Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Achieve low nitrogen combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

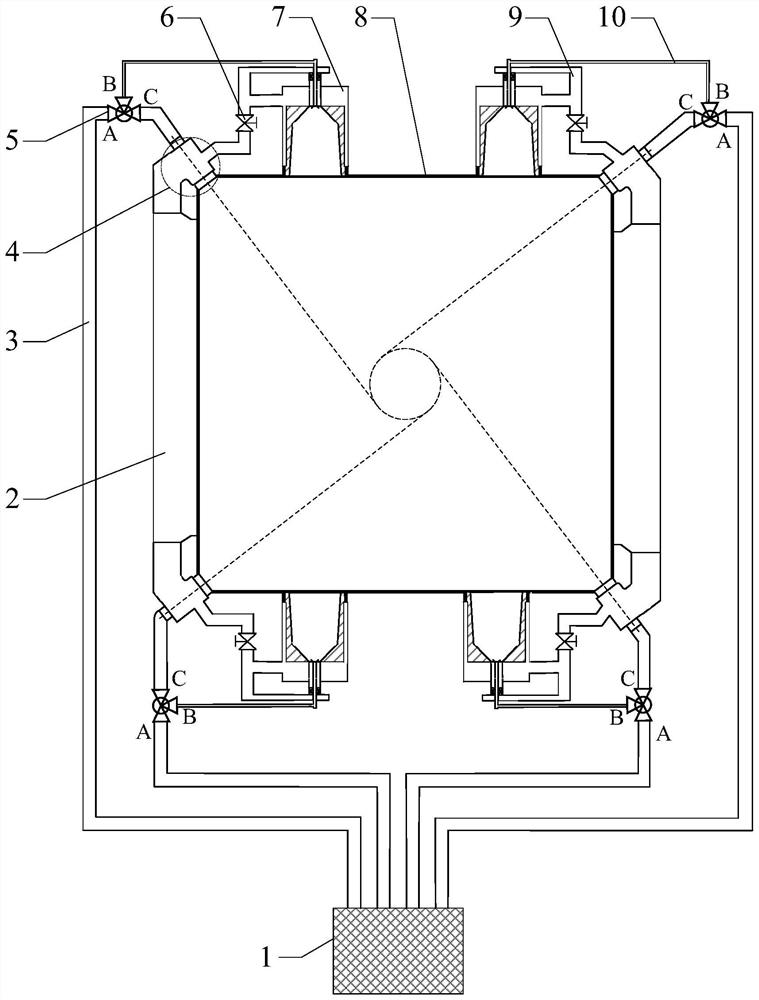

Ultralow boiler smoke emission device

PendingCN107270268AAchieve low nitrogen combustionReduce areaCombination devicesDispersed particle filtrationAir preheaterEmission standard

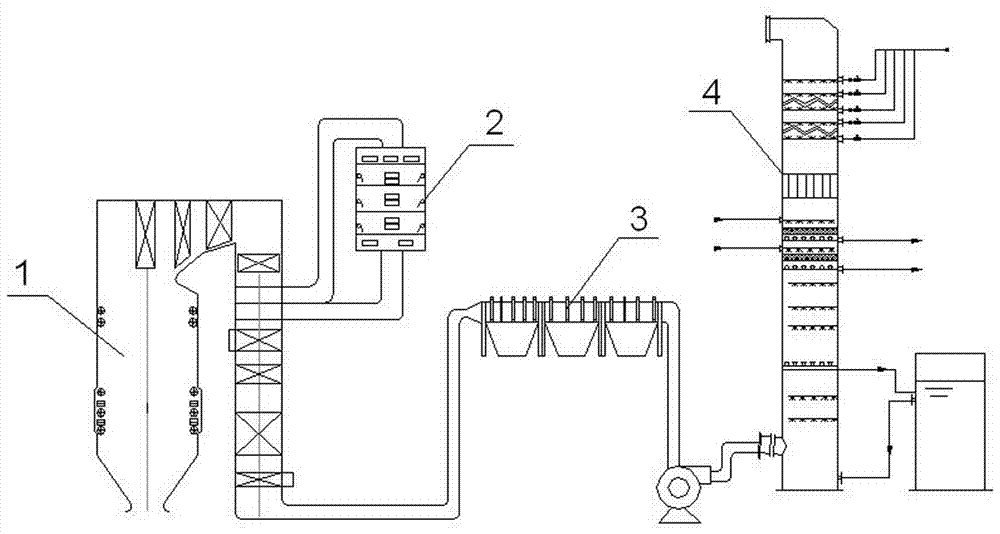

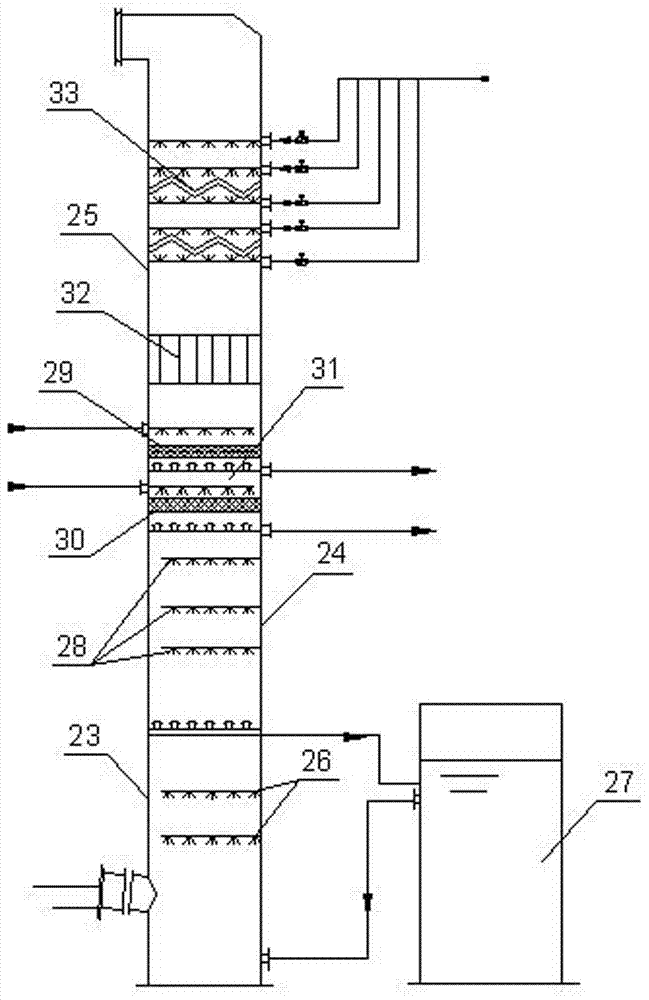

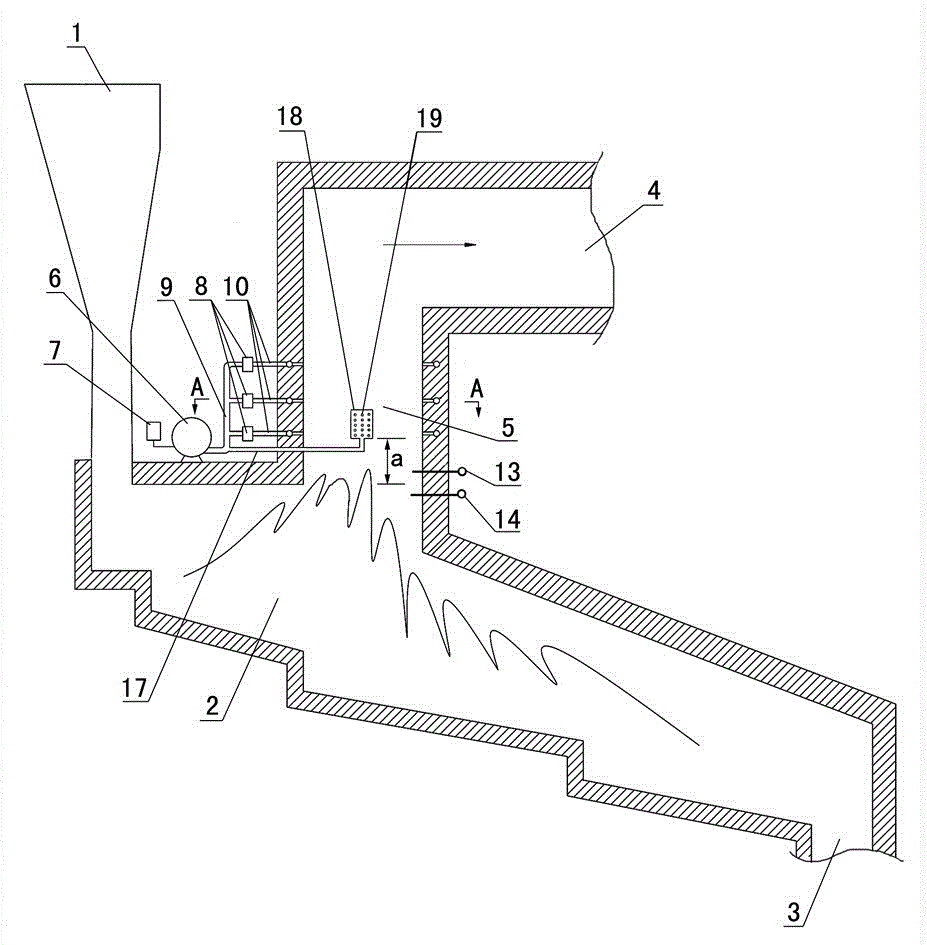

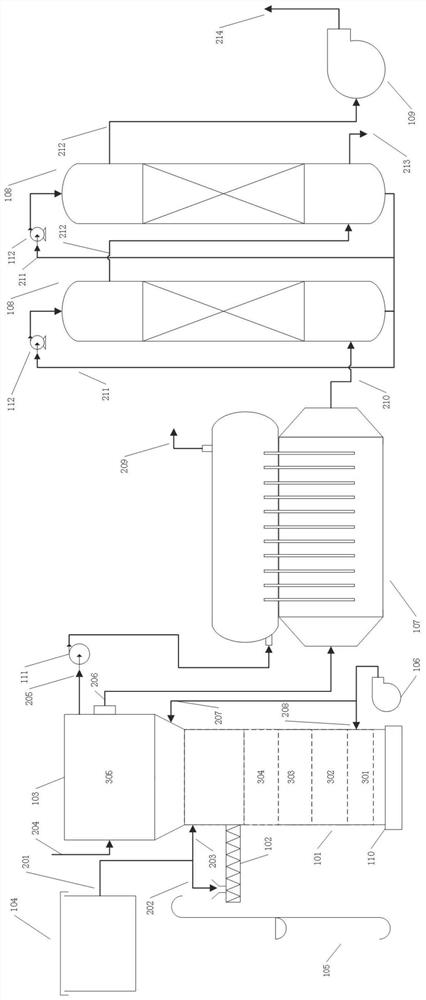

The invention discloses an ultralow boiler smoke emission device. The ultralow boiler smoke emission device comprises a coal fired boiler, a denitration reactor, a bag type dust remover and a desulfuration tower. The coal fired boiler comprises a hearth, a main combustor and a flue. The main combustor is arranged at the lower portion of the hearth. Two layers of over fire air spraying ports are formed in the upper portion of the hearth. A smoke guide-out pipeline and a smoke guide-in pipeline are arranged between a previous-level economizer and a previous-level air pre-heater in the flue and are connected with an inlet and an outlet of the denitration reactor correspondingly, and an outlet of the flue is sequentially connected with the bag type dust remover and the desulfuration tower. The desulfuration tower is internally provided with a washing section, an absorption section and a mist removing section from bottom to top. Two water washing spraying layers are arranged above the absorption section, and a PP filler layer is arranged between the upper water washing spraying layer and the lower water washing spraying layer. The mist removing section is sequentially provided with a pipe type mist remover and a ridge mist remover from bottom to top. By means of the ultralow boiler smoke emission device, the content of NOX, SO2 and soot in the boiler smoke can be reduced, the national ultralow emission standard is met, and long-period running target of the device is achieved.

Owner:河南开祥精细化工有限公司

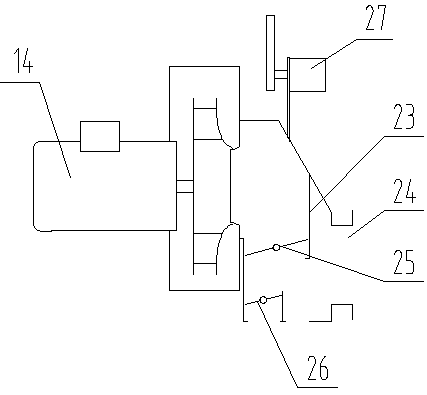

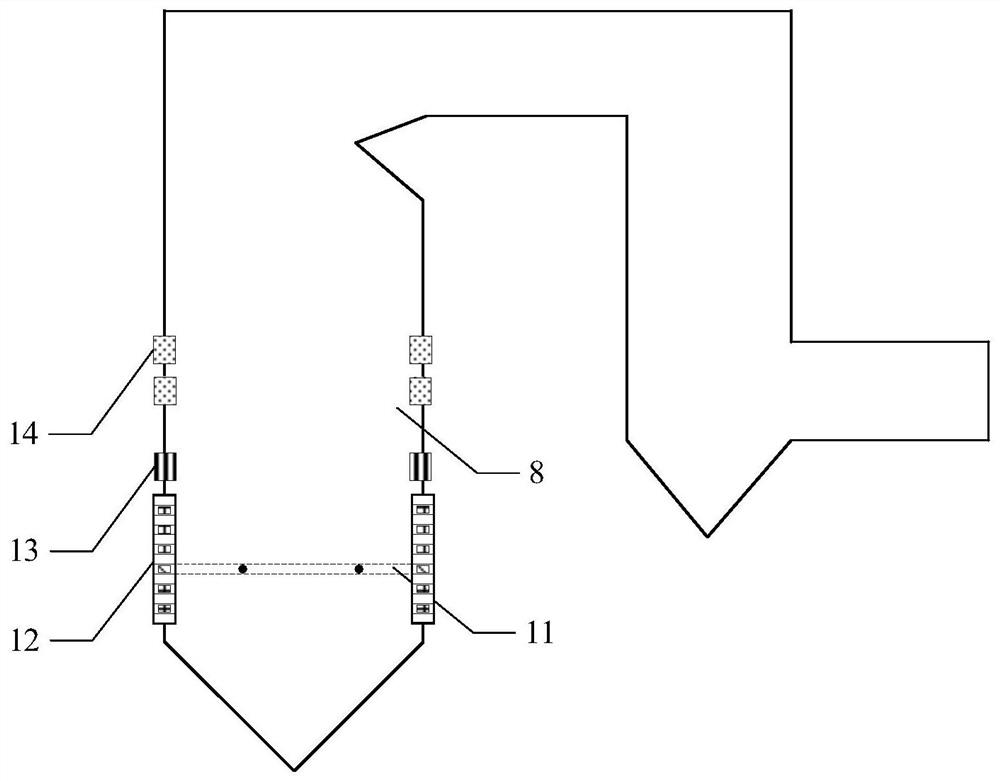

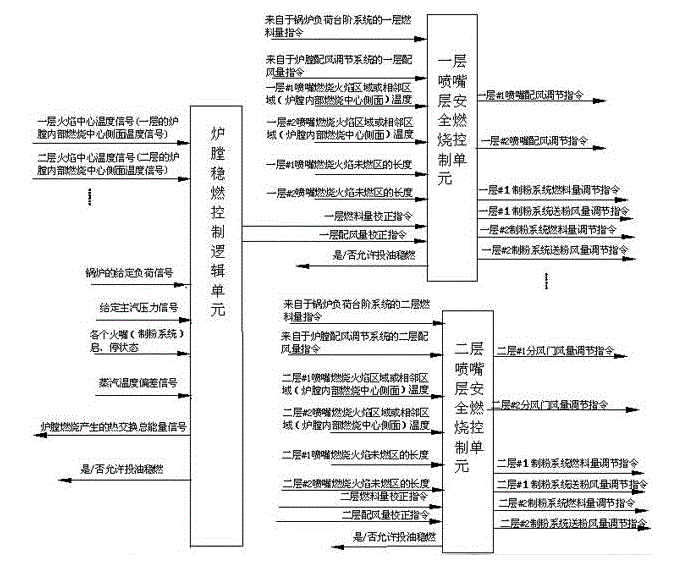

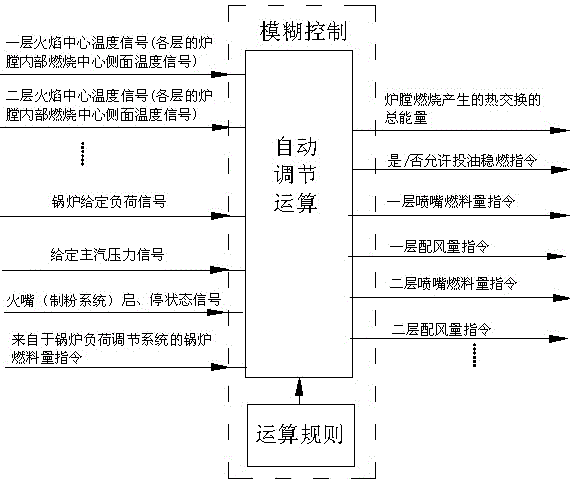

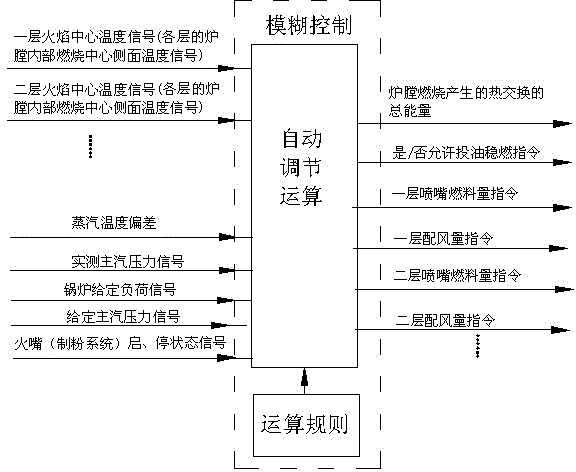

Automatic control method for preventing extinguishment and realizing ideal combustion for hearth

ActiveCN103047678AAutomatically adjust coal consumptionPrevent deflagrationCombustion regulationAutomatic controlCombustion

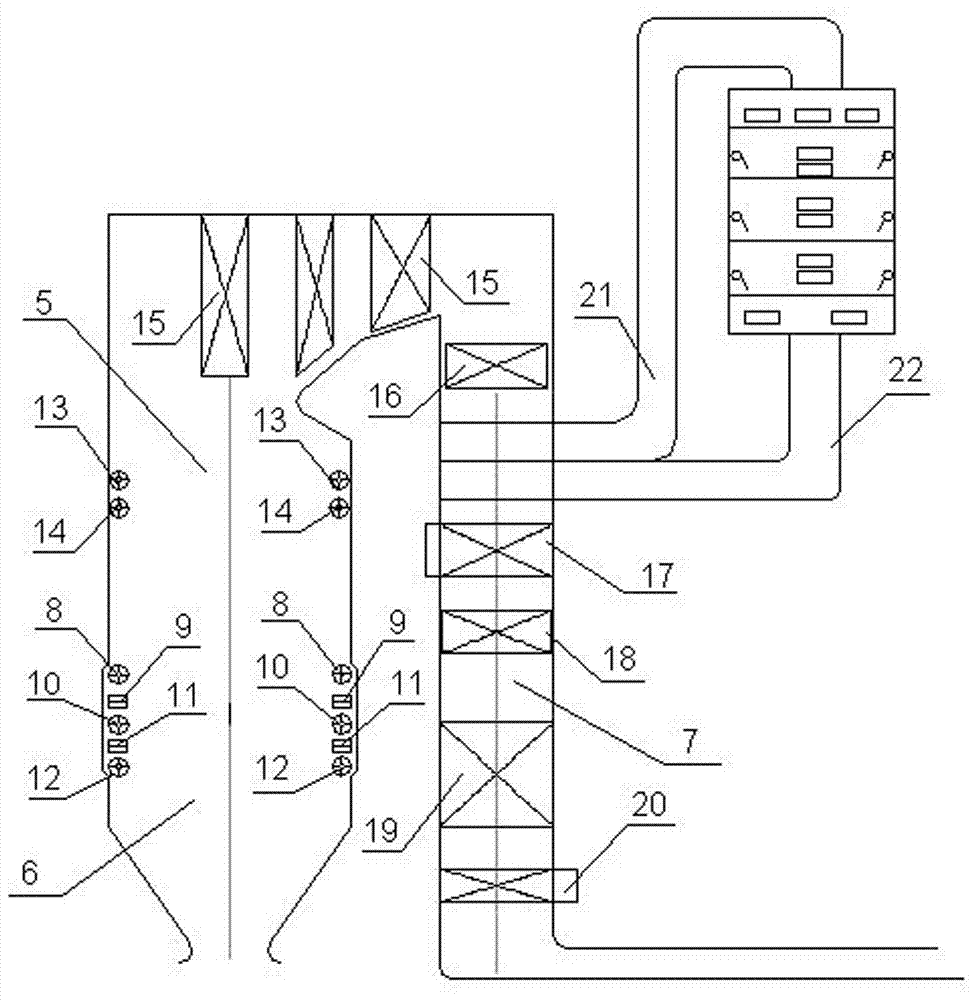

The invention discloses an automatic control method for preventing extinguishment and realizing ideal combustion for a hearth. The automatic control method is implemented by the aid of a full hearth control unit, signals inputted into the full hearth control unit at least include center temperature signals of various flame layers, given load signals of a boiler and starting and stopping state signals of various nozzles or pulverizing systems, automatic control operation is carried out inside the full hearth control unit, and signals outputted after automatic control operation at least include one type of fuel quantity instructions or fuel quantity correcting instructions of the various layers, air distribution quantity instructions or air distribution quantity correcting instructions of the various layers, oil feed combustion stabilizing instructions and total heat exchange energy signals generated during combustion of the hearth. The automatic control method has the advantages that the fuel coal quantity of the boiler and air quantities of the combustion nozzles can be adjusted automatically, excessively high temperature of the inside of the hearth is prevented, the boiler keeps in a stable combustion state, the extinguishment condition is stopped, the automatic control method is safe and convenient, and accordingly purposes of preventing extinguishment and realizing ideal low-nitrogen combustion are achieved for the hearth.

Owner:刘建松

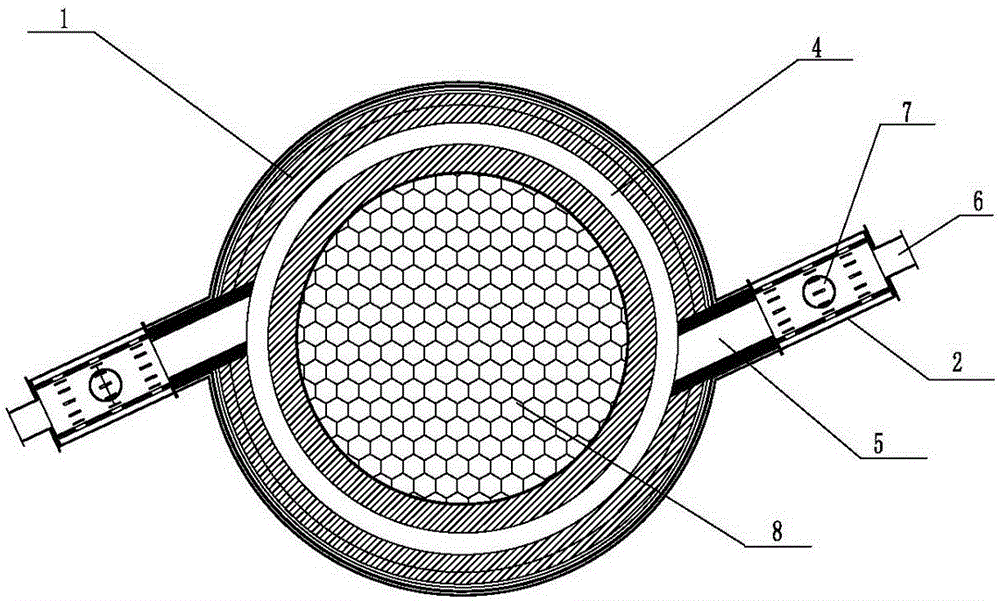

Temperature-controllable burner achieving central flow guide and adjustment and cyclone classification

ActiveCN106196054AReduce dosageInhibition of decomposition and reductionIndirect carbon-dioxide mitigationGaseous fuel burnerAirflowEngineering

The invention relates to a temperature-controllable burner achieving central flow guide and adjustment and cyclone classification. The temperature-controllable burner achieving central flow guide and adjustment and cyclone classification effectively solves the multiple problems that gas of different heat values and combustion-supporting air cannot be evenly mixed, the gas classified combustion effect is poor, distribution of a gas flow field is not uniform, and the combustion temperature cannot be controlled. A premixed gas cyclone loop channel with an upper opening is arranged on the upper portion inside a burner wall. One or more premixed gas inlet channels are connected to the outer side of the premixed gas cyclone loop channel. The outer end of each premixed gas inlet channel extends out of the burner wall to be connected with an external gas flow premixer. The end of the external gas flow premixer is provided with a gas inlet pipe. The outer wall of the external gas flow premixer is connected with an air inlet pipe. The top of the burner wall is provided with a secondary gas flow spray inlet. A stacked body composed of multiple ceramic porous bodies is built in a stacked manner inside the burner wall. The top of the stacked body is in a pit shape. The bottom of the stacked body is provided with a burner gas flow outlet. By the adoption of the temperature-controllable burner achieving central flow guide and adjustment and cyclone classification, the combustion temperature and the combustion intensity can be adjusted, the combustion stability is improved, energy is saved, environmental friendliness is achieved, safety and stability are achieved, and the discharge amount of harmful gases is reduced.

Owner:陈维汉

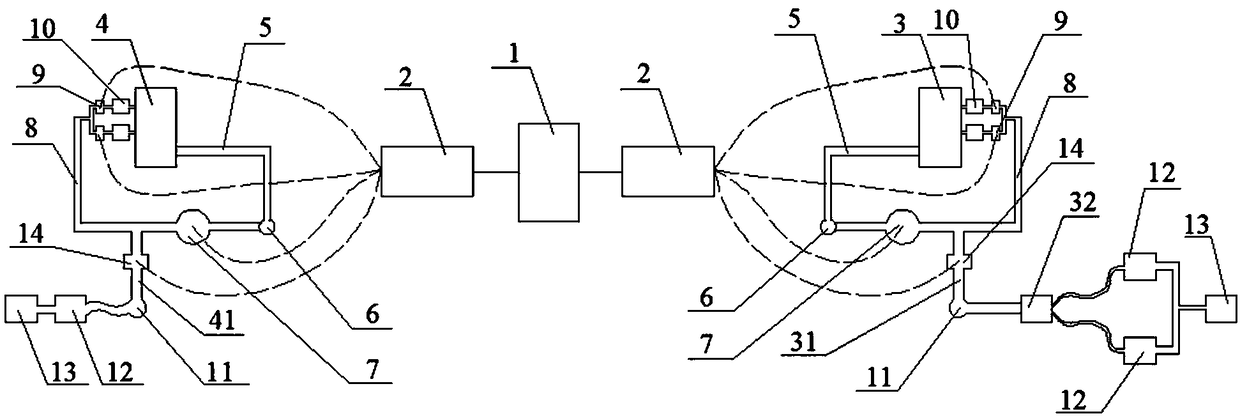

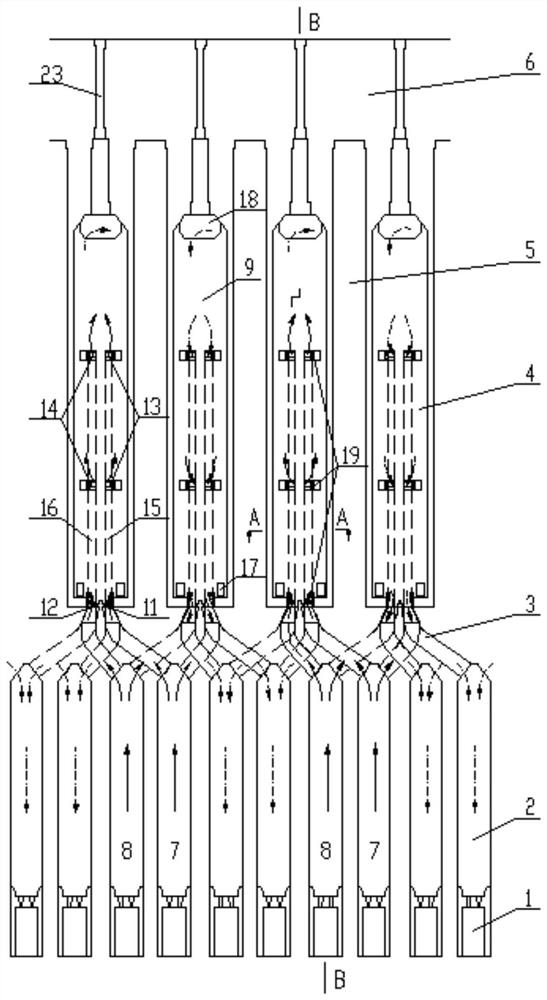

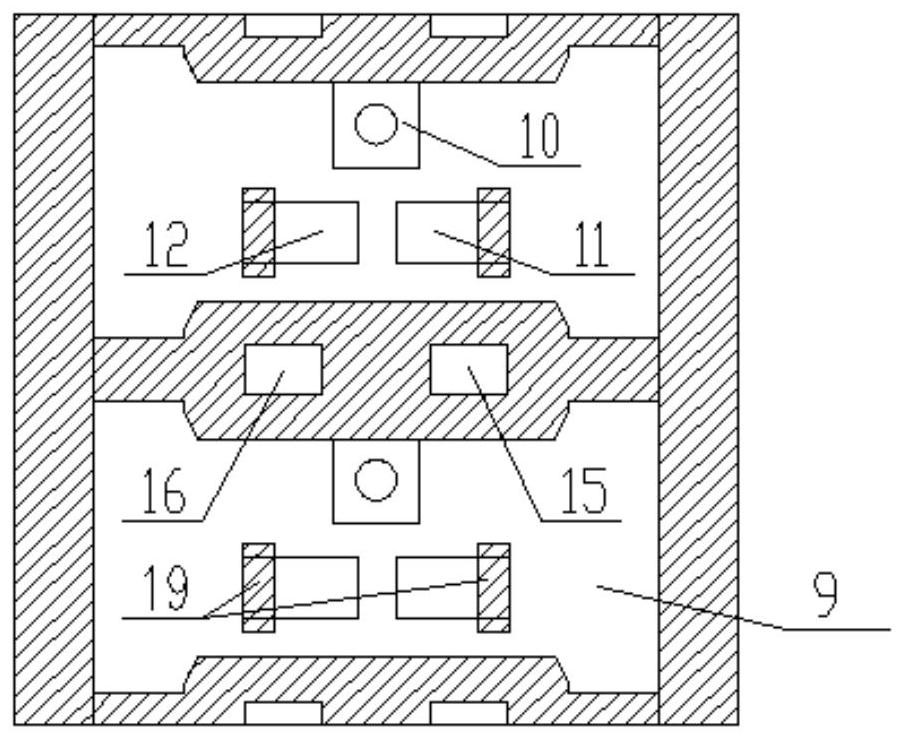

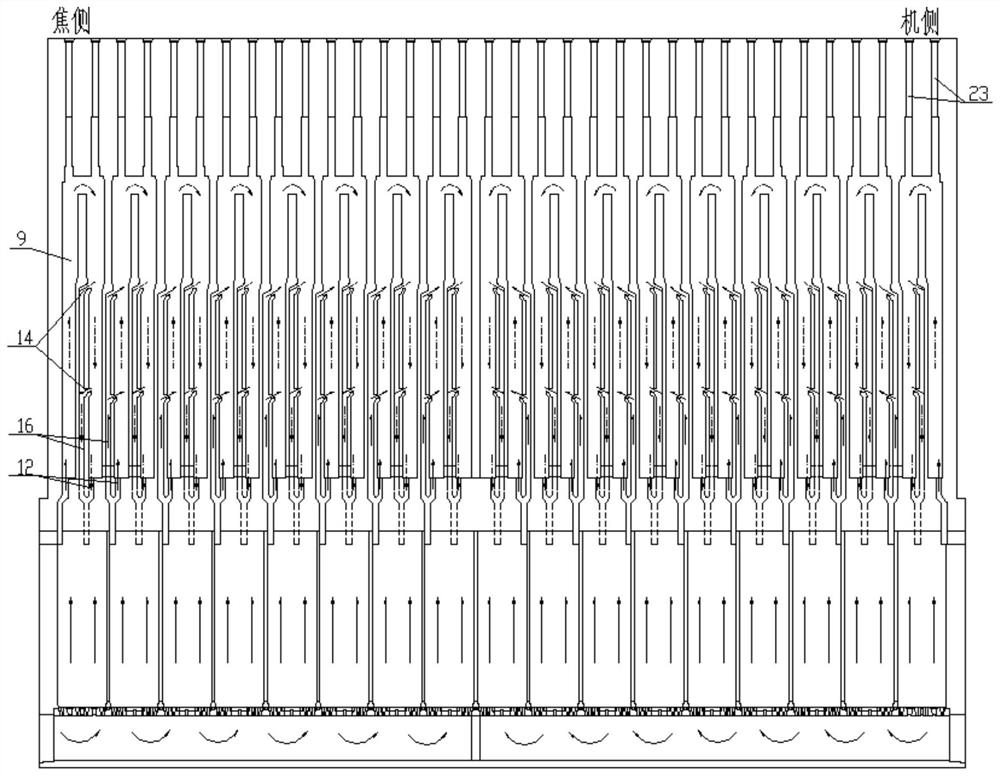

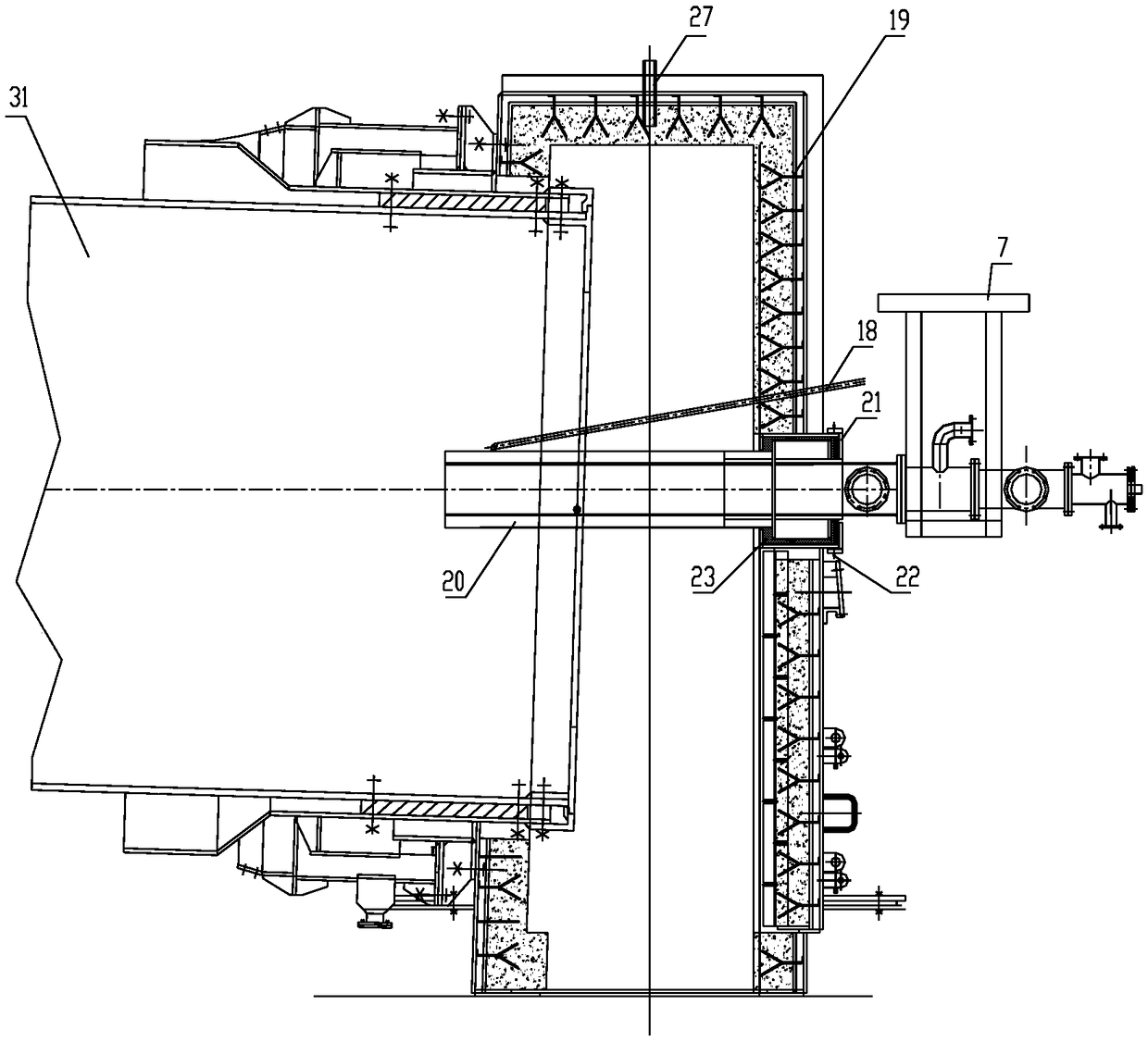

Device for reducing nitric oxide in coke oven flue gas through exhaust gas circulation

PendingCN108916888AReduce the temperatureControl generationFuel supply regulationIncinerator apparatusFlue gasLow nitrogen

The invention discloses a device for reducing nitric oxide in coke oven flue gas through exhaust gas circulation. The device comprises a PLC control panel. The PLC control panel is connected with twoindustrial personal computers. The two industrial personal computers are connected with a single heating coke oven outer circulation system and a reheating coke oven outer circulation system. The single heating coke oven outer circulation system is connected with a single heating coke oven. The reheating coke oven outer circulation system is connected with a reheating coke oven. The air is provided for the single heating coke oven and the reheating coke oven through a first waste gas mixing unit and a second waste gas mixing unit correspondingly and mixed with coke oven waste gas. The mixing ratio is adjusted by adjusting the opening degree of a gate plate. The flame center temperature of a coke oven burning point can be reduced so as to control the generation amount of NOX and achieve low-nitrogen burning.

Owner:SHANXI HEIMAO JIAOHUA CO LTD

Low-nitrogen gas burner with adjustable and self-circulation exhaust gas in furnace

PendingCN108730978ATo achieve the purpose of automatic recyclingNo power lossGaseous fuel burnerCombustion apparatusLow nitrogenEngineering

The invention relates to a low-nitrogen gas burner with an adjustable and self-circulation exhaust gas in a furnace. The low-nitrogen gas burner with the adjustable and self-circulation exhaust gas inthe furnace comprises a combustion cylinder with an axial air inlet, a radial gas inlet and an axial outlet, wherein a gas pipe connected with the radial gas inlet is coaxially arranged in the combustion cylinder; an ignition device and a flame stabilizing plate are arranged on the axial outlet; the combustion cylinder comprises a first cylinder body and a second cylinder body sequentially connected along the gas axial conveying direction; multiple reflowing holes are formed in the second cylinder body; a gas reflowing amount adjusting structure for adjusting the sizes of the reflowing holesis correspondingly arranged in the combustion cylinder; an air guiding plate coaxially sleeves at a position, close to the reflowing holes, on the gas pipe; the air guiding plate extends toward the gas axial output direction so as to form a hollow-shaped circular truncated cone periphery wall with a gradually increased opening; an air guiding channel is formed between the hollow-shaped circular truncated cone periphery wall and the second cylinder body; and the sectional dimension of the air guiding channel along the gas axial conveying direction is gradually reduced. According to the structure, the aims of self circulation and secondary combustion of gas are achieved through a negative pressure difference, and low-nitrogen emission is realized.

Owner:浙江炬烁热能设备制造有限公司

Regulation method for low-nitrogen emission of reheating coke oven

ActiveCN113122284ASolve the common problem of high emissionsAchieve low nitrogen combustionCombustible gas coke oven heatingEnergy inputThermodynamicsBrick

The invention relates to a method for adjusting low-nitrogen emission of a reheating coke oven. The method comprises the following steps: (1) adjusting bricks are arranged according to a lean gas heating mode; (2) when rich gas is adopted for heating, the air outlets and / or lean gas outlets of one or more sections in a vertical flame path are blocked by the adjusting bricks, so the amount of combustion-supporting air entering the bottom, the middle and the upper part of the vertical flame path can be independently and quantitatively adjusted, and low-nitrogen emission during rich gas heating is realized; and (3) when lean gas is adopted for heating, the adjusting bricks used for blocking the air outlets or the lean gas outlets in the step (2) are moved away, the initial state that the adjusting bricks are arranged according to the lean gas heating mode is recovered, and low-nitrogen emission during lean gas heating is achieved. According to the invention, one or more segmented outlets of air or lean gas in the vertical flame path are opened or closed, so the reheating coke oven which conducts segmented heating can realize low-nitrogen combustion no matter lean gas heating or rich gas heating is adopted.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

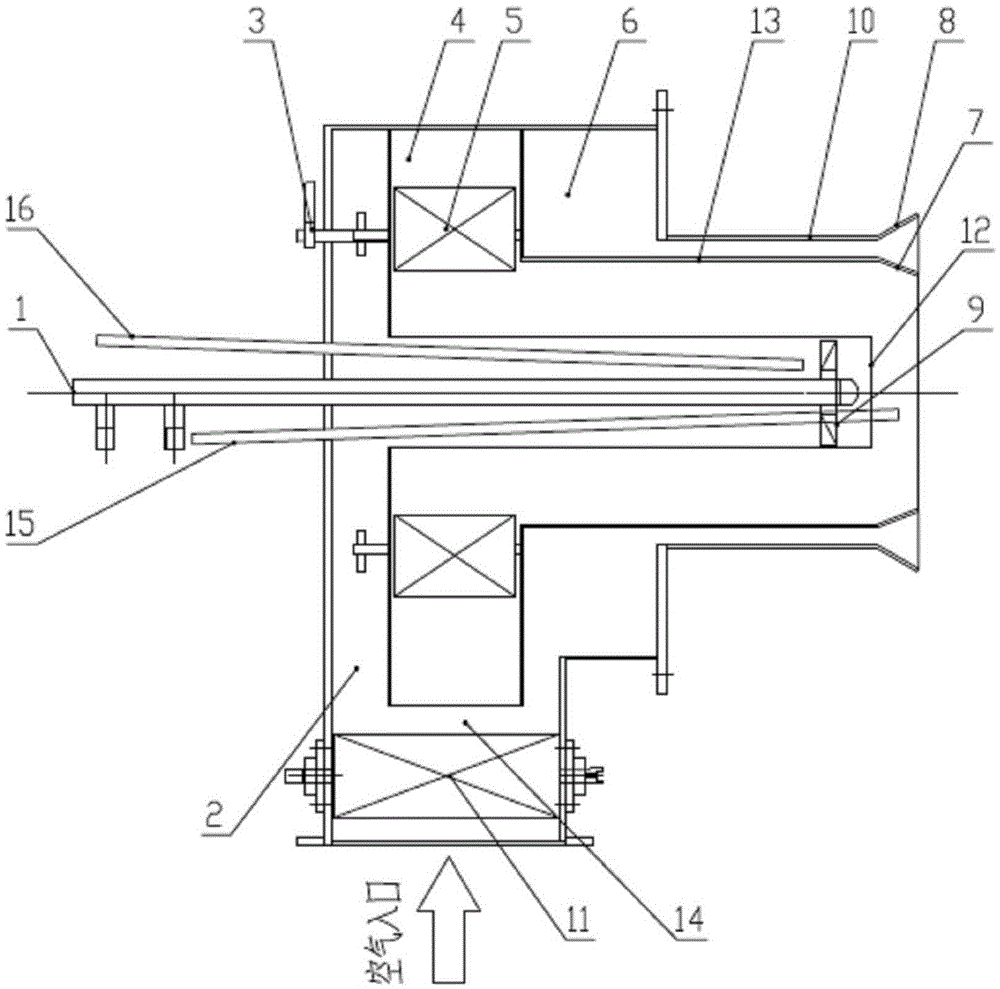

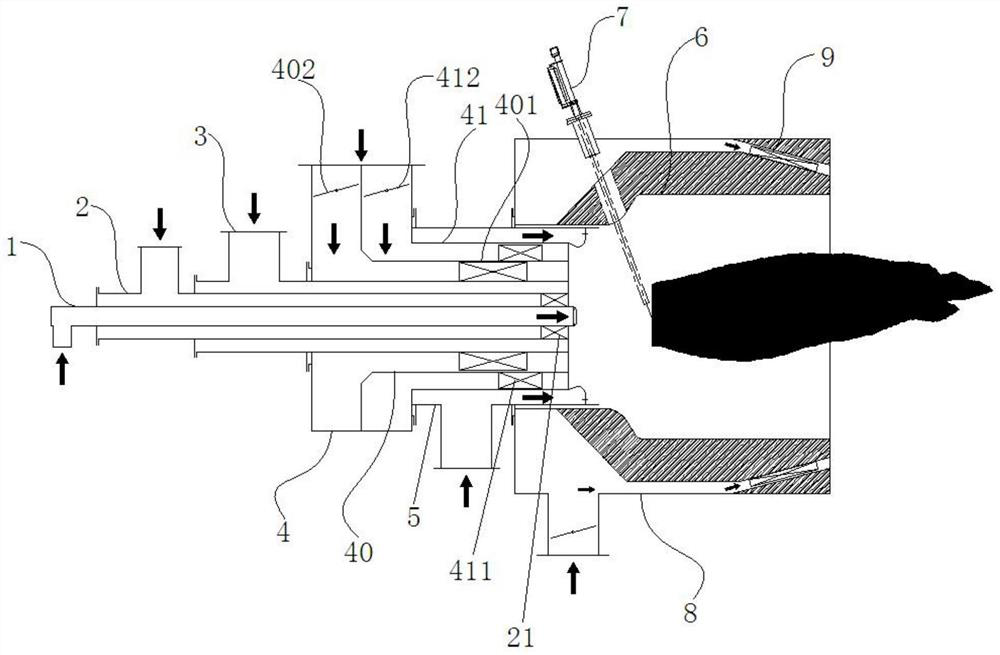

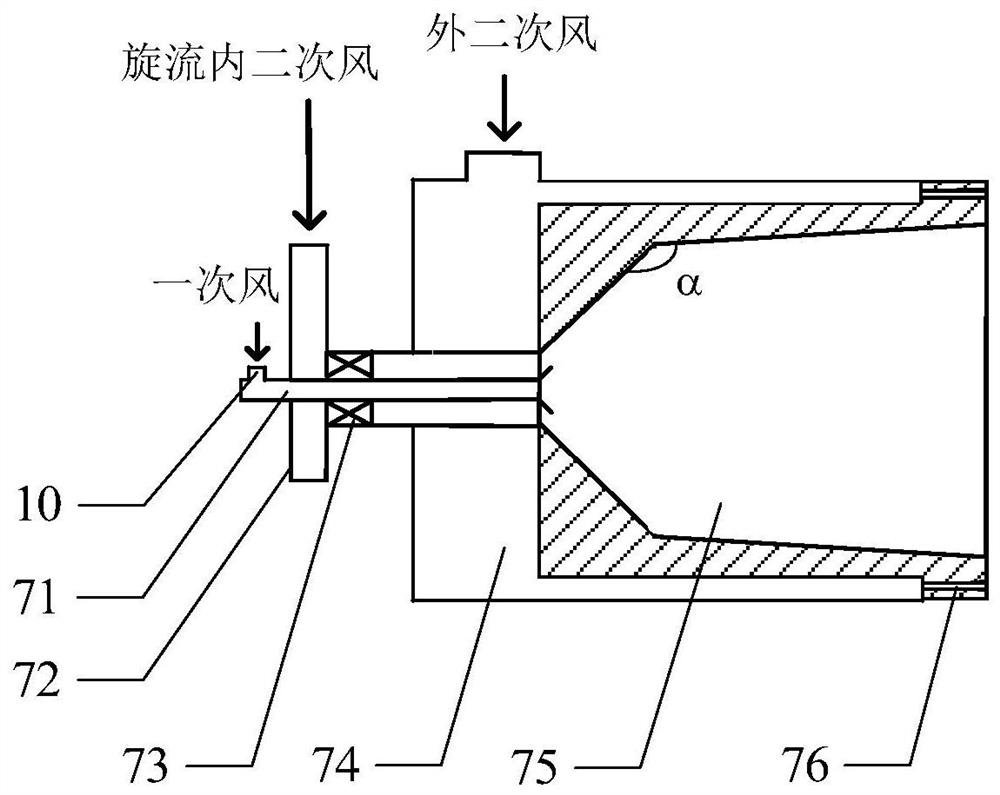

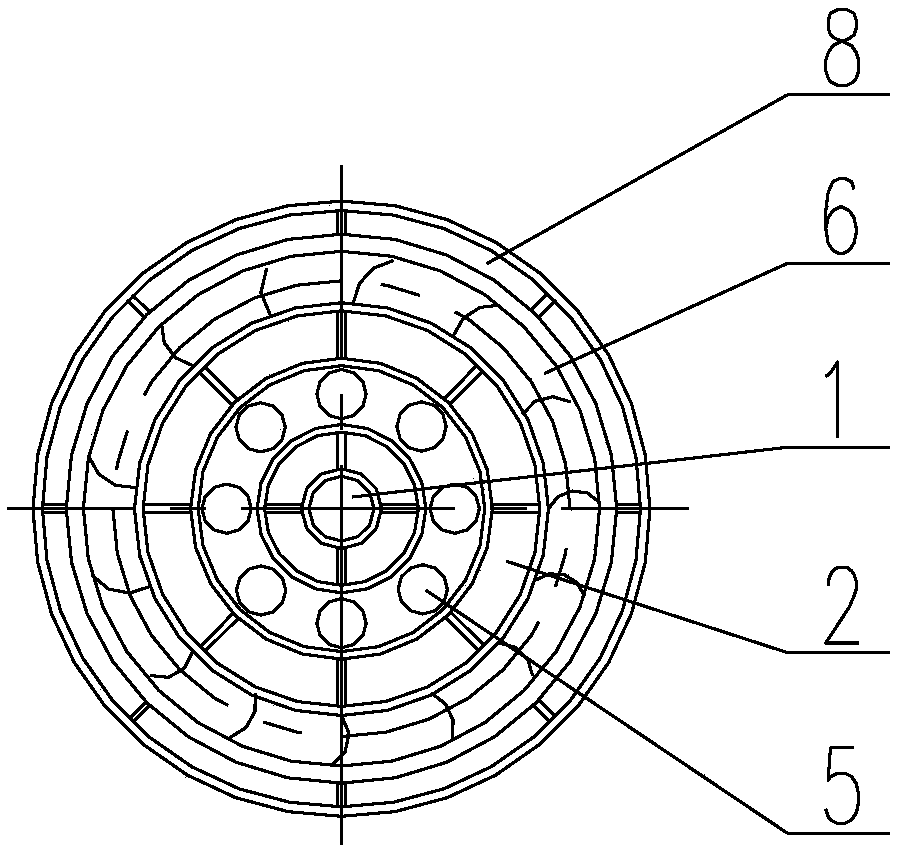

Crude oil swirling low-nitrogen burner of steam-injection boiler

InactiveCN105526585AGuaranteed to burnRealize ignition and stable combustionBurnersNitrogen oxidesLow nitrogen

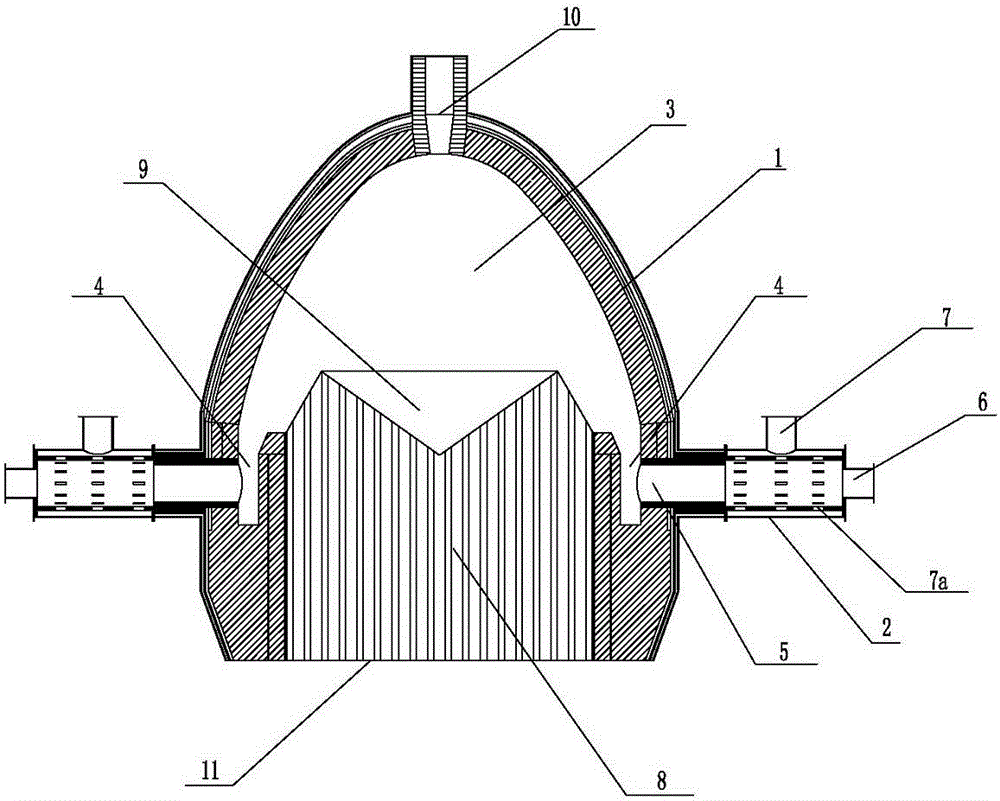

The invention discloses a swirling crude oil burner, utilizing burning crude oil, of a steam-injection boiler. Such a crude oil swirling low-nitrogen burner comprises, in an air flow direction, an air inlet, a control damper, a central air chamber, a secondary air chamber, a peripheral air chamber, a secondary air nozzle and a peripheral air nozzle in order. Central air orderly flows through the central air chamber, a central air duct and a flame stabilizer. Secondary air orderly flows through the secondary air chamber, a secondary air swirling plate, a secondary air duct and the secondary air nozzle. Peripheral air orderly flows through the peripheral air chamber, a peripheral air duct and the peripheral air nozzle. An oil gun, a flame detector and the flame stabilizer all are arranged in the central air duct. The burner provided by the present invention organizes air for combustion via reasonable staging to realize staged combustion of the crude oil, and therefore, the generation of nitrogen oxides may be effectively reduced and nitrogen emissions may be reduced; in addition, the burner has the advantages of simple system, easy maintenance, low maintenance cost and long service life.

Owner:南京创能电力科技开发有限公司

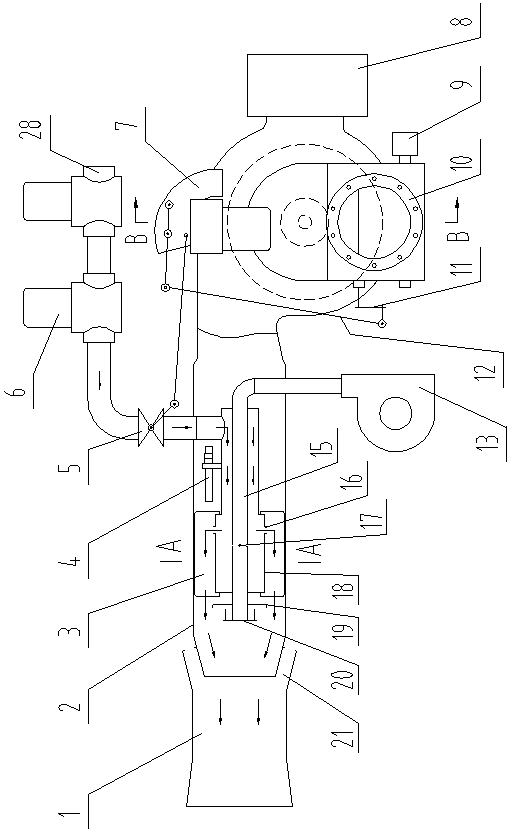

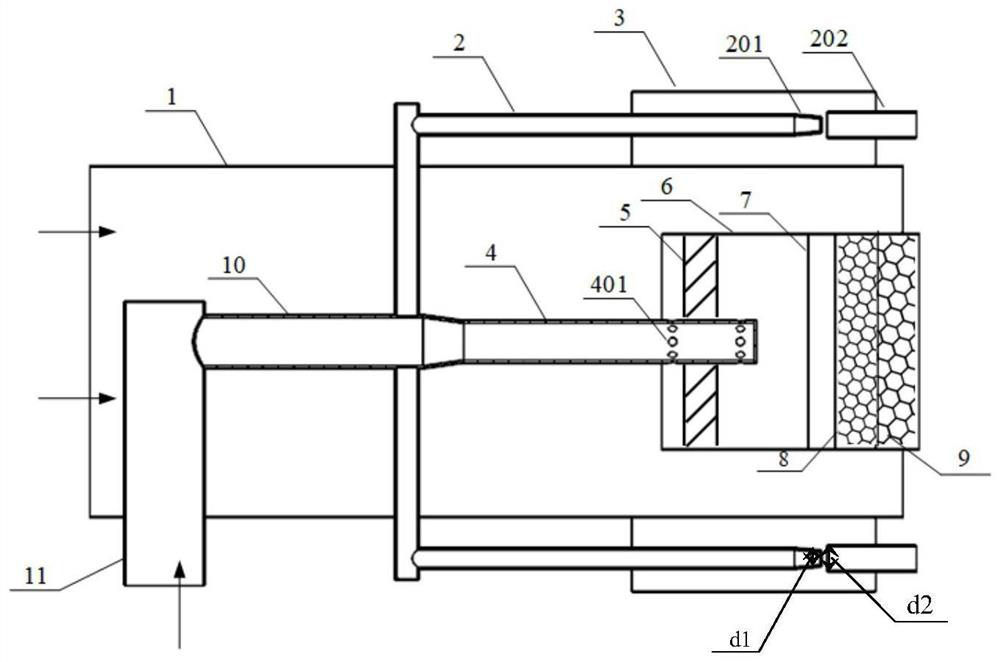

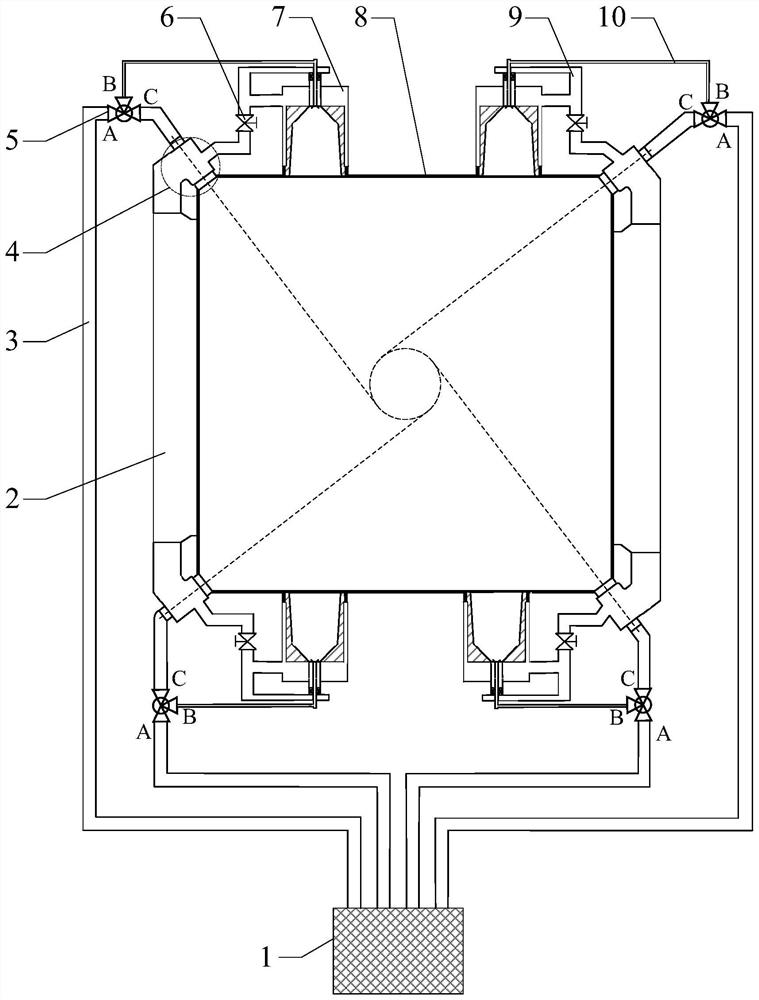

Low nitrogen oxide emission burner device

PendingCN109579009AEliminate flash explosion riskLarge thermal load turndown ratioGaseous fuel burnerGas separationOxide

The invention relates to a low nitrogen oxide emission burner device. A tubular gas chamber is arranged inside an air pipe; a multi-chamber premixer structure is formed by gas separation plates and gas spray orifices on the outer cylindrical surface of the gas chamber; a central air pipe is arranged inside the air pipe; a gas inlet hole is formed in the outer circular surface of the central air pipe; one end of the central air pipe is connected to a kindling material draught fan, and the other end of the central air pipe is provided with a kindling material burning head; the front end of the air pipe is provided with a secondary mixing device which sucks part of flue gas in a furnace hearth by a gas inlet annular passage of a furnace chamber of the secondary mixing device through the negative pressure effect formed by high-speed and high-temperature airflow at the front end of the air pipe; the air pipe is connected to a main draught fan which is connected to an air inlet channel; a flue gas introduction cavity and an air introduction cavity are arranged inside the air inlet channel; two stages of ventilation doors are arranged at the lower part of the air introduction cavity; andthe proportion of air and flue gas entering the main draught fan is adjusted through the two stages of ventilation doors. The low nitrogen oxide emission burner device is based on two-premixing, two-mixing, two-air distribution, two-adjustment and one-stabilization design structure and realizes the ultra-low nitrogen combustion.

Owner:唐山冀东石油机械有限责任公司 +1

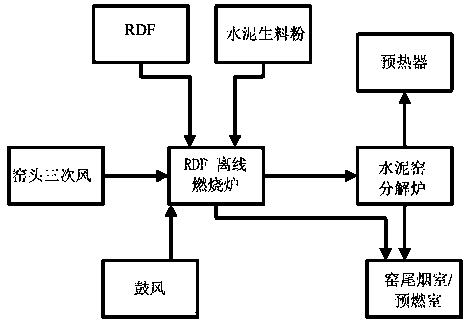

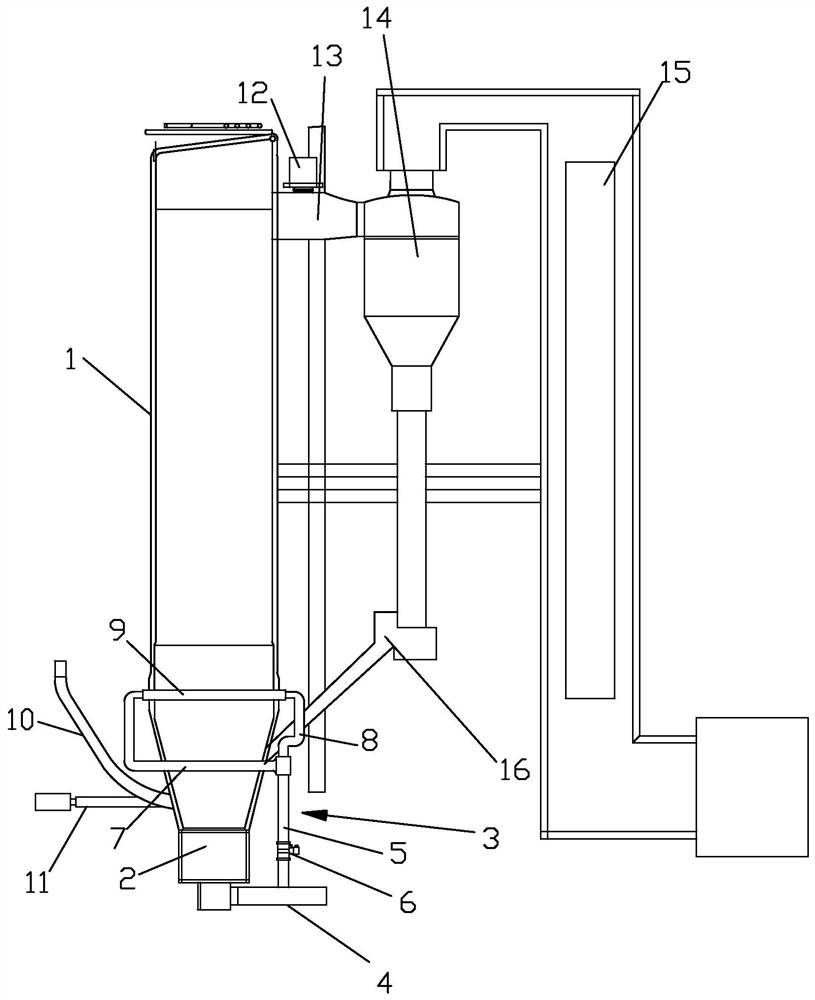

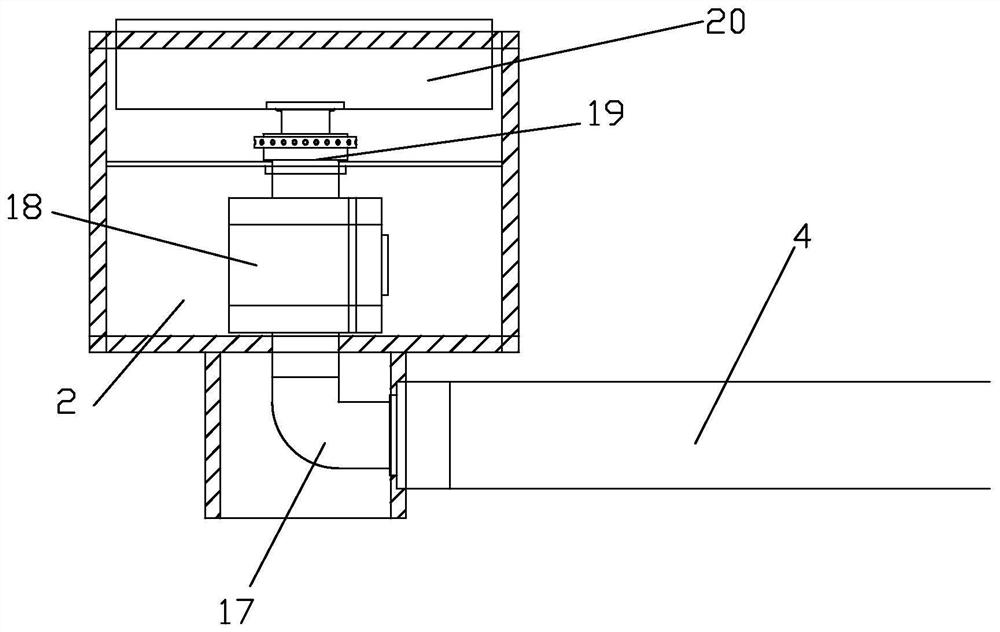

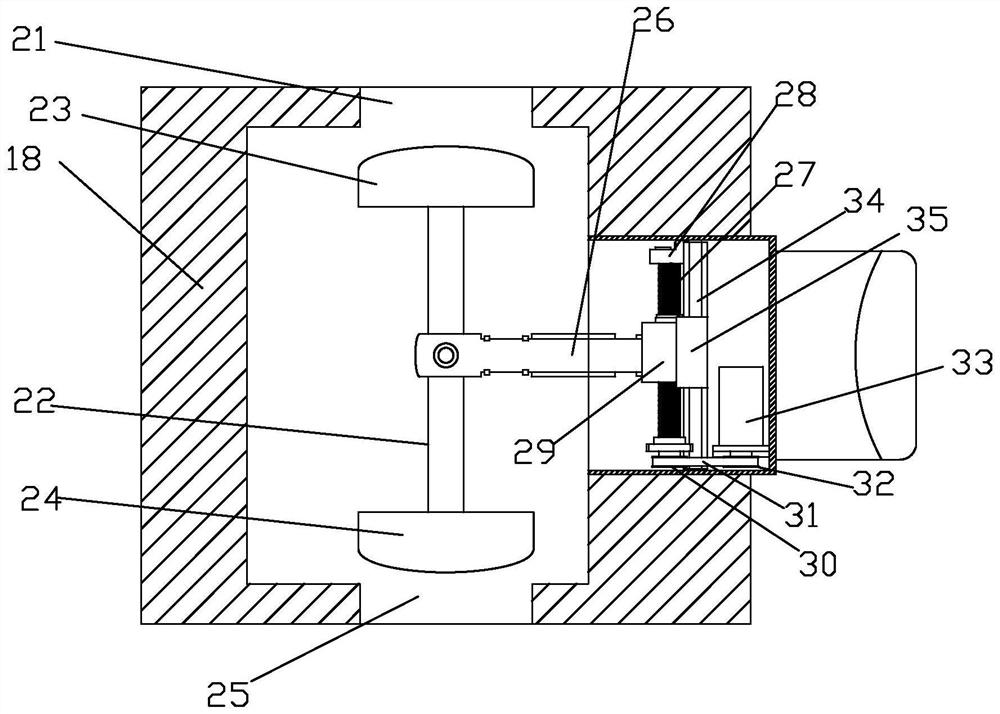

RDF (Refuse Derived Fuel) off-line burning technology and system

The invention relates to an RDF (Refuse Derived Fuel) off-line burning technology and system. According to the RDF (Refuse Derived Fuel) off-line burning technology, an off-line burning furnace for burning RDF is arranged outside a cement kiln decomposing furnace. The RDF off-line burning technology is characterized in that the RDF and a part of cement raw material powder are put into the off-line burning furnace and are burned, meanwhile, kiln hood tertiary air is fed into a furnace body of the off-line burning furnace so as to ensure that the RDF is burned at a high temperature, and meanwhile, oxygen is supplied for the burning of the RDF; a blower device is used for blasting from the bottom of the off-line burning furnace, so that the RDF and the cement raw material powder are suspended in the furnace body of the off-line burning furnace; waste gas generated in the off-line burning furnace through burning, another part of cement raw material powder and low-density fly ash generated after the RDF is burned are directly fed into the cement kiln decomposing furnace and are decomposed and burned, and high-density waste residues generated by the off-line burning furnace and hot raw materials enter a feed-end chamber together and are calcined to become clinker. The low-nitrogen combustion can be realized in the cement kiln decomposing furnace. The burning temperature in the off-line burning furnace reaches up to 1000 to 1200 DEG C, so that the RDF is fully and effectively burned, and the generation of dioxin is avoided; meanwhile, the construction cost is reduced.

Owner:华新环境工程有限公司 +2

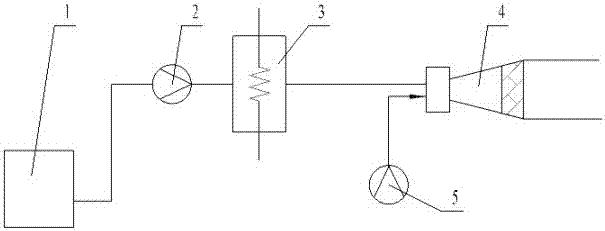

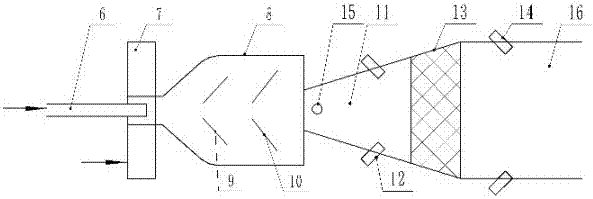

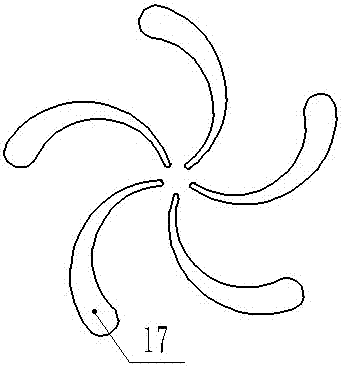

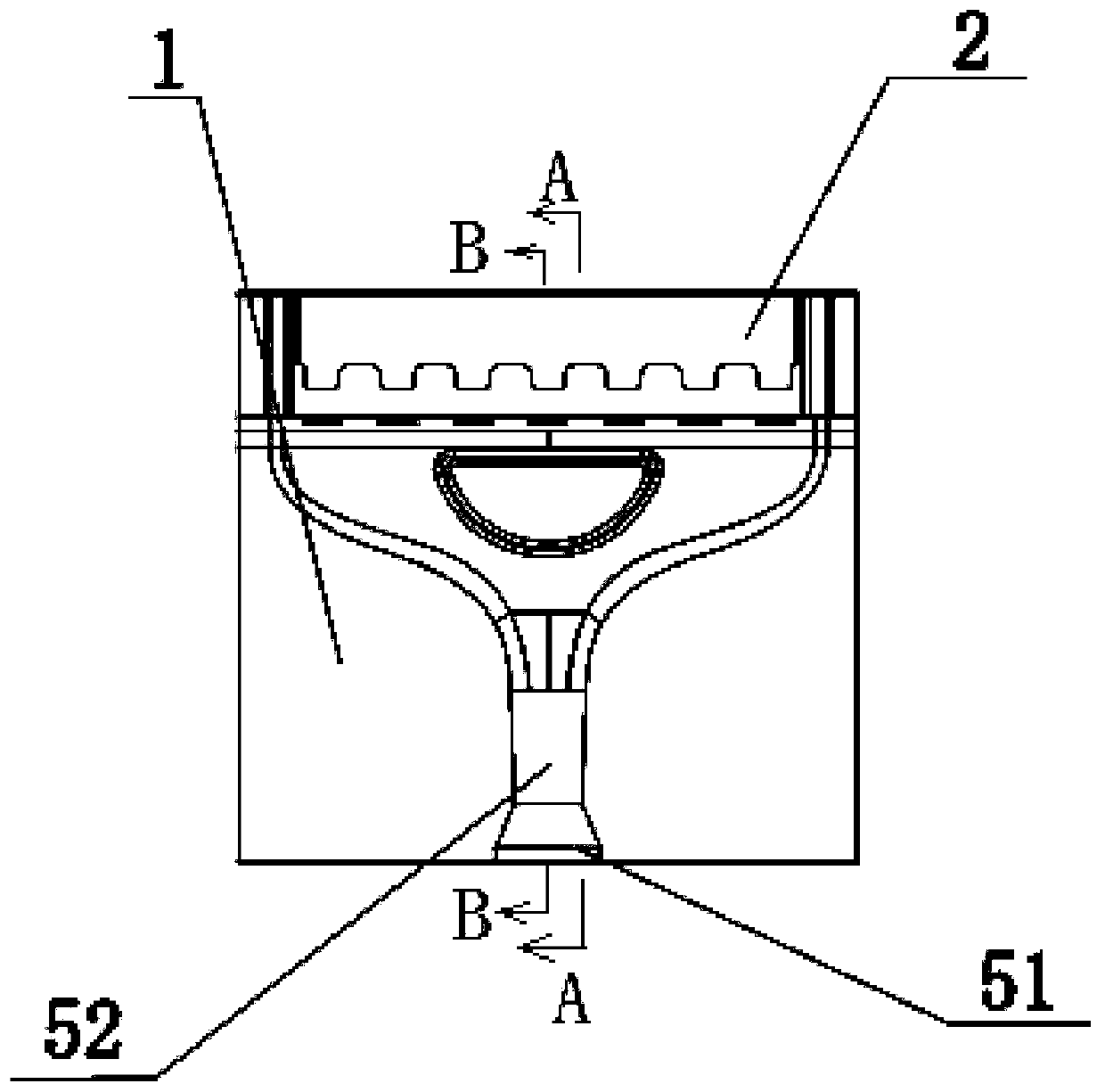

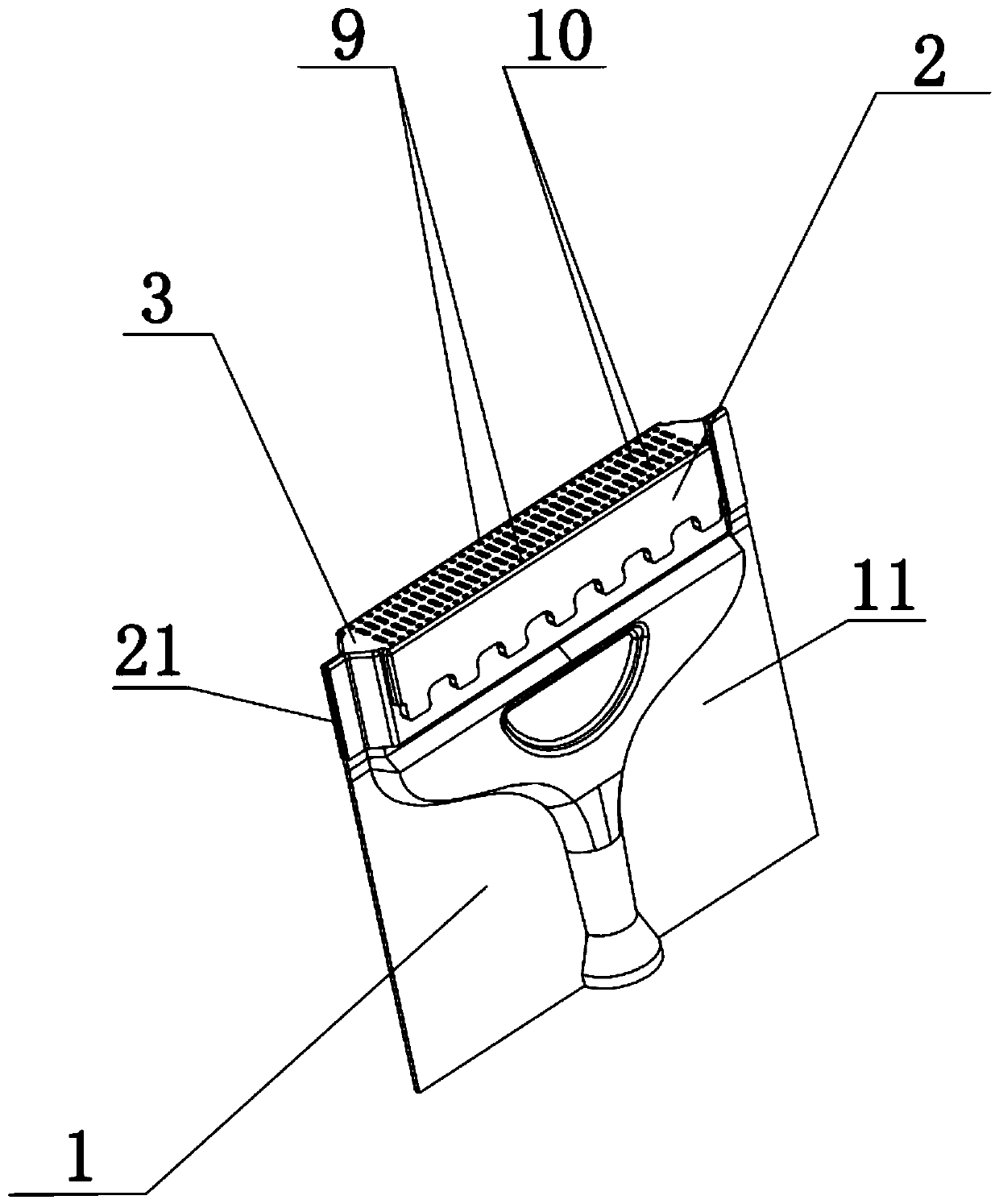

Low-boiling-point fuel staged combustion device and system

PendingCN107062212AImprove the mixing effectGuaranteed combustion effectBurnersBottle neckBoiling point

The invention discloses a low-boiling-point fuel staged combustion system which comprises a fuel storage tank, a fuel pump, an evaporator, a graded combustion device and a fan. The fuel pump lifts low-boiling-point fuel in the fuel storage tank into the evaporator to be heated to form steam-state fuel; the steam-state fuel passes through a steam-state fuel injection pipe to enter the staged combustion device; primary air passes through a fan to enter a primary air cavity of the graded combustion device, makes contact with the steam-state fuel at the tail end of the steam-state fuel injection pipe to enter a premixing chamber, the front end of the premixing chamber is in a bottle neck shape, and a swirl plate is arranged on the front portion of the premixing chamber and located behind the front end in the bottle neck shape; after the primary air and the steam-state fuel are premixed under stirring of the swirl plate, the mixture enters a divergent chamber connected with the premixing chamber to be ignited by an igniter arranged at the front end of the divergent chamber for combustion; secondary air enters the middle rear portion of the divergent chamber from a secondary air pipe, and stable combustion of the steam-stage fuel is kept. The low-boiling-point fuel staged combustion system has the advantages that the air combustion mixing effect is good, and staged air distribution achieves low-nitrogen combustion.

Owner:北京醇能科技有限公司

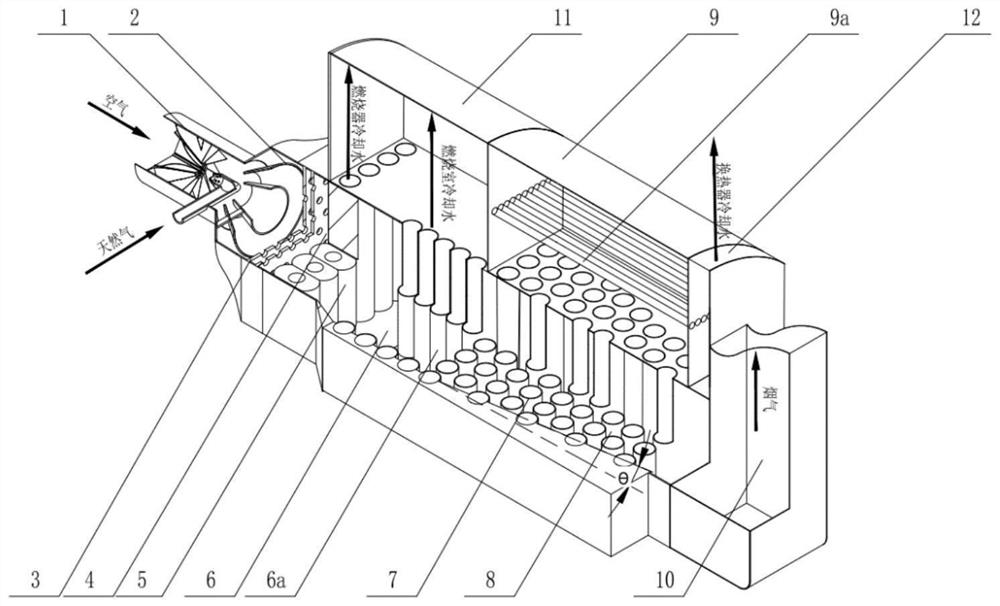

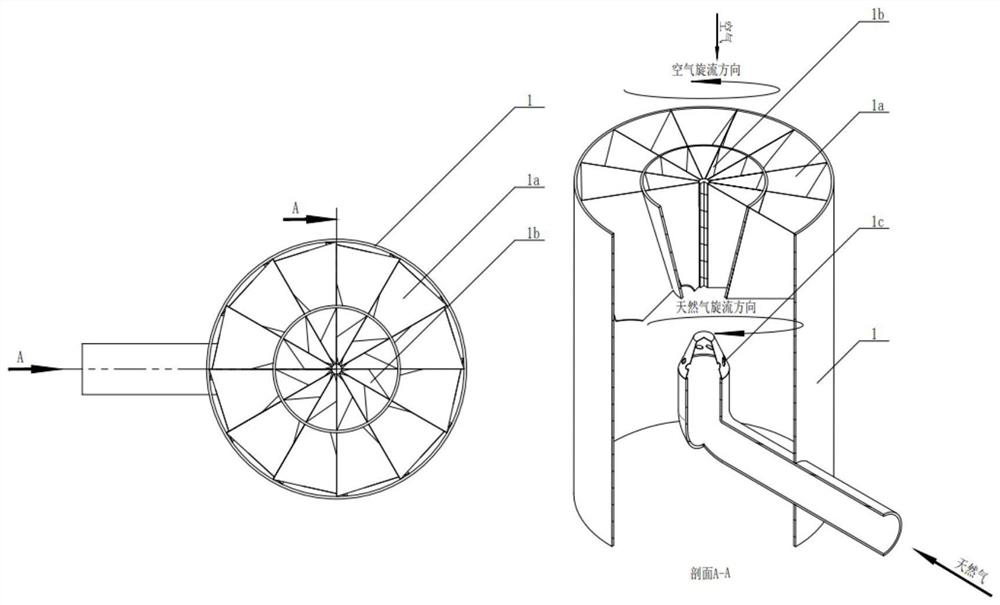

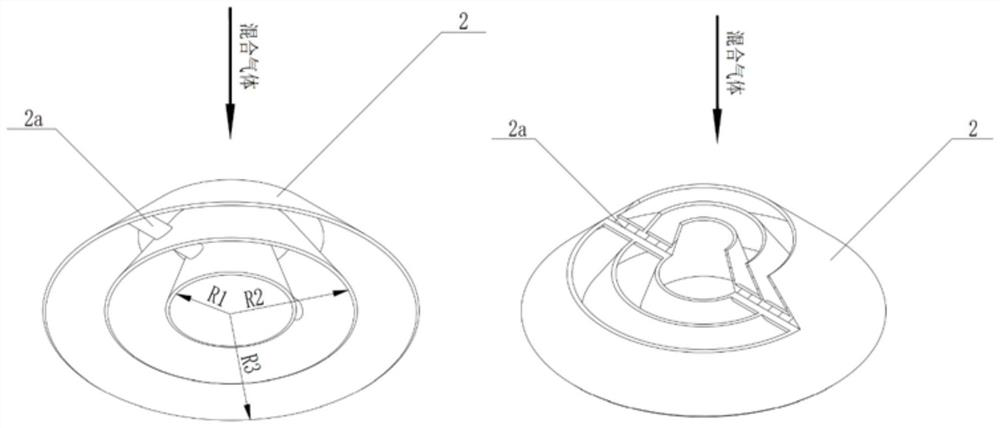

Premixing low-nitrogen gas boiler

ActiveCN114811945AImprove water cooling effectImprove mixing uniformityIndirect carbon-dioxide mitigationWater heatersCombustion chamberWater vapor

The invention discloses a premixing low-nitrogen gas boiler which comprises a countercurrent rotational flow mixer, the countercurrent rotational flow mixer achieves hedging mixing of natural gas and air, a guide plate is arranged at a mixed gas outlet of the countercurrent rotational flow mixer, an upper flow equalizing plate and a lower flow equalizing plate are arranged below the guide plate, the upper flow equalizing plate is located above the lower flow equalizing plate, and the lower flow equalizing plate is located above the upper flow equalizing plate. A channel for enhancing mixing of mixed gas is arranged between the upper flow equalizing plate and the lower flow equalizing plate, the comb-shaped water-cooling combustor is arranged at the rear end of the lower flow equalizing plate, the combustion chamber is arranged at the rear end of the comb-shaped water-cooling combustor, and the ladder-shaped tapered hearth with the vacuum tube bundle arranged inside, the vacuum tube bundle and a working medium water vapor mixture in the vacuum water tank form an inner loop. Uniformity of mixed gas can be improved, combustion stability is guaranteed, the possibility of combustion tempering is reduced, the radiation heating capacity of a hearth can be improved, the local temperature of an outlet of the combustor and the overall temperature of the hearth are greatly reduced, and low-temperature and low-nitrogen combustion is achieved. And the cost is low, and large-scale popularization and application can be realized.

Owner:XI AN JIAOTONG UNIV +1

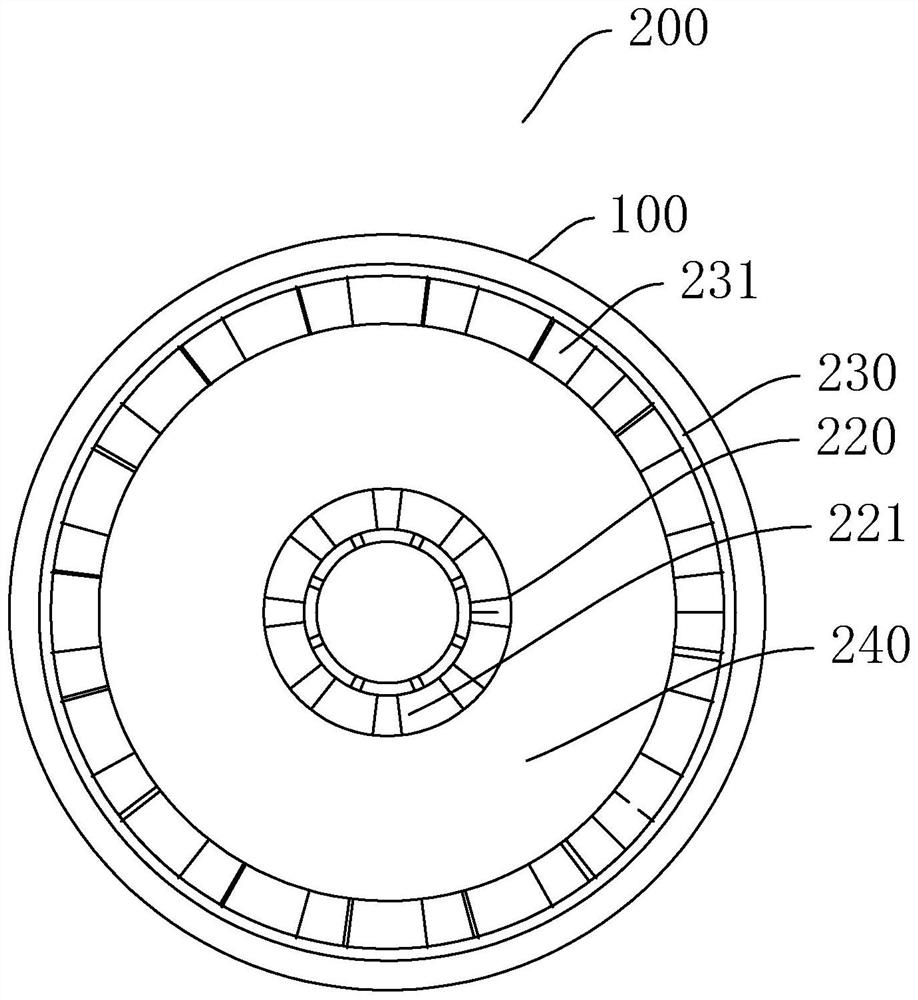

Double-rotational-flow low-nitrogen burner

PendingCN114811582AReduce generationEmission reductionGaseous fuel burnerCombustion chamberCombustor

The double-rotational-flow low-nitrogen combustor comprises a first shell, an airflow conveying assembly is arranged in the first shell and divides a cavity in the first shell into a combustion-supporting chamber and a combustion chamber, the combustion-supporting chamber communicates with a first combustion-supporting air inlet, and the combustion chamber is provided with a combustion opening; the airflow conveying assembly comprises a combustion-supporting gas rotational flow component and a fuel injection head, the combustion-supporting gas rotational flow component is provided with a first-stage rotational flow area and a second-stage rotational flow area which are both annular, and the fuel injection head is arranged in the middle of the first-stage rotational flow area and arranged on one side of the combustion cavity in a protruding mode. The first-stage rotational flow area is provided with a plurality of first-stage rotational flow channels which are annularly arranged at intervals; and the second-stage rotational flow area is provided with a plurality of second-stage rotational flow channels which are annularly arranged at intervals. Part of ammonia gas of ammonia fuel can be subjected to cracking reaction under the high-temperature oxygen-deficient condition to form hydrogen and ammonia gas to be combusted, so that the generation amount of fuel type nitric oxide is greatly reduced, and low-nitrogen combustion is realized.

Owner:佛山仙湖实验室

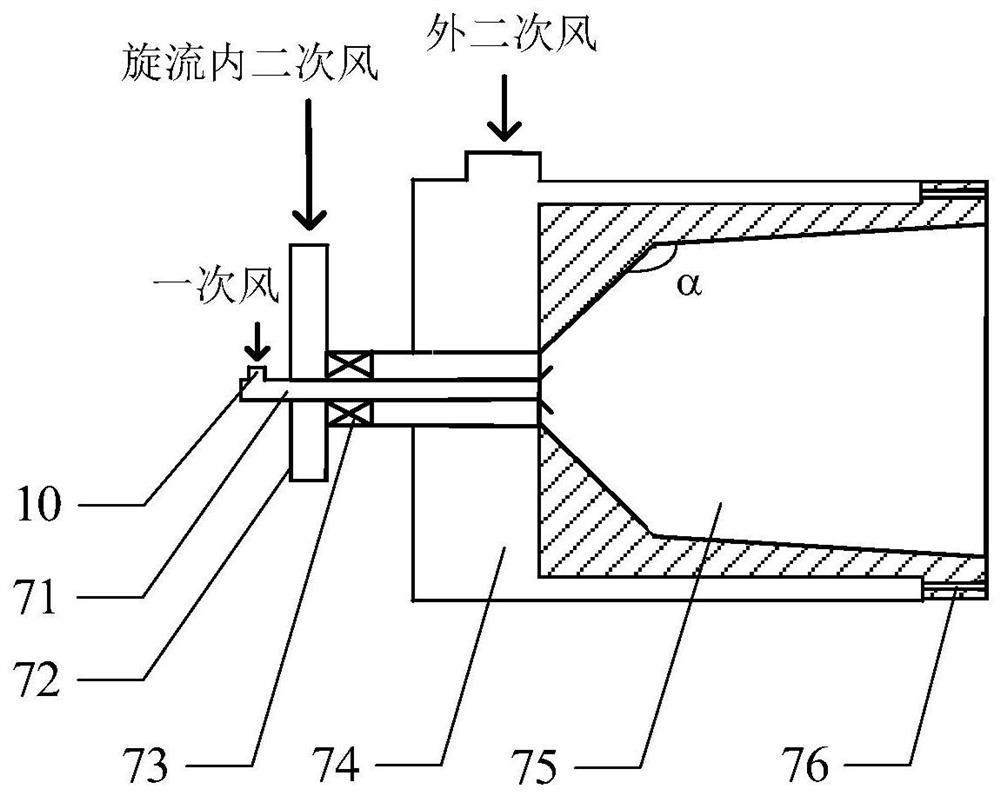

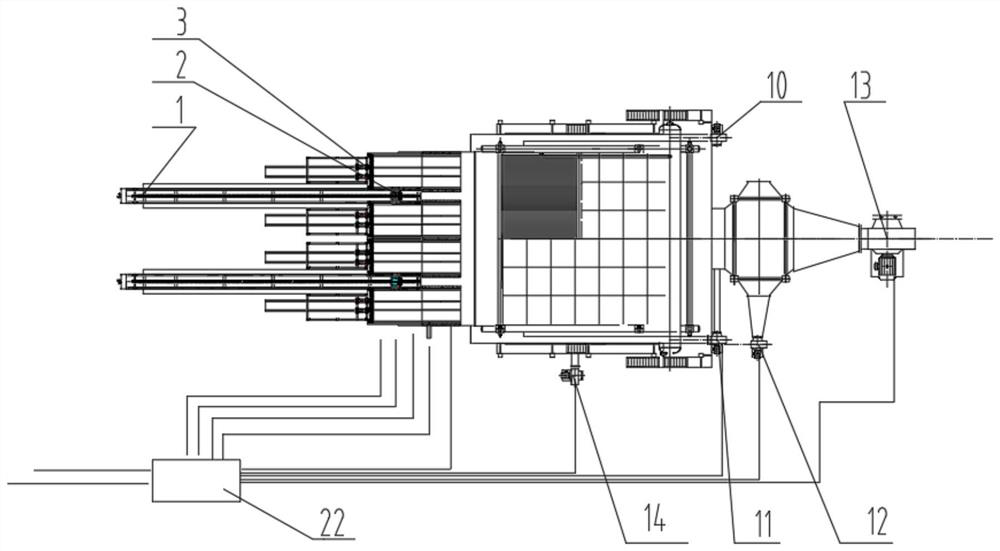

Ultralow-load stable-combustion pre-pyrolysis combustion system and ultralow-load operation method

ActiveCN112484021AGuaranteed uptimeSuppress generationFuel supply regulationNon-combustible gases/liquids supplyCombustion systemThermodynamics

The invention discloses an ultralow-load stable-combustion pre-pyrolysis combustion system and an ultralow-load operation method. The ultralow-load stable-combustion pre-pyrolysis combustion system comprises a coal mill, a wind box, first powder feeding pipelines, direct-current combustors, a powder feeding pipeline reversing valve, a secondary wind adjusting valve, pre-pyrolysis swirling combustors, a boiler furnace, a secondary wind pipeline and a main combustor; the central height of a spraying nozzle of each pre-pyrolysis swirling combustor is the same as the height of a spraying nozzle ofthe corresponding direct-current combustor on the same layer; the coal mill is communicated with the direct-current combustors and the pre-pyrolysis swirling combustors through the first powder feeding pipelines; the pre-pyrolysis swirling combustors are mounted on the front and rear walls of the boiler furnace; the wind box is arranged on the side wall, adjacent to the pre-pyrolysis swirling combustors, of the boiler furnace; and the wind box is communicated with the direct-current combustors and the pre-pyrolysis swirling combustors. pulverized coal can be subjected to low-temperature pyrolysis in precombustion chambers of the pre-pyrolysis swirling combustors, pyrolysis products are mixed with external secondary wind and then a mixture is sprayed into the boiler furnace to be stably burnt, so as to ensure stable operation of a boiler under the ultralow load and meet the deep peak regulation requirement.

Owner:XI AN JIAOTONG UNIV

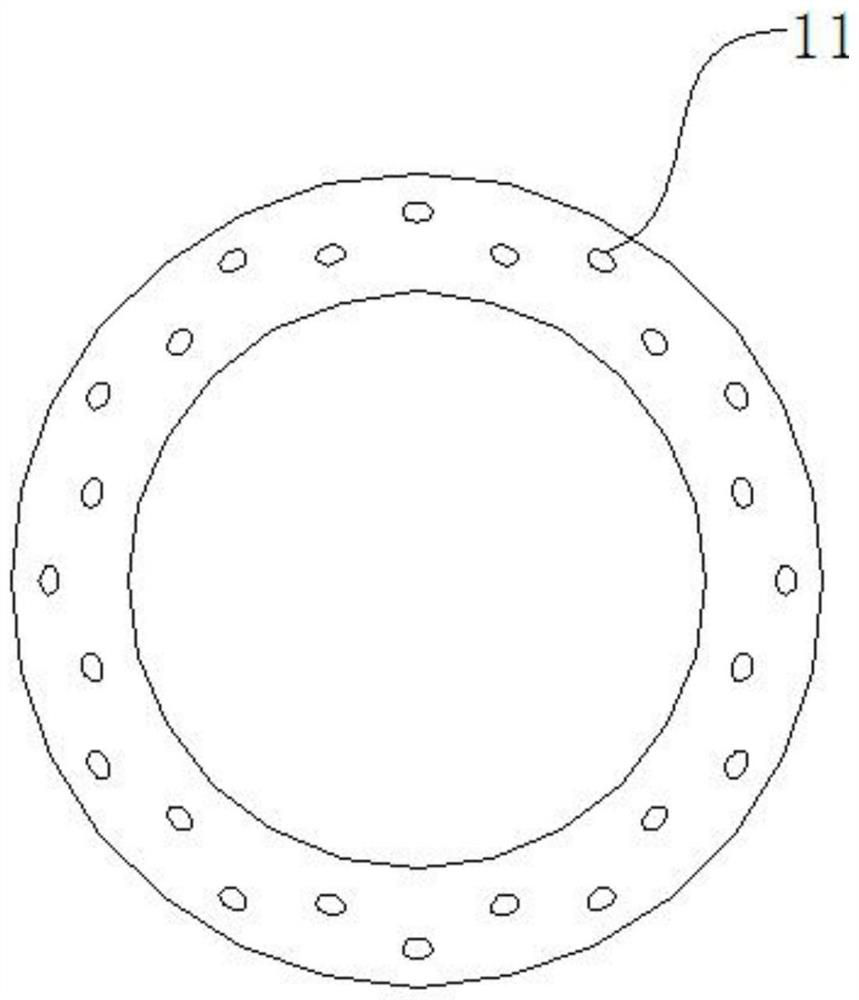

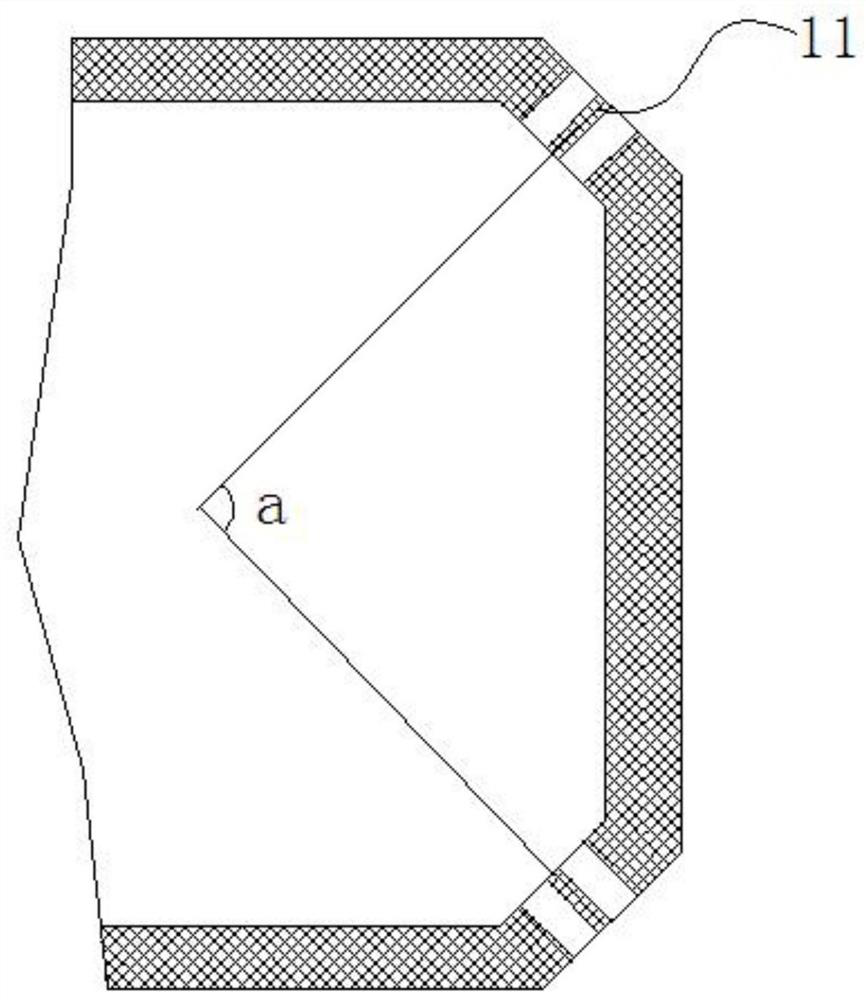

Dual-fuel combustor with graded ignition, graded air distribution and flue gas recirculation, and boiler

The invention provides a dual-fuel combustor with graded ignition, graded air distribution and flue gas recirculation, and a boiler. The dual-fuel combustor with graded ignition, graded air distribution and flue gas recirculation comprise an ignition gas pipe, a central air pipe, a primary air chamber, a secondary air chamber, a main combustion chamber, a pre-combustion chamber, an ignition gun and a circulating air chamber, wherein the central air pipe sleeves outside the ignition gas pipe; the primary air chamber sleeves outside the central air pipe; the secondary air chamber sleeves outsidethe primary air chamber; the main combustion chamber sleeves outside the secondary air chamber; air outlets of the central air pipe, the primary air chamber and the secondary air chamber, and gas outlets of the ignition gas pipe and the main combustion chamber are located in the pre-combustion chamber; the ignition gun is installed on the pre-combustion chamber; and the circulating air chamber isarranged outside the pre-combustion chamber. The problems that an existing dual-fuel combustor is not ideal in low-nitrogen combustion effect, poor in operation safety and the like are solved, and the purposes of improving the combustion efficiency and reducing NOX initial emission are achieved.

Owner:泰山燃控(泰安)有限公司

Multifunctional multi-level turbulence strong combustion device

InactiveCN105157037ASolve uneven oxygen supplyGood burning effectIncinerator apparatusAir volumeCombustion chamber

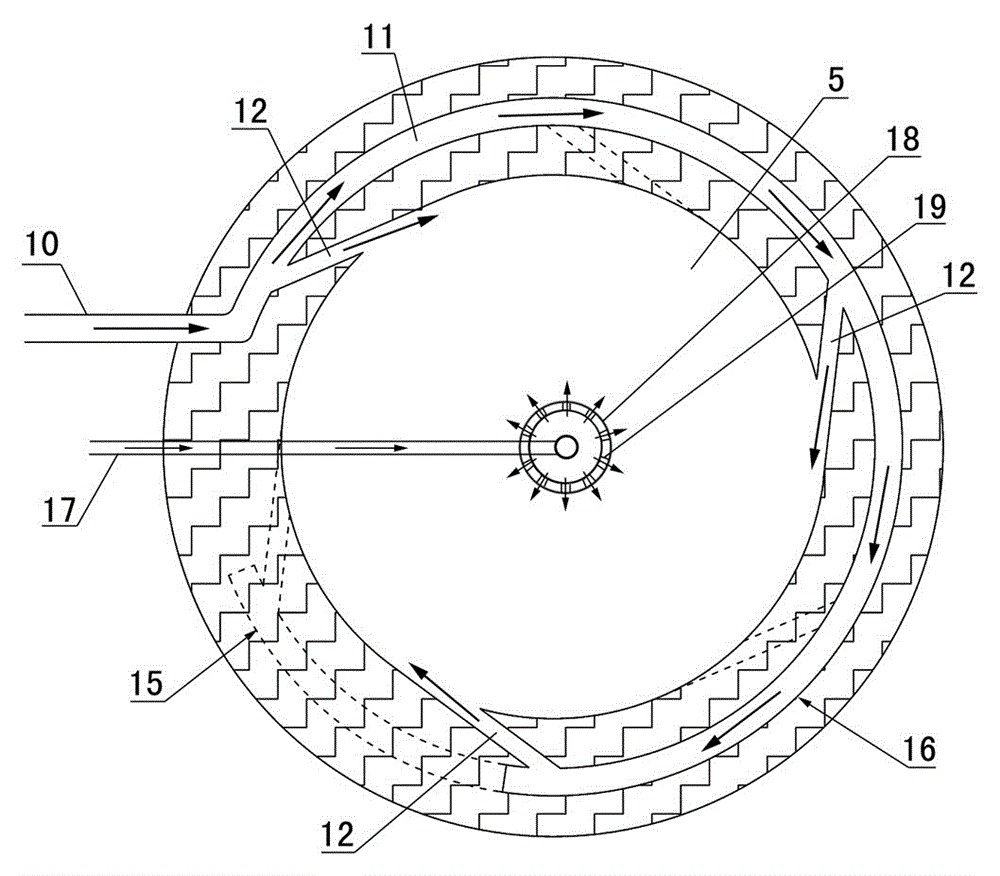

A multifunctional multi-level turbulence strong combustion device comprises a strong combustion chamber wall, a vertical cylindrical strong combustion chamber located on the inner side of the strong combustion chamber wall, and an air blower located on the outer side of the strong combustion chamber wall. The strong combustion chamber wall is internally provided with an upper turbulence oxygen conveying channel, a middle turbulence oxygen conveying channel and a lower turbulence oxygen conveying channel. Air outlets of the turbulence oxygen conveying channels which are vertically adjacent are arranged in a dislocation manner. Air inlets of the turbulence oxygen conveying channels are communicated with branch oxygen supply pipelines on the outer side of the strong combustion chamber wall. The branch oxygen supply pipelines are communicated with a master oxygen supply pipeline. The master oxygen supply pipeline is communicated with an air outlet of the air blower. The branch oxygen supply pipelines are provided with single-layer air volume adjusters. The air blower is connected with an air blower frequency converter. The strong combustion chamber wall is provided with a smoke flow measuring instrument and a smoke oxygen content measuring instrument which are inserted in the cylindrical strong combustion chamber. When an incinerator with the device combusts different substances, the oxygen inlet manners and the oxygen inlet amount can be adjusted and controlled according to specific situations, and accordingly sufficient combustion of the incinerator is guaranteed.

Owner:王红卫

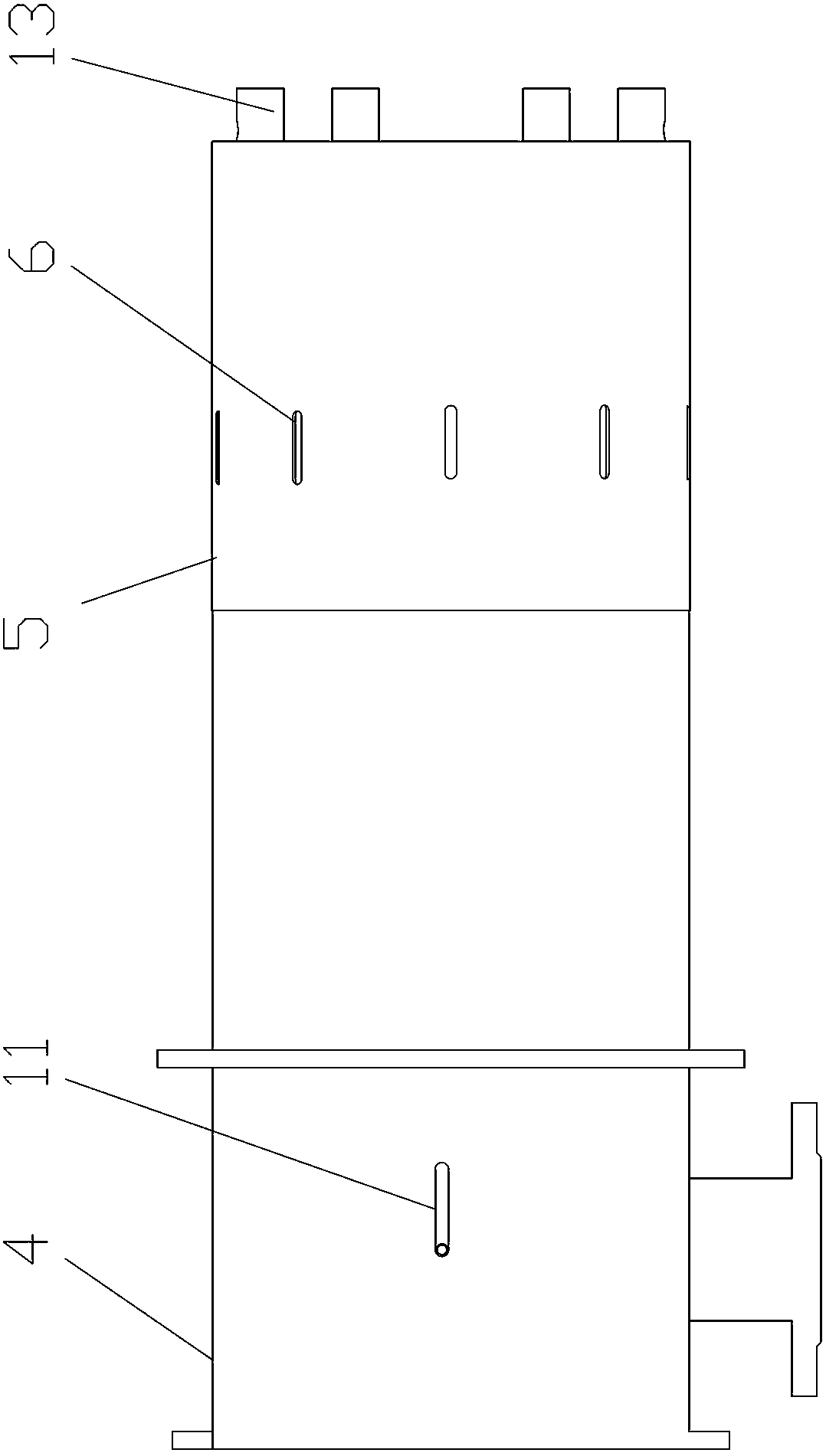

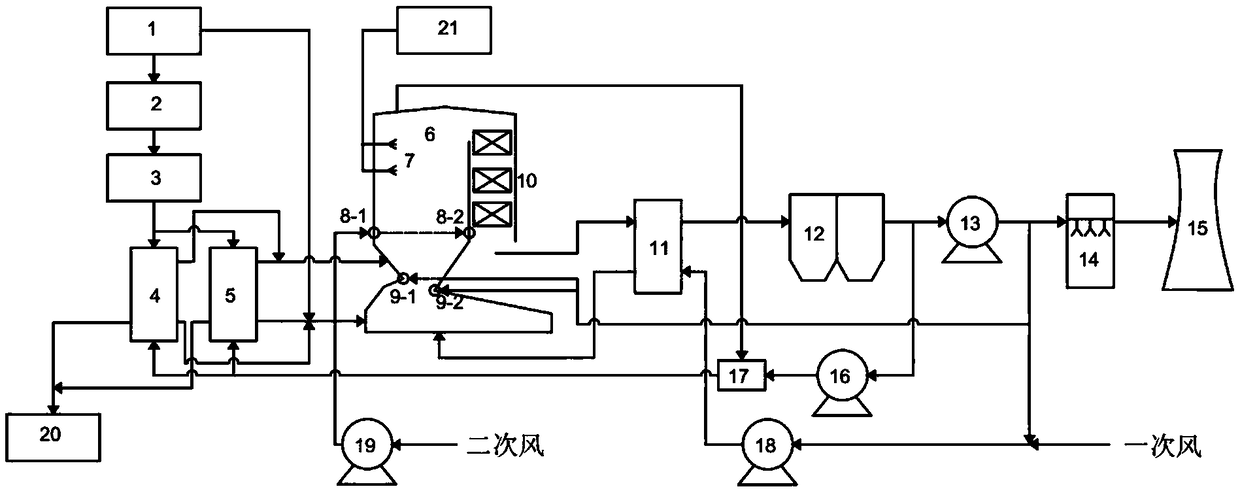

Biomass boiler system with self biomass upgrading function

InactiveCN109054873AReduce production energy consumptionEasy to implementDirect heating destructive distillationBiofuelsBiomass boilerBiomass feedstock

The invention discloses a biomass boiler system with a self biomass upgrading function. The biomass boiler system comprises a biomass charcoal preparation unit, a boiler, an air preheater, a dust remover, a system induced draft fan and a desulfurizing and smoke exhausting device, wherein the air preheater, the dust remover, the system induced draft fan and the desulfurizing and smoke exhausting device are sequentially connected to a boiler smoke exhausting opening; the biomass charcoal preparation unit comprises a raw material cabin, a breaking machine, a granulating machine and a carbonizingfurnace; the raw material cabin, the breaking machine and the granulating machine are sequentially connected, and the upper part of the carbonizing furnace is connected with an outlet of the granulating machine; the raw material cabin is used for storing a biomass raw material; combustible smoke exhausted out by the upper part of the carbonizing furnace can be inflated into the boiler to be combusted through an air opening at the upper part of a throat, and biomass charcoal prepared by the carbonizing furnace can be exhausted from the bottom to be supplied to the boiler to be combusted througha feeding opening; an upgrading induced draft fan is arranged behind the dust remover to lead low-temperature smoke out to be sent into a smoke mixer to be mixed with high-temperature smoke led out from the boiler to be sent into the smoke mixer; 200 to 450 DEG C mixed smoke obtained in the smoke mixer can be sent into the bottom of the carbonizing furnace to be used for providing heat and low-oxygen environment in a biomass carbonizing process.

Owner:XI AN JIAOTONG UNIV

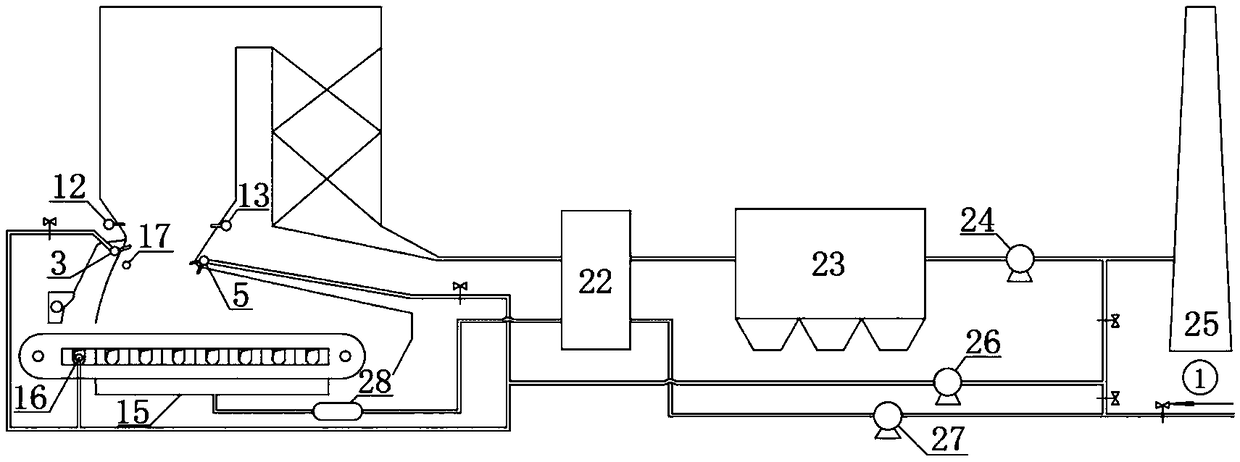

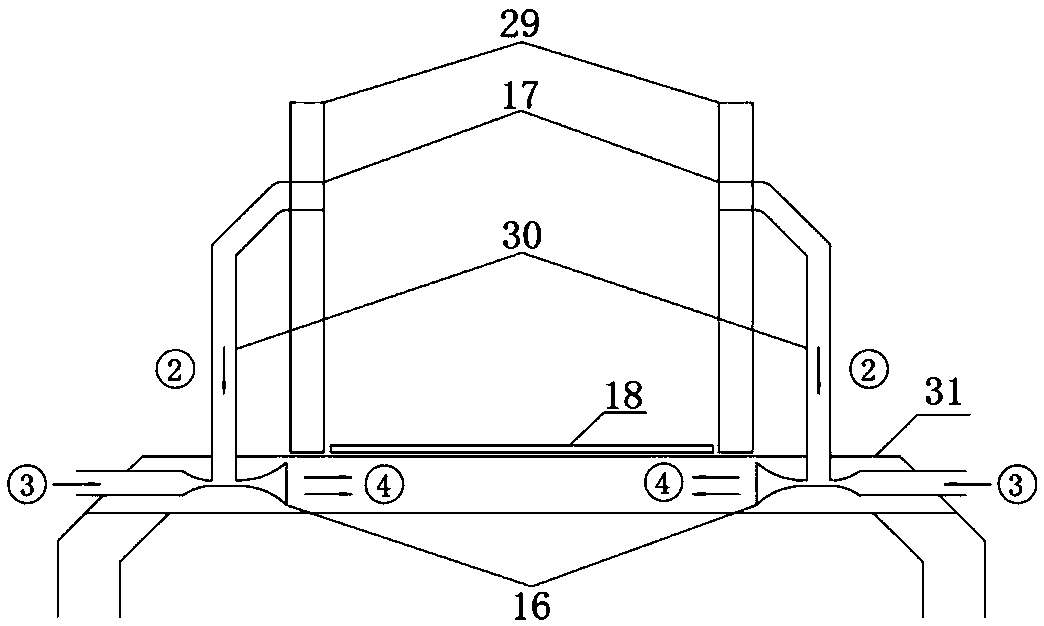

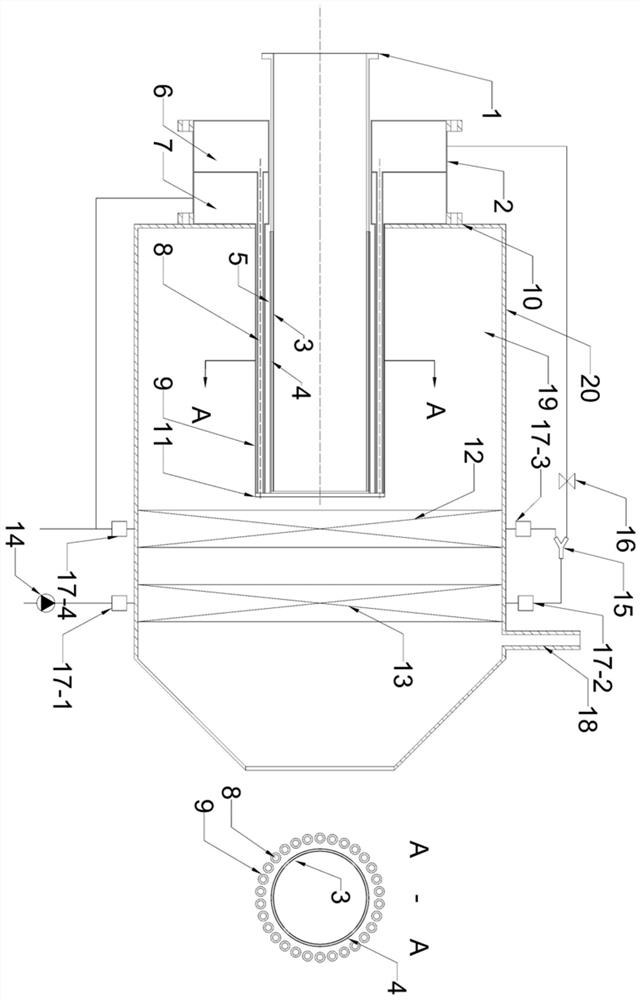

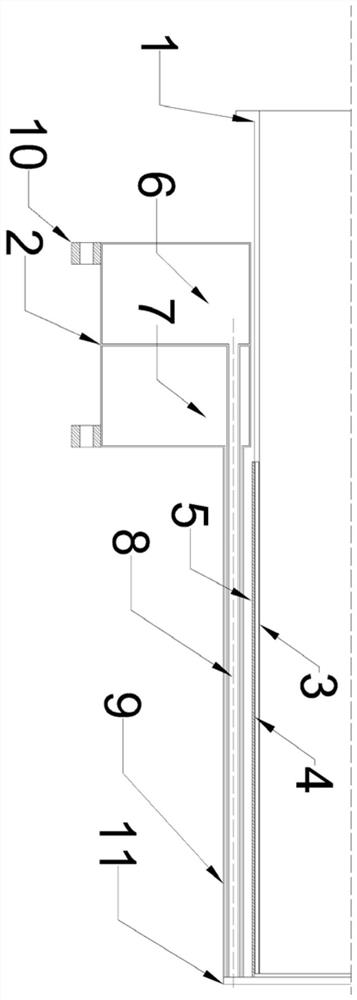

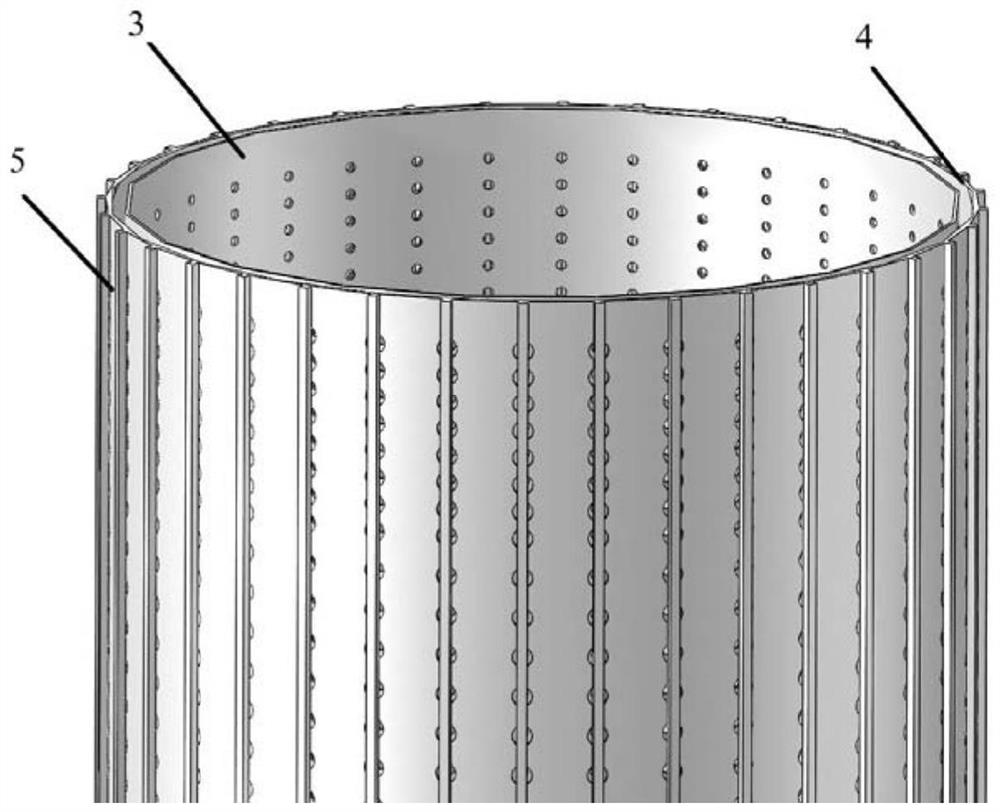

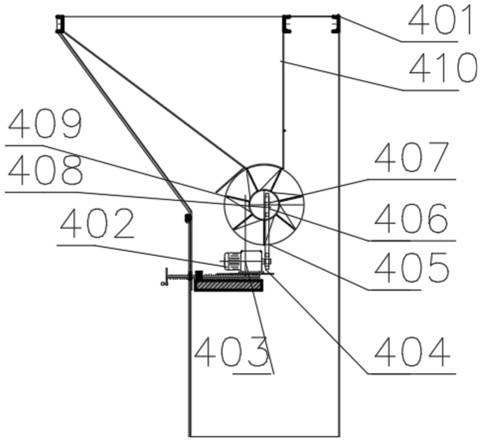

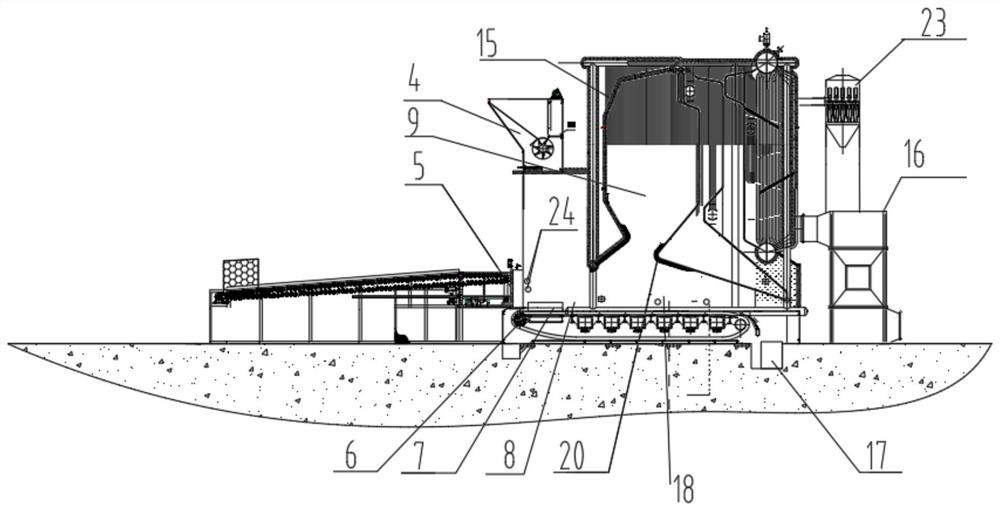

Layer-burning boiler for achieving fuel-air-smoke three-stage low-nitrogen burning and system thereof

PendingCN109297014AEnsure complete burnoutReduce outputSolid fuel combustionCombustion apparatusGas solidCombustion chamber

The invention discloses a layer-burning boiler for achieving fuel-air-smoke three-stage low-nitrogen burning and a system of the layer-burning boiler for achieving fuel-air-smoke three-stage low-nitrogen burning. The boiler comprises a front arch, a rear arch corresponding to the front arch, a hearth, a throat, a burning chamber and a conveying belt below the hearth, wherein the hearth, throat andthe burning chamber are sequentially formed through the front arch and the rear arch from bottom to top, and complete burning of volatile components can be ensured. In the system, some recycling smoke from an outlet of a smoke extraction fan and a certain amount of water vapor produced by a steam generator are doped in primary air fed into other air bins except for a volatile component air bin, the oxygen content of primary air introduced into a fire grate can be reduced through recycling smoke, the water steam and hot coke are subjected to a water-gas reaction on the fire grate to generate CO and H2, partial gas-solid reaction is converted into gas phase reaction, and on the other hand, CO can increase the thickness of a reduction layer above a coal layer, and NOx generated by coal layerburning is effectively reduced; and on the condition of no large auxiliary machine equipment is added, generation of NOx can be actively reduced, and the dual purposes of energy saving and emission reduction are achieved.

Owner:XI AN JIAOTONG UNIV

Low-nitrogen oxide combustor

PendingCN110296398AReduce surface temperatureLower combustion temperatureNon-combustible gases/liquids supplyGaseous fuel burnerSingle injectionLow nitrogen

The invention discloses a low-nitrogen oxide combustor which comprises an inner shell and an outer shell installed on the outer side of the inner shell. One end of the outer shell is provided with a fire hole plate or provided with a fire hole core, and a thick flame channel is formed between the outer shell and the inner shell. A pre-mixing channel and a thin flame channel which communicate witheach other are formed in the shell, a thick flame pre-mixing gas inlet communicating with the pre-mixing channel and the thick flame channel is formed in the inner shell, and a secondary air inlet forexternal air to enter the thin flame channel is formed in the inner shell. The pre-mixing channel is upwards vertical and forms a T shape with the fire hole plate. By means of the low-nitrogen oxidecombustor, diversion of thick flames and thin flames is achieved, the problem that a combustor simple in structure in the existing industry is not obvious in NOx emission effect is solved, NOx emission is effectively controlled through a single-injection channel, and meanwhile NOx emission is effectively controlled through a T-shaped single-injection channel. By means of the low-nitrogen oxide combustor, the structure and forming are simple, the size is convenient to control, the cost is low, and the combustion performance is stable.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

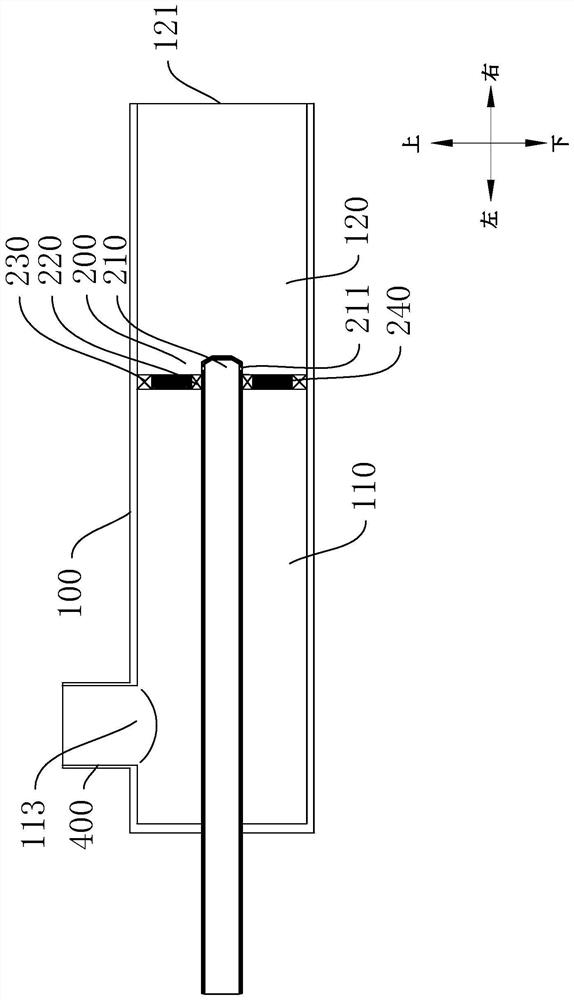

Double-heat-reflux partially-premixed low-nitrogen combustor and combustion method

PendingCN112113218AExtended combustion rangeAchieve low nitrogen combustionIndirect carbon-dioxide mitigationGaseous fuel burnerThermodynamicsCombustor

The invention discloses a double-heat-reflux partially-premixed low-nitrogen combustor and combustion method. The double-heat-reflux partially-premixed low-nitrogen combustor comprises a guide cylinder, a main fuel pipe and an on-duty fuel pipe; and an injection control baffle is arranged on the front portion of the main fuel pipe and arranged on the periphery of the main fuel pipe in a surrounding mode to form an injection area, an injection pipe is arranged at the front end of an outlet of the main fuel pipe, an outlet of the injection pipe extends out of the injection area, an on-duty fuelpremixing cavity is arranged on the front portion of the guide cylinder, a main air channel is formed between the premixing cavity and the guide cylinder, the front portion of the on-duty fuel pipe isprovided with a plurality of on-duty fuel nozzles and extends into the on-duty fuel premixing cavity, a swirl disc, a first porous medium unit and a second porous medium unit are arranged in the on-duty fuel premixing cavity from back to front, and the porosity of the first porous medium unit is smaller than that of the second porous medium unit. The combustor has the advantages of being good inadaptability and stable in combustion, the contradiction between great reduction of the oxygen content during low-NOx combustion and combustion stability is overcome, and low NOx emission can be achieved.

Owner:TSINGHUA UNIV

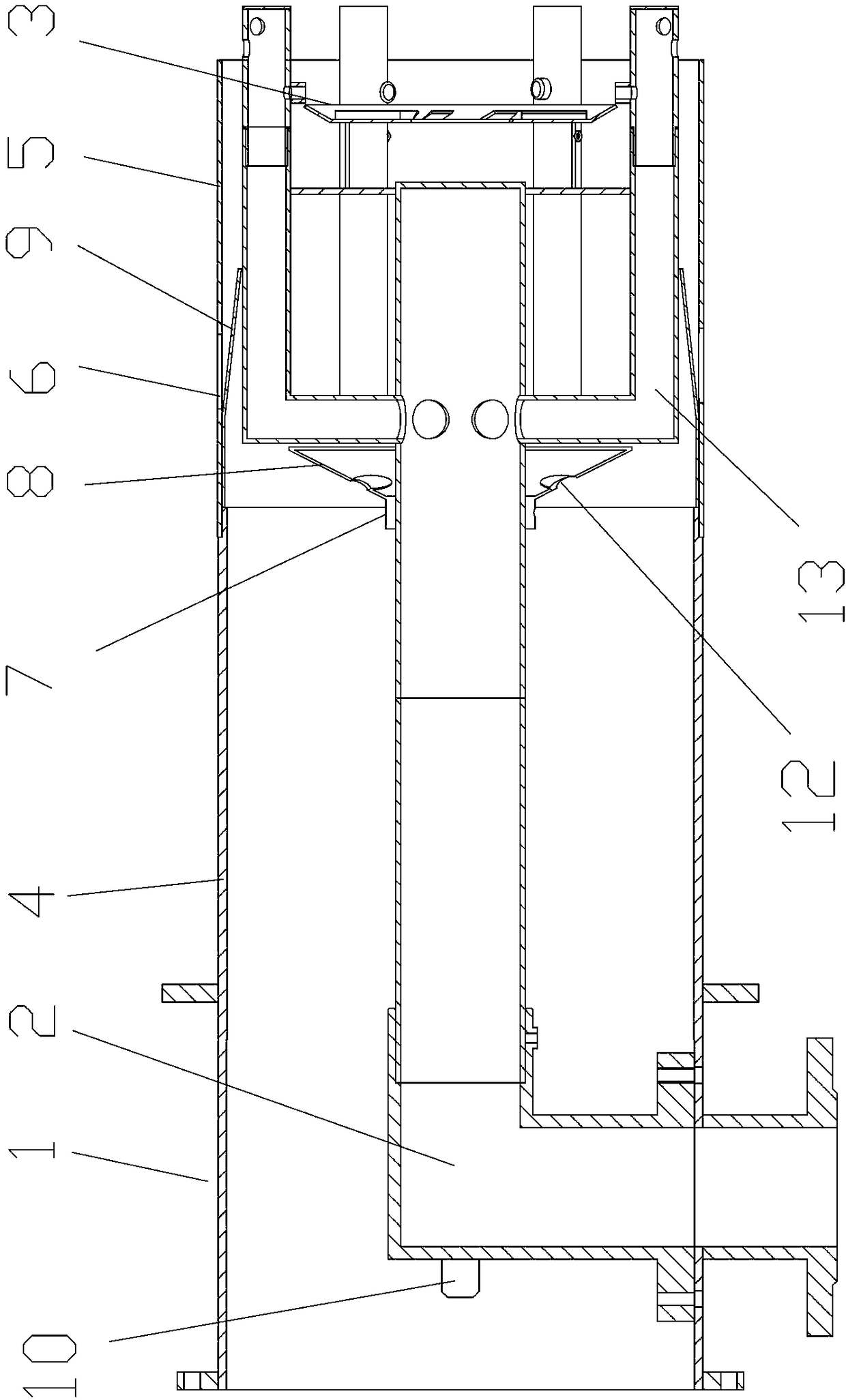

Low-nitrogen hot water boiler with replaceable sleeve type water-cooling burning head

ActiveCN113720018AFulfillment of replacement requirementsEasy to checkAir heatersHeat transfer modificationCombustion chamberThermodynamics

The invention discloses a low-nitrogen hot water boiler with a replaceable sleeve type water-cooling burning head. The boiler comprises a combustion chamber and the sleeve type water-cooling burning head arranged at a fuel gas inlet of the combustion chamber, the sleeve type water-cooling burning head comprises a porous graphite burning head and a water cooling part, and the porous graphite burning head comprises an opening section and a double-layer graphite thin cylinder section; the opening section is arranged outside the combustion chamber, the double-layer graphite thin cylinder section is arranged inside the combustion chamber, and multiple rows of through holes are formed in the double-layer graphite thin cylinder section in the length direction; one end of the water cooling part is arranged on the opening section of the porous graphite burning head in a sleeving manner, the other end of the water cooling part is arranged at the outer side of the double-layer graphite thin cylinder section in the length direction and connected with a metal baffle, and the water cooling part is detachably connected with the outer wall of the combustion chamber; and according to the low-nitrogen hot water boiler, the difficulty in checking and replacing a water cooling pipe in the long-term service process of a water cooling combustor is overcome, meanwhile, the effects of treating the combusted flue gas, recycling the heat of the flue gas and reducing the content of pollutants in the flue gas are achieved, and the clean low-nitrogen combustion effect is achieved.

Owner:XI AN JIAOTONG UNIV

Combustion device, biomass fuel gasification direct-combustion boiler and incineration method

PendingCN111947129ABurn fullyImprove efficiencySolid fuel combustionLump/pulverulent fuel feeder/distributionAir preheaterCold air

The invention is applicable to the technical field of agriculture, and provides a combustion device, a biomass fuel gasification direct-combustion boiler and an incineration method. The combustion device comprises a furnace body forming a fuel combustion space; a pellet fuel hopper used for storing pellet fuel and forming uniform discharging arrangement; a porous feeding hole used for feeding thepellet fuel and preventing cold air from entering the furnace body; a fire grate arranged below the pellet fuel hopper and used for bearing and conveying materials so as to enable the fuel to be dried, distilled and combusted at the upper part of the fire grate; an air preheater communicating with the furnace body and used for feeding heated air into the furnace body and increasing the temperatureof combustible air; a slag remover arranged at the bottom of the furnace body at the tail end of the fire grate and used for conveying ash slags to the outside of the furnace body; and an electric control room for controlling all driving pieces to automatically operate. The combustion device, the biomass fuel gasification direct-combustion boiler and the incineration method provided by the invention have the advantage that biomass bales are directly gasified and combusted; and the application capacity is high, the sufficiency in combustion is realized, the heat exchange efficiency is high, the heat dissipation is reduced, and dust accumulation is avoided.

Owner:宋铭宇

An ultra-low load stable combustion preheating and decomposing combustion system and ultra-low load operation method

ActiveCN112484021BFlexible position adjustmentMeet temperature requirementsFuel supply regulationNon-combustible gases/liquids supplyCombustion systemCombustion chamber

The invention discloses an ultra-low-load stable combustion pre-pyrolysis combustion system and an ultra-low-load operation method, including a coal mill, an air box, a first powder feeding pipeline, a direct current burner, a powder feeding pipeline reversing valve, and a secondary air adjustment Valve, preheating and deswirling burner, boiler furnace, secondary air duct and main burner; the center height of the nozzle of the preheating and deswirling burner is the same as the height of the nozzle of the direct-flow burner on the floor; the coal mill passes through the first The powder feeding pipeline is connected to the direct-flow burner and the preheating deswirl burner, the preheating deswirl burner is installed on the front and rear walls of the boiler furnace, and the air box is arranged on the side adjacent to the boiler furnace where the preheating deswirl burner is installed On the wall, the air box is connected with the direct-flow burner and the preheating solution swirl burner; it can make the pulverized coal undergo low-temperature pyrolysis in the pre-combustion chamber of the preheating solution swirl burner, and the pyrolysis product is mixed with the external secondary air, and then Spray into the boiler furnace for stable combustion, ensure the stable operation of the boiler under ultra-low load, and meet the needs of deep peak regulation.

Owner:XI AN JIAOTONG UNIV

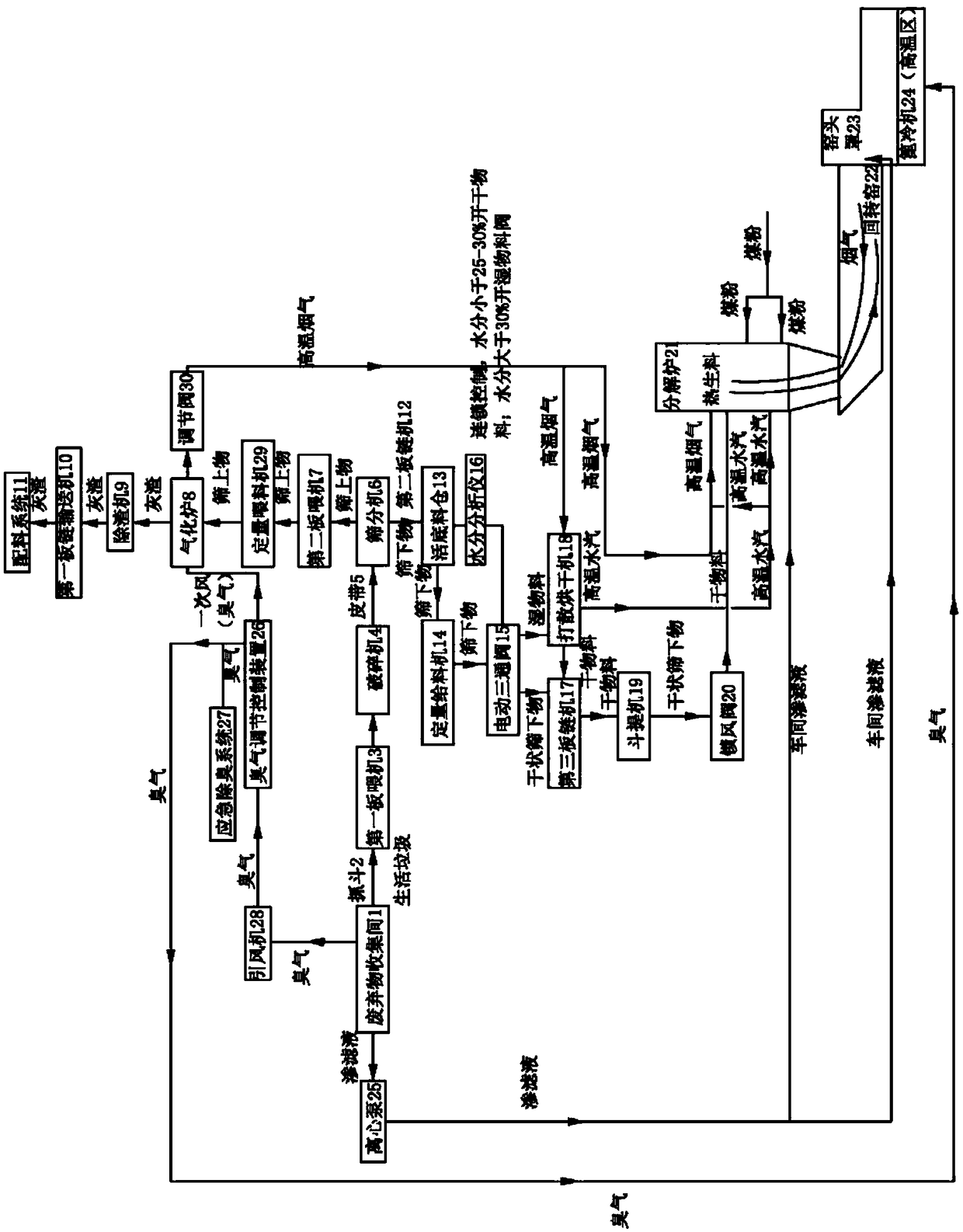

Method and system for separating waste for cement production

The invention discloses a method and system for separating waste for cement production. The method comprises the following steps: firstly, separating the waste into large-grain waste and small-grain waste, then separating high-temperature flue gas and inorganic ash from the large-grain waste by heating and gasification, then conveying the high-temperature flue gas into a decomposition furnace, andconveying the inorganic ash, used as a cement kiln raw material, into a batching system. The system comprises a sieving machine; a material inlet of the sieving machine is communicated with a waste collection chamber, and a first material outlet of the sieving machine is communicated with a material inlet of a gasification furnace; a gas outlet of the gasification furnace is communicated with a high-temperature flue gas inlet of the decomposition furnace; a material outlet of the gasification furnace is communicated with a material inlet of the batching system; a second material outlet of thesieving machine is communicated with a material inlet of the decomposition furnace. According to the method and the system which are disclosed by the invention, by out-of-kiln cold and hot dual separation of the household waste, the phenomenon that the household waste with factors such as high water moisture, low heat value and non-uniform particle size is directly put into the kiln is avoided, and dioxin can be fully burnt.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

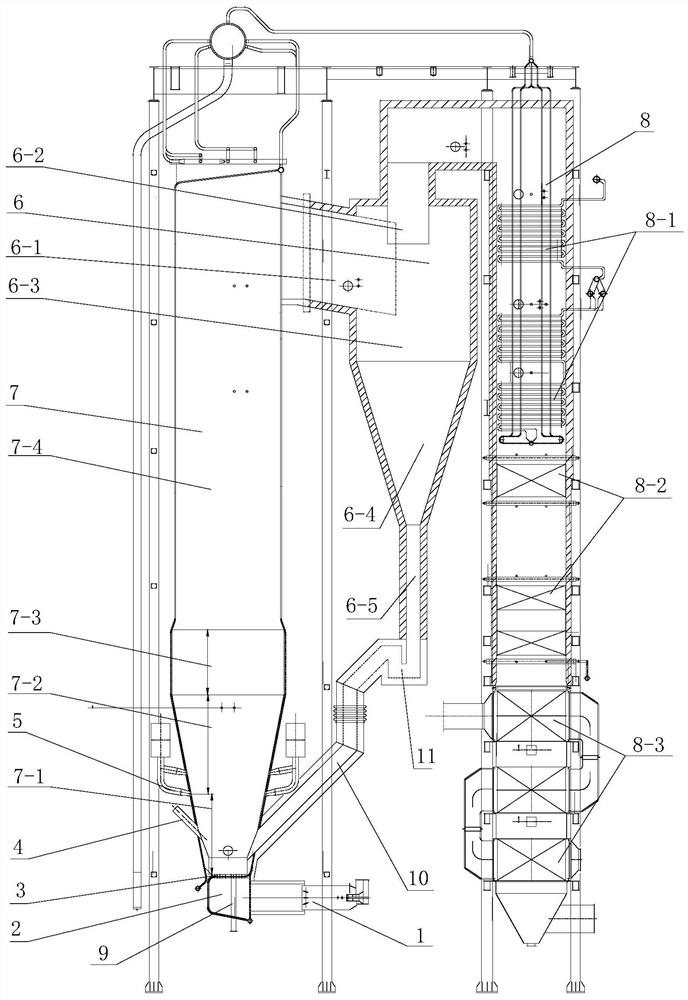

Semi-coke powder circulating fluidized bed boiler based on material and heat balance

InactiveCN111664445AExtended burn timeAchieve low nitrogen combustionFluidized bed combustionApparatus for fluidised bed combustionFluidized bedCoke

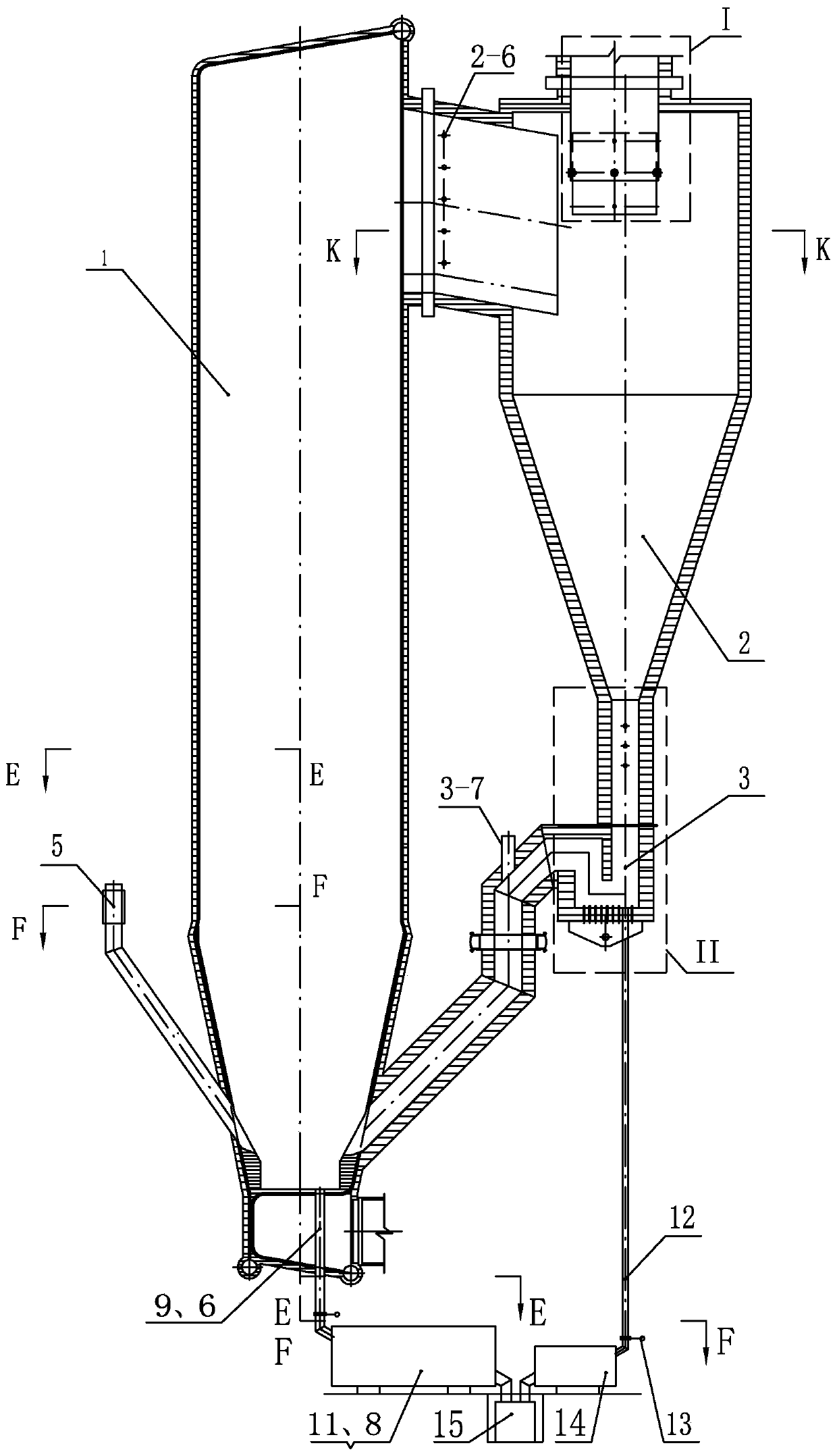

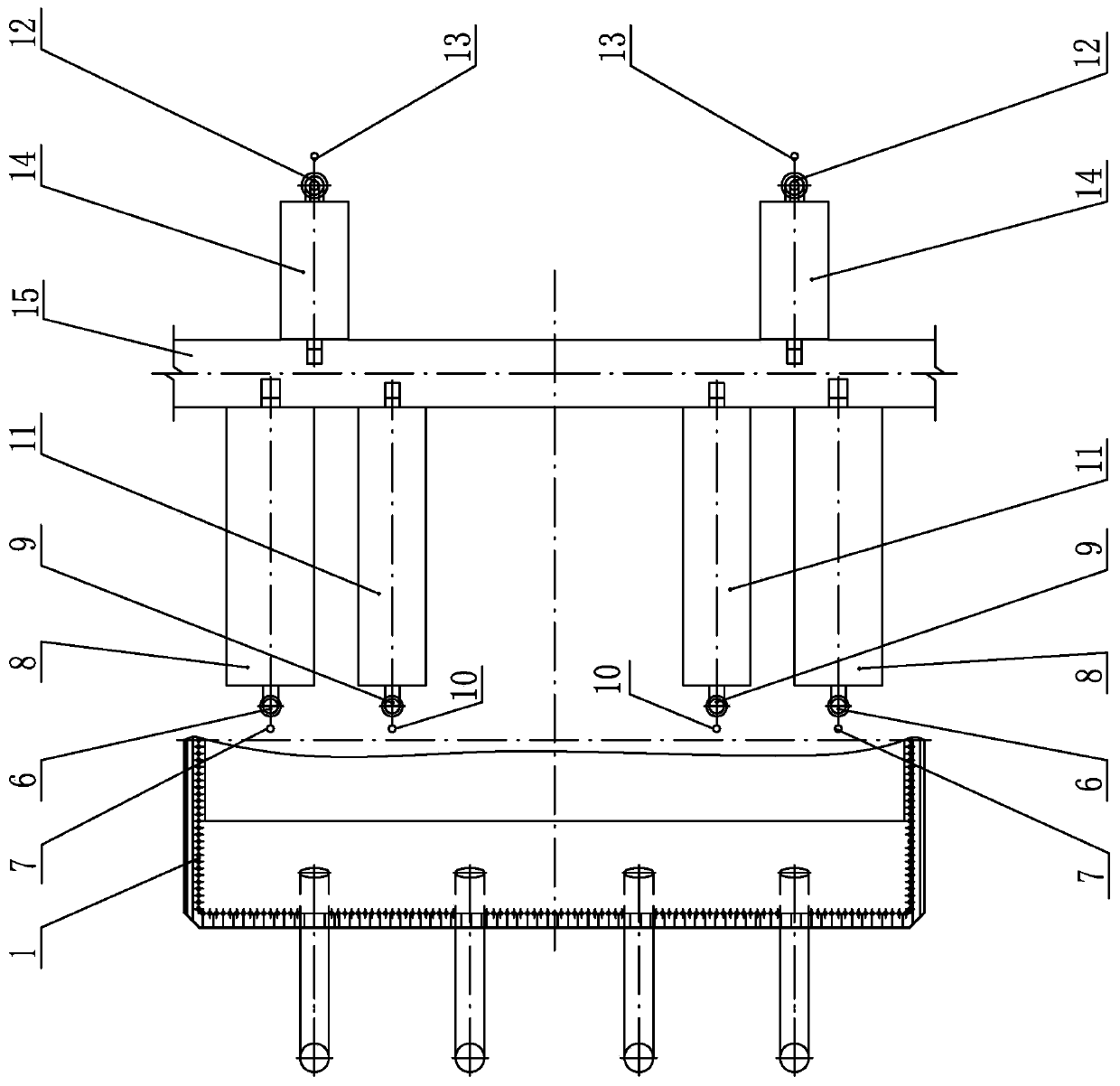

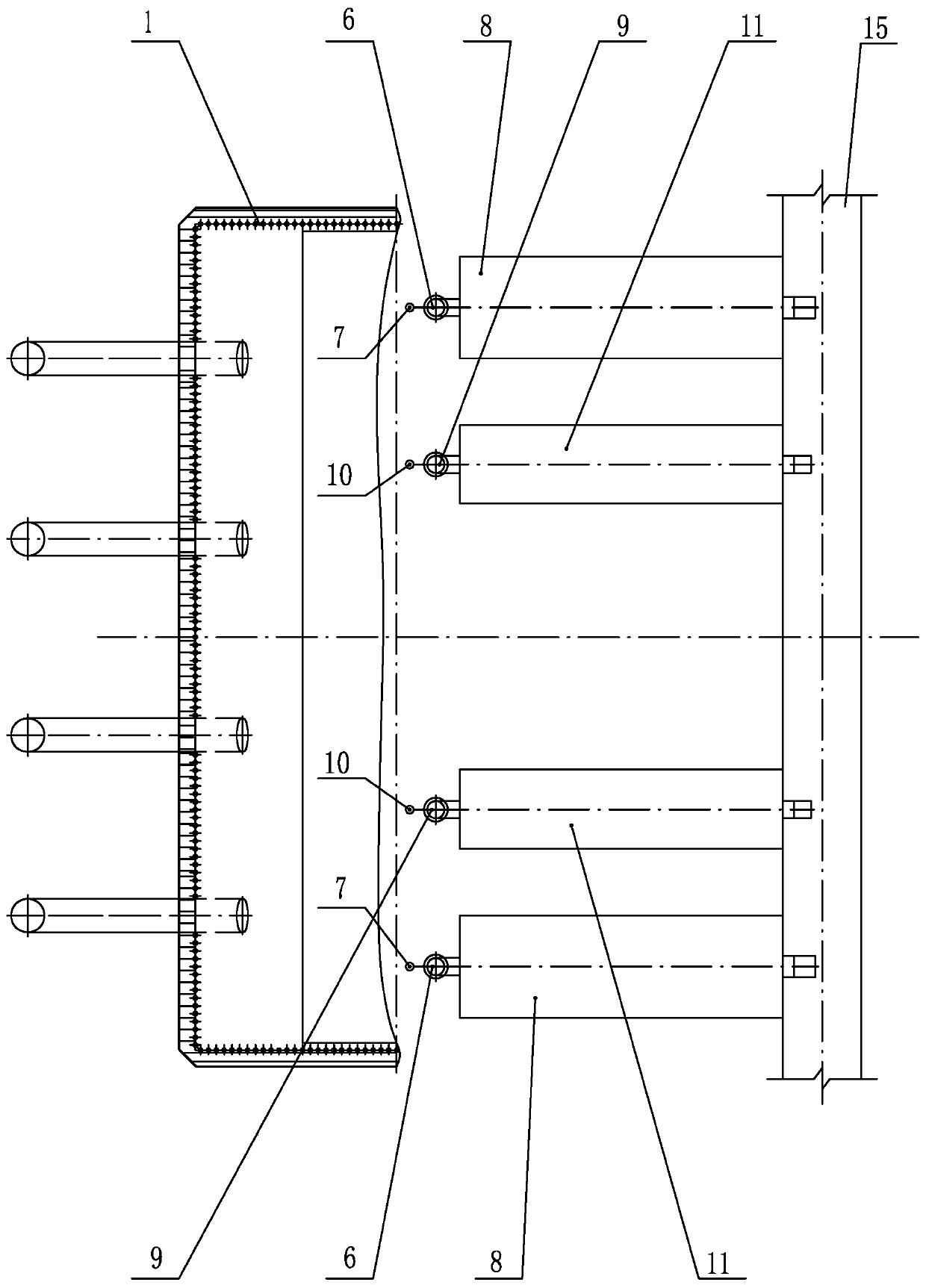

The invention discloses a semi-coke powder circulating fluidized bed boiler based on material and heat balance. The semi-coke powder circulating fluidized bed boiler comprises a boiler body and a tailflue, wherein the boiler body and the tail flue are connected through a cyclone separator, a fluidized air distribution bed for supplying primary air is arranged at the bottom of the boiler body, a secondary air distribution device used for supplying secondary air is arranged on the side wall of the boiler body, the separation efficiency of the cyclone separator is not lower than 99.8%, the secondary air distribution device is provided with an upper secondary tuyere and a lower secondary tuyere, and a hearth of the boiler body is divided into a first zone, a second zone, a third zone and a fourth zone. According to the semi-coke powder circulating fluidized bed boiler based on material and heat balance, stable and efficient combustion of pure semi-coke powder can be realized on the premise of low-sulfur and low-nitrogen discharge.

Owner:青岛特利尔科技有限公司

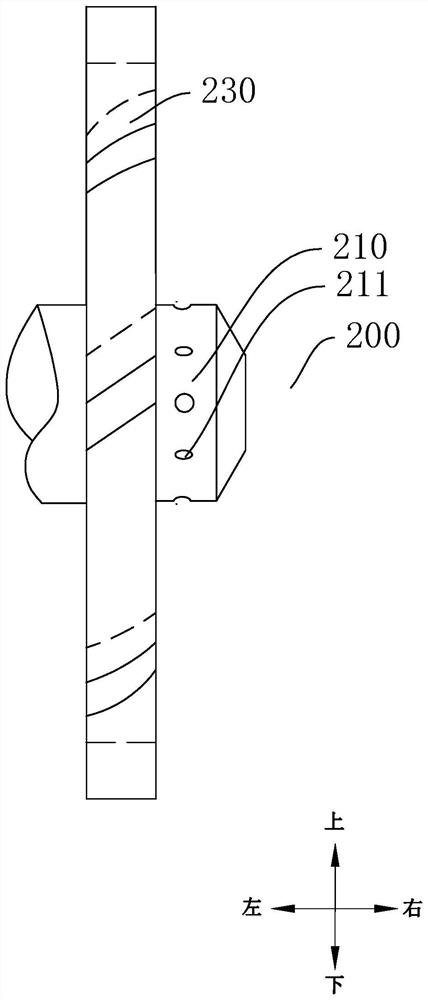

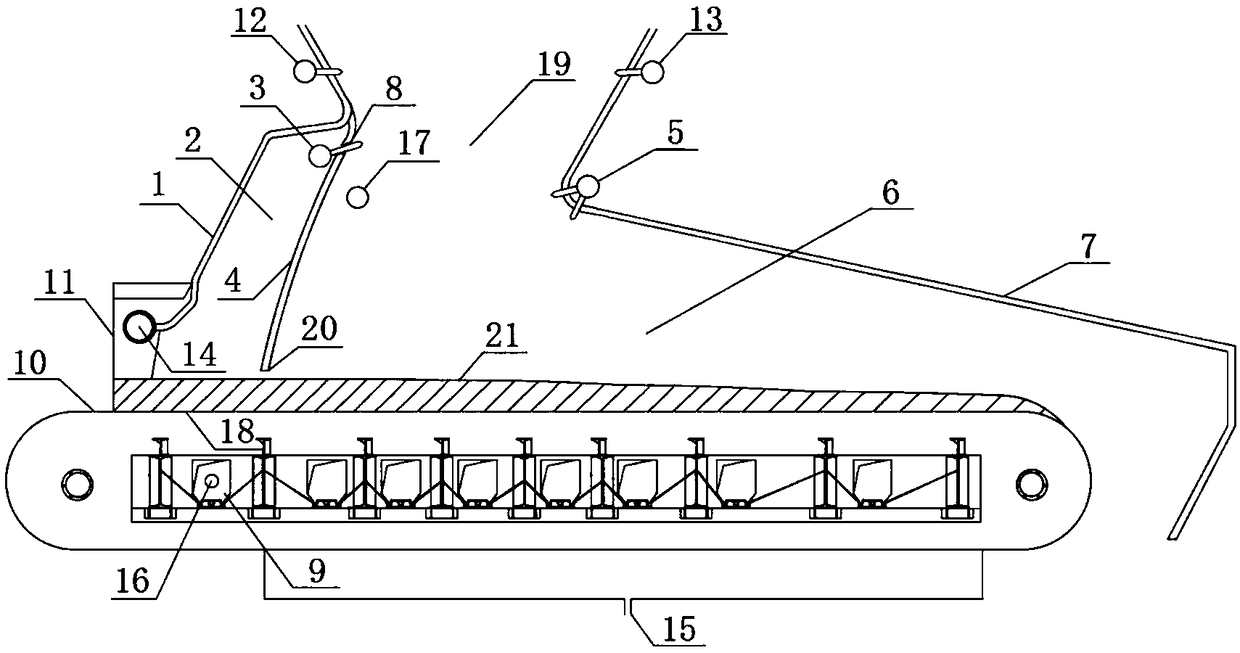

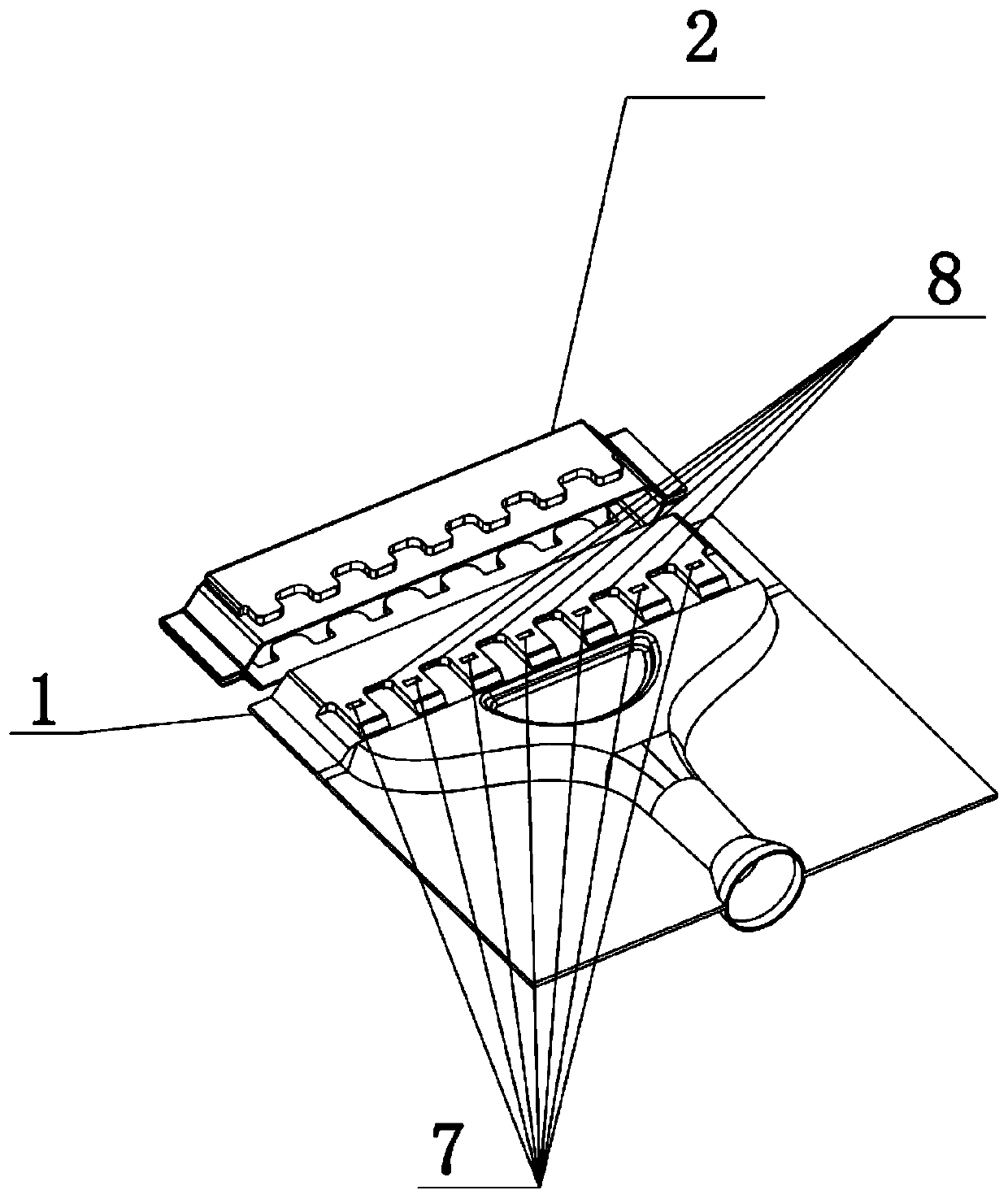

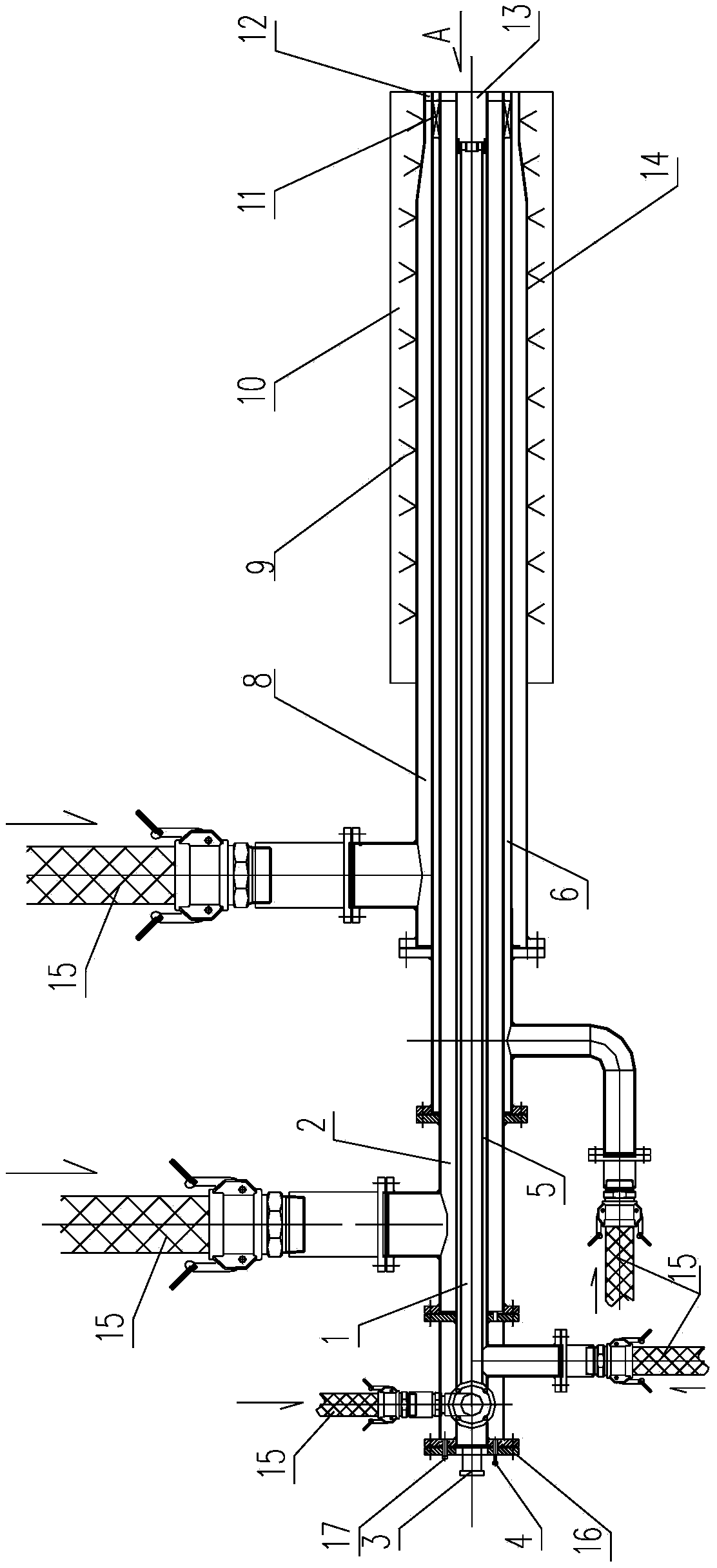

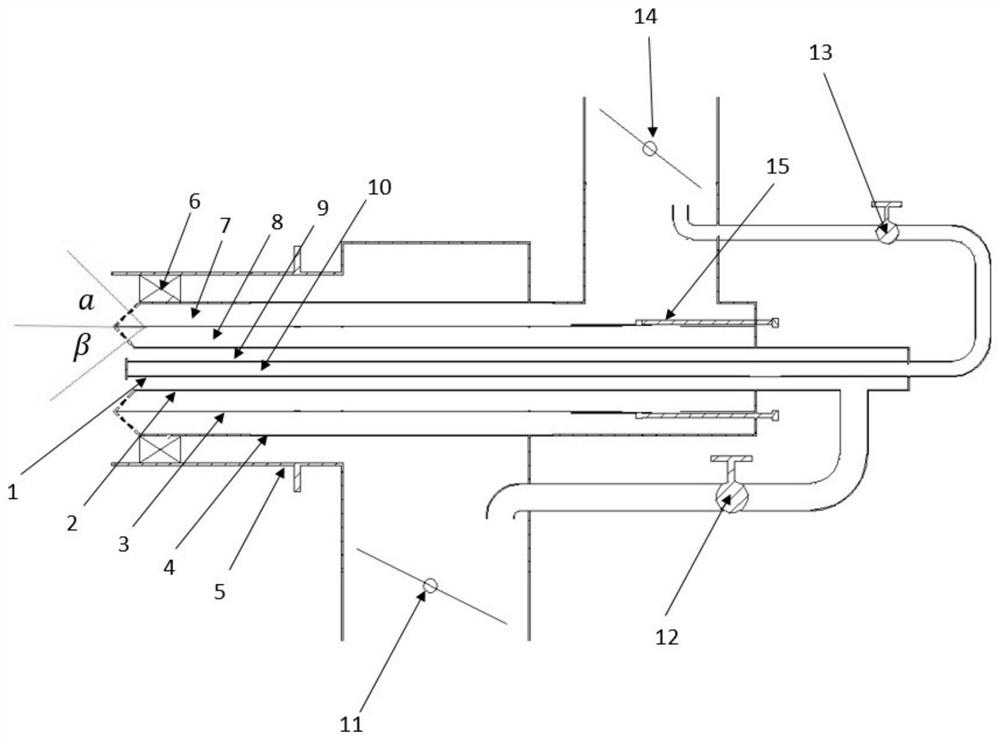

Flame-adjustable burner, and installation structure and application method thereof

PendingCN108759460AShorten the travel distanceFree from high temperature burningRotary drum furnacesCombustorEngineering

The invention relates to a flame-adjustable burner, and an installation structure and an application method thereof. The flame-adjustable burner comprises a burner body, air pipes, gas pipes and flowmeasuring and adjusting devices, wherein the air pipes and the gas pipes are connected with the burner body; the flow measuring and adjusting devices are arranged on the air pipes and the gas pipes. The burner body is provided with a center air duct, an inner ring gas duct, an inner ring air duct, an outer ring gas duct and an outer ring air duct from inside to outside in sequence. The flame-adjustable burner provided by the invention is adjustable in flame length, contour and air-fuel ratio. Gas and distributed air can be uniformly and completely mixed. While the calcinations temperature is satisfied, and low-NOx emission can be realized; moreover, the flame-adjustable burner is capable of being automatically adjusted, safe and controllable in the burning process. The flame-adjustable burner has two working positions and can meet the requirements for normal operation and ignition, realize angle fine adjustment through a flexible seal and ensure that flames do not sweep a kiln liner.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

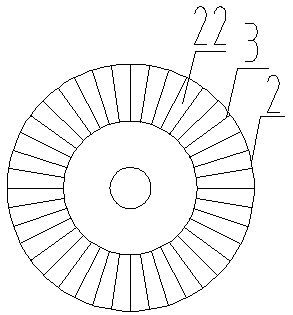

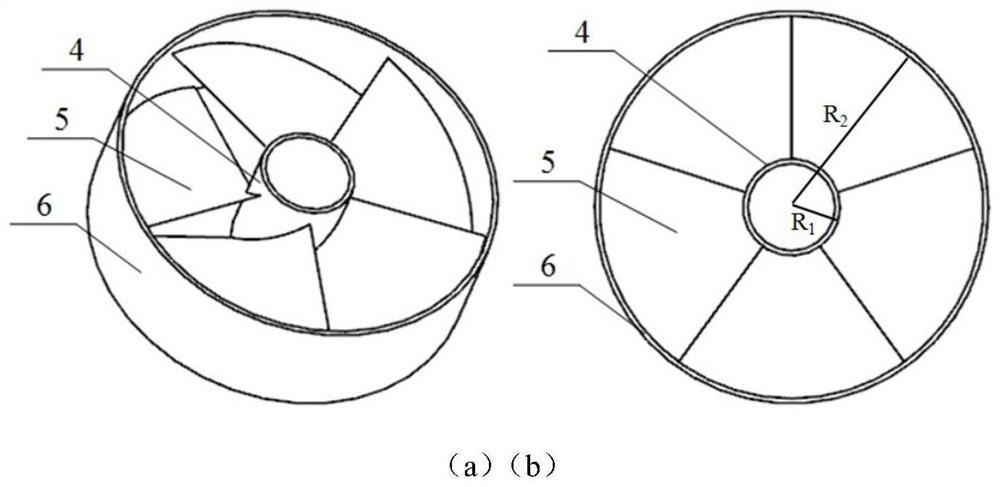

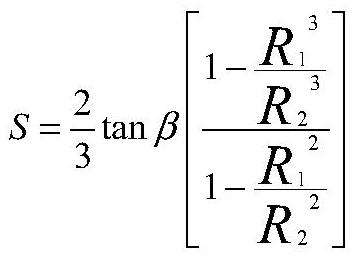

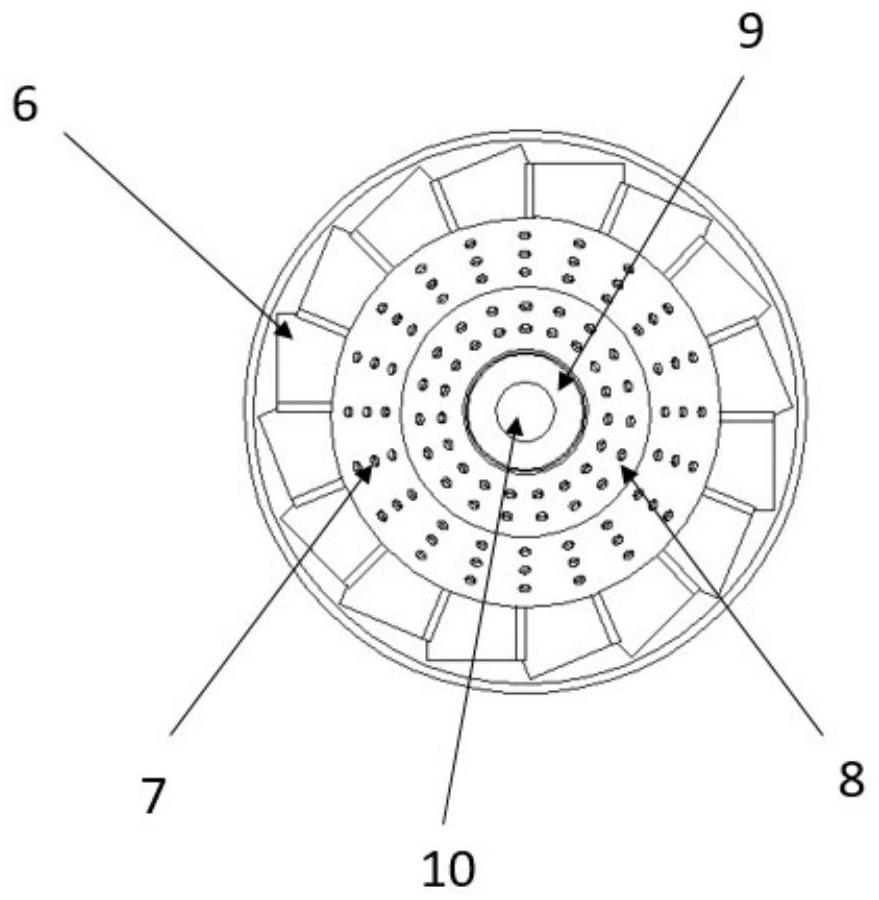

Multi-stage adjustable low-nitrogen gas burner suitable for coke oven gas

PendingCN112161267ASuppress generationReduce manufacturing costGaseous fuel burnerCombustorEmission standard

The invention discloses a multi-stage adjustable low-nitrogen gas burner suitable for coke oven gas. A rotational flow device is arranged between a secondary fuel barrel and a burner box shell; a combustion air inlet is formed in the side face of the burner box shell; a combustion air baffle is arranged at the combustion air inlet; the combustion air inlet is divided into two paths, wherein one path communicates with a center air barrel through a center air adjusting valve, and the other path communicates with the burner box shell; a gas fuel inlet is formed in the outer side of the burner boxshell; a main gas fuel adjusting baffle is arranged at the gas fuel inlet; and the gas fuel inlet is divided into three paths, wherein the first path communicates with a center fuel barrel through acenter fuel adjusting valve, the second path communicates with a primary fuel barrel through an adjusting device, and the third path communicates with the secondary fuel barrel. The burner can meet the emission standard.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

An automatic control method for fire protection and idealized combustion in a furnace

ActiveCN103047678BAutomatically adjust coal consumptionPrevent deflagrationCombustion regulationThermodynamicsAutomatic control

The invention discloses an automatic control method for preventing extinguishment and realizing ideal combustion for a hearth. The automatic control method is implemented by the aid of a full hearth control unit, signals inputted into the full hearth control unit at least include center temperature signals of various flame layers, given load signals of a boiler and starting and stopping state signals of various nozzles or pulverizing systems, automatic control operation is carried out inside the full hearth control unit, and signals outputted after automatic control operation at least include one type of fuel quantity instructions or fuel quantity correcting instructions of the various layers, air distribution quantity instructions or air distribution quantity correcting instructions of the various layers, oil feed combustion stabilizing instructions and total heat exchange energy signals generated during combustion of the hearth. The automatic control method has the advantages that the fuel coal quantity of the boiler and air quantities of the combustion nozzles can be adjusted automatically, excessively high temperature of the inside of the hearth is prevented, the boiler keeps in a stable combustion state, the extinguishment condition is stopped, the automatic control method is safe and convenient, and accordingly purposes of preventing extinguishment and realizing ideal low-nitrogen combustion are achieved for the hearth.

Owner:刘建松

Industrial wastewater incineration treatment system and process

ActiveCN112944368AAchieve low nitrogen combustionCombustion technology mitigationIncinerator apparatusIndustrial waste waterWater vapor

The invention discloses an industrial wastewater incineration treatment system and process, and relates to the technical field of industrial wastewater treatment. The industrial wastewater incineration treatment system comprises a gasification incineration device, a heat recovery device and a washing spraying device. By introducing other low-grade fuels, waste is treated with waste, and certain heat energy is produced. Light and heavy components of wastewater are separated in a gasification / incineration device by utilizing a'rectification type 'drying principle, the heavy components comprise high-boiling-point organic matter, alkali, salt and the like, the light components comprise low-boiling-point organic matter, water and the like, and the organic matter is degraded into carbon dioxide, water and a small number of other components through gasification / incineration. A large amount of water vapor is condensed, recycled water is recycled and can be sent to quenching coke, and low-nitrogen combustion is realized by utilizing a selective non-catalytic reduction (SNCR) principle.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

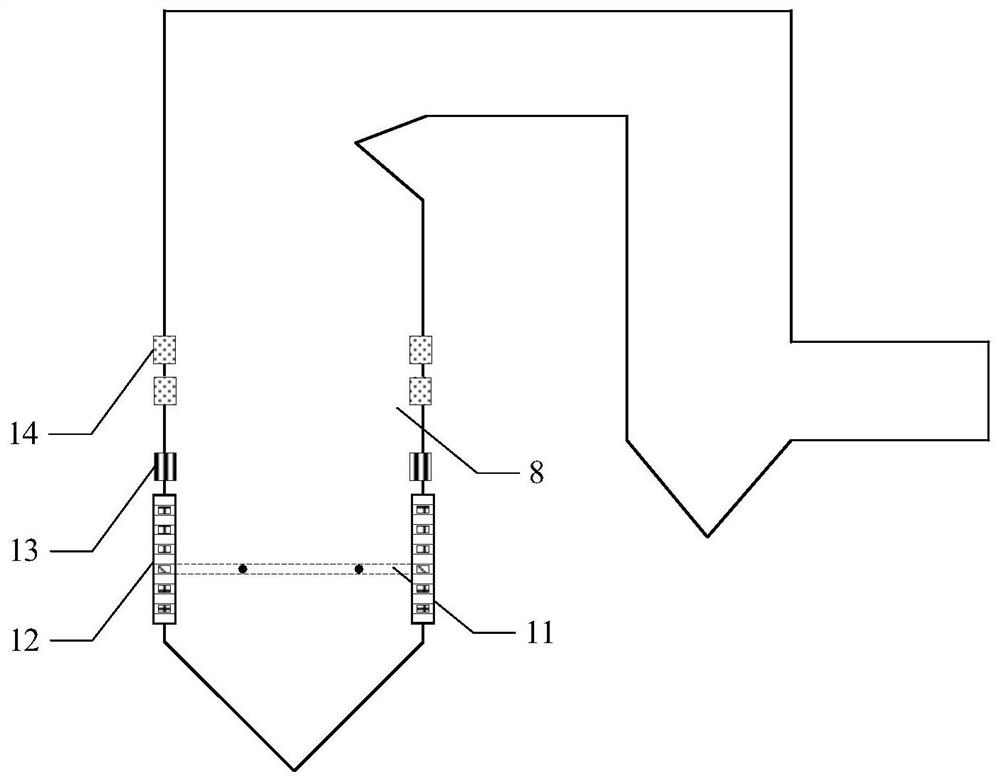

Separating and returning adjusting and controlling system of low-emission type circulating fluidized bed boiler and integrated method

PendingCN111536507AIncrease or decrease the overall lengthFlexible adjustment of total lengthFluidized bed combustionApparatus for fluidised bed combustionSlagControl system

The invention provides a separating and returning adjusting and controlling system of a low-emission type circulating fluidized bed boiler and an integrated method. The separating and returning adjusting and controlling system of the low-emission type circulating fluidized bed boiler comprises a hearth, a separation device, a returning device, a slag discharging pipe, a slag discharging adjustmentvalve, a slag cooler, a coal slag discharging pipe, a coal slag discharge adjusting valve, a coal slag cooler, an ash discharging pipe, an ash discharging adjusting valve, an ash cooling machine anda coal slag removing machine. The inlet end of the ash discharging pipe extends into an air chamber to communicate with the bottom of a returning valve. The position of a moving cylinder is adjusted in a fixed cylinder. The integration method comprises the steps of firstly, under the condition that the load of the boiler descends or the caloric value of the fuel of the boiler descends, conductingfuel combustion and smoke and ash separation; and secondly, discharging the coal slag. According to the separating and returning adjusting and controlling system of the low-emission type circulatingfluidized bed boiler and the integrated method, by means of independent control over the amounts of separated ash and returning ash, discharging coal slag and discharging ash or integrated control over the amounts of separated ash and returning ash, discharging coal slag and discharging ash, the amount of separated ash, the amount of returning ash and the bed material of a bed hearth can be adjusted when the boiler is under a low load or fuel suddenly changes, so that the temperature field in the hearth is reasonable and uniform, the boiler can operate stably, stably and efficiently for a longtime, and ultra-low emission of NOX and SO2pollutans is achieved.

Owner:哈尔滨红光锅炉总厂有限责任公司

Low-nitrogen combustion circulating fluidized bed boiler and its application method

ActiveCN110500577BSuppress generationThe principle is simpleFluidized bed combustionApparatus for fluidised bed combustionNitrogen oxidesFluidized bed

The invention discloses a low-nitrogen combustion circulating fluidized bed boiler and a using method thereof. The low-nitrogen combustion circulating fluidized bed boiler comprises a furnace, an airinlet system, a separating system and a coal inlet system, wherein the air inlet system involves an air inlet pipe, a primary air inlet device and a secondary air inlet pipeline system, the air inletpipe is connected with the primary air inlet device and the secondary air inlet pipeline system, and the primary air inlet device is arranged at the lower end of the furnace; the primary air inlet device is internally provided with a primary air inlet pipe, an air inlet buffer and an air distribution plate, and the primary air inlet pipe communicates with a primary air combustion area; and the secondary air inlet pipeline system communicates to a secondary air combustion area, and the secondary air combustion area is located downstream the primary air combustion area. According to the boiler and the method, coal is subjected to staged combustion in the boiler through the primary air inlet device and the secondary air inlet pipeline system, primary combustion is carried out under the low oxygen condition, secondary combustion is carried out under the low fuel condition, so that the generation of nitrogen oxides during two-time combustion is greatly inhibited, the principle is simple, and the practicability is high.

Owner:SICHUAN CHUANGUO BOILER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com