Manipulator design method for installing mill lining

A design method and manipulator technology, applied in the direction of manipulators, program control manipulators, manufacturing tools, etc., can solve the problems of heavy grasping, removal, replacement and installation, inconvenient on-site replacement and installation, poor maintenance safety, etc., to improve work Efficiency and maintenance safety, improvement of labor intensity, effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

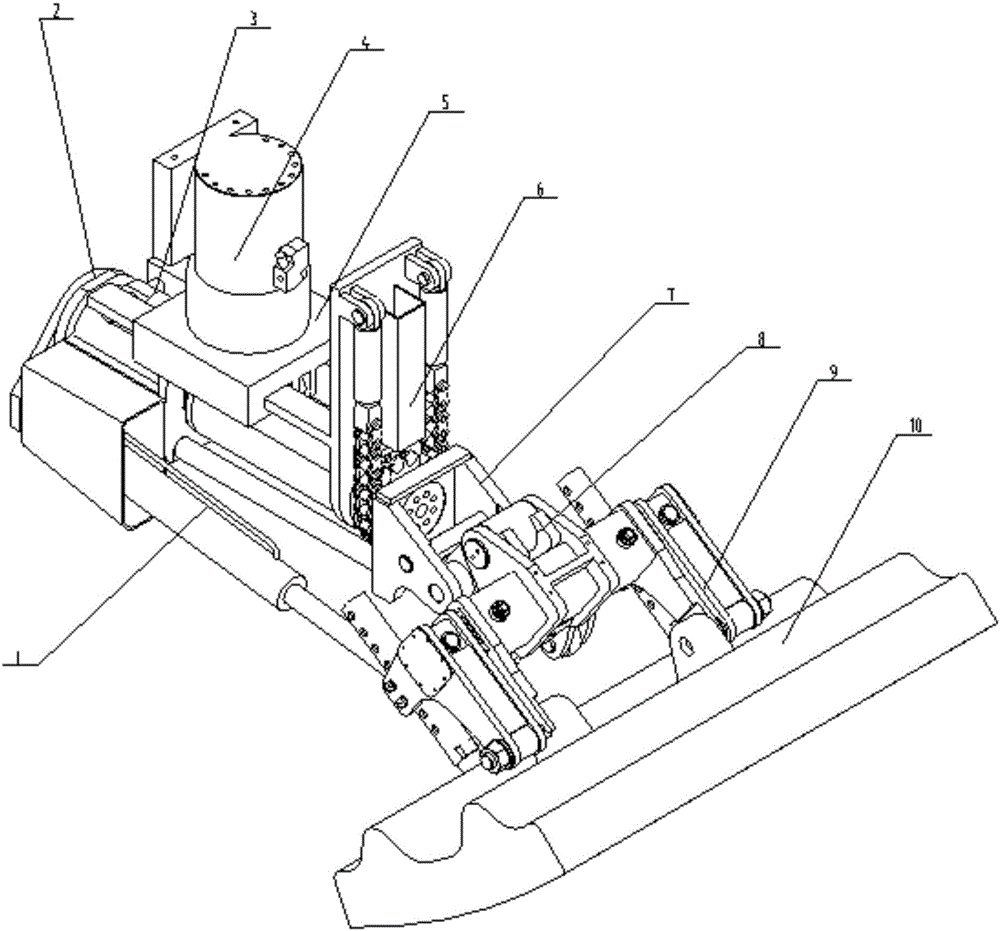

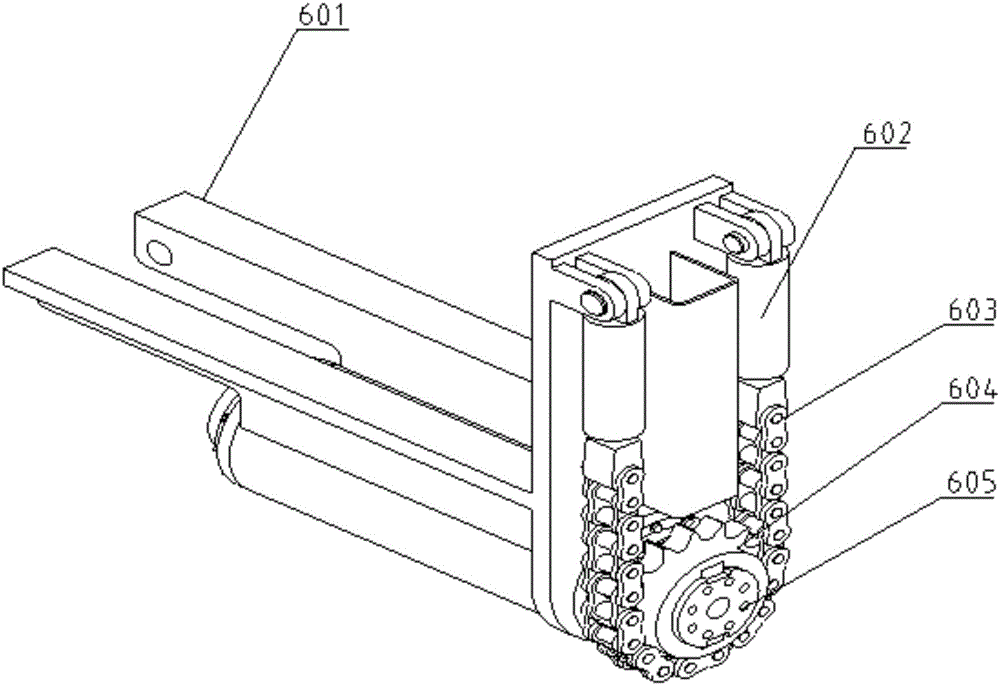

[0026] The present invention relates to a method for designing a manipulator for installing a mill liner. The manipulator is respectively designed with a rolling device, a grabbing device, other accessories and a first oil cylinder, a second oil cylinder, a third oil cylinder, The fourth oil cylinder, the swing oil cylinder, the first oil cylinder has the function of rolling joint in the rolling device, the second oil cylinder has the function of moving forward and backward, the third oil cylinder has the function of pitch joint, and the fourth oil cylinder has the function of grasping in the grabbing device. Joint action, the oscillating cylinder has an up and down swing joint action, and through these different joint actions, the manipulator can achieve multiple displacements in the spatial position.

[0027] combine Figure 1-4 , it is given that the board 10 to be relined has two lifting lugs with the same structure, the two lifting lugs are configured with lifting holes w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com