Directly moving type high-flow directional flow servo valve and control system using servo valve

A large-flow, direct-acting technology, applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problems of long adjustment time and poor stability of the hydraulic system, and achieve no temperature zero drift, zero position The effect of accurate positioning and accurate control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

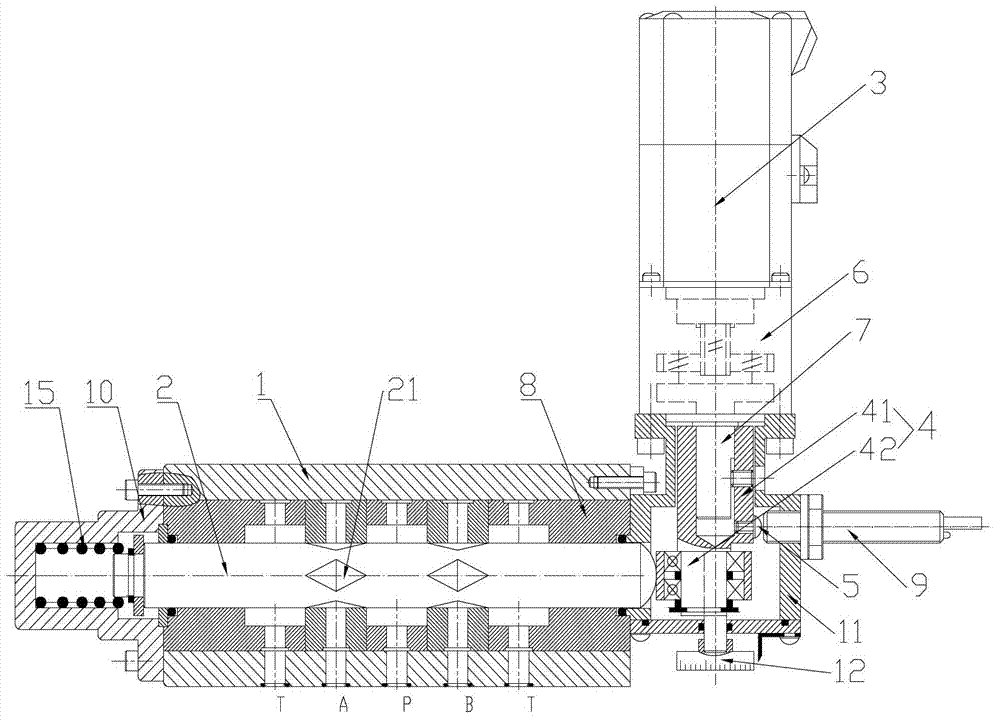

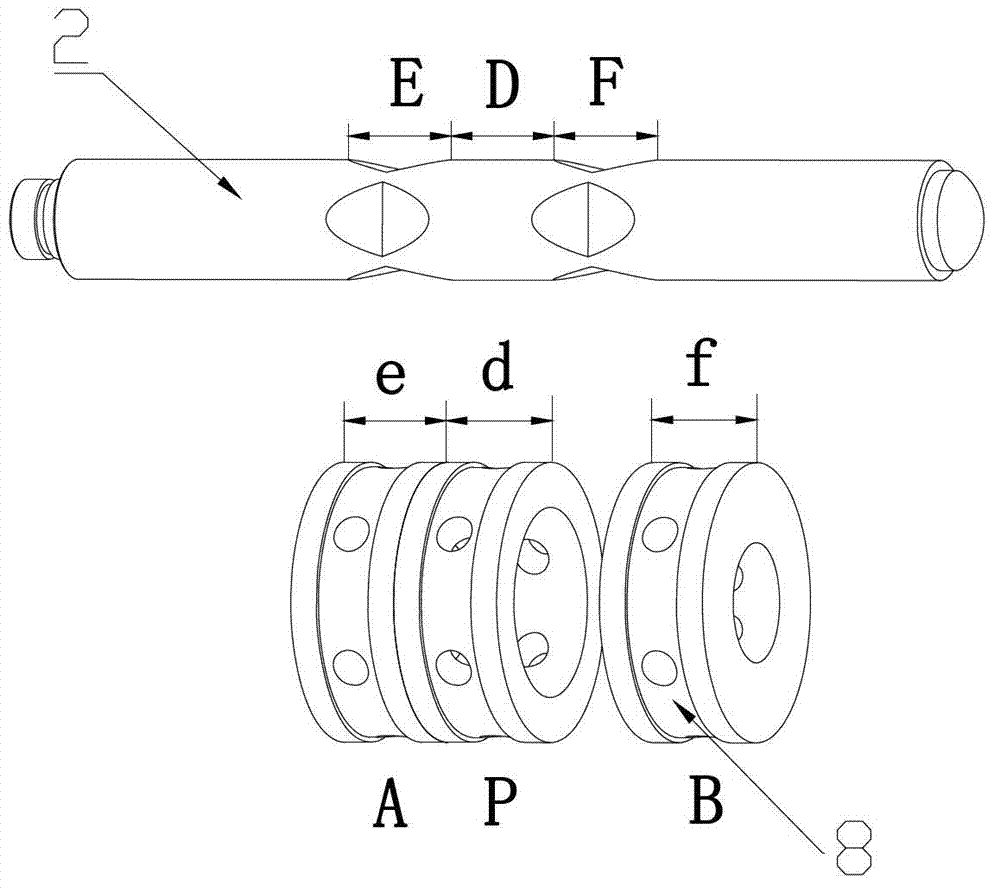

[0030] figure 1 It is a direct-acting large flow directional flow servo valve disclosed in the present invention, which includes a valve body 1, a valve core 2 is arranged in the valve body 1; a servo motor 3 for controlling the movement of the valve core 2, and a The cam mechanism between the servo motor 3 and the valve body 1 is provided in the cam box 11, and the cam box 11 is sealed and connected with the valve body 1 and the servo motor 3 respectively. The cam mechanism includes: a camshaft 4 driven by the servo motor 3, the camshaft 4 includes an eccentric section 42 and a driving section 41, and one end of the spool 2 is pressed against the axial surface of the eccentric section 42 On the axial surface of the driving section 41, a zero induction head 5 is provided; on the cam box 11, an induction sensor 9 is provided corresponding to the zero induction head 5, and the induction sensor 9 is used to connect to the controller , the controller receives the signal from the ...

Embodiment 2

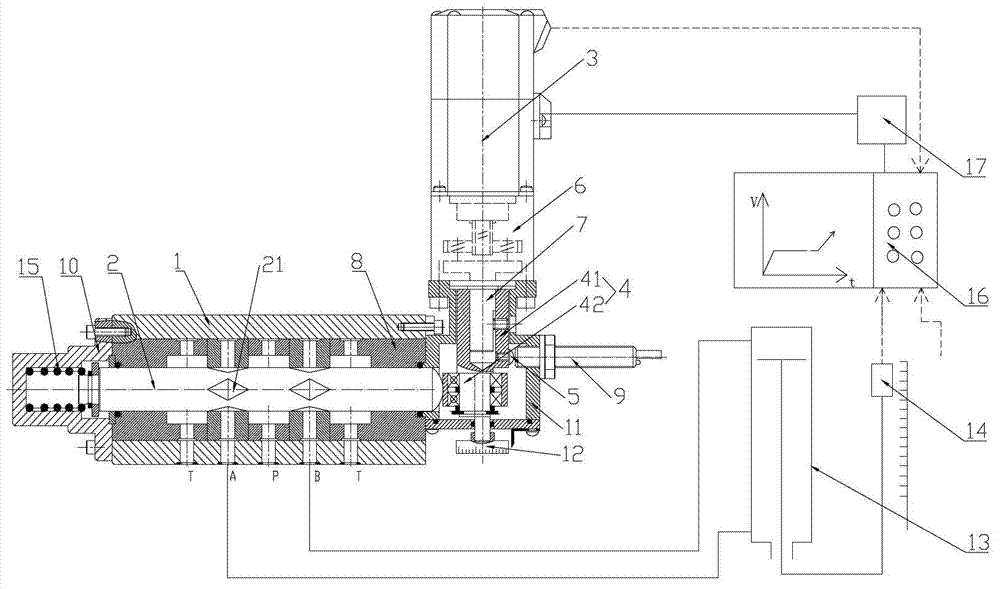

[0047] like Figure 4 As shown, adopt one described controller 16, three described drivers 17 and three flow servo valves described in Embodiment 1, three described hydraulic actuators 13: hydraulic cylinder (oil motor), and three One position detection device 14: a linear encoder (rotary encoder) can realize the interpolation linkage real-time control of three hydraulic cylinders (oil motors) for spatial curves.

Embodiment 3

[0049] like Figure 5 As shown, using one controller 16, six drivers 17 and six servo valves in Embodiment 1, six hydraulic actuators 13: performing hydraulic cylinders (oil motors), six positions Detection device 14: linear encoder (rotary encoder), can realize the parallel servo control of the six-degree-of-freedom hydraulic heavy-duty manipulator or processing manipulator, and create a new field of hydraulic servo machinery application in super-large heavy industrial equipment and military equipment. Multi-axis linkage hydraulic servo control. Such as: radar tracking, satellite navigation, unmanned driving, remote reduction of ships, automatic aiming and launching of ship-borne missiles and other equipment hydraulic servo control.

[0050] In other embodiments, the position detection device 14 can also be a displacement sensor for detecting displacement. At the same time, the hydraulic actuator 13 can also use a hydraulic motor according to the application. At this time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com