Method and device for controlling oxygen content in drum type cut tobacco drying process

A drying process, oxygen content technology, applied in the preparation of tobacco, application, tobacco, etc., can solve the problem of unable to control the oxygen content of shredded tobacco, and achieve the effect of control accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

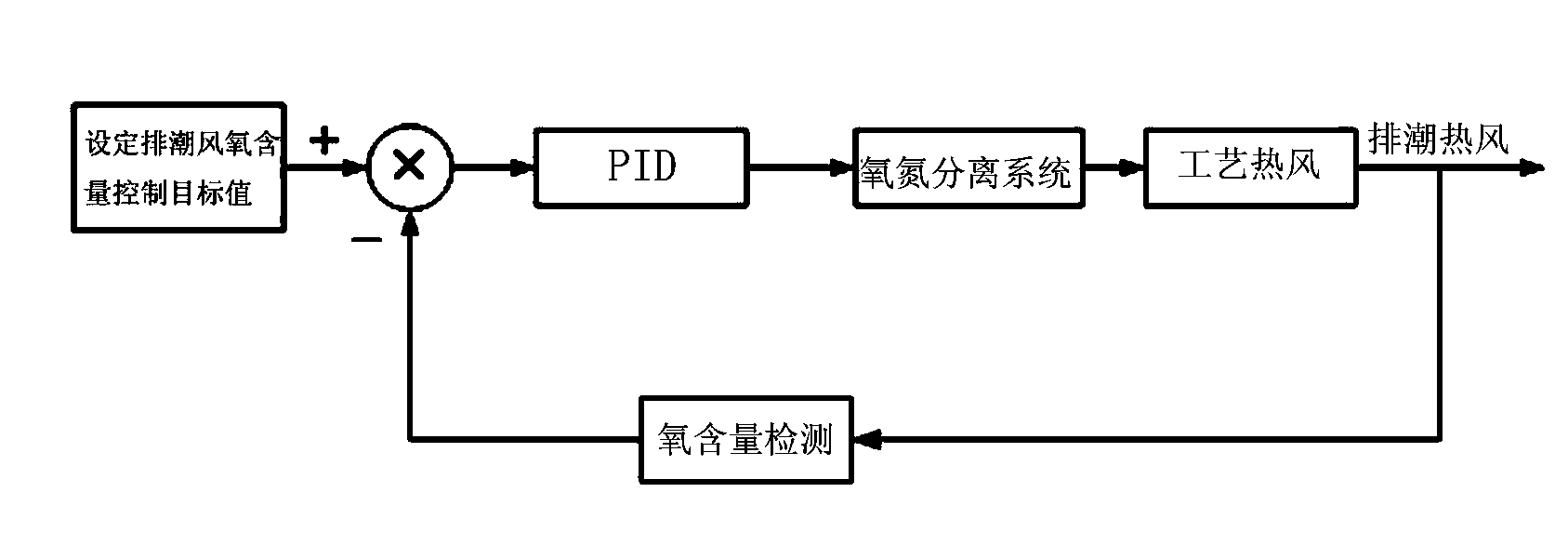

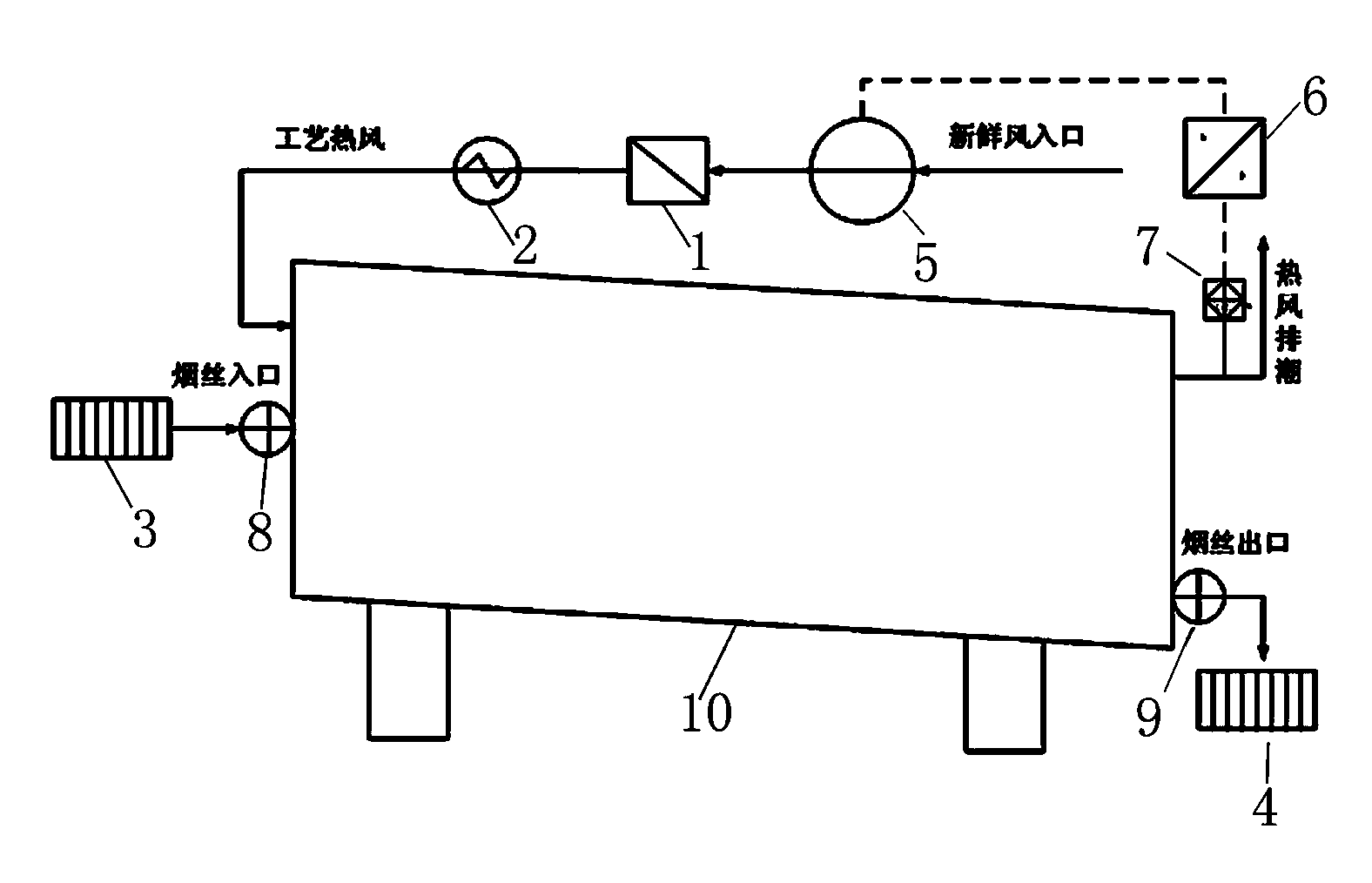

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take grade A cigarettes and shred the shredded tobacco, and carry out drum drying according to the process parameters in Table 1.

[0022] Table 1 Embodiment 1 parameter setting

[0023] parameter name

[0024] Implementation effect evaluation: Organize professional cigarette smokers to conduct sensory evaluation on the shredded tobacco produced by parameter 1 and parameter 2 respectively. The results showed that the shredded tobacco produced by parameter 2 had more aroma, less miscellaneous gas and less irritating smoke than the shredded tobacco produced by parameter 1. The implementation effect shows that the oxygen content in the shredded tobacco drying process is reduced, which is conducive to improving the taste and smoking quality of shredded tobacco.

Embodiment 2

[0026] Take B brand cigarettes and shred the shredded tobacco, and carry out drum drying under the condition of oxygen content of 1%-5% according to the process parameters in Table 2.

[0027] Table 2 Parameter setting of Embodiment 2

[0028] parameter name

[0029] Implementation effect evaluation: Professional cigarette smokers are organized to conduct sensory evaluation on the shredded tobacco produced by the five parameters. The results showed that the cut tobacco of B brand was dried under the condition of parameter 2, that is, the oxygen content was controlled at 2%, and the taste and smoking quality of the shredded tobacco were the best. Therefore, for the production of brand B cigarettes, the oxygen content in the drying process should be set at 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com