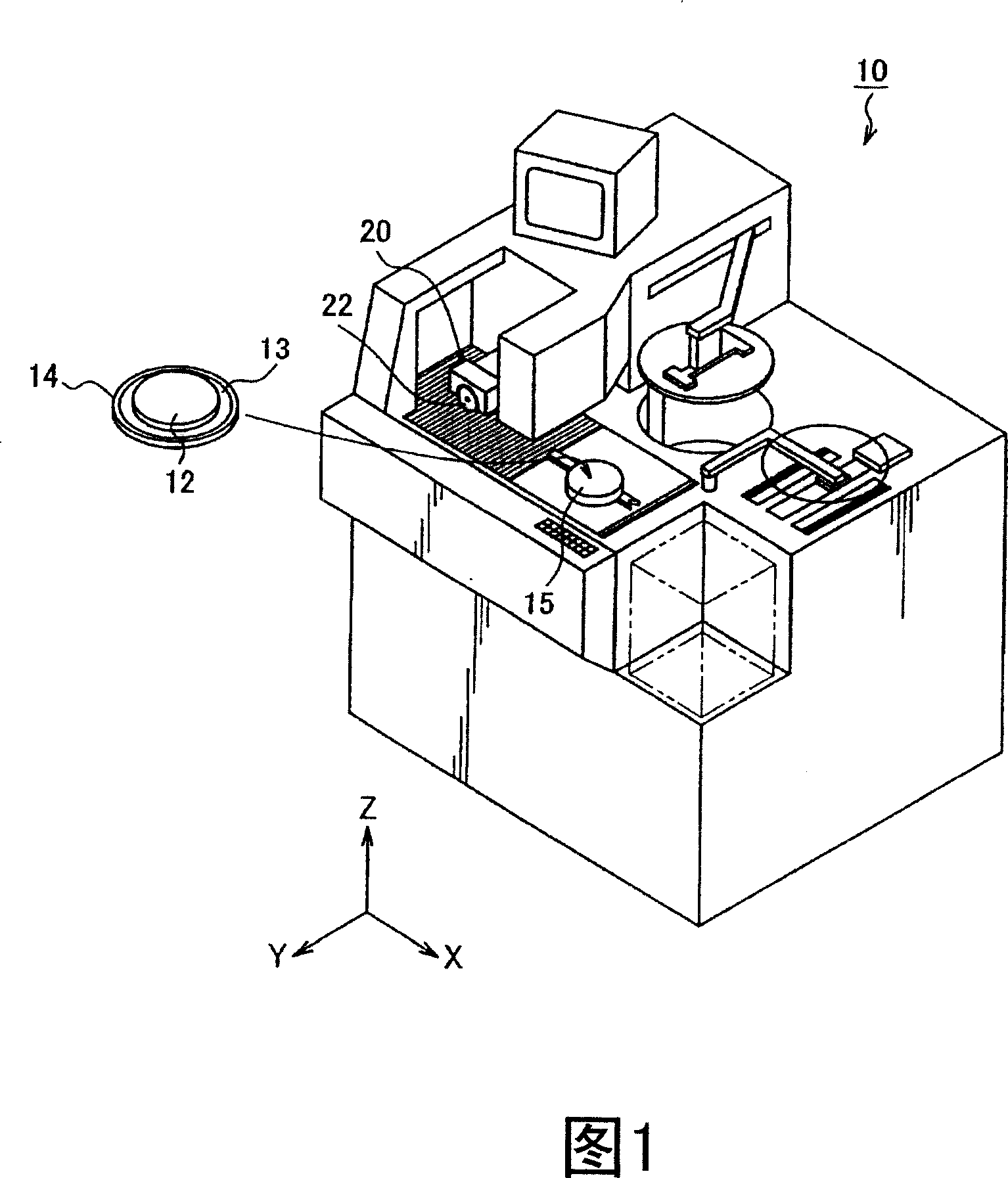

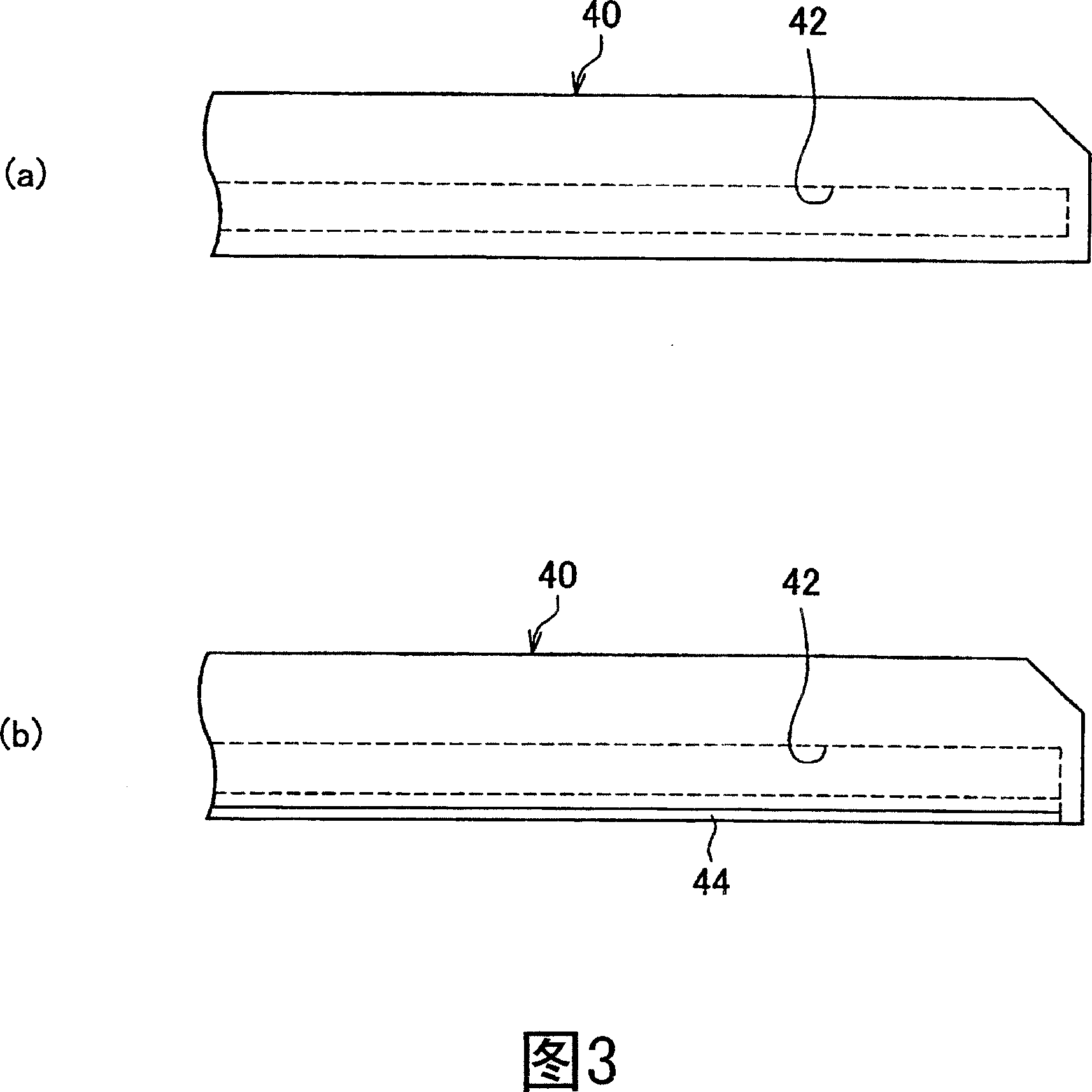

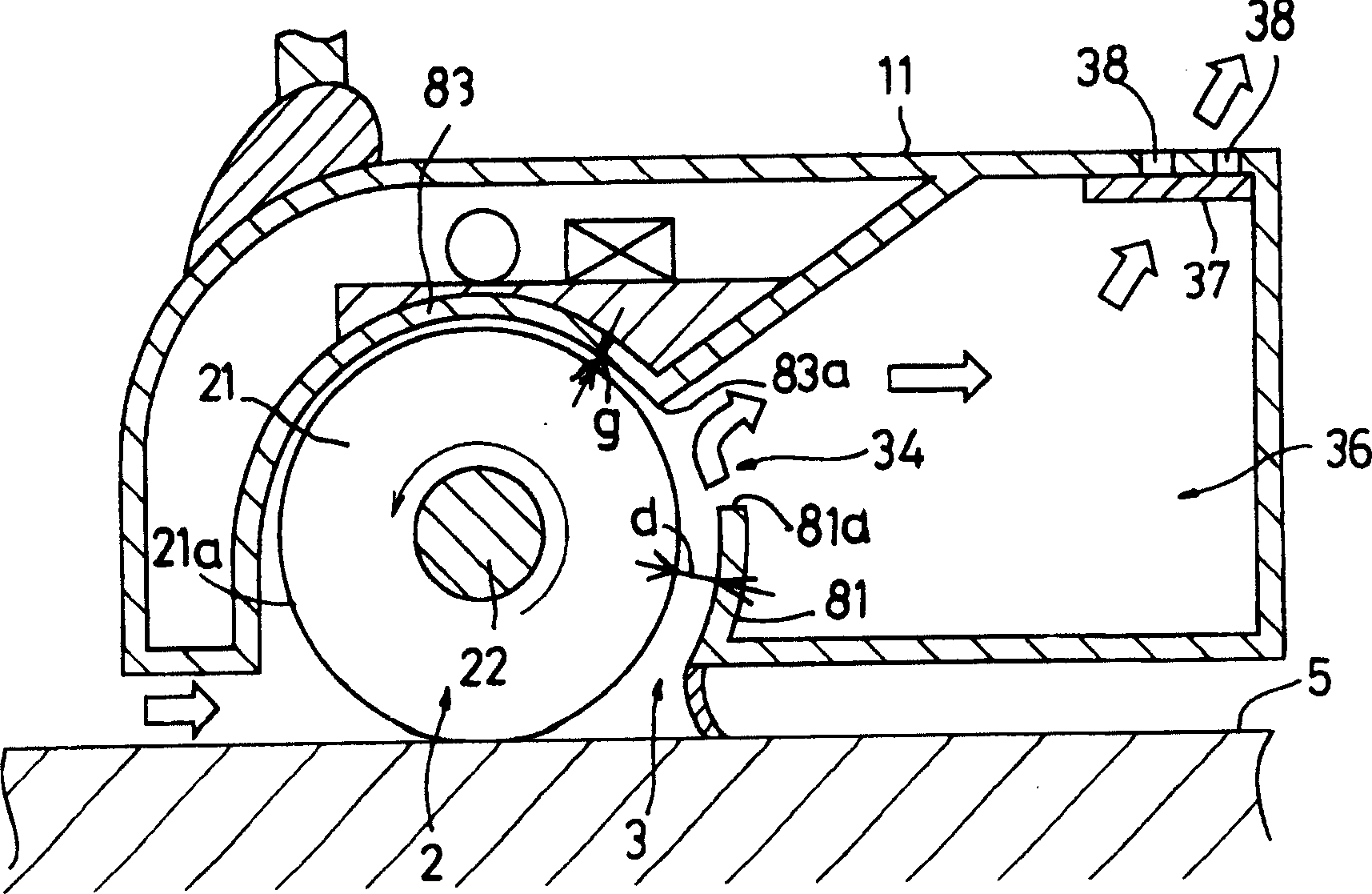

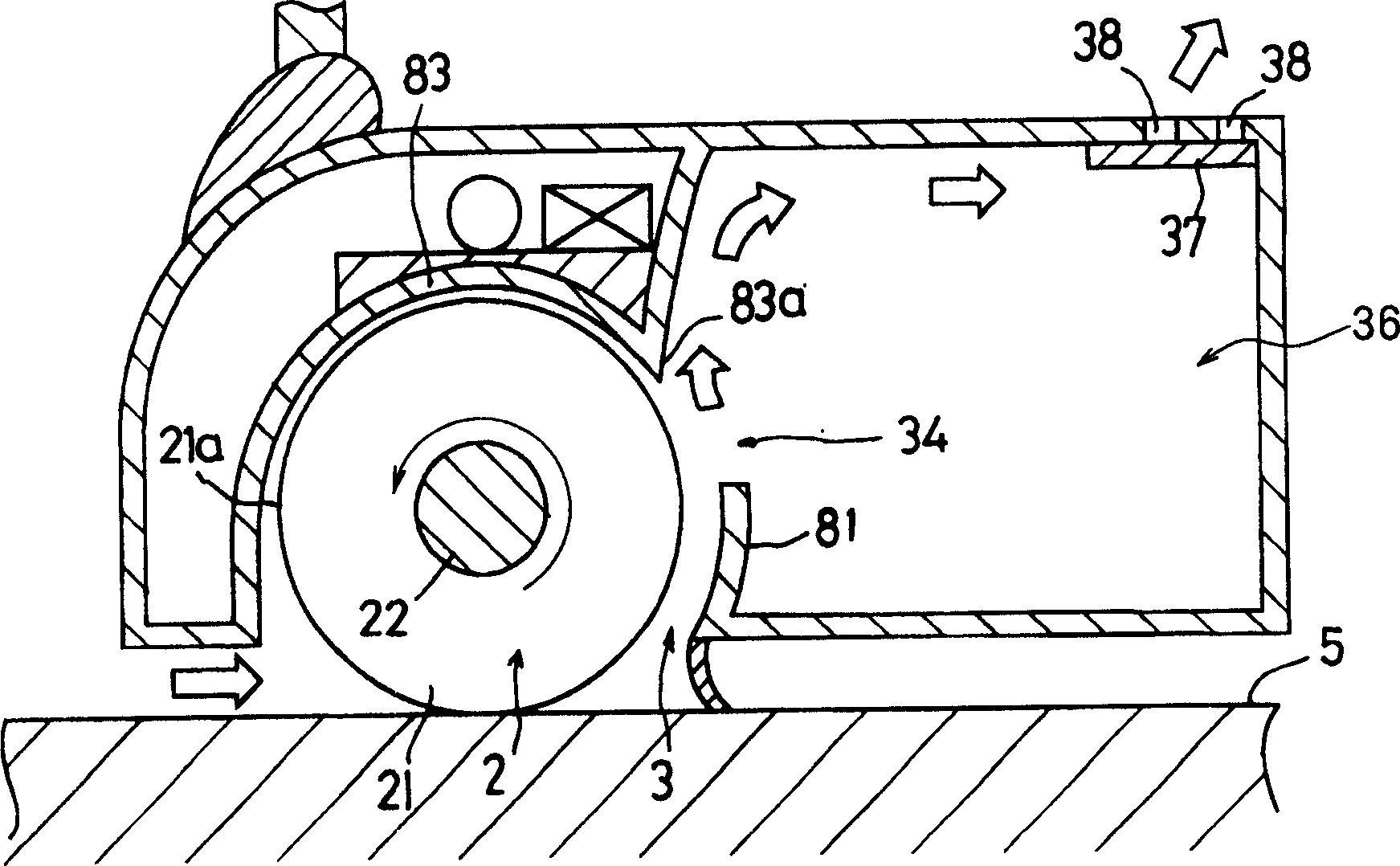

Cutting device

ActiveCN1974168APrevent outflowPrevent adhesionSemiconductor/solid-state device manufacturingFine working devicesEngineeringMachining

The invention provides a cutting device which more surely prevents adhering of chips to the surface of a workpiece. This cutting device is provided with: a cutting blade, a cutting liquid supply means for supplying cutting liquid to the cutting blade and a machining point of the workpiece; and a blade cover arranged to cover an outer periphery of the cutting blade. The cutting device is further provided with a cutting chip control means oppositely arranged to hold the cutting blade on both spindle axial direction sides of the cutting blade to inject liquid toward a position separated by a prescribed distance from the machining point on the surface of the workpiece from both sides of the cutting blade. The cutting chip control means forms liquid walls along the cutting direction on both the sides of the cutting blade not to splash the chips generated by cutting the workpiece in the spindle axial direction by injecting the liquid, and separates the chips from the surface of the workpiece by a flow of the injected liquid.

Owner:DISCO CORP

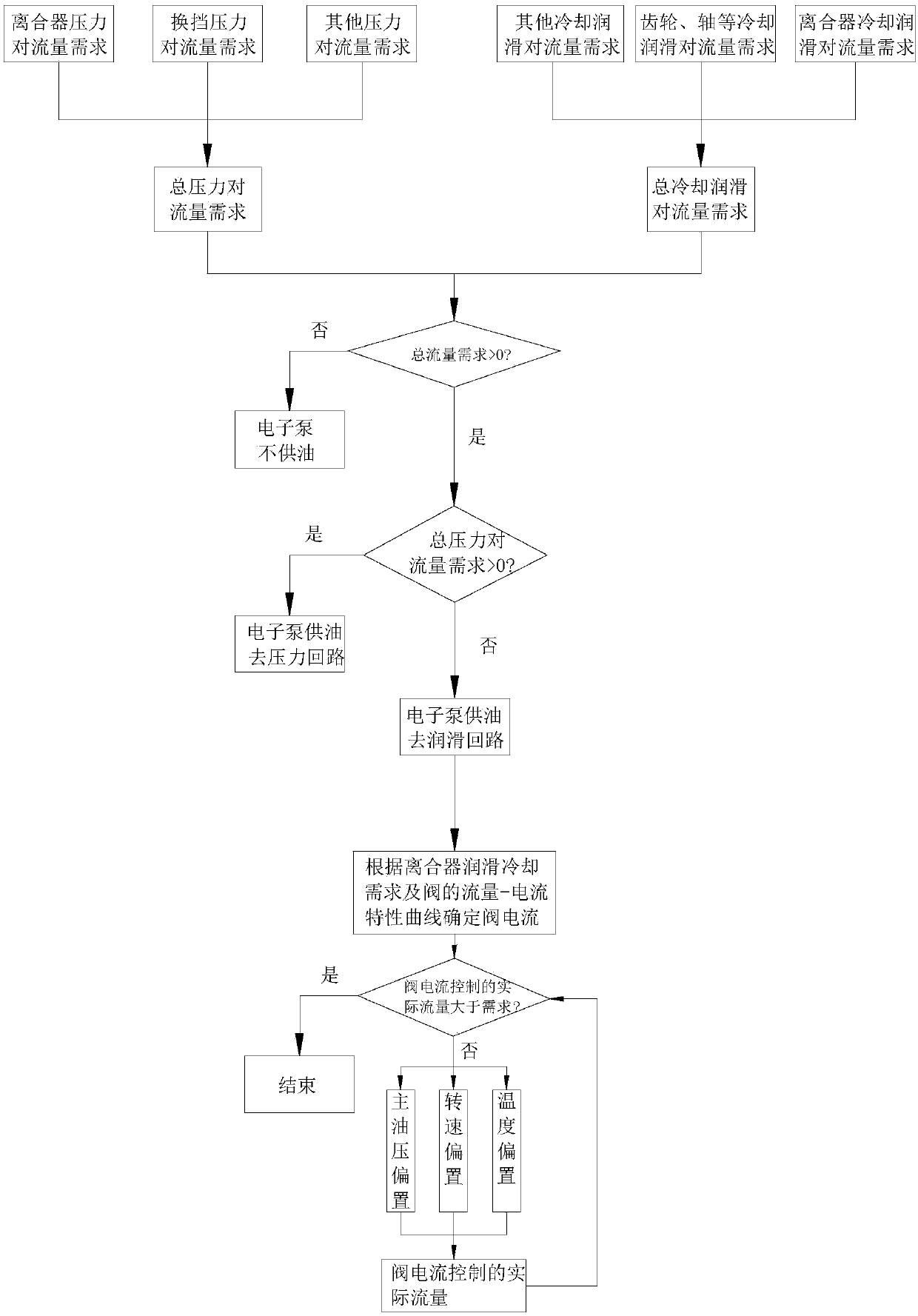

Transmission hydraulic system, control method and vehicle

The invention provides a transmission hydraulic system, a control method and a vehicle. The control method comprises the steps of obtaining the requirement of total pressure for the flow and the requirement of total cooling lubricating for the flow in the hydraulic system; judging whether the requirement of total pressure for the flow is larger than zero or not; if yes, controlling an electronic pressure to supply oil to a pressure loop, and if not, controlling the electronic pump to supply oil to the lubricating loop; when the electronic pump supplies oil to the lubricating loop, according tothe clutch cooling lubricating needs, determining the flow, and according to a correction coefficient, correcting the flow. The method has the beneficial effects of being low in energy consumption and high in fuel economy, safety and reliability are achieved, and the vehicle taking comfort is improved.

Owner:GREAT WALL MOTOR CO LTD

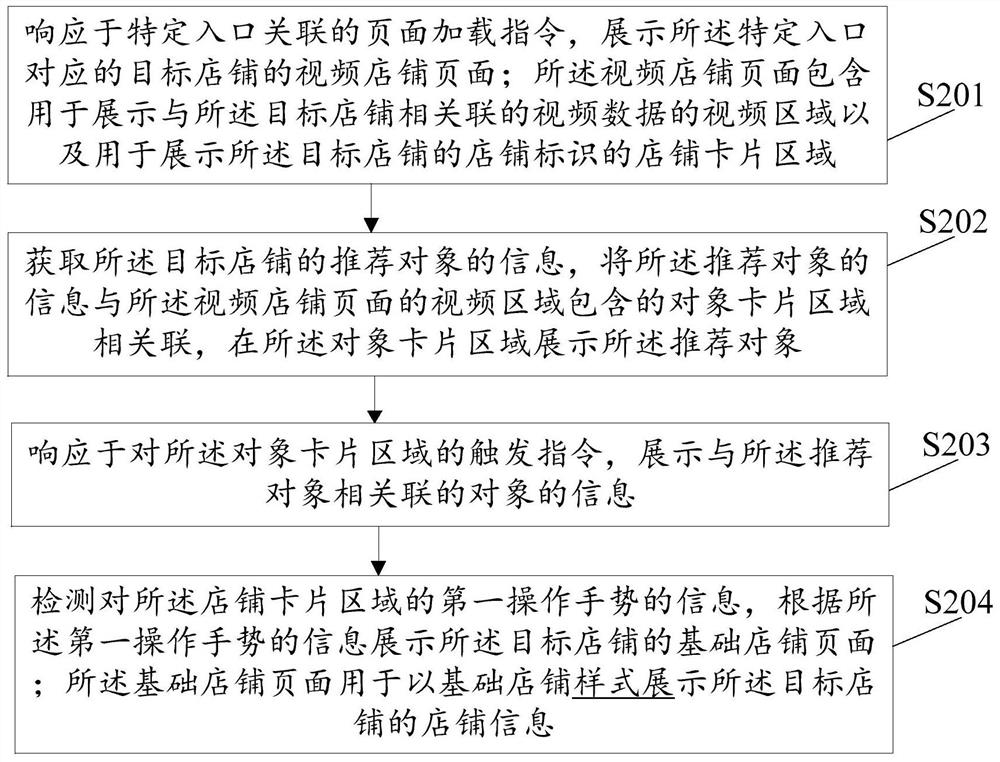

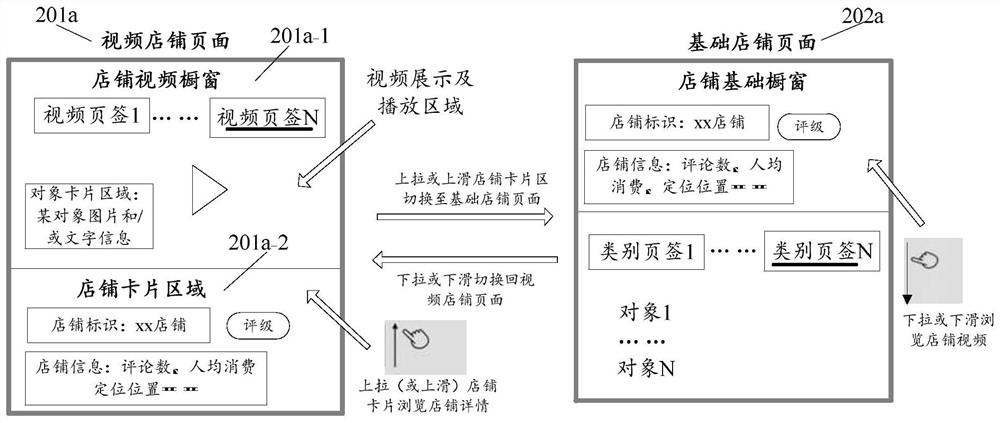

Shop data processing method and device

ActiveCN112770187AAvoid insufficient trafficHigh trafficSelective content distributionComputer graphics (images)Information presentation

The invention discloses a shop data processing method. The method comprises the following steps: displaying a video shop page of a target shop corresponding to a specific entrance, wherein the video shop page comprises a video area used for displaying video data associated with the target shop and a shop card area used for displaying a shop identifier of the target shop; acquiring information of a recommended object of the target shop, and displaying the recommended object in the object card area; in response to a trigger instruction for the object card area, displaying information of an object associated with the recommended object; detecting information of a first operation gesture for the shop card area, and displaying a basic shop page of the target shop according to the information of the first operation gesture; and using the basic shop page for displaying shop information of the target shop in a basic shop style. By adopting the method, the user traffic and the retention rate are improved.

Owner:KOUBEI SHANGHAI INFORMATION TECH CO LTD

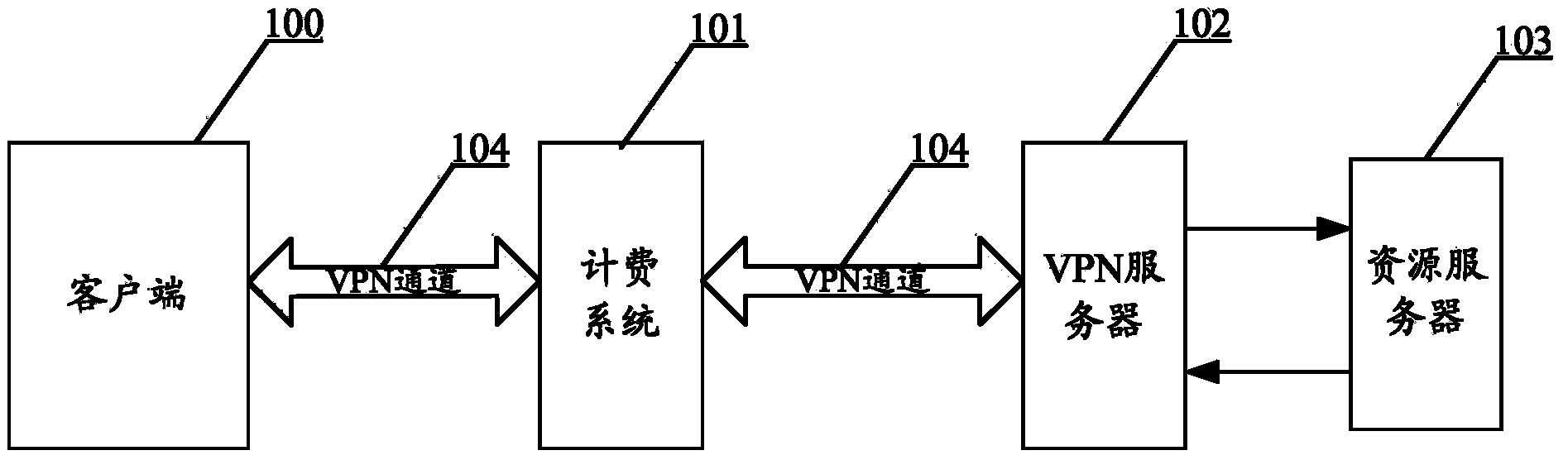

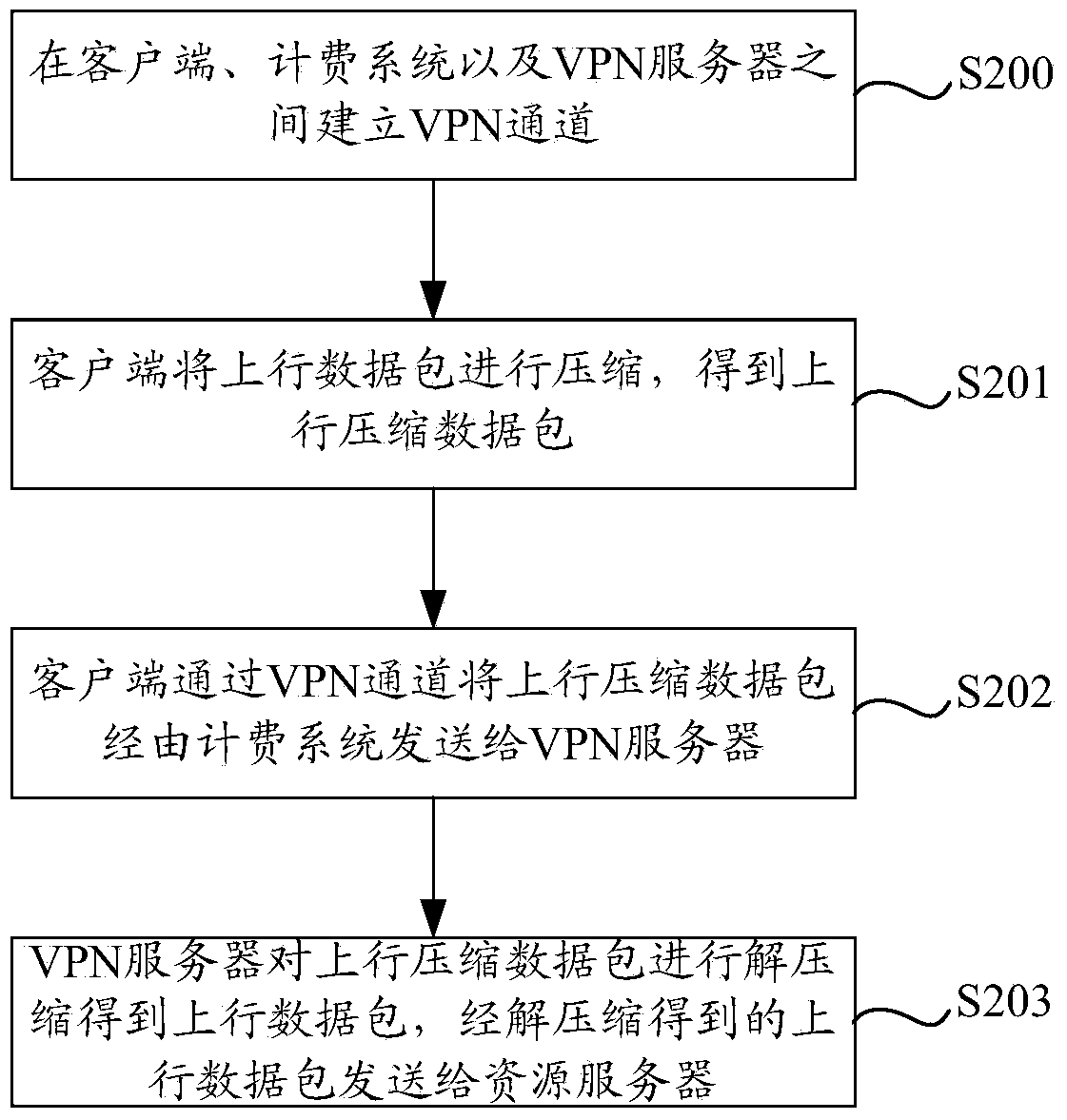

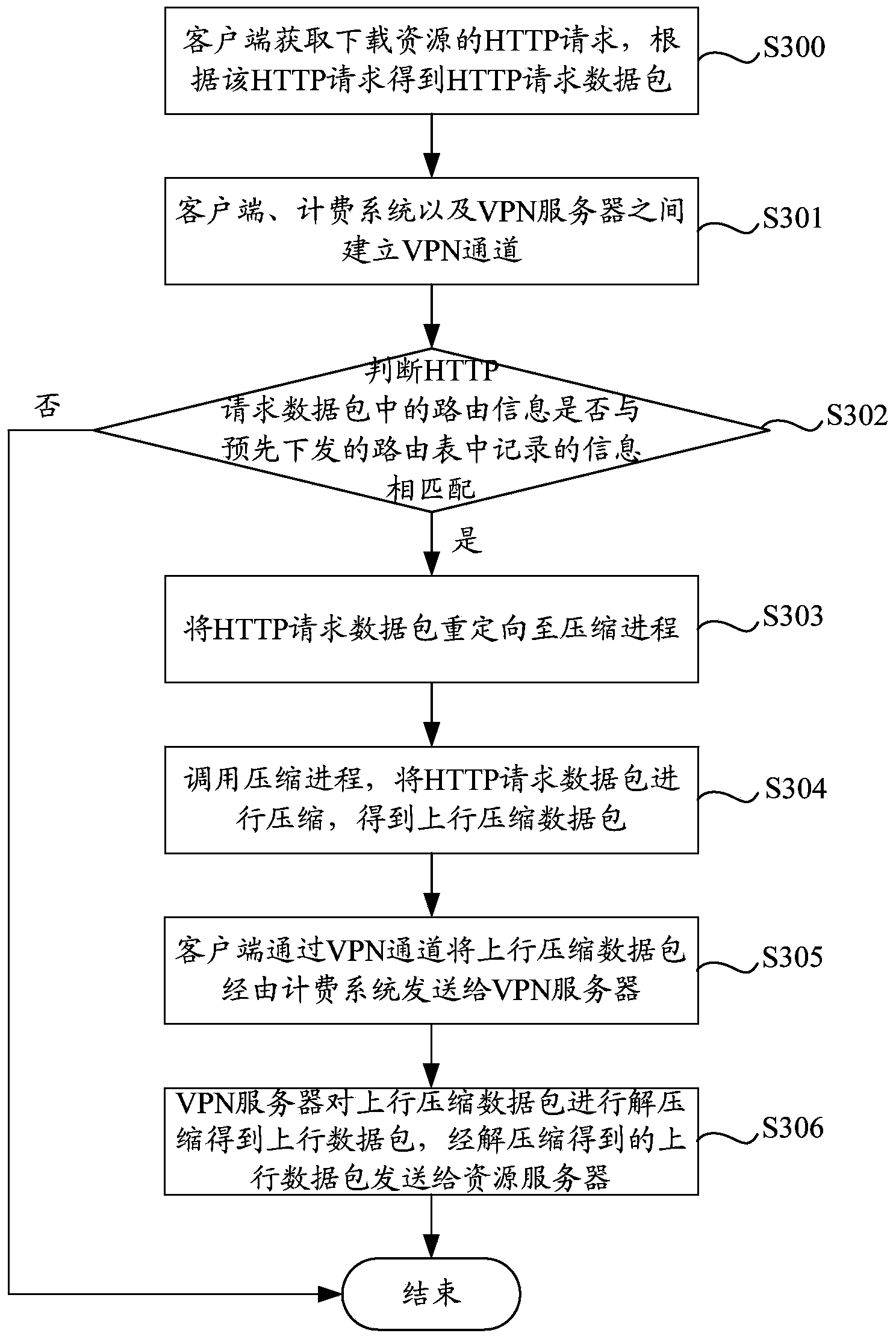

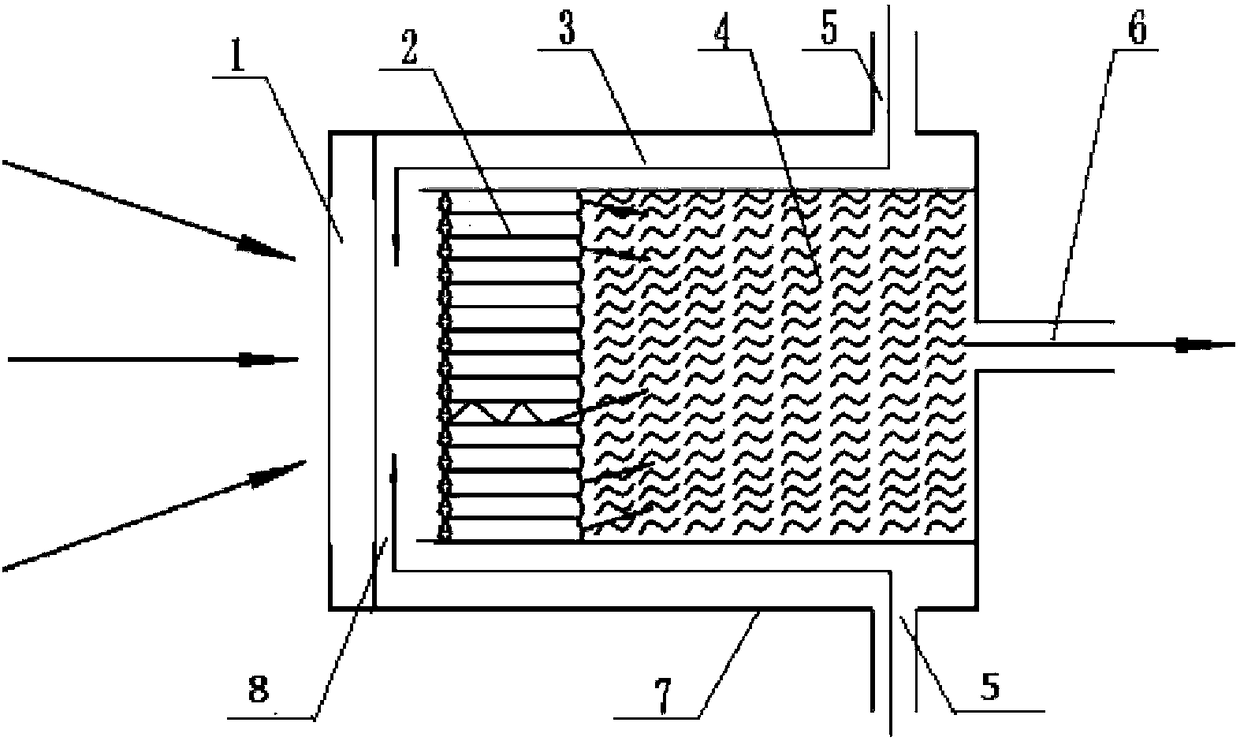

Traffic optimization method and system performed on mobile terminal device and client

ActiveCN104038916AReduce trafficAvoid insufficient trafficAccounting/billing servicesNetwork traffic/resource managementTraffic capacityPrivate network

The invention discloses a traffic optimization method and system performed on a mobile terminal device, a client and a VPN (Virtual Private Network) server. The method comprises the following steps: compressing an uplink data package to obtain an uplink compressed data package; sending the uplink compressed data package to the VPN server by a charging system through a VPN channel; uncompressing the uplink compressed data package through the VPN server to obtain an uplink data package; sending the uncompressed uplink data package to a resource server. According to the method, the VPN server is utilized to compress and uncompress the uplink / downlink data package, thus the data volume calculated by the charging system is less than that of the data package to be transmitted really before compressing, and as a result, the purpose of saving traffic is realized.

Owner:北京鸿享技术服务有限公司

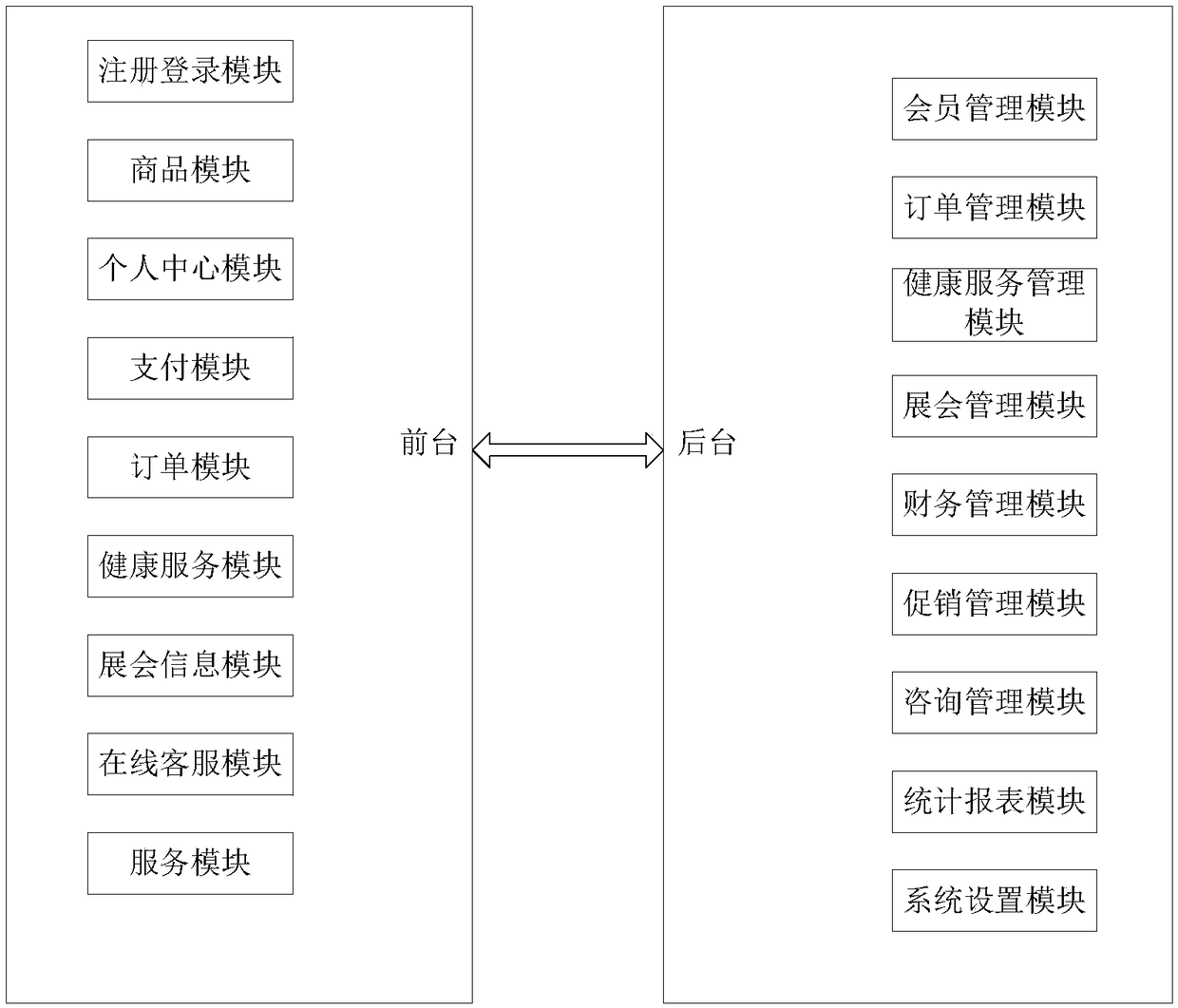

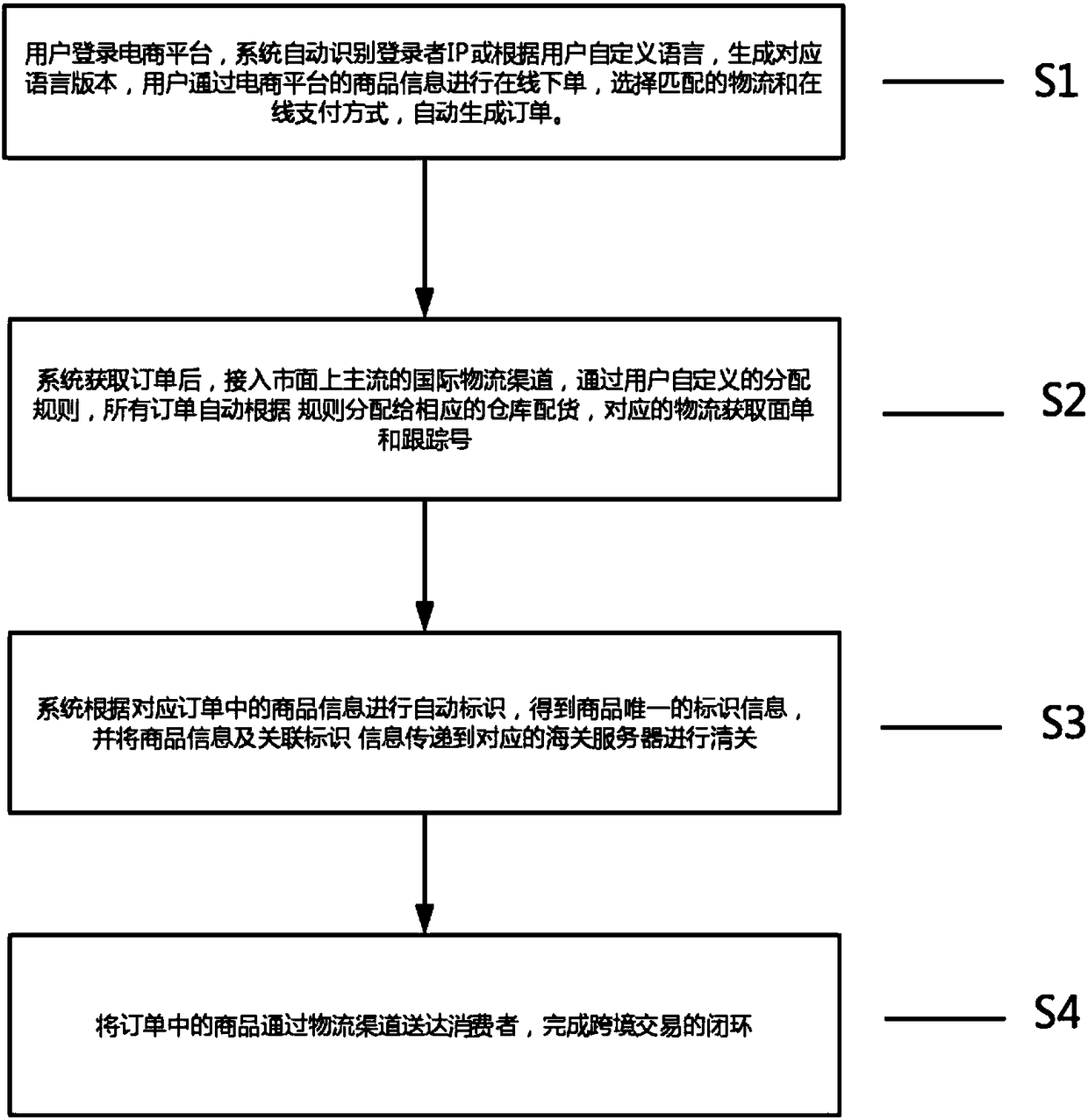

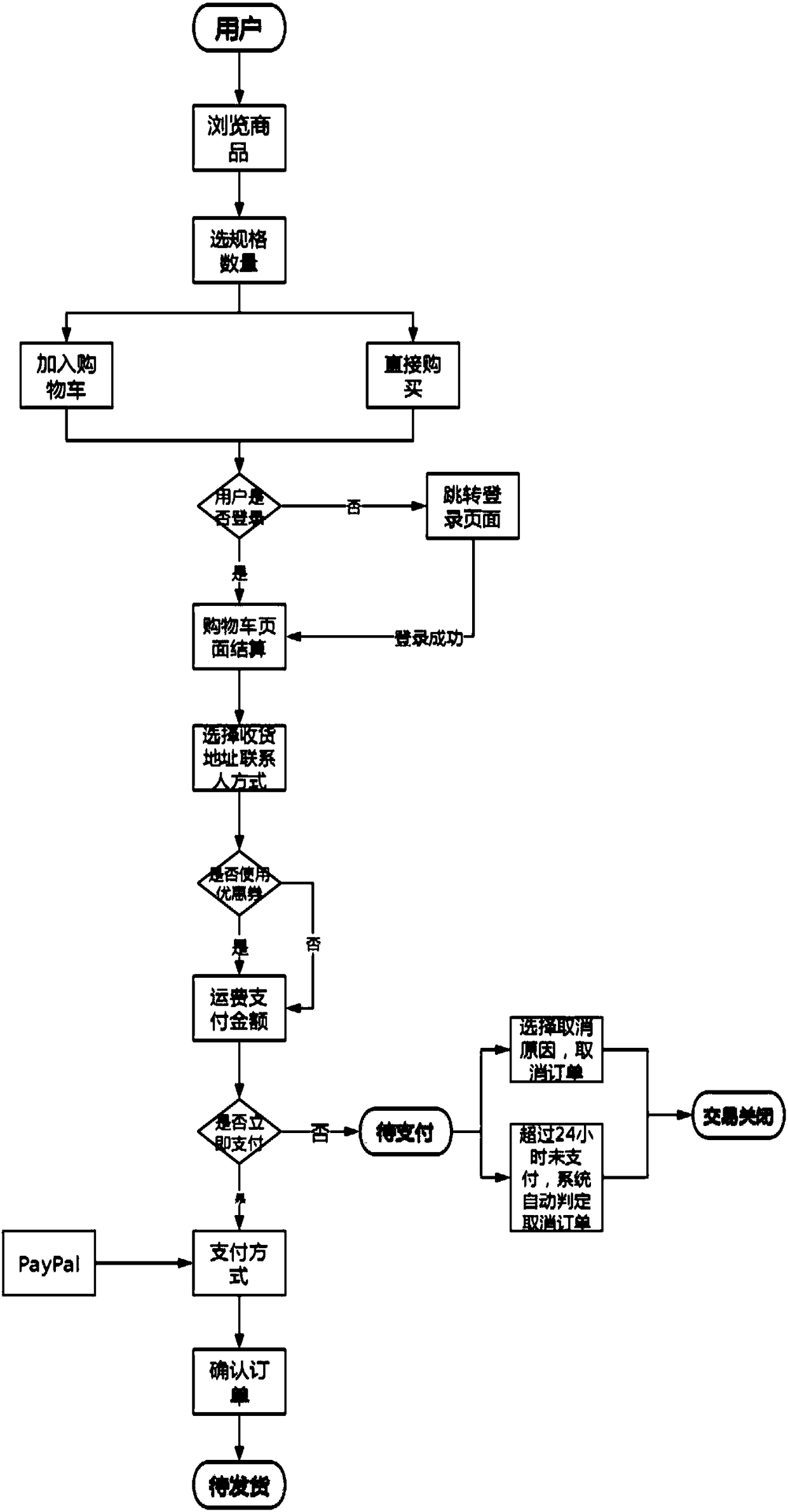

Health industry cross-border electronic commerce platform and implementation method thereof

PendingCN108460669AIncrease attractivenessIncrease stickinessHealth-index calculationBuying/selling/leasing transactionsPaymentLogistics management

The invention discloses a health industry cross-border electronic commerce platform and an implementation method. The platform comprises two parts, namely a foreground and a background; the foregroundcomprises a registeration and login module, a commodity module, a personal center module, a payment module, an order module, a health service module, an exhibition information module, an on-line customer service module and a logistics module; and the background comprises a member management module, an order management module, a health service management module, an exhibition management module, afinancial management module, a promotion management module, a consulting management module, a statistical form module and a system setting module. Through the technical scheme of the invention and through effective combination of information technology means and health detection as well as big data, cross-border, even transboundary product and service exchange is realized; and by the method, goodproducts and services of different countries can be provided for customers of another country at the first time.

Owner:GUANGDONG FOOD & DRUG VOCATIONAL COLLEGE

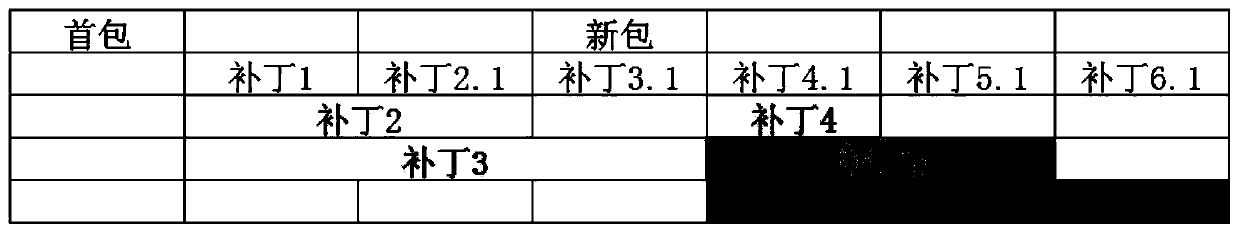

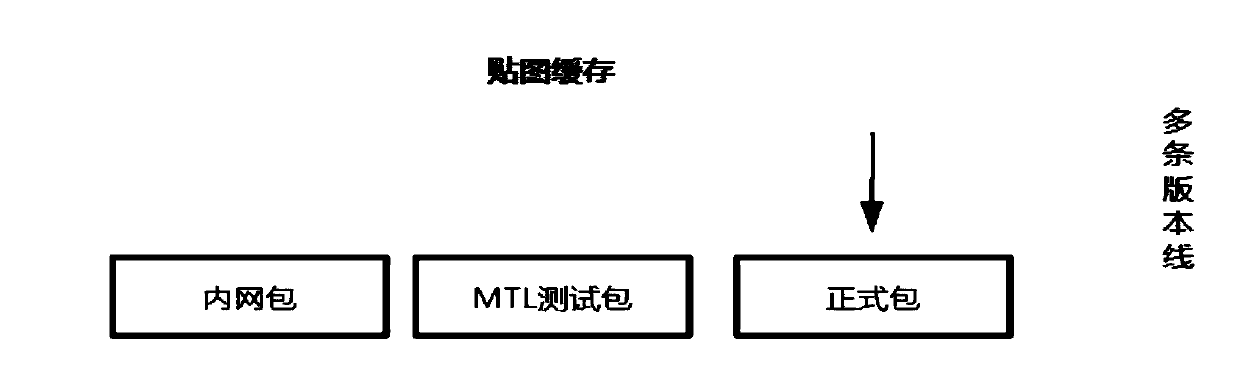

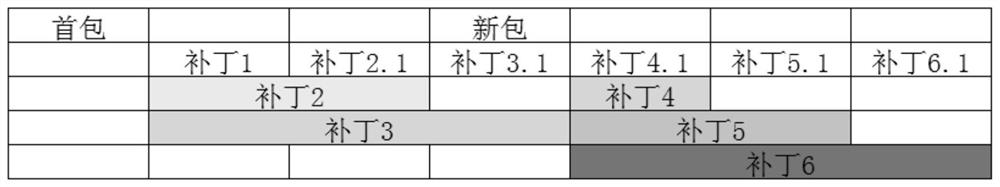

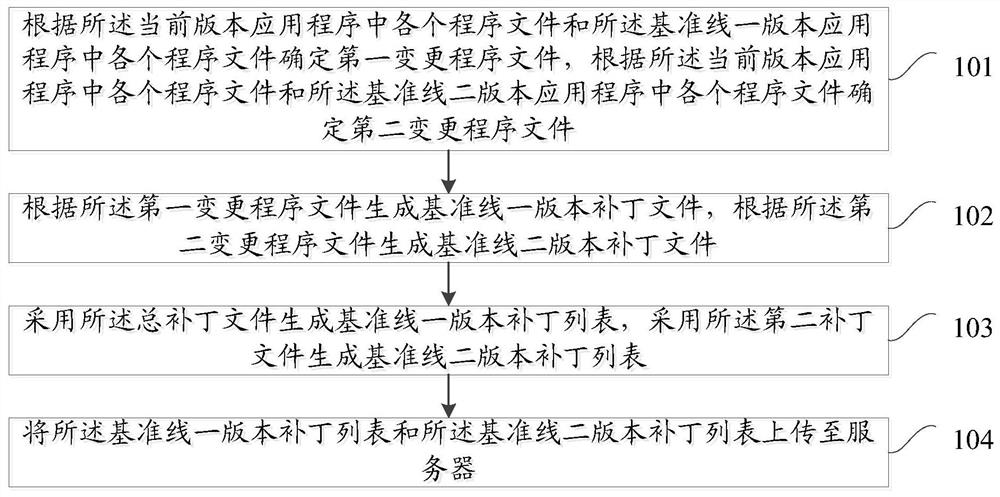

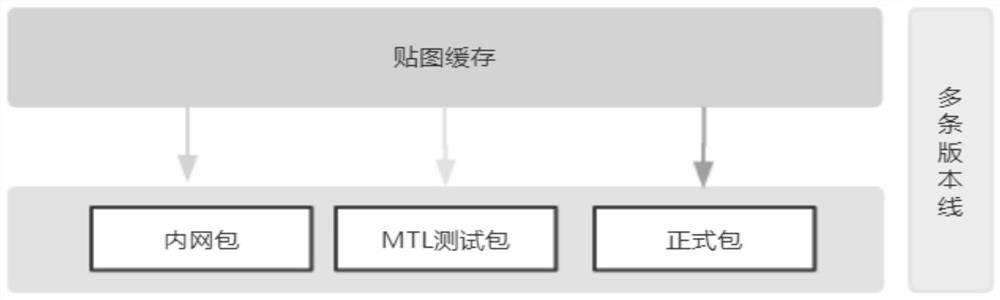

Patch file processing method and device

The embodiment of the invention provides a patch file processing method and device. The method comprises the following steps of: determining a first change program file according to each program filein the application program of the current version and each program file in the application program of the first version of the reference line, and determining a second change program file according toeach program file in the application program of the current version and each program file in the application program of the second version of the reference line; Generating a datum line first versionpatch file according to the first change program file, and generating a datum line second version patch file according to the second change program file; Generating a datum line first version patch list by adopting the total patch file, and generating a datum line second version patch list by adopting the second patch file; And uploading the datum line first version patch list and the datum linesecond version patch list to a server. By applying the embodiment of the invention, a user can complete the updating of the application program without consuming more time and flow.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

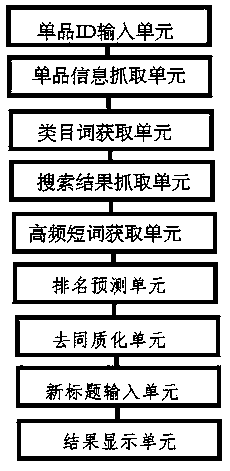

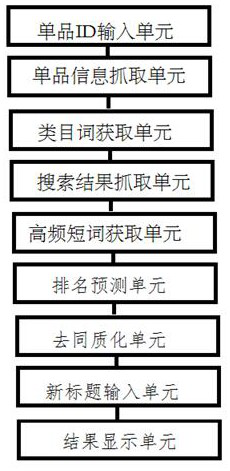

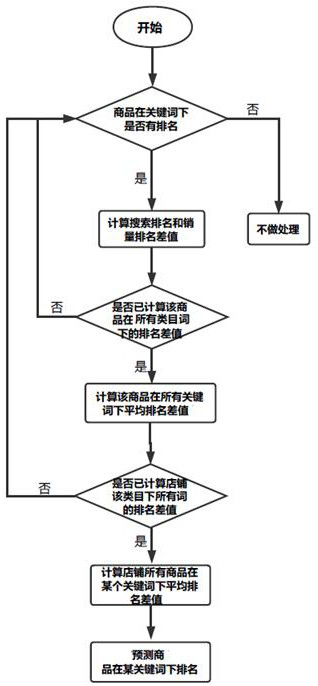

E-commerce title optimization system and optimization method

ActiveCN108804541AIncrease incomeAvoid insufficient trafficNatural language data processingData miningE-commerceSingle item

The invention discloses an e-commerce title optimization system and optimization method. The e-commerce title optimization system comprises a single item ID input unit, a single item information capturing unit, a category word obtaining unit, a search result capturing unit, a high-frequency short word obtaining unit, a rank prediction unit, a de-homogenization unit, a new title input unit and a result display unit. The method comprises a single item ID input step, a single item information capturing step, a category word obtaining step, a search result capturing step, a high-frequency short word obtaining step, a rank prediction step, a de-homogenization step, a new title input step and a result display step. By mining and analyzing each keyword under each category and the search results,more benefits are obtained by reasonable combination of keywords, more flow for commodities is brought and the flow becomes more precise.

Owner:SUZHOU WINNDOO NETWORK TECH CO LTD

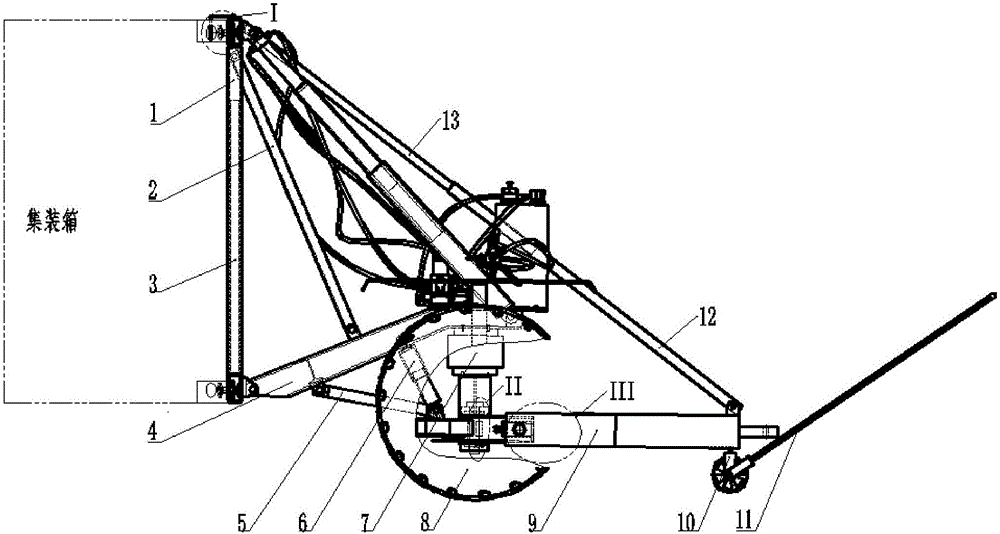

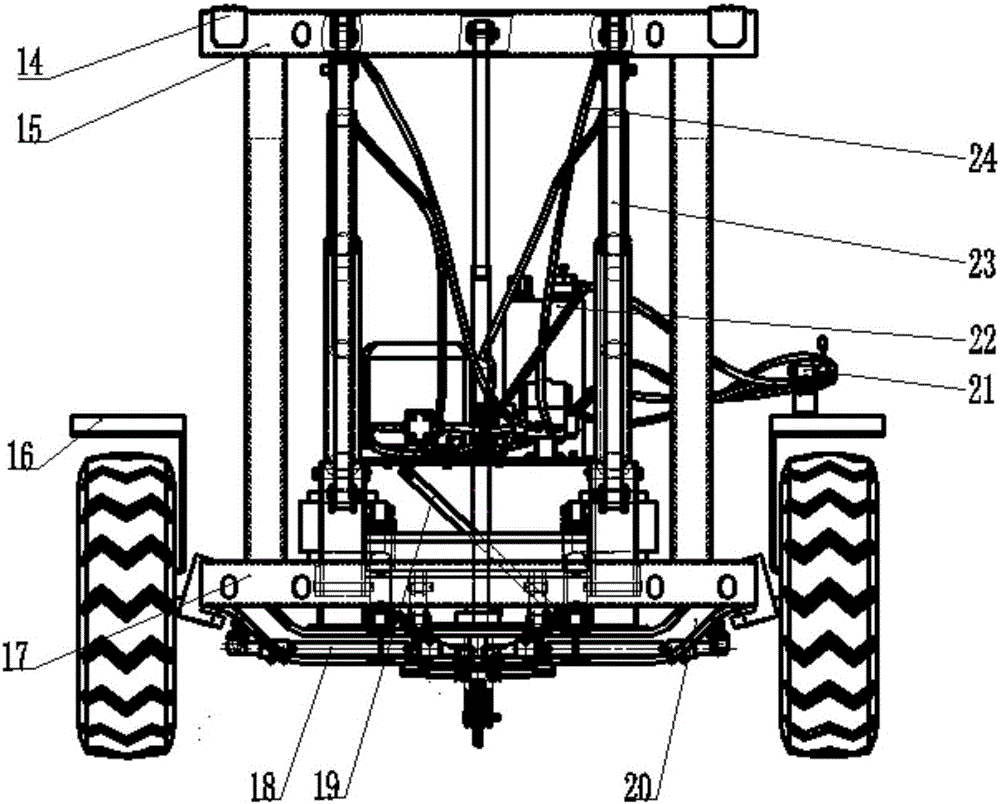

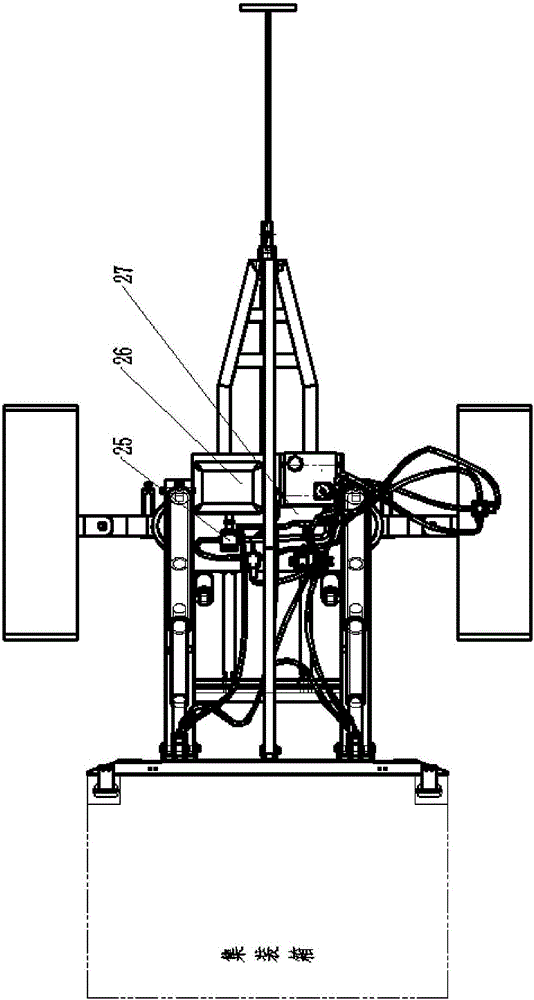

Rapid maneuvering loading and unloading transport cart for containers

InactiveCN105883673AReduce shipping costsEasy to transportLifting devicesHydraulic cylinderThird party

The invention discloses a rapid maneuvering loading and unloading transport cart for containers. The rapid maneuvering loading and unloading transport cart is suitable for special operation occasions such as field operations, disaster rescue, the wilds and airports and comprises a supporting mechanism, a hoisting mechanism, a traction mechanism, a hydraulic mechanism, a power mechanism and an auxiliary mechanism. The supporting mechanism comprises an axle with wheels mounted at the two ends and a frame connected with the axle. The hoisting mechanism is a gate type lifting frame connected with the frame and is used for lifting, loading and unloading the containers. The traction mechanism is connected with the axle. The hydraulic mechanism is mounted on the supporting mechanism. Two dual-stage hydraulic cylinders are hinged between the lifting frame and the frame and used for driving the hoisting mechanism. The power mechanism is an independent engine. Compared with a traditional transport cart for the containers, the rapid maneuvering loading and unloading transport cart is small in size and light, and can be used for loading and unloading of the containers of other transport vehicles, the containers can be transported through traction of other maneuvering vehicles in the medium distance and the short distance, and container transportation does not rely on a crane, a forklift and other third-party hoisting equipment any more, so that transport cost is reduced.

Owner:YANSHAN UNIV

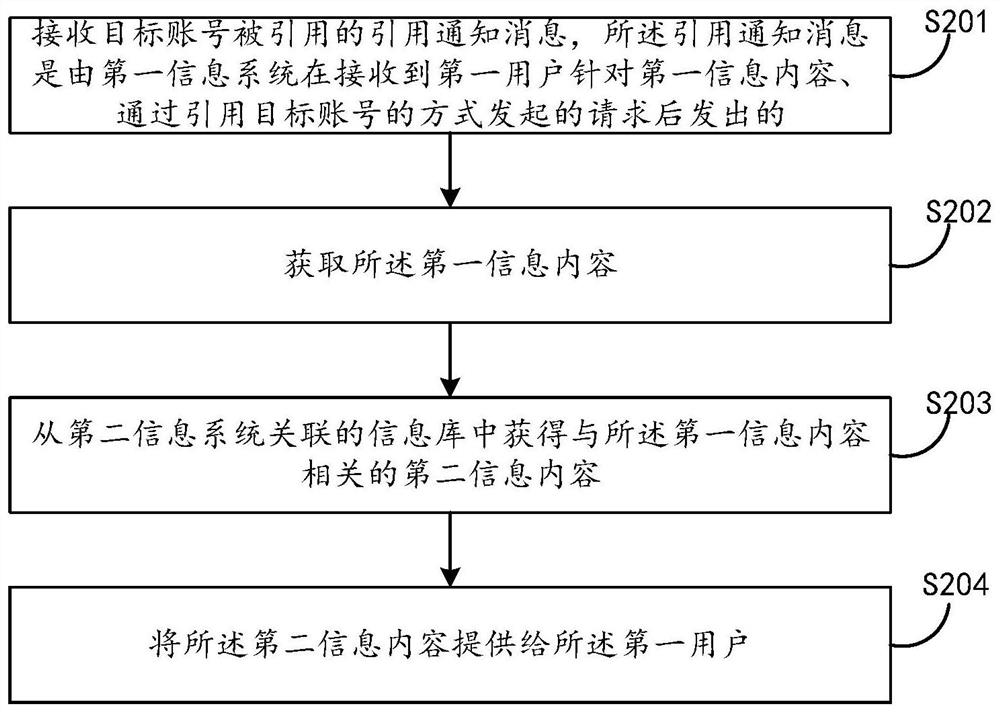

Information providing method and device and electronic equipment

PendingCN113297474AAvoid insufficient trafficEasy accessDigital data information retrievalBuying/selling/leasing transactionsInformation repositoryNetworked system

The embodiment of the invention discloses an information providing method and device and electronic equipment, and the method comprises the steps: receiving a reference notification message that a target account is referenced, wherein the reference notification message is sent by a first information system after the first information system receives a request initiated by a first user for first information content in a manner of referencing the target account, wherein the first information content comprises information content generated in the first information system, and the target account is associated with a second information system; obtaining the first information content; obtaining second information content related to the first information content from an information base associated with a second information system; and providing the second information content to the first user. According to the embodiment of the invention, the related commodity object information can be more conveniently provided for the content interested by the user of the social network system.

Owner:ALIBABA GRP HLDG LTD

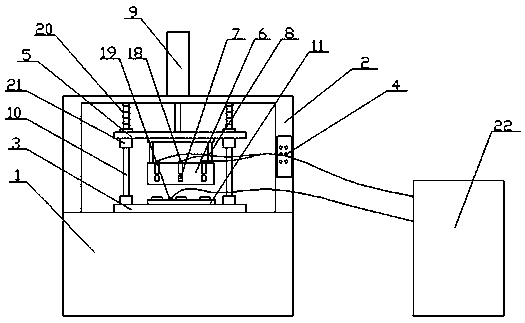

A gear deburring process

ActiveCN108746898BJet speedAvoid the risk of breakdownElectrochemical machining apparatusElectrolytic agentGear wheel

The invention relates to a gear burr removing technology. The technology comprises the following specific steps that 1, a burr removing device is constructed; 2, a gear is placed; 3, conducting and discharging are carried out; 4, an electrolyte is sprayed; 5, the gear is washed ultrasonically; 6, antirust treatment is carried out; and 7, the gear is naturally dried in air and delivered from storage. The technology has the following advantages that an anode terminal and a cathode terminal are utilized for conducting and discharging, the electrolyte is sprayed to the gear fast from bottom to top, the spraying speed is high, the electrolyte is sprayed in a centralized manner, and the burr removing effect is achieved; meanwhile, the burr removing effect is remarkable, the risk that the gear isbroken down is avoided, time for burr removing is short, and efficiency is high; the concentration of sodium nitrate is low, harm to the human body is avoided, corrosion to the surface of the gear isavoided, and meanwhile, the good burr removing effect can be ensured; and as the electrolyte spraying speed is high and the flow amount is large, the complex washing step in the later period is omitted, the gear only needs to be washed with clear water, the gear is washed ultrasonically, and thus greasy dirt on the surface of the gear can be decomposed and emulsified.

Owner:NANTONG ZHONGLV GEAR CO LTD

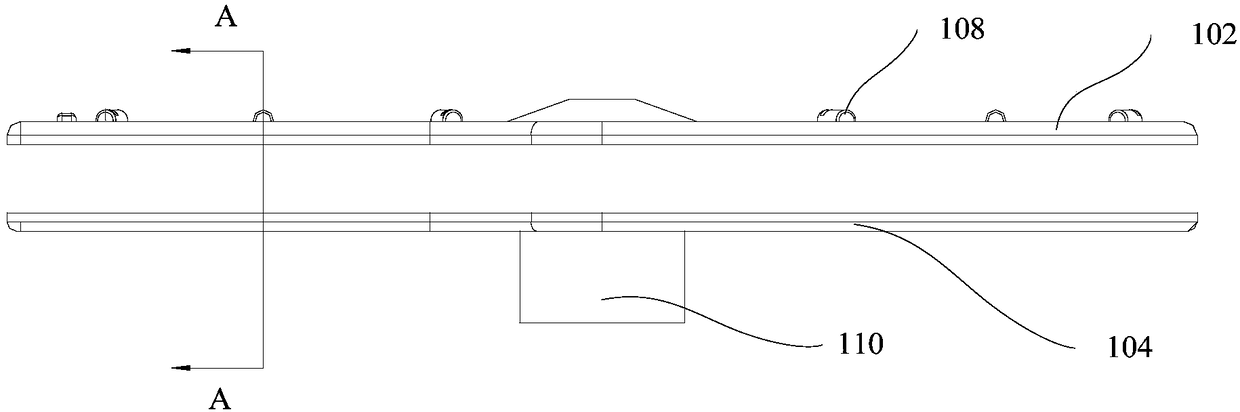

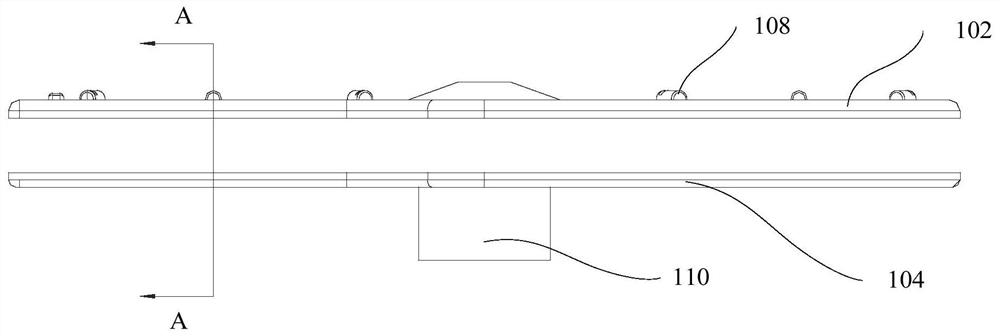

Spraying arm and cleaning device

ActiveCN109395902AIncrease jet areaReduce technical effectSpray nozzlesLiquid spraying apparatusSpray nozzleEngineering

The invention provides a spraying arm and a cleaning device. The spraying arm and the cleaning device are used for cleaning a device body, wherein the spraying arm comprises a first body, a second body, a flow guide part and a nozzle, and the second body and the first body define a hollow cavity; the guide part is located on the outer wall of the first body, and one side surface of the flow guidepart is a flow guide surface; the nozzle is arranged on the outer wall of the first body, a flow channel is formed in the nozzle, and the flow channel communicates with the hollow cavity; and the flowchannel extends along the outer wall of the first body, a cleaning liquid is enabled to hit on the flow guide surface after flowing out along the outer wall of the first body. Due to the fact that the cleaning liquid becomes a jet area increasing the cleaning liquid when the bearing frame body is guided by a flow guiding surface, the cleaning range of the spraying arm is further enlarged accordingly, and the situation that a cleaning dead angle is caused due to incomplete coverage of the cleaning range of the spraying arm is avoided; and meanwhile, due to the fact that the cleaning range of the spraying arm is enlarged, the time for cleaning by the spraying arm is shortened, so that the technical effect of saving the cleaning fluid is achieved, and the use cost of a product is reduced.

Owner:MIDEA GRP CO LTD

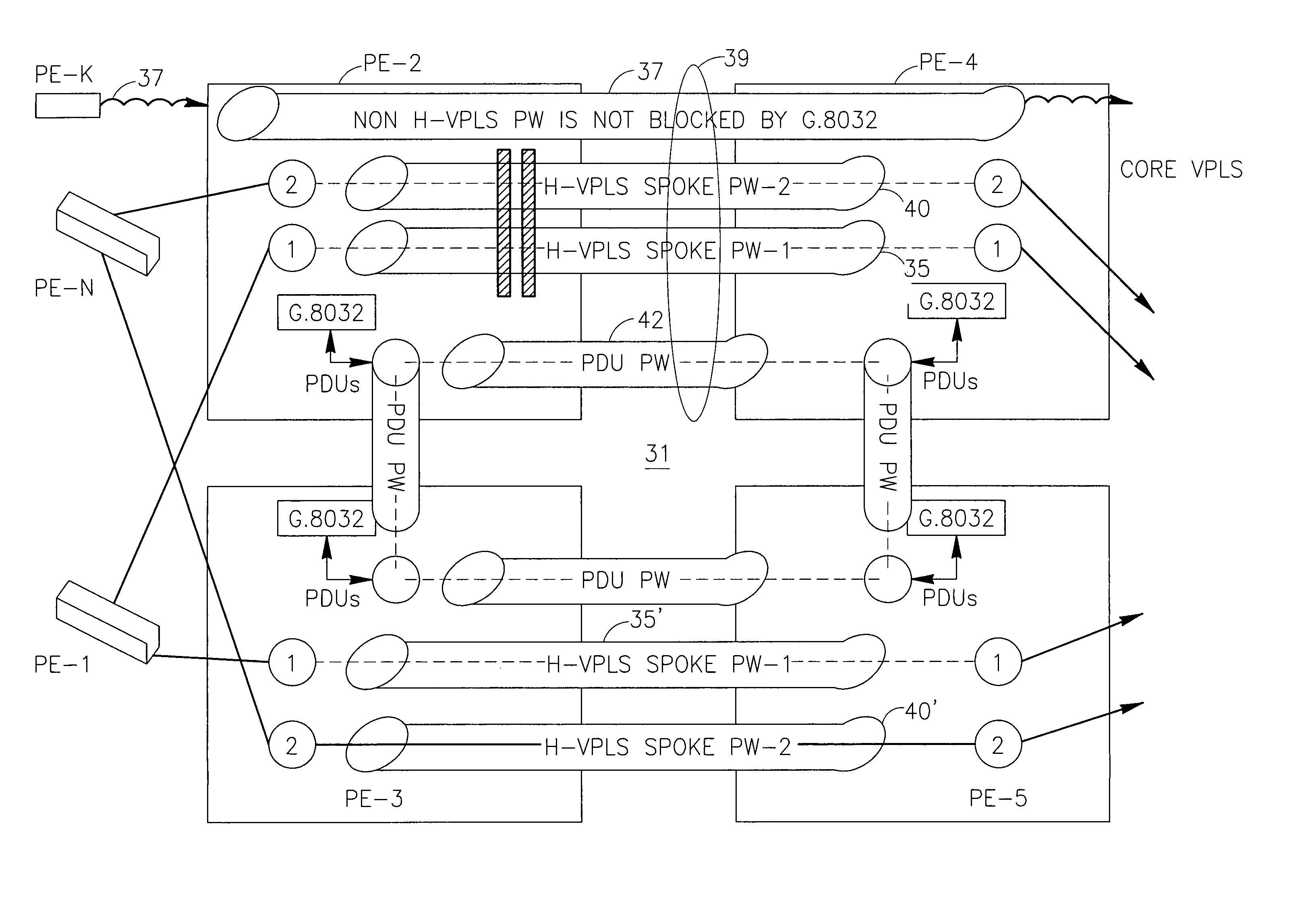

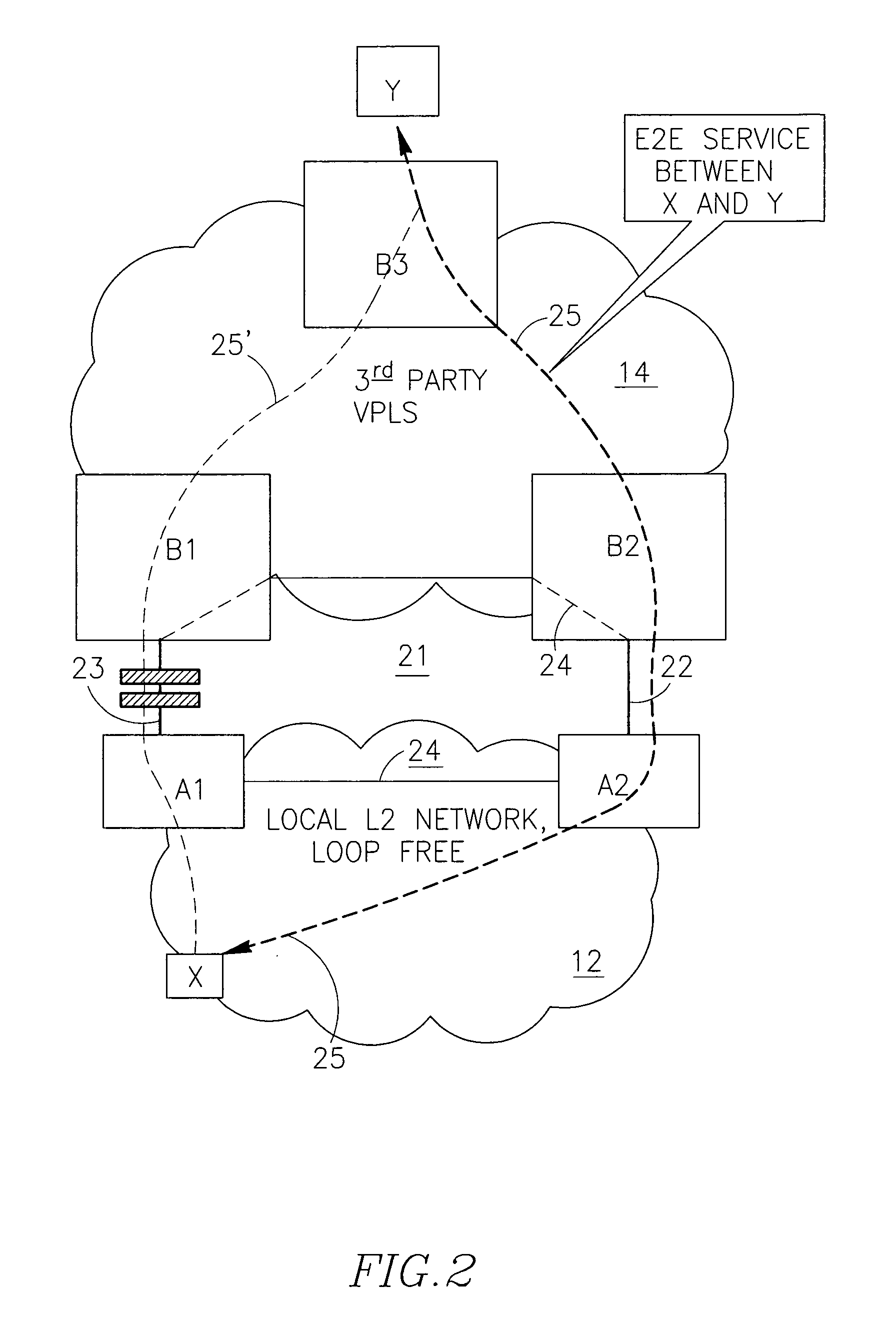

Technique for dual homing interconnection between communication networks

ActiveUS8724519B2Avoid insufficient trafficAvoid trafficError preventionFrequency-division multiplex detailsData streamTelecommunications network

A dual homing technique for ensuring loop free transmission of traffic between telecommunication networks such as VPLS by utilizing a loop protocol in the dual homed connection. The technique also provides selective handling of VPLS data streams protected and non-protected by the dual homing loop protocol.

Owner:ECE TELECOM LTD

Method of supporting fulfillment of E-commerce blast sell orders

InactiveCN108182618AGood exposure opportunityLots of trafficBuying/selling/leasing transactionsTraffic volumeOrder fulfillment

The invention discloses a method of supporting fulfillment of E-commerce blast sell orders, which belongs to the technical field of order fulfillment. The method comprises steps: orders are received,commodity description guide is built, when a consumer selects an sku which does not exist in platform store commodities, more other skus are selected, and a message is left for the selected sku in anorder note; according to the left message, a corresponding sku is translated automatically, and a sold commodity is associated with a material commodity; selection of a single unit from a commodity set is completed; in a control system for the material processing facility, the commodity identifier of each selected unit is associated with a container identifier of an empty transmission container inmultiple transmission containers; each transmission container containing a single unit is introduced to a transmission mechanism; and delivery of the order is completed. More skus can be hung below the same commodity, a better ranking and a better exposure opportunity are acquired, and more traffic is acquired.

Owner:商派软件有限公司

E-commerce title optimization system and optimization method

ActiveCN108804541BIncrease incomeAvoid insufficient trafficNatural language data processingData miningAlgorithmData mining

The invention discloses an e-commerce title optimization system and optimization method. The e-commerce title optimization system comprises a single item ID input unit, a single item information capturing unit, a category word obtaining unit, a search result capturing unit, a high-frequency short word obtaining unit, a rank prediction unit, a de-homogenization unit, a new title input unit and a result display unit. The method comprises a single item ID input step, a single item information capturing step, a category word obtaining step, a search result capturing step, a high-frequency short word obtaining step, a rank prediction step, a de-homogenization step, a new title input step and a result display step. By mining and analyzing each keyword under each category and the search results,more benefits are obtained by reasonable combination of keywords, more flow for commodities is brought and the flow becomes more precise.

Owner:SUZHOU WINNDOO NETWORK TECH CO LTD

A solar heat absorber with a composite structure of glass tube bundles and porous media

InactiveCN106440418BEfficient Transmission ConversionIncrease the areaSolar heating energyHeat transfer optimizationPorous mediumOptoelectronics

The invention discloses a glass tube bundle and porous medium composite structure solar absorber which comprises a solar absorber shell, wherein a quartz glass window is formed in one end of the solar absorber shell, and a medium outlet is formed in the other end of the solar absorber shell; the solar absorber shell and the quartz glass window are connected into a whole, and a cavity is formed between the solar absorber shell and the quartz glass window; glass tube bundles and porous media are sequentially arranged inside the cavity along the solar incident direction; a preheating channel is formed among the solar absorber shell, the glass tube bundles and the porous media; a first medium inlet is formed in one end of the preheating channel; and after preheated in the preheating channel, the media converge sunlight at the second medium inlet so as to enter the glass tube bundles. Because the glass tube bundles are small in solar absorption and small in external radiation energy, the thermal efficiency of the system is improved. Meanwhile, the incident sunlight is transmitted to the porous medium by the glass tube bundles, so that medium distribution is matched with sunlight flow density, while the porous medium is mainly capable of converting solar radiation energy into internal energy of working media; and therefore, the problem that the existing porous medium solar absorber is low in thermal efficiency and reliability is effectively solved.

Owner:FUJIAN UNIV OF TECH

Method, system, and client for realizing traffic optimization on mobile terminal equipment

ActiveCN104038916BReduce trafficAvoid insufficient trafficAccounting/billing servicesNetwork traffic/resource managementPrivate networkNetwork packet

The invention discloses a traffic optimization method and system performed on a mobile terminal device, a client and a VPN (Virtual Private Network) server. The method comprises the following steps: compressing an uplink data package to obtain an uplink compressed data package; sending the uplink compressed data package to the VPN server by a charging system through a VPN channel; uncompressing the uplink compressed data package through the VPN server to obtain an uplink data package; sending the uncompressed uplink data package to a resource server. According to the method, the VPN server is utilized to compress and uncompress the uplink / downlink data package, thus the data volume calculated by the charging system is less than that of the data package to be transmitted really before compressing, and as a result, the purpose of saving traffic is realized.

Owner:北京鸿享技术服务有限公司

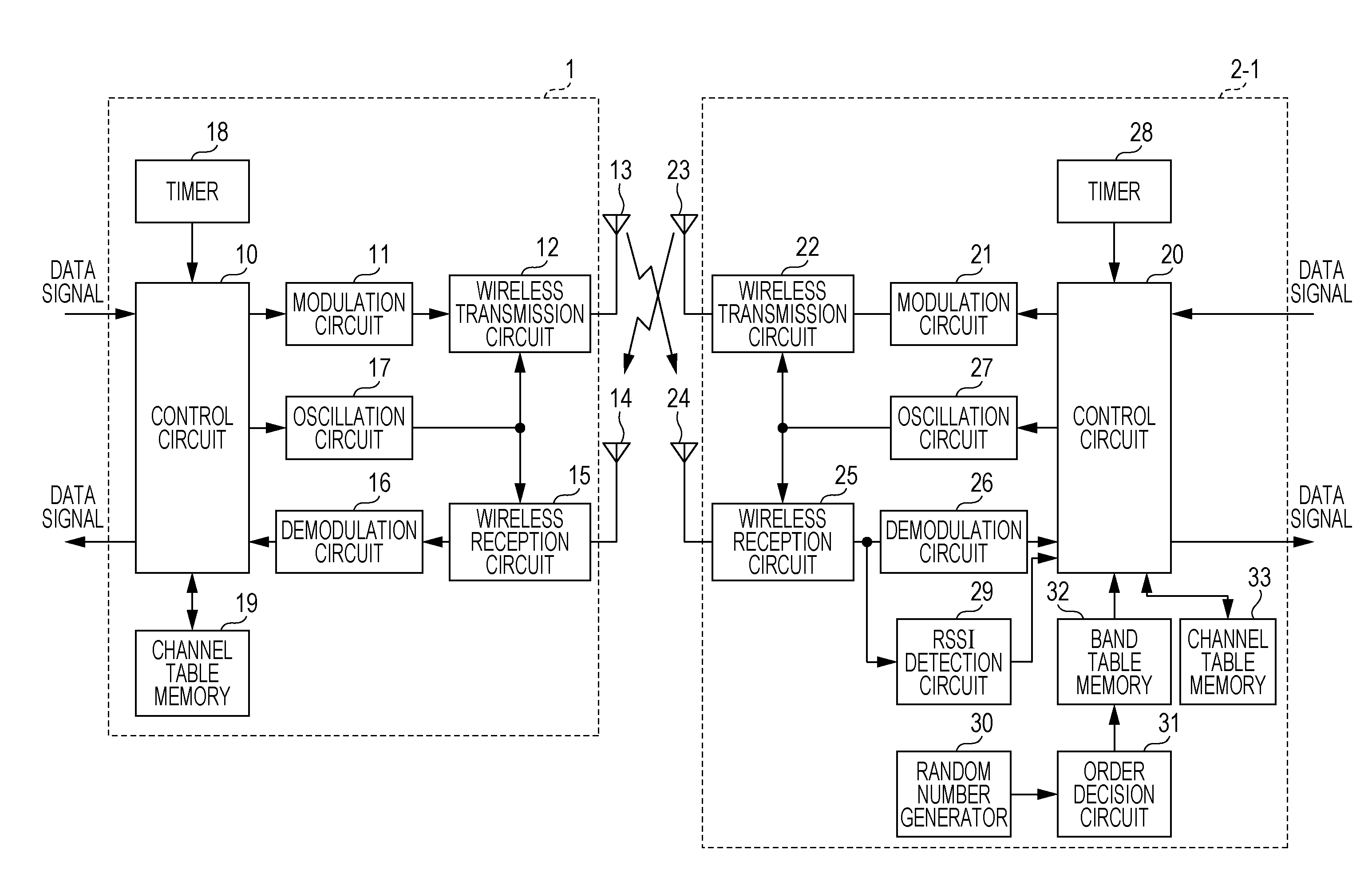

Wireless communications system and wireless communication device

InactiveUS20160183150A1Reduce distractionsImprove efficiencyWireless commuication servicesCommunications systemControl circuit

A first wireless communication device includes first wireless communication circuitry that selectively operates in one of a plurality of bands and first control circuitry that sets a band in which the first wireless communication circuitry operates. The first control circuitry switches bands such that the first wireless communication circuitry operates in all of the plurality of bands within a certain cycle time. A second wireless communication device includes second wireless communication circuitry that selectively operates in one of the plurality of bands and second control circuitry that sets a band in which the second wireless communication circuitry operates. The second control circuitry switches to a different band when the second wireless communication device has been unable to communicate with the first wireless communication device.

Owner:PANASONIC CORP

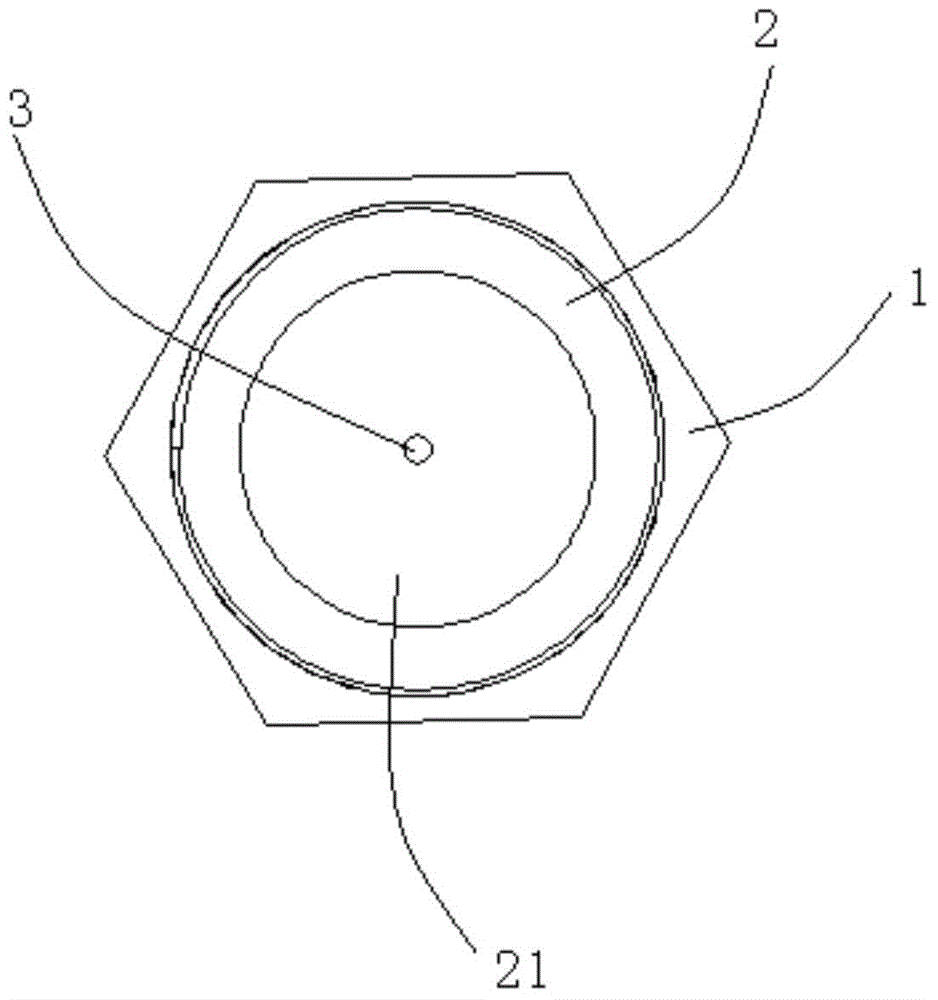

Flow control joint and air inlet valve of scroll type air compressor

InactiveCN104153995AIncrease pressureAvoid insufficient trafficRotary/oscillating piston pump componentsLiquid fuel engine componentsInlet valveControl engineering

The invention provides a flow control joint. The flow control joint comprises a first main body, a second main body and a control hole, wherein a first blind hole is formed in the first main body; one side of the first main body extends outwards to form the second main body; the second main body is provided with a second blind hole; the control hole is positioned between the first blind hole and the second blind hole and communicated to the second blind hole from the first blind hole. One flow control joint is arranged at each of an oil return inlet and an oil return outlet of a gas inlet valve; an oil return pipe is arranged at the joint of the flow control joint and an oil-gas tank and is directly communicated with the oil-gas tank. The gas generated by the flow control joint is high in pressure, high in flow and high in gas rising speed.

Owner:JIANGSU SUBA MACHINERY

Spray Arms and Cleaning Units

ActiveCN109395902BIncrease jet areaReduce technical effectSpray nozzlesLiquid spraying apparatusPhysicsNozzle

The invention provides a spray arm and a cleaning device, which are used for cleaning the device. The spray arm includes: a first body, a second body, a guide part and a nozzle; the second body and the first body form a hollow cavity; the guide The flow part is located on the outer wall of the first body, and one side of the flow guide part is a flow guide surface; the nozzle is arranged on the outer wall of the first body, and a flow channel is arranged in the nozzle, and the flow channel communicates with the hollow cavity; the flow channel is along the The outer wall of the first body is extended so that the cleaning fluid flows out along the outer wall of the first body and hits the flow guide surface. Since the cleaning liquid is diverted by the diversion surface, the jet area of the cleaning liquid is increased, so the cleaning range of the spray arm is also expanded, which avoids the occurrence of cleaning dead angles caused by the incomplete coverage of the cleaning range of the spray arm; at the same time , due to the expansion of the cleaning range of the spray arm, the time used for cleaning the spray arm is reduced, thereby achieving the technical effect of saving cleaning fluid and reducing the use cost of the product.

Owner:MIDEA GRP CO LTD

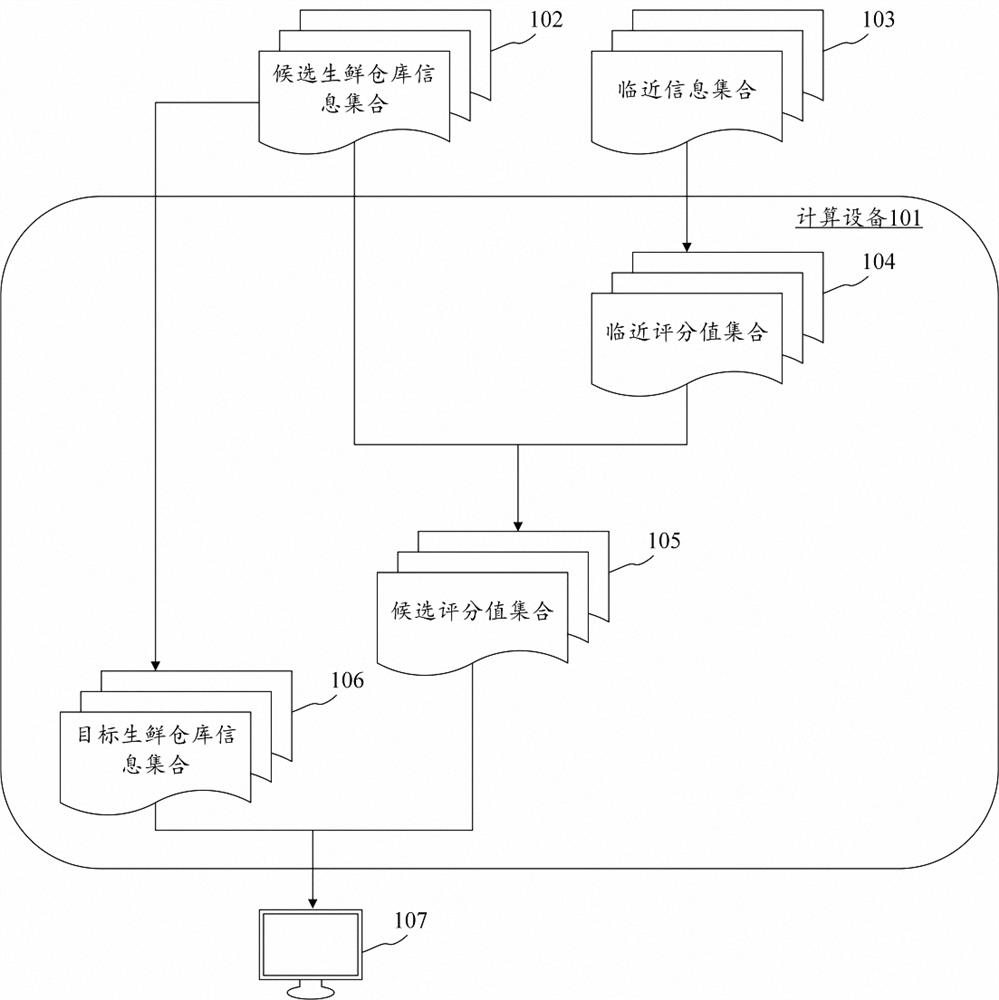

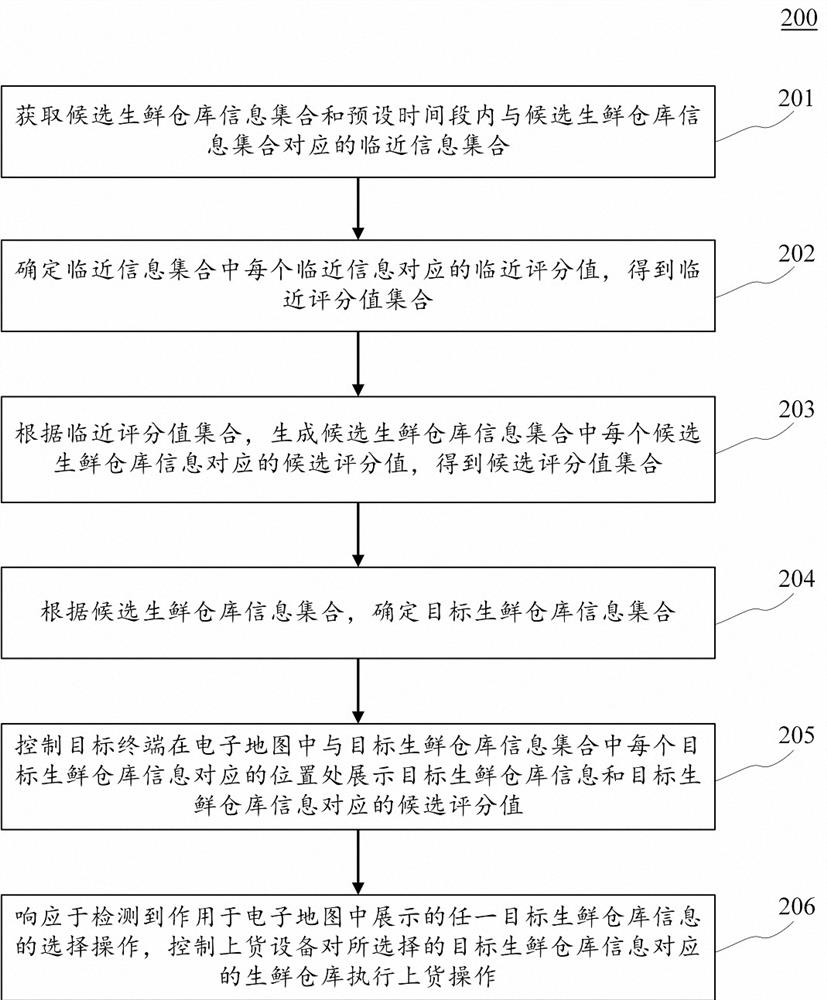

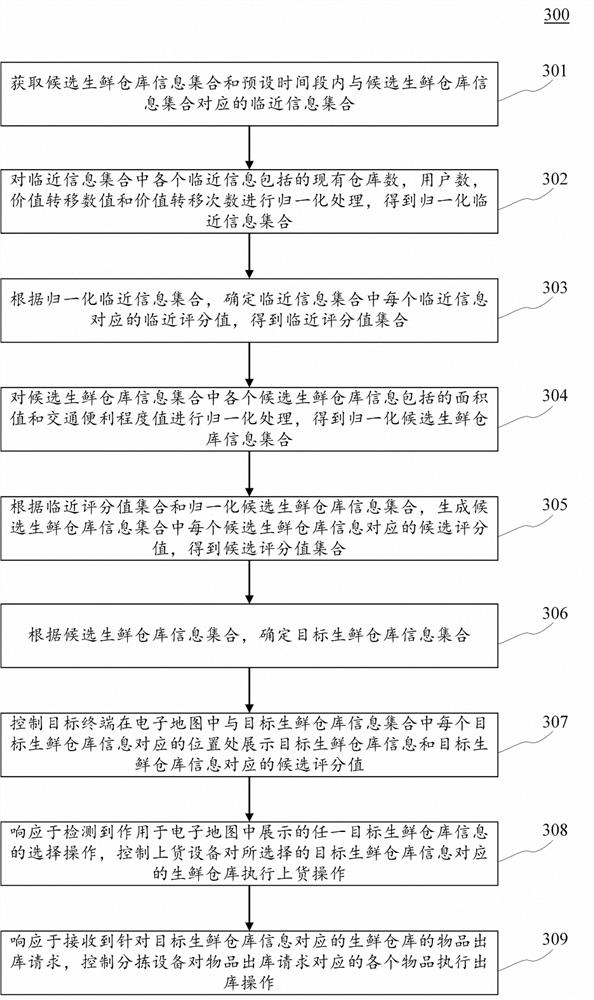

Loading equipment control method and device, electronic equipment and computer readable medium

ActiveCN112712325AMeet delivery timeliness requirementsEase of evaluationLogisticsFresh foodEngineering

The embodiment of the invention discloses a loading equipment control method and device, electronic equipment and a computer readable medium. A specific embodiment of the method comprises the steps of obtaining a candidate fresh food warehouse information set and an adjacent information set corresponding to the candidate fresh food warehouse information set in a preset time period; determining a proximity score value corresponding to each part of proximity information in the proximity information set; generating a candidate score value corresponding to each part of candidate fresh food warehouse information in the candidate fresh food warehouse information set; determining a target fresh food warehouse information set; controlling the target terminal to display the target fresh food warehouse information and the candidate score value corresponding to the target fresh food warehouse information at a position corresponding to each part of target fresh food warehouse information in the target fresh food warehouse information set in an electronic map; and controlling the loading equipment to carry out loading operation on the fresh food warehouse corresponding to the selected target fresh food warehouse information. According to the embodiment, the requirement of a user for timeliness can be met, and the turnover rate of fresh goods is increased.

Owner:BEIJING MISSFRESH ECOMMERCE CO LTD

Coke tower vent gas recycling method

The invention belongs to the technical field of coking, and discloses a coke tower vent gas recycling method, which comprises the following steps that 1, after reaction of a coke tower is finished, vent gas is introduced into an emptying tower, and the emptying tower performs gas-liquid separation on the vent gas; 2, the separated liquid enters an oil liquid recovery tank, and the separated gas enters a water washing tower; 3, the gas entering the water washing tower is subjected to water washing by using the water washing tower to remove hydrogen sulfide and part of impurities; and 4, the washed gas is introduced into a fractionating tower to remove water drops entrained in the gas, and then the gas is introduced into a gas compressor. According to the coke tower vent gas recycling method, the vent gas is recycled, the coke tower vent gas has the advantages of being high in heat value, large in flow and the like, is stable in pressure, and can be easily merged into a fuel gas pipe network, and after the vent gas is recycled, enough fuel gas amount can be provided for the fuel gas pipe network, so that the use amount of liquefied gas of the fuel gas pipe network is reduced, and the purposes of saving energy, reducing consumption, improving quality and improving efficiency are achieved.

Owner:SHANDONG QINGYISHAN PETROCHEM TECH CO LTD

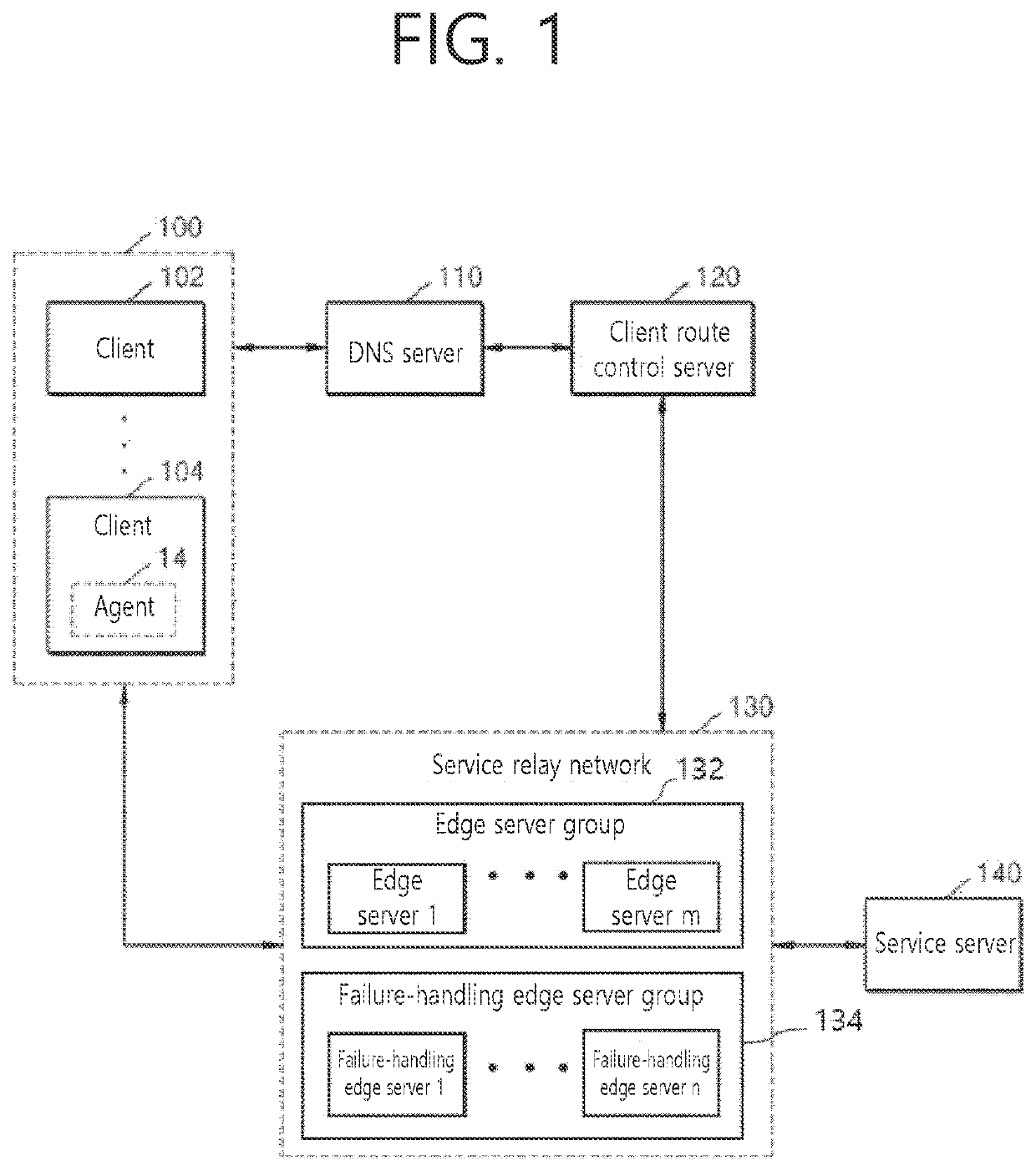

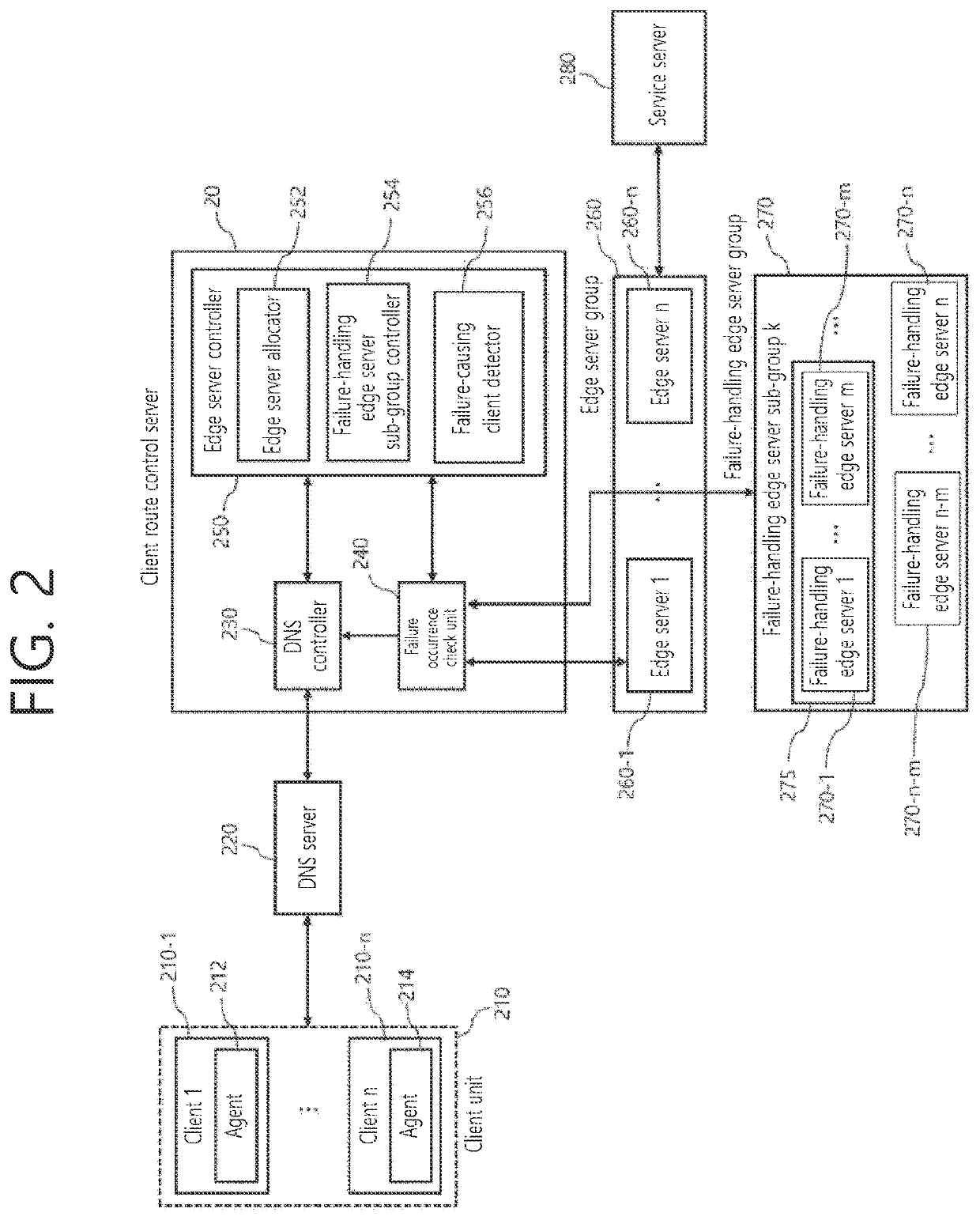

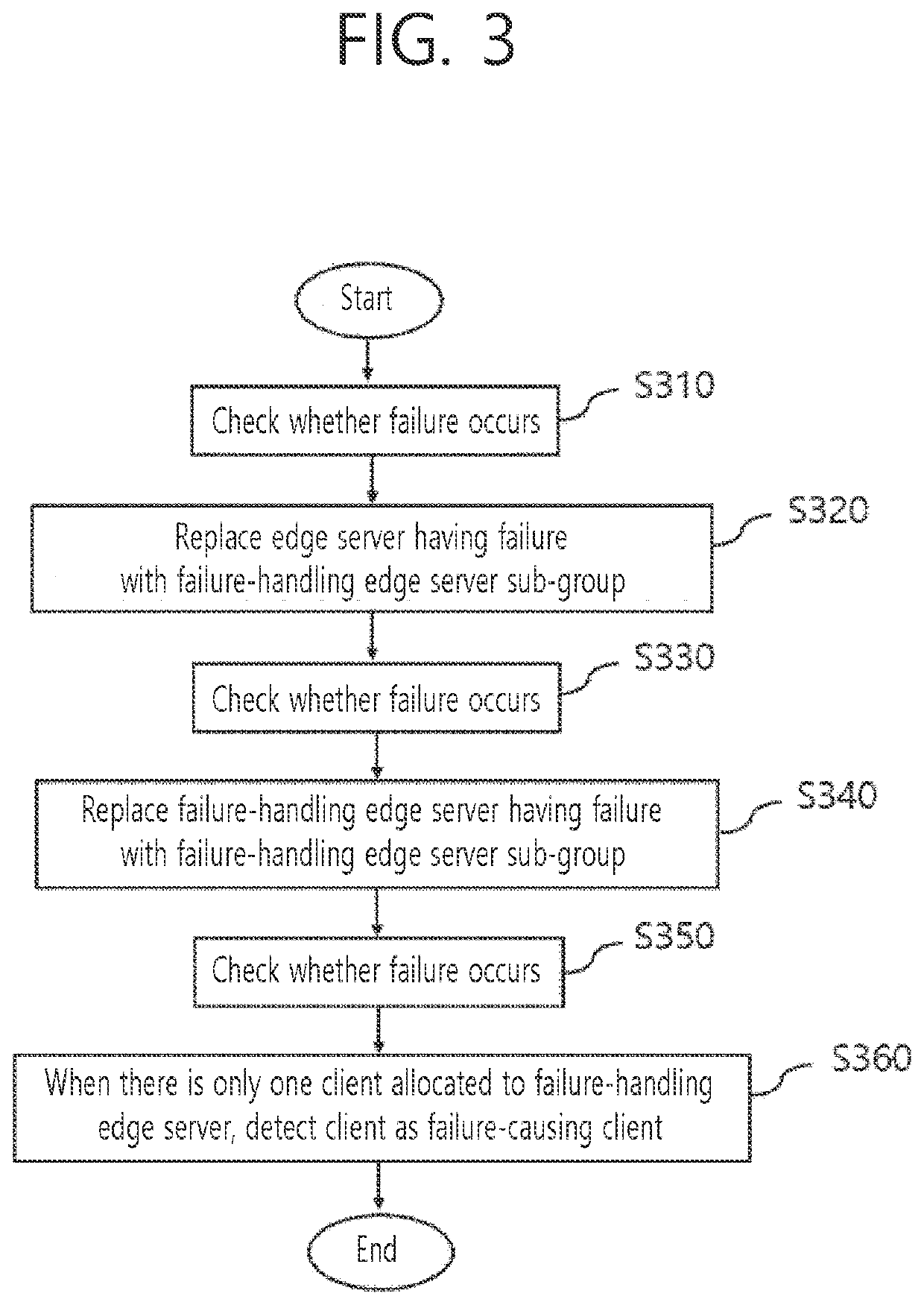

Method and system for detecting failure-causing client with failure handling edge server grouping

InactiveUS20220360485A1Guarantee service continuityGuaranteed continuityTransmissionEdge serverEngineering

Provided is a client terminal access control method, and the method includes: allocating a communication process of a first client group comprising a plurality of client terminals to an edge server; when a failure occurs in an operation of the edge server, allocating a communication process of a second client group comprising at least one client terminal belonging to the first client group to a failure-handling edge server; and determining whether a failure occurs in an operation of the failure-handling edge serve.

Owner:INNOGS KOREA CORP

Dust collector

InactiveCN1245135CAvoid insufficient trafficImprove dust collection efficiencySuction nozzlesExhaust-air diffusionEngineeringDust collector

A dust collecting device has a suction port in a bottom of frame member, a dust collecting chamber and a rotating brush chamber 39 disposed in the frame member, the rotating brush chamber being communicating with the dust collecting chamber through an air passage port. A rotating brush driven by a motor to rotate is provided in the rotating brush chamber. The dust on floor can be swept up by the rotation of the rotating brush and collected in the dust collecting chamber through the air passage port. The frame member is provided with a brush cover wall covering the rotating brush from top and facing the rotating brush chamber, and an air stream guide wall between the rotating brush chamber and the dust collecting chamber, and a stop wall extending from an upper end of the air stream guide wall in the interior of the dust collecting chamber.

Owner:SANYO ELECTRIC CO LTD

Method and device for processing patch files

ActiveCN109766114BMuch timeAvoid insufficient trafficSoftware deploymentProgramming languageApplication procedure

An embodiment of the present invention provides a method and device for processing patch files, the method comprising: determining a first change program according to each program file in the current version of the application program and each program file in the baseline-version application program file, according to each program file in the current version application program and each program file in the baseline version 2 application program to determine a second change program file; generate a baseline version 1 patch file according to the first change program file, according to The second change program file generates a baseline two version patch file; adopts the total patch file to generate a baseline one version patch list, adopts the second patch file to generate a baseline two version patch list; The version patch list and the baseline 2 version patch list are uploaded to the server. By applying the embodiment of the present invention, the user can update the application program without consuming much time and traffic.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com