Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Avoid Flow Dead Zones" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

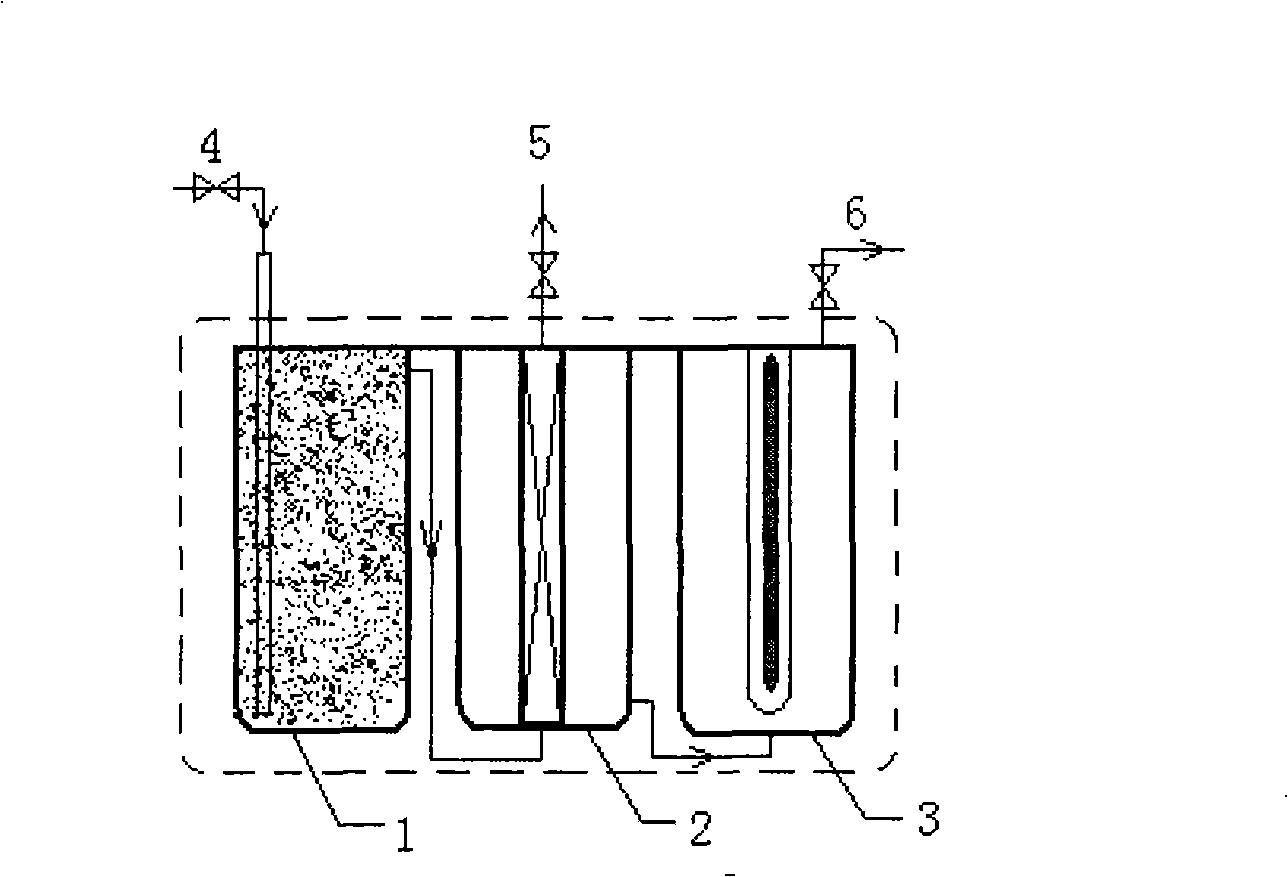

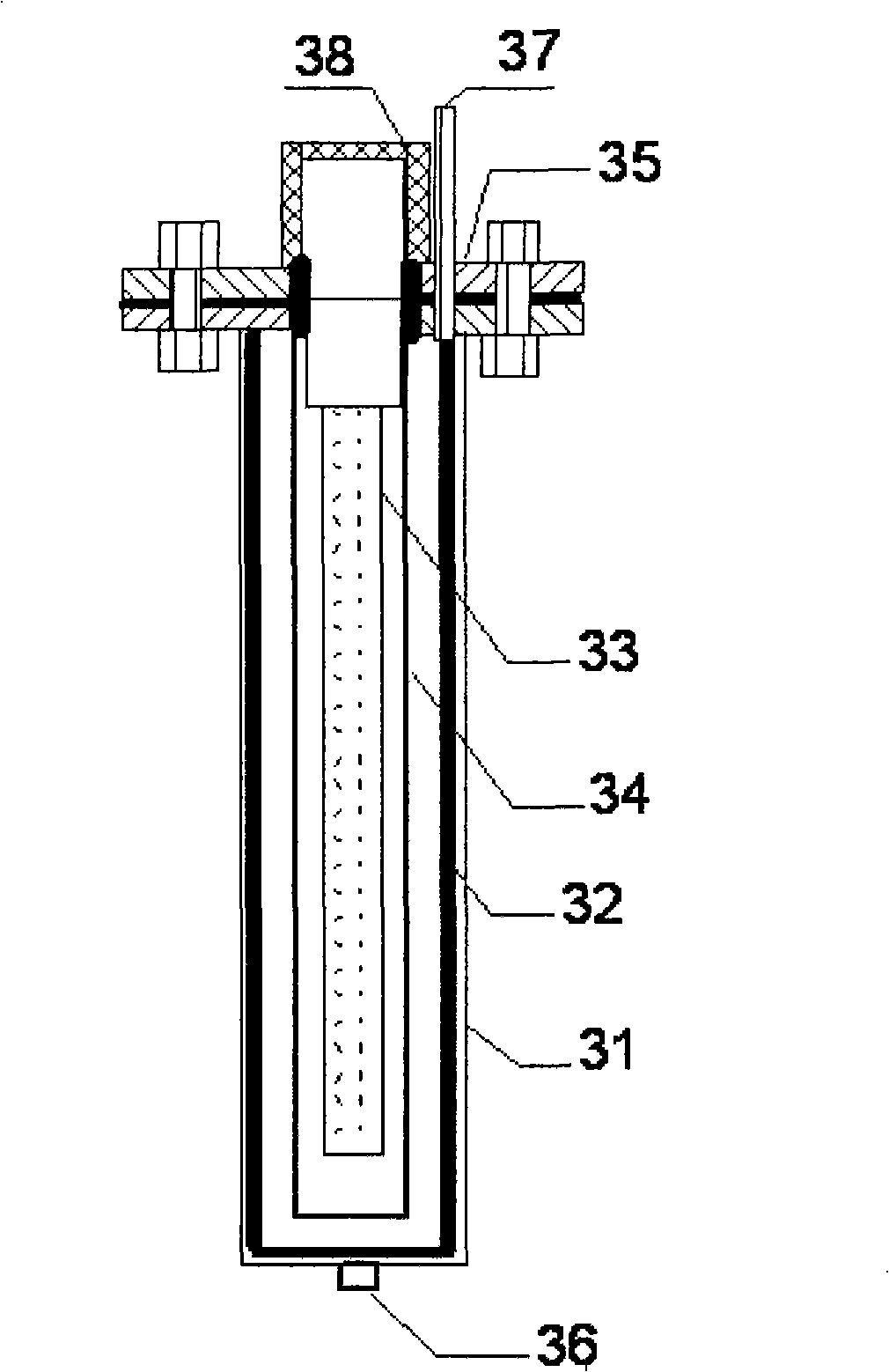

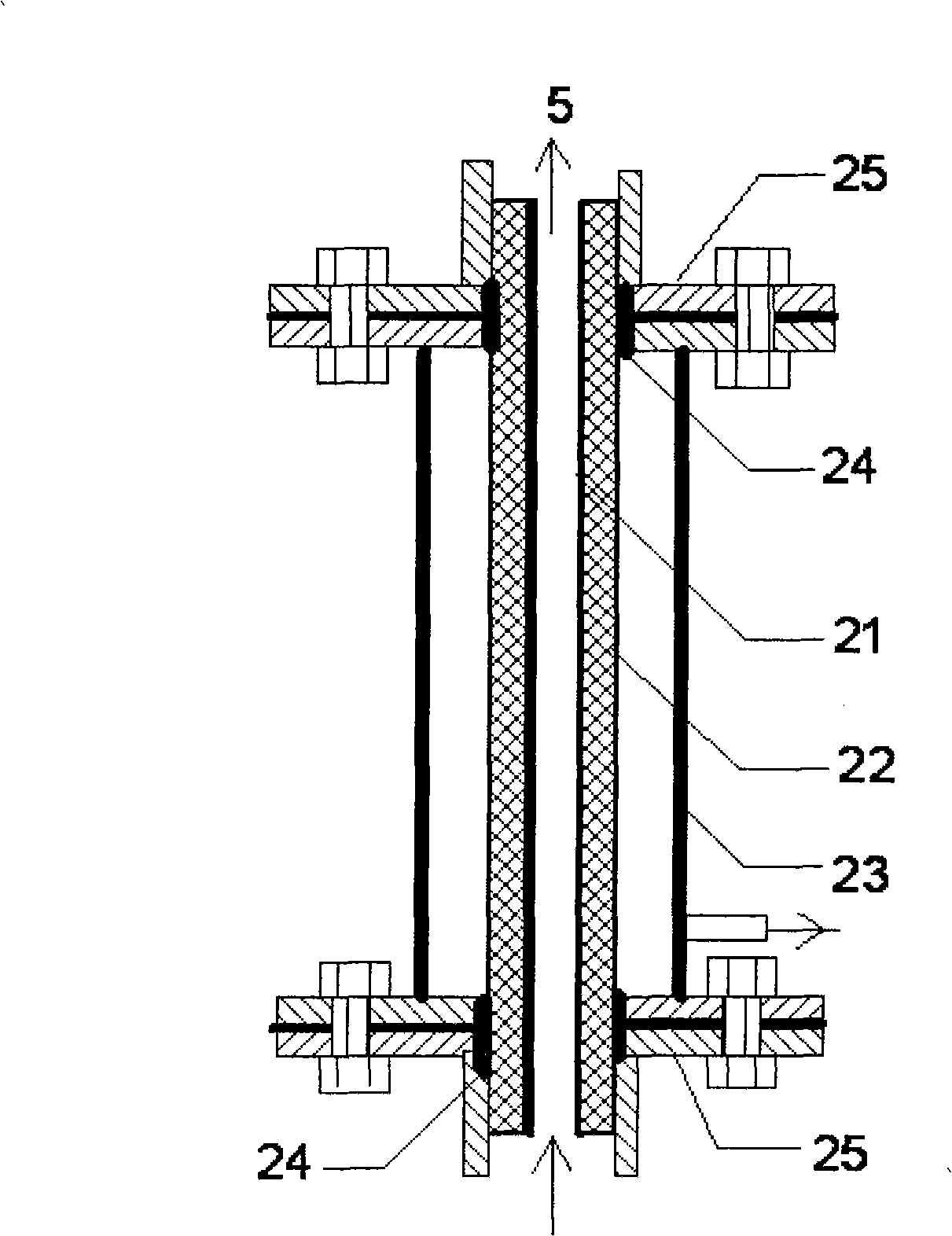

Drinking water purifying device combining photocatalysis and inorganic membrane filtration technology

InactiveCN101538098AAvoid replacementAvoid pollutionWater/sewage treatment by irradiationMultistage water/sewage treatmentActivated carbon filtrationFiltration technique

The invention relates to a drinking water purifying device combining photocatalysis and inorganic membrane filtration technology, comprising an active carbon filtration assembly, an inorganic membrane filtration assembly and a photocatalysis membrane assembly. Water flows into the active carbon filtration assembly and then passes through the inorganic membrane filtration assembly, and finally, purified drinking water flows out of the photocatalysis membrane assembly. The inorganic membrane filtration assembly and the photocatalysis membrane assembly are both mounted vertically to prevent sediment from polluting membranes and avoiding dead flow areas; the active carbon can be soaked in edible alcohol for being utilized repeatedly; the inorganic membrane of the inorganic membrane filtration assembly has high mechanical strength and can resist corrosion; and all assemblies of the device have long service lives and have no needs of frequent cleaning and replacement. The invention adopts the photocatalysis membrane action for sterilization, has good effect, can purify water in depth, loads phtocatalyst on stainless steel or the inner wall of a glass tube and adopts an ultraviolet source to inspire the photocatalysis membrane to react so as to achieve the purpose of sterilization and trace organic matter degradation, have no problems of catalyst separation, and can not cause second water pollution.

Owner:HAINAN NORMAL UNIV

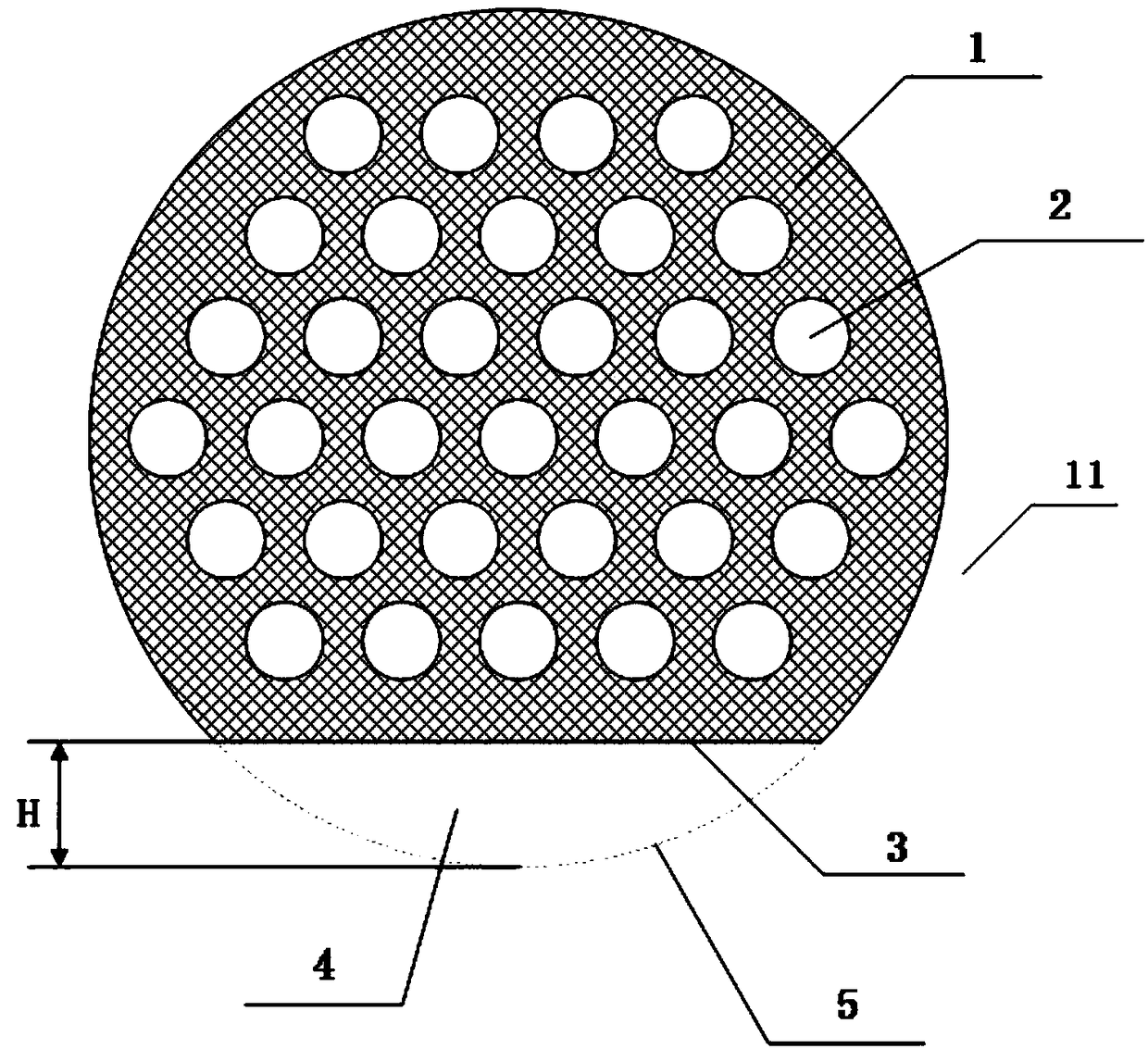

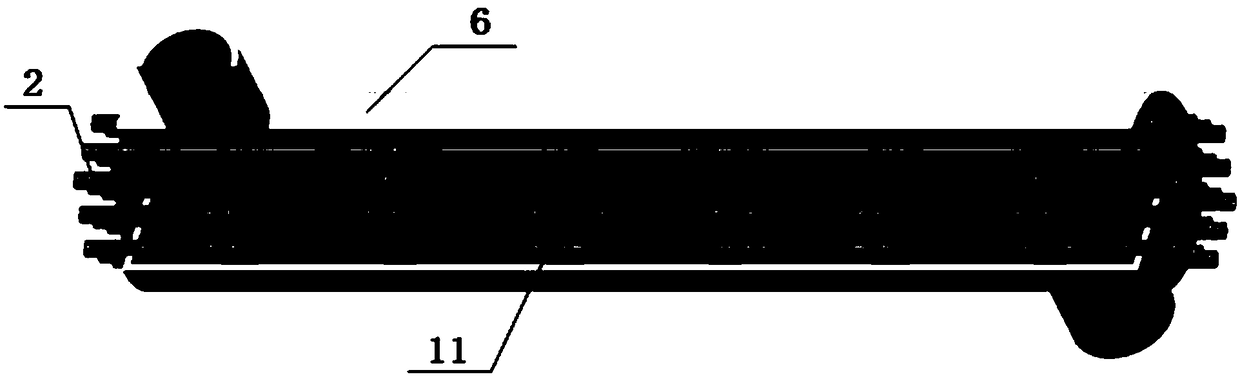

External guide single shell pass support-free crosscharge curve surface tube energy-saving heat exchanger

InactiveCN101871737AEnhance vertical mixingImprove heat transfer performanceHeat exchanger casingsStationary tubular conduit assembliesEngineeringCorrosion

The invention discloses an external guide single shell pass support-free crosscharge curve surface tube energy-saving heat exchanger, which comprises a shell, a first tube plate, a second tube plate, a first close cover, a second close cover, a strapping steel strip, a heat exchange tube bundle, a first external guide barrel and a second external guide barrel. Shells in a first annular inner cavity and a second annular inner cavity are uniformly provided with a plurality of through holes; heat exchange tubes in the heat exchange tube bundle are crosscharge curve surface tubes which are formed by flattening and twisting circular tubes serving as parent tubes; the cross section of the crosscharge curve surface tubes is oval; and the crosscharge curve surface tubes are contacted in turn and form the tube bundle by means of the self support of contact points of the crosscharge curve surface tubes. The shell pass fluid can uniformly enter a shell pass, and non-flowing regions are reduced. The heat exchange tube bundle consists of the support-free crosscharge curve surface tubes, so turbulence degree of the shell pass fluid is improved and the heat transfer in the tubes is enhanced; and the shell pass is not provided with baffle plates, so the non-flowing regions between the tubes are eliminated, and dirt deposition and corrosion of a tube pass are reduced.

Owner:SOUTH CHINA UNIV OF TECH

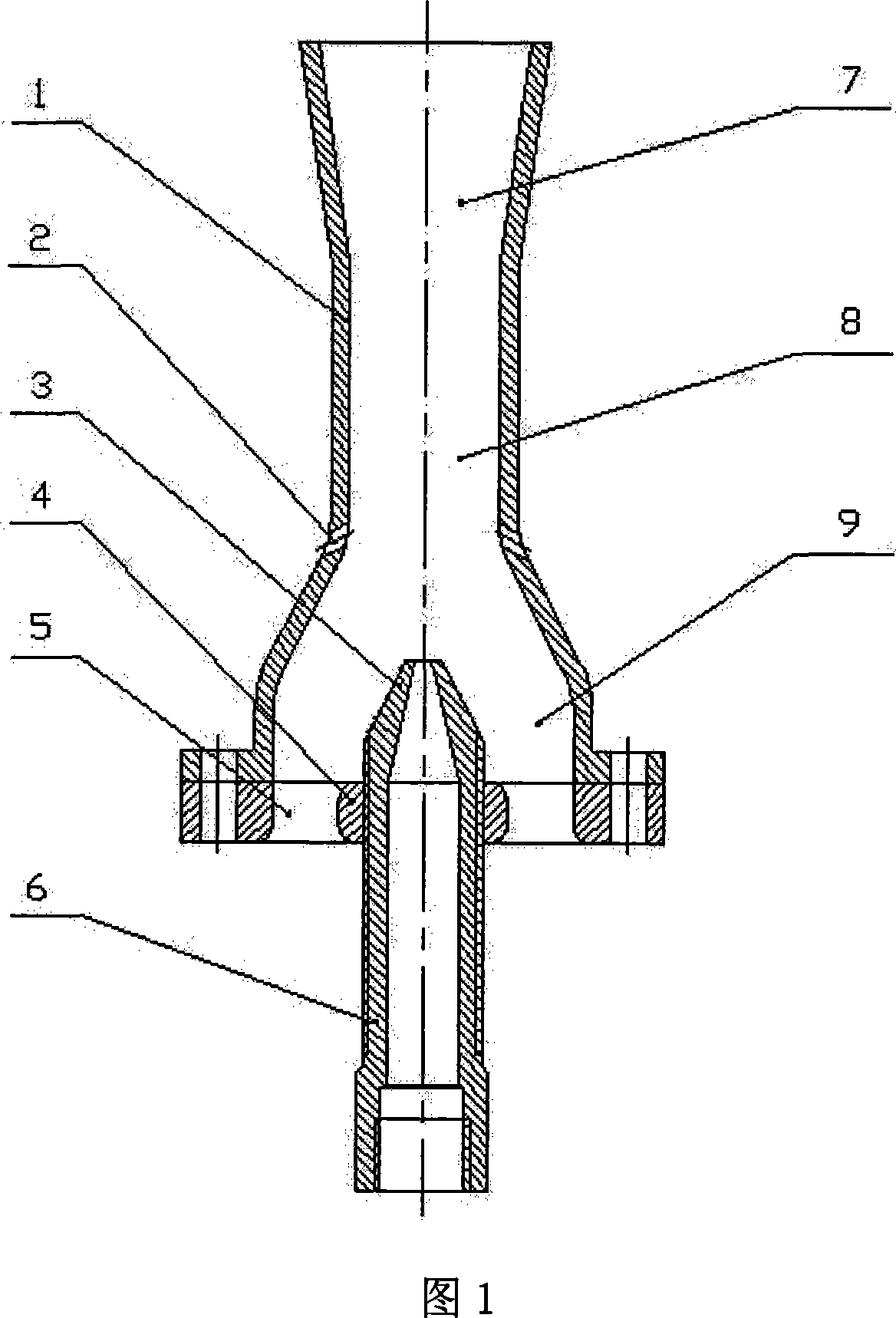

Jet current atomizing mixer for bioreactor

InactiveCN101185859AQuick responseOvercome energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringReducer

The invention relates to a jet spray hybrid bioreactor, comprising a reducer pipe, a ledger plate, a jet spray muzzle, and a compressed air ingress pipe, which is characterized in that the reducer pipe is specially designed to have a dispersion cavity, a hybrid cavity, and a jet spray cavity in sequence from the top down. A plurality of liquid reactant suction inlets are provided at the intersection of the hybrid cavity and the jet spray cavity and distributed evenly and circumferentially. The intersection angle between the axial lead of a hole and the axial lead of the reducer pipe is 45-90 degrees. A plurality of liquid reactant suction inlets are provided on the ledger plate. The ledger plate and the reducer pipe, and the ledger plate and top end of the jet spray muzzle are connected respectively by screw threads. The outlet of the jet spray muzzle is extended deeply into the reducer pipe. The lower end of the jet spray muzzle is connected with the compressed air ingress pipe. The invention has the advantages that the invention makes use of the pumping action of high speed airflow to automatically absorb in liquid reactants, thus realizing multiple-angle stirring, high efficiency and energy saving, without dead flow zone, and the structure is simple and the operation control is convenient.

Owner:JIANGSU UNIV

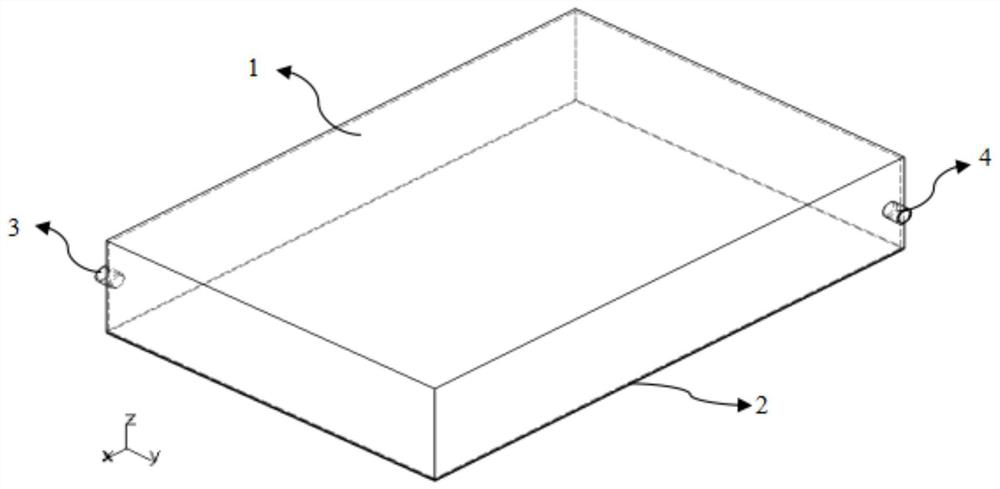

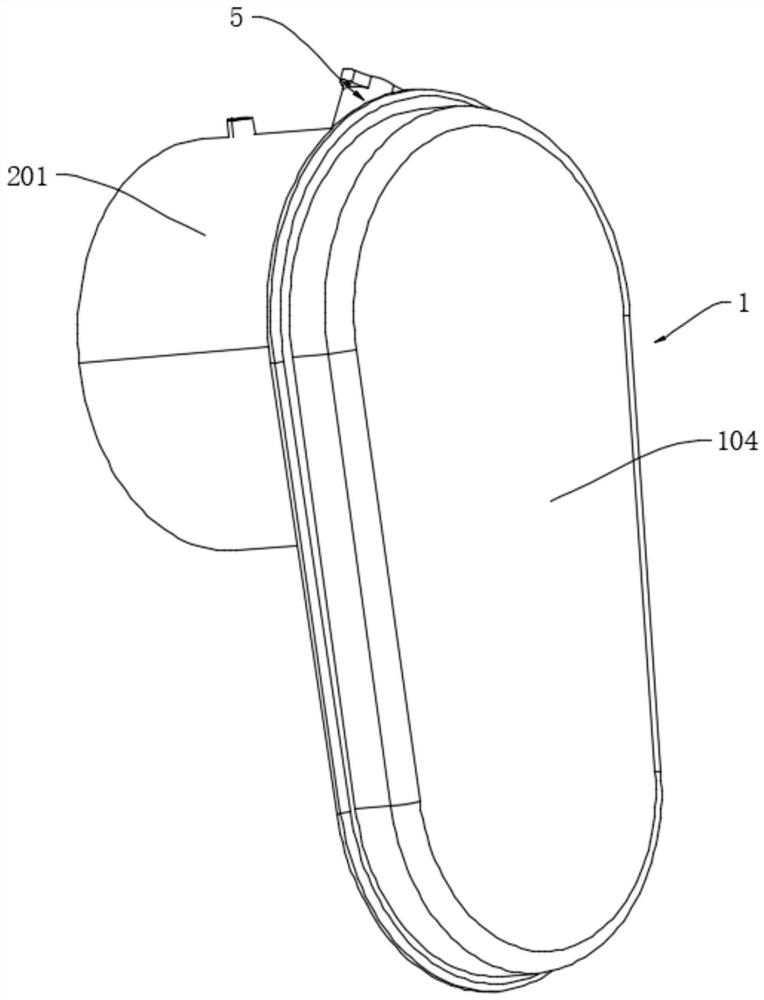

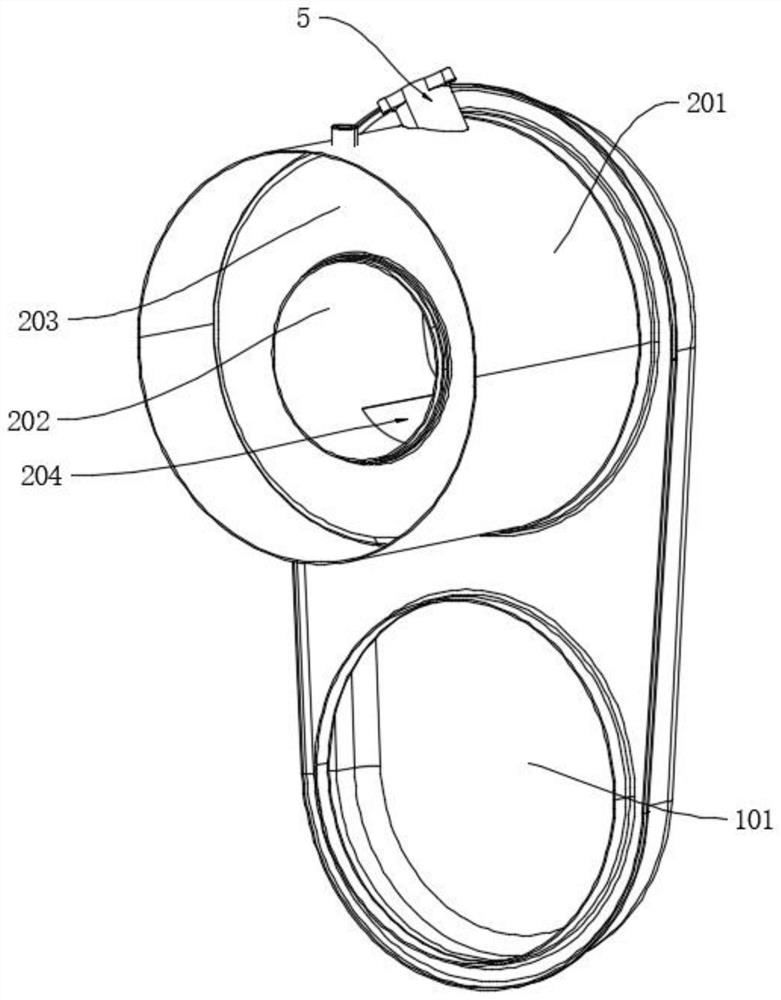

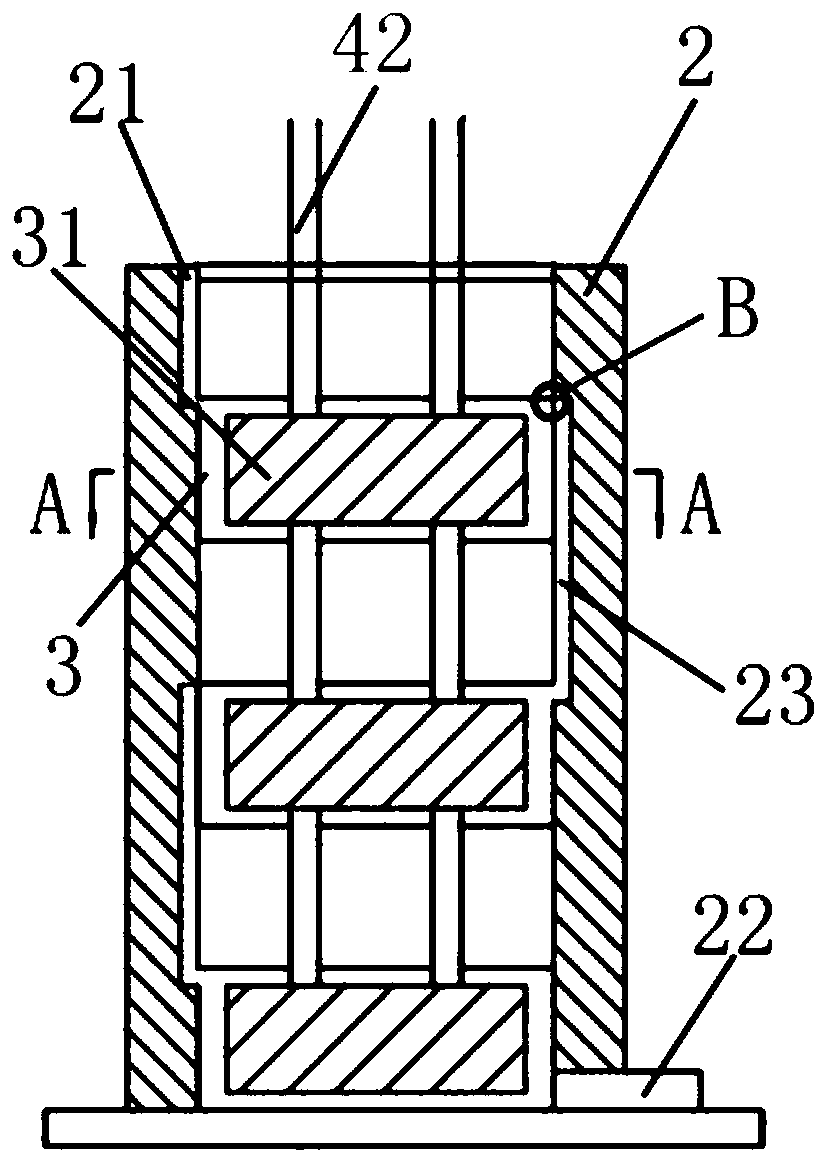

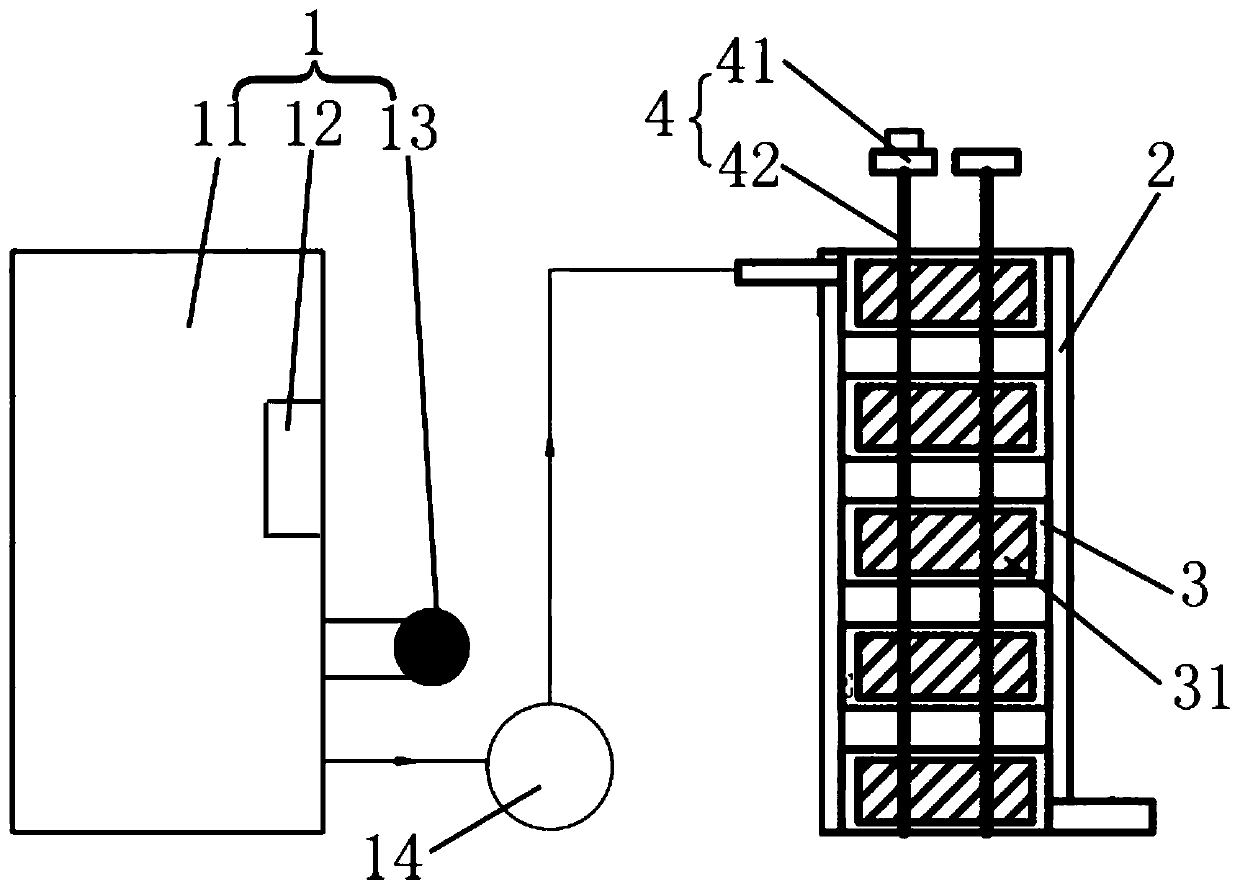

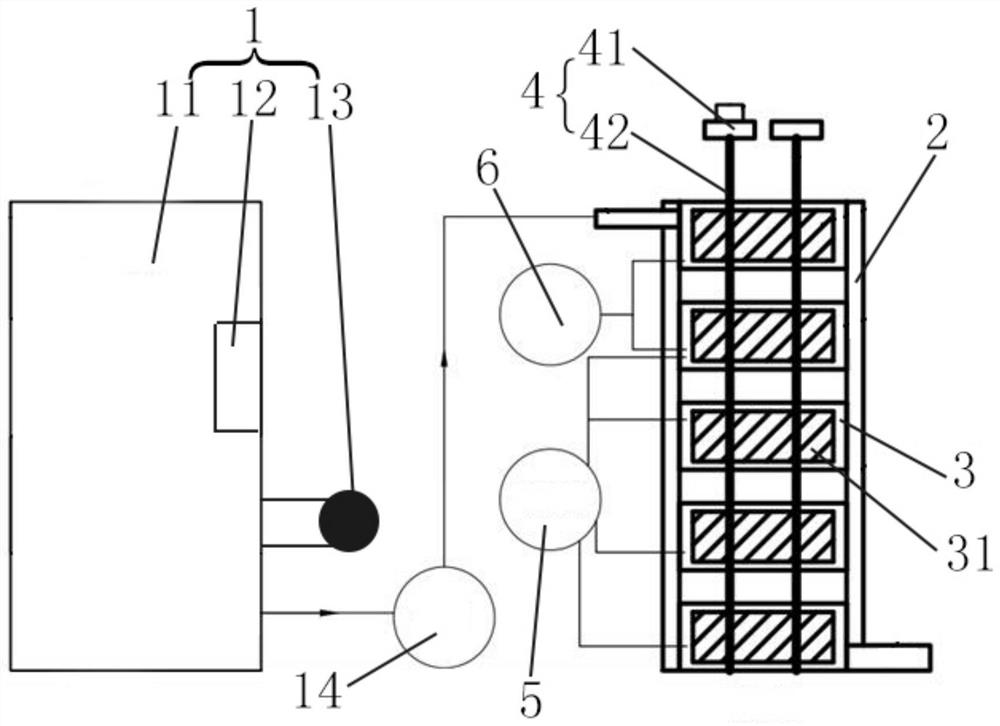

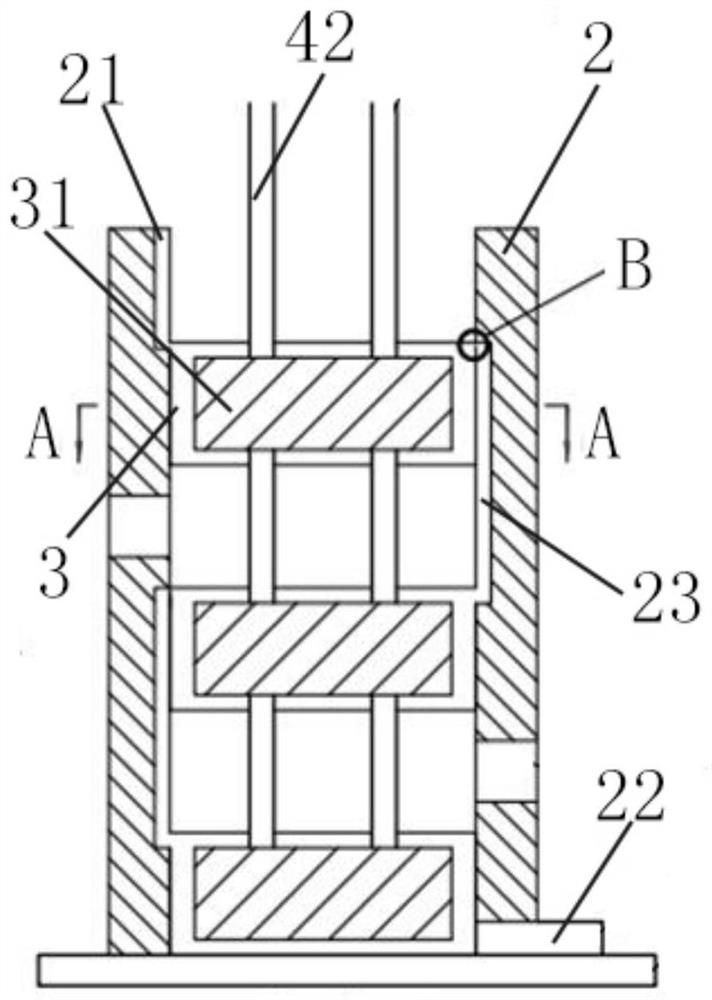

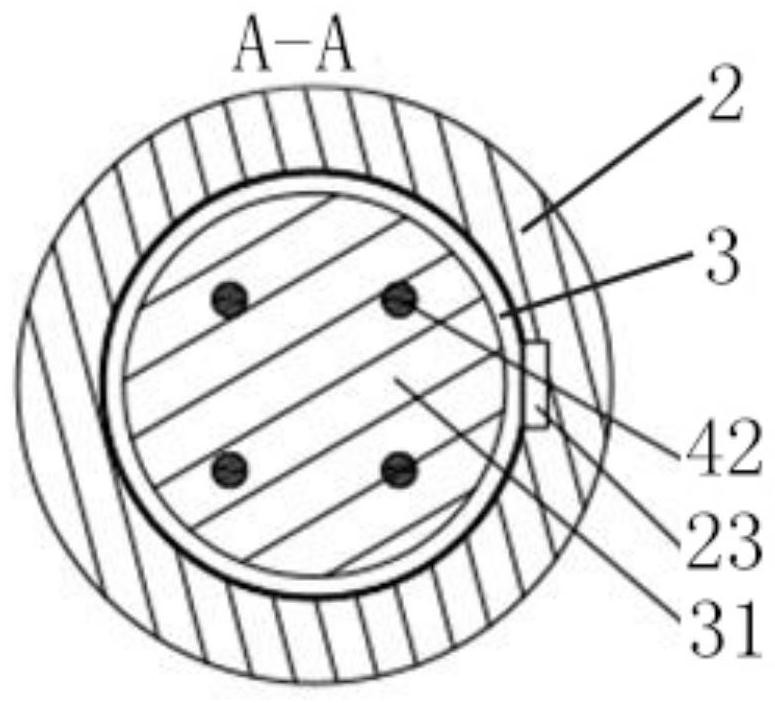

Immersed liquid cooling battery pack

PendingCN112103594AIncrease energy densityEasy to assembleSecondary cellsCell component detailsEngineeringElectrical and Electronics engineering

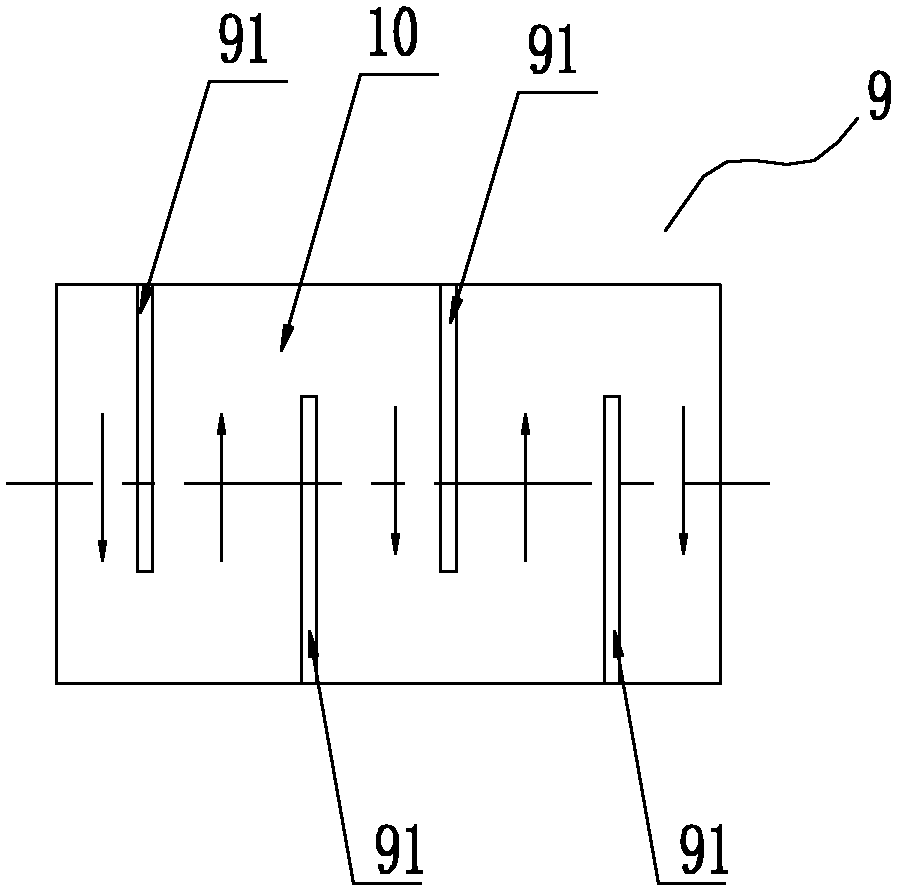

The invention discloses an immersed liquid cooling battery pack. The immersed liquid cooling battery pack comprises a shell, at least one battery pack is arranged in the shell, and each battery pack comprises a plurality of battery cells arranged at intervals in the first direction; a liquid inlet cavity and a liquid outlet cavity are formed in the two sides of the battery pack in the second direction, and the second direction is perpendicular to the first direction; a liquid inlet is formed in one of the two ends, in the first direction, of the liquid inlet cavity, and a liquid outlet is formed in the end, different from the liquid inlet, of the two ends, in the first direction, of the liquid outlet cavity, so that cooling liquid enters the liquid inlet cavity from the liquid inlet, flowsinto the liquid outlet cavity after flowing through the battery pack and flows out from the liquid outlet; and a flow equalizing plate is arranged between the liquid inlet cavity and the battery pack, the flow equalizing plate is arranged in the first direction, a liquid through hole is formed in the flow equalizing plate, and a plurality of flow deflectors which are arranged at intervals in thesecond direction are arranged at the liquid through hole. The immersed liquid cooling battery pack provided by the invention is high in heating / cooling efficiency, good in uniformity and simple in structure.

Owner:清华大学苏州汽车研究院(吴江) +1

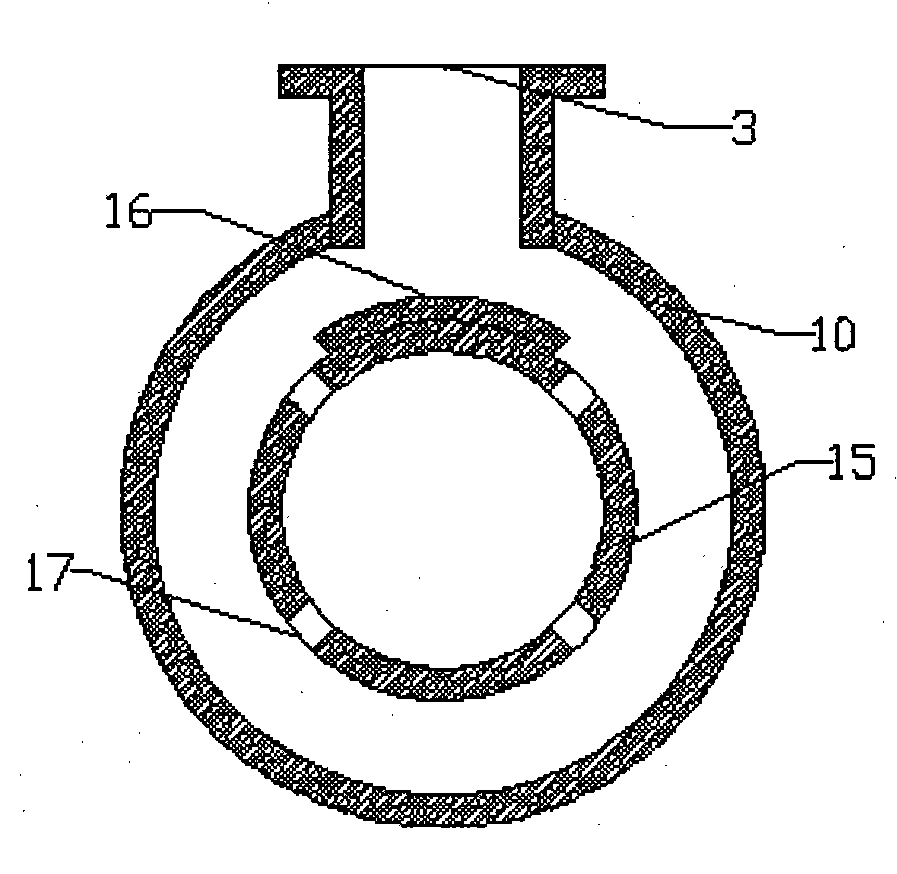

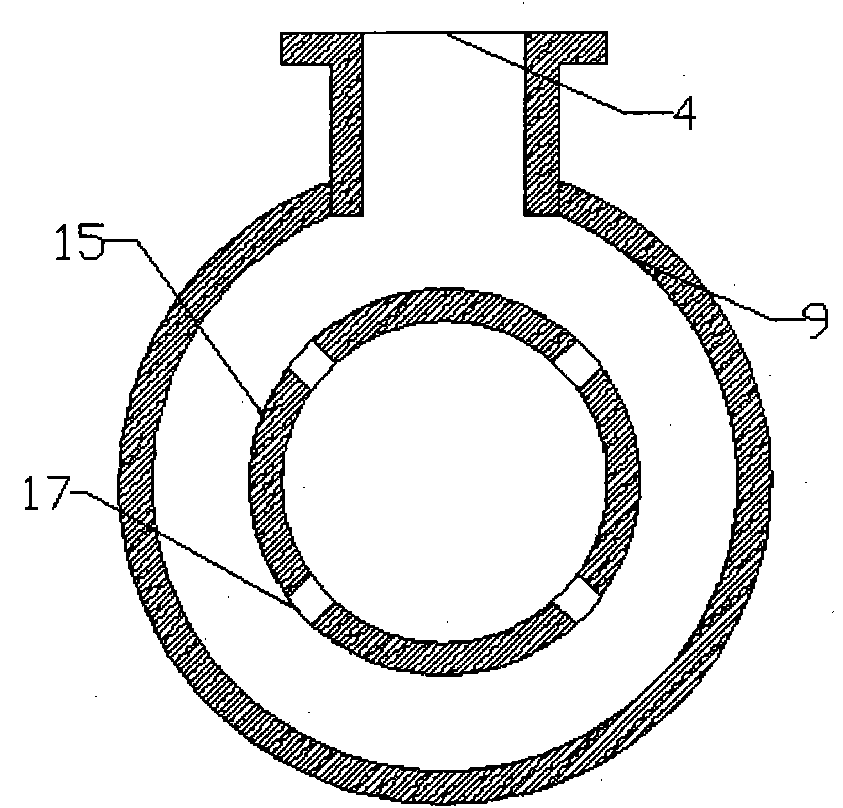

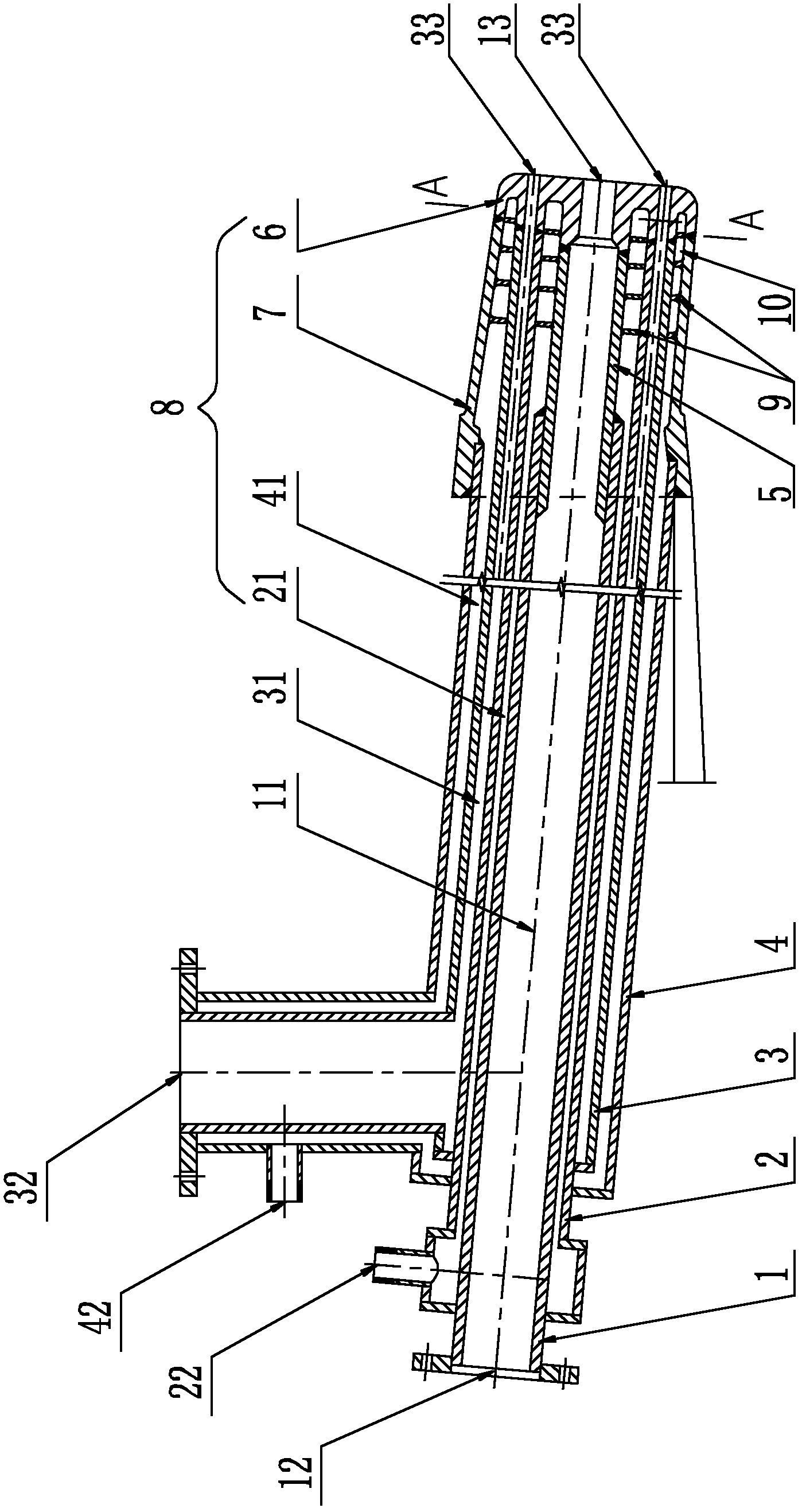

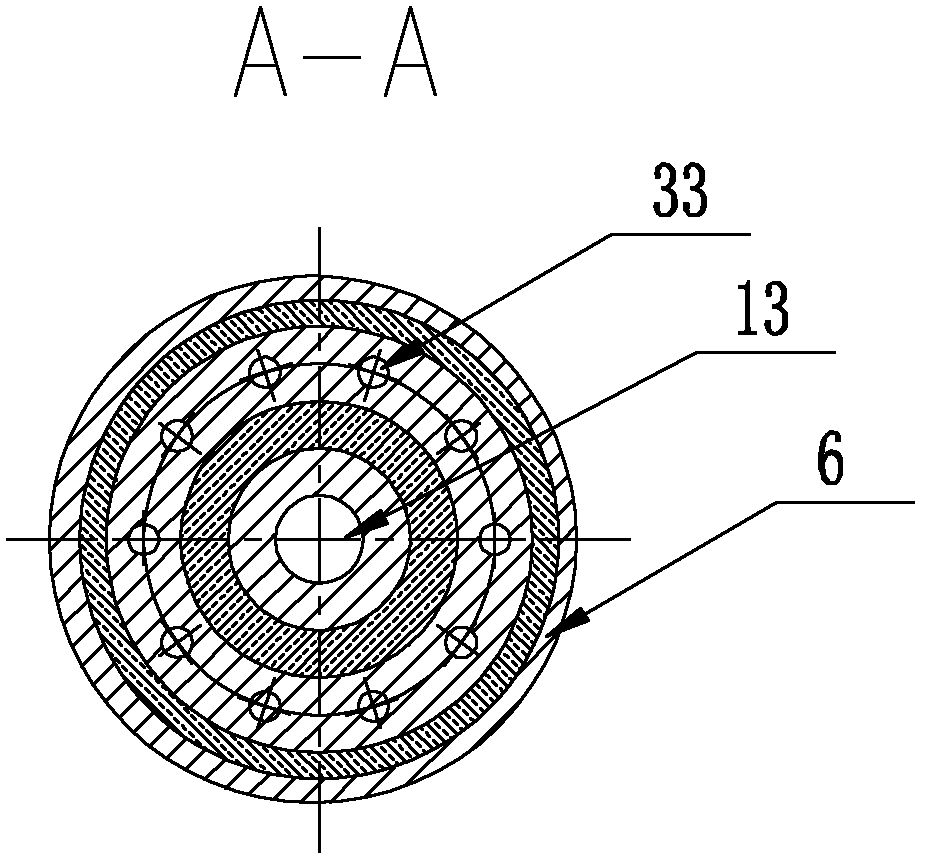

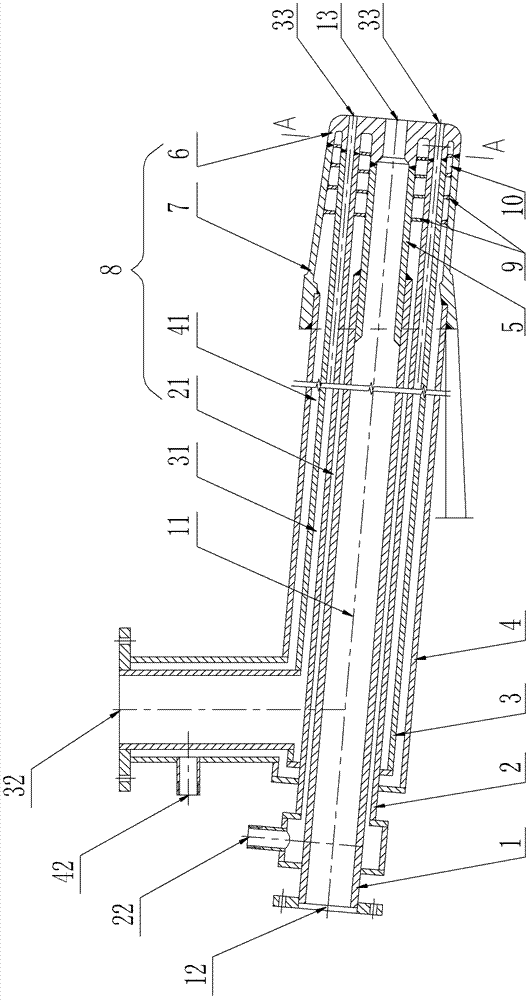

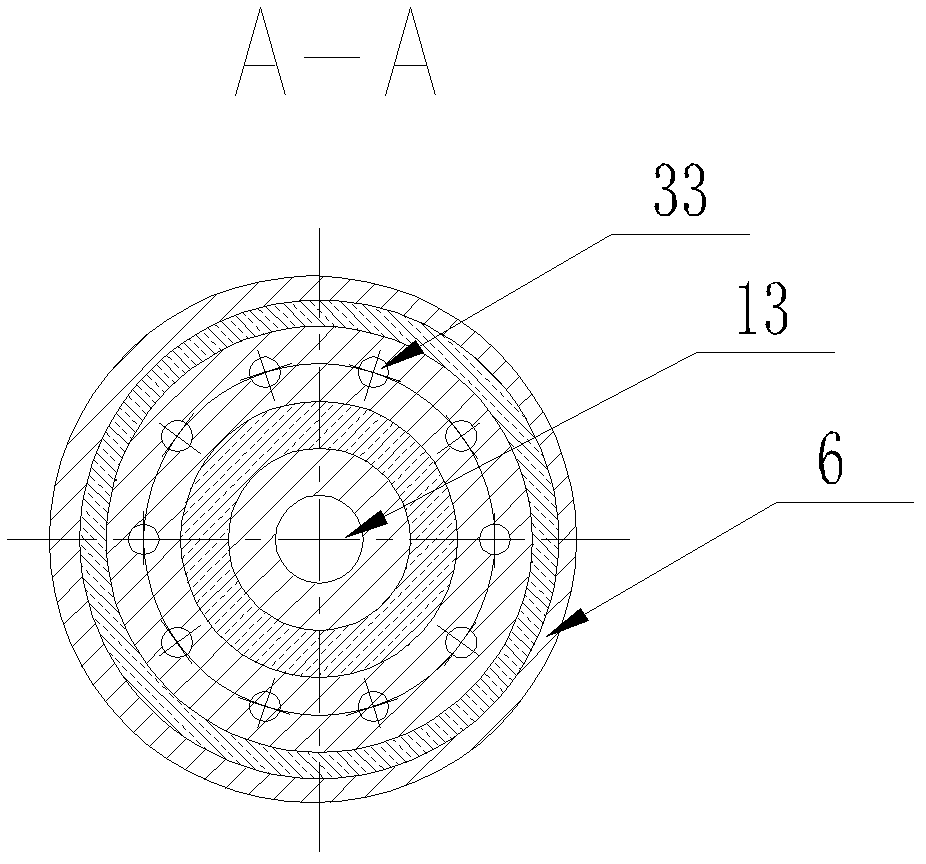

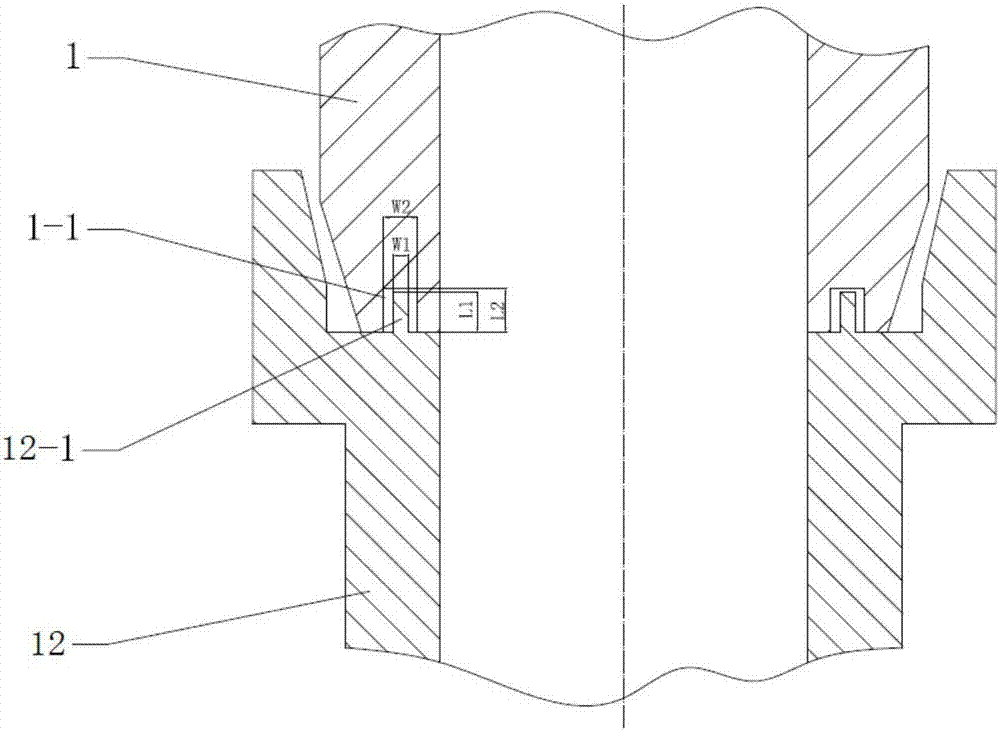

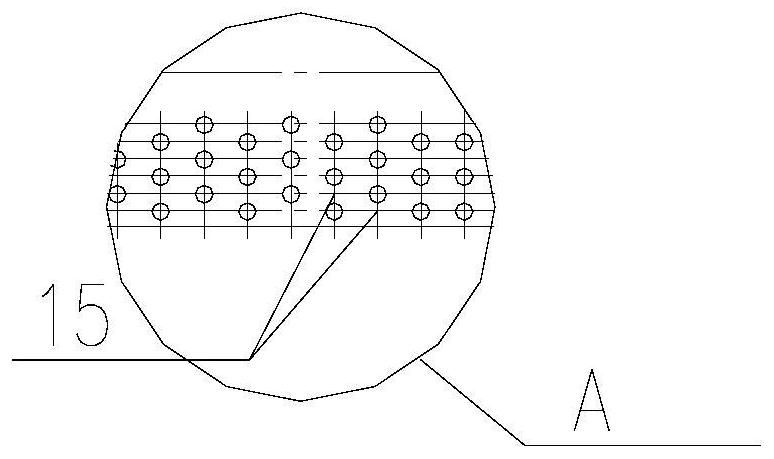

Combined type tuyere small sleeve

The invention discloses a combined type tuyere small sleeve which comprises a central sleeve, an internal sleeve, a first sleeve, a second sleeve and a third sleeve, wherein the central sleeve is fixedly socketed with the internal sleeve to form an oxy-coal medium channel; the gap between the first sleeve and the central sleeve forms a cooling water inflow channel, the gap between the second sleeve and the first sleeve forms a gas medium channel, the gap between the third sleeve and the second sleeve forms a cooling water backflow channel, a front cap and a rear cap which are in an integratedstructure are fixedly connected with one ends far away from a water inflow port and a water backflow port of the cooling water inflow channel and the cooling water backflow channel, and the cooling water inflow channel and the cooling water backflow channel are communicated through the front cap and the rear cap, thus forming a cooling water circulating channel; and the front cap is provided withan oxy-coal medium outlet and a gas medium outlet. The invention has the advantages of simple structure, good cooling effect, high reliability and safety, and long service life.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Novel baffle plate

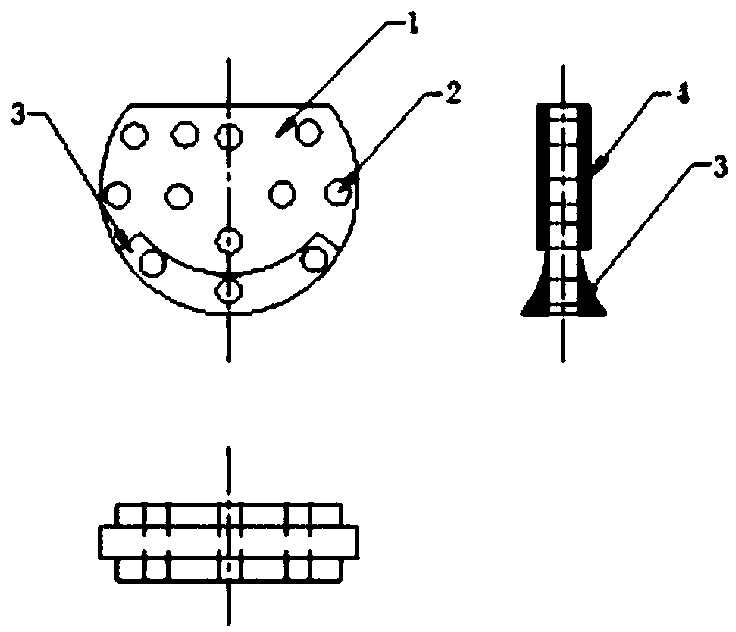

The invention relates to a novel baffle plate. The novel baffle plate comprises a baffle plate, round holes, a flow guide structure and an anti-corrosive coating, wherein the baffle plate is a segment-shaped baffle and is made of stainless steel; round holes are uniformly formed in the surface of the baffle plate; an opening area of each circular hole is 60%-90% of an overall area; each round hole is a through hole with a hole diameter of 8mm-20mm; the flow guide structure is in an arc structure, and is welded on the round end face of the baffle plate so as to prevent a right-angle transition area from being formed at the welding position between the baffle plate and a condenser, and remove a flow dead area formed at the same position; the anti-corrosive coating is located at the outer end face of the baffle plate, so as to prevent corrosion on the baffle plate in the condenser, caused by an acidic solution or an alkaline solution. According to the baffle plate mounted in the condenser, when passing through the baffle plate mounted in the condenser, the fluid in the condenser flows through the round hole. The hole diameter is reduced and the flow-through speed of the liquid is accelerated, so that the flowing liquid is avoided in the condenser. The fluid flows with a certain radian in a transition manner through the flow guide structure of the baffle plate, so that the flowing dead area is overcome. The novel baffle plate provided by the invention has the advantages of simple structure and convenience for manufacturing.

Owner:天津知顺科技有限公司

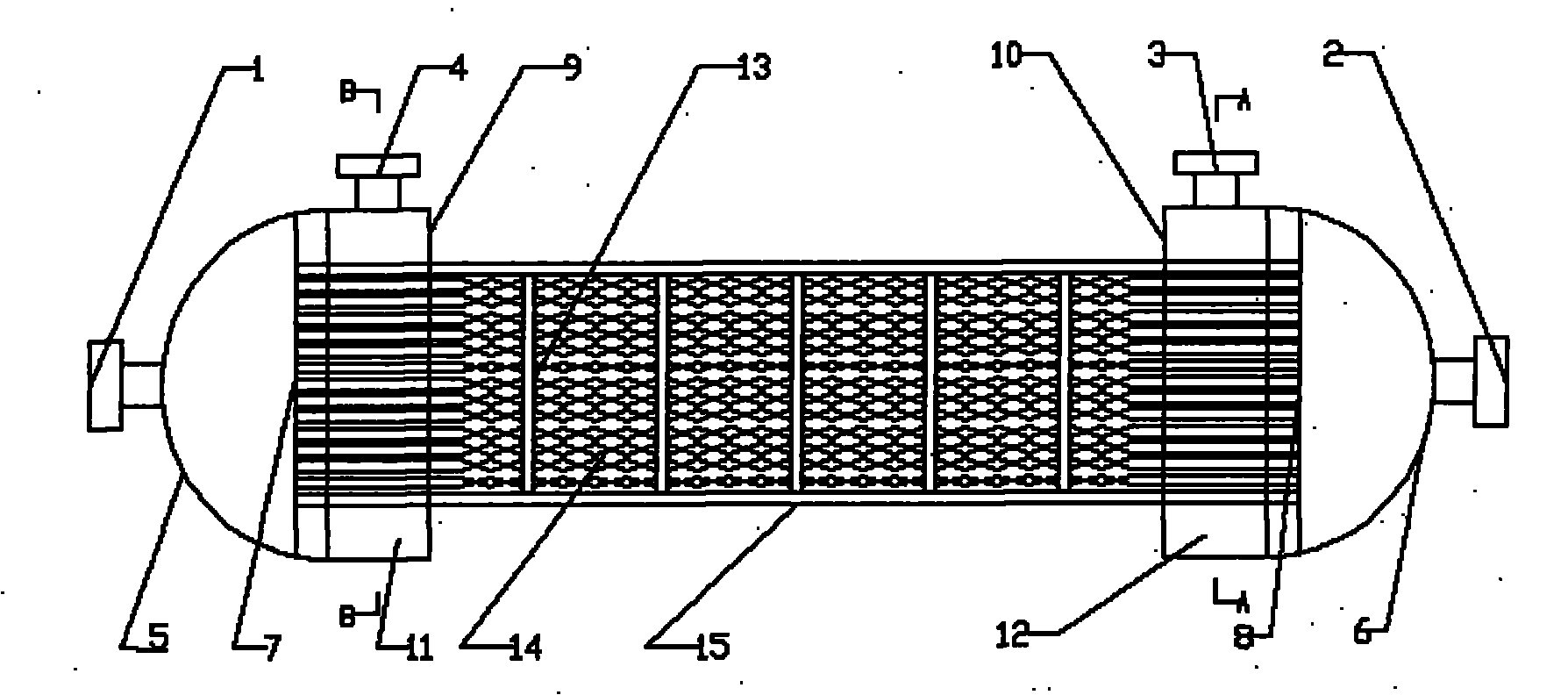

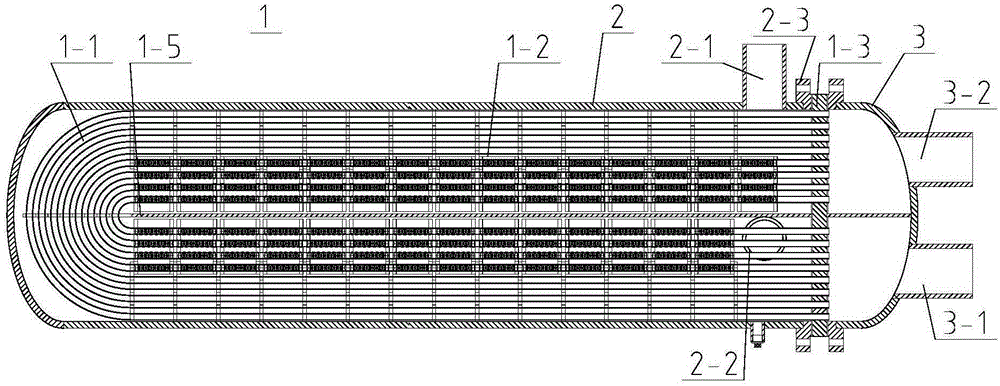

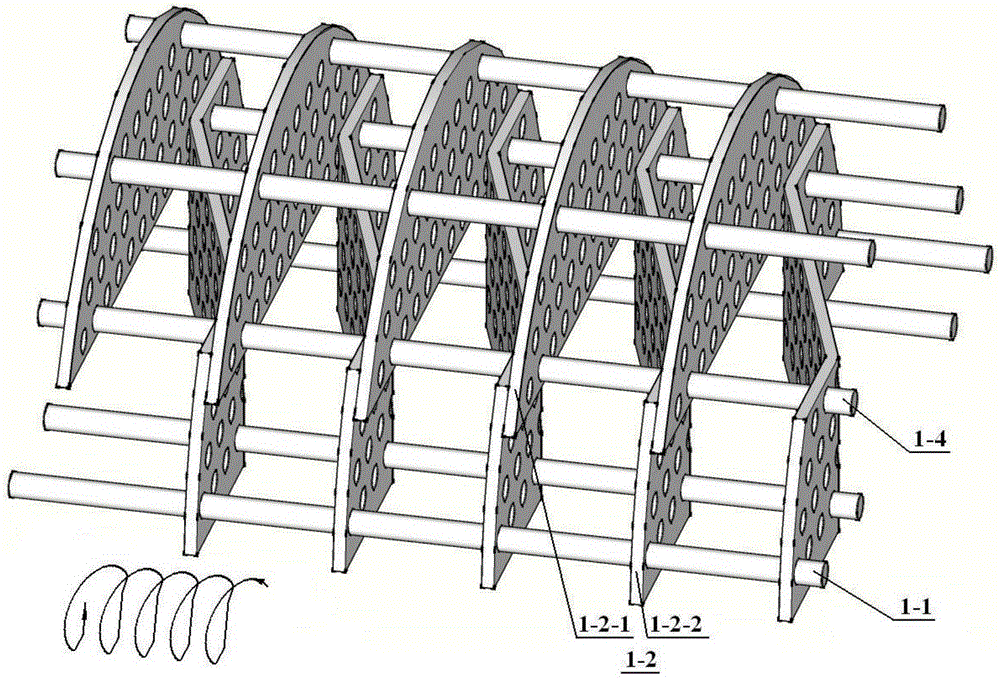

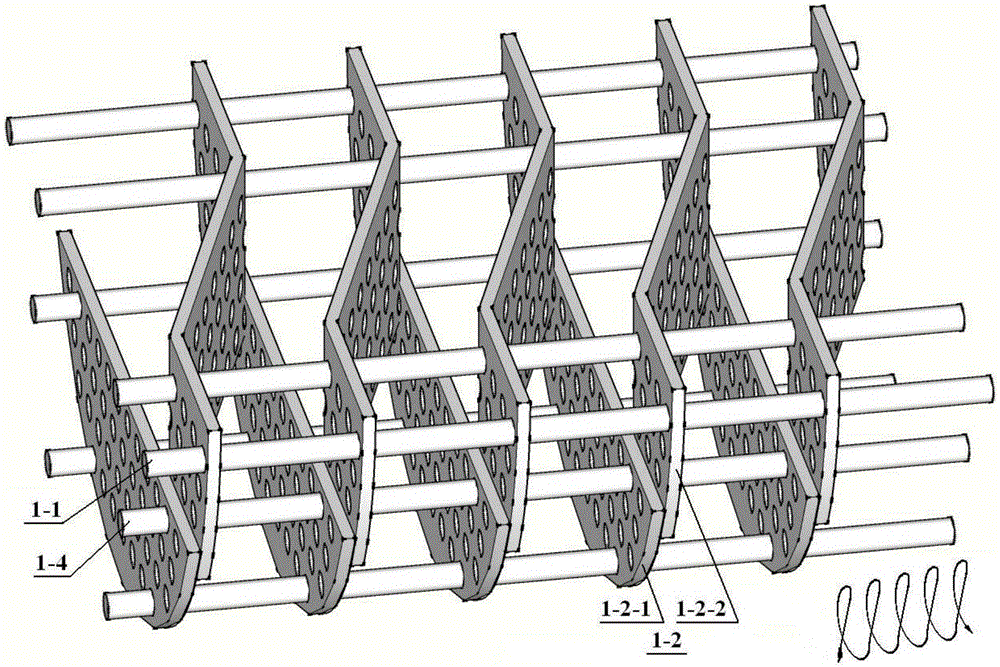

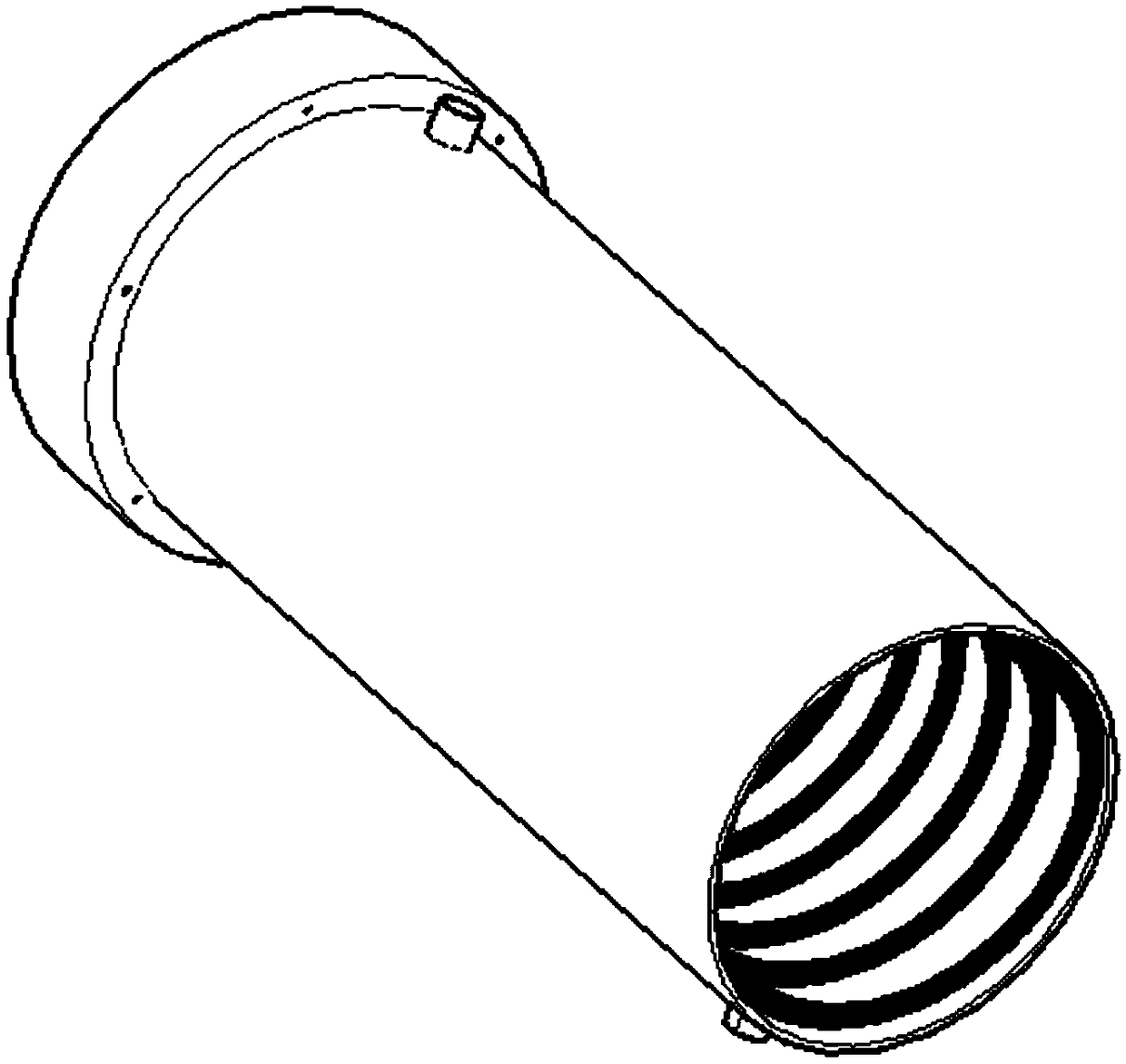

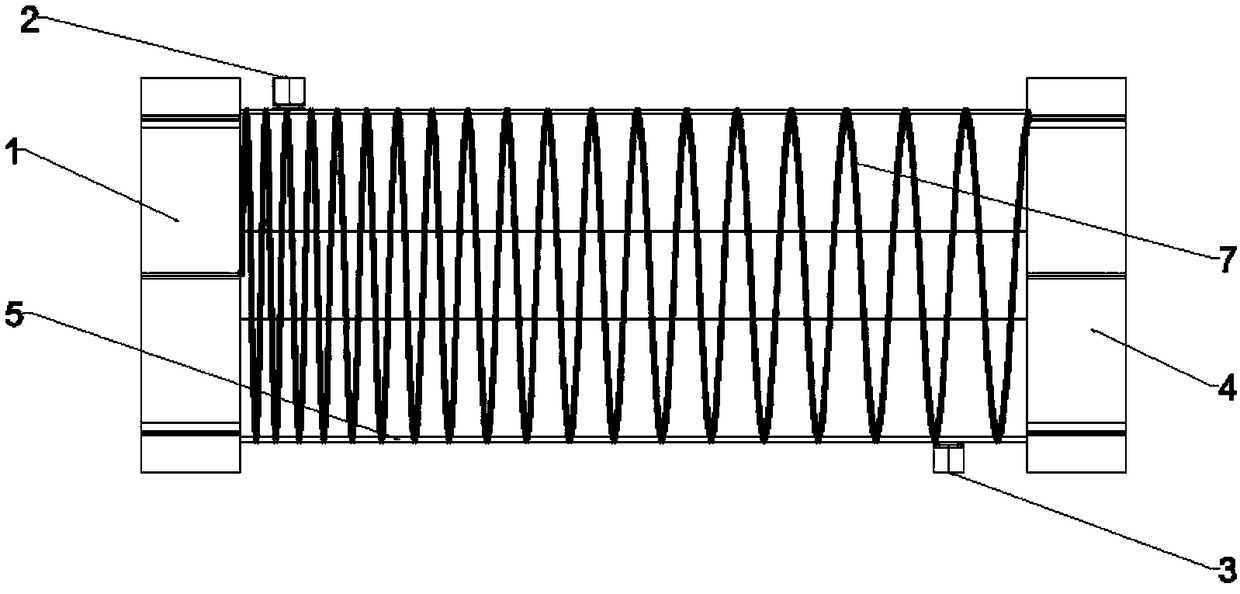

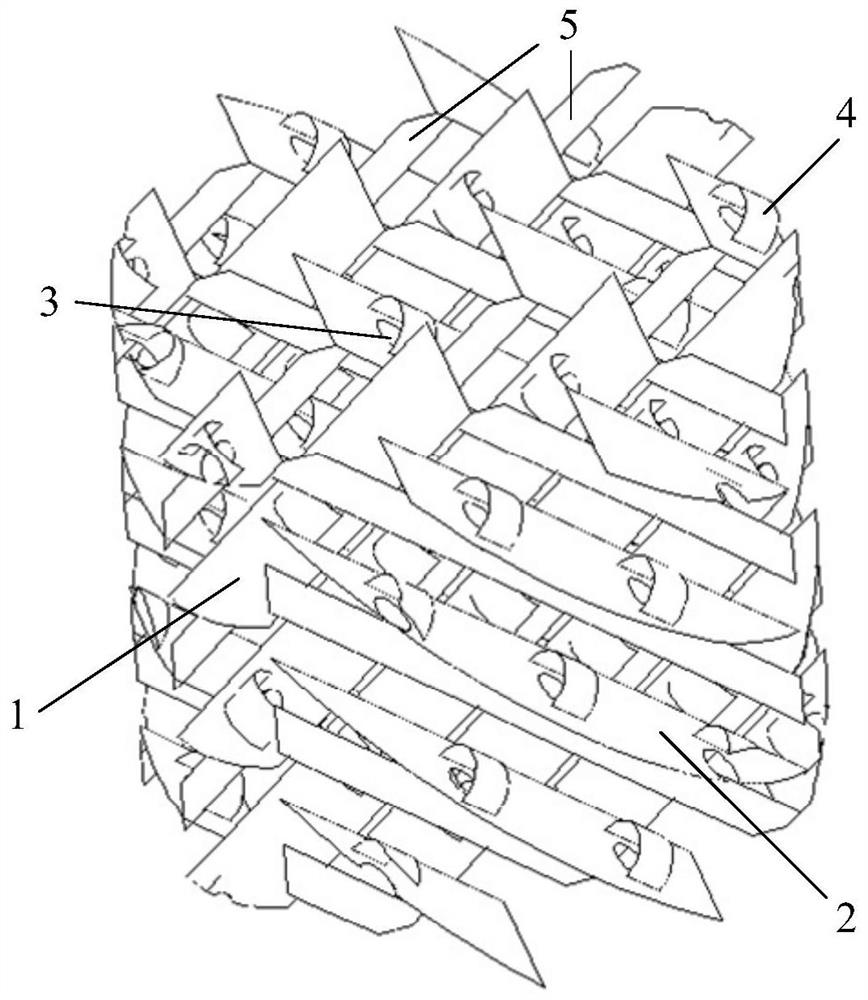

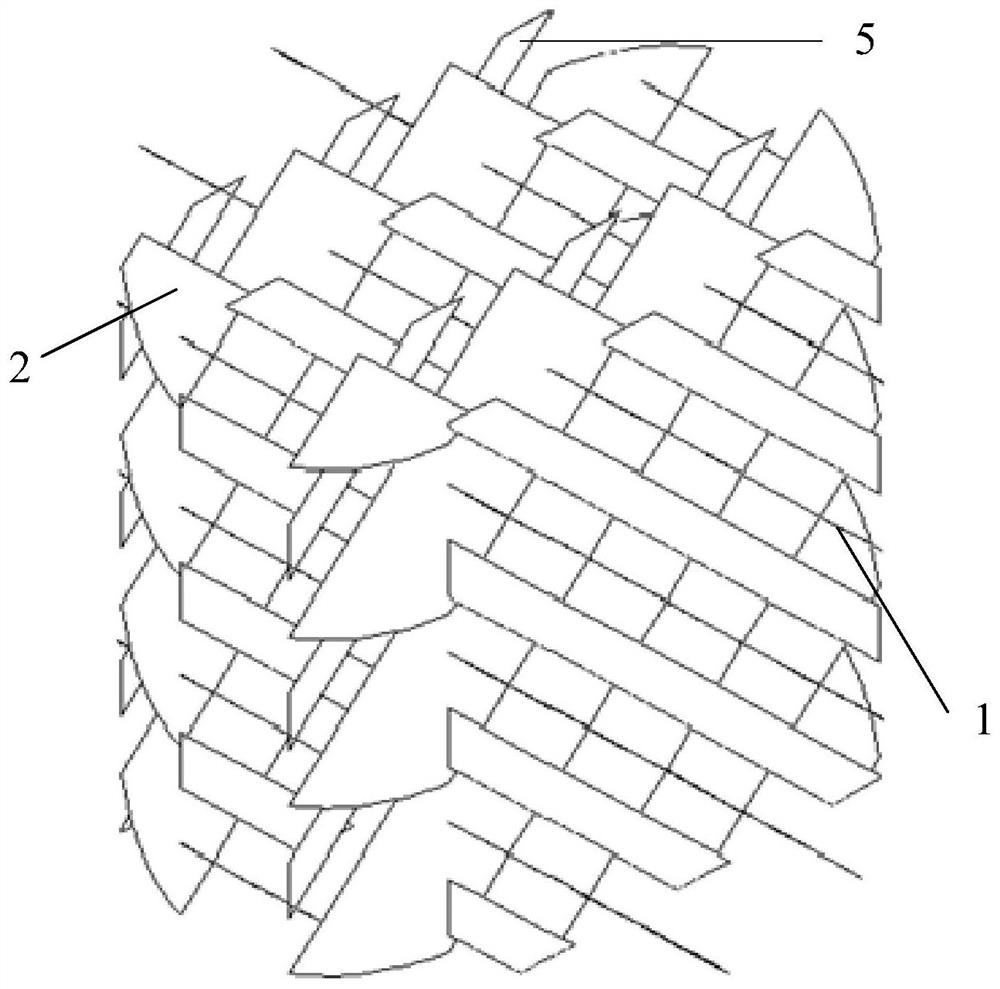

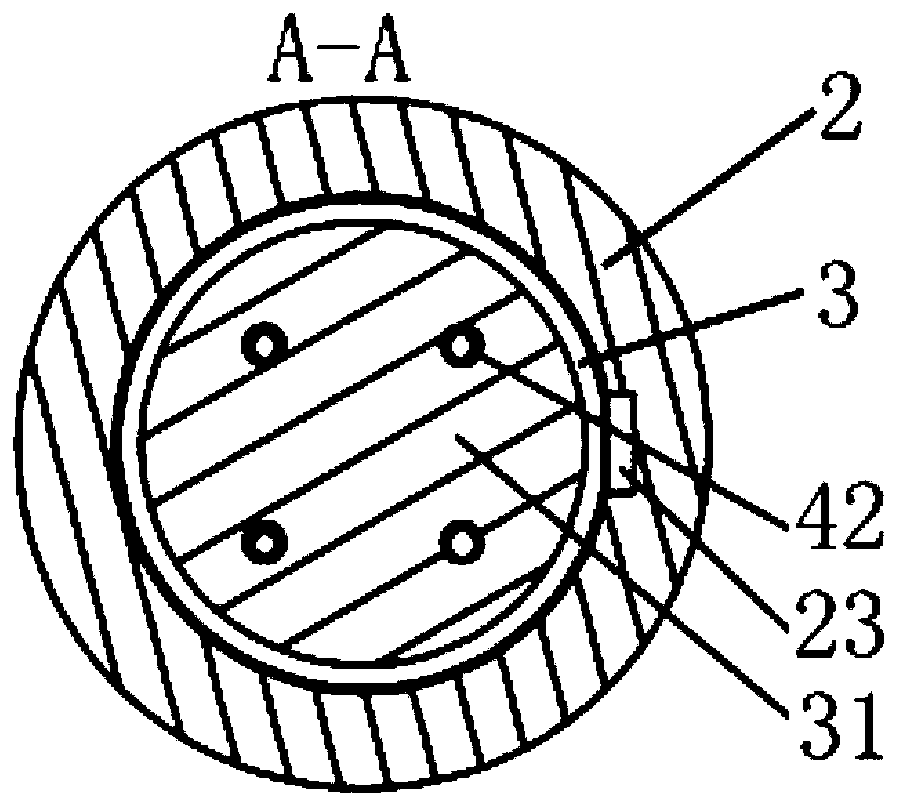

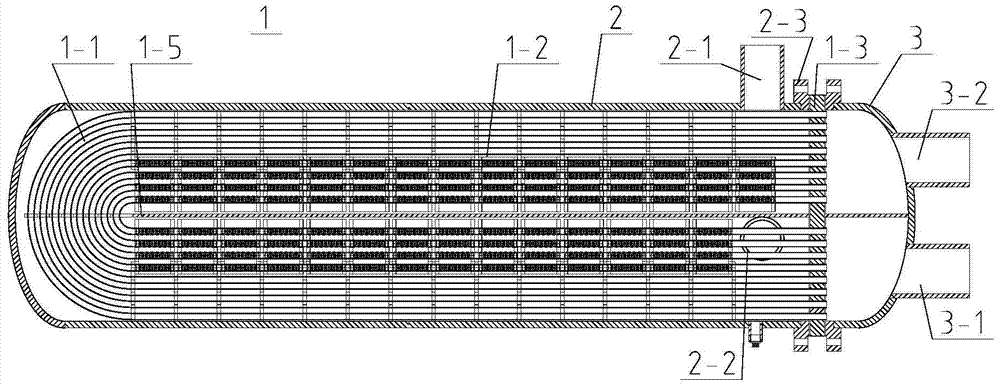

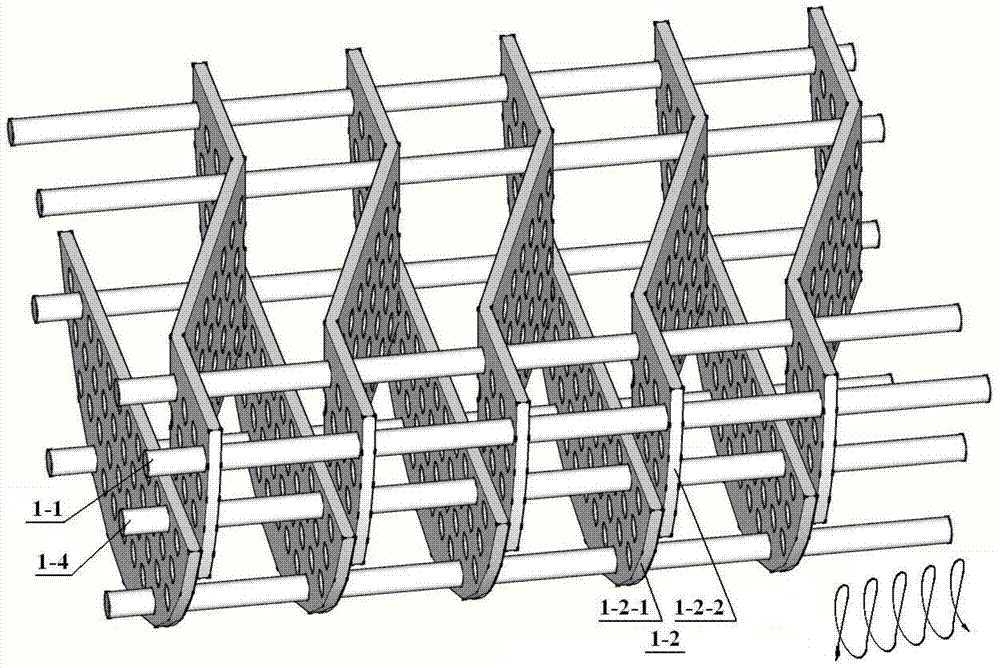

Reverse flow type spiral baffle plate U-shaped pipe bundle heat exchanger

ActiveCN105202948AEasy to fixOvercome the limitation that it can only be arranged in a cylindrical spaceHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerEngineering

A reverse flow type spiral baffle plate U-shaped pipe bundle heat exchanger is composed of a U-shaped pipe bundle core body, a shell and a water chamber. The U-shaped pipe bundle core body is composed of a U-shaped pipe bundle, spiral baffle plate assemblies, pipe plates, pull rod sleeve assemblies and longitudinal partition plates. The upper cylindrical area and the lower cylindrical area of each spiral baffle plate assembly are each composed of a flat plate round-notch-shaped baffle plate and an arc end strip-shaped baffle plate. Each arc end strip-shaped baffle plate is composed of an inclined section, a left bent flat section and a right bent flat section. Every two corresponding baffle plates are provided with an overlapped area of a row of pipes. The structural limitation that ordinary spiral baffle plates can hardly be arranged in semi-cylindrical spaces and numerous defects of arch baffle plate heat exchangers can be overcome, the purpose of arranging spiral baffle plate passageways in a semi-cylindrical space to obtain the reverse flow type U-shaped pipe bundle heat exchanger is achieved, and the reverse flow type spiral baffle plate U-shaped pipe bundle heat exchanger has the advantages of being high in heat conduction coefficient, low in flowing resistance, and the like.

Owner:SOUTHEAST UNIV

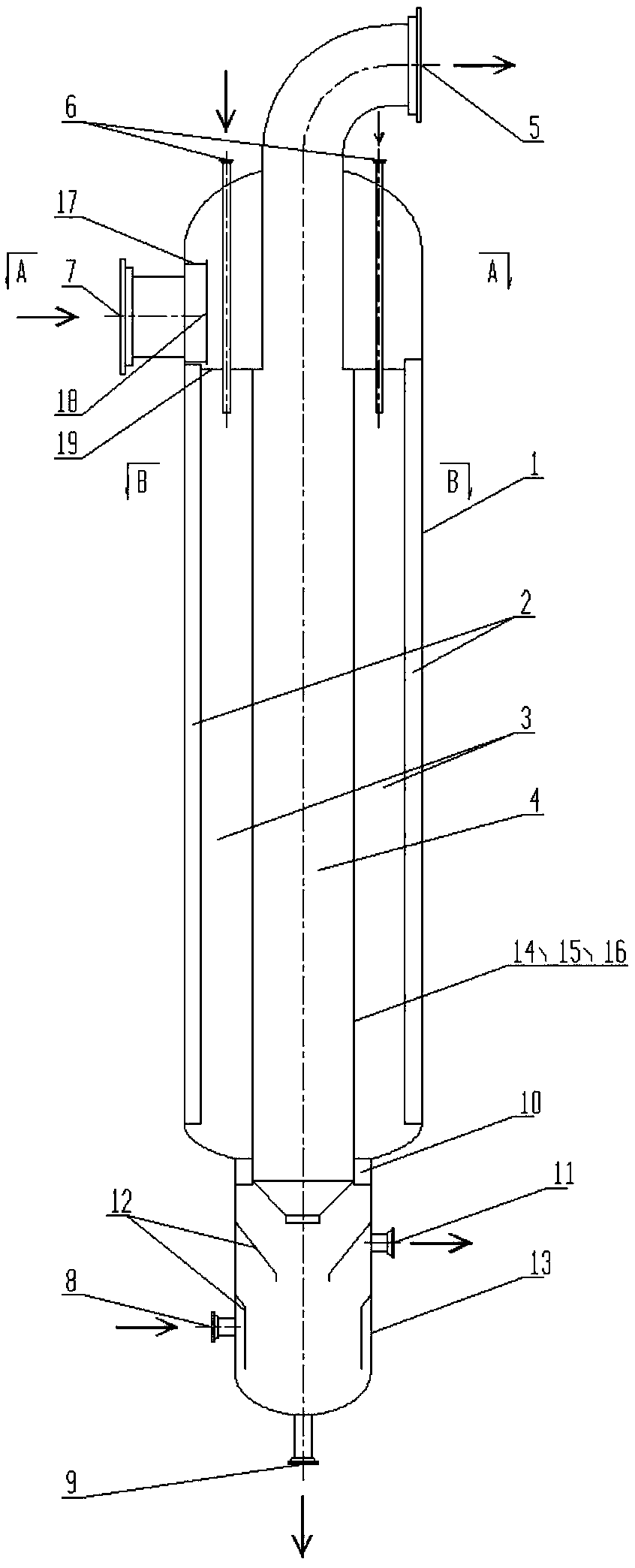

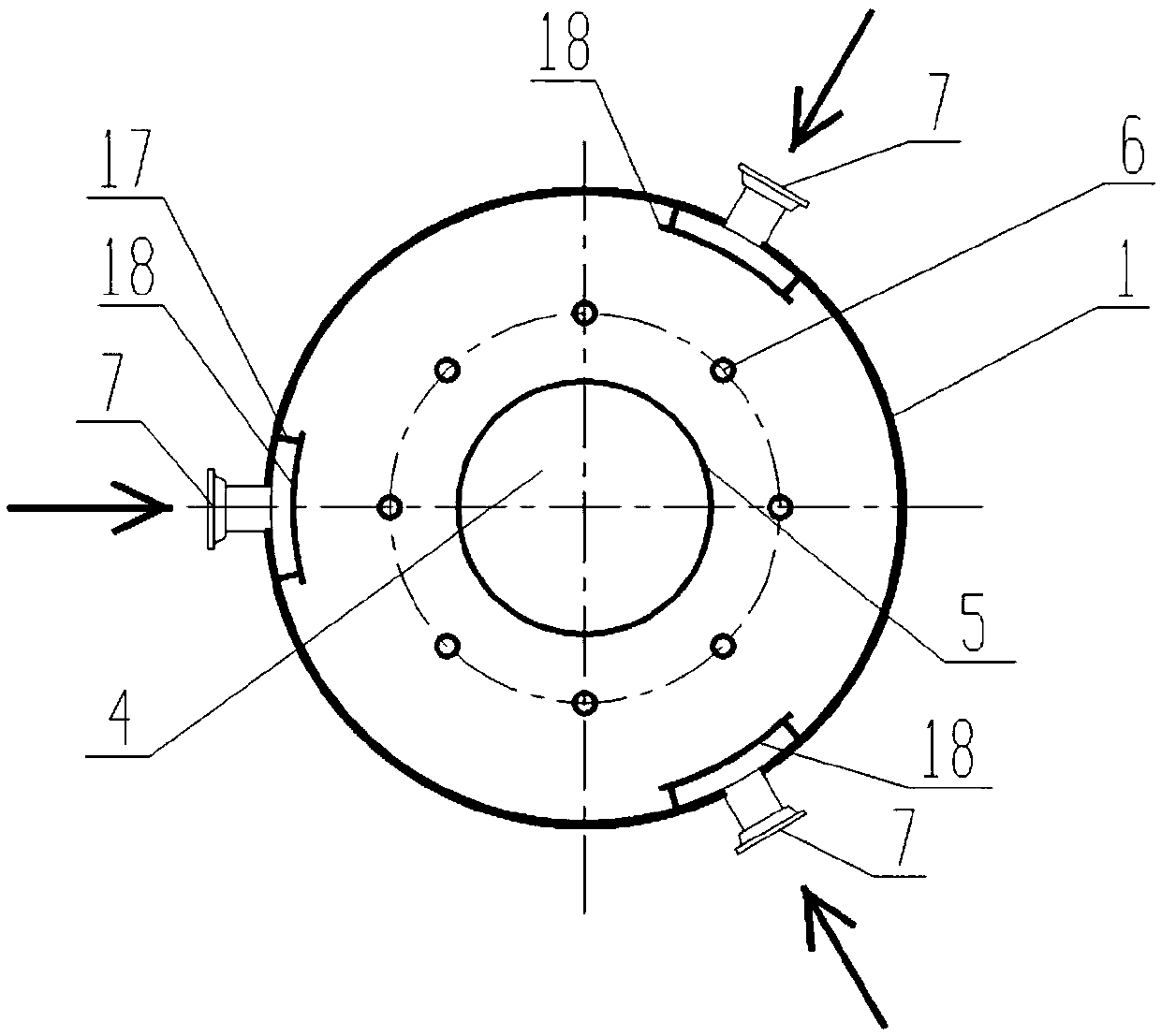

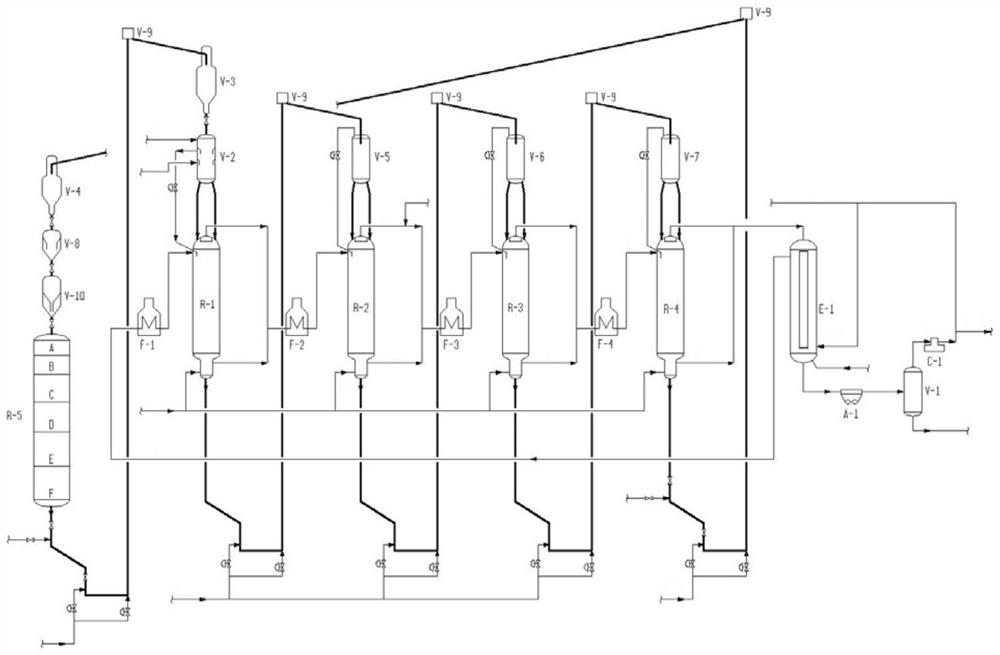

Reforming reactor and application thereof

ActiveCN109603690ASmall sizeFacilitate the dehydrocyclization reactionChemical/physical processesLine tubingHydrogen

The invention relates to a reforming reactor and application thereof. Mixed hydrogen is subjected to subsection, lifted hydrogen and stripped hydrogen are respectively introduced in different reactors, the molar ratio of H2 to HC in the reforming reactor is reasonably adjusted, and therefore compared with the prior art, the yield of aromatic hydrocarbon and hydrogen is greatly increased. Comparedwith the prior art, the reforming reactor adopts a radial reactor structure with an inlet formed in the side and an outlet formed in the top, the height of the reactor can be effectively reduced, theproblem that the larger top space of the reactor is wasted is solved, and a center cylinder and a fanshaped cylinder can be conveniently maintained; a catalyst collecting hopper is arranged at the bottom of the reforming reactor, hydrogen is adopted for steam stripping, through steam stripping, hydrocarbon components carried by a catalyst can be obtained, the rising temperature of the catalyst isalso reduced, and the reforming reactor is beneficial for safe operation, subsequent equipment and material selection for pipelines.

Owner:SHANGHAI HOTO PETROCHEM ENG

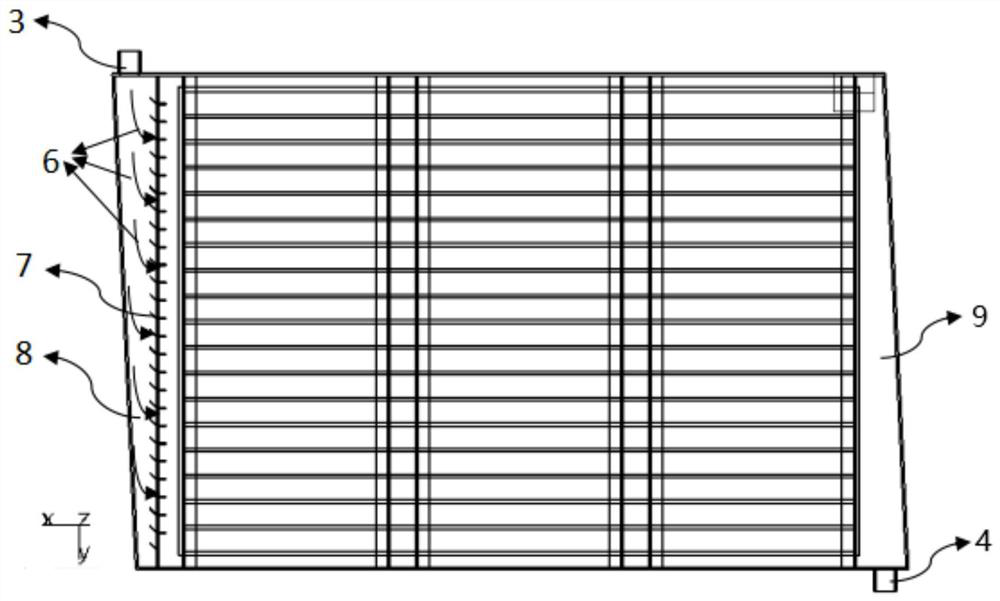

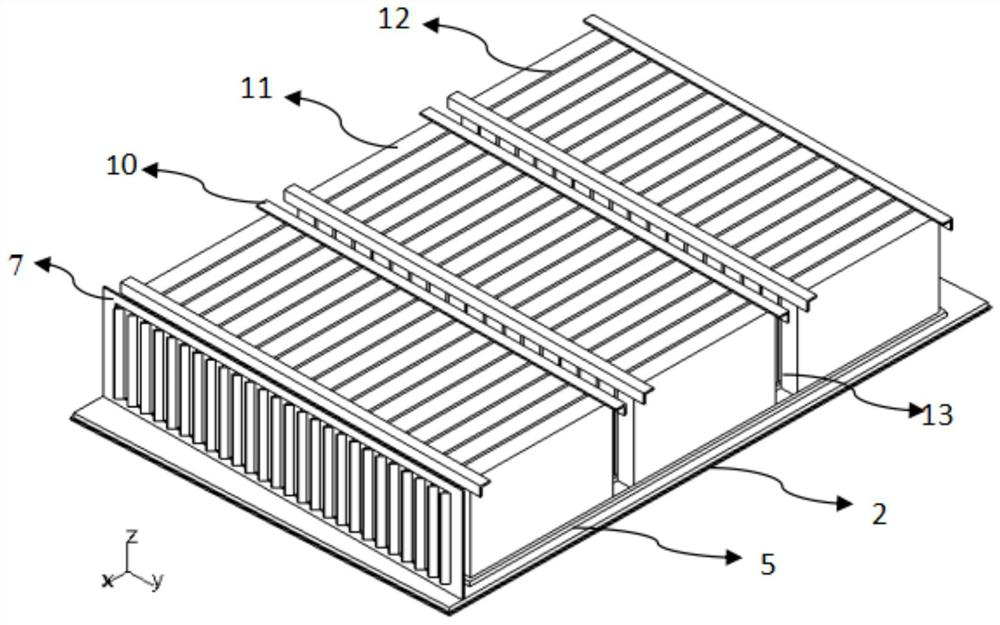

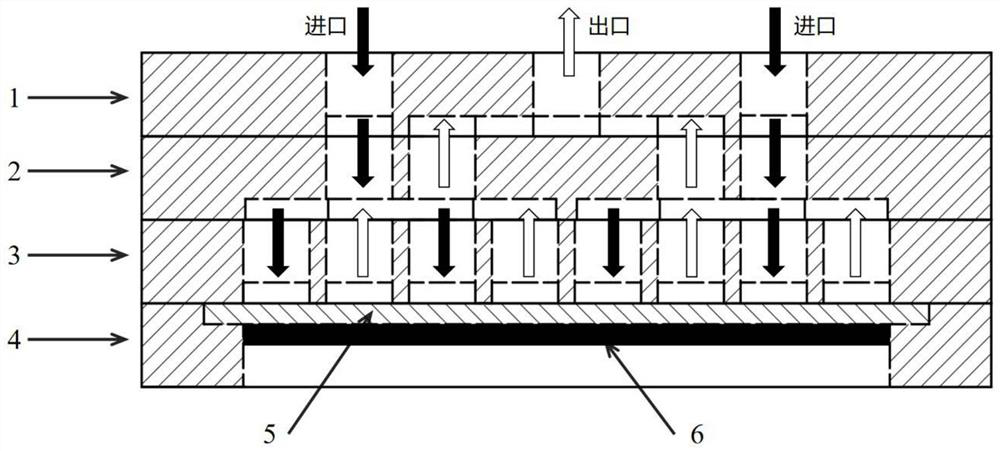

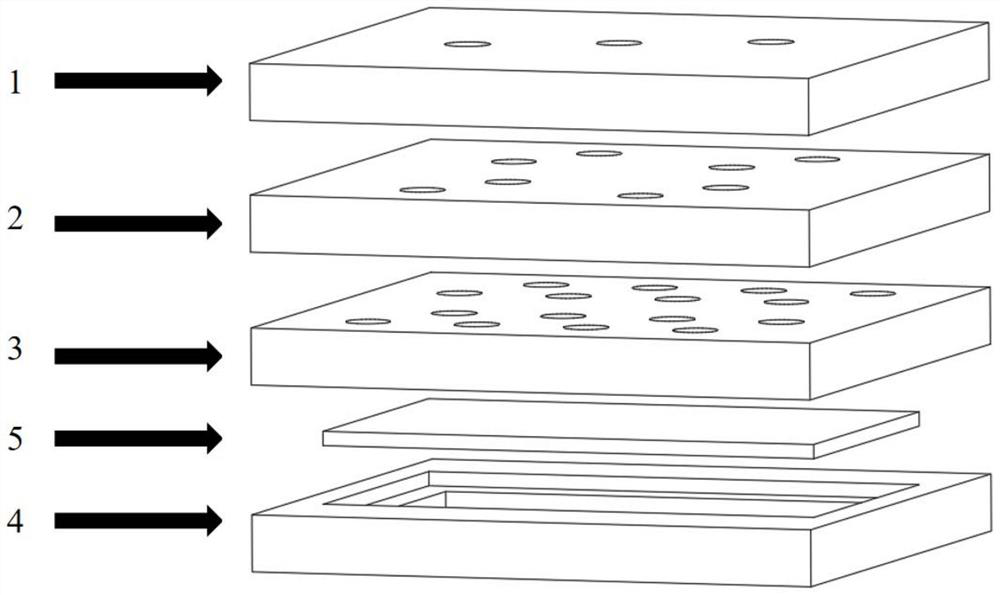

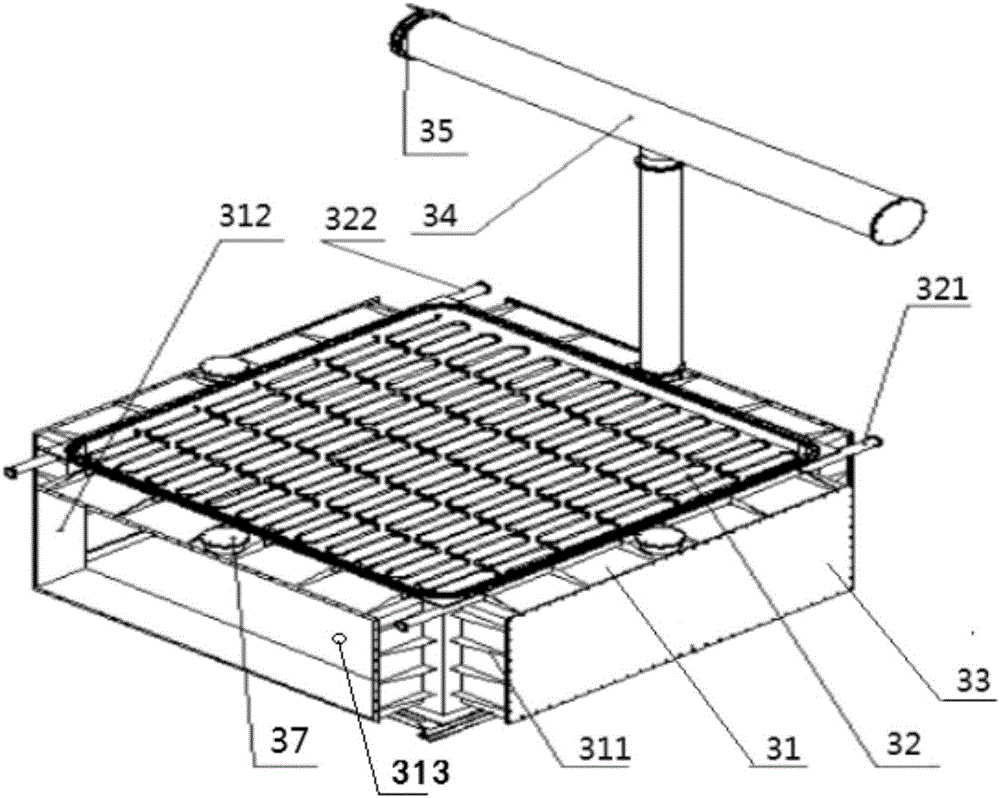

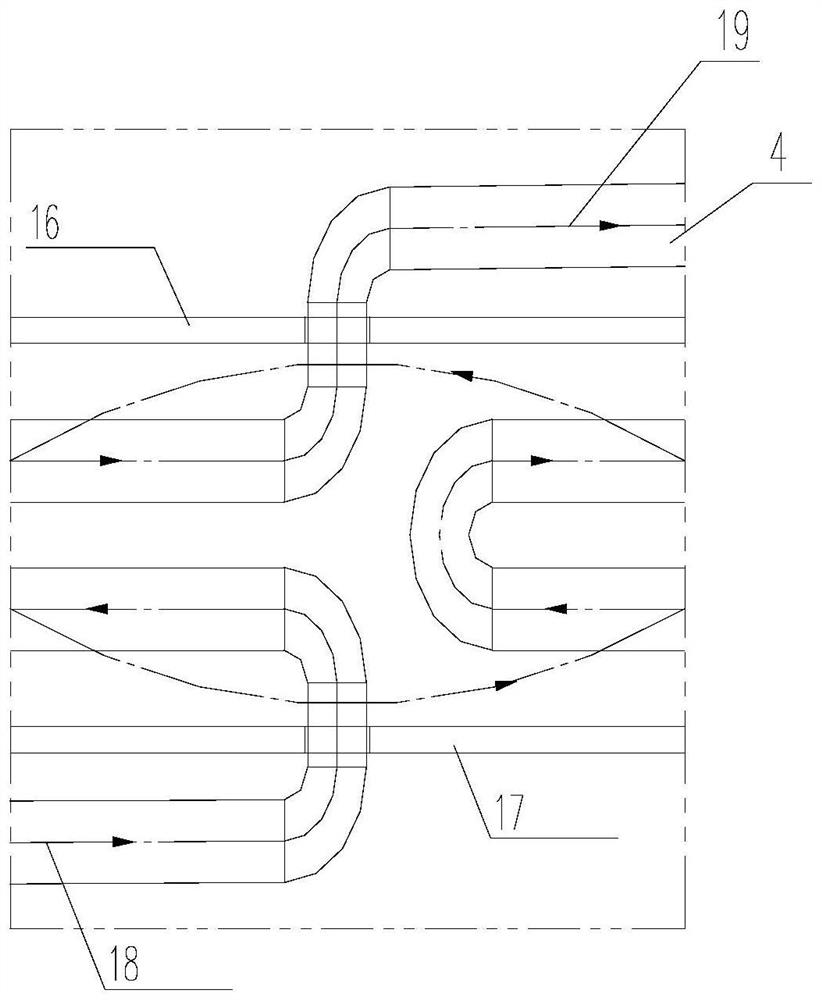

Hierarchical manifold micro-channel heat dissipation device

PendingCN114141733AAvoid Flow Dead ZonesAvoid the problem of premature dry burningSemiconductor/solid-state device detailsSolid-state devicesHeat fluxThermodynamics

The invention discloses a graded manifold micro-channel heat dissipation device. The graded manifold micro-channel heat dissipation device mainly comprises a first-stage micro-channel, a second-stage micro-channel, a third-stage micro-channel and a bottom plate part. The four layers of channels are packaged through the bonding technology, working medium inlets and working medium outlets are located in the top, and the number of the micro-channels and the number of the manifold channels can be increased according to the heat exchange area. A heat exchange working medium flows into the third-stage micro-channel through the first-stage micro-channel and the second-stage micro-channel, is split into the last eight inlets from the first two inlets and flows to the surface of the analog chip, and the temperature distribution uniformity of the surface of the analog chip is improved through uniform distribution of the working medium. And the working medium after heat exchange is converged into the first-stage micro-channels through the third-stage micro-channels and the second-stage micro-channels, and finally is converged to an outlet in the middle through the two first-stage micro-channels to flow out. The flow channel is segmented into a plurality of micro-channel units, the flow length is shortened, so that the pressure drop is reduced, a thermal boundary layer is difficult to develop in the micro-channel, and the heat exchange coefficient is increased and the total thermal resistance is reduced. The device has the advantages of being small in occupied area, low in power consumption and high in heat dissipation capacity, and can be used for meeting the heat dissipation requirement exceeding the heat flux density.

Owner:XI AN JIAOTONG UNIV

Mixer for U-shaped tail gas after-treatment device and U-shaped tail gas after-treatment device

PendingCN113446092AExtended heating pathGood for atomization and crushingSilencing apparatusMachines/enginesEngineeringMechanical engineering

The invention provides a mixer for a U-shaped tail gas after-treatment device and the U-shaped tail gas after-treatment device comprising the mixer. The heating path of air flow to urea is prolonged, the heat utilization efficiency of tail gas is improved, the urea fully absorbs heat and exerts the heat, the risk of urea crystallization is effectively reduced, the mixer comprises a mixer shell, the mixer shell comprises a gas inlet connected to a DPF unit and a gas outlet connected to an SCR unit, a mixing cavity is formed in the mixer shell, the mixer is characterized in that a flow guide plate is arranged at the position, close to the gas inlet, in the mixer shell, a gas mixing channel is formed in the mixing cavity, a urea nozzle is arranged on the gas mixing channel, and gas entering from the gas inlet is guided by the flow guide plate to enter the gas mixing channel, and is discharged from the gas outlet after flowing through the gas mixing channel.

Owner:无锡恒和环保科技有限公司

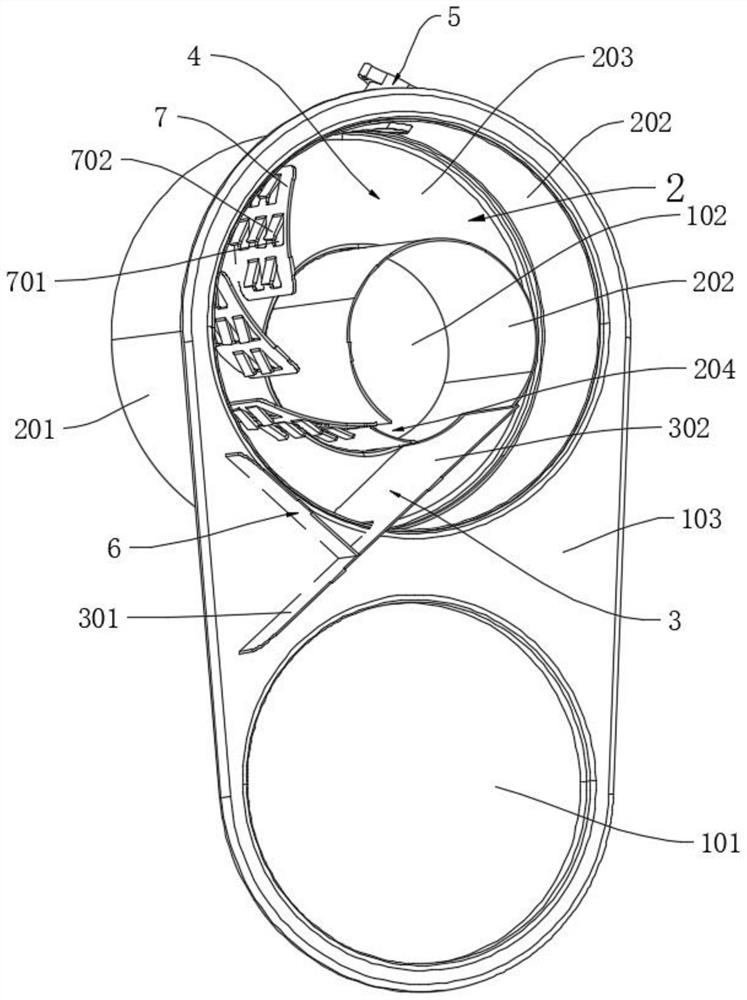

Scraper type anti-blocking discharging bin

InactiveCN102502127AReduce the chance of cloggingAvoid Flow Dead ZonesLarge containersAutomatic controlMotor drive

The invention discloses a scraper type anti-blocking discharging bin which is mainly characterized by being provided with a discharging bin body, wherein the discharging bin body is divided into an upper part, a middle part and a lower part; the upper part is a fixed bin segment, and an upper opening of the upper part is connected with a silo; the middle part is a rotating body and is an easily-plugging part of the discharging bin; the lower part is also a fixed bin segment, and a lower opening of the lower part is connected with a feeder inlet spile; the periphery of the rotating body is fixedly provided with gears, a motor drives the rotating body to do rotary motion through a speed reducer and the gears at the periphery of the rotating body, and the inner wall of the rotating body is fixedly provided with scrapers arranged from top to bottom along the wall of the discharging bin; the upper parts of the scrapers cling to the inner wall of the fixed bin segment at the upper part of the discharging bin, and the lower parts of the scrapers cling to the inner wall of the fixed bin segment at the lower part of the discharging bin. Due to the adoption of the technical scheme, compared with the prior art, the scraper type anti-blocking discharging bin has the advantages of simple structure, convenience in installation, automation in control, reliability in running, low maintenance and easiness in popularization.

Owner:姚汉东

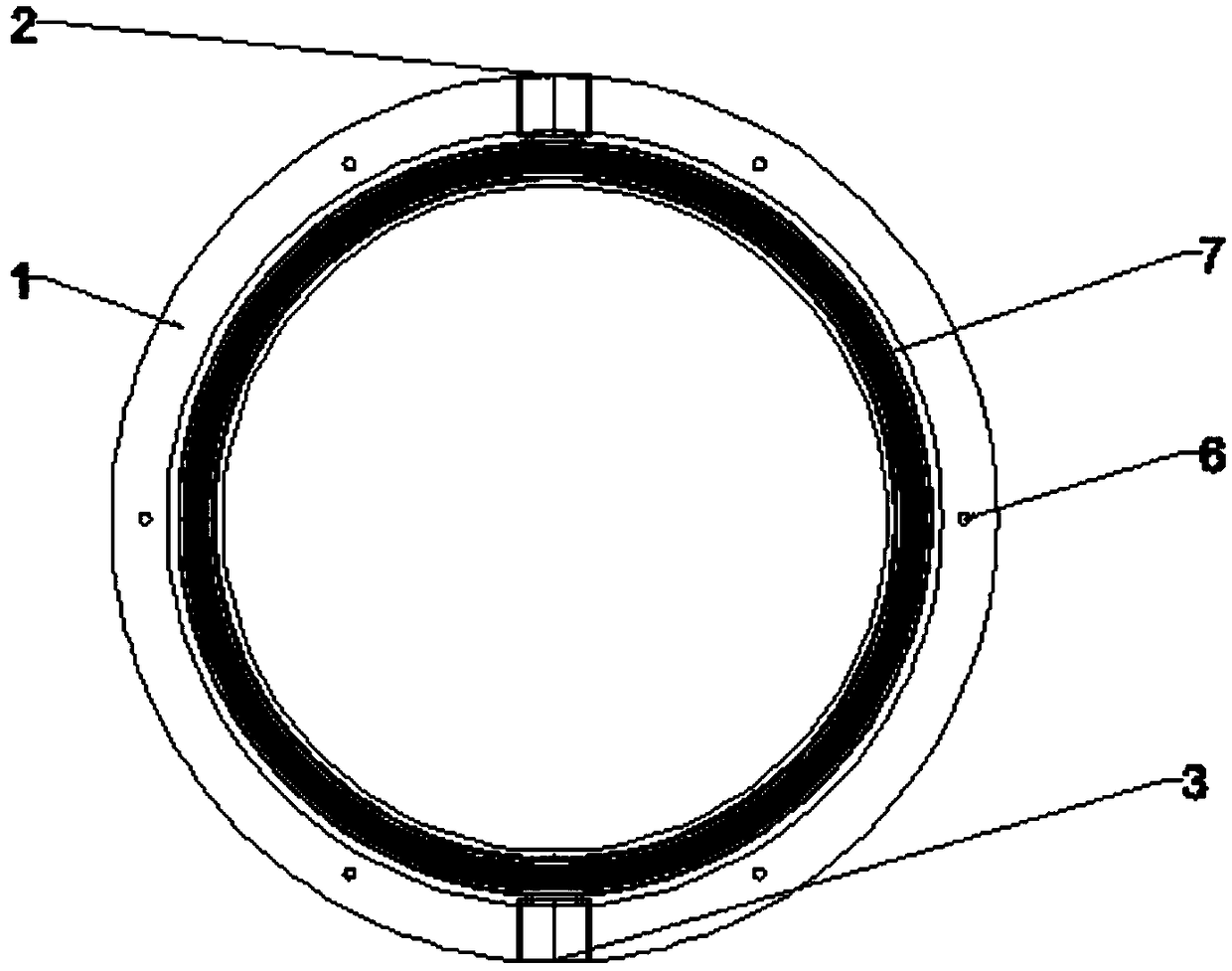

Baffle plate and shell-and-tube heat exchanger

InactiveCN109341379AAvoid Flow Dead ZonesSmall pressure dropHeat exchanger casingsStationary tubular conduit assembliesDead bandMetallic materials

The invention provides a baffle plate and a shell-and-tube heat exchanger. The baffle plate comprises a body provided with a pipe hole and is installed in a cylindrical shell of the heat exchanger. One side of the edge face of the body is an installing face. The installing face is attached to the inner wall of the shell. The other side of the edge face of the body is a circulation notch face. Thecirculation notch face and the inner wall of the shell form a circulation notch in a surrounding mode, and a medium passes through the circulation notch. The body is made of foam metal material. The turbulence degree of flowing can be improved effectively, the influence caused by a common baffle plate on flowing form change is lowered, then the flowing dead zone of a traditional shell-and-tube heat exchanger is avoided effectively, and the effects that heat exchange efficiency of the heat exchanger is promoted effectively and pressure drop is lowered are achieved.

Owner:TIANJIN UNIV

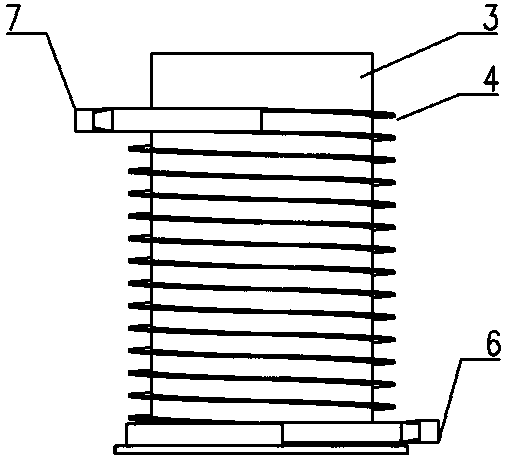

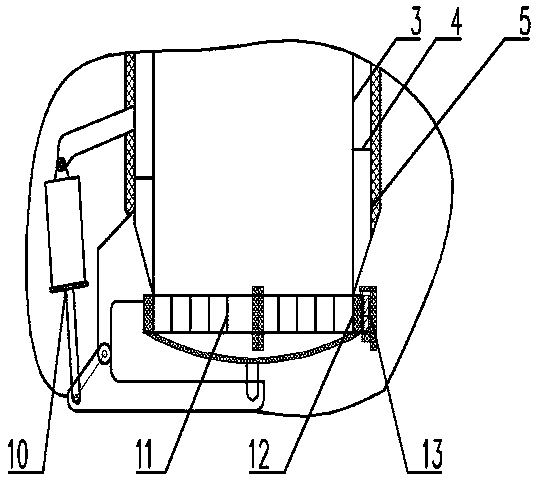

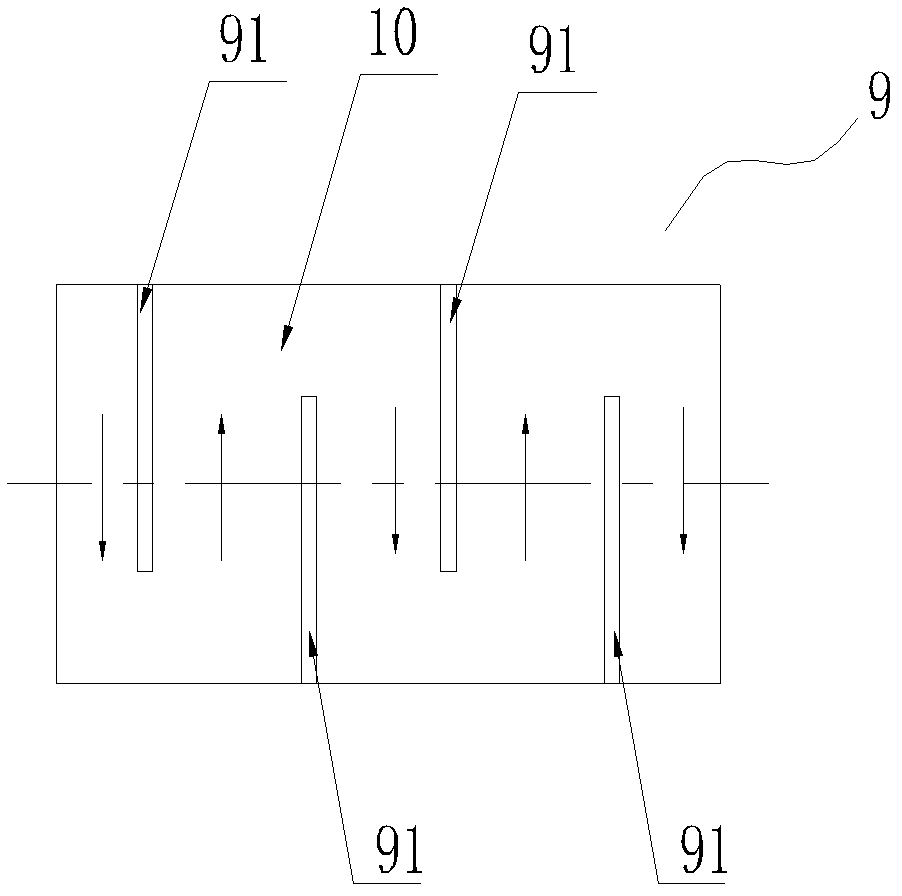

Spiral turbulent-flow blade based emitting device barrel cooling water jacket

The invention provides a spiral turbulent-flow blade based emitting device barrel cooling water jacket. The spiral turbulent-flow blade based emitting device barrel cooling water jacket comprises a water jacket body, a water inlet and a water outlet, wherein the water jacket body is barrel-shaped, and sleeves a emitting device barrel; the water inlet and the water outlet are separately positionedin upper and lower wall surfaces of the two ends of the water jacket body; and the inner wall of the water jacket body is equipped with a spiral water conveying blade in the peripheral direction fromthe front end to the rear. The spiral turbulent-flow blade based emitting device barrel cooling water jacket can perform efficient cooling on the barrel in a continuous shooting process of the emitting device.

Owner:NANJING UNIV OF SCI & TECH

Exhaust mixing device and engine

ActiveCN110905644ALarge expansion ratioImprove distribution uniformityExhaust apparatusSilencing apparatusNitrogen oxidesEngineering

The invention discloses an exhaust mixing device and an engine. The exhaust gas mixing device comprises a turbulent flow mixer and a rectifying device, wherein the turbulent flow mixer is arranged inthe exhaust pipe and located on an upstream of an NOx sensor, the rectifying device is arranged in the exhaust pipe and located below the NOx sensor, and the rectifying device is used for lifting exhaust gas flow in the direction where the NOx sensor is located. The exhaust mixing device is advantaged in that the turbulent flow mixer and the rectifying device are matched for use, so distribution uniformity of nitric oxide in the exhaust gas can be improved, a gas flowing dead zone is avoided, the NOx sensor can accurately monitor the flowing gas, a concentration level of average nitric oxide of the gas in the whole exhaust pipe is obtained, meanwhile, the rectifying device enables a narrow-diameter structure to be formed in the exhaust pipe, the exhaust pipe can have a large expansion ratio, and the silencing capacity for low-frequency noise is improved.

Owner:WEICHAI POWER CO LTD +1

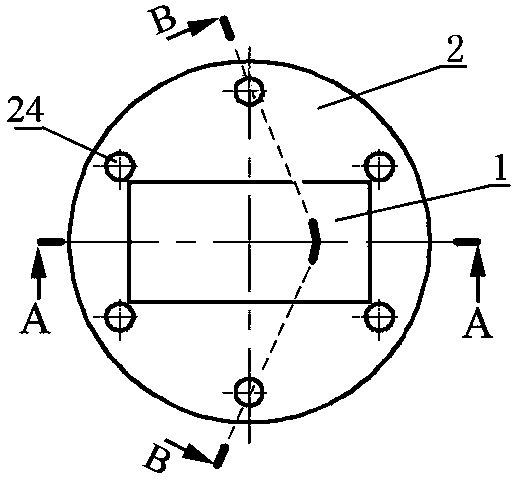

Mold for extrusion formation of equal-thickness in-plane bent plate

ActiveCN109382417AEliminates the disadvantage of reboundEliminates the disadvantage of easy wrinklingExtrusion diesIn planeEngineering

The utility model relates to a mold for extrusion formation of an equal-thickness in-plane bent plate. The mold is connected and mounted with an extruder, and comprises an extrusion barrel liner, an adjustment mold and a forming mold which are connected in sequence, wherein an inner cavity arranged in a running-through manner along the extrusion direction of an extrusion rod is arranged in the mold; the inner cavity comprises a rectangular cavity located in the extrusion barrel liner and used for enabling the extrusion rod to push a blank, a forming hole located in the forming mold and used for extruding the blank, pushed by the extrusion rod from the inner cavity of the mold, into a flat plate, and a specially-shaped cavity located in the adjustment mold and used for cooperating the extrusion action of the extrusion rod to change and adjust the shape of the blank to enable the blank extruded out from the forming hole to become the required equal-thickness in-plane bent plate. The moldcan extrude equal-thickness in-plane bent plates with different curvatures; furthermore, the thickness size of the in-plane bent plate can be guaranteed; no phenomena of thinning of an outer ring, easy wrinkling of an inner ring and the like occur; in addition, the equal-thickness in-plane bent plate has no counter-acting force opposite to a bending direction of the equal-thickness in-plane bentplate, so that springback opposite to the bending direction cannot occur.

Owner:河南合力盛达铝业科技发展有限公司

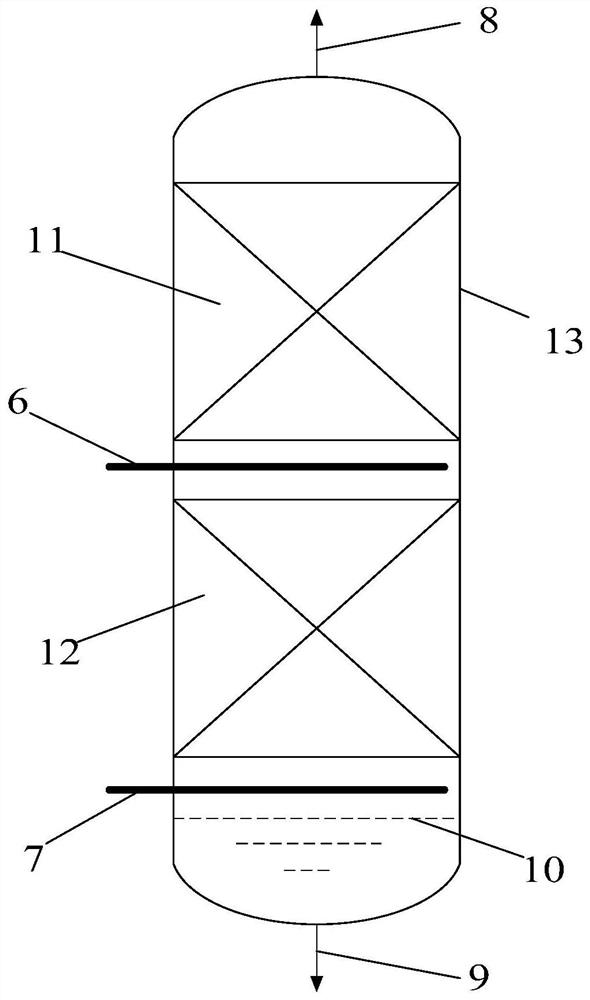

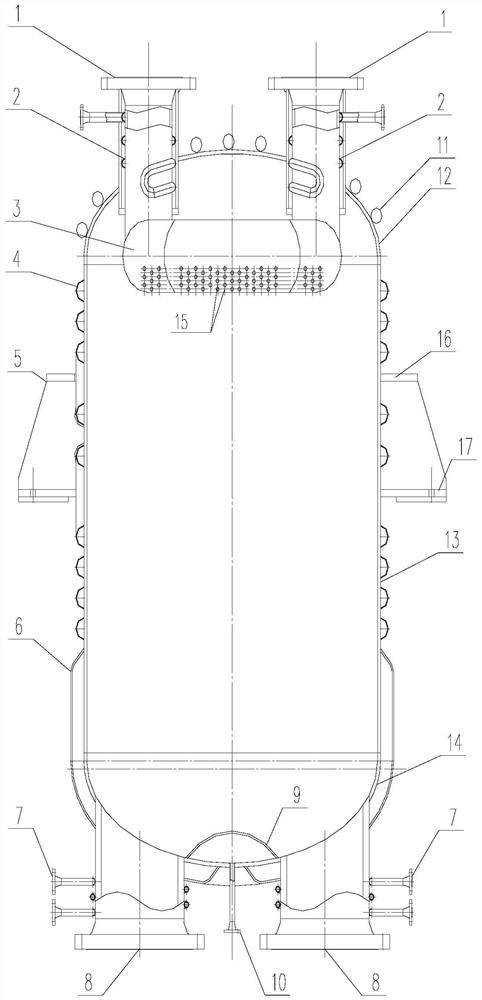

Packed extraction tower, application thereof and residual oil solvent deasphalting method

PendingCN112370814ASimple structureEasy to installLiquid solutions solvent extractionHydrocarbon oils refining control/regulationPhysical chemistrySolvent

The invention relates to a packed extraction tower, application thereof and a residual oil solvent deasphalting method. The packed extraction tower is composed of a shell, a raw material inlet locatedat the middle part of the shell, an extraction solvent inlet located at the lower part of the shell, a tower top extraction phase outlet, a tower bottom raffinate phase outlet and extraction structured packing; the extraction structured packing fills the shell of the extraction tower; and the extraction structured packing is grid type packing. The packed extraction tower provided by the inventionis suitable for a heavy oil solvent deasphalting process, and is high in separation efficiency and large in treatment capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

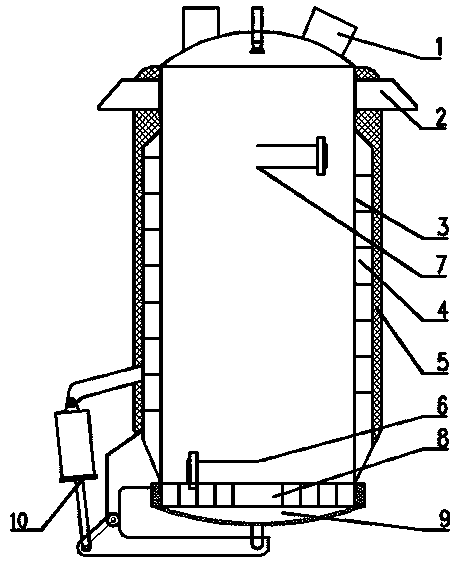

Smoke heating traditional Chinese medicine extraction tank

PendingCN110523104AAvoid Flow Dead ZonesFull flowChemical/physical/physico-chemical processesSolid solvent extractionLinkage conceptChinese herbology

The invention discloses a smoke heating traditional Chinese medicine extraction tank. The smoke heating traditional Chinese medicine extraction tank comprises a feeding opening, a liquid inlet, a washing opening, support feet and a tank body. The tank body is provided with a heat preservation layer for heat insulation; one side of the tank body is provided with an air cylinder linkage device for controlling bottom residue discharging; the air cylinder linkage device is hinged to the bottom of a sealing cover; the bottom of the tank body is provided with a residue outlet; an air cylinder drivesan opening shaft to enable a residue outlet door of the residue outlet to be open or close and to lock the door; a smoke inlet is formed in one side of the tank body; a smoke outlet is formed in theother side of the tank body; a spiral piece channel for smoke flowing is formed between the inner wall and the outer wall of the tank body; smoke flows in along the tangential direction of a cylinderwall; the lower end of a spiral piece enters the interlayer along the tangential direction of the inlet and the cylinder wall; the bottom is provided with a disc for heating; spiral sheets are arranged in the disc; the spiral sheets are arranged in a mode of combining clockwise flowing-in and anticlockwise flowing-out; the spiral sheets are inserted into the disc in an intersecting mode; the discis placed in a sealing cover structure connected with an upper-layer cylinder body; and the lower disc is connected with the tank body through a pneumatic locking structure.

Owner:HEBEI UNIV OF TECH

Combined type tuyere small sleeve

The invention discloses a combined type tuyere small sleeve which comprises a central sleeve, an internal sleeve, a first sleeve, a second sleeve and a third sleeve, wherein the central sleeve is fixedly socketed with the internal sleeve to form an oxy-coal medium channel; the gap between the first sleeve and the central sleeve forms a cooling water inflow channel, the gap between the second sleeve and the first sleeve forms a gas medium channel, the gap between the third sleeve and the second sleeve forms a cooling water backflow channel, a front cap and a rear cap which are in an integrated structure are fixedly connected with one ends far away from a water inflow port and a water backflow port of the cooling water inflow channel and the cooling water backflow channel, and the cooling water inflow channel and the cooling water backflow channel are communicated through the front cap and the rear cap, thus forming a cooling water circulating channel; and the front cap is provided with an oxy-coal medium outlet and a gas medium outlet. The invention has the advantages of simple structure, good cooling effect, high reliability and safety, and long service life.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

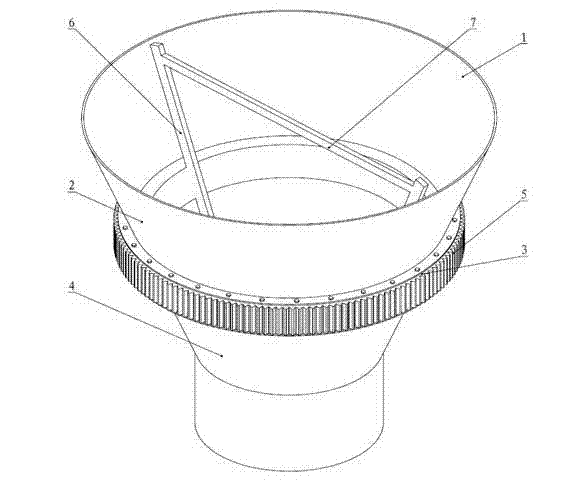

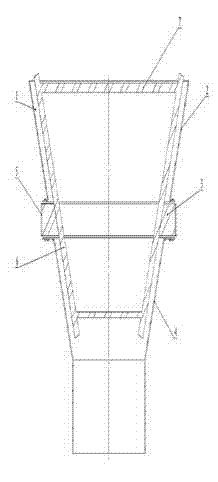

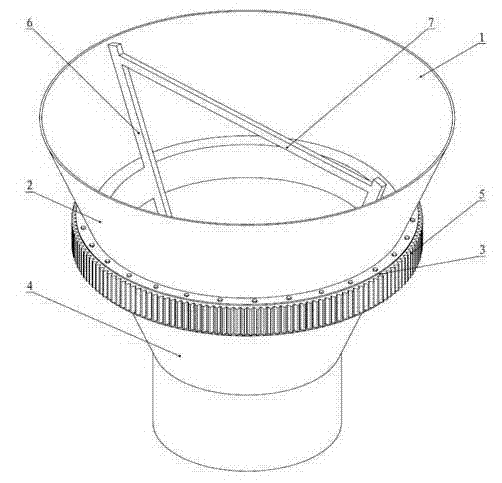

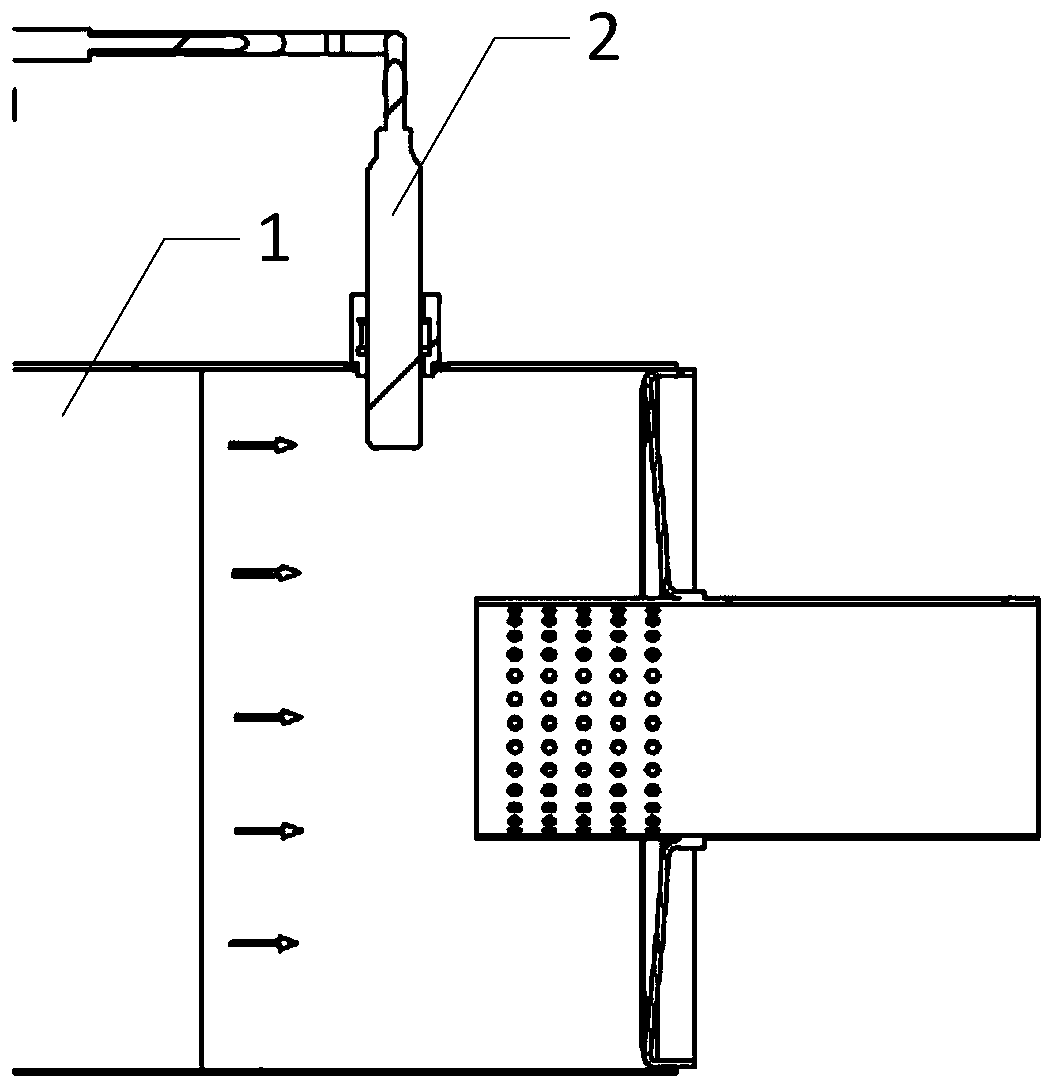

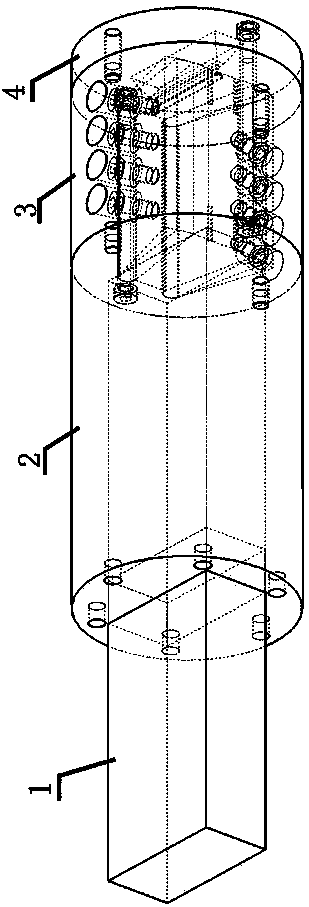

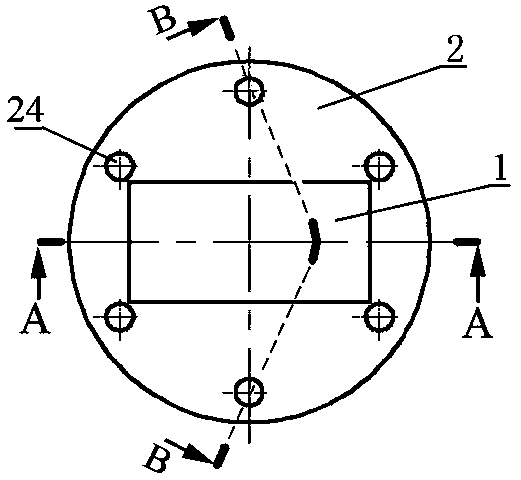

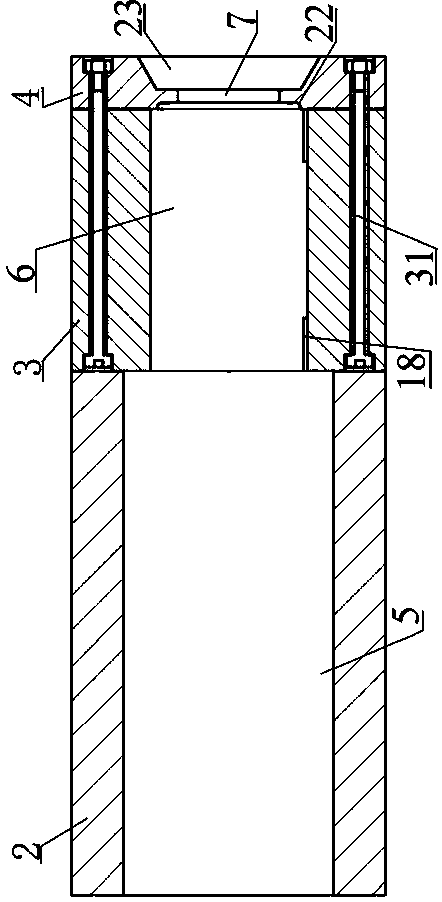

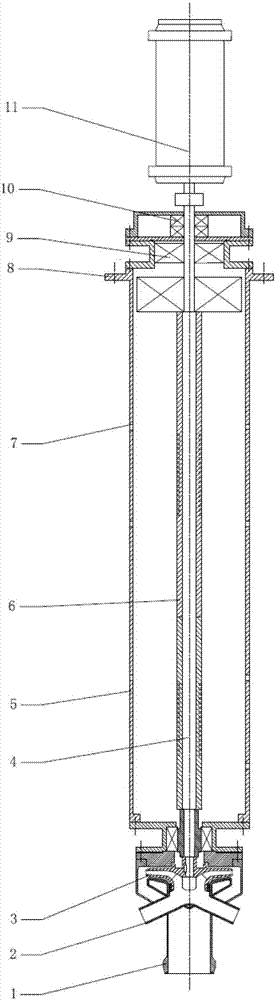

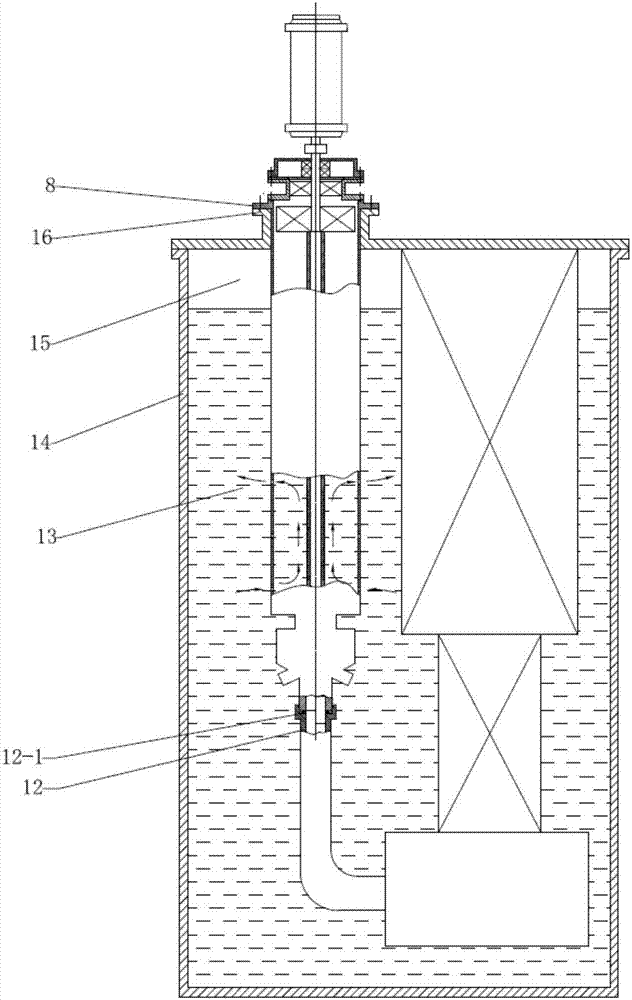

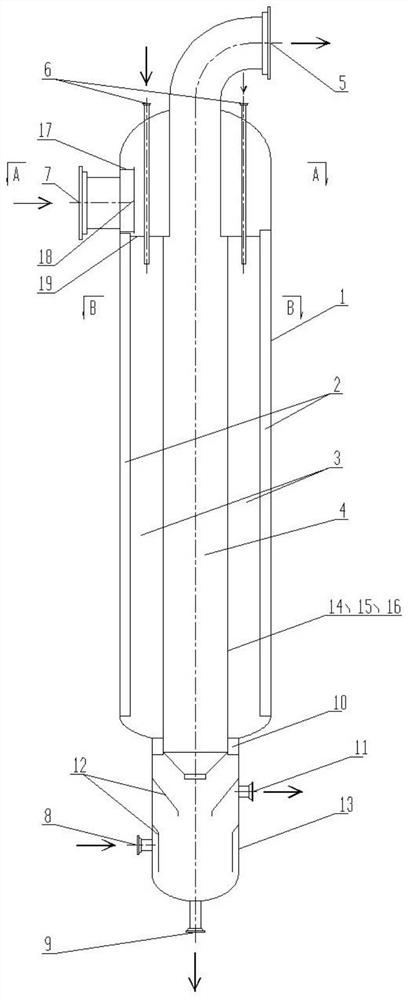

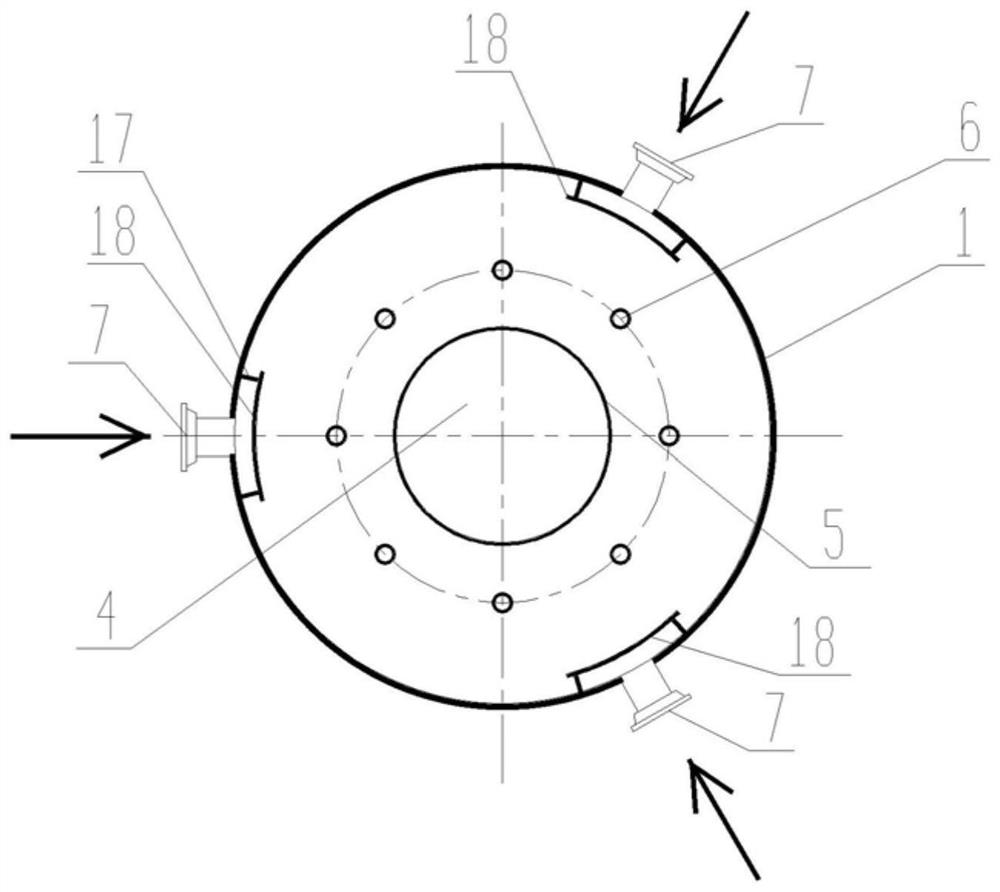

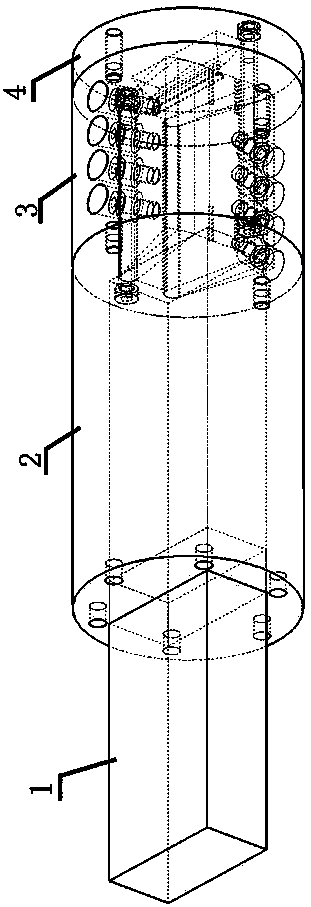

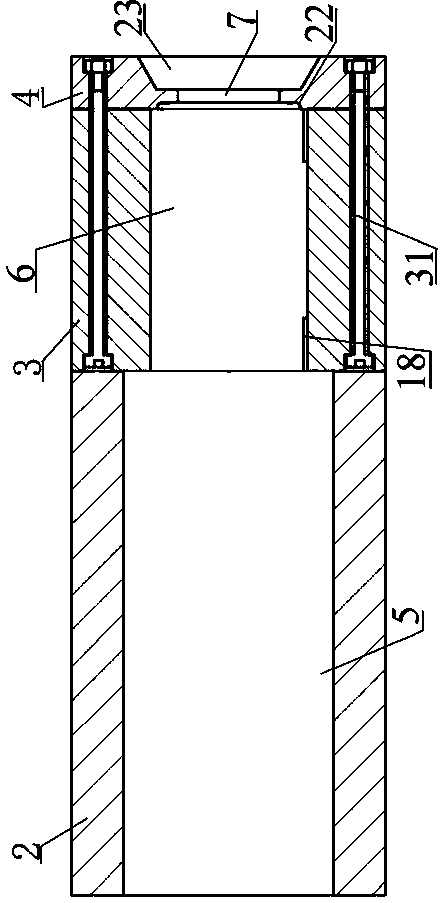

A vertical pump for a pool reactor

ActiveCN106593934BAvoid Flow Dead ZonesCompact structurePump componentsPumpsEngineeringCirculating pump

The invention discloses a vertical pump for a pool type reactor. The vertical pump for the pool type reactor comprises a pump shaft, a vertical pump shell, a hydraulic component, a power input component and a circulation component. The pump shaft is arranged in the vertical pump shell. The upper end of the pump shaft extends out of the vertical pump shell to be connected with the power input component. The lower end of the pump shaft extends out of the vertical pump shell to be connected with the hydraulic component. The circulation component is arranged on the portion, in liquid, of the pump shaft and used for generating upward or downward flowing power when the pump shaft rotates. The portion, corresponding to the circulation component, of the vertical pump shell is provided with two or more communicating holes. At least two of the communicating holes are located at different heights. The vertical pump is mainly applied to the pool type reactor and used as a main circulation pump for driving coolant, and the vertical pump for the pool type reactor can provide a enough pressure head; and besides, because the circulation component is installed on the pump shaft, the coolant in the pump shell can communicate with coolant in a reactor pool, and the coolant in the pump shell is protected against a flowing dead zone.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

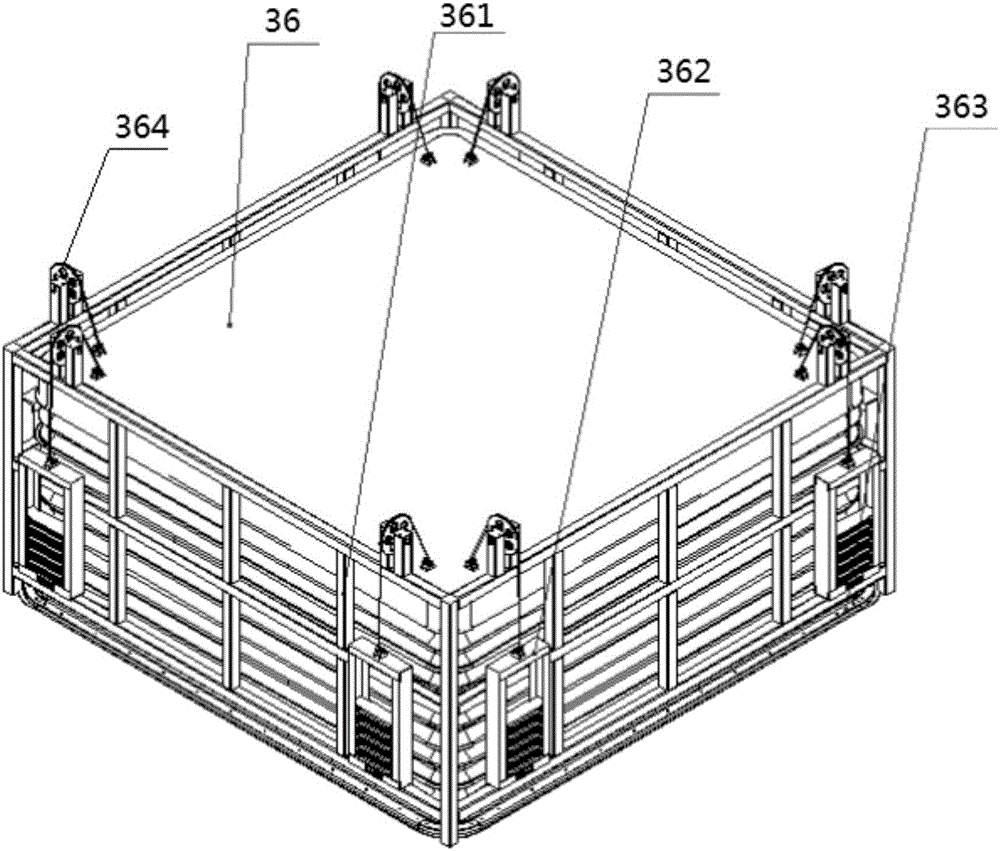

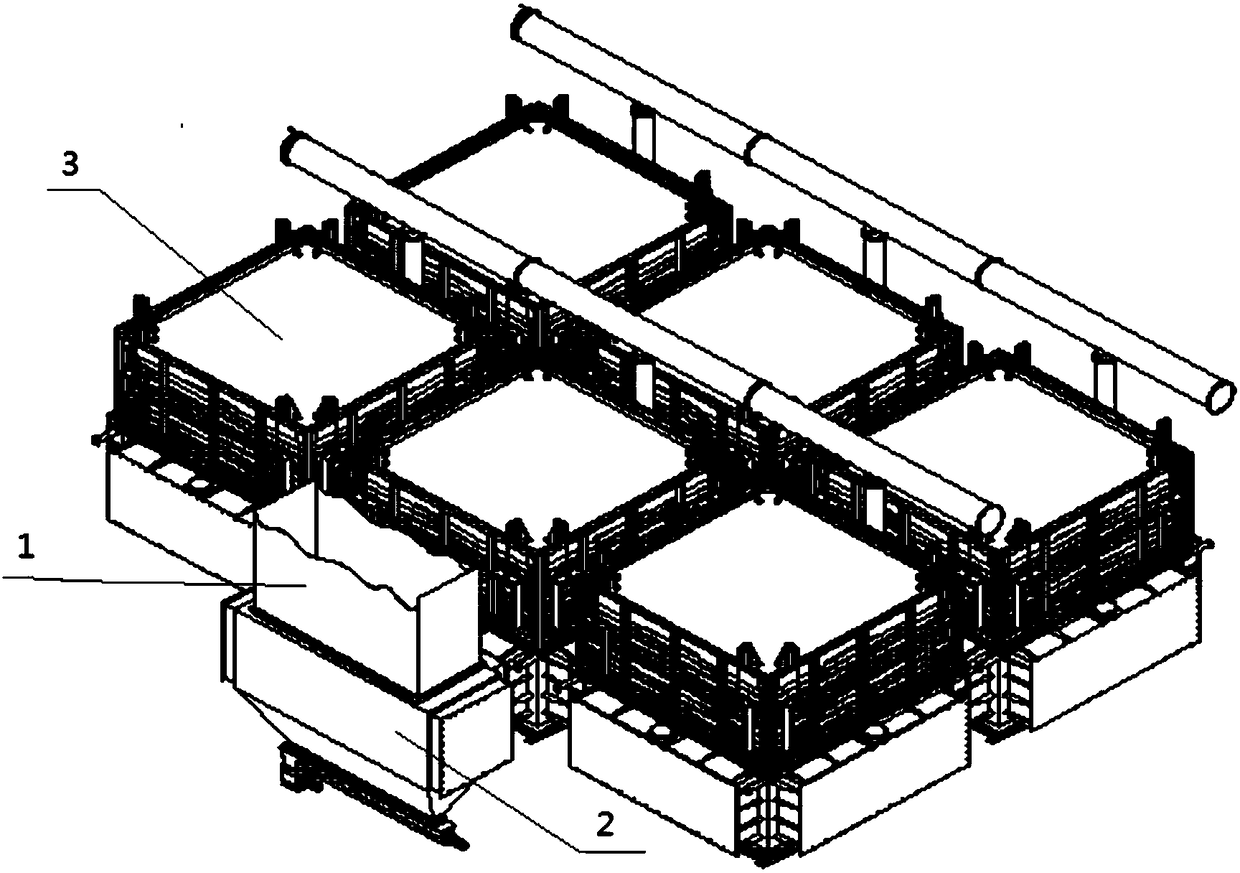

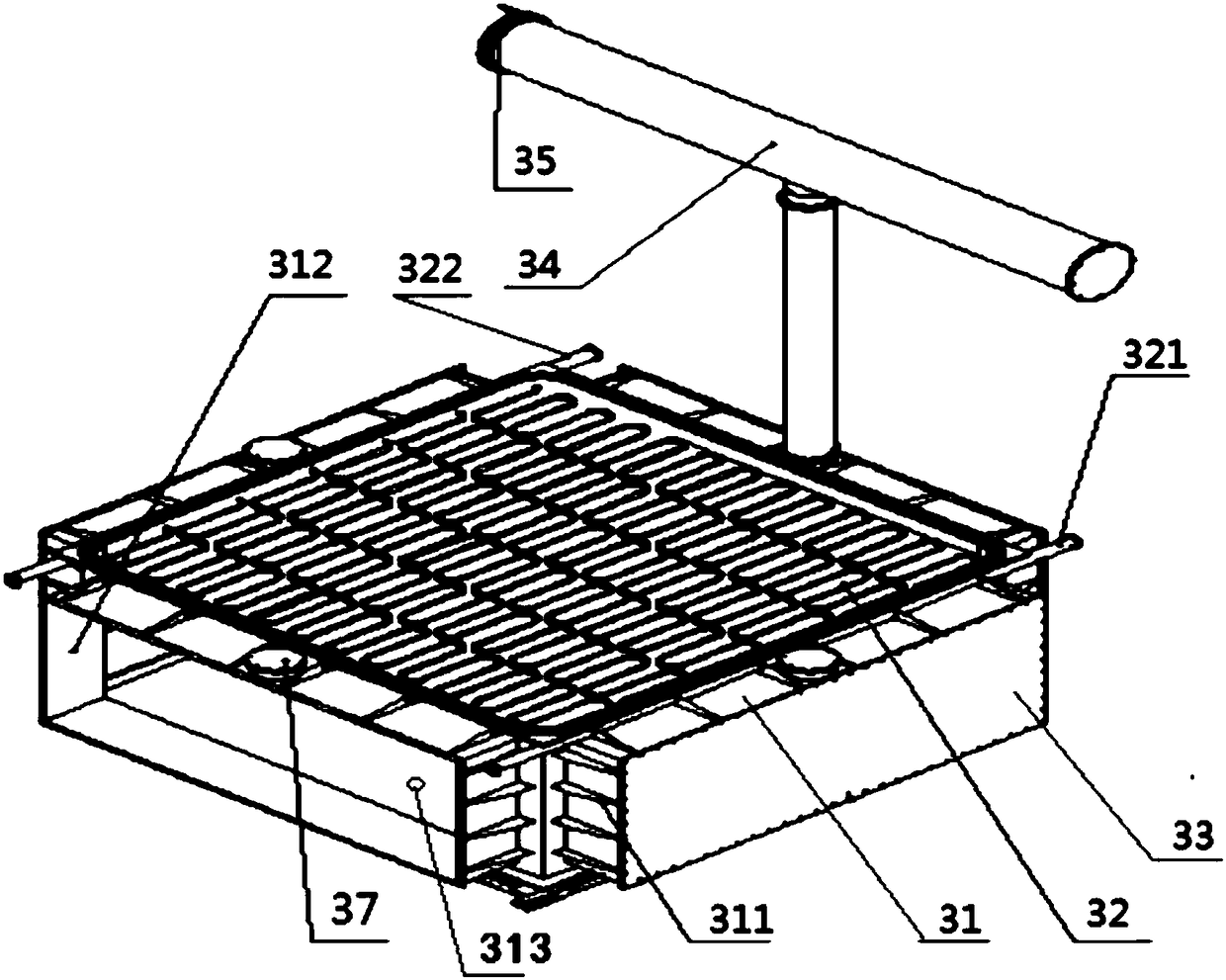

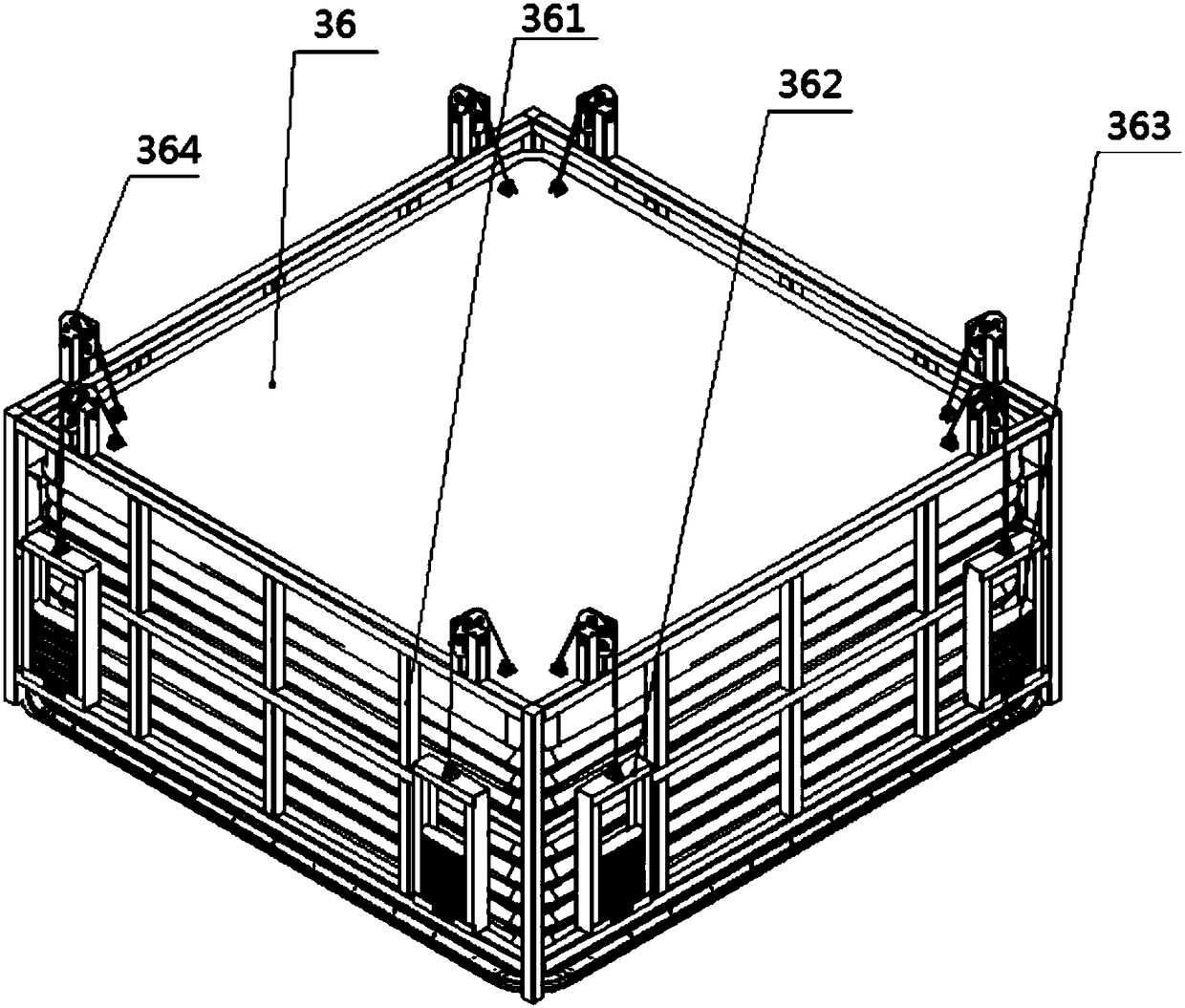

Collecting device for instantaneously-released high-temperature high-pressure high-humidity waste gas

ActiveCN106180112AIncrease profitImprove liquidityDispersed particle separationDirt cleaningGas collecting tubeHigh humidity

The invention provides a collecting device for instantaneously-released high-temperature high-pressure high-humidity waste gas, and belongs to the field of waste gas treatment. The collecting device comprises a gas collecting pipeline, an automatic separating unit and a plurality of buffer thermal exchange units; one end of the gas collecting pipeline communicates with the outer part, and the other end of the gas collecting pipeline is connected to an inlet of the automatic separating unit; one outlet of the automatic separating unit is connected to inlets of the buffer thermal exchange units; the plurality of the buffer thermal exchange units are arranged in a communication mode; and each buffer thermal exchange unit communicates with an external gas treatment device through a gas exhaust pipeline. The collecting device belongs to a modularized design, is simple in structure, and can be expanded according to practical needs, so that collection of different-displacement waste gas is realized.

Owner:关新华

High-temperature, high-pressure, and high-humidity exhaust gas collection device for instant release

ActiveCN106180112BIncrease profitImprove liquidityDispersed particle separationDirt cleaningGas collecting tubeHigh humidity

The invention provides a collecting device for instantaneously-released high-temperature high-pressure high-humidity waste gas, and belongs to the field of waste gas treatment. The collecting device comprises a gas collecting pipeline, an automatic separating unit and a plurality of buffer thermal exchange units; one end of the gas collecting pipeline communicates with the outer part, and the other end of the gas collecting pipeline is connected to an inlet of the automatic separating unit; one outlet of the automatic separating unit is connected to inlets of the buffer thermal exchange units; the plurality of the buffer thermal exchange units are arranged in a communication mode; and each buffer thermal exchange unit communicates with an external gas treatment device through a gas exhaust pipeline. The collecting device belongs to a modularized design, is simple in structure, and can be expanded according to practical needs, so that collection of different-displacement waste gas is realized.

Owner:关新华

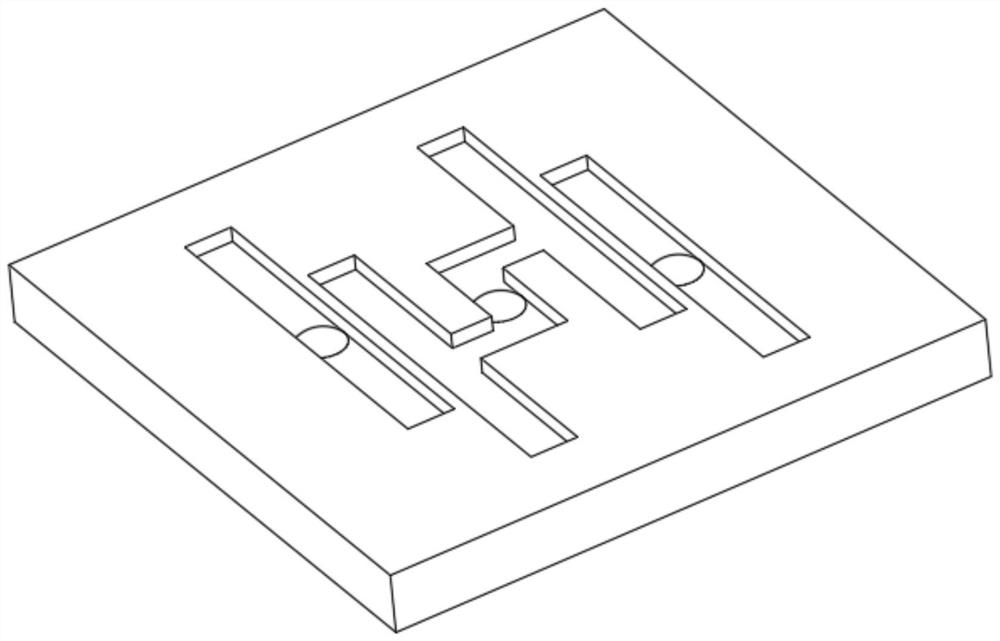

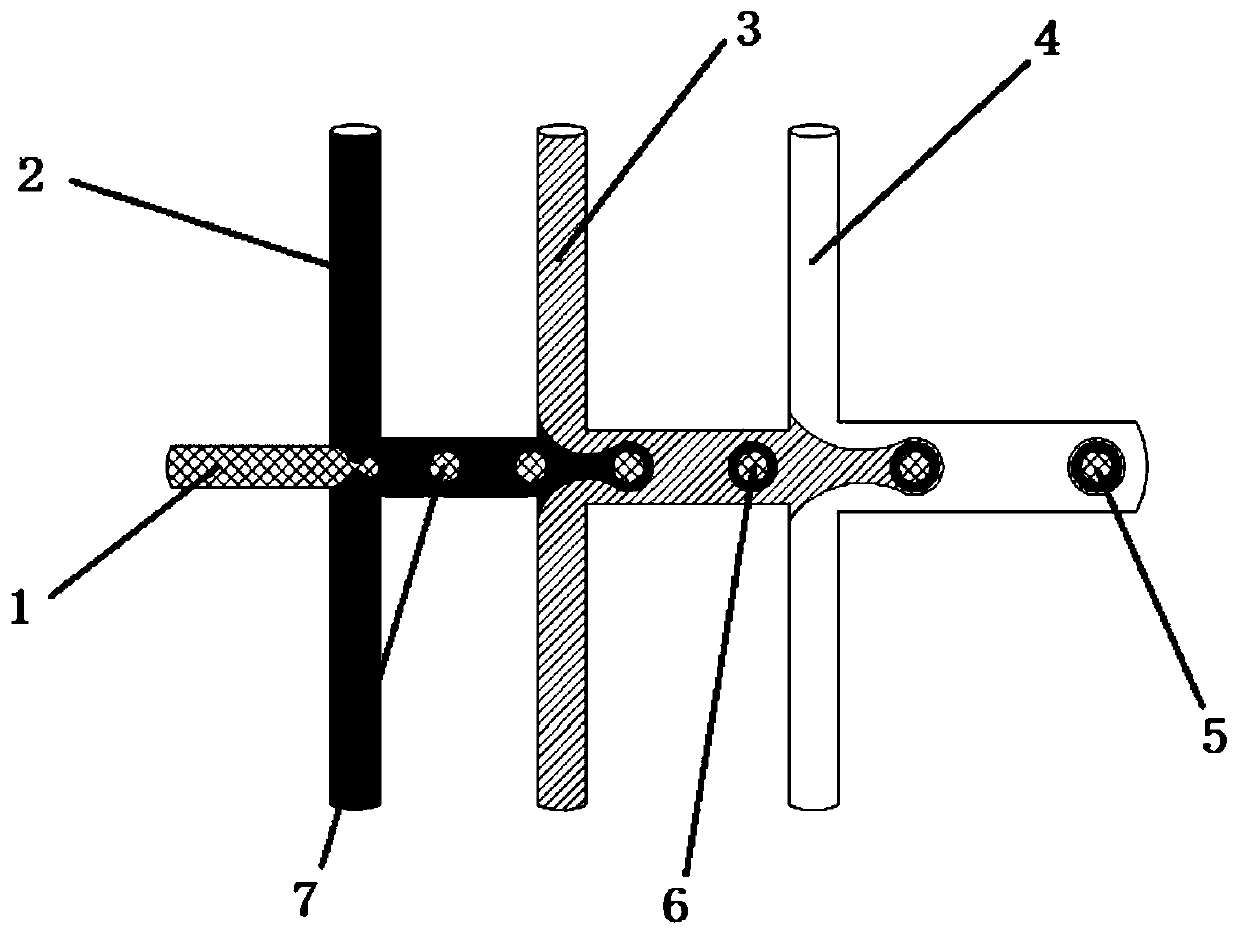

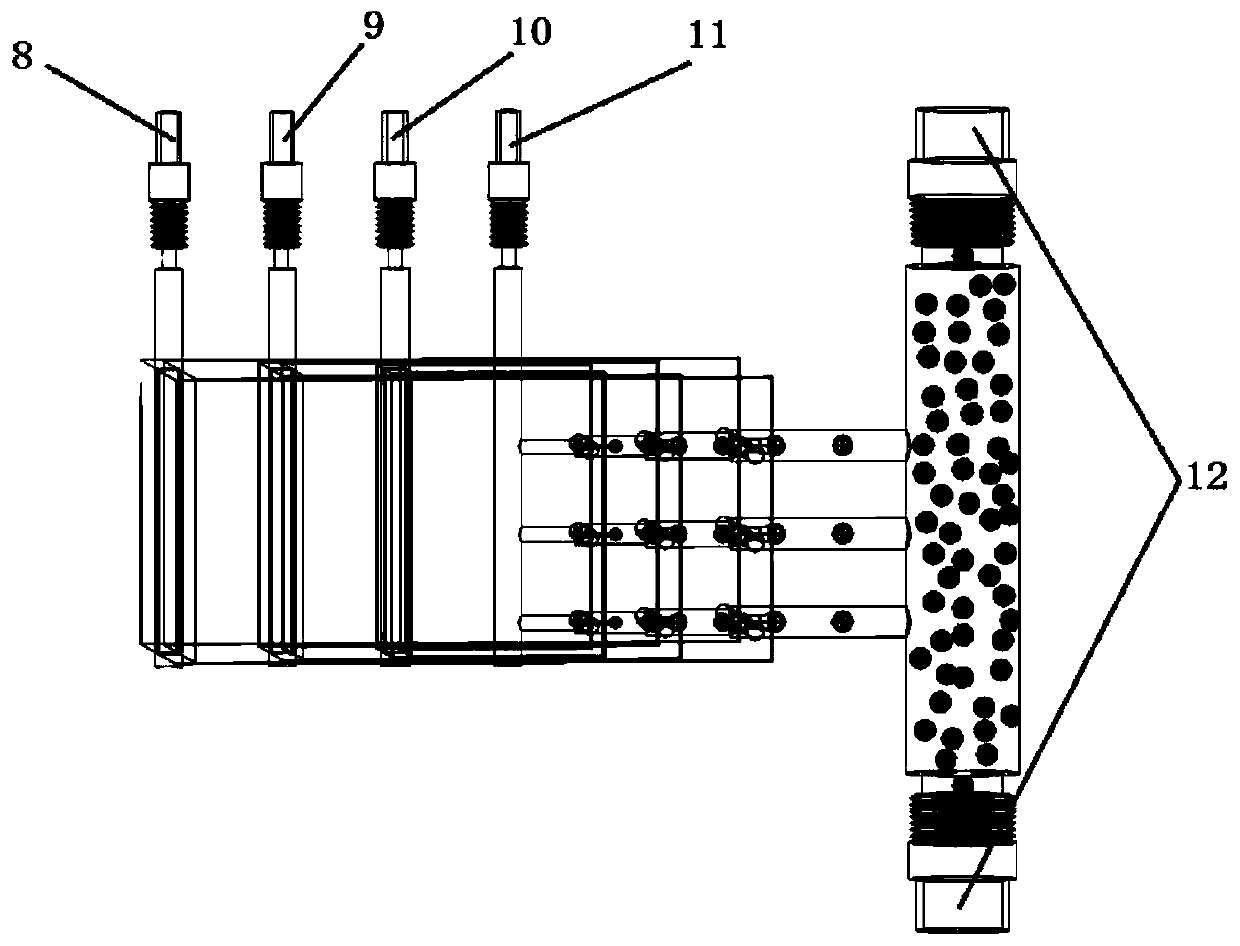

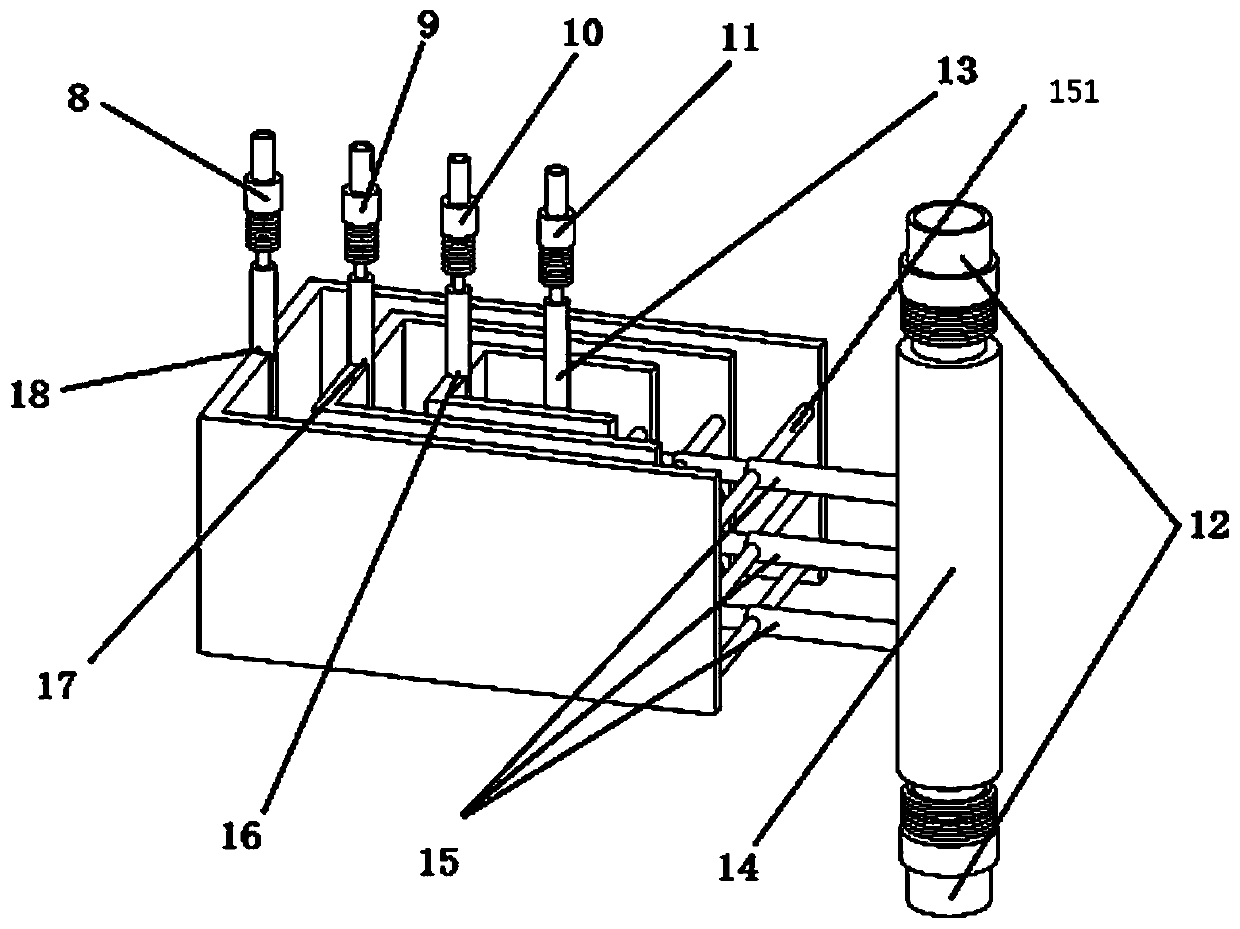

A three-dimensional parallel multiple emulsion rapid preparation device

ActiveCN107433213BFast preparationEfficient preparationLaboratory glasswaresModular designMechanical engineering

The invention discloses a three-dimensional parallel device for rapidly preparing multiple emulsions. The apparatus comprises an inner fluid distribution channel which is connected with an inner fluid inlet adapter tube; a plurality of outer fluid distribution channels which are respectively connected with outer fluid inlet adapter tubes; an emulsion collecting channel which is connected with an outlet adapter tube; and a plurality of emulsion generating units connected between the inner fluid distribution channel and the emulsion collecting channel and respectively connected with the outer fluid distribution channels. The three-dimensional parallel device for rapidly preparing multiple emulsions, adopting modular design, has the advantages of good expandability, high space utilization rate, realization of rapid and highly-efficient production of the multiple emulsions, uniformity in distribution of the fluid in the device, and avoiding of flowing dead zones, so the high monodispersbility and the high uniformity of emulsion production are guaranteed.

Owner:SOUTHEAST UNIV

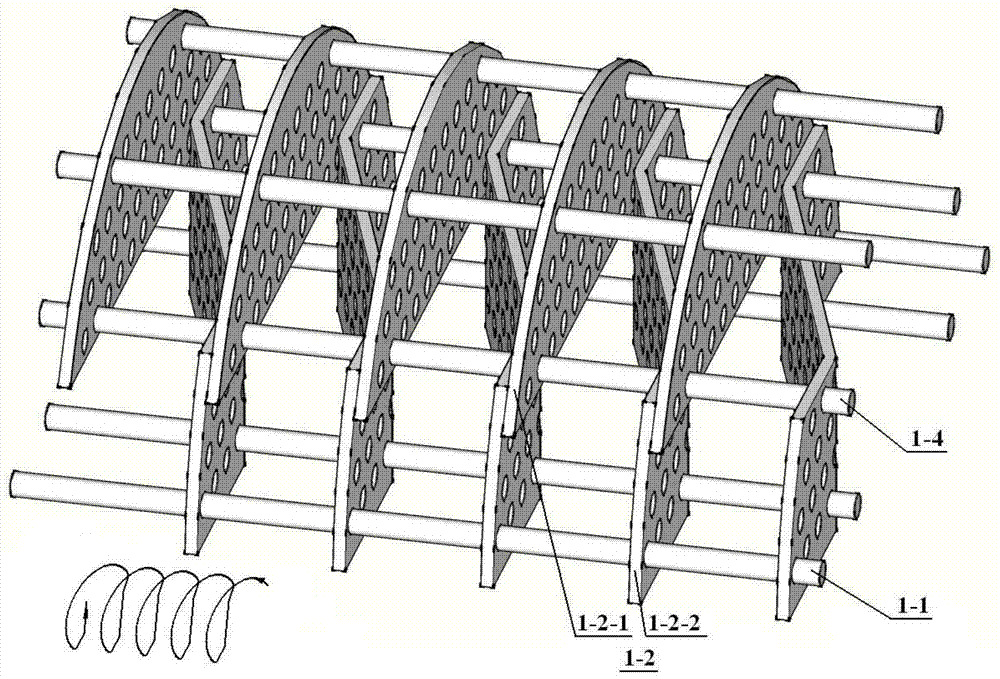

A vibrating anaerobic purification equipment

ActiveCN108529745BImprove processing efficiencyIncrease contactWater treatment parameter controlTreatment with anaerobic digestion processesMicroorganismProcess engineering

The invention relates to the technical field of sewage treatment, and in particular to a vibrating anaerobic purification equipment, which includes a biochemical tower vibration device. The biochemical tower includes a tower body and a plurality of biochemical units arranged in the tower body; microbial fillers are provided in the biochemical units. ; The vibration device is used to apply vibration to the microbial filler in at least one biochemical unit; multiple biochemical units are arranged from top to bottom in the biochemical tower, and the water body in the upper biochemical unit can flow down to the lower biochemical unit , an anaerobic environment is formed in the biochemical tower. This kind of vibrating anaerobic purification equipment does not need to be equipped with a reflux device, so that its volume can be made relatively small, the manufacturing cost is low, and it is easy to transfer.

Owner:NORTHEASTERN UNIV LIAONING

A counterflow spiral baffle U-shaped tube bundle heat exchanger

ActiveCN105202948BEasy to fixOvercome the limitation that it can only be arranged in a cylindrical spaceHeat exchanger casingsStationary tubular conduit assembliesEngineeringHeat transfer coefficient

A countercurrent spiral baffle U-shaped tube bundle heat exchanger, which is composed of a U-shaped tube bundle core, a shell and a water chamber; the U-shaped tube bundle core is composed of a U-shaped tube bundle, a spiral baffle assembly, a tube plate, It is composed of tie rod sleeve assembly and longitudinal partition plate; the spiral baffle assembly is composed of a set of flat circular baffles and a set of inclined sections and left and right folded flat sections in the upper and lower semi-cylindrical regions. It is composed of arc-shaped end strip baffles; two sets of baffles are provided with an overlapping area of a row of pipes. The present invention can overcome the structural limitation that the common spiral baffles are difficult to arrange in the semi-cylindrical space and many disadvantages of the arcuate baffle heat exchanger, and solves the problem of arranging the spiral baffle channels in the semi-cylindrical space to realize the U-shaped counterflow The tube bundle heat exchanger has the advantages of high heat transfer coefficient and small flow resistance.

Owner:SOUTHEAST UNIV

A reforming reactor and its application

ActiveCN109603690BSmall sizeFacilitate the dehydrocyclization reactionChemical/physical processesThermodynamicsPtru catalyst

Owner:SHANGHAI HOTO PETROCHEM ENG

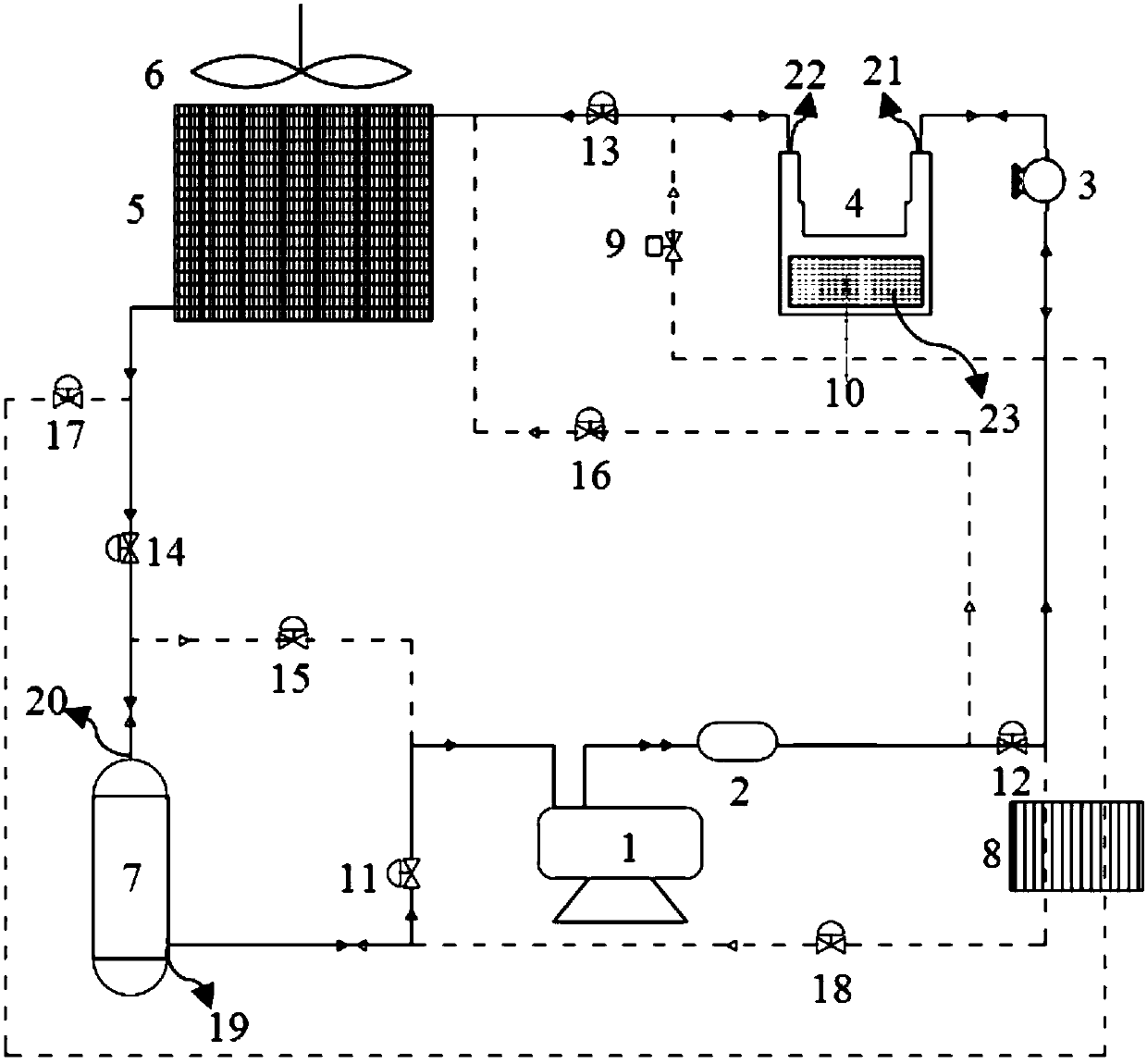

A multifunctional carbon dioxide system and its operating method

ActiveCN108269774BGuaranteed uptimeLow costSemiconductor/solid-state device detailsSolid-state devicesEngineeringCold plate

The invention discloses a multifunctional carbon dioxide system and an operation method therefor. An integrated drive device communicates with a gas-liquid separation device through a first flow control device; the integrated drive device communicates with the gas-liquid separation device through a fifth flow control device; a heat exchange cold plate communicates with the integrated drive devicethrough a second flow control device; the heat exchange cold plate communicates with the gas-liquid separation device through an eighth flow control device; a condensing device communicates with the heat exchange cold plate through a third flow control device; the condensing device communicates with the integrated drive device through a sixth flow control device; the condensing device communicateswith the gas-liquid separation device through a fourth flow control device and; and the condensing device communicates with the heat exchange cold plate through a seventh flow control device. The cooling system disclosed by the invention is not limited by environment temperature, and electronic equipment can efficiently run under a stable working condition and can play an energy-saving role. According to the operation method for the cooling system disclosed by the invention, the electronic equipment can be prevented from being damaged in a conversion process of the cooling system.

Owner:XI AN JIAOTONG UNIV

A Die for Extrusion Forming of In-plane Bending Plates of Equal Thickness

ActiveCN109382417BEliminates the disadvantage of reboundEliminates the disadvantage of easy wrinklingExtrusion diesEngineeringThinning

A mold for extrusion molding of inner curved plates of equal thickness. The mold is connected and installed with an extruder, and includes an extrusion cylinder liner, an adjusting mold and a forming mold connected in sequence. The inner cavity set through the extrusion direction, including the rectangular cavity in the inner lining of the extrusion cylinder for the extrusion rod to push the blank, and the blank in the forming die for pushing the extruded rod out of the mold cavity The forming hole that is extruded into a flat plate, located in the adjusting die, is used to cooperate with the extrusion action of the extrusion rod to change and adjust the shape of the billet so that the billet becomes the required equal-thickness in-plane bending when it is extruded from the forming hole Shaped cavity of the plate. The invention can extrude inner curved plates of equal thickness with different curvatures, and can ensure the thickness of the in-plane curved plates without thinning of the outer ring and easy wrinkling of the inner ring. There will be no reaction force opposite to the bending direction, and there will be no rebound in the opposite direction to the bending direction.

Owner:河南合力盛达铝业科技发展有限公司

A vibrating sewage treatment equipment

ActiveCN108408904BAvoid failureImprove liquidityTreatment with aerobic and anaerobic processesActivated sludgeMicroorganism

The present invention relates to the technical field of sewage treatment, and in particular to a vibrating sewage treatment equipment, which includes a pre-treatment device, a biochemical tower and a vibration device. The biochemical tower includes a tower body and a plurality of biochemical units arranged in the tower body; The treatment device is used to send pre-treated sewage to the biochemical unit; the biochemical unit is equipped with microbial filler, which is suitable for putting activated sludge into the biochemical unit. During the sewage treatment process, an aerobic zone is formed in the biochemical unit. In the anoxic zone and the anaerobic zone, the vibration device is used to apply vibration to the microbial packing in at least one biochemical unit; multiple biochemical units are arranged from top to bottom in the biochemical tower, and the water body in the upper biochemical unit can flow down In the biochemical unit located on the lower floor, the biochemical tower is equipped with a ventilation structure. This kind of vibrating sewage treatment equipment does not need to be equipped with an aeration device, a backflow device, or multiple functional pools, so that its volume can be made smaller, the manufacturing cost is low, and it is easy to transfer.

Owner:NORTHEASTERN UNIV LIAONING

A kind of nitrogenous wastewater treatment method

ActiveCN108609731BRealize processingIncrease contactTreatment with anaerobic digestion processesActivated sludgeMicroorganism

The invention relates to the technical field of wastewater treatment, and in particular to a method for treating nitrogen-containing wastewater, which includes the following steps: pre-processing the nitrogen-containing wastewater; injecting the pre-treated nitrogen-containing wastewater into a biochemical unit, which is provided with a Microbial filler and activated sludge, the microbial filler contains domesticated microbial colonies; the nitrogen-containing wastewater is treated in the biochemical unit, and during the process of treating the nitrogen-containing wastewater, at least part of the microbial filler is driven to vibrate; Water drains. This nitrogen-containing wastewater treatment method does not require the input of carbon sources and aeration devices during the wastewater treatment process, and effectively avoids pipeline blockage and the occurrence of flow dead zones.

Owner:NORTHEASTERN UNIV LIAONING

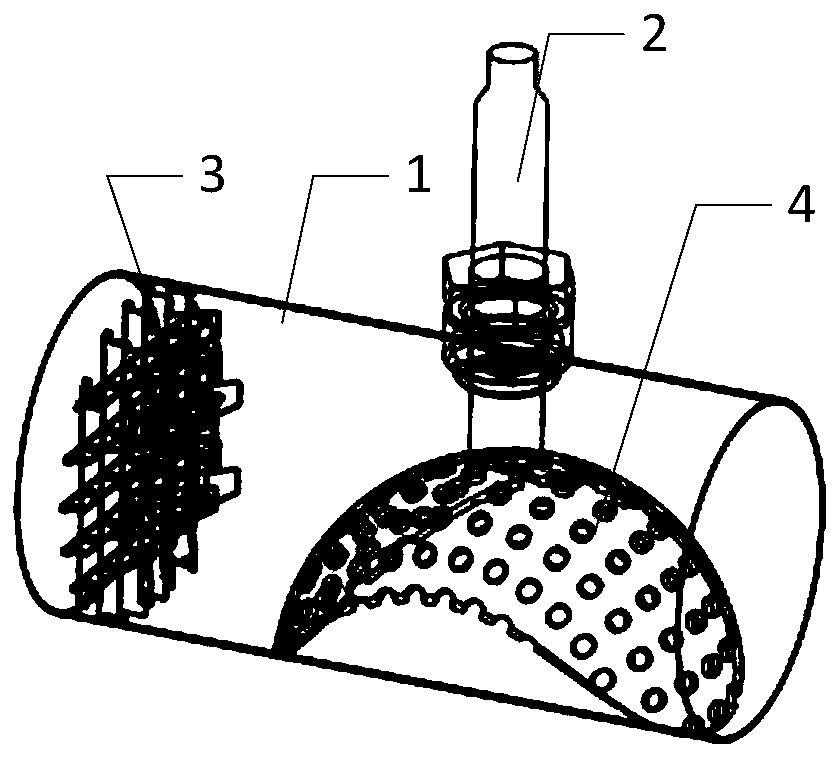

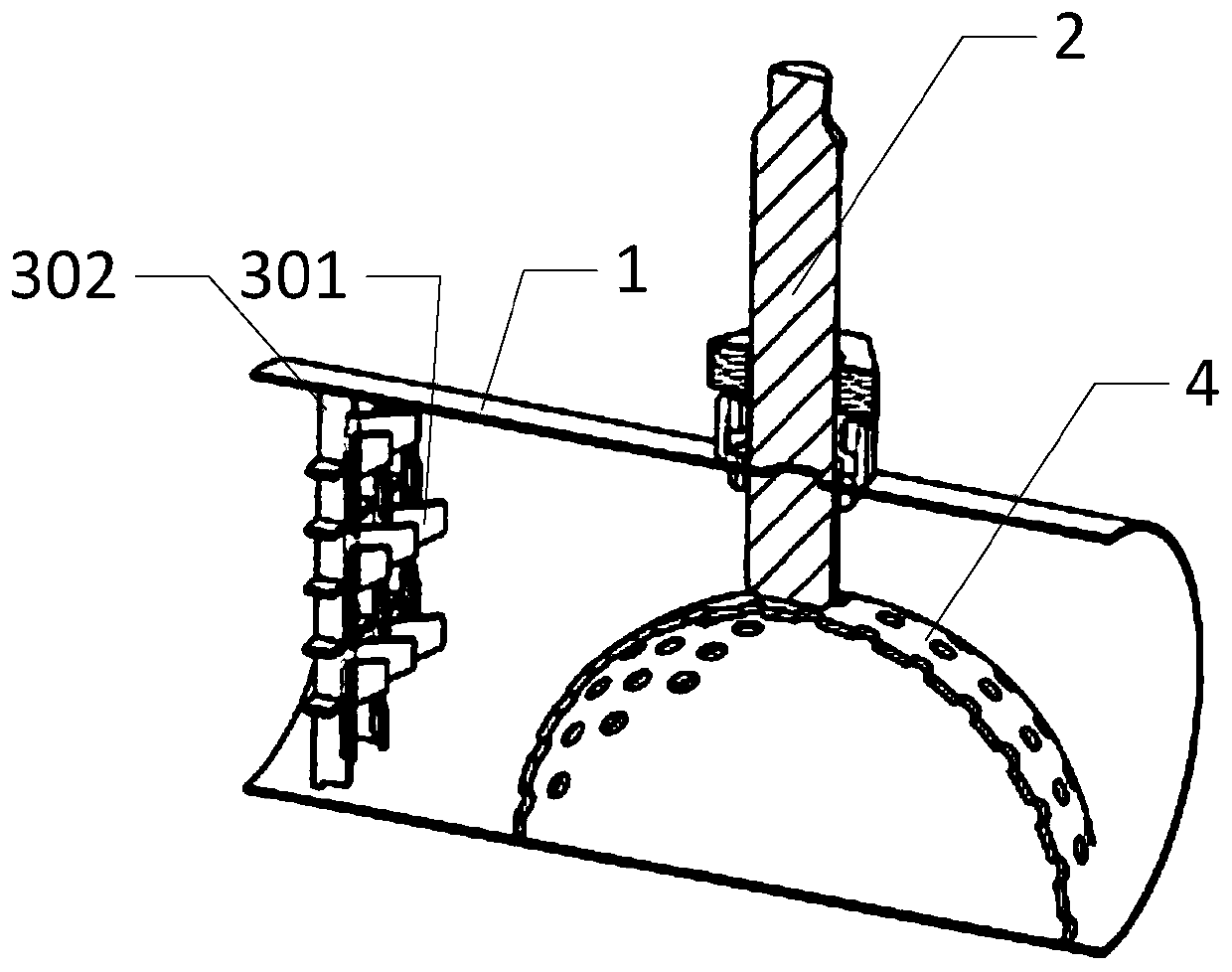

Novel devolatilization device

PendingCN114849255AImprove performanceAvoid Flow Dead ZonesEvaporator accessoriesChemical industryEngineeringVertical cylinder

The invention discloses a novel devolatilization device which comprises a vertical cylinder, an upper end socket and a lower end socket are arranged at the upper end and the lower end of the cylinder respectively, at least one pair of feed ports are connected to the upper end socket, at least one pair of discharge ports are connected to the lower end socket, and a devolatilization distributor hung below the upper end socket is arranged in the cylinder. The devolatilization distributor is a closed outer ring formed by connecting a plurality of devolatilization distribution pipes with the same diameter end to end, a middle connecting pipe communicated with an outer ring pipeline is arranged in an inner ring of the outer ring, flow distribution holes are formed in the lower semicircular pipe wall of each devolatilization distribution pipe, the flow distribution holes are arranged in a triangular mode, the hole diameter ranges from 2 mm to 6 mm, and the devolatilization distributor is provided with an open hole opposite to a feeding port. And the feeding hole is welded and fixed with the devolatilization distributor through the opening and is communicated with the devolatilization distributor through a pipeline By optimizing the inlet and outlet structures of the devolatilization device, optimizing the external heating of the equipment, and optimizing the devolatilization distributor and the flow distribution holes, the devolatilization separation efficiency is improved, and the product quality is further improved.

Owner:广东寰球广业工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com