Fuel jet device of engine

A fuel injection device and fuel injection technology, applied in fuel injection pumps, fuel injection control, engine control, etc., can solve the problems of output unstable voltage, difficulty in correctly outputting 0V, cost increase, etc., and achieve high-precision fuel control, The effect of improving detection accuracy and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiment 1

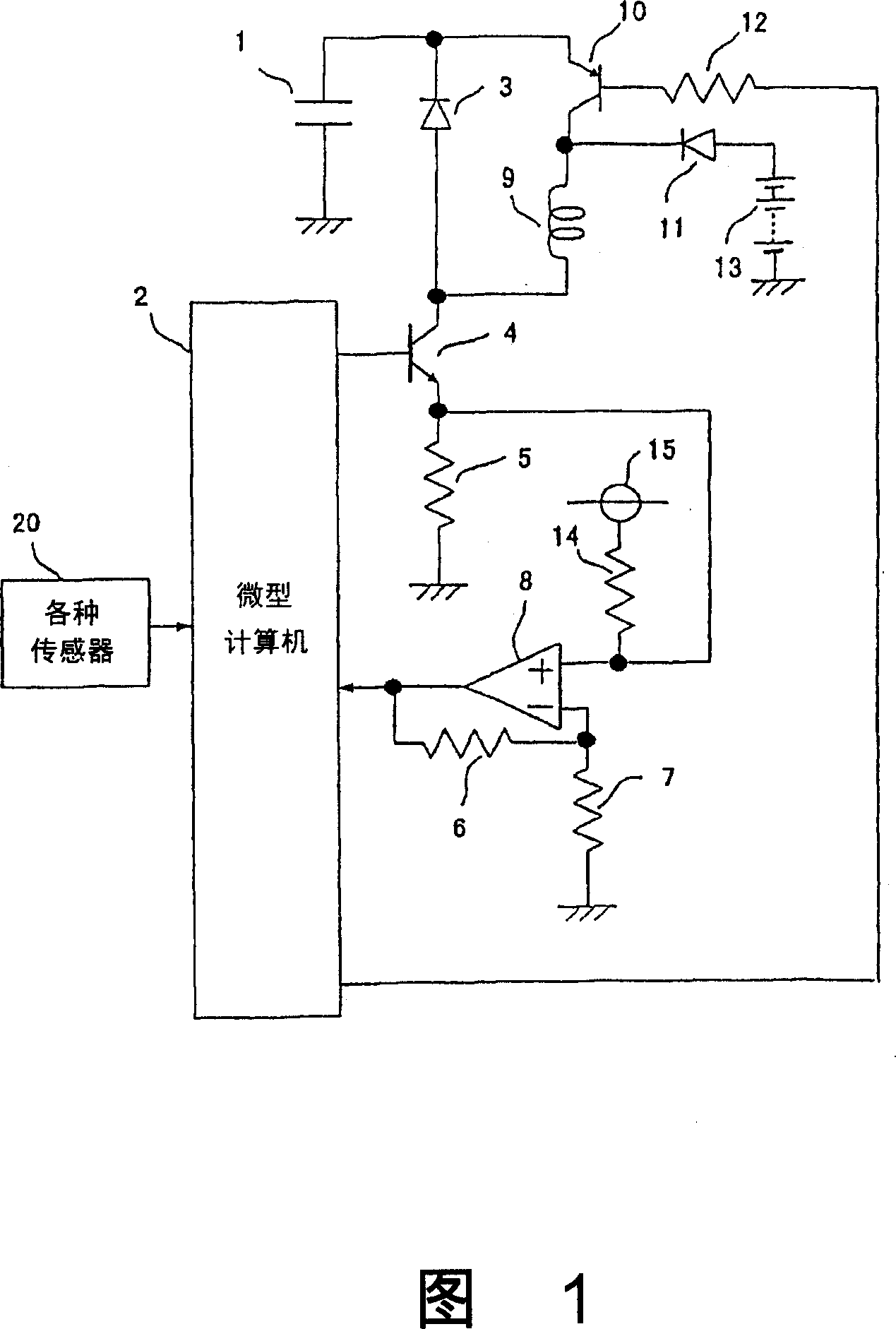

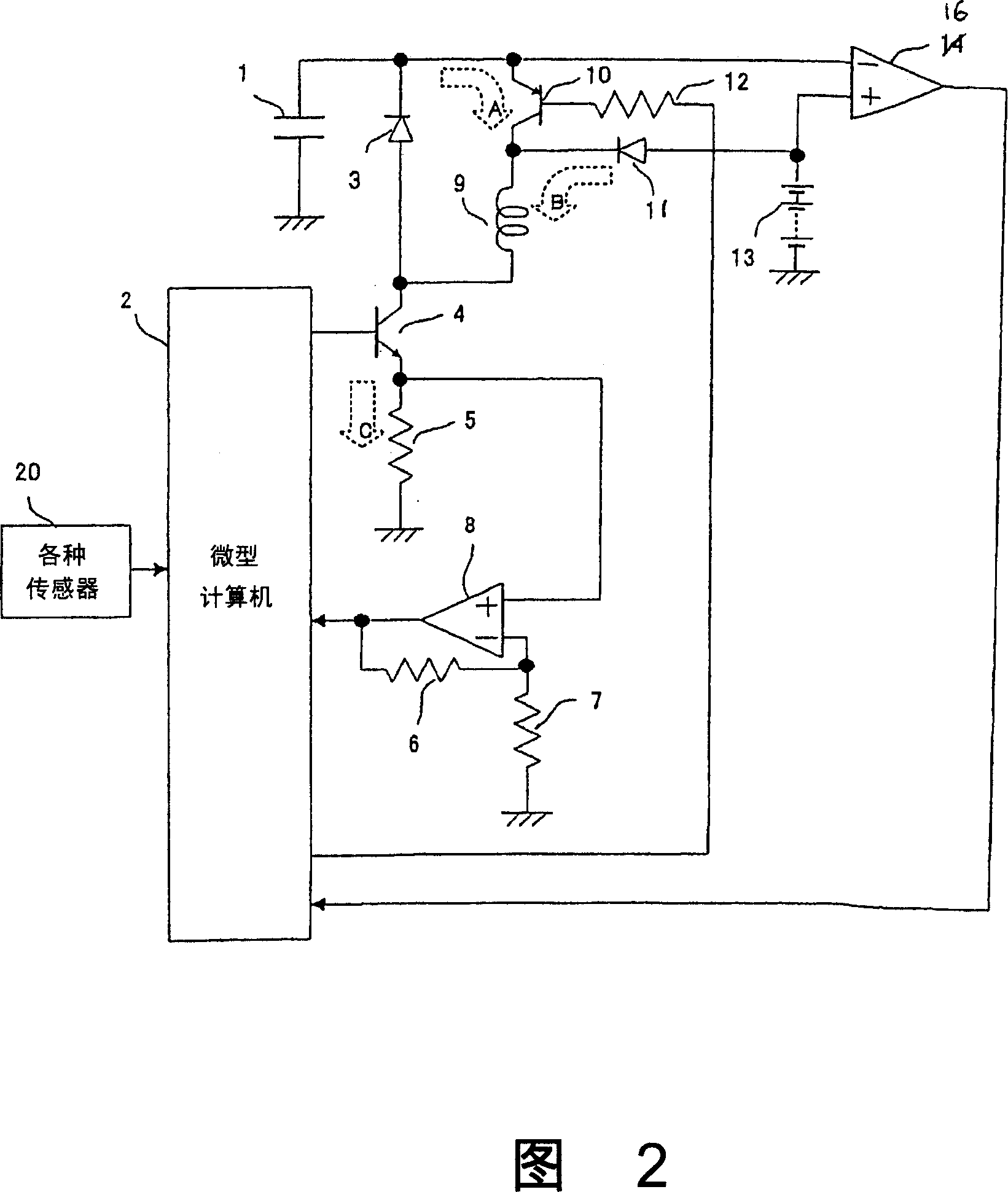

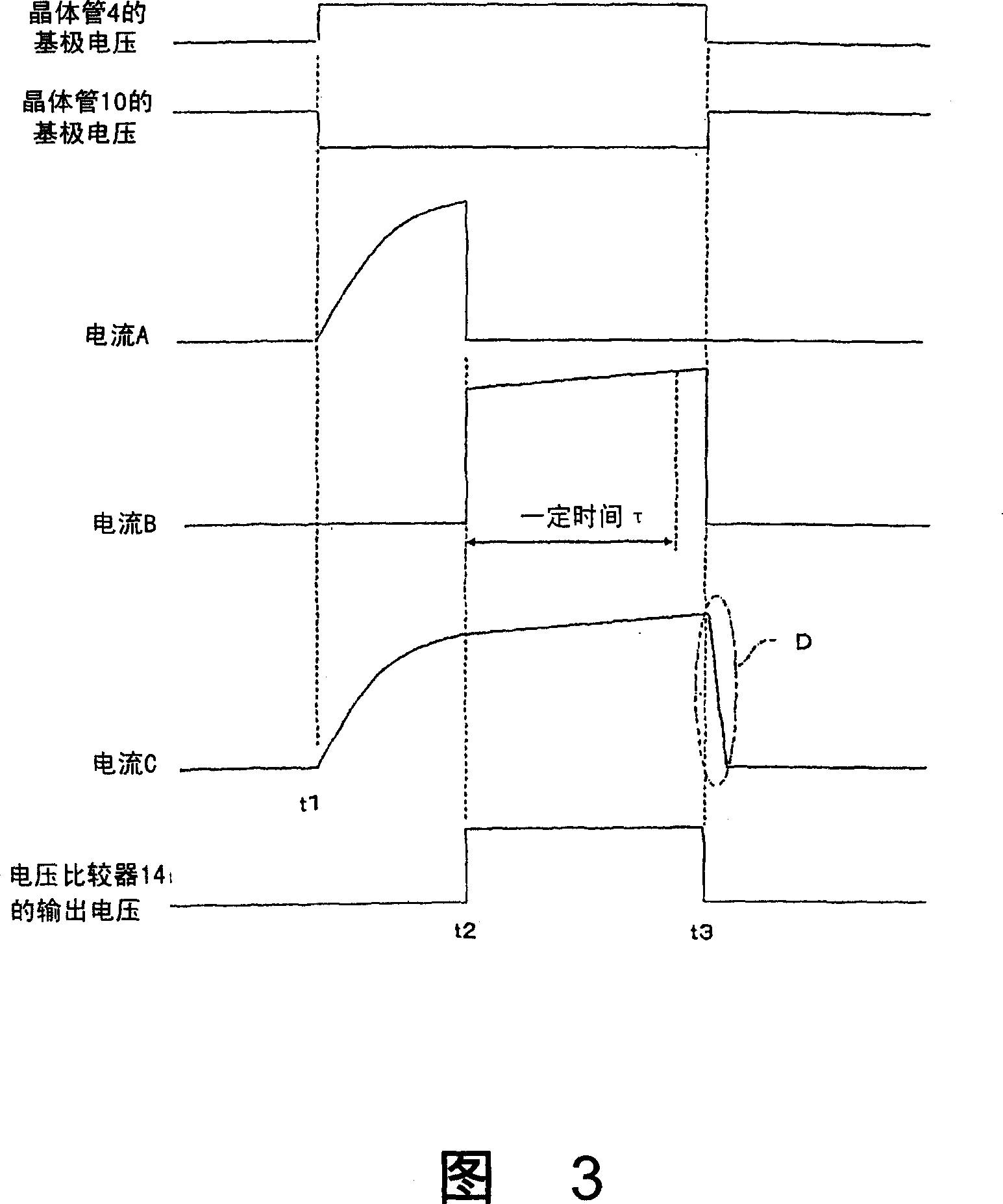

[0033] Fig. 1 shows a circuit diagram of a fuel injection system for an engine according to Embodiment 1 of the present invention.

[0034] The device shown in Figure 1 includes: a capacitor 1 with one end grounded, a microcomputer 2 with a CPU and various memory components, a diode 3 whose cathode is connected to the other end of the capacitor, and an output terminal (collector) connected to the anode of the diode 3 Transistor 4 , resistors 5 to 7 , 12 , 14 , operational amplifier 8 that detects the electromagnetic coil current flowing through transistor 4 , and electromagnetic coil 9 that is energized / disconnected by transistor 4 .

[0035] The device of Fig. 1 also includes: a transistor 10 inserted between one end of the electromagnetic coil 9 and the cathode of the diode 3, a diode 11 whose cathode is connected to one end of the electromagnetic coil 9, a battery 13 inserted between the anode of the diode 11 and the ground, connected by A bias power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com