Sand conveying mixed discharge system and control method

A control method and mixed arrangement technology, which is applied in chemical instruments and methods, mixers, earthwork drilling and mining, etc., can solve the problems that the whole line cannot be used, achieve simple and convenient control scheme, ensure control accuracy, and simplify equipment structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

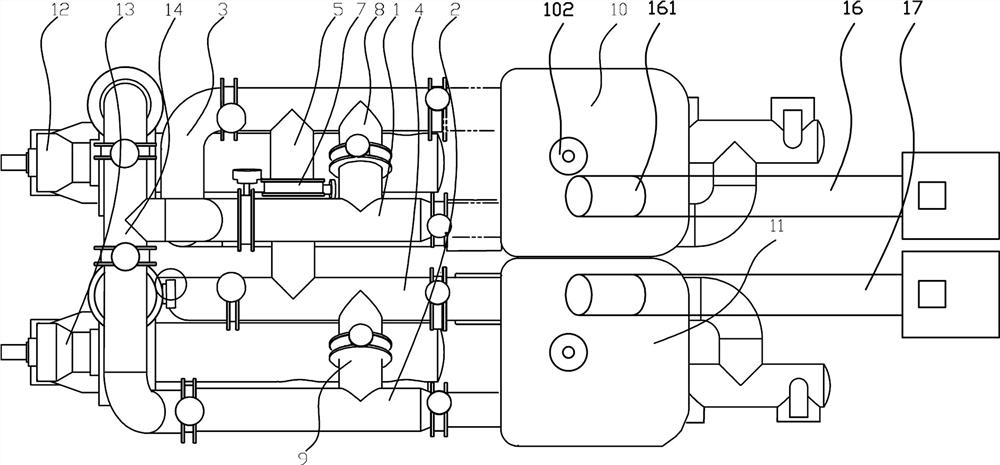

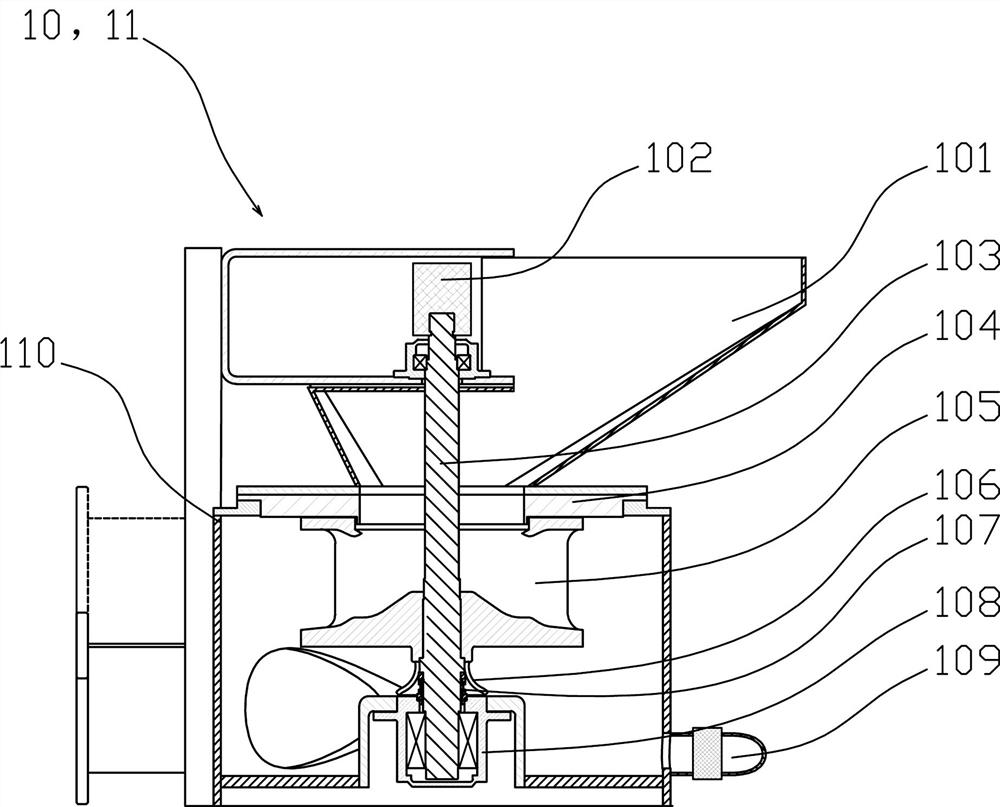

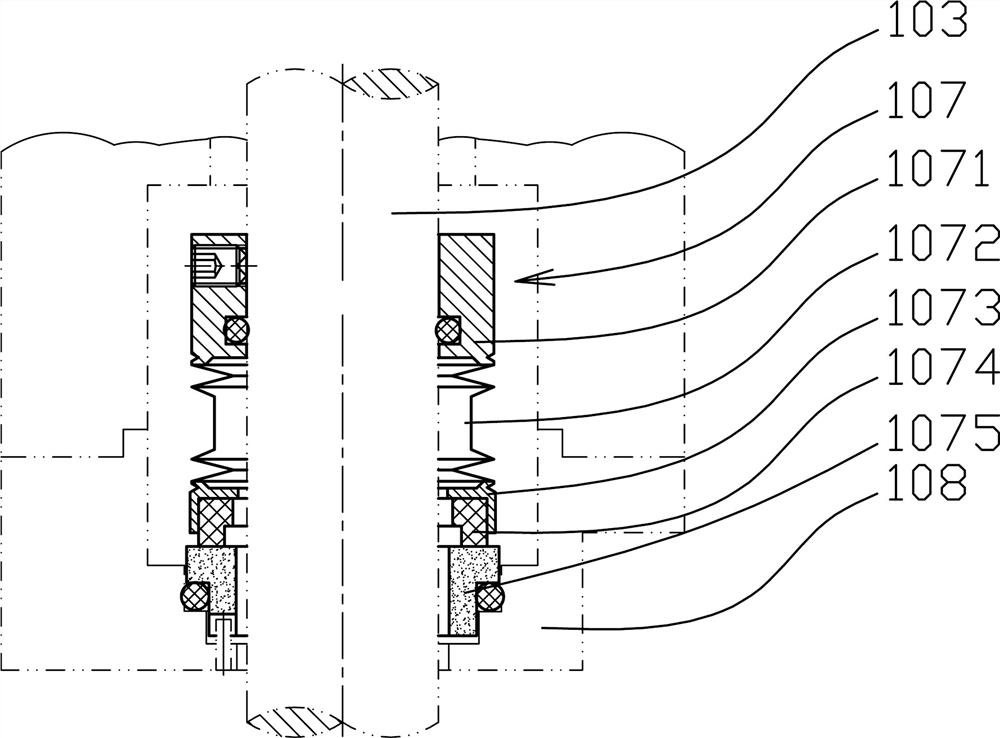

[0040] Such as figure 1 , 4 , 5, 6, 8, a kind of sand conveying mixed discharge system, it comprises mixing device, is provided with airtight tank body 110 in mixing device, the top of tank body 110 is provided with feed hopper 101, feed hopper 101 The booster impeller 105 driven to rotate by the drive device is provided below, the booster impeller 105 is provided with a top opening communicating with the feed hopper 101, and a side wall opening is also provided to feed the material by the centrifugal force of the booster impeller 105 rotation. The granular material in the bucket 101 is thrown into the tank body 110 from the side wall opening;

[0041] The mixed drainage inlet pipeline and the mixed drainage outlet pipeline are in communication with the tank body 110, a liquid supply pump is provided on the mixed drainage inlet pipeline, an output pressure sensor is arranged on the mixed drainage outlet pipeline, and an output pressure sensor is installed on the mixed drainag...

Embodiment 2

[0071]Such as Figure 1~8 Among them, a control method using the above-mentioned sand conveying mixed discharge system includes the following steps:

[0072] S1. Based on the output pressure value of the output pressure sensor, compare the output pressure value with the preset output pressure value;

[0073] S2. When the output pressure value is higher than the preset output pressure value, reduce the speed of the driving device of the liquid supply pump to reduce the pressure of the liquid medium input into the tank 110 of the mixing device, and the speed of the driving device of the liquid supply pump Feedback adjustment according to the input pressure sensor to form a closed-loop control;

[0074] When the output pressure value is lower than the preset output pressure value, then increase the rotational speed of the driving device of the liquid supply pump to increase the pressure of the liquid medium input into the tank 110 of the mixing device, and the rotational speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com