Temperature-controllable burner achieving central flow guide and adjustment and cyclone classification

A swirl classification and burner technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of uncontrollable combustion temperature, uneven distribution of airflow and flow field, and poor gas classification combustion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

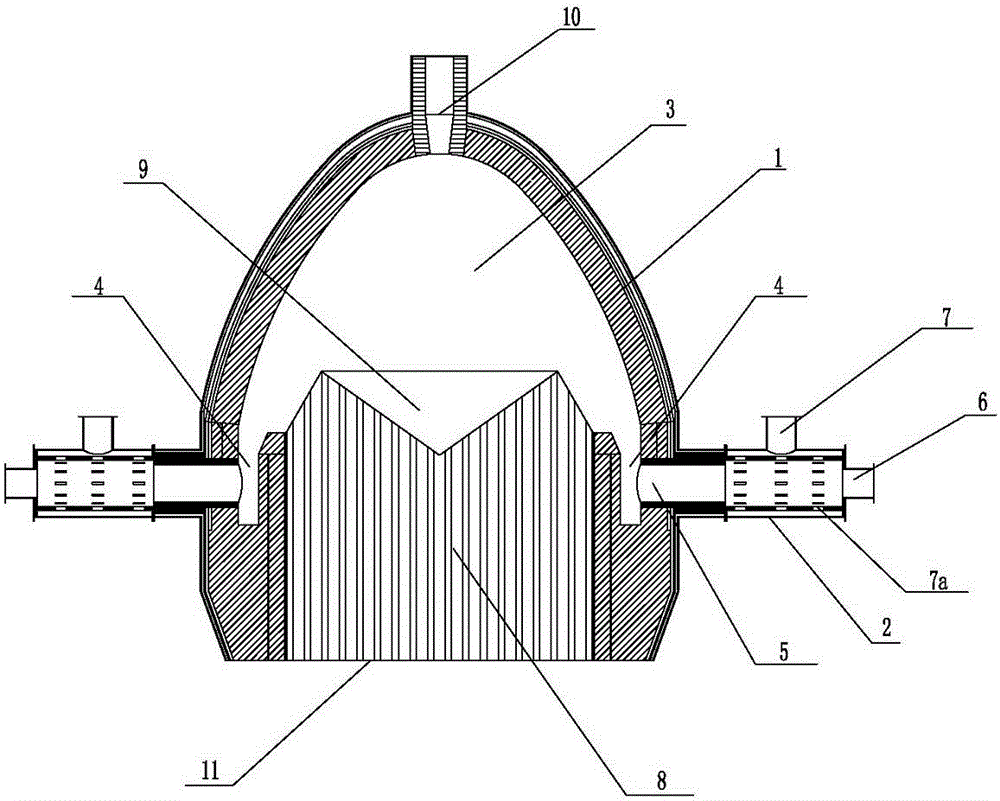

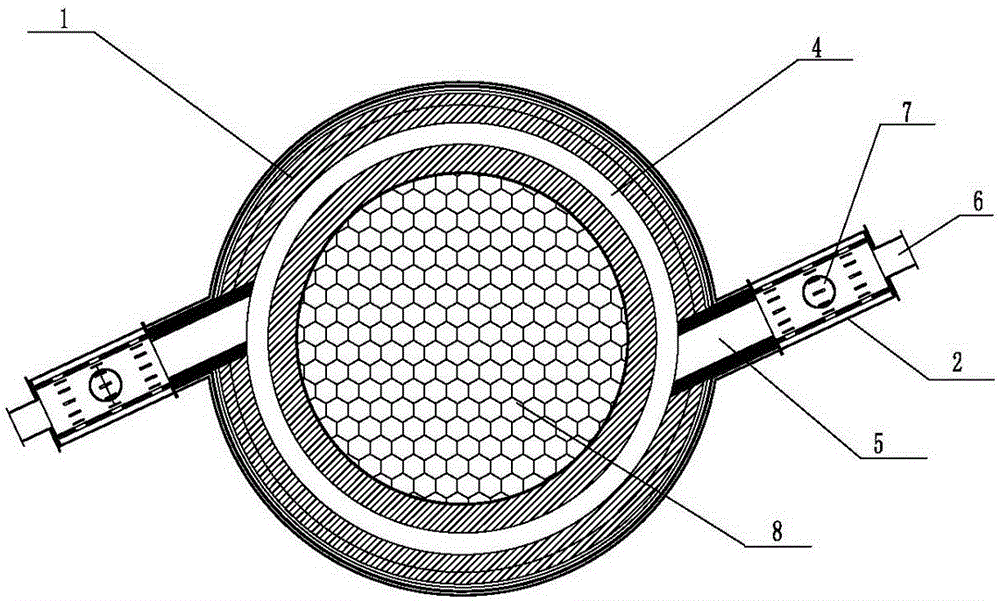

[0008] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] Such as Figure 1-Figure 2 As shown, the present invention includes a burner wall, a combustion chamber, an external airflow premixer, a premixed air inlet channel, a premixed air swirl ring, a secondary airflow injection inlet, a ceramic porous body and a burner airflow outlet, The burner wall 1 is composed of the connection of the upper hemispherical dome and the lower cylinder. The inner cavity of the burner wall is the combustion chamber 3. The upper part of the cylinder wall is provided with a premixed air swirl loop 4 with an upper opening. The outer wall of the premixed cyclone flow ring is horizontally connected with one or more premixed gas inlet passages 5, and the outer end of the premixed gas inlet passage protrudes from the cylinder and the outer wall of the burner. The airflow premixer 2 is connected, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com