Mixer for U-shaped tail gas after-treatment device and U-shaped tail gas after-treatment device

A tail gas post-treatment and mixer technology, which is applied in exhaust devices, mufflers, gas passages, etc., can solve problems such as low SCR conversion efficiency, unfavorable urea pyrolysis and hydrolysis, and short mixer strokes, etc., to reduce crystallization risk, increase the gas flow rate, and improve the effect of heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. The relevant components in the invention are not drawn according to the number, shape and size of the components in actual implementation. The type, quantity and proportion of each component in actual implementation can be changed arbitrarily, and the layout of the components may also be changed for complex.

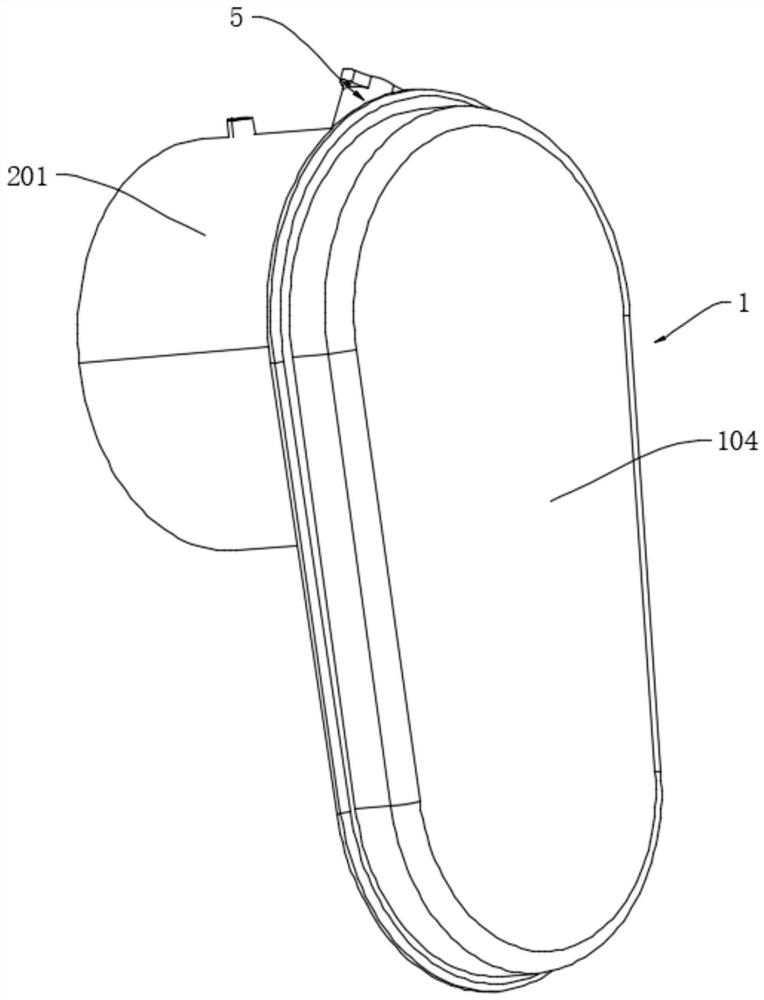

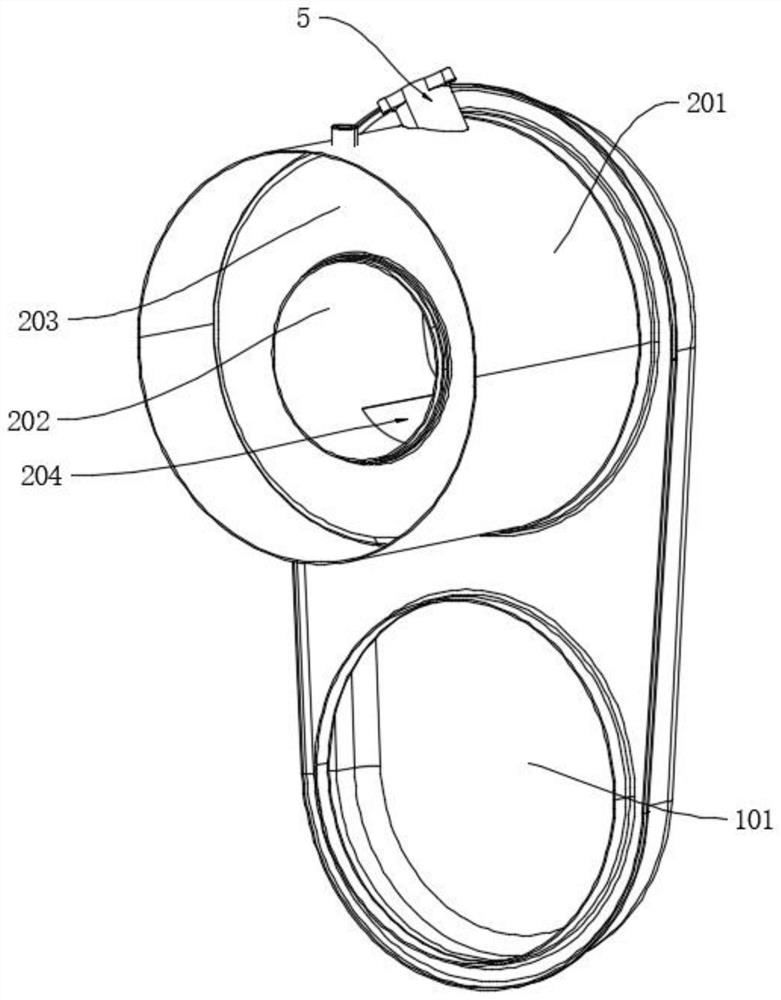

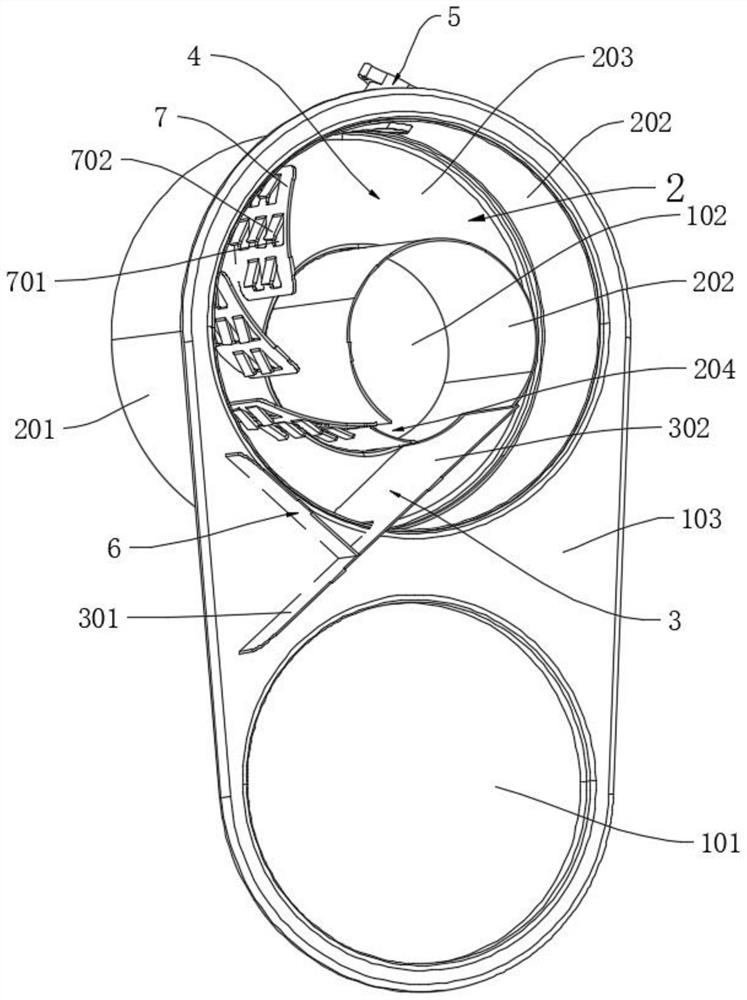

[0024] See Figure 1 to Figure 3 , a mixer for a U-shaped exhaust gas aftertreatment device according to the present invention includes a mixer housing 1, the mixer housing includes an air inlet 101 connected to a DPF unit and an air outlet 102 connected to an SCR unit, and the mixer housing A mixing chamber 2 is provided in the body, a deflector 3 is provided in the mixer housing 1 near the air inlet 101, a gas mixing channel 4 is provided in the mixing chamber 2, and a urea nozzle 5 is provided on the gas mixing channel 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com