Gear burr removing technology

A deburring and gear technology, applied in the field of gears, can solve the problems of strong corrosion on the surface of castings, time spent in tens of seconds, and troublesome cleaning process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Present embodiment is a kind of gear deburring process, and its specific steps are as follows:

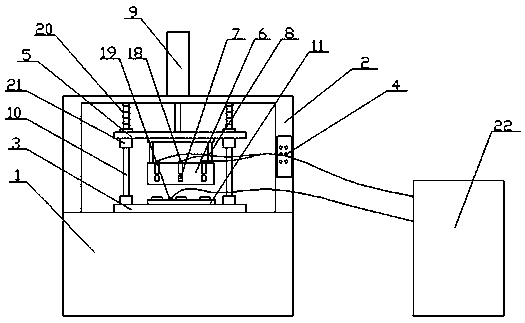

[0047] (1) Construction of the deburring device: the deburring device includes

[0048] A body group, the body group includes an electrolyte tank 1, and a casing 2 placed around the top of the electrolyte tank 1. The front part of the casing 2 is an open structure, and a working area is formed inside it. Boss 3, there is a gap between the boss 3 and the electrolyte tank 1 to allow the electrolyte to flow in, and the housing 2 is provided with a control box 4;

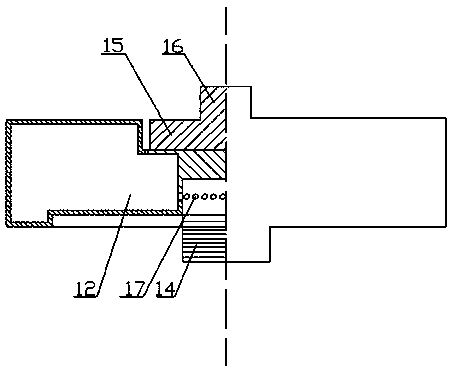

[0049] An upper module, the upper module includes a connecting block 5 and a pressure cover 6, the lower end surface of the pressure cover 6 is an open structure, and the inside of the pressure cover 6 is a cavity structure, and the inside of the pressure cover 6 is provided with a plurality of horizontal and evenly arranged The set briquetting block 7 is provided with a plurality of vertically arranged connecting ro...

Embodiment 2

[0059] Present embodiment is a kind of gear deburring process, and its specific steps are as follows:

[0060] (1) Construction of the deburring device: the deburring device includes

[0061] A body group, the body group includes an electrolyte tank 1, and a casing 2 placed around the top of the electrolyte tank 1. The front part of the casing 2 is an open structure, and a working area is formed inside it. Boss 3, there is a gap between the boss 3 and the electrolyte tank 1 to allow the electrolyte to flow in, and the housing 2 is provided with a control box 4;

[0062] An upper module, the upper module includes a connecting block 5 and a pressure cover 6, the lower end surface of the pressure cover 6 is an open structure, and the inside of the pressure cover 6 is a cavity structure, and the inside of the pressure cover 6 is provided with a plurality of horizontal and evenly arranged The set briquetting block 7 is provided with a plurality of vertically arranged connecting ro...

Embodiment 3

[0072] Present embodiment is a kind of gear deburring process, and its specific steps are as follows:

[0073] (1) Construction of the deburring device: the deburring device includes

[0074] A body group, the body group includes an electrolyte tank 1, and a casing 2 placed around the top of the electrolyte tank 1. The front part of the casing 2 is an open structure, and a working area is formed inside it. Boss 3, there is a gap between the boss 3 and the electrolyte tank 1 to allow the electrolyte to flow in, and the housing 2 is provided with a control box 4;

[0075] An upper module, the upper module includes a connecting block 5 and a pressure cover 6, the lower end surface of the pressure cover 6 is an open structure, and the inside of the pressure cover 6 is a cavity structure, and the inside of the pressure cover 6 is provided with a plurality of horizontal and evenly arranged The set briquetting block 7 is provided with a plurality of vertically arranged connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com