Jet current atomizing mixer for bioreactor

A technology of bioreactor and mixer, which is applied in the direction of bioreactor/fermenter combination, fluid mixer, specific-purpose bioreactor/fermenter, etc. It can solve the problem of poor gas-liquid mixing effect, reactor height and diameter Large, difficult to sterilize and other problems, to achieve the effect of speeding up the reaction speed, eliminating the large aspect ratio, and convenient operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

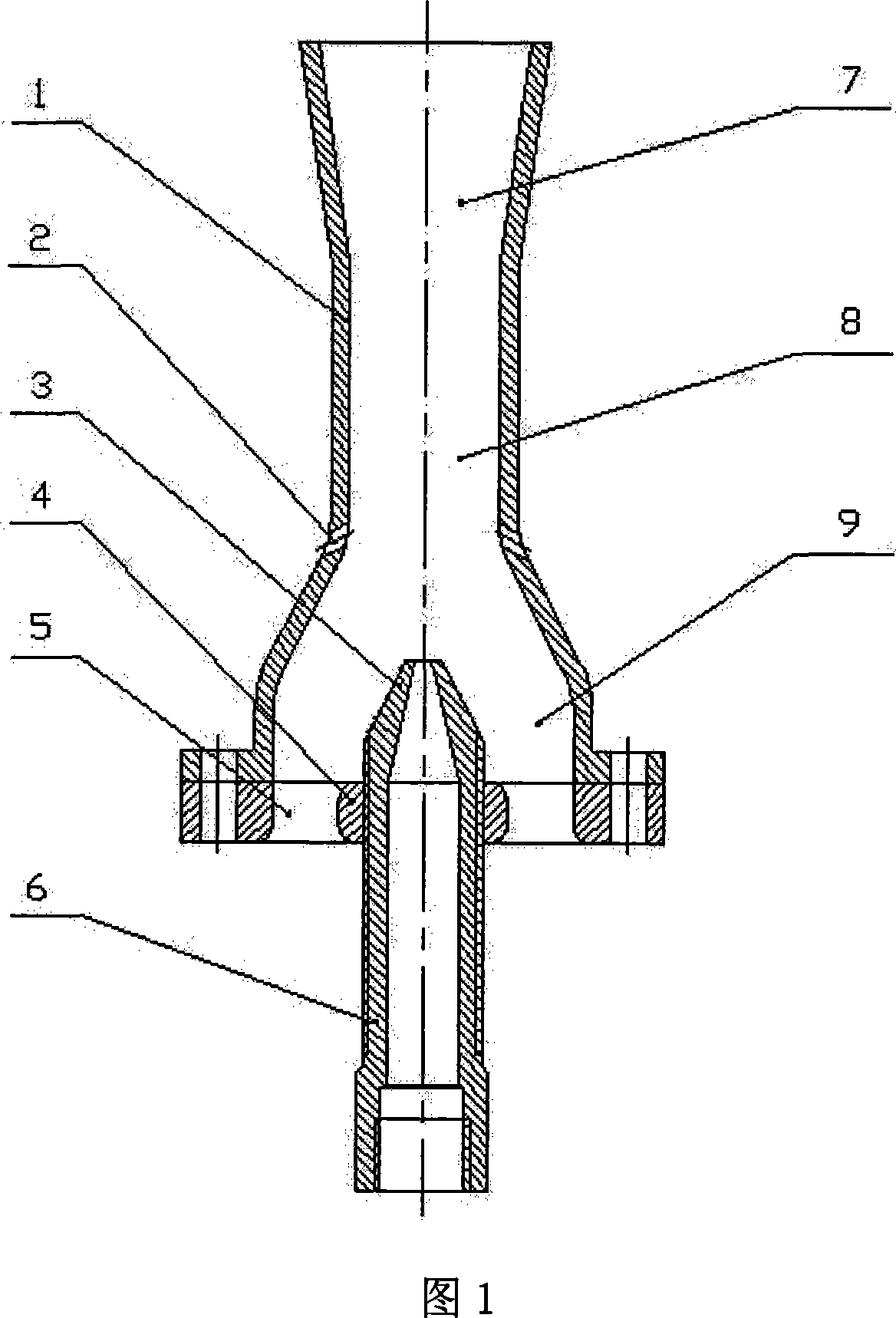

[0010] As shown in the figure, the variable diameter tube (1) consists of a diffusion chamber (7), a mixing chamber (8) and a jet atomization chamber (9) from top to bottom, and between the mixing chamber (8) and the jet atomization chamber (9 ) at the junction of 4 liquid reactant suction ports (2), which are evenly distributed in the circumferential direction, and the angle between the axis of the hole and the axis of the reducing tube is 45°; the fixed plate (4) is provided with 3 suction ports for liquid reactant mouth (5); the variable diameter pipe (1) is connected with the fixed plate (4) with threads, the fixed plate (4) is connected with the upper end of the jet atomizing nozzle (3) with threads, and the outlet of the jet atomizing nozzle (3) goes deep into the variable diameter The pipe (1), the lower end of the jet stream atomizing nozzle (3) is connected with the compressed air introduction pipe (6).

[0011] Compressed air enters the jet atomizing mixer from the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com