Method for realizing real-time metering of water-stable mixed materials

A real-time measurement and material technology, used in chemical instruments and methods, batching and batching instruments, batching weighing instruments, etc., can solve problems such as failure to achieve production ratio, deviation, and failure to achieve expected results, and achieve increased accuracy. , the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

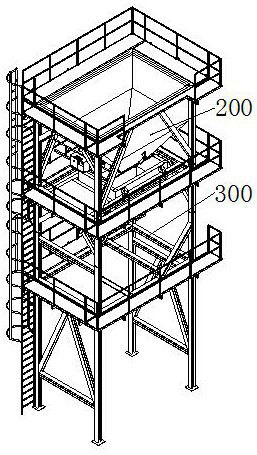

[0041] combine figure 1 , a real-time metering method for realizing water-stabilized mixed materials, comprising an air control unit, a metering mechanism and a belt conveyor 100 connected to the metering mechanism, comprising the following steps:

[0042] S1. The material is transported into the transition bin 200 of the metering mechanism, and the transition bin 200 screens the material;

[0043]S2. The air control unit issues a feeding command, the discharge door 2 at the bottom of the transition bin 200 is opened, and materials with different particle sizes are sent into the weighing hopper 300 at the bottom of the transition bin 200, and the air control unit weighs and samples the weighing hopper 300 ;

[0044] S3. When the material in the weighing bucket 300 reaches the upper limit, the air control unit sends an instruction to close the discharge door 2 and detects the total weight of the weighing bucket 300 and the material;

[0045] S4. When the air control unit judg...

Embodiment 2

[0048] combine Figure 1-5 , a device for realizing a real-time metering method for water-stabilized mixing materials, including an air control unit, a metering mechanism, and a belt conveyor 100 connected to the metering mechanism, and the metering mechanism includes a transition bin 200 and a metering bucket 300, The bottoms of the transition bin 200 and the weighing bucket 300 are equipped with a discharge door 2 controlled by an air control unit to start and stop. The material is continuously discharged from the weighing bucket 300. While the material is continuously discharged, the load cell-1 weighs in real time. Measure the weight of the weighing bucket 300 and the remaining material in the weighing bucket 300, the discharged material is the difference between the total weight of the initial weighing bucket 300 and the total weight of the current weighing bucket 300, because the load cell-1 is not affected by the impact of the material , to further improve the accuracy ...

Embodiment 3

[0054] combine Image 6 , the belt conveyor 100 includes a front drum 3, a rear drum 4 and a conveyor belt 5 connecting the front drum 3 and the rear drum 4, and the front drum 3 and the rear drum 4 are provided with evenly spaced rollers for supporting Some guide rollers 6 of the conveyor belt 5, the belt conveyor 100 is provided with a weighing section, and the weighing section includes a plurality of guide rollers 6 located between adjacent two guide rollers 6 As well as the weighing idler roller 7 arranged between two adjacent guide idler rollers 6 , the belt conveyor 100 is also provided with a speed sensor 8 for detecting the running speed of the conveyor belt 5 .

[0055] The weighing idler 7 is connected with a load cell 2 9 through a weighing platform, and the load cell 9 and the speed sensor 8 are all connected to the air control unit through a PLC controller, and the PLC controller is connected to the air control unit according to the speed The measured value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com