Hierarchical manifold micro-channel heat dissipation device

A technology of heat dissipation device and micro-channel, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc. The effect of reducing thermal resistance and shortening the effective length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention are described in further detail below:

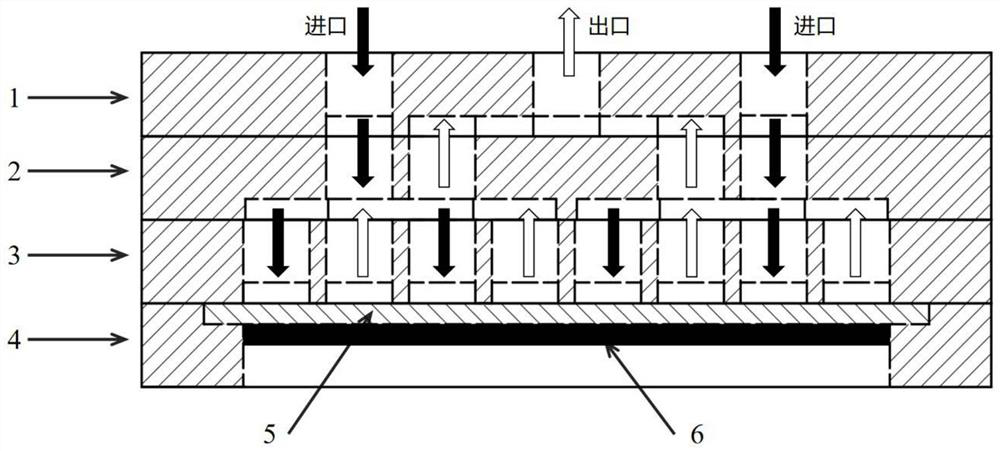

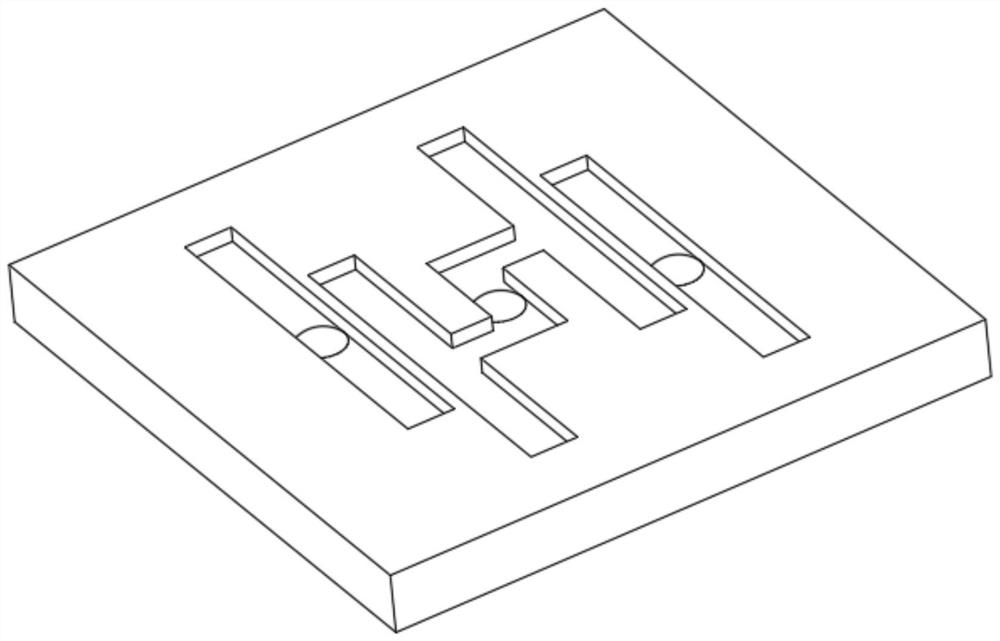

[0047] The present invention realizes the flow and heat transfer enhancement of traditional parallel microchannels through complex flow channel design, and adds a multi-stage flow splitting device, and develops a layered manifold microchannel heat dissipation with pressure drop, small thermal resistance, and uniform wall temperature distribution. device.

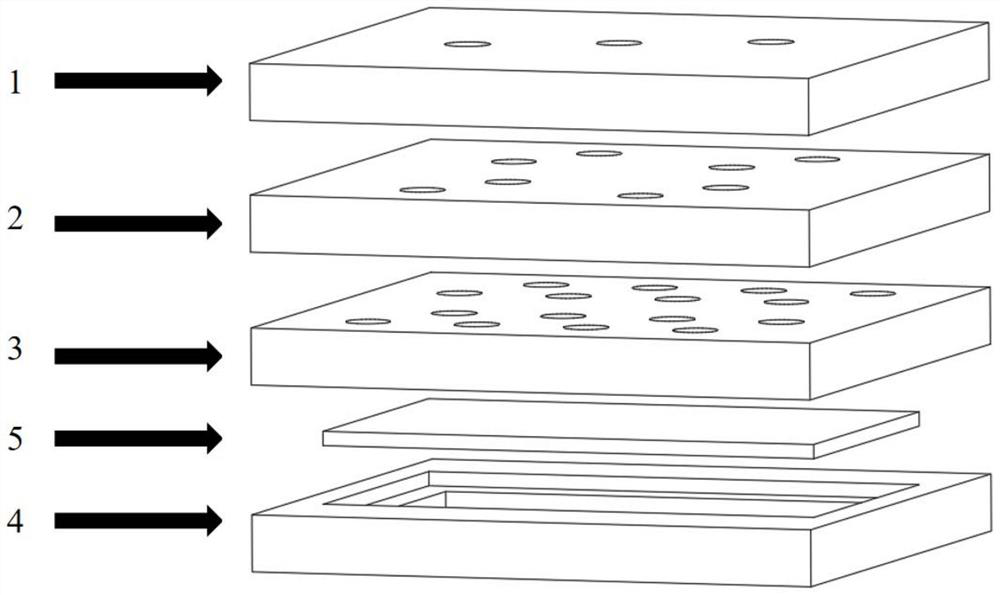

[0048] A hierarchical manifold microchannel cooling device, including a first-layer substrate 1 (the lower surface of the first-layer substrate 1 is designed with four first-level microchannels, and the upper surface is designed with two first-level working fluid inlets and one first-level working fluid inlet. quality outlet), the second layer substrate 2 (the lower surface of the second layer substrate 2 is designed with eight secondary microchannels, and the middle part of each secondary microchannel is provided with a through hole), the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com