A telescope lens barrel milling processing fixture

A technology of milling processing and telescope, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult to guarantee the size of the processing position, unable to automatically adjust the center, low work efficiency, etc., to meet the needs of convenient processing and improve The effect of high-speed turning processing quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

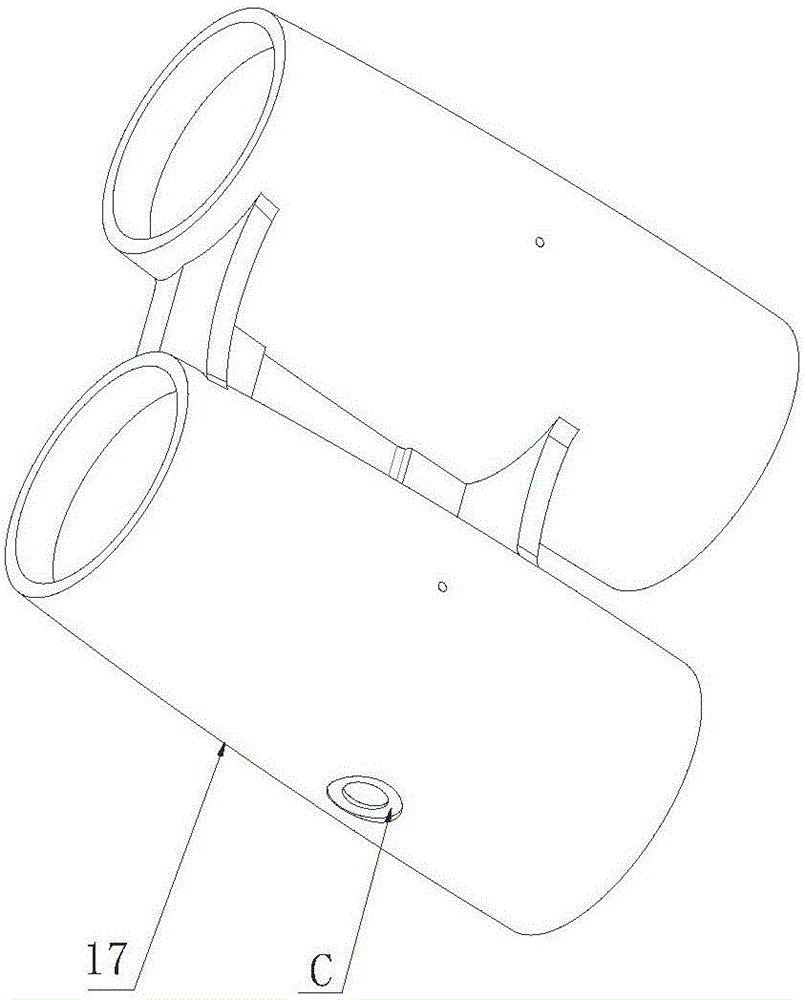

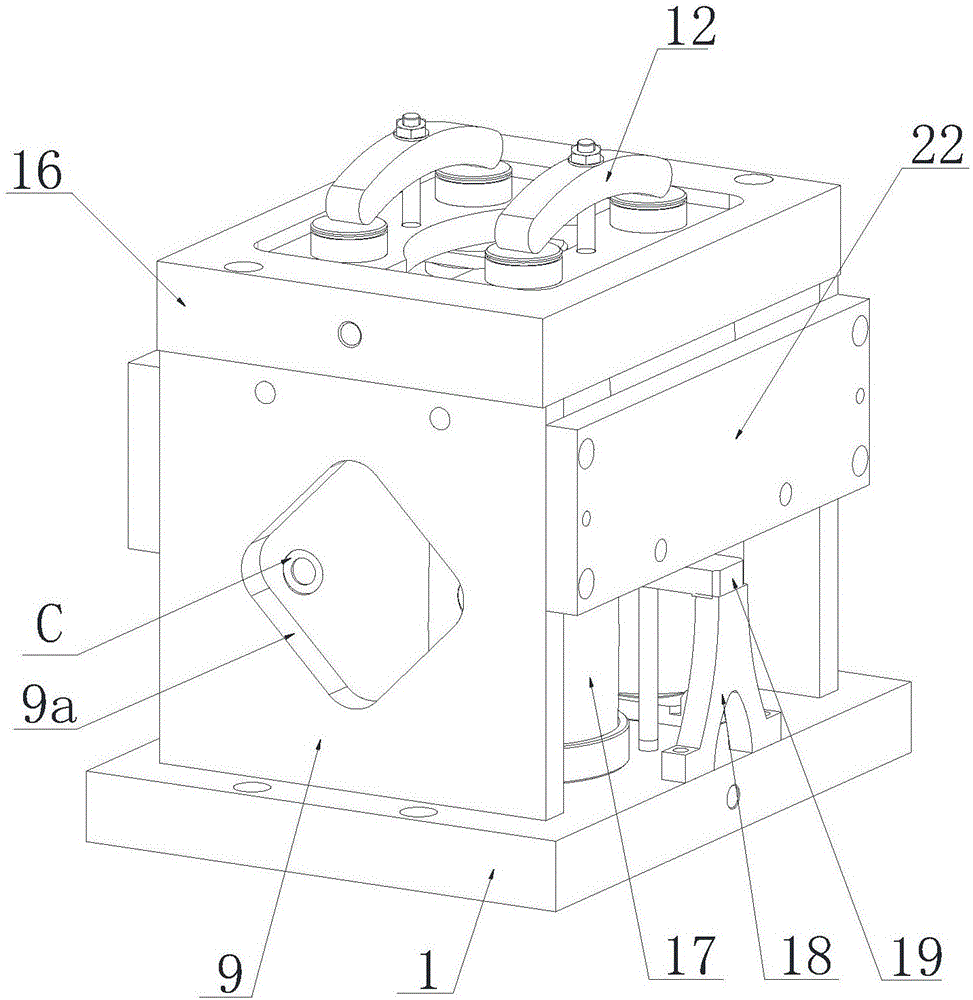

[0013] Such as Figure 1 to Figure 5 Shown: the present invention mainly is made up of clamping body, positioning device, clamping device. The present invention can clamp two pairs of telescope lens barrels at one time. The clamp body is surrounded by the bottom plate 1, the left side plate and the right side plate 9, the cover plate 16, the front side top plate and the rear side top plate 22, and a rhombus hole 9a is opened in the center of the left side plate and the right side plate 9, The diamond-shaped hole is facing the position of the hole C to be milled on the outer curved surface of the telescope lens barrel. Side plates of different shapes and opening forms can also be used, as long as they can meet the supporting function of the side plates of the clamp body and ensure the exposure of the processing position to facilitate the processing of the machine tool. Described positioning device is divided into the big end positioning device and the small end positioning de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com