Network access system for submerged arc furnace gas pipe network and control method of network access system

A gas pipeline network and control method technology, applied in pipeline systems, furnaces, blast furnaces, etc., can solve problems affecting production safety and production efficiency, lack of real-time performance and accuracy, and lack of monitoring of gas quality, so as to improve the level of automation control , Accurate detection data, improve the effect of quality monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

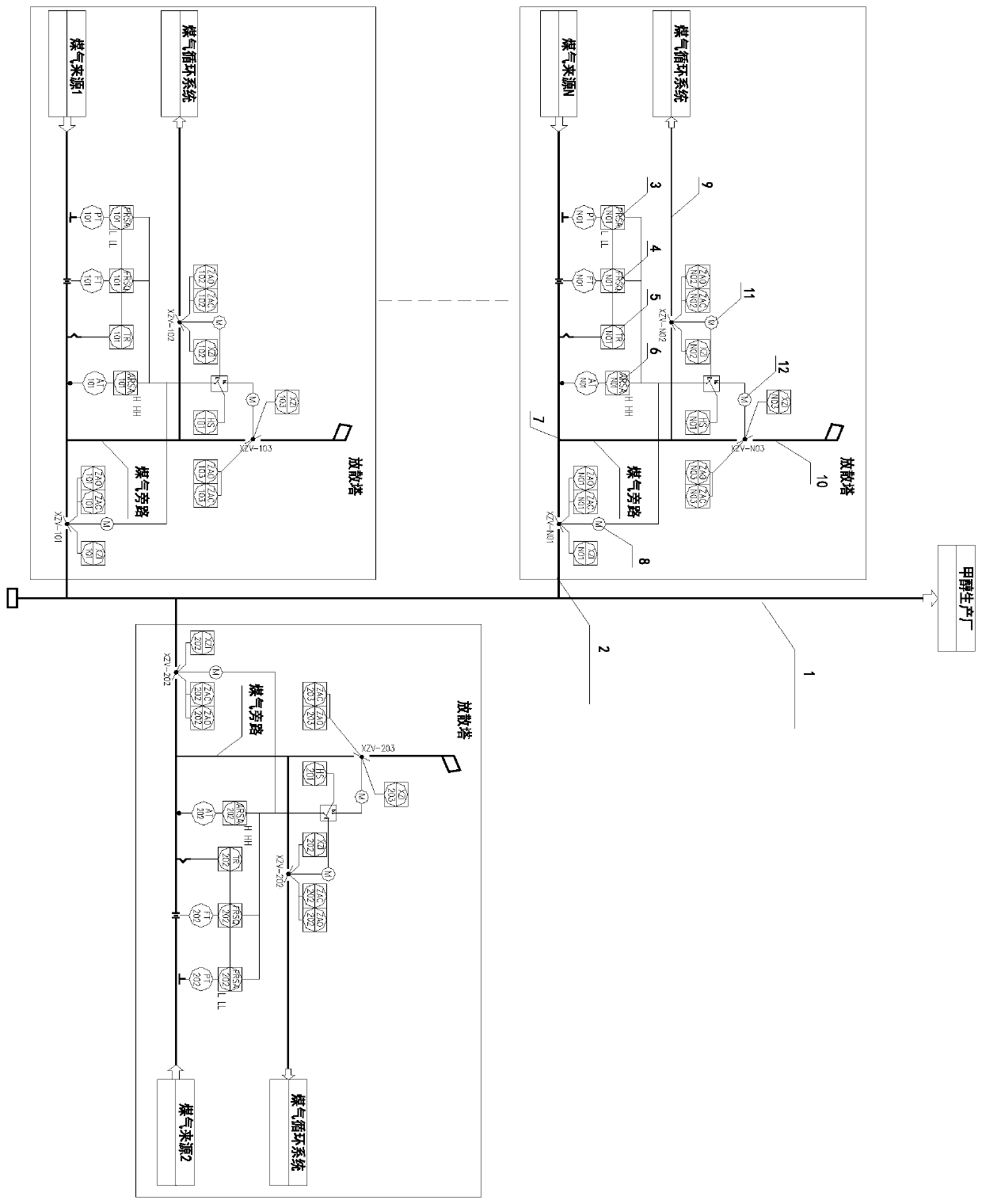

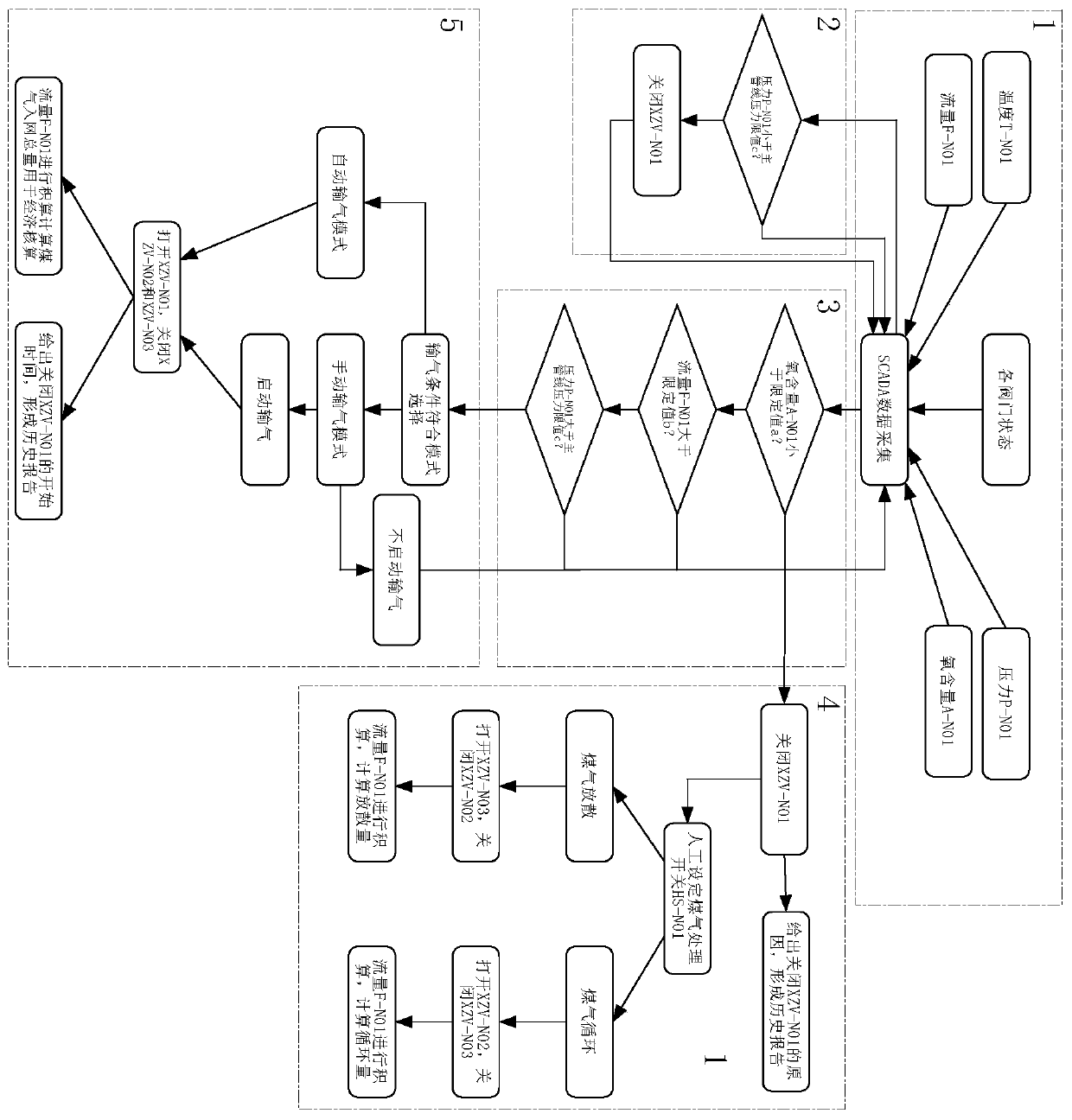

[0032] Such as figure 1 As shown, a submerged arc furnace gas pipeline network network access system, the submerged arc furnace gas pipeline network includes a gas backbone network and a plurality of gas branch pipes connected to it. In the figure, the submerged arc furnace gas pipeline network is composed of a gas The backbone network 1 is composed of many gas branch networks 2 (subnet numbers 1, 2, 3...N), and each gas branch network corresponds to a submerged arc furnace metallurgical plant.

[0033] The network connection system includes a gas return bypass pipe 9, a release bypass pipe 10, a branch pipe cut-off valve 8, a return bypass cut-off valve 11, a release bypass cut-off valve 12, and a flow totalizer arranged on each gas branch pipe 2. Instrument 4, pressure transmitter 3, oxygen content online analyzer 6. Gas oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com