Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Achieving Control Accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

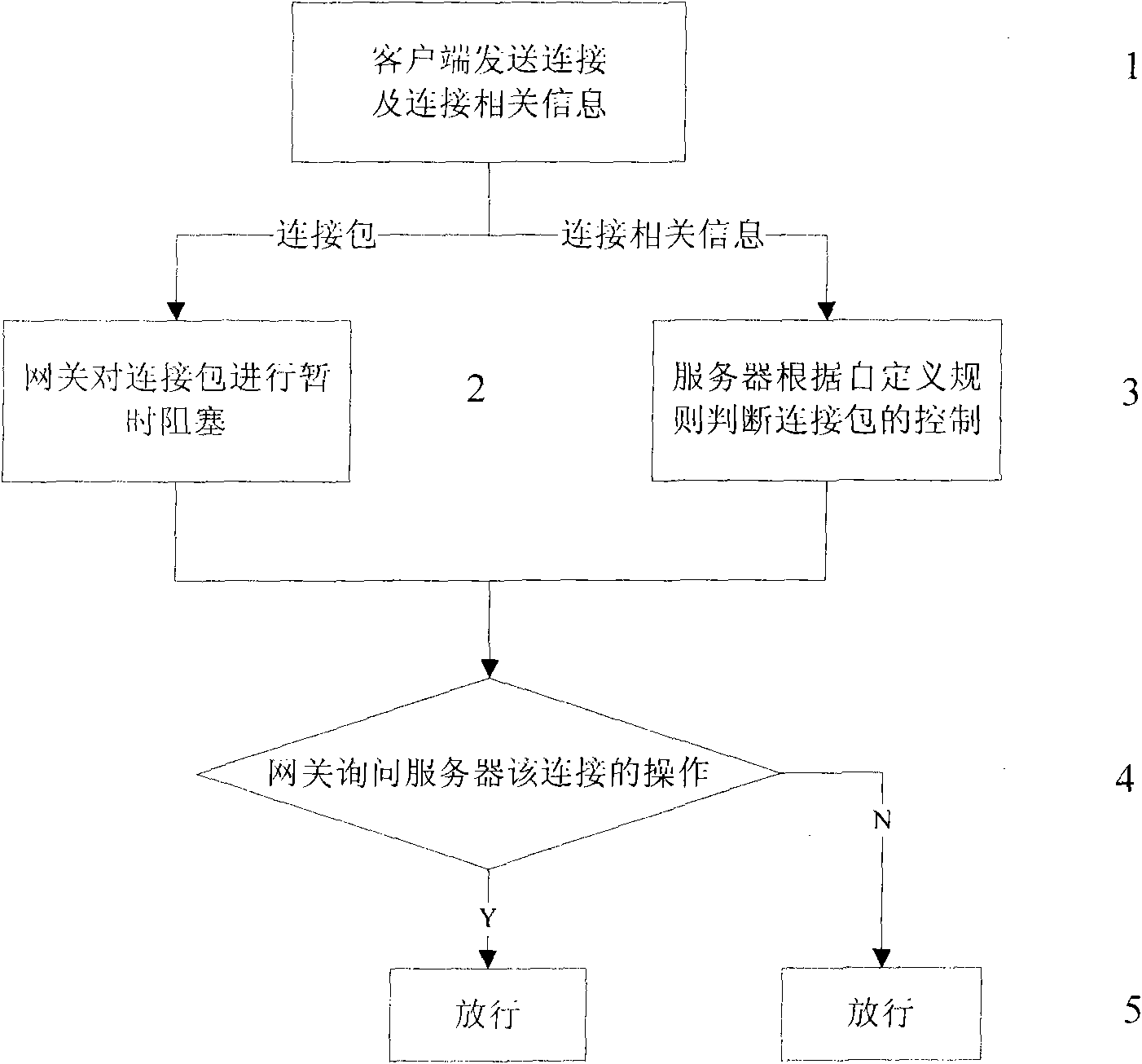

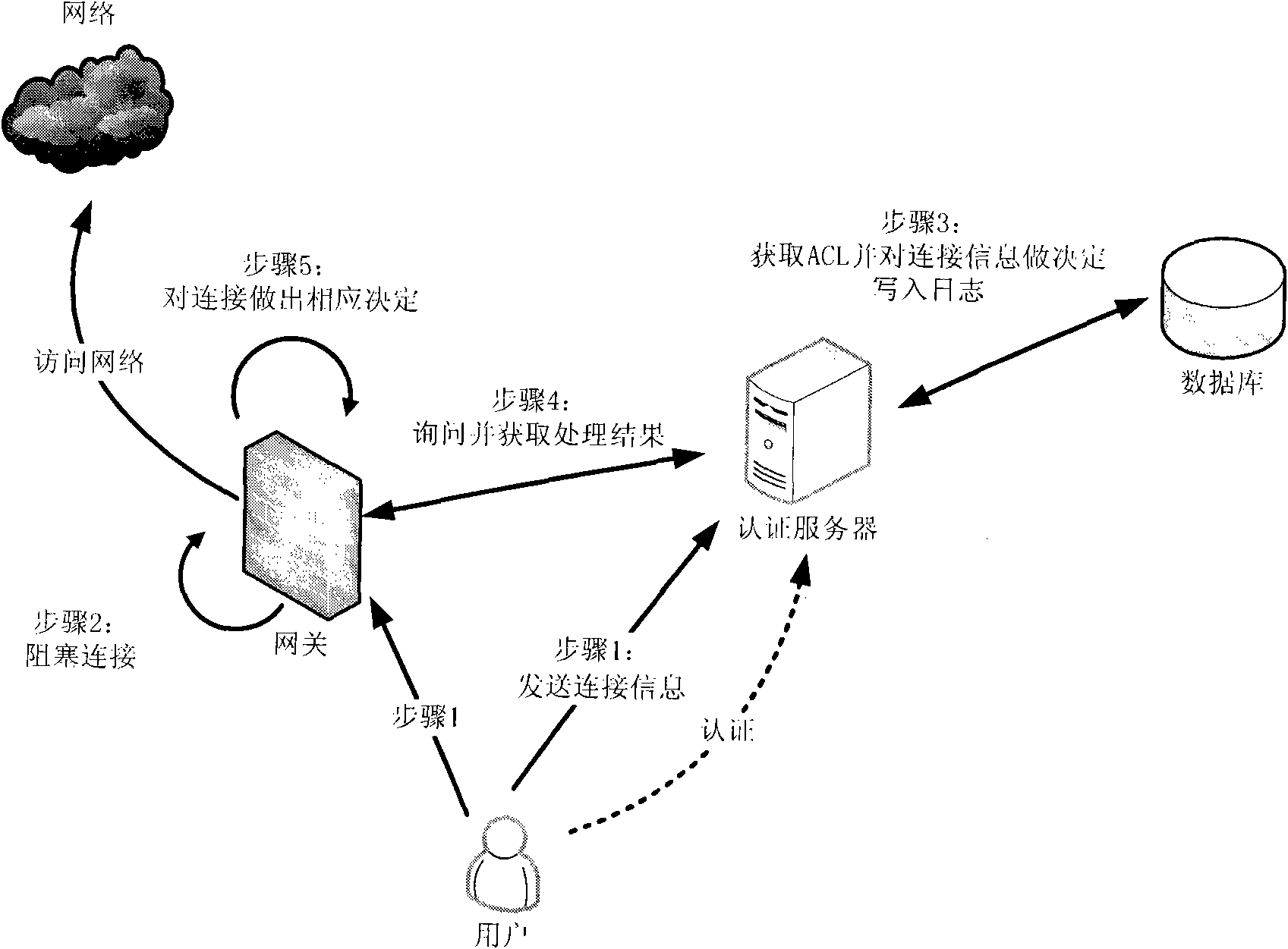

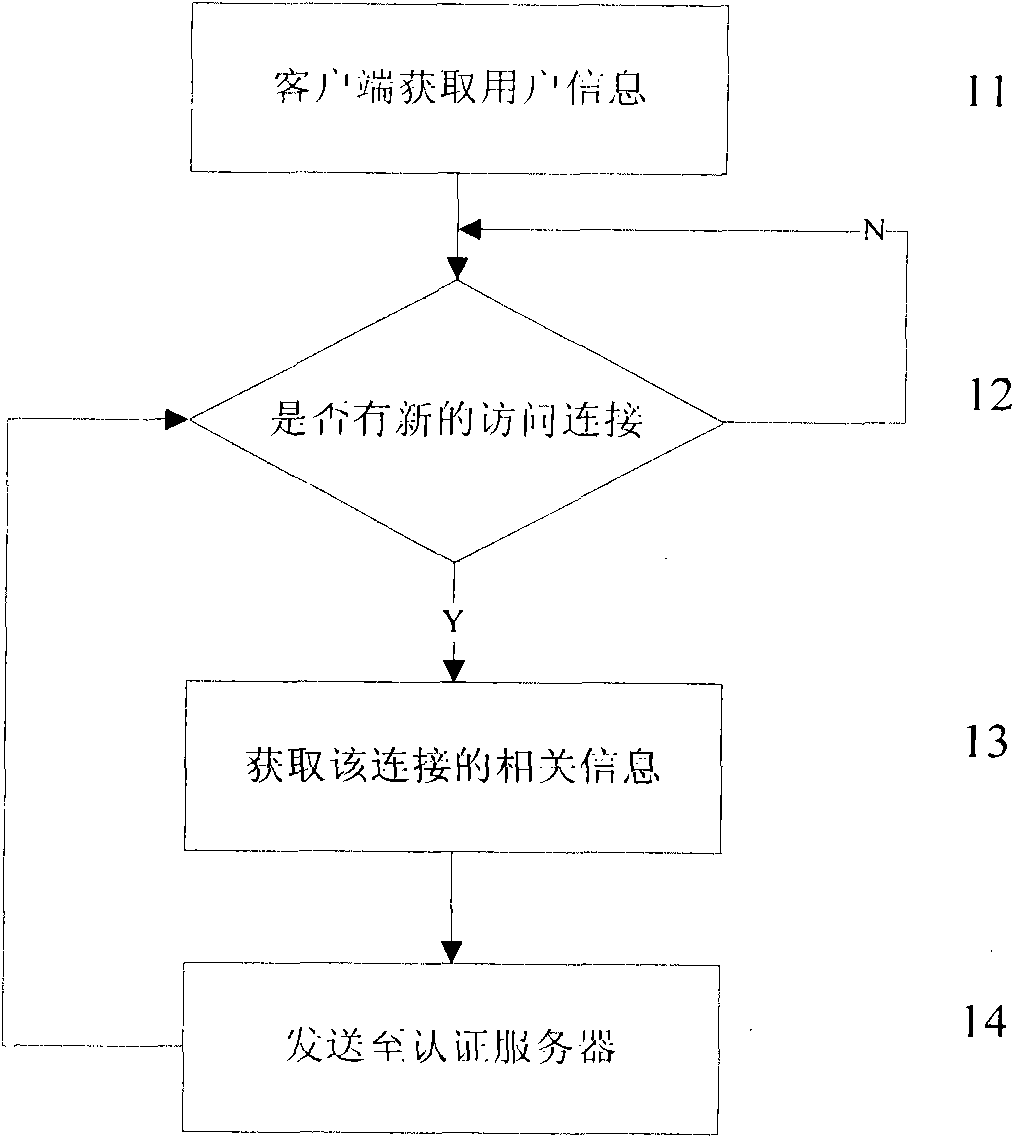

Fine-granularity network access control method based on user connection information

InactiveCN101616076ASolve the problem of falsified informationIncrease flexibilityNetwork connectionsGranularityAuthentication server

The invention relates to a fine-granularity network access control method based on user connection information, with the core thought of realizing the network access control method which audits the connection initiated by the user based on user identity and authority through the architectures of a gateway, an authentication server and a client. The method realizes a proposal that each connection initiated by the client and network application programs which initiate the connection can be audited and controlled at the authentication server terminal by binding each connection initiated by the client and the user identity. The method controls the network access of multiple users in the local area network, has relatively high control accuracy and flexibility and can satisfy the control requirement of multi-level of network access and flexible user logging method.

Owner:WUHAN UNIV OF TECH

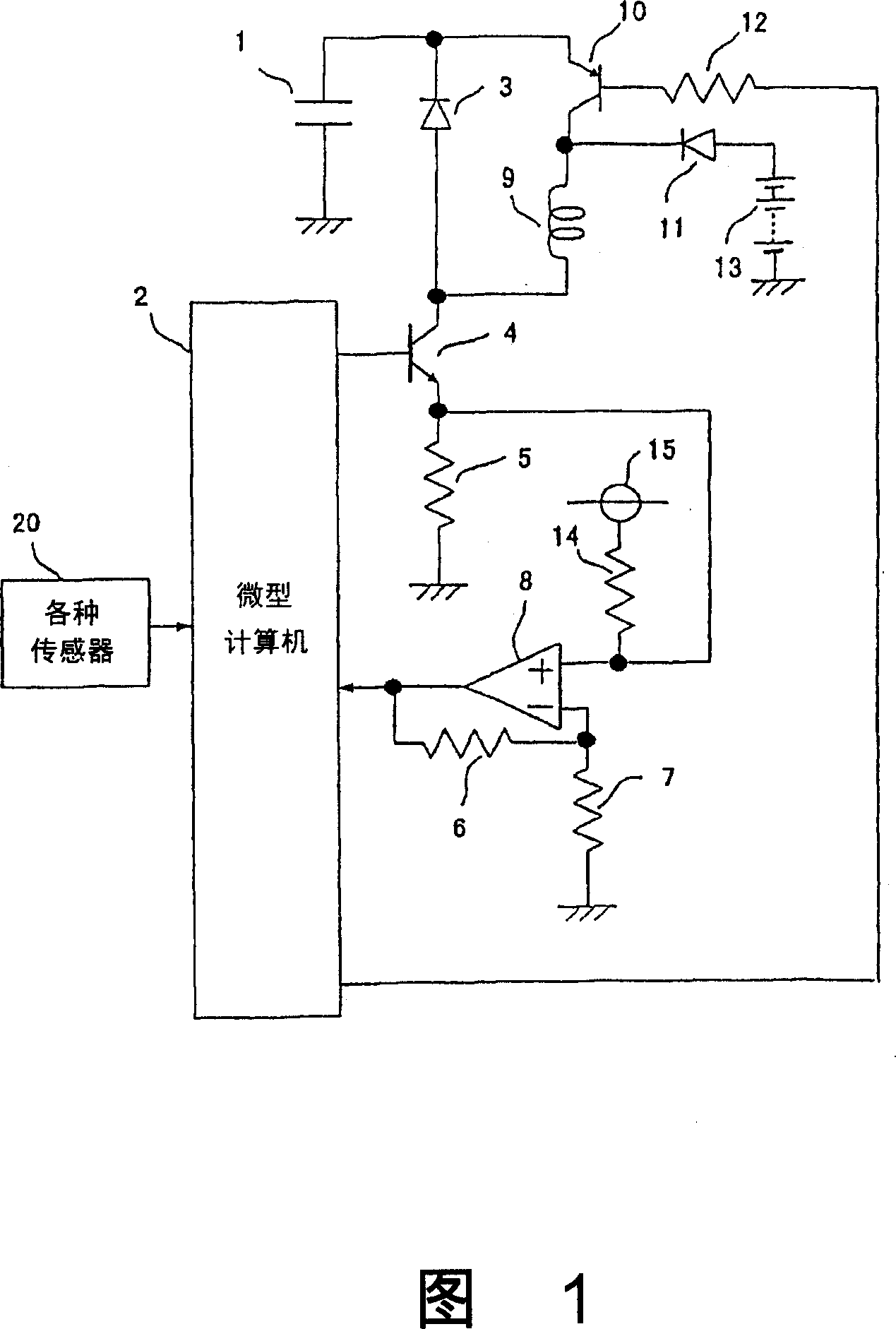

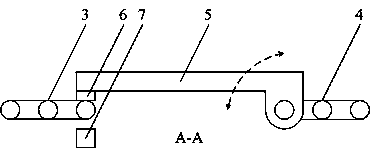

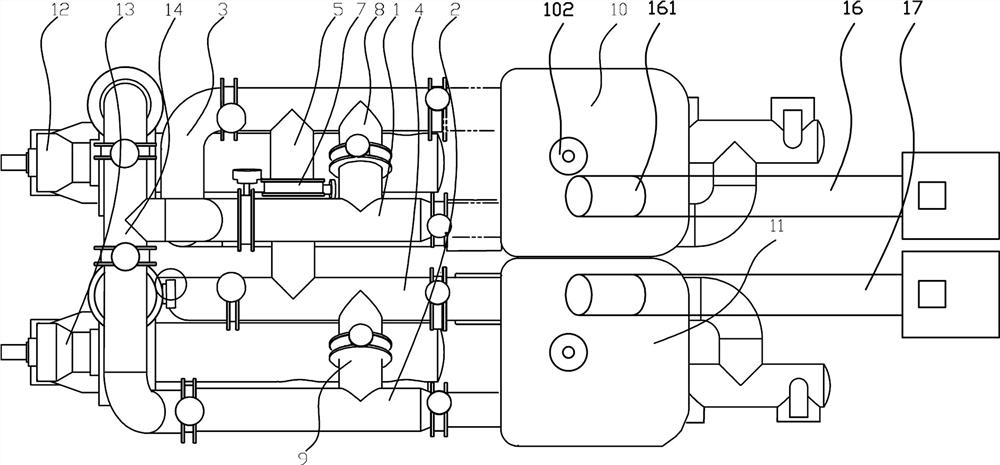

Fuel jet device of engine

InactiveCN1975141AImprove detection accuracyStable outputElectrical controlInternal combustion piston enginesMicrocomputerAudio power amplifier

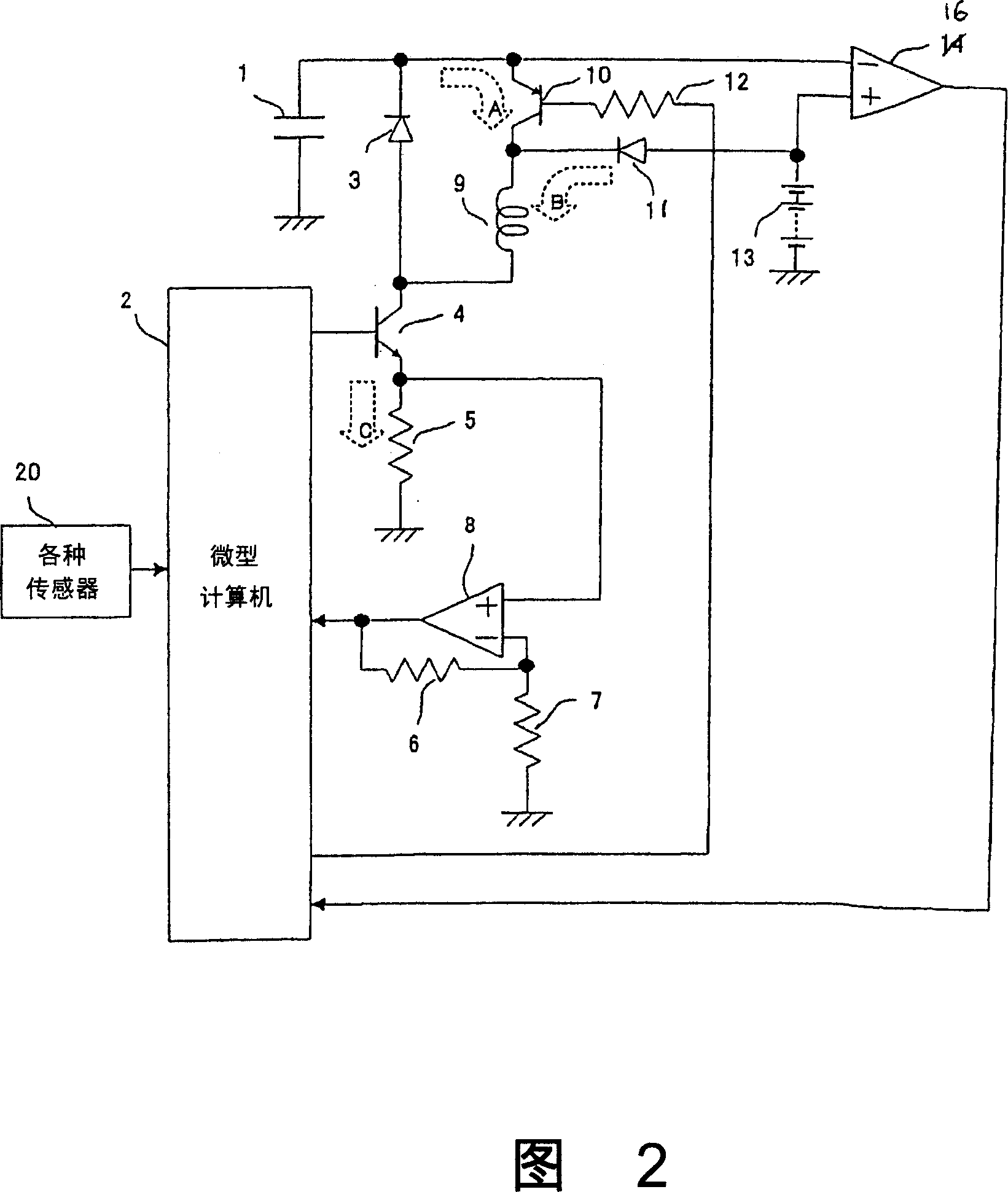

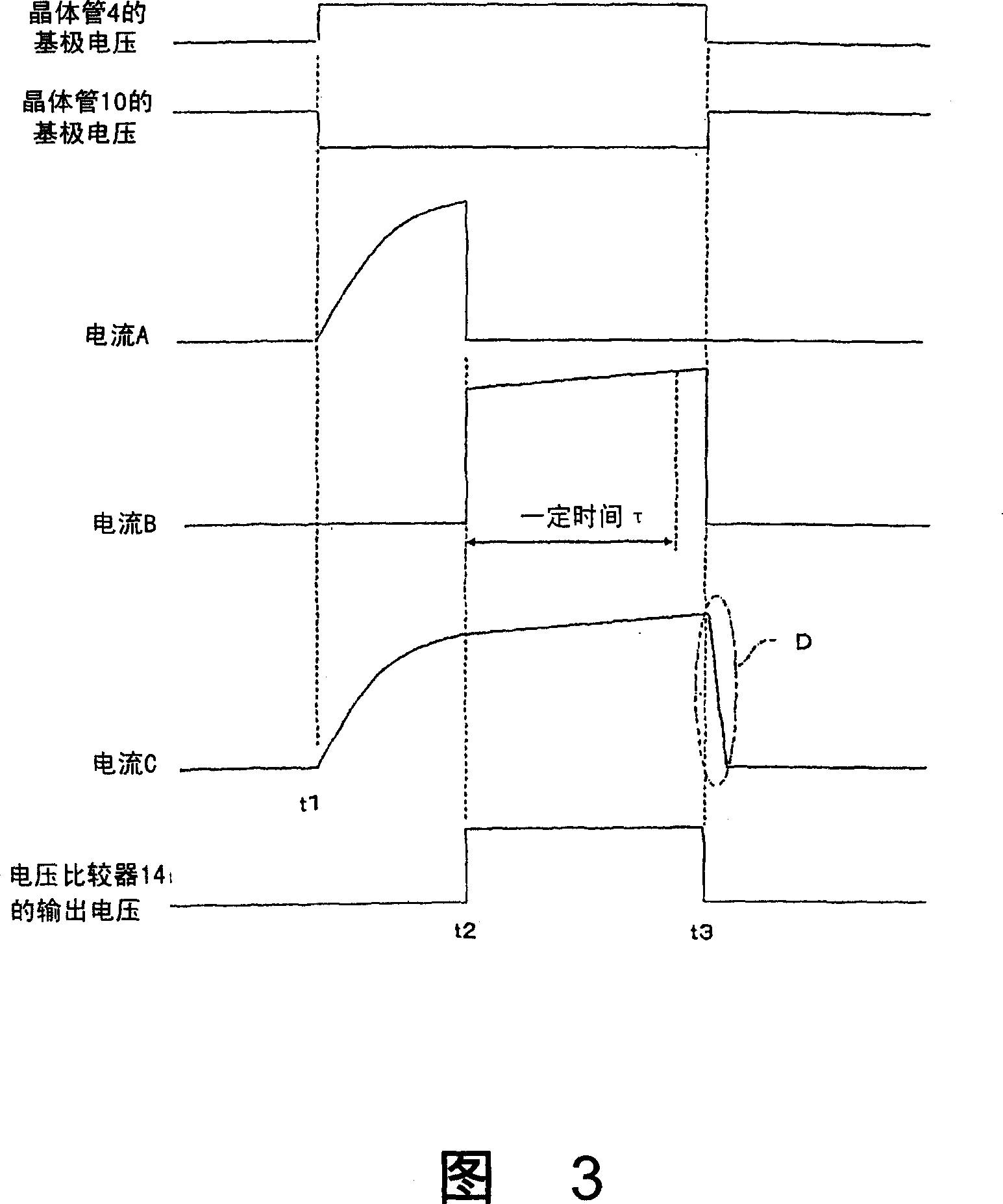

The invention provides a fuel injection device for engine which can detect the current on the electromagnetic winding in high precision so as to achieve the high precision of the control of the fuel injection module by arranged a biasing circuit on the detecting member for the electromagnetic winding current. The device comprises: a fuel injection module with functions that can drive a plunger to move forward and backward so as to suck the fuel or increase pressure to inject fuel when the electromagnetic winding 9 is electrified, and several sensors 20 for detecting the running state of the engine, and a control unit constituted by a micro-computer 2 for generating a driving signal to the fuel injection module according to the running state, and a current detecting member containing an operation amplifier 8 for detecting the electromagnetic winding current. The biasing current supplied by the biasing source 15 flow through the current detecting member firstly to stabilize the current value before electrified so as to achieve the high precision of the current detecting of the fuel injection module.

Owner:MITSUBISHI ELECTRIC CORP

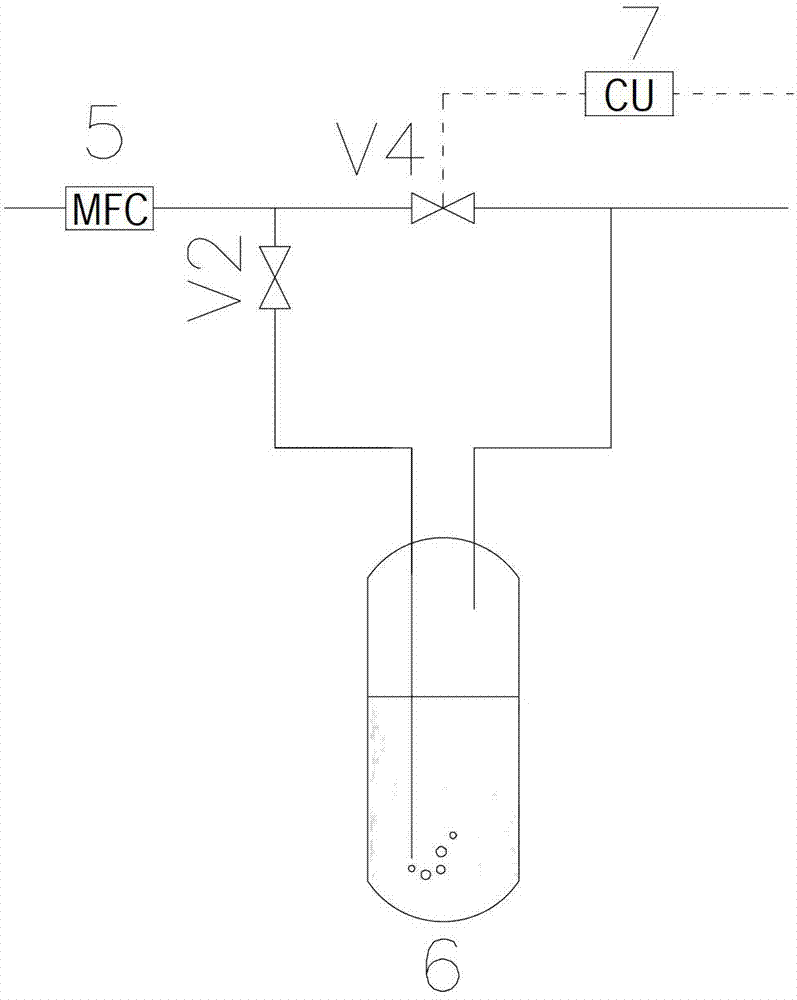

Method and device for controlling oxygen content in drum type cut tobacco drying process

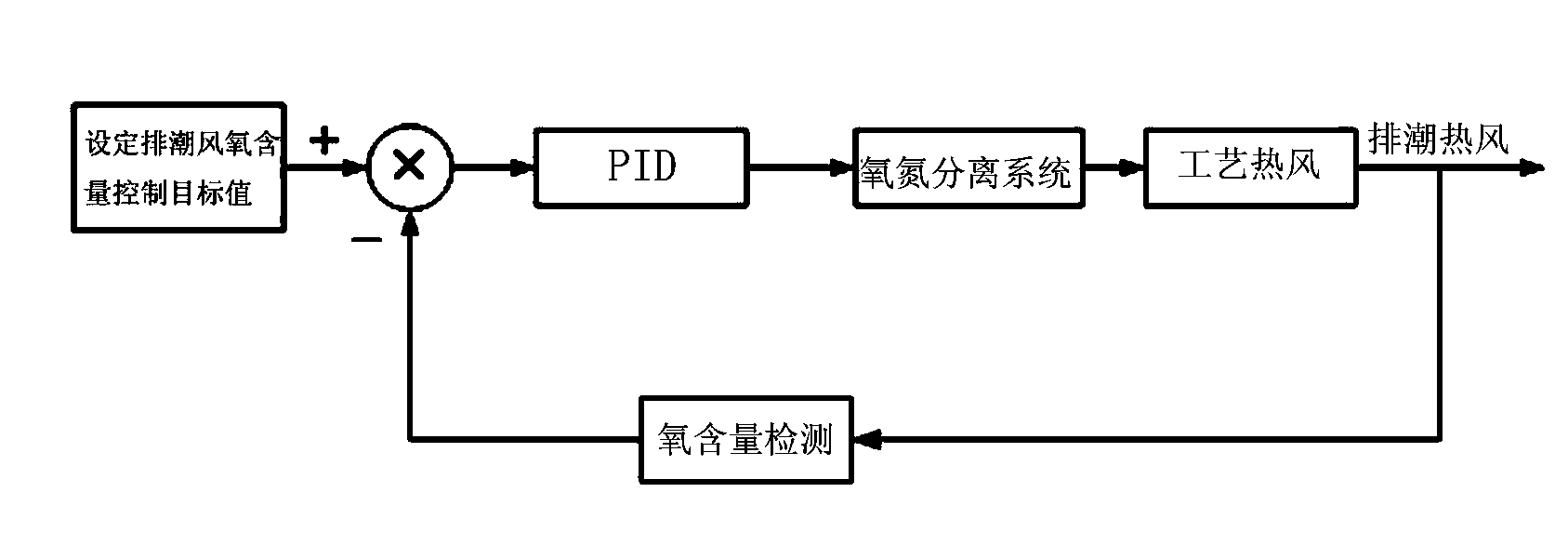

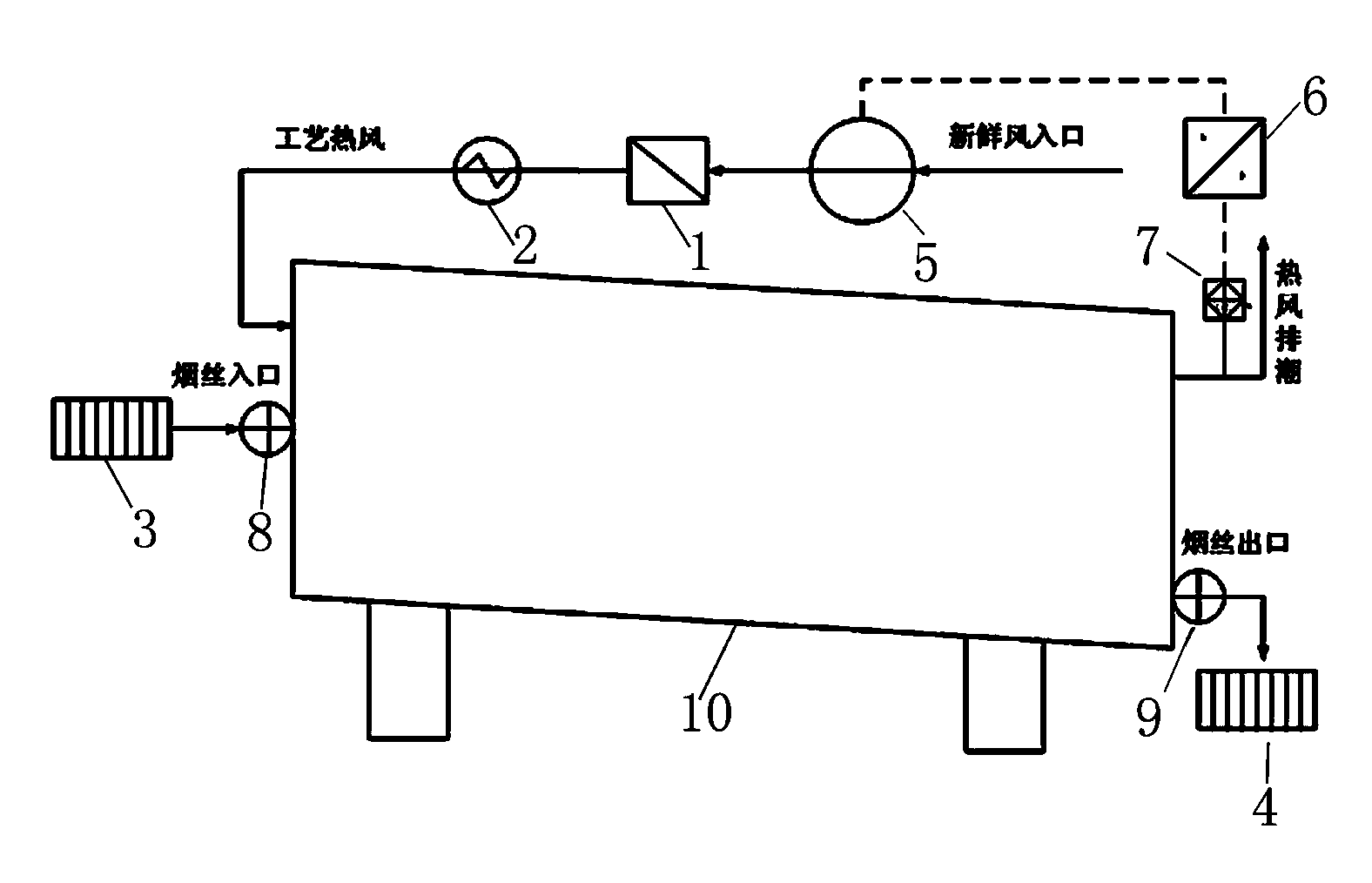

InactiveCN103564632AControl oxygen contentIncrease oxygen content before the control deviceTobacco preparationAir volumeProportion integration differentiation

The invention relates to a method and a device for controlling the oxygen content in the drum type cut tobacco drying process. An oxygen-nitrogen separation system is added in front of the traditional drum fresh air quantity control device, and can be used for enabling the oxygen content of the gas entering a drying drum to be adjustable; two cut tobacco feeding gas-locking devices are respectively added at a drum cut tobacco inlet and a drum cut tobacco outlet, so that the oxygen content in the drum is avoided being influenced by the ambient air which permeates into the drum through an inlet and an outlet of the drum; an oxygen content detection device is added into a drum hot air moisture removal pipeline and can be used for detecting the oxygen content in the moisture removal hot air in real time; a proportion integration differentiation (PID) control unit is added, and can be used for automatically adjusting the oxygen-nitrogen separation system by comparing the detection result of the oxygen content in the moisture removal hot air with the set control target value of the oxygen content in the moisture removal hot air so as to control the oxygen content of the hot air entering the drum and finally realize the control accuracy and stability of the oxygen content in the moisture removal hot air.

Owner:CHINA TOBACCO FUJIAN IND

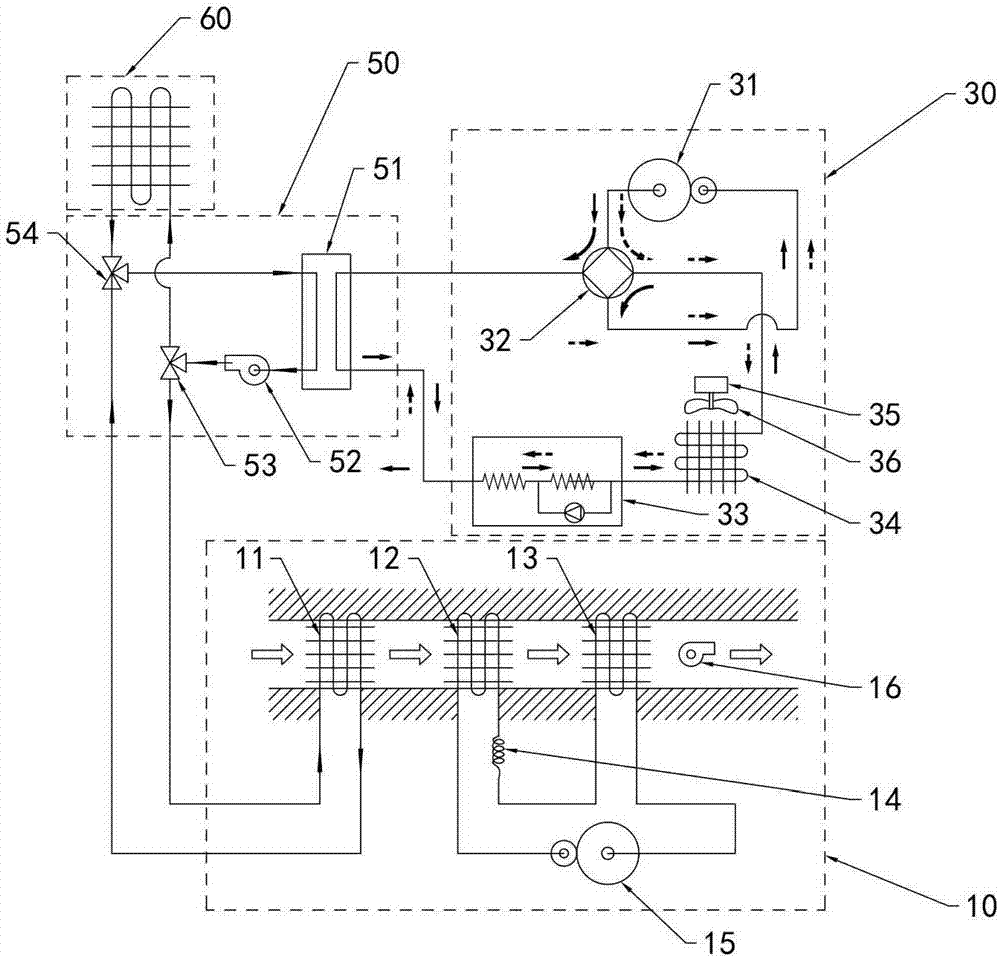

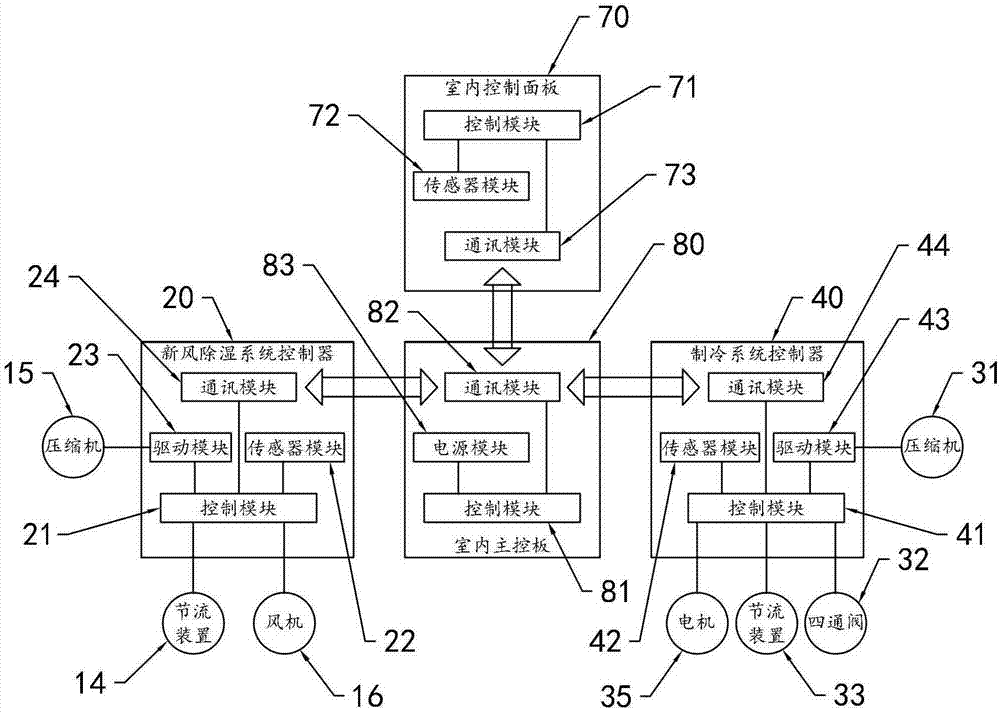

Fresh air dehumidifying system for low-temperature radiation air conditioner and control method of system

InactiveCN107477738ALow costAchieve independent controlSpace heating and ventilation safety systemsLighting and heating apparatusAir filterFrequency conversion

The invention discloses a fresh air dehumidifying system for a low-temperature radiation air conditioner. The system comprises a refrigeration system, a refrigeration system controller, a radiation system capable of exchanging heat with the refrigeration system through a water circulation system, a control panel, a mater control board, a fresh air dehumidifying system and a fresh air dehumidifying system controller; the fresh air dehumidifying system comprises a frequency conversion compressor, a surface air cooler, an evaporator, a condenser and a direct-current frequency conversion draught fan, an air filter net is arranged on one side of the surface air cooler, an outlet of the water circulation system is connected with an inlet of the radiation system and an inlet of the surface air cooler, an inlet of the water circulation system is connected with an outlet of the radiation system and an outlet of the surface air cooler, an exhaust opening of the frequency conversion compressor is connected with an inlet of the condenser, an outlet of the condenser is connected with an inlet of the evaporator, an outlet of the evaporator is connected with an air inlet of the frequency conversion compressor, and the fresh air dehumidifying system controller comprises a communication module, a control module, a drive module and a sensor module. The invention further discloses a control method of the fresh air dehumidifying system for the low-temperature radiation air conditioner.

Owner:四川酷比特科技有限公司

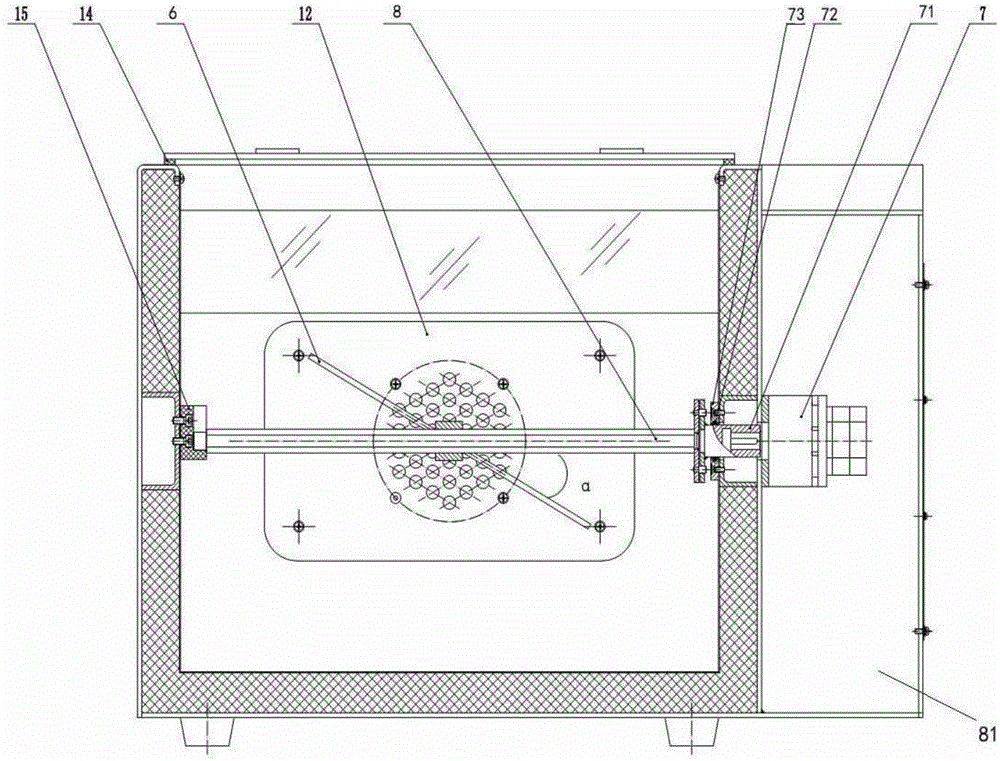

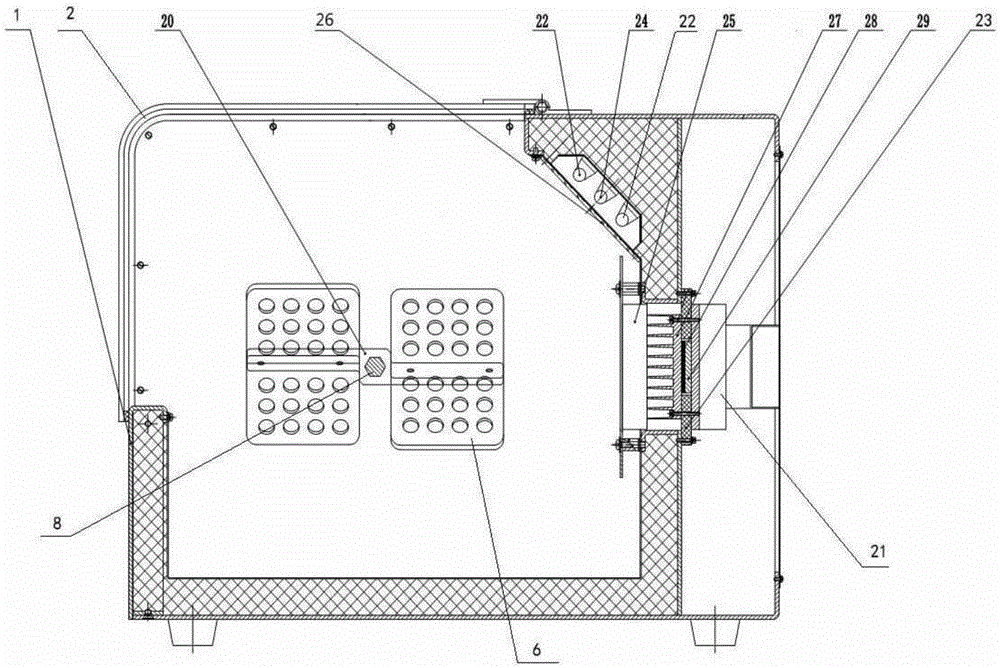

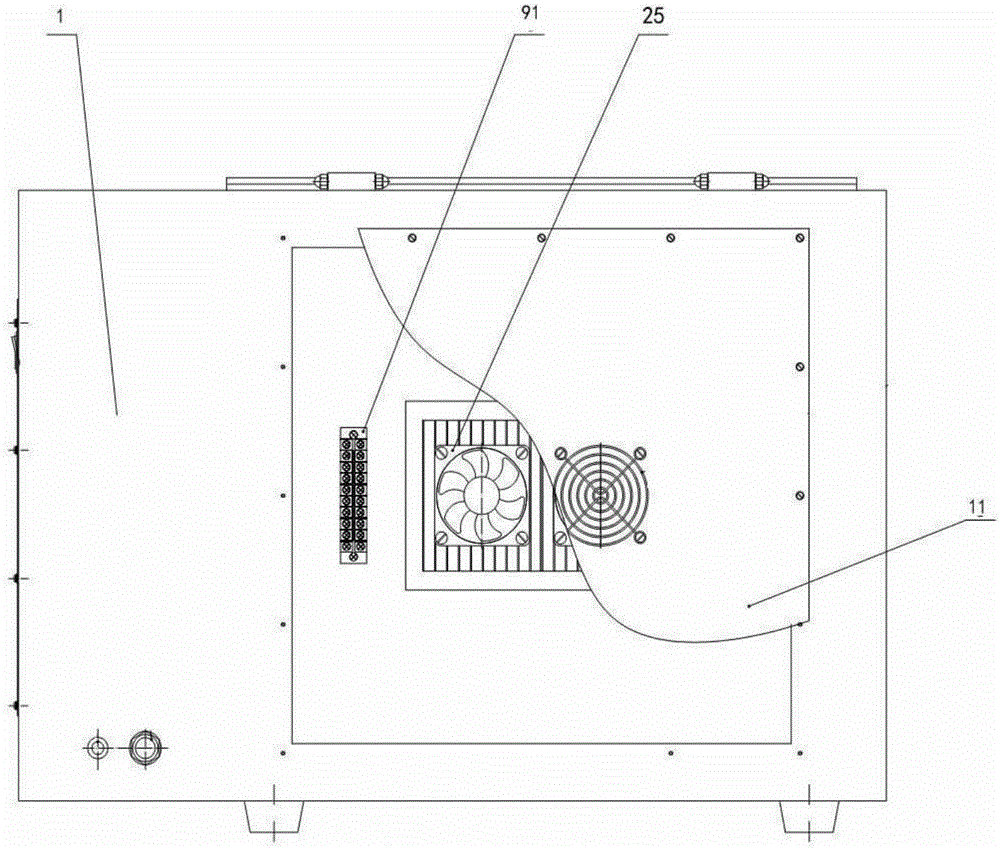

Biochemical reaction cabinet

InactiveCN105170055AObtain temperature value in real timePrecise temperature controlEnergy based chemical/physical/physico-chemical processesTemperature controlBiochemical engineering

The invention relates to a biochemical reaction cabinet. The biochemical reaction cabinet comprises a box body equipped with a box door, and a lightning component arranged in the box body and used for providing light. The biochemical reaction cabinet also comprises temperature control members, a control member and a temperature sensor. The temperature control members comprise a heating device and a refrigeration device. The arranged temperature sensor can obtain the temperature in the box body in real time, then the temperature value is sent to the control member, the control member carries out comparison with a temperature set value, if the practical temperature is higher than the set value, the refrigeration device is controlled to run, when the practical temperature is lower than the set value, the heating device is controlled to run, and thus the temperature is kept constant. The heating device and the refrigeration device are arranged to control the temperature of the box body accurately, the temperature in the box body is controlled in a large scope, after the box door is closed, the interior of the box body is sealed, no air circulation is generated inside and outside the box body, no material exchange is carried out, temperature control precision is achieved, and thus the temperature in the box body can be kept constant.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

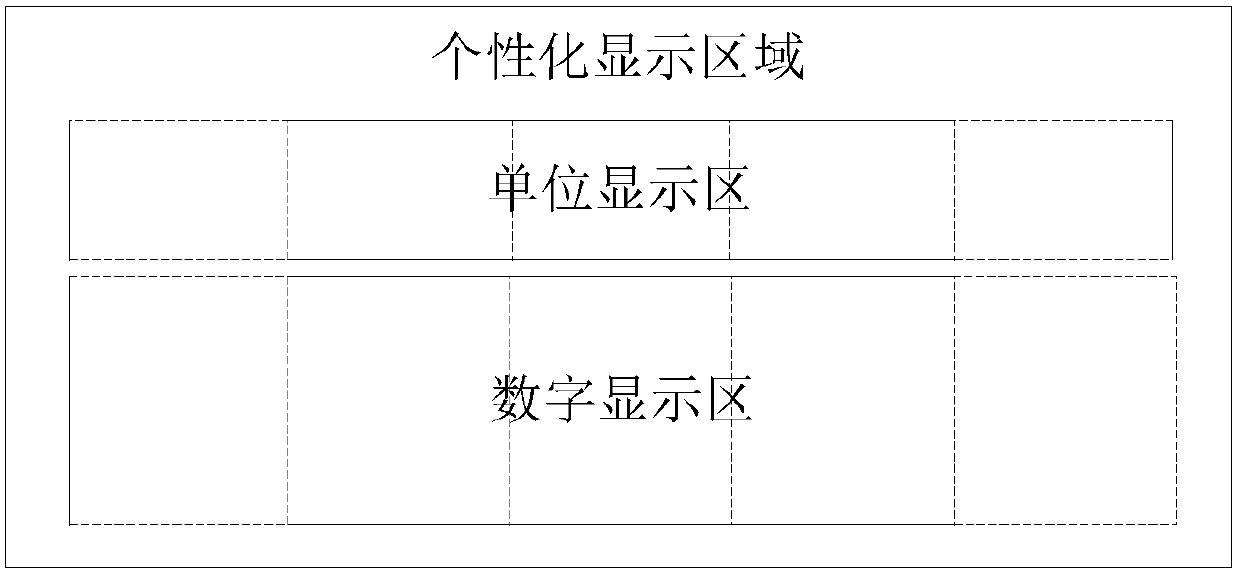

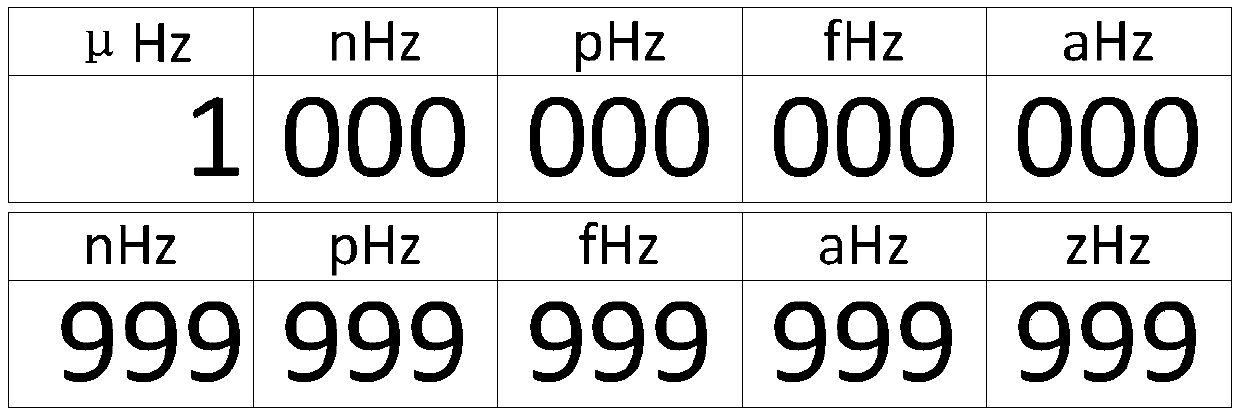

Personalized numerical value display method for high-precision measuring instrument

ActiveCN107941256AImplement anti-shake controlPrecise positioningIndication of measured valuesMeasuring instrumentData mining

The invention provides a personalized numerical value display method for a high-precision measuring instrument. A table format personalized display area of two rows and multiple columns is set; a first row is a unit display area used for displaying an ary and a unit of a measurement result; a second row is a digital display area used for displaying a measured numeric value. After measurement datais sent to an interface, the measurement data is first stored in an underlying code in a form of an initial state. At this time, the unit of the current measurement data is determined by via a measurement mode, an ary unit of the current data is determined according to the numeric value, and the numeric value is partitioned in such a way that one data group consists of three bits; the last two arefilled into a two-dimensional array of display data and drawn on a corresponding area of a display interface. Via the method, significant digit and precision control of the measured numeric value ina personalized display area can be realized, control of digits behind a decimal point of the numerical value can be achieved, control of display of the numeric value at a left part or a right part canbe realized, users are provided with a friendly and personalized digital display mode, and usage efficiency of the users is improved.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

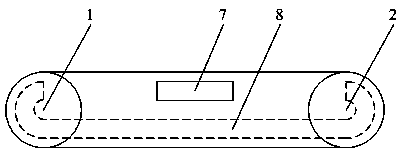

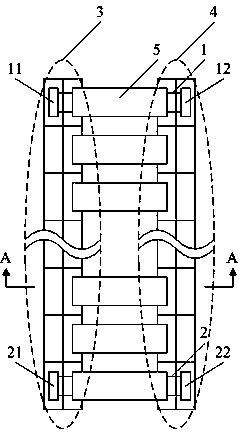

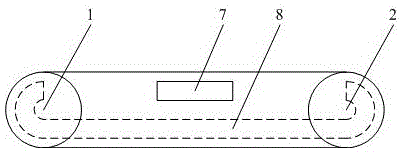

Electromagnetic principle-based driving belt with automatic sieving function

The invention discloses an electromagnetic principle-based driving belt with an automatic sieving function and belongs to the field of material sorting and conveying. The driving belt is provided with a sieving plate, the front end of the sieving plate is lapped on the third sub-chain of a front chain from the front to the back, the rear end is in shaft connection with the first sub-chain of a rear chain from the front to the back and rotates around the first sub-chain of the rear chain from the front to the back, a permanent magnet is arranged at the bottom of the front end of the sieving plate, a repellent electromagnet and an attractive electromagnet are longitudinally arranged in the plane with a drive front gear and a driven front gear, and the polarities of the attractive electromagnet and repellent electromagnet are opposite. By means of the structure, the electromagnetic principle-based driving belt with the automatic sieving function realizes the integration and synchronous running of conveying and sieving, optimizes the material sieving streamline and is capable of directly sieving objects according to the object quality without additional equipment.

Owner:HUNAN CHANGZHONG MACHINERY

Sand conveying and mixed discharging system and control method

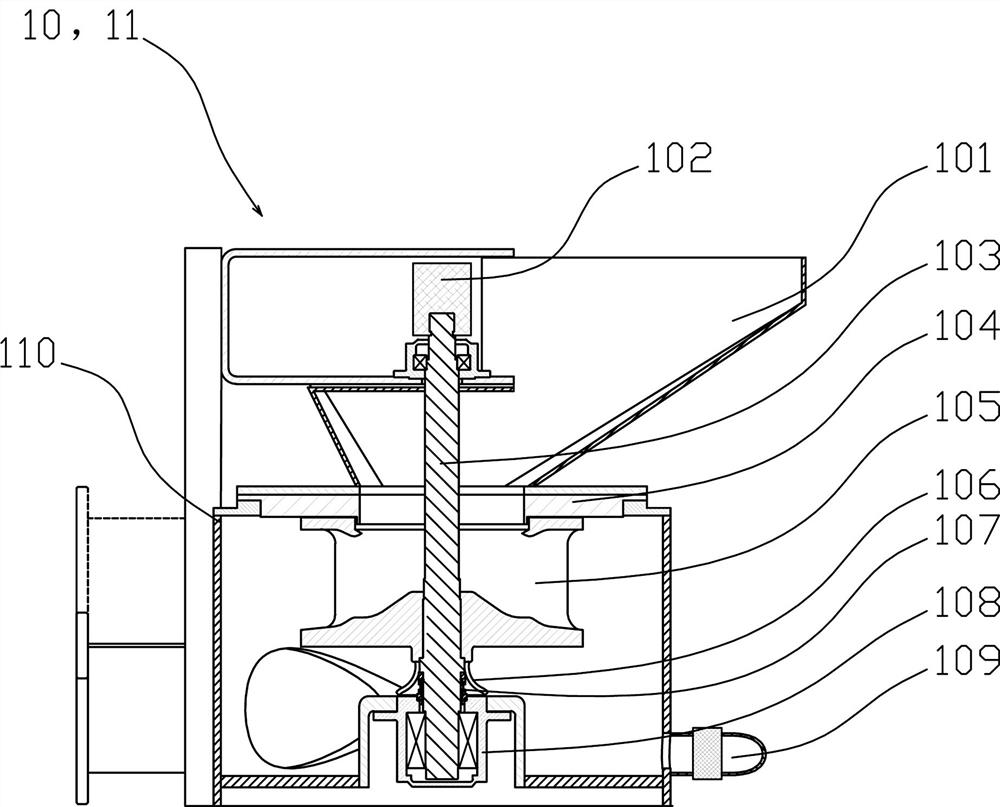

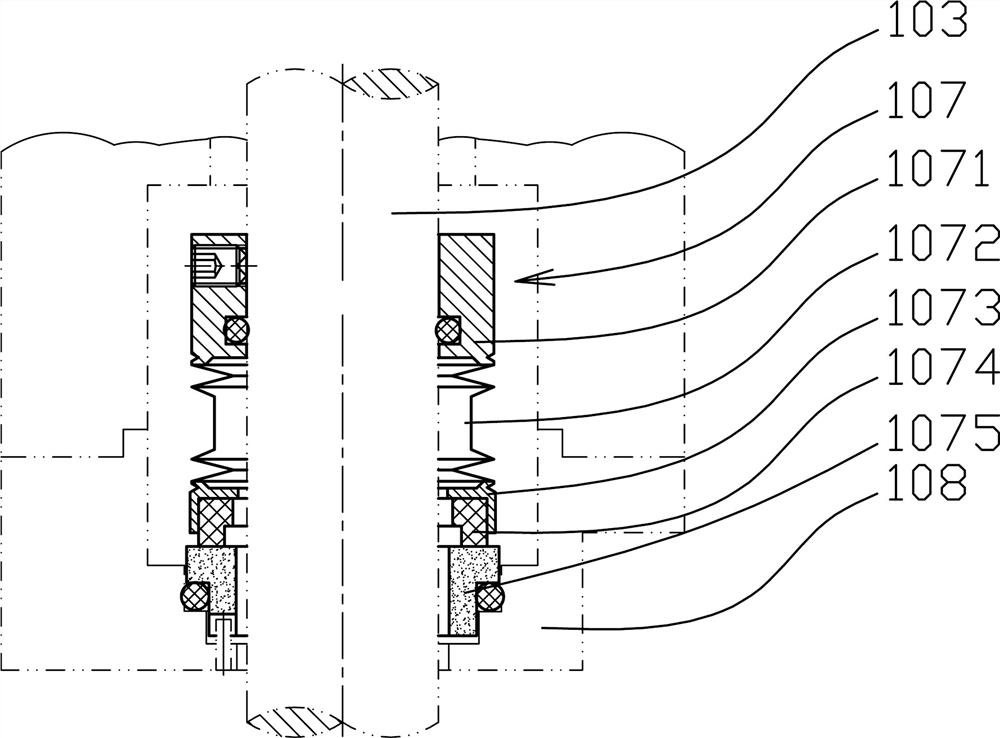

ActiveCN111005710AStable output pressureRelieve pressureTransportation and packagingFluid removalImpellerStructural engineering

The invention provides a sand conveying and mixed discharging system and a control method. The sand conveying and mixed discharging system comprises a mixed discharging device, the structure of the mixed discharging device is characterized in that a feeding hopper is arranged at the top of a tank body, a main shaft is vertically arranged in the tank body by penetrating the feeding hopper, the mainshaft is connected with a driving device driving the main shaft to rotate, a booster impeller is arranged below the feeding hopper, the booster impeller is fixedly connected with the main shaft and rotates along with the main shaft, a top opening is formed in the middle of the top of the booster impeller, the bottom of the feeding hopper communicates with the top opening, a side wall opening is formed in the side wall of the booster impeller, the top opening communicates with the side wall opening, a bearing seat is arranged at the bottom of the main shaft, and a sealing device is arranged between the main shaft and the end part of the bearing seat. According to the system, through the arrangement of the structure of the booster impeller, the centrifugal force can be utilized to maintainthe pressure in the tank body, so that an additional pressurized feed tank is not arranged, the equipment structure is greatly simplified, the installation space of the equipment is reduced, and the equipment volume is reduced.

Owner:中石化四机石油机械有限公司 +2

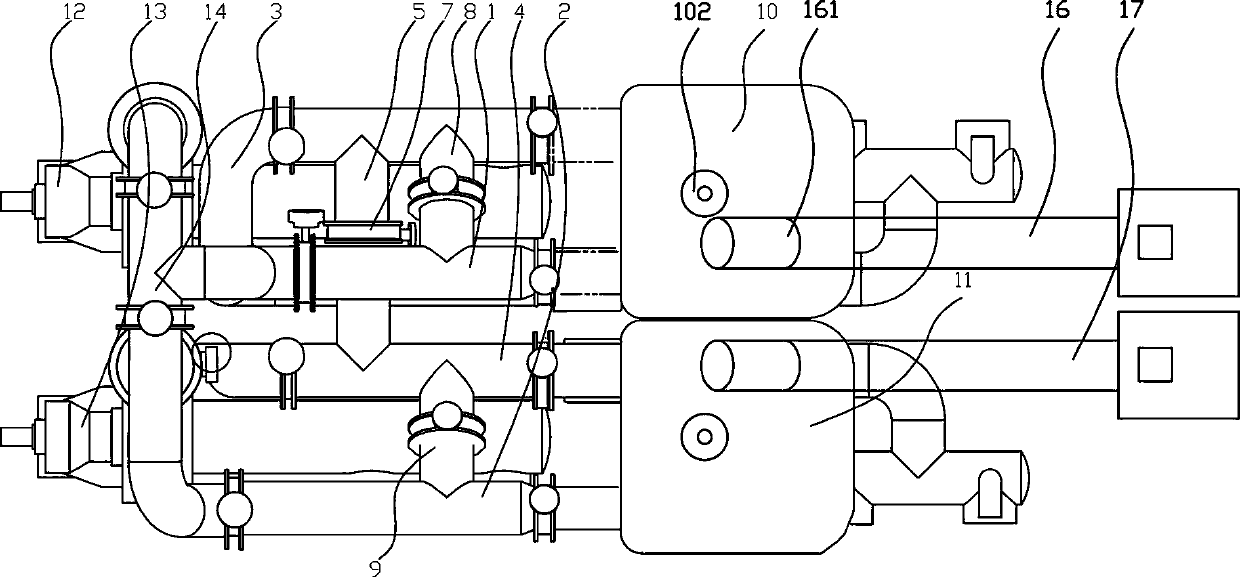

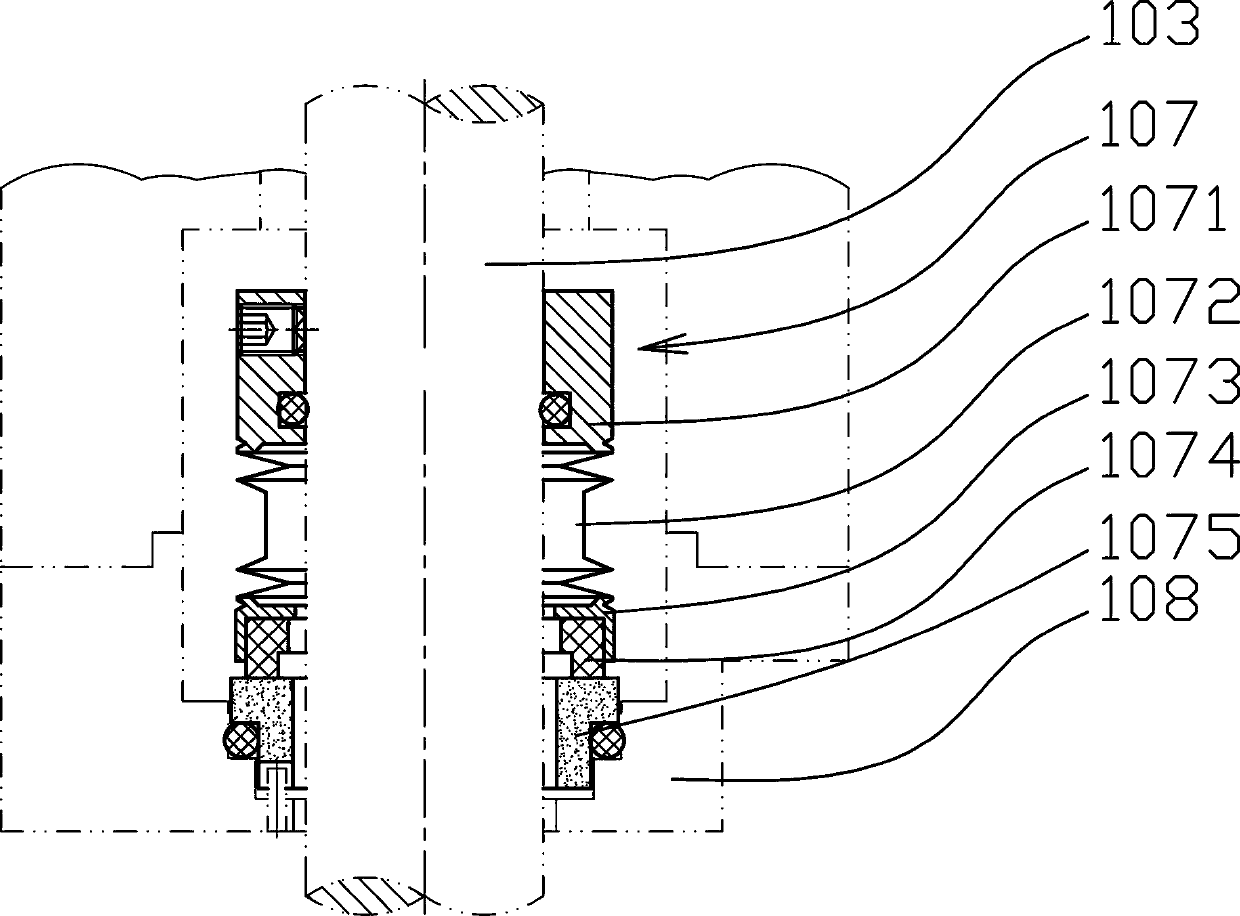

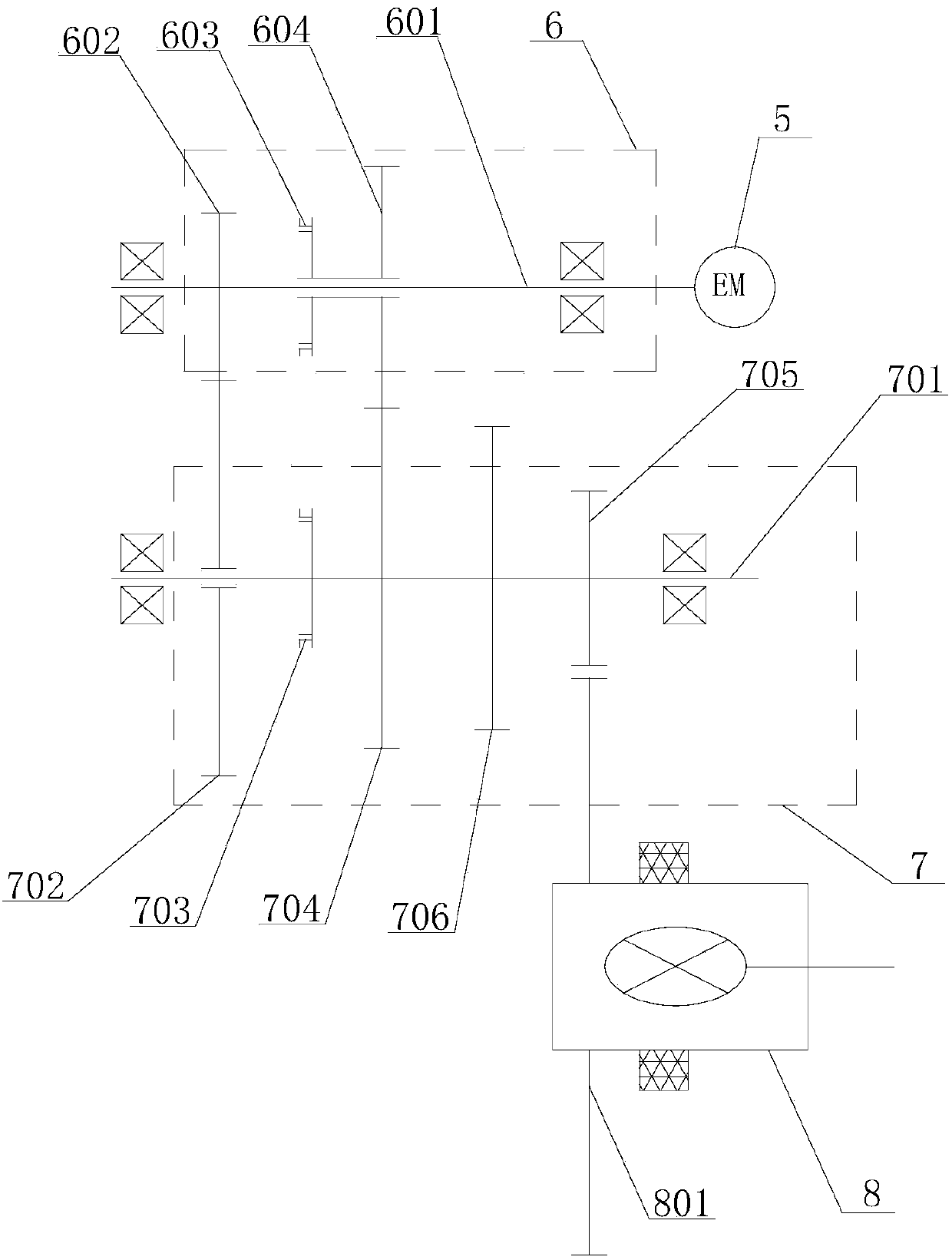

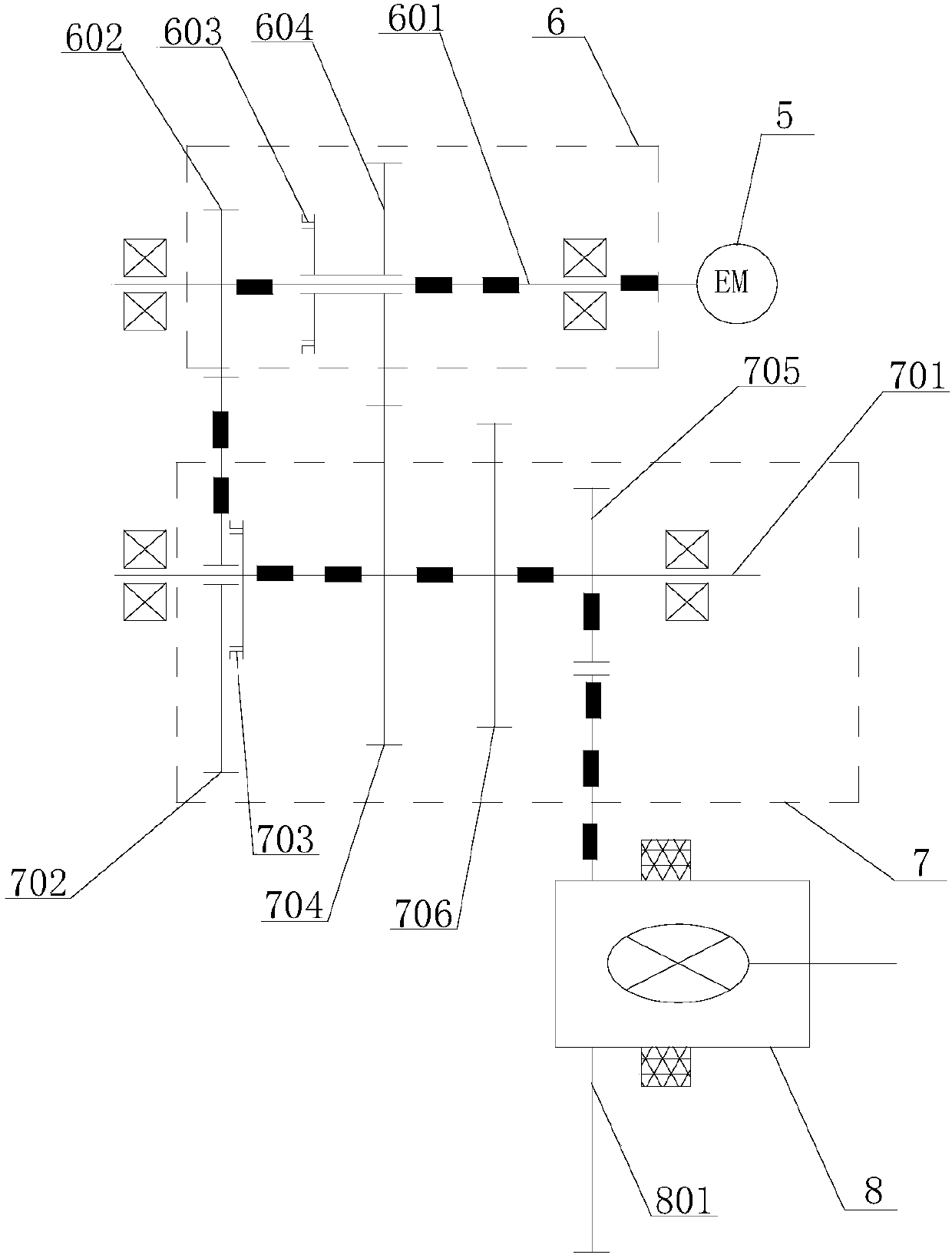

Two-shaft type two-gear electric car speed changer and electric car

InactiveCN107701666ASmooth switchingAchieving Control AccuracyToothed gearingsGearing controlElectric carsVariator

The invention discloses a two-shaft type two-gear electric car speed changer. The two-shaft type two-gear electric car speed changer comprises a motor, an input shaft assembly, an output shaft assembly and a differential assembly which are in transmission connection sequentially. The input shaft assembly comprises an input shaft, a first-gear driving gear, a second-gear synchronizer and a second-gear driving gear; the first-gear driving gear is fixed to the input shaft, and the second-gear synchronizer and the second-gear driving gear are made into a whole and then arranged on the input shaftin a sleeving mode; the output shaft assembly comprises an output shaft, a first-gear driven gear, a first-gear synchronizer and a second-gear driven gear; the output shaft is sleeved with the first-gear driven gear; and the first-gear synchronizer and the second-gear driven gear are both fixed to the output shaft. The invention further discloses an electric car comprising the two-shaft type two-gear electric car speed changer. The problems that an existing electric car is not provided with a speed changer or only provided with a single-gear speed changer, and has certain limitations on powerperformance, economical performance, climbing gradient and acceleration performance are solved.

Owner:NINGBO SHANGZHONGXIA AUTOMATIC TRANSMISSION +1

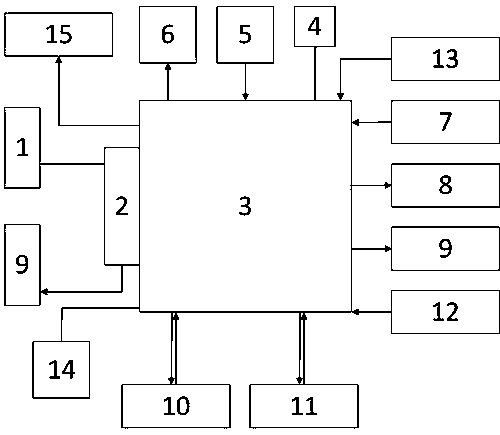

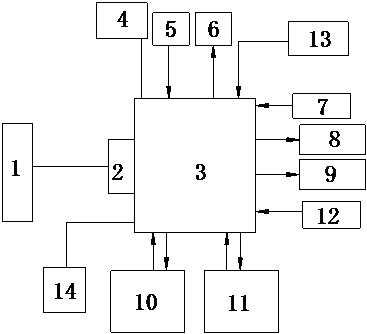

ARM-based 3D printer control system

InactiveCN108656560AAchieving Detection AccuracyAchieving Control AccuracyAdditive manufacturing apparatusManufacturing data aquisition/processingElectricityCommunication interface

The invention discloses an ARM-based 3D printer control system, and relates to the technical field of 3D printer tools. The ARM-based 3D printer control system is characterized in that an upper computer is connected to a communication interface through a wire, the communication interface is installed on a communication port of an ARM micro-controller, and the power end of the ARM controller is connected to a power module through a wire; the input end of the ARM controller is electrically connected to a temperature detector, an angle detector, a smoke detection sensor and a camera correspondingly, the output end of the ARM controller is electrically connected to a heating bed, a three-axis stepping motor, a material extrusion motor and a fault alarm correspondingly, the storage end of the ARM controller is electrically connected to a storage module, and a touch display screen is connected to the input and output ends of the ARM controller through a data line; a pressure sensor is arranged at the lower part of the heating bed; and a radiator is installed inside the touch display screen, and a protective frame is installed on the outer side of the touch display screen. According to the ARM-based 3D printer control system, information detection and accurate control can be realized, and safety and fault detection can be realized, the use is convenient, the operation is simple and convenient, and the time can be saved.

Owner:HARBIN UNIV OF SCI & TECH

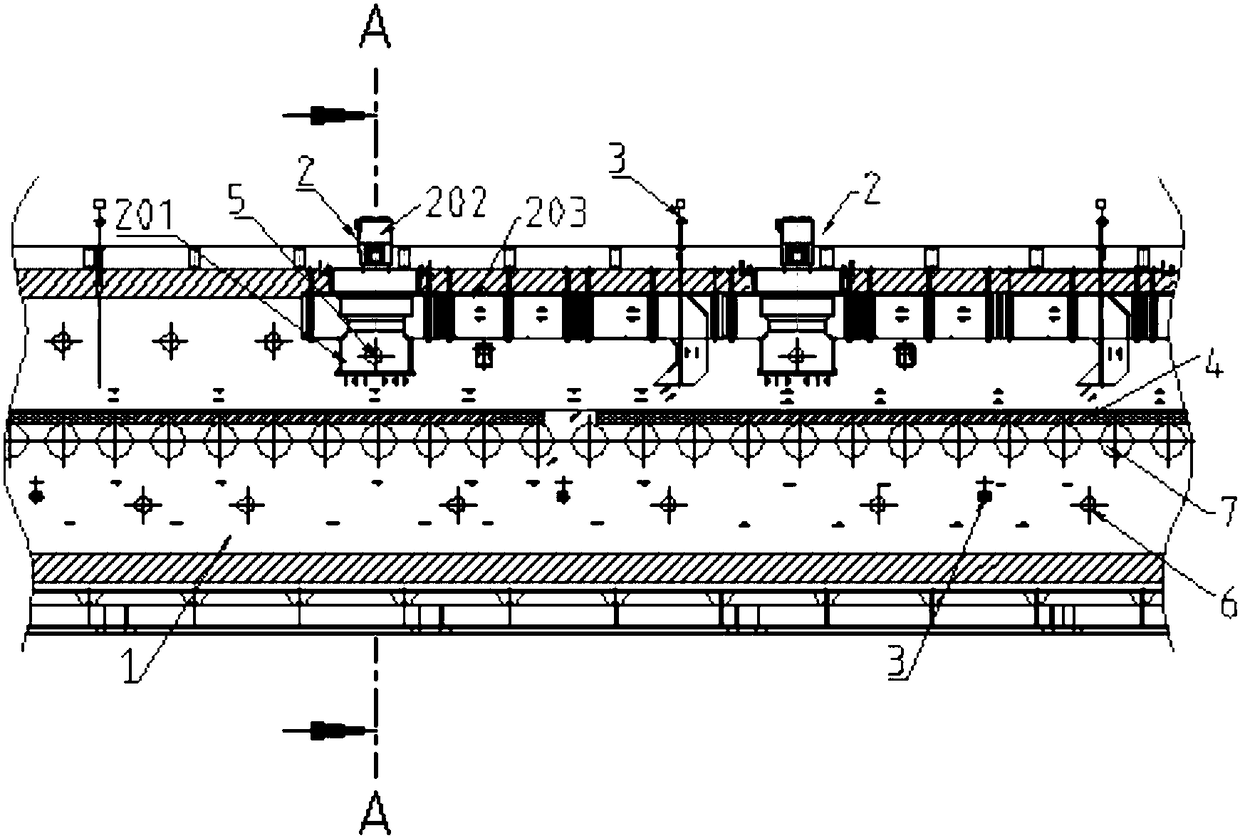

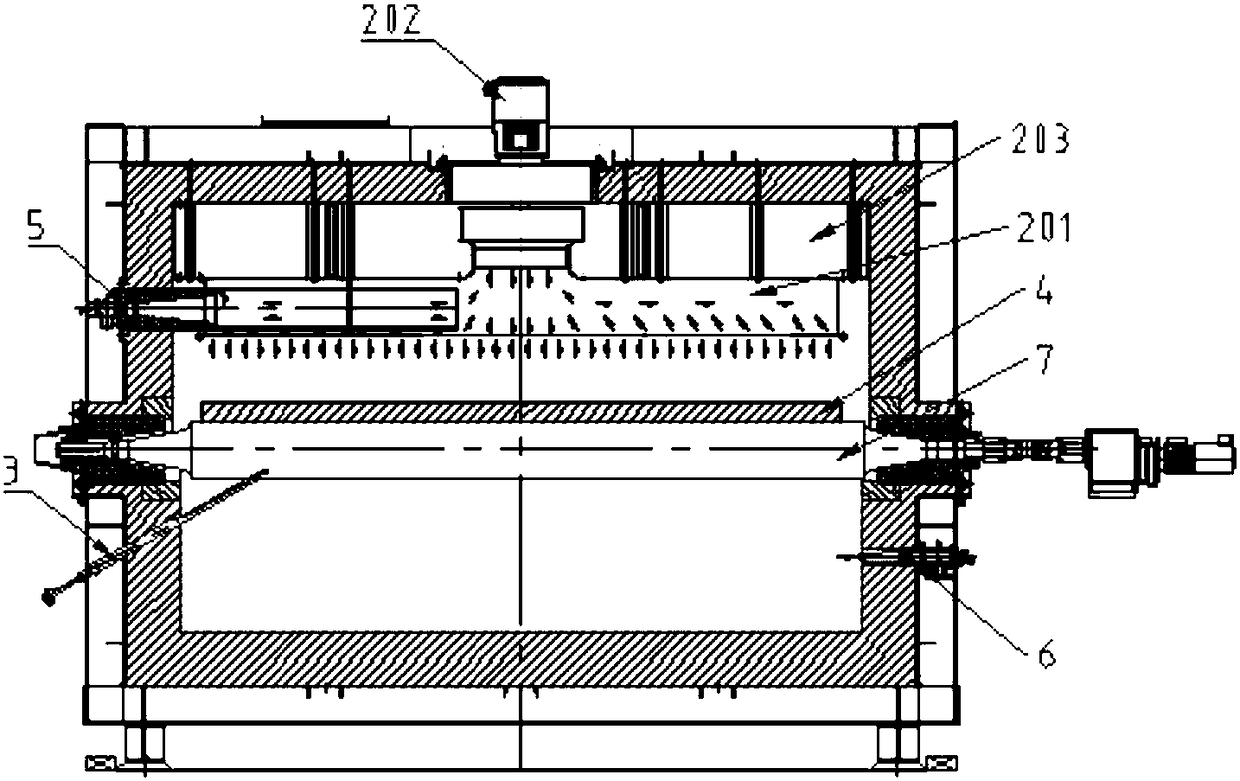

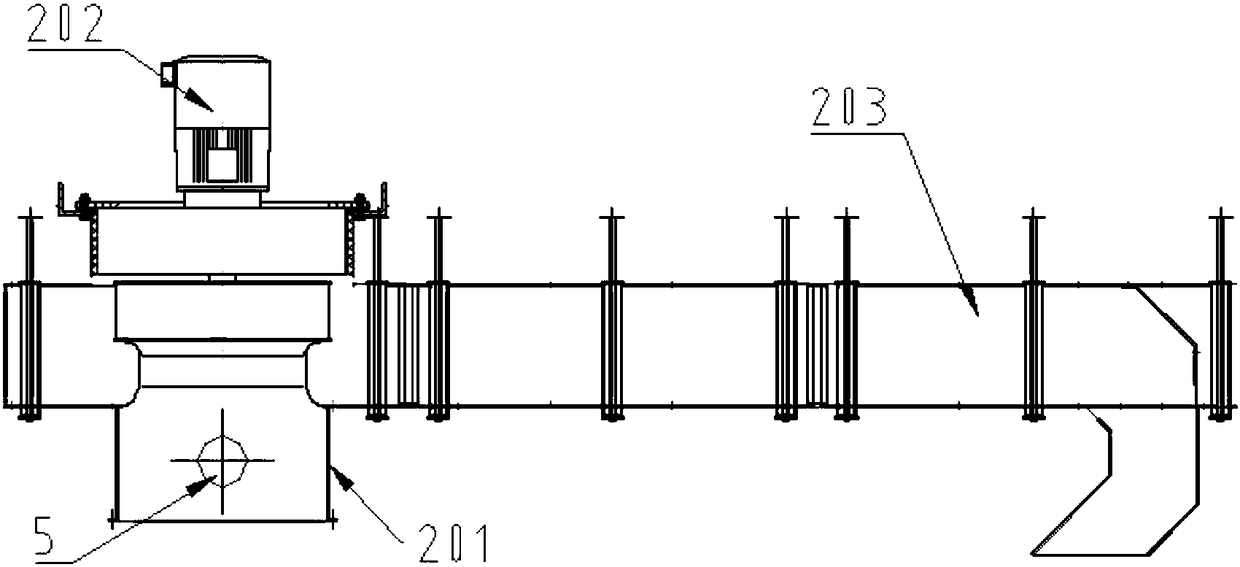

Wide and thick plate roller hearth furnace system with severe convection circulating devices

PendingCN108546815AGuaranteed temperature uniformityUniform temperatureFurnace typesHeat treatment furnacesFlue gasEngineering

The invention provides a wide and thick plate roller hearth furnace system with severe convection circulating devices. In the furnace length direction, the multiple flue gas severe convection circulating devices are arranged on the upper portions of furnace rollers of a heat preservation segment of a wide and thick plate low-temperature tempering roller hearth furnace. Each flue gas severe convection circulating device comprises a centrifugal fan, a flow guide air suction pipeline, a flow guide air outlet pipeline and an upper nozzle, wherein a flame spray-out opening of the upper muzzle is connected with the flow guide air suction pipeline, an air suction opening of the centrifugal fan is connected with the flow guide air suction pipeline, and an air outlet of the centrifugal fan is connected with the flow guide air outlet pipeline. The adjacent flue gas severe convection circulating devices are connected end to end. According to the wide and thick plate roller hearth furnace system,uniformity of flue gas temperature and control precision of the flue gas temperature can be achieved better, and therefore temperature uniformity of wide and thick plates is guaranteed.

Owner:ТЕНОВА ТЕКНОЛОДЖИЗ (ТЯНЬЦЗИНЬ) КО., ЛТД.

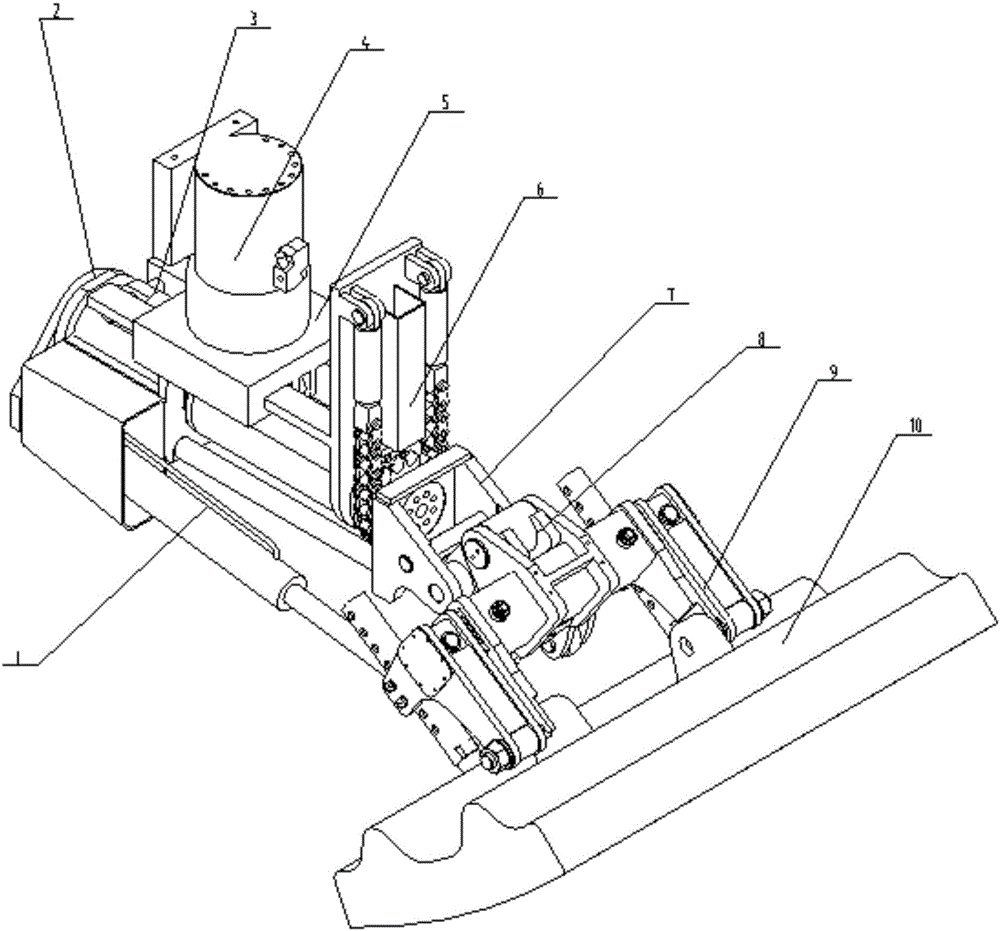

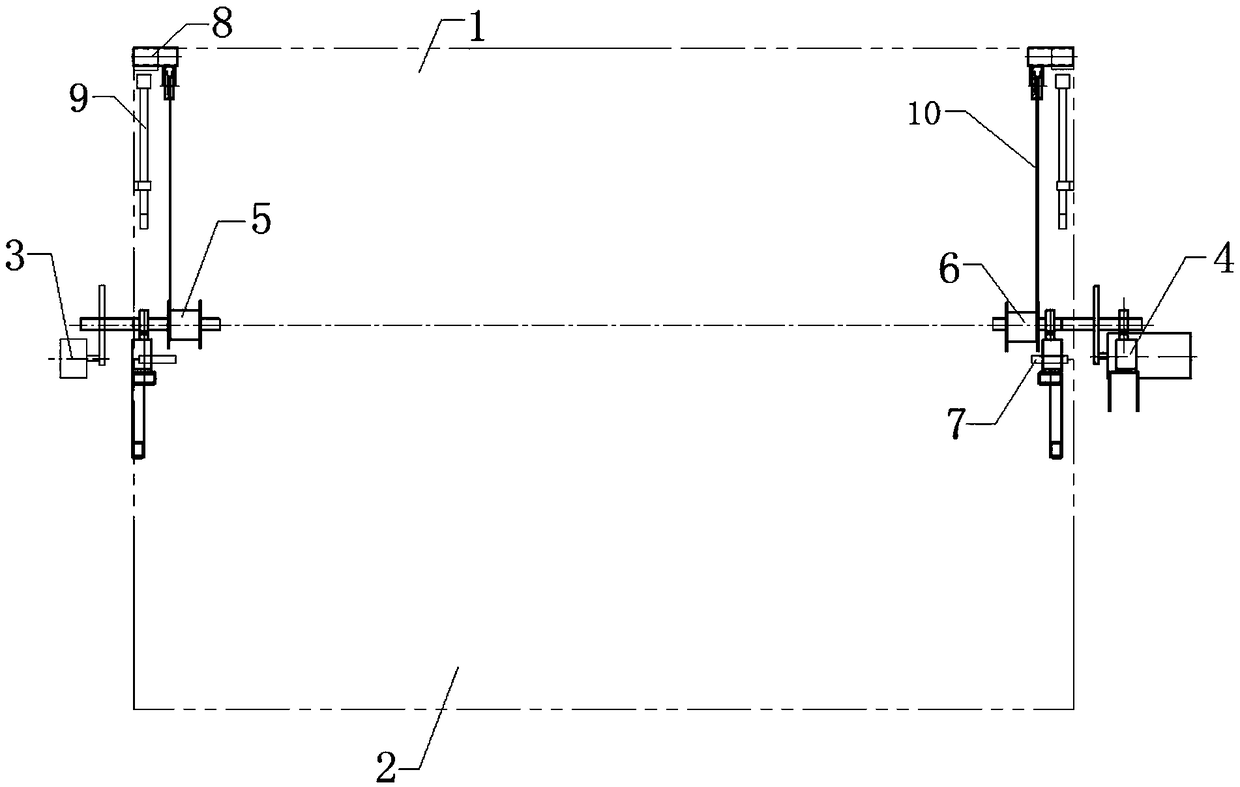

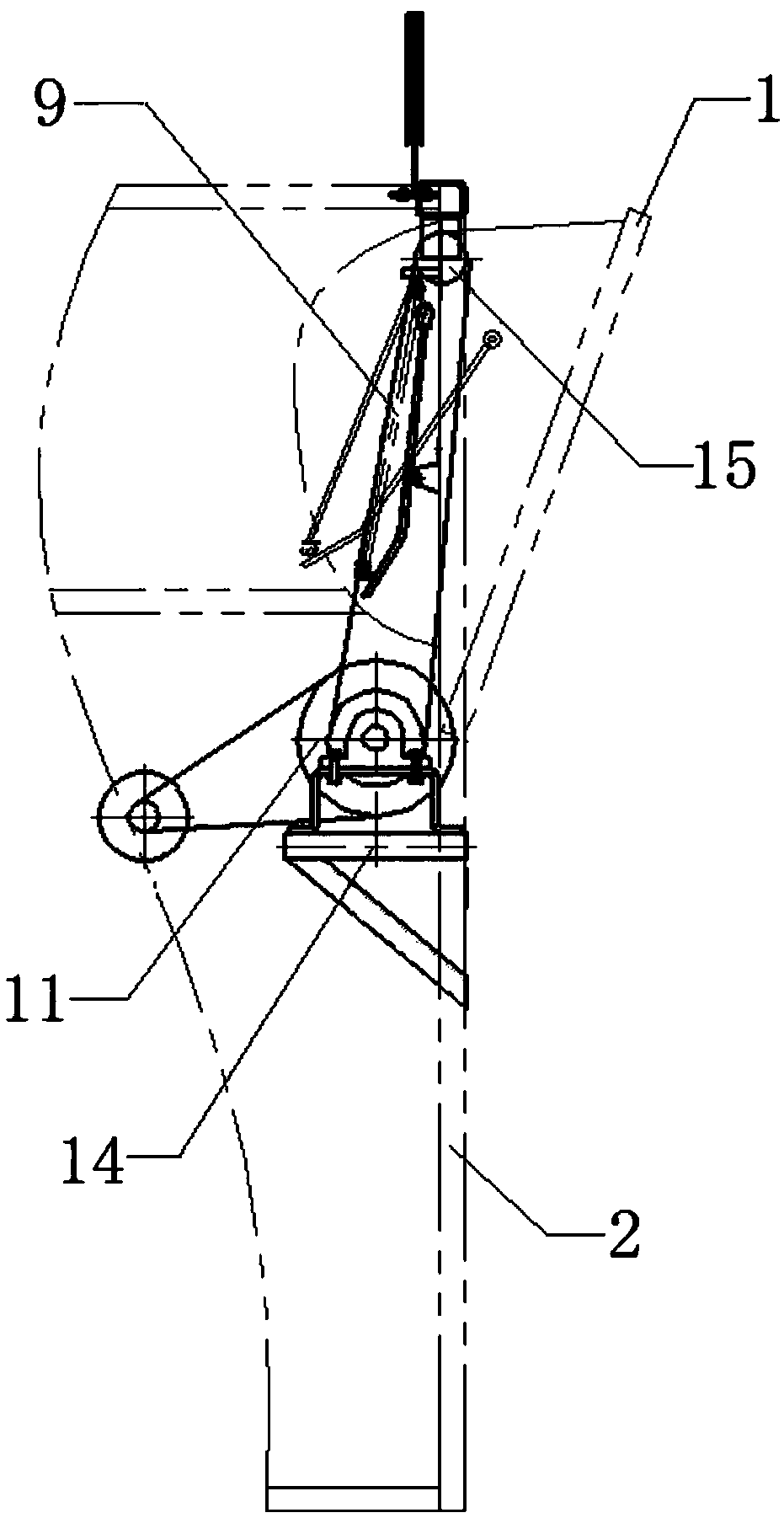

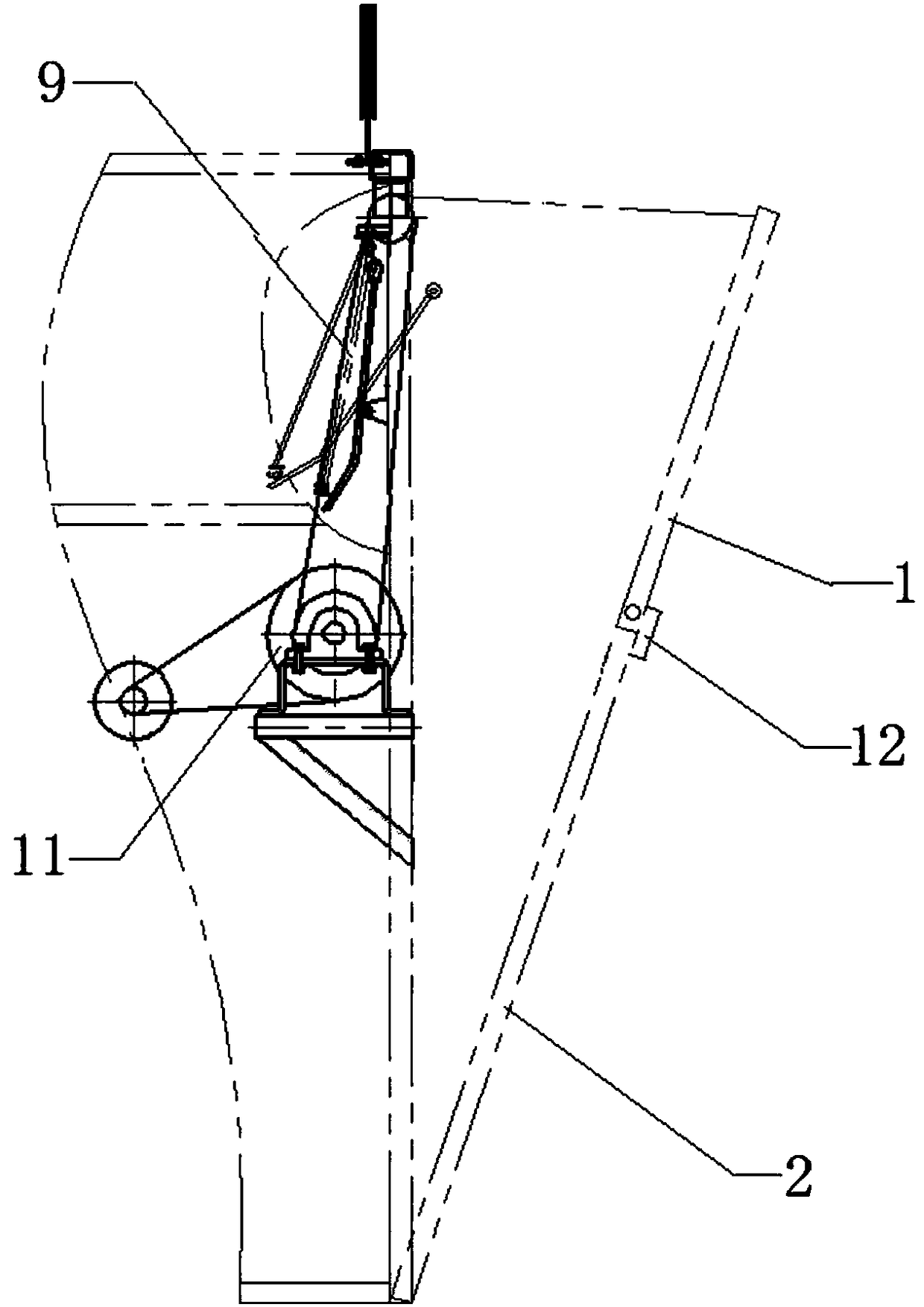

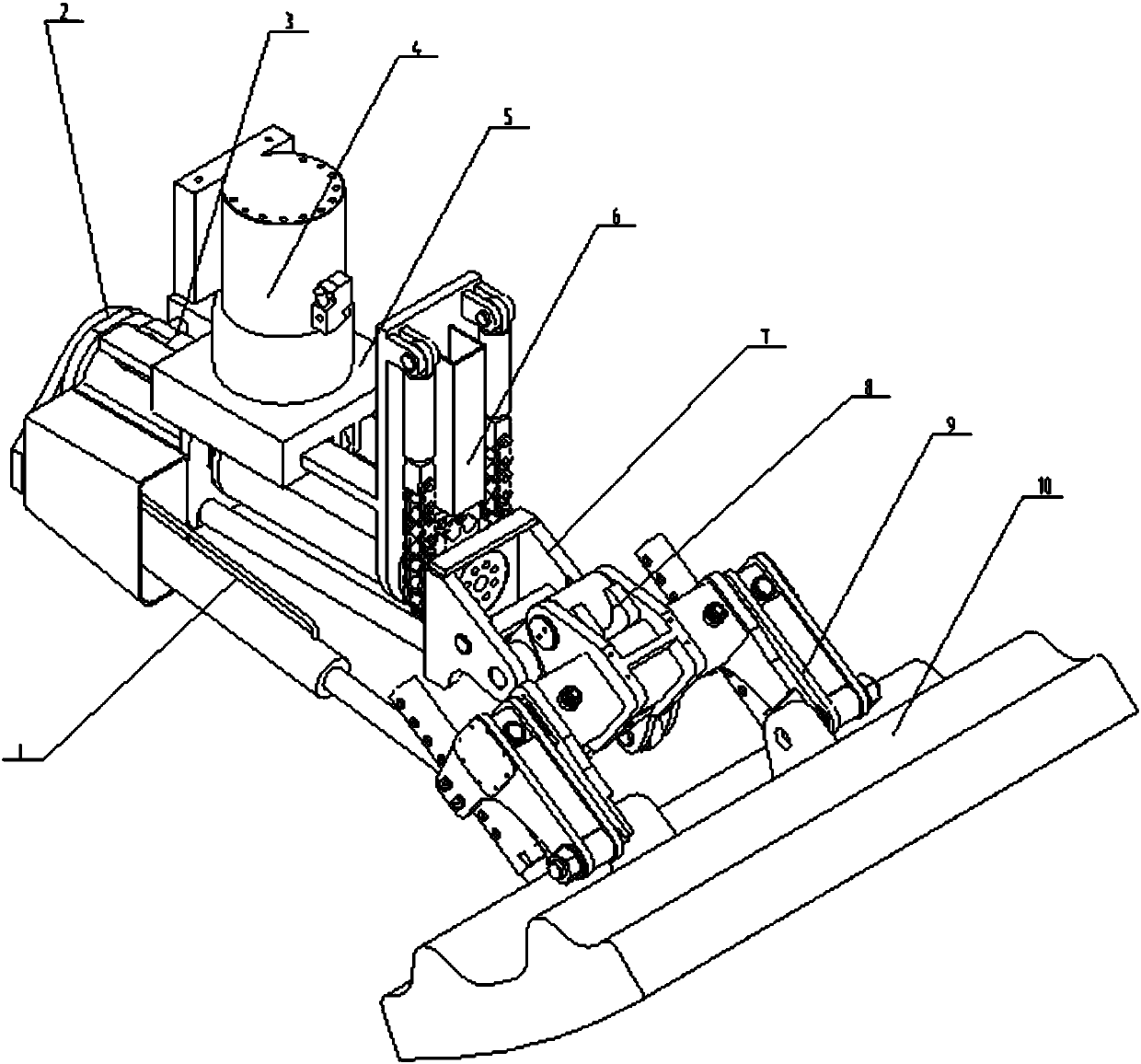

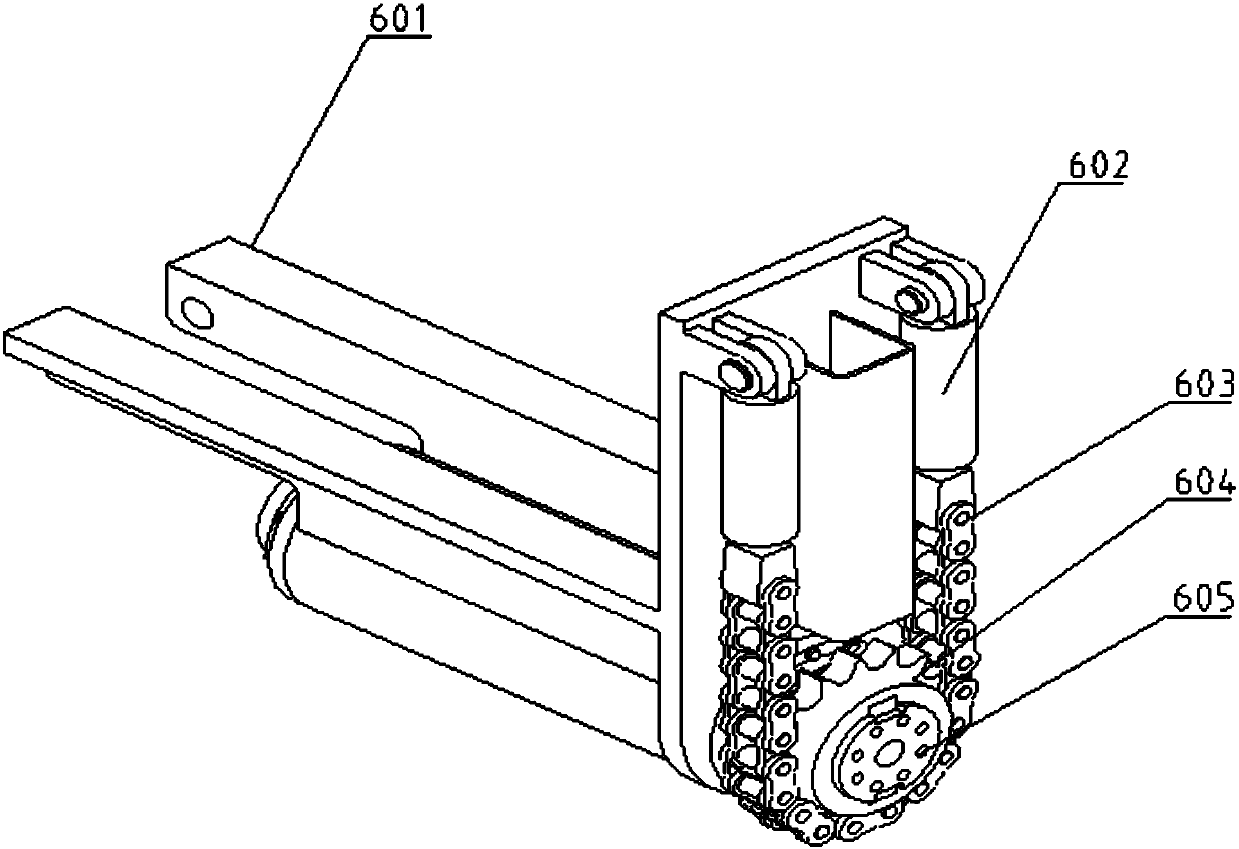

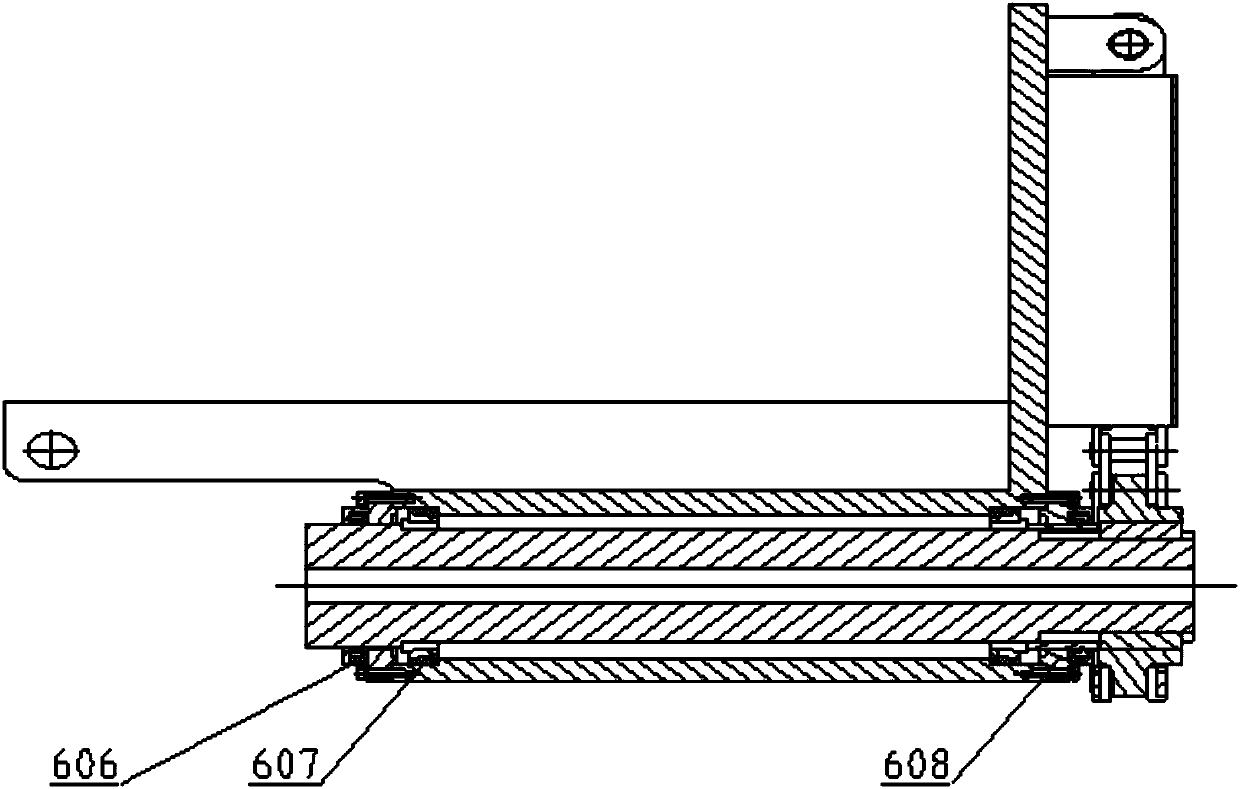

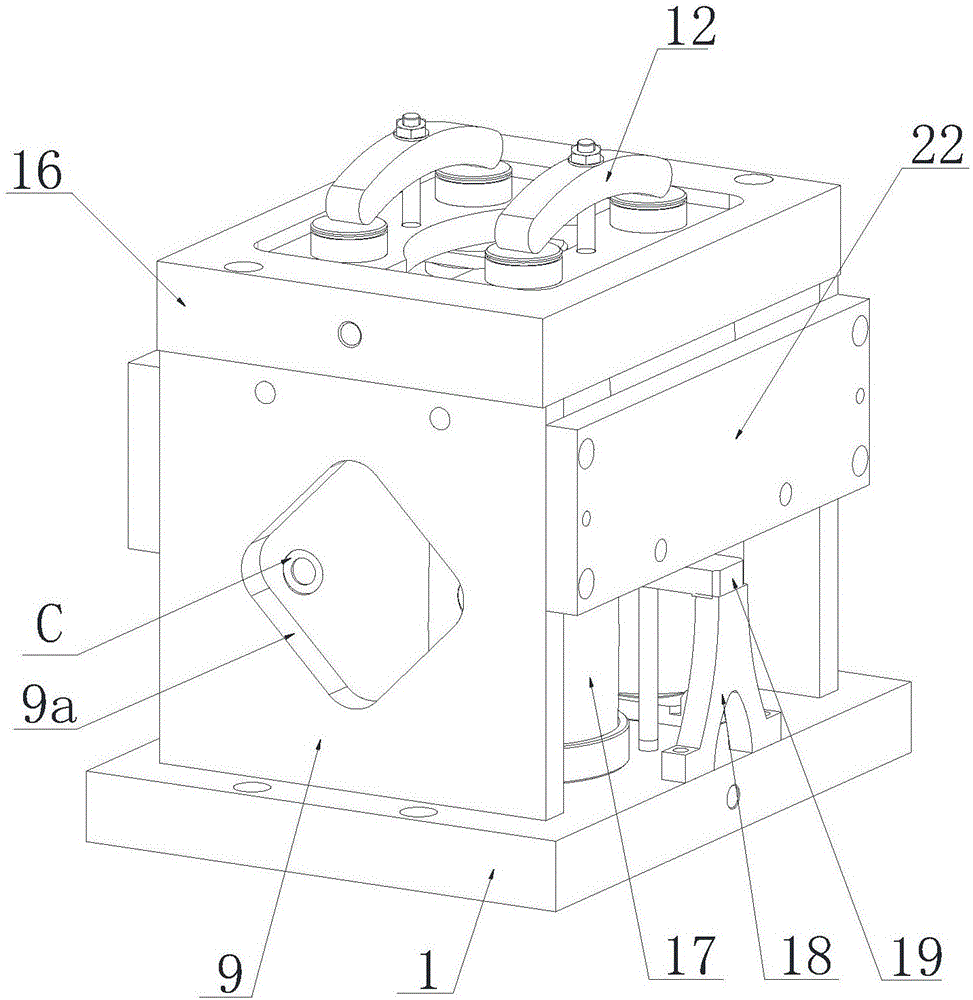

Manipulator design method for installing mill lining

ActiveCN106737617AAchieve precise positioningImprove work efficiency and maintenance safetyProgramme-controlled manipulatorManipulatorEngineering

The invention provides a manipulator design method for installing a mill lining. A rolling pendulum device, a gripping device, other accessories and a first cylinder, a second cylinder, a third cylinder, a forth cylinder and a swinging cylinder fit to the accessories are designed in the manipulator, wherein the first cylinder has the rolling joint action in the rolling pendulum device, and the second cylinder has the joint action of back-and-forth movement; the third cylinder has the pitch joint action, and the forth cylinder has the gripping joint action in the gripping device; the swinging cylinder has the joint action of up-and-down swing; multiple displacements of the manipulator in space are achieved through these different joint actions, and the high-load drive of the manipulator is achieved through arranging these cylinders; the structure size of the manipulator is reduced. In the invention, the degree of mechanization and automation in the replacement of the mill lining is greatly improved, and the labor intensity is reduced; the replacement time of the lining is shortened, and potential safety hazards in manual operation are avoided.

Owner:LUOYANG CITIC HIC AUTOMATION ENG

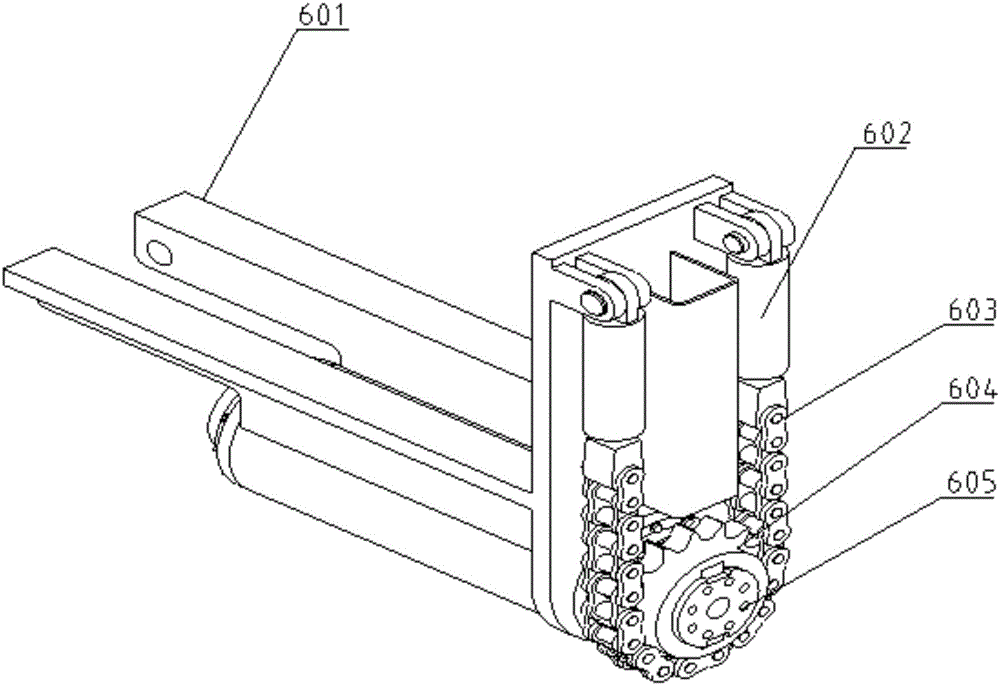

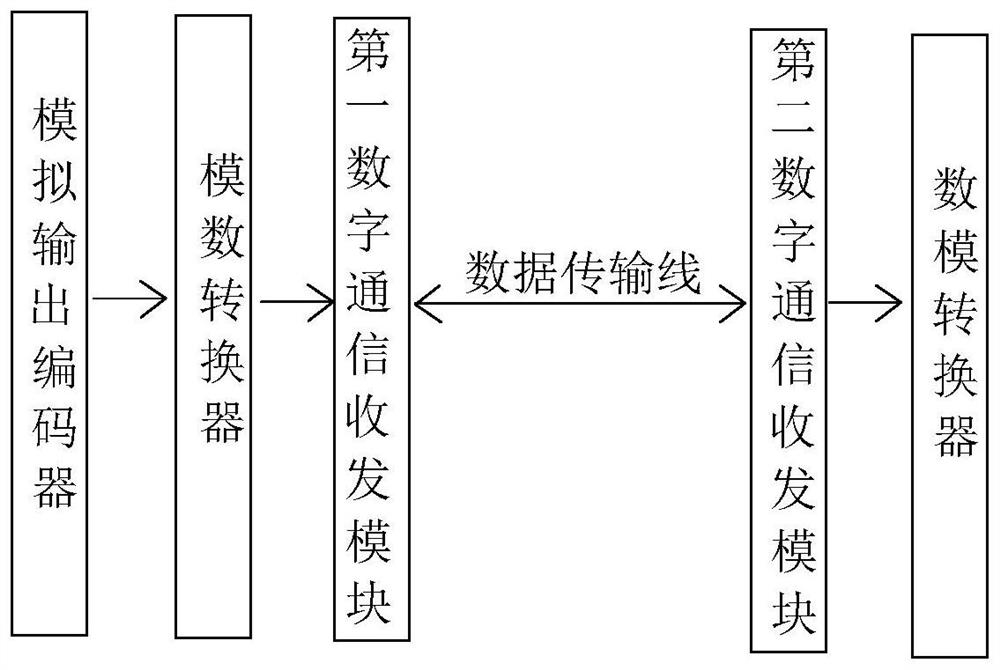

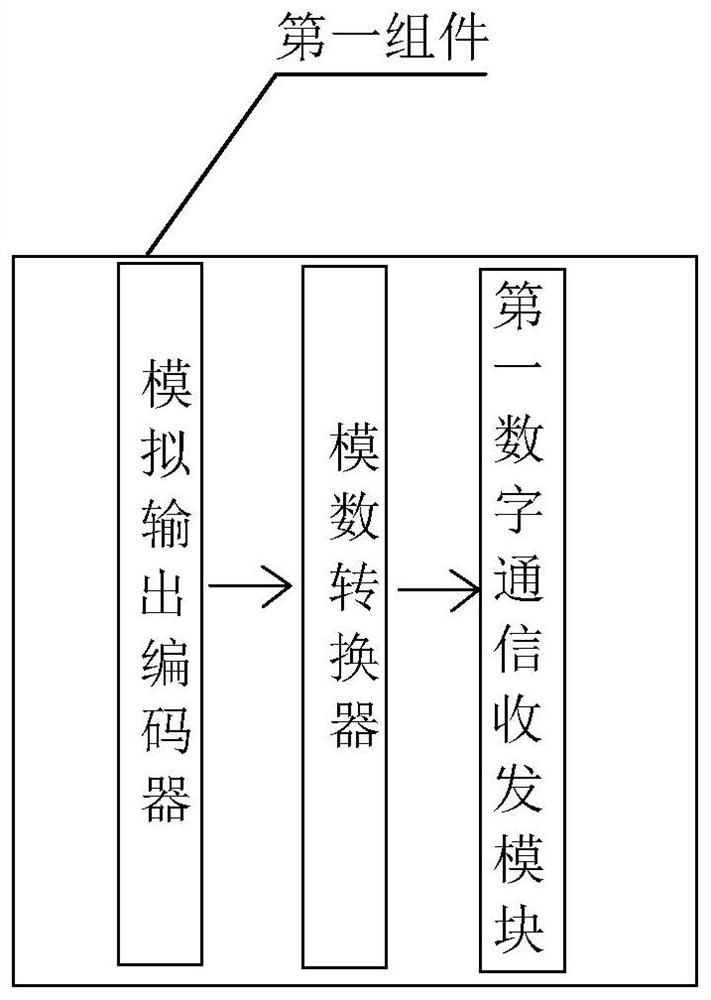

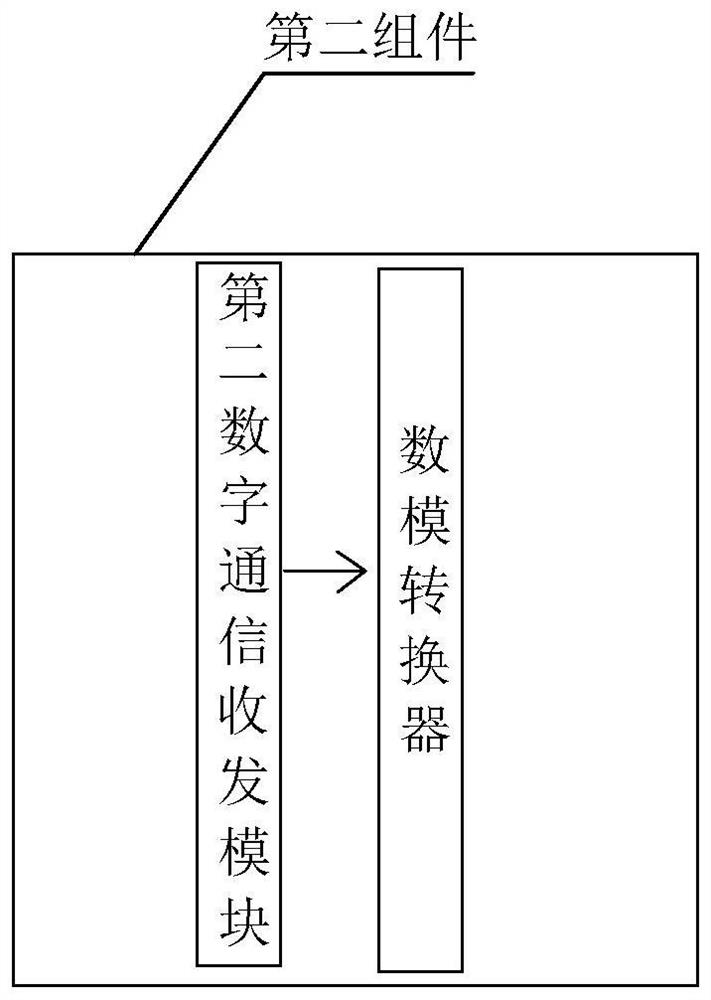

Application method of analog output encoder based on analog access port driver

PendingCN114268317AReduce connectionsOvercome the defects of multiple cores in data transmission linesAnalogue/digital conversionProgramme controlInformation processingSoftware engineering

The invention relates to the application field of analog output encoders, in particular to an analog output encoder using method based on an analog access port driver. The analog output encoder using method is good in anti-interference performance. According to the technical scheme, analog information output by the analog output encoder is converted into digital information through the analog-to-digital converter, after information processing, the number of wire cores of the data transmission line is greatly reduced in a serial digital communication transmission mode, the data transmission line can be sent to the position near the driving controller in a long-line mode, and the data transmission efficiency is improved. Data information is converted into analog information through a digital-to-analog converter, and then the digital-to-analog converter is connected with a driving controller. Compared with the prior art, the method provided by the invention has the characteristics of good anti-interference performance, low cost and high stability, is suitable for a driving controller adopting an analog information port in the existing market, and particularly can still realize accurate driving control in a high-speed state.

Owner:浙江锐鹰传感技术有限公司

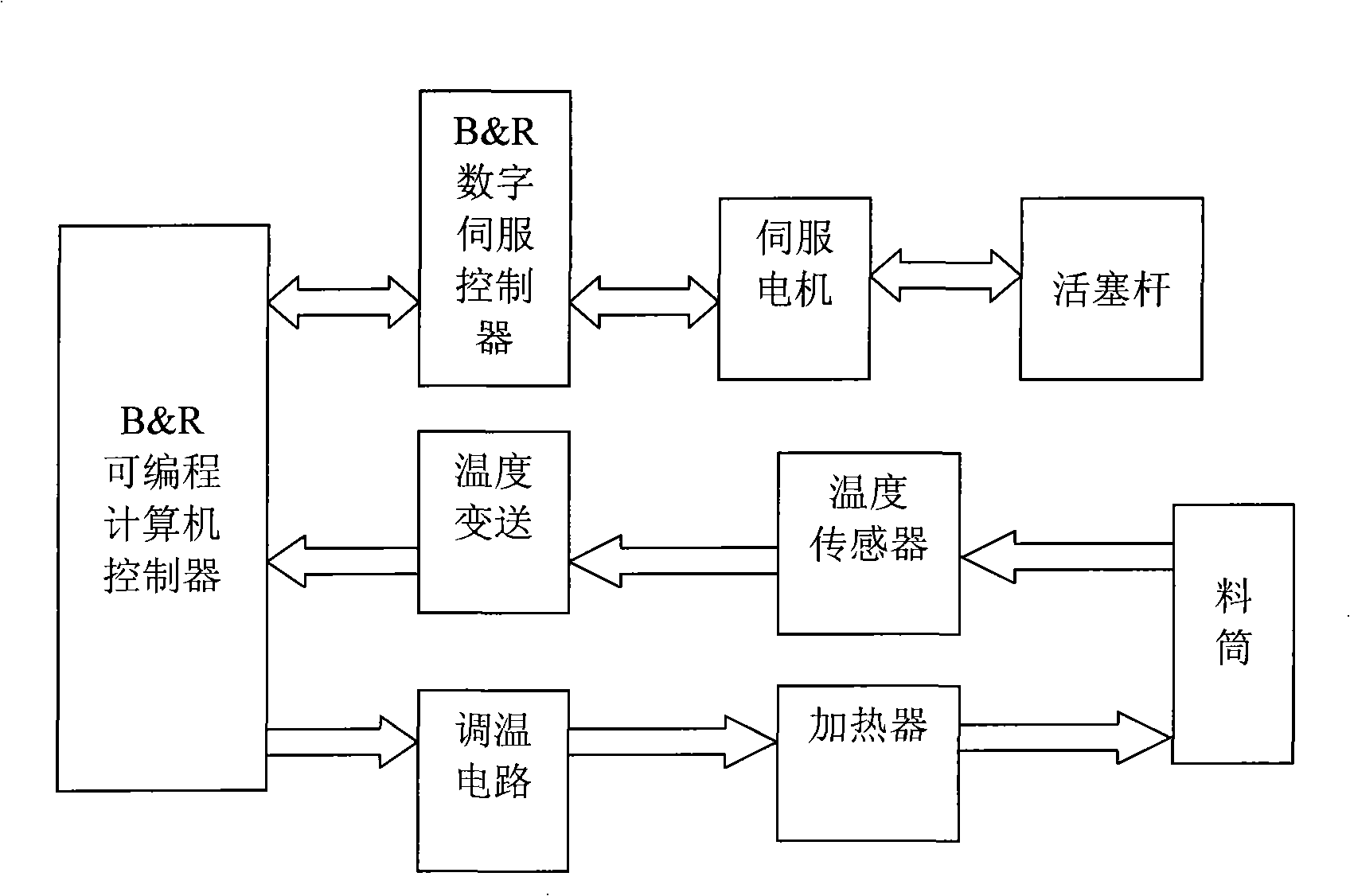

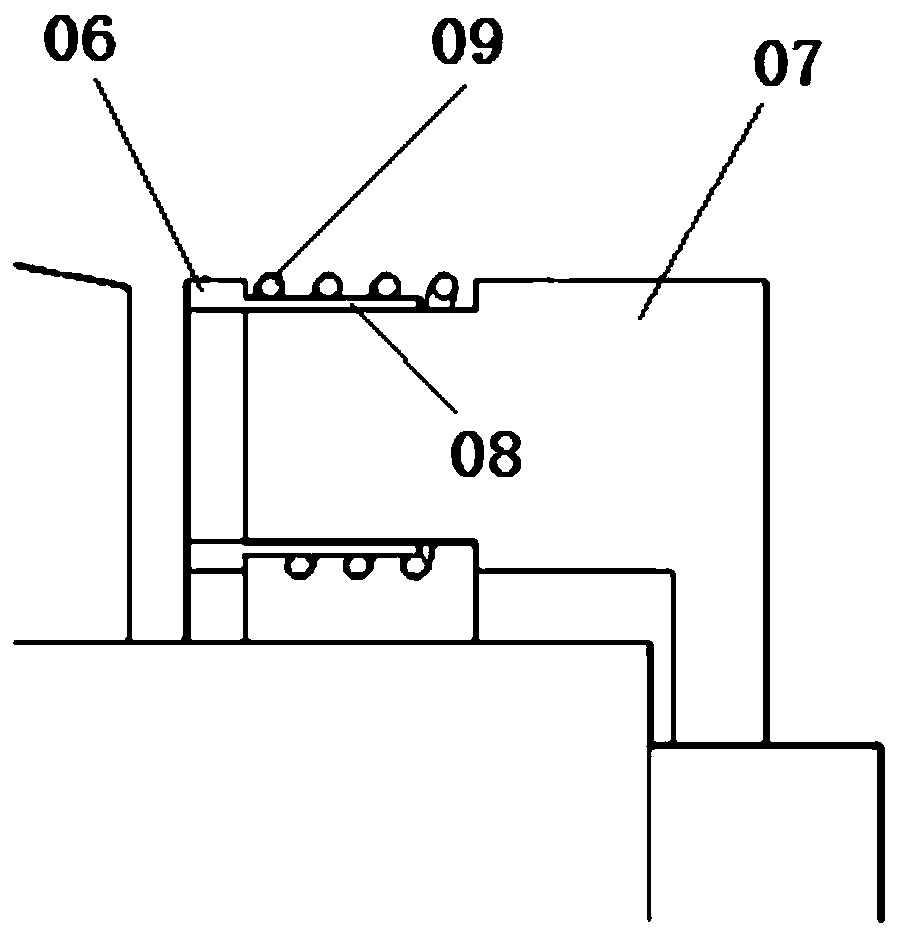

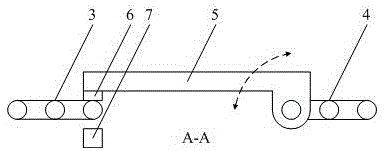

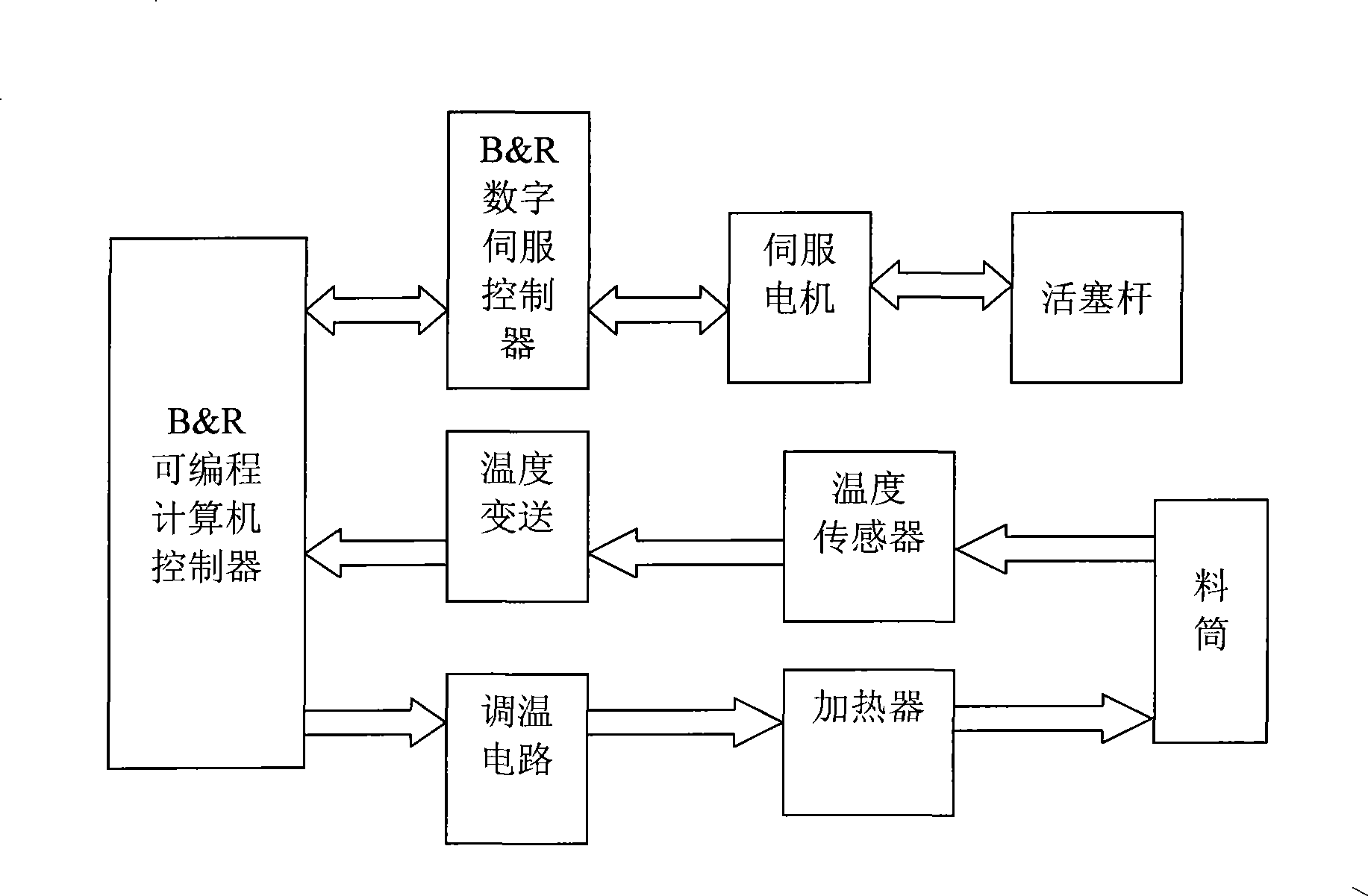

Electrical control method of rheological measurement device

ActiveCN101430266BRealize collaborative controlEfficient use ofFlow propertiesTemperature controlMeasurement device

The invention relates to an electric control method of a rheological testing device. A programmable computer controller is used as a controller. The method uses a digital intelligent servo system control the motion speed of a piston rod and a parametric control algorithm to collocate the speed ring parameter of the servo system at different operation speed sections of the piston rod. A temperature sensor and a special conversion module are used for detecting barrel temperature and transforming signals. Control programs including intelligent temperature control, digital intelligent servo and the like are defined with different circulating periods and stored in a user memory of the programmable computer controller according to task grades, so as to control and adjust the temperature of a barrel and the motion speed of the piston rod. The invention realizes the speed regulation ratios index of 1:20000 of the piston rod, obtains good dynamic and static indexes and integrates the precise detection technology and intelligent control algorithm, thereby realizing the control precision of plus or minus 0.1 DEG C of the temperatures of three sections of the barrel and realizing the cooperative control of a complex control object of the multifunctional rheological testing device.

Owner:HUNAN UNIV OF TECH +1

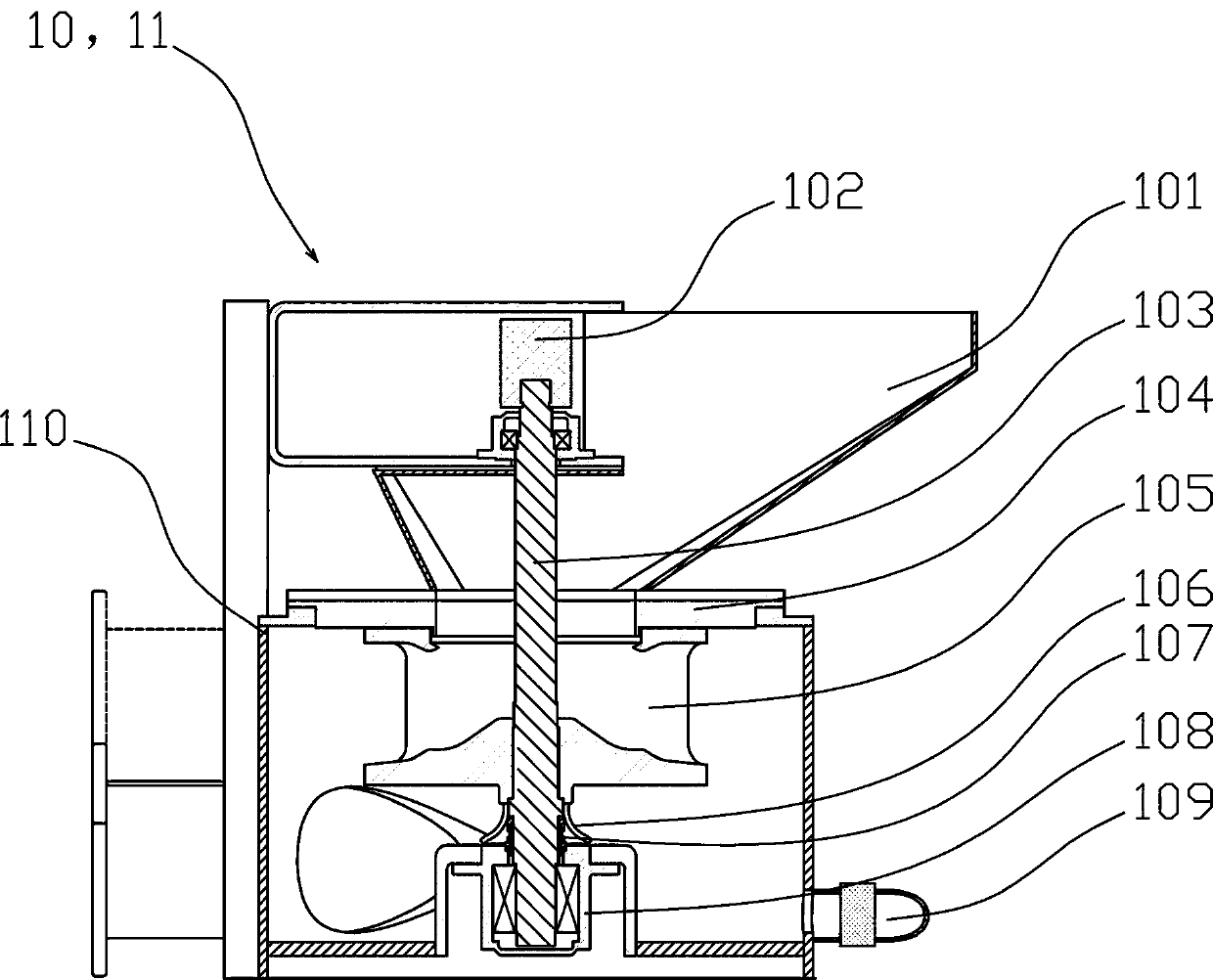

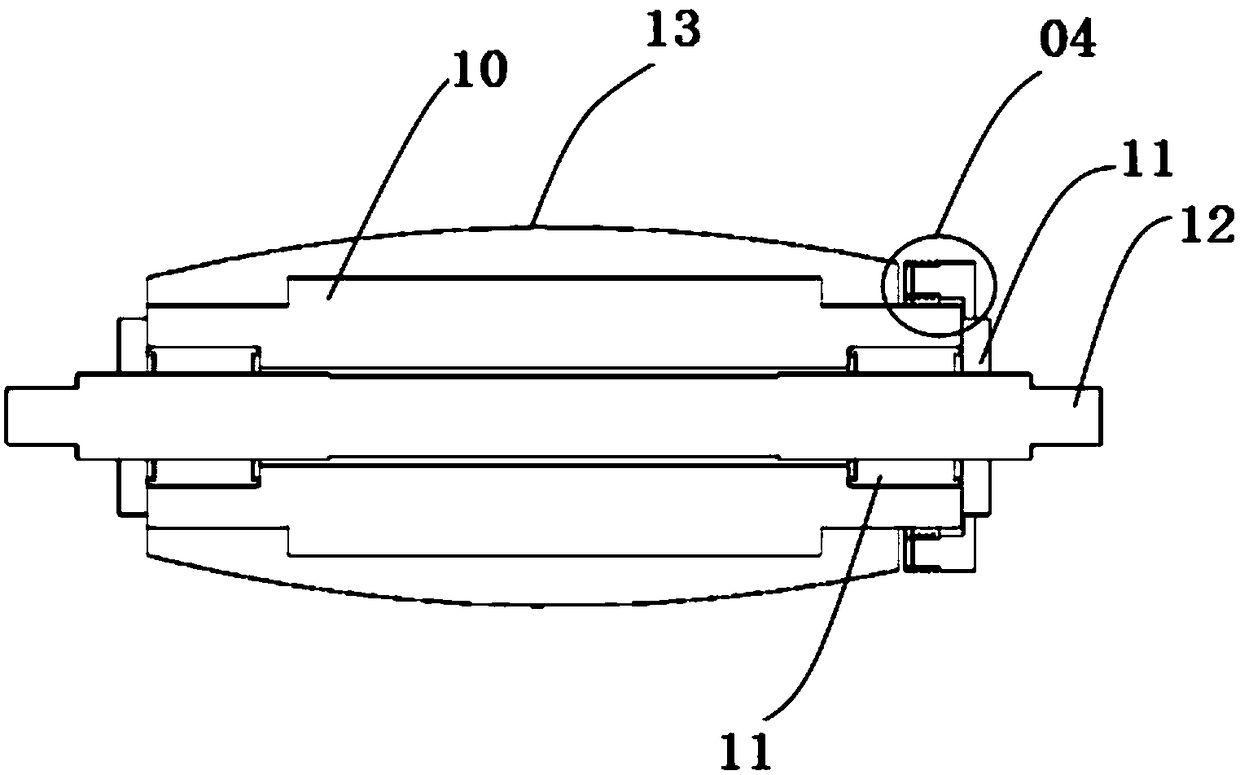

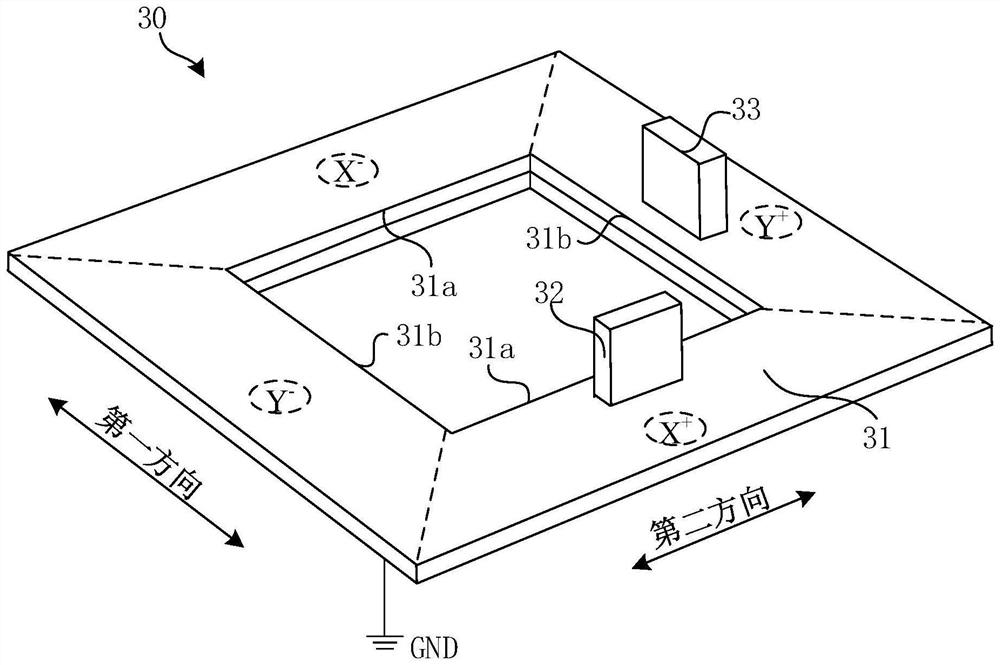

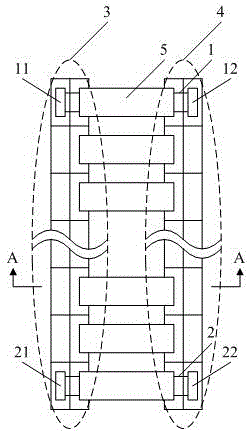

An omnidirectional wheel device, robot and control method thereof

The invention provides an omnidirectional wheel device, a robot and a control method of the device. The omnidirectional wheel device comprises a main shaft, a center wheel, multiple sub-wheels, sub-wheel fixing plates and conductive components. The center wheel and the sub-wheel fixing plates sleeve the main shaft and can rotate around the main shaft, and the center wheel is located between the two sub-wheel fixing plates; the sub-wheels are arranged on the outer circumference surface of the center wheel and connected between the two sub-wheel fixing plates; the conductive components are further arranged at the ends of the main shaft and located at the sides, away from the center wheel, of the sub-wheel fixing plates, and braking components are arranged at the sides, close to the conductive components, of the sub-wheels and coupled to the conductive components; the conductive components are configured to send control signals to the braking components of the designated sub-wheels; the braking components are configured to brake the sub-wheels which the braking components belong to when receiving the control signals sent by the conductive components. According to the omnidirectional wheel device, the corresponding sub-wheels are controlled to stop rotating by the braking components, and accordingly the precision of braking the sub-wheels is controlled.

Owner:BOE TECH GRP CO LTD

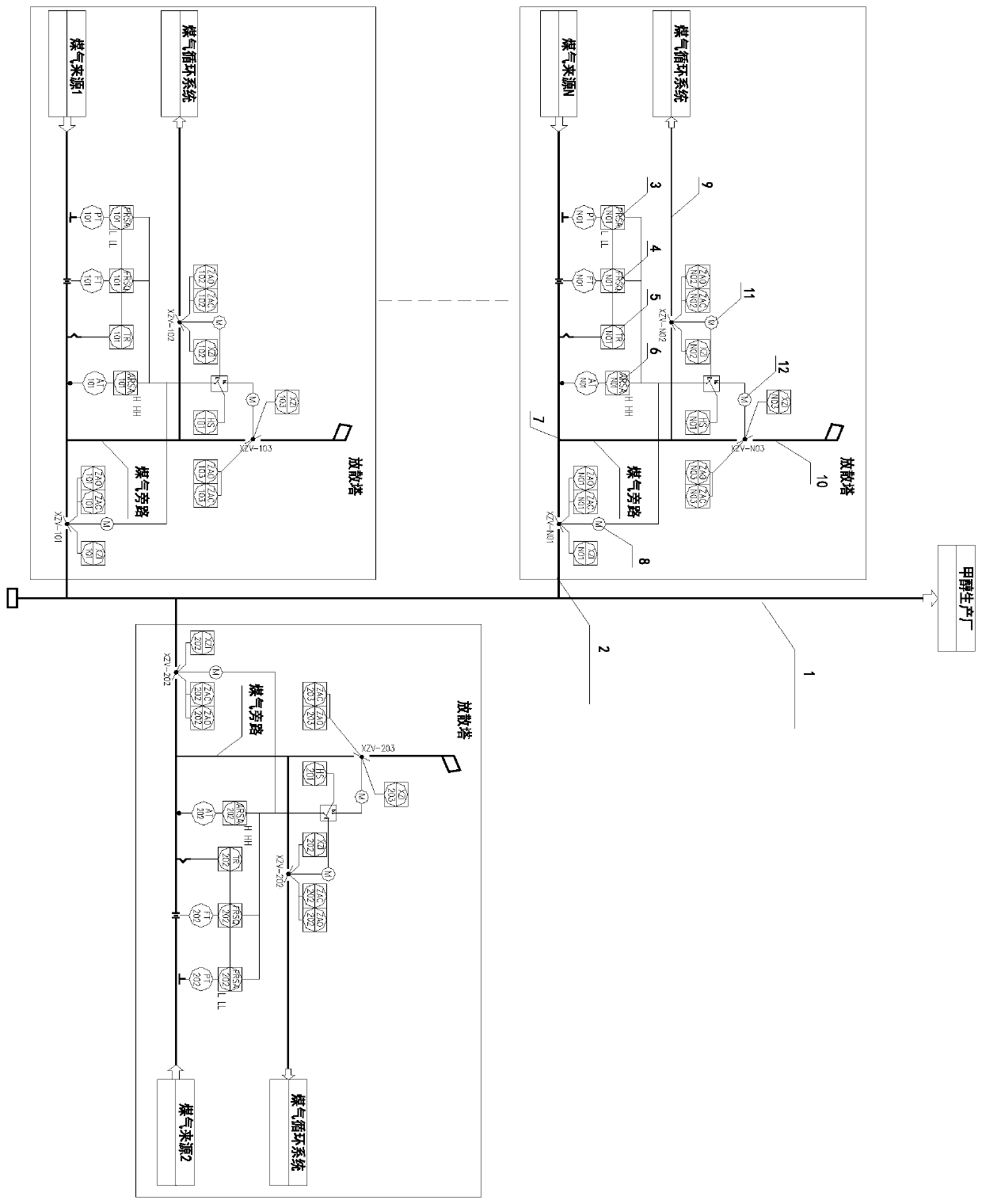

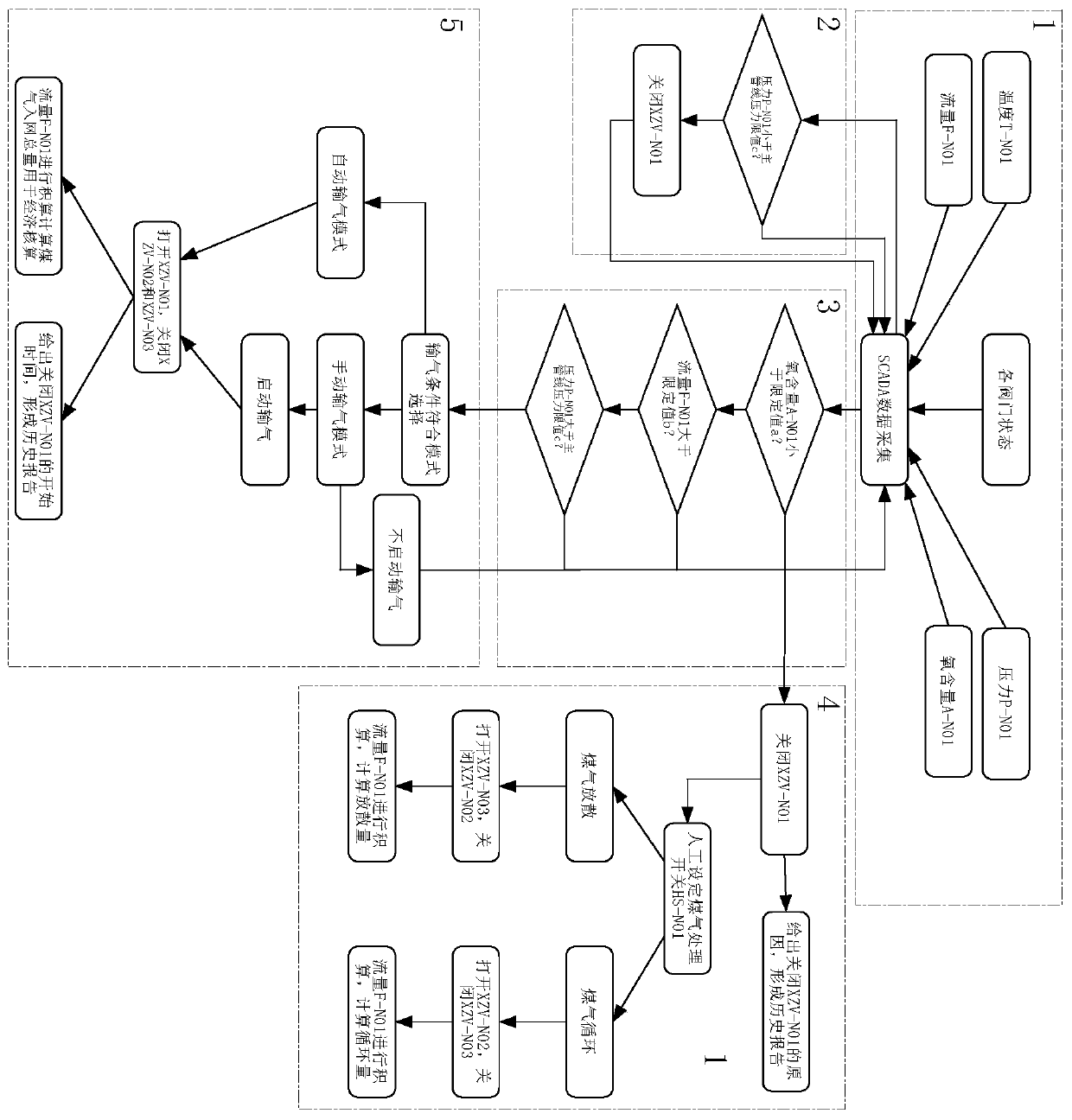

Network access system for submerged arc furnace gas pipe network and control method of network access system

PendingCN111288299AThe detection data is accurateRealize dynamic real-time measurementBlast furnace componentsBlast furnace detailsThermodynamicsRemote control

The invention provides a network access system for a submerged arc furnace gas pipe network and a control method of the network access system. The submerged arc furnace gas pipe network comprises a gas main network and a plurality of gas branch pipes connected thereto; the network access system comprises a gas return bypass pipe, a release bypass pipe, a branch pipe cut-off valve, a return bypasscut-off valve, a release bypass cut-off valve, a flow totalizer, a pressure transmitter, and an oxygen content online analyzer that are installed on each gas branch pipe. The cut-off valves are arranged before a branch line enters a network, gas bypasses are arranged between the cut-off valves and oxygen content measurement points to ensure that gas can return through the bypasses after a branch line remote control valve is cut off and ensure that the gas in the branch pipes is always in a state of flow update, and gas parameter indexes can be monitored accurately in a real-time manner beforethe gas is fed into the network to ensure that the network access gas transporting operation is performed after network access conditions are met and ensure that the quality of the network access gasmeets the requirements for methanol production; and the quantity of the network access gas is accurately metered for economic calculation.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Omnidirectional wheel device, robot and control method of device

The invention provides an omnidirectional wheel device, a robot and a control method of the device. The omnidirectional wheel device comprises a main shaft, a center wheel, multiple sub-wheels, sub-wheel fixing plates and conductive components. The center wheel and the sub-wheel fixing plates sleeve the main shaft and can rotate around the main shaft, and the center wheel is located between the two sub-wheel fixing plates; the sub-wheels are arranged on the outer circumference surface of the center wheel and connected between the two sub-wheel fixing plates; the conductive components are further arranged at the ends of the main shaft and located at the sides, away from the center wheel, of the sub-wheel fixing plates, and braking components are arranged at the sides, close to the conductive components, of the sub-wheels and coupled to the conductive components; the conductive components are configured to send control signals to the braking components of the designated sub-wheels; the braking components are configured to brake the sub-wheels which the braking components belong to when receiving the control signals sent by the conductive components. According to the omnidirectional wheel device, the corresponding sub-wheels are controlled to stop rotating by the braking components, and accordingly the precision of braking the sub-wheels is controlled.

Owner:BOE TECH GRP CO LTD

Two-level side door opening and closing mechanism of van vehicle

PendingCN108412361AOpen smoothlyImprove the efficiency of manual door opening and closingPower-operated mechanismWing openersAutomatic controlEngineering

A two-level side door opening and closing mechanism of a van vehicle comprises a first-level door and a second-level door arranged at the compartment opening position. The top of the first-level dooris located on the top of the opening position of a compartment; the bottom of the first-level door is hinged to the top of the second-level door; the bottom of the second-level door is hinged to the bottom of the compartment; a locking device is further arranged on the top of the second-level door; the side wall of the compartment is provided with a locking groove matched with the locking device;automatic door popping-open mechanisms, a control unit and a wire winding mechanism arranged on the side wall of the compartment are further included; the automatic door popping-opening mechanisms arearranged between the upper portion of the side, facing the compartment, of the first-level door and the compartment; the control unit is connected with the automatic door popping-opening mechanisms,the wire winding mechanism and the locking device; and the wire winding mechanism is connected with the top of the first-level door. Compared with the prior art, according to the two-level side door opening and closing mechanism of the van vehicle, efficiency is effectively improved, the labor force is saved, a safety coefficient is increased, and automatic control and precision control can be conveniently achieved.

Owner:CHONGQING TIEMA TENGFEI AUTO

A design method of manipulator for installing mill liner

ActiveCN106737617BAchieve positioningImprove work efficiencyProgramme-controlled manipulatorEngineeringManipulator

The invention provides a manipulator design method for installing a mill lining. A rolling pendulum device, a gripping device, other accessories and a first cylinder, a second cylinder, a third cylinder, a forth cylinder and a swinging cylinder fit to the accessories are designed in the manipulator, wherein the first cylinder has the rolling joint action in the rolling pendulum device, and the second cylinder has the joint action of back-and-forth movement; the third cylinder has the pitch joint action, and the forth cylinder has the gripping joint action in the gripping device; the swinging cylinder has the joint action of up-and-down swing; multiple displacements of the manipulator in space are achieved through these different joint actions, and the high-load drive of the manipulator is achieved through arranging these cylinders; the structure size of the manipulator is reduced. In the invention, the degree of mechanization and automation in the replacement of the mill lining is greatly improved, and the labor intensity is reduced; the replacement time of the lining is shortened, and potential safety hazards in manual operation are avoided.

Owner:LUOYANG CITIC HIC AUTOMATION ENG

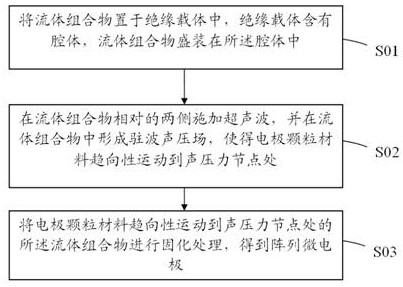

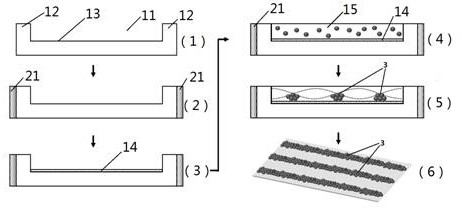

Array microelectrode, preparation method thereof and ultrasonic device

InactiveCN114524407AQuality improvementImprove production efficiencyDecorative surface effectsNanosensorsMicroelectrodeSound pressure

The invention discloses an array microelectrode, a preparation method thereof and an ultrasonic device for preparing the array microelectrode. The preparation method of the array microelectrode comprises the steps that a fluid composition is placed in an insulating carrier, the insulating carrier comprises a cavity, and the fluid composition is contained in the cavity; ultrasonic waves are applied to the two opposite sides of the fluid, and a standing wave sound pressure field is formed in the fluid composition, so that the electrode particle material tends to move to a sound pressure node; and curing the fluid composition which tends to move the electrode particle material to the sound pressure node to obtain the array microelectrode. The ultrasonic device comprises an insulating carrier for containing a fluid composition and an ultrasonic wave generating unit for providing ultrasonic waves for the fluid composition.

Owner:SHENZHEN UNIV

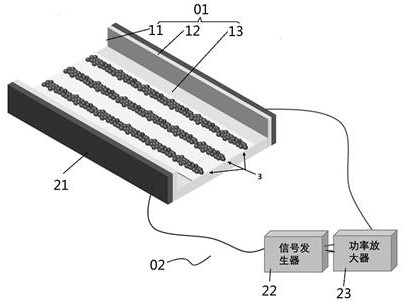

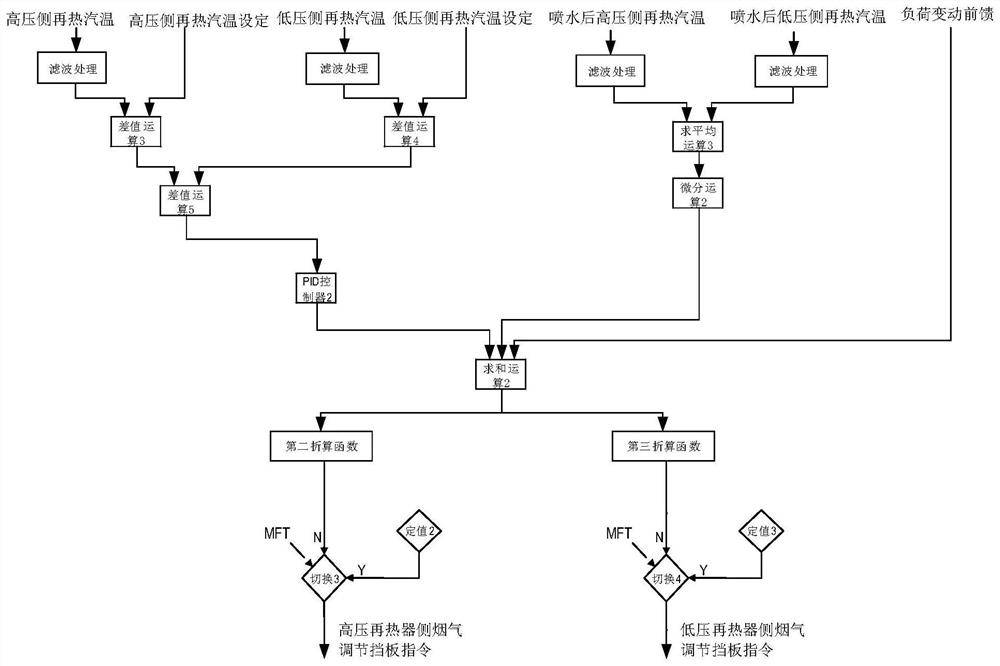

A method for controlling the reheat steam temperature of a double reheat unit

ActiveCN109654475BSafe and stable operationResolve Mutual CouplingSuperheating controlThermodynamicsFlue gas

The invention discloses a secondary reheating unit reheating steam temperature control method. The secondary reheating unit reheating steam temperature control method comprises a flue gas recirculation fan variable-frequency control method and a flue gas adjusting baffle opening degree control method; and a leading differential feedforward unit for the reheating steam temperature after water spraying and a feedforward unit for load changing are arranged in each control method, and meanwhile an overriding and locking control unit for special circumstances is arranged in each control circuit. According to the secondary reheating unit reheating steam temperature control method, the problems that the primary reheating steam temperature and the secondary reheating steam temperature of an ultra-supercritical secondary reheating unit intercouple with each other and are low in adjusting speed are solved, the total heat absorption capacity of a primary reheater and a secondary reheater is controlled through flue gas recirculation fan variable-frequency controllers separately, the primary reheating steam temperature and the secondary reheating steam temperature are controlled through reheater flue gas adjusting baffles, the control measures such as feedforward, overriding and locking are taken, the control precision and the response speed of the primary reheating steam temperature and the secondary reheating steam temperature of the ultra-supercritical secondary reheating unit are achieved, and meanwhile safe and stable running of the unit is guaranteed.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

Method for realizing real-time metering of water-stable mixed materials

PendingCN113878724AHigh precisionImprove measurement accuracyMixing operation control apparatusPretreatment controlControl engineeringControl theory

The invention relates to a method for realizing real-time metering of water-stable mixed materials. A pneumatic control unit, a metering mechanism and a belt conveyor connected with the metering mechanism are included. The method comprises the following steps that S1, the materials are conveyed into a transition bin of the metering mechanism to be screened; S2, the pneumatic control unit sends out a feeding instruction, the materials with different particle sizes are fed into a metering hopper at the bottom of the transition bin, and meanwhile weighing and sampling are carried out on the metering hopper; S3, when the materials in the metering hopper reach the upper limit, the pneumatic control unit closes a discharging door and detects the total weight of the metering hopper and the materials; and S4, when the total weight of the metering hopper and the materials reaches a preset value, the discharging door at the bottom of the metering hopper is opened, the materials are fed into the belt conveyor, and metering of the materials is completed. According to the method for real-time metering, on the basis of an electric control device, the transition bin and the metering hopper are arranged to meter a continuous working occasion, and the transition bin and the metering hopper are cooperatively controlled to obtain the weight or the flow of the materials, so that the metering accuracy is increased.

Owner:河南省光大路桥工程有限公司

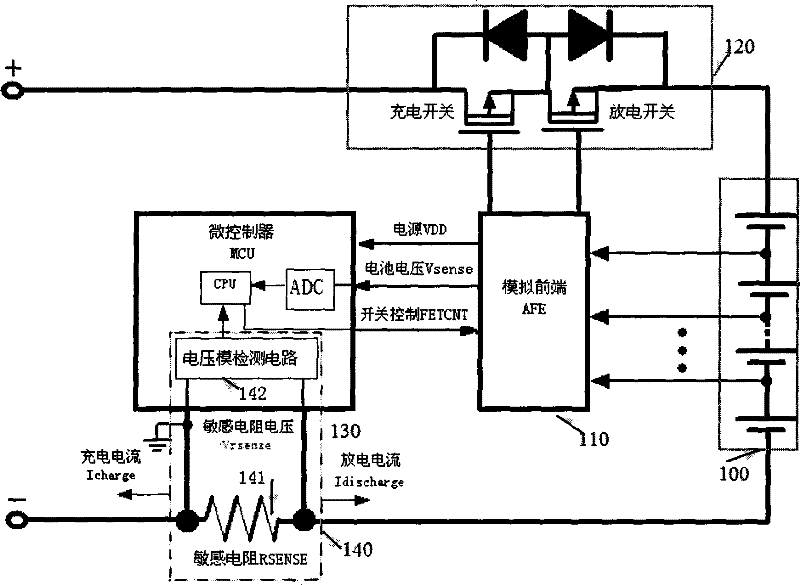

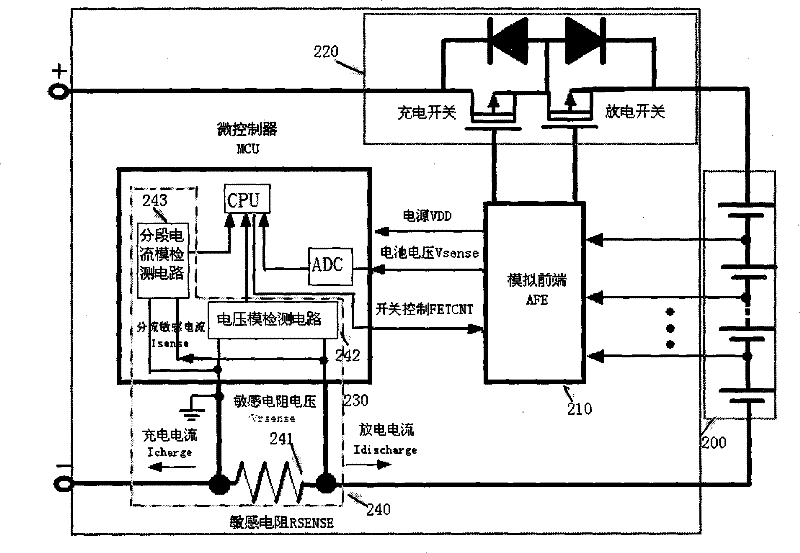

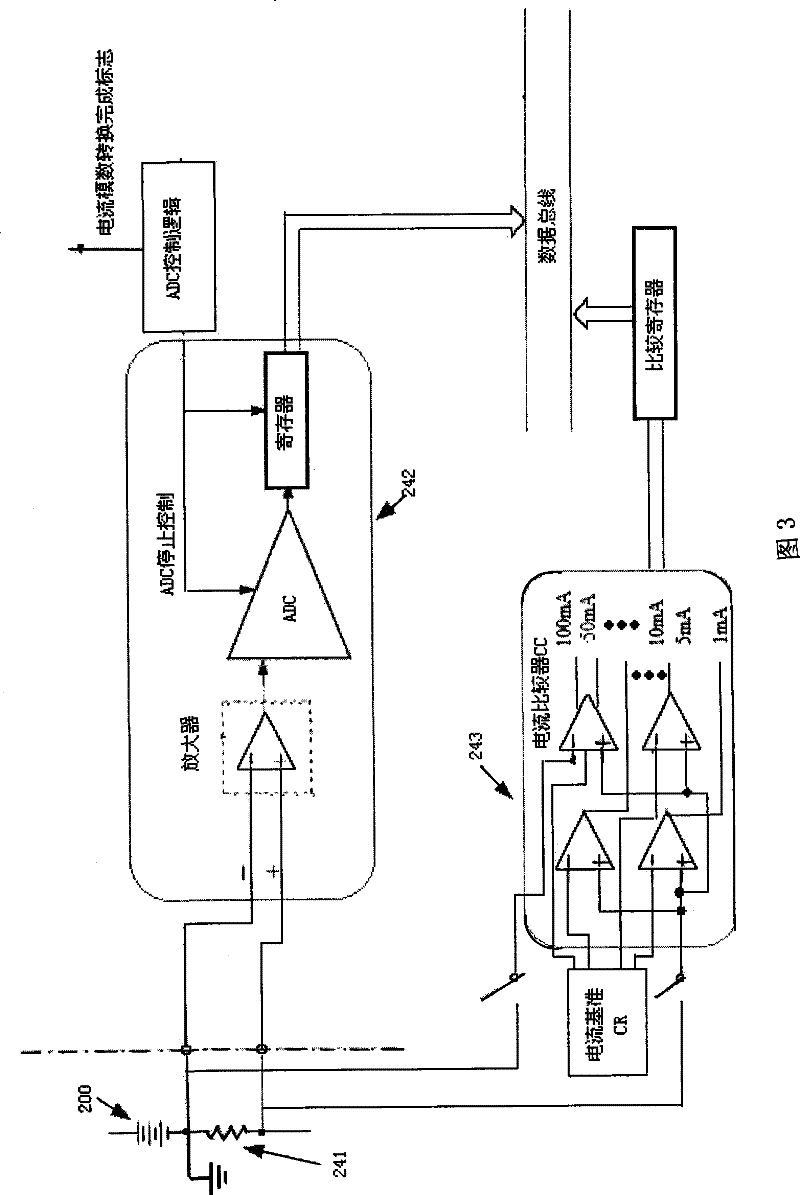

Lithium battery/battery pack metering and protection circuit based on current segment detection technology

InactiveCN101567475BRealize short circuit protectionImplement overcurrent/overvoltage protectionBatteries circuit arrangementsEmergency protective circuit arrangementsOvervoltageElectrical battery

The invention relates to a lithium battery / battery pack measuring and protecting method based on a current subsection detecting technique, which realizes intelligent controls of electric quantity detection for batteries, charge and discharge control, overcurrent / overvoltage protection, short circuit protection, and the like, and adopts a micro-control unit (MCU) mode to realize precision measuring control and intelligent management. The MCU transmits battery sampling voltage and current data to an analog-to-digital converter (ADC) to carry out quantitative analysis; the quantitative data and optimization data prestored in the MCU are compared; and the minimus information is fed back to a switch controlled by an analog front end (AFE) module to precisely control parameters of charge and discharge current, voltage, and the like. The detection mode of the MCU for the charge and discharge current of the batteries adopts the subsection detecting technique, wherein the charge and discharge current of the batteries are converted into digital signals by a voltage-mode converting circuit and a current-mode comparator, and the digital signals are sent to a central processing unit (CPU) in the MCU to carry out analysis and battery control. The invention improves the measuring precision, reduces the cost of design and production of chips and reduces the power consumption of the chips.

Owner:TIANJIN VAST TECH

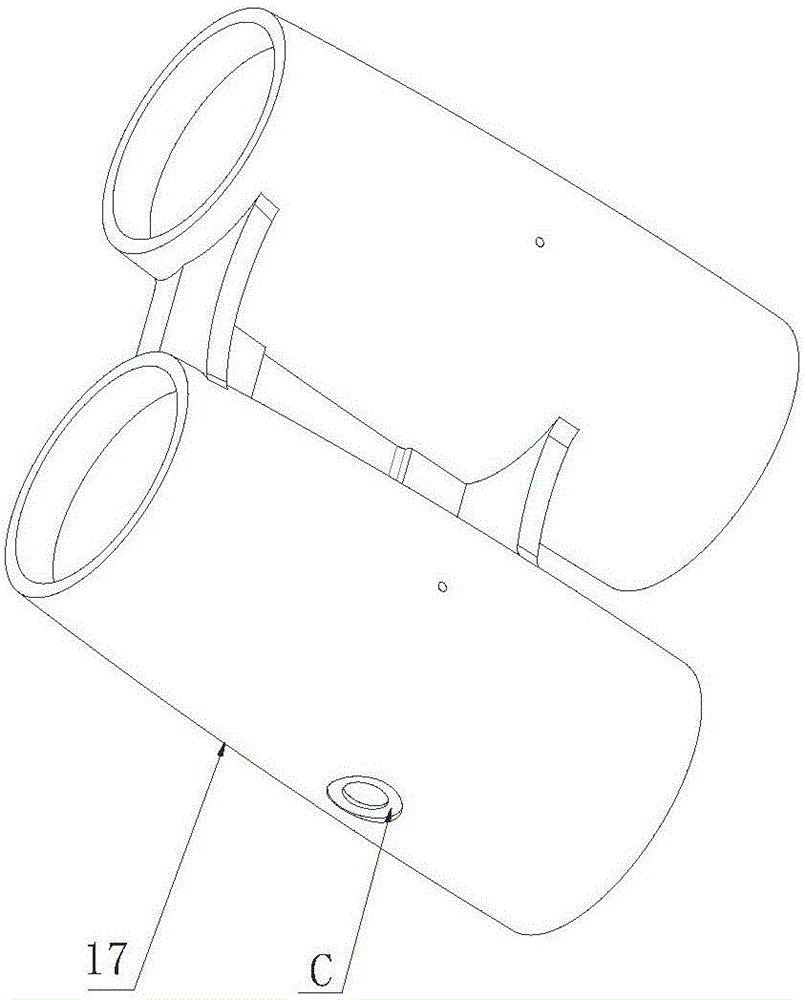

A telescope lens barrel milling processing fixture

InactiveCN105171475BImprove processing qualityGuaranteed accuracyPositioning apparatusMetal-working holdersEngineeringPosition control

A milling clamp for telescope lens barrels comprises a clamp body, a positioning device and a clamping device. The clamp body is formed by a bottom plate, a left side plate, a right side plate, a cover plate, a front side top plate and a rear side top plate in an enclosed mode. The center of the left side plate and the center of the right side plate are each provided with a hole. The positioning device comprises large end positioning device bodies and small end positioning device bodies which are arranged on the two telescope lens barrels symmetrically. A first part of the clamping device comprises inverted-Y-shaped supports symmetrically arranged in the middles of the front side and the rear side of the bottom plate, long threaded rods located at the inner sides of the inverted-Y-shaped supports and pressing blocks which are pressed on the inverted-Y-shaped supports, and the inner end and the outer end of each pressing block are installed on the corresponding long threaded rods in a sleeving mode. A second part of the clamping device comprises a main rod, an adjusting threaded rod, middle pressing blocks and a main adjusting nut, wherein the main rod is vertically installed in the center of the bottom plate, and the top of the main rod is provided with an inner threaded hole; the adjusting threaded rod is installed in the inner threaded hole in the top end of the main rod in a matched mode; the middle pressing blocks are sequentially installed on the adjusting threaded rod in a sleeving mode; the top end of the adjusting threaded rod is inserted in the cover plate. By means of the clamp, position control and accuracy control over outer machining surfaces of the telescope lens barrels can be achieved rapidly and accurately.

Owner:YUNNAN TENGDA MACHINERY MFG CO LTD +1

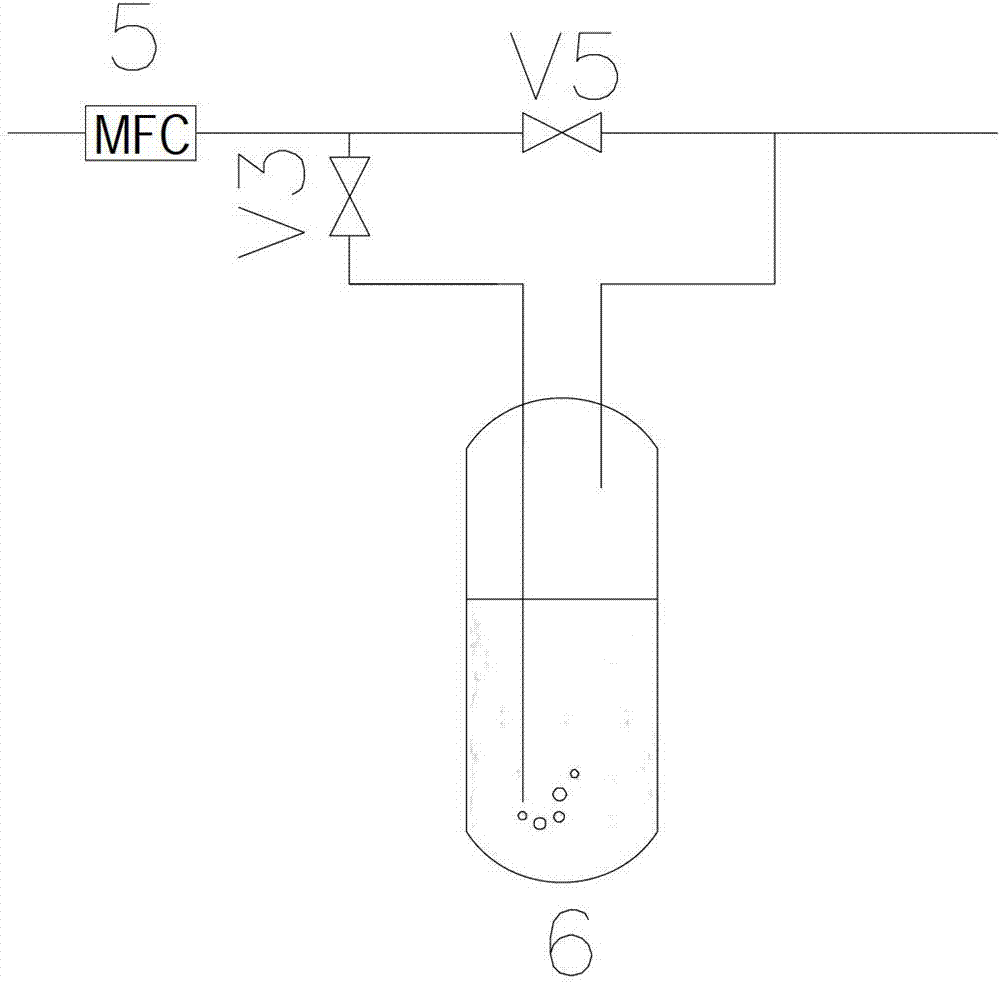

Air purification filtering material testing experimental system

InactiveCN102928323BMeet switchMeet simultaneous measurementPermeability/surface area analysisAbsorption filterEngineering

The invention discloses an air purification filtering material testing experimental system which comprises an air compressor, a silica gel drying pipe, a particle matter filter and an active carbon absorption filter which are connected together through a pipeline in sequence, wherein the input end of the air compressor is connected with an air intake pipeline; the output end of the active carbon absorption filter is connected with a first mass flow controller and a second mass flow controller respectively through pipelines; the output end of the first mass flow controller is connected with a humidity control unit through the pipeline; the output end of the second mass flow controller is connected with a pollutant generating unit through the pipeline; the output ends of the humidity control unit and the pollutant generating unit are respectively connected with an input port of a mixing bottle through the pipelines; and an output port of the mixing bottle is connected with a filtering material testing unit through the pipeline. With the adoption of the air purification filtering material testing experimental system, the switchover of single channel testing clamps of different specifications is realized, the synchronous measurement on a plurality of samples is also realized; and the control precision (of a testing working situation) which is provided by relevant internal standards can be realized.

Owner:TIANJIN UNIV

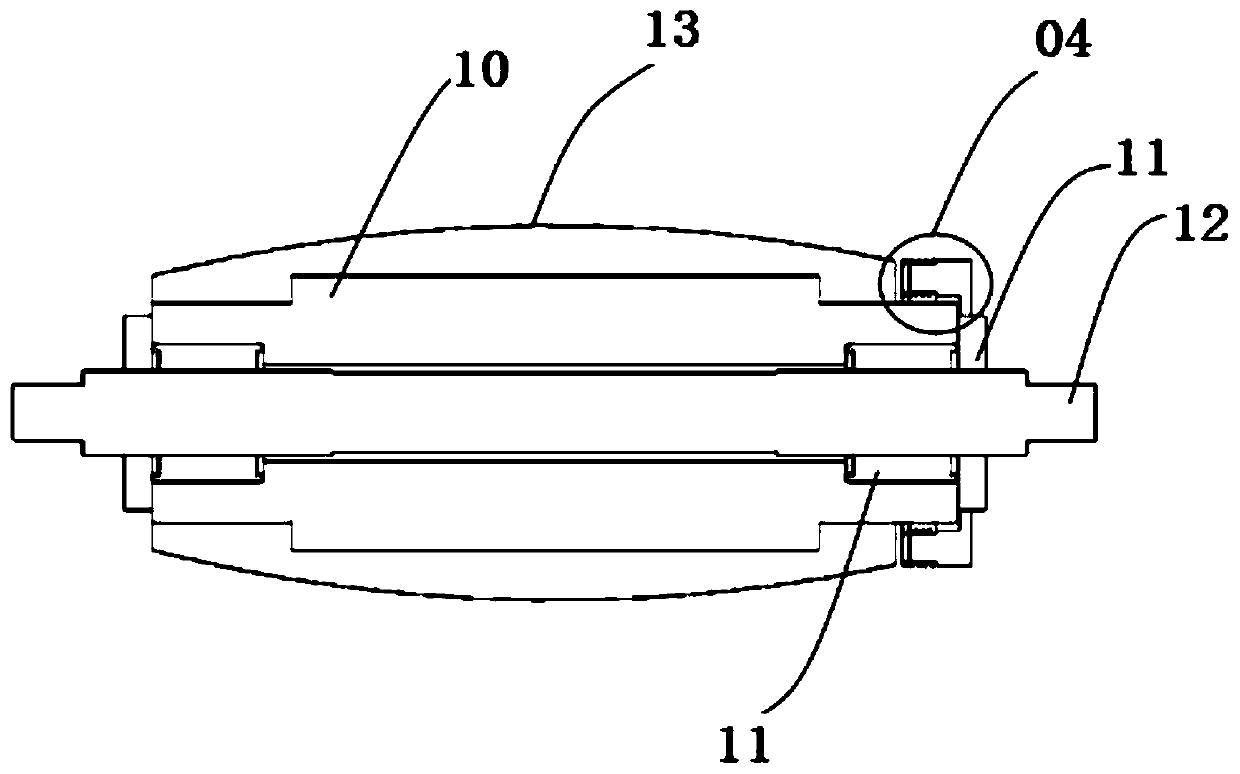

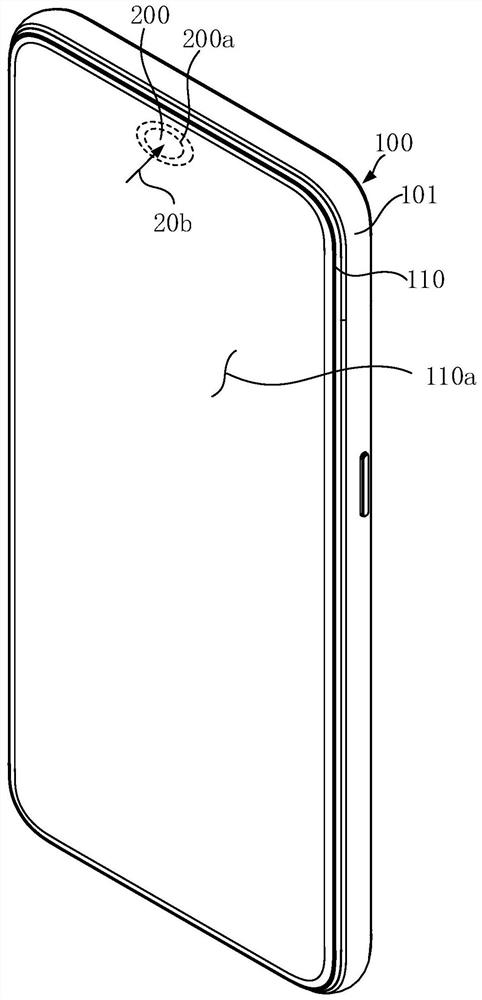

Mobile terminal and camera module thereof

PendingCN114650355AAchieve Optical Image StabilizationAchieving Control AccuracyTelevision system detailsColor television detailsControl signalEngineering

The invention relates to a mobile terminal and a camera module thereof, the camera module comprises a lens base, a lens and a piezoelectric driving unit, the lens is movably arranged on the lens base through a carrier, the piezoelectric driving unit comprises an annular piezoelectric plate, a first friction head and a second friction head, the annular piezoelectric plate surrounds the peripheral side of the lens and is connected with the lens base, and the first friction head is connected with the annular piezoelectric plate. The annular piezoelectric plate drives the first friction head to drive the carrier to move along a first direction under a first preset voltage so as to compensate shooting jitter of the lens in the first direction, and the annular piezoelectric plate drives the second friction head to drive the carrier to move along a second direction under a second preset voltage so as to compensate shooting jitter of the lens in the second direction. The first direction and the second direction intersect. According to the mobile terminal and the camera module thereof, the motion stroke of the carrier is only related to the periodicity of the control signal of the voltage introduced into the annular piezoelectric plate, so that when long-stroke motion needs to be realized, the maximum current does not need to be increased, and the power consumption can be effectively reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Sand conveying mixed discharge system and control method

ActiveCN111005710BStable output pressureRelieve pressureTransportation and packagingFluid removalImpellerCentrifugal force

The invention provides a sand conveying mixed discharge system and a control method, including a mixed discharge device. The structure of the mixed discharge device is: a feeding hopper is provided on the top of the tank body, and a main shaft is installed in the tank body through the feeding hopper vertically. The main shaft is connected with the driving device that drives it to rotate, and a booster impeller is arranged under the feed hopper, which is fixedly connected with the main shaft and rotates with the main shaft; there is a top opening in the middle of the top of the booster impeller, and the feed hopper The bottom of the booster impeller is connected to the top opening, the side wall of the booster impeller is provided with a side wall opening, and the top opening is connected to the side wall opening; a bearing seat is provided at the bottom of the main shaft, and a sealing device is provided between the end of the main shaft and the bearing seat. Through the structure of the booster impeller, the centrifugal force can be used to maintain the pressure in the tank, so that there is no need to set up an additional booster feed tank, which greatly simplifies the structure of the equipment, reduces the installation space of the equipment, and reduces the volume of the equipment.

Owner:中石化四机石油机械有限公司 +2

A conveyor belt with automatic screening function based on electromagnetic principle

The invention discloses an electromagnetic principle-based driving belt with an automatic sieving function and belongs to the field of material sorting and conveying. The driving belt is provided with a sieving plate, the front end of the sieving plate is lapped on the third sub-chain of a front chain from the front to the back, the rear end is in shaft connection with the first sub-chain of a rear chain from the front to the back and rotates around the first sub-chain of the rear chain from the front to the back, a permanent magnet is arranged at the bottom of the front end of the sieving plate, a repellent electromagnet and an attractive electromagnet are longitudinally arranged in the plane with a drive front gear and a driven front gear, and the polarities of the attractive electromagnet and repellent electromagnet are opposite. By means of the structure, the electromagnetic principle-based driving belt with the automatic sieving function realizes the integration and synchronous running of conveying and sieving, optimizes the material sieving streamline and is capable of directly sieving objects according to the object quality without additional equipment.

Owner:HUNAN CHANGZHONG MACHINERY

Electrical control method of rheological measurement device

ActiveCN101430266ARealize collaborative controlEfficient use ofFlow propertiesTemperature controlMeasurement device

The invention relates to an electric control method of a rheological testing device. A programmable computer controller is used as a controller. The method uses a digital intelligent servo system control the motion speed of a piston rod and a parametric control algorithm to collocate the speed ring parameter of the servo system at different operation speed sections of the piston rod. A temperature sensor and a special conversion module are used for detecting barrel temperature and transforming signals. Control programs including intelligent temperature control, digital intelligent servo and the like are defined with different circulating periods and stored in a user memory of the programmable computer controller according to task grades, so as to control and adjust the temperature of a barrel and the motion speed of the piston rod. The invention realizes the speed regulation ratios index of 1:20000 of the piston rod, obtains good dynamic and static indexes and integrates the precise detection technology and intelligent control algorithm, thereby realizing the control precision of plus or minus 0.1 DEG C of the temperatures of three sections of the barrel and realizing the cooperative control of a complex control object of the multifunctional rheological testing device.

Owner:HUNAN UNIV OF TECH +1

3D printer control system based on ARM

InactiveCN113290865AAchieving Detection AccuracyAchieving Control AccuracyAdditive manufacturing apparatusManufacturing data aquisition/processingGratingComputer printing

The invention discloses a 3D printer control system based on an ARM, and relates to the technical field of 3D printer tools. An upper computer is connected with a communication interface through a wire, the communication interface is installed on a communication port of an ARM microcontroller, the power supply end of the ARM microcontroller is connected with a power supply module through a wire, and the input end of the ARM controller is connected with a thermocouple temperature detector, a capacitive grating sensor, a smoke particle and flame sensor and a pulse thermal imaging sensor. The output end of the ARM controller is electrically connected with a heating bed (electric heating device), a stepping motor with a grating, a material extrusion motor (stepping extrusion motor) and a power supply detection sensor, the storage end of the ARM controller is electrically connected with a storage module, and a touch display screen is connected with the input and output end of the ARM controller through a data line. A radiator is mounted in the pulse thermal imaging sensor, and a protective frame is mounted on the outer side of the pulse thermal imaging sensor. According to the 3D printer control system, information detection and accurate control can be realized, safety and fault detection can be realized, the use is convenient, the operation is simple and convenient, and the time can be saved.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com