Automatic powder spraying explosion suppressor for coal mine fire protection

An automatic powder spraying explosion suppression technology, applied in dust prevention, mining equipment, fire prevention, etc., can solve the problems of complex structure of explosion suppressor, unsatisfactory start-up and injection speed and sensitivity, single function, etc., and achieve explosion suppression concentration The effect of rapid formation, fast start and injection speed, and guaranteed injection flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

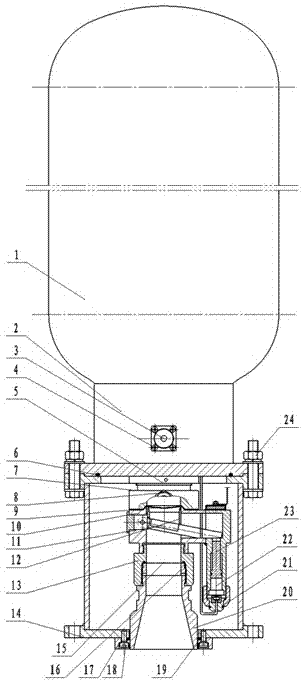

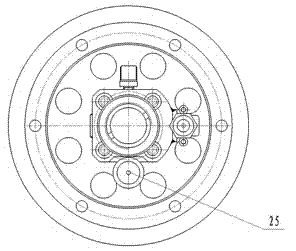

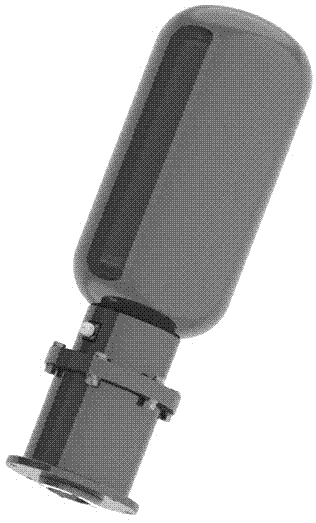

[0020] In the figure: 1 powder storage cylinder, 2 sheath, 3 short-circuit cap, 4 power connector, 5 locking spare cap, 6 sealing ring, 7 flange plate, 8 filling valve, 9 sealing diaphragm, 10 fastening flange , 11 lever, 12 shearing ring, 13 spout body, 14 connecting flange, 15 explosion-proof device, 16 sealing gland, 17 gland, 18 countersunk screw, 19 sealing ring, 20 conical spout, 21 compression nut assembly Into, 22 electric squib, 23 starter, 24 bolt combination, 25 pressure switch.

[0021] Lock the spare cap 5 to fix the sheath 2 on the lower end of the powder storage cylinder, the power connector 4 is fixed on the sheath 2 by screws, the short-circuit cap 3 is installed on the power connector 4, and the sheath 2 and the connecting flange 14 pass through Stainless steel bolts, nuts, spring washers, flat washers and sealing rings are fixed together, and the connecting flange 14 is installed on the butt joint flange of the gas pipeline through asbestos sheet, sealant, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com