Electromagnetic principle-based driving belt with automatic sieving function

A technology based on automatic screening and electromagnetic principles, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of difficult to be efficiently applied in the industrial field, unable to operate synchronously, and the selection of items is single.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

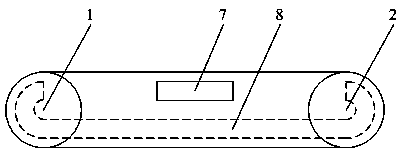

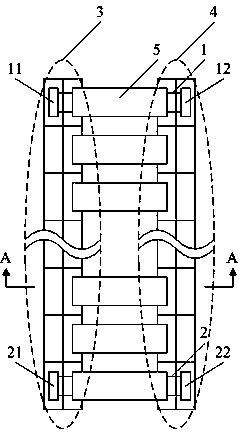

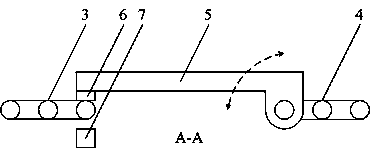

[0019] A conveyor belt with automatic screening function based on electromagnetic principles in this embodiment, the front view is as follows figure 1 shown; top view as figure 2 As shown, the direction from left to right in the top view is the direction from front to back described in the embodiment; image 3 yes figure 2 A schematic diagram of the A-A direction. The conveyor belt includes a drive shaft (1), a driven shaft (2) and a conveyor belt; the drive shaft (1) is provided with a drive front gear (11) and a drive rear gear (12), and the drive shaft (2) A driven front gear (21) and a driven rear gear (22) are provided; the driving front gear (11) and the driven front gear (21) are in the same vertical plane, driving the front chain (3) to form a circle Angular rectangular shape rotation, the driving rear gear (12) and the driven rear gear (22) are in the same vertical plane, driving the rear chain (4) to rotate in a rounded rectangular shape; the front chain (3) inc...

specific Embodiment 2

[0022] In this embodiment, on the basis of the specific embodiment 1, a controller (9) is added, and the control output end of the controller (9) is connected to the repelling electromagnet (7) and the attracting electromagnet (8), and the connection method is Parallel connection, at the same time, the driving shaft (1) is driven by the motor to rotate, and the speed data of the motor is sent to the controller (9) through the data input terminal of the controller (9). The schematic diagram of the circuit structure is as follows Figure 4 shown.

[0023] If the item to be tested on the conveyor belt is detected to be unqualified, the controller (9) calculates the speed of the conveyor belt according to the rotation speed of the motor, and calculates the The action time of the repelling electromagnet (7) is obtained, and when the item to be tested is conveyed above the repelling electromagnet (7) by the conveyor belt, the controller (9) sends a signal to the repelling electromag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com