Low-nitrogen combustion circulating fluidized bed boiler and its application method

A circulating fluidized bed, low-nitrogen combustion technology, applied in combustion methods, fluidized bed combustion equipment, combustion types, etc., can solve problems such as undetermined nitrogen oxide content and inhalation time, lung structure changes, etc. To achieve the effect of easy control and manipulation, reduce the probability of misoperation, and reduce equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

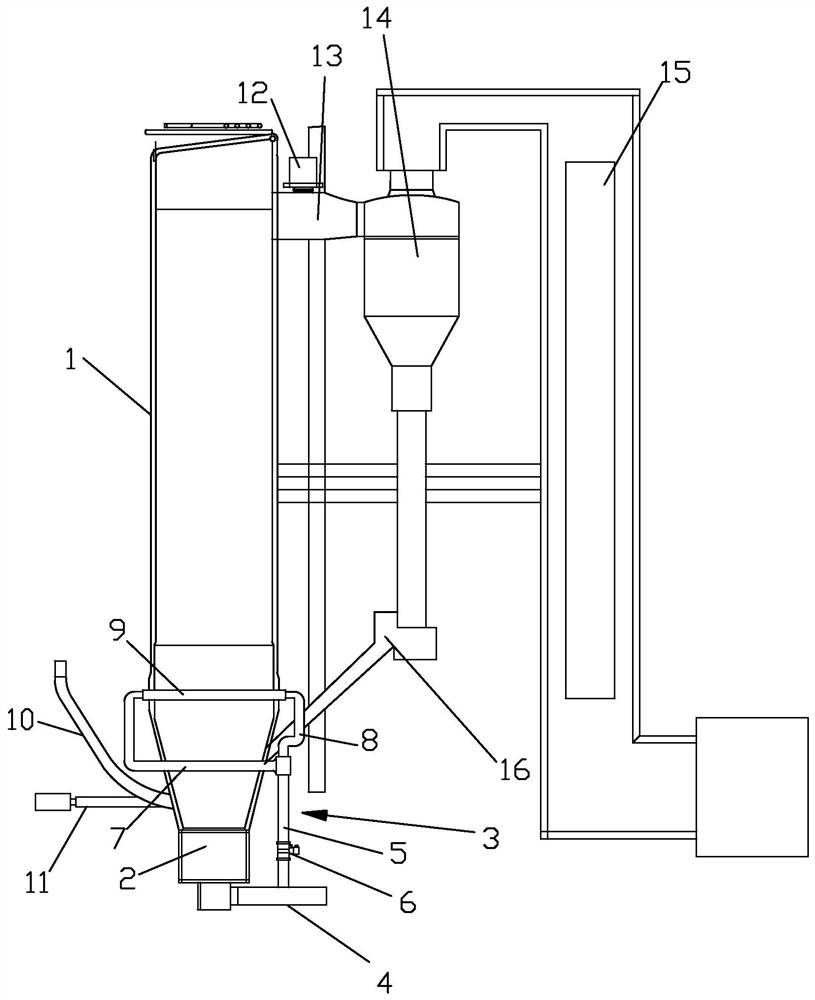

[0035] The present invention proposes a low-nitrogen combustion circulating fluidized bed boiler and its use method:

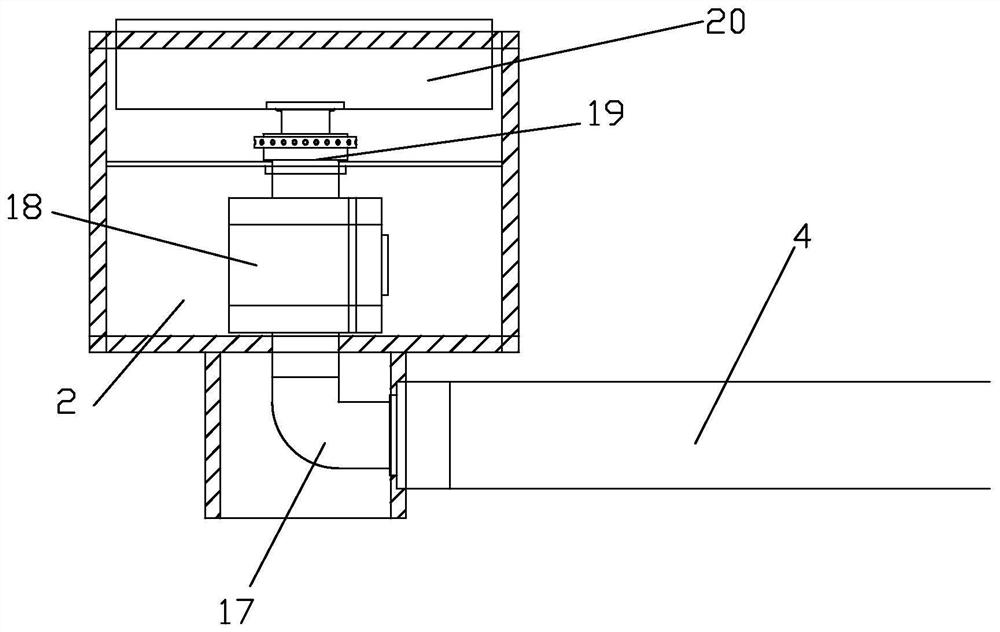

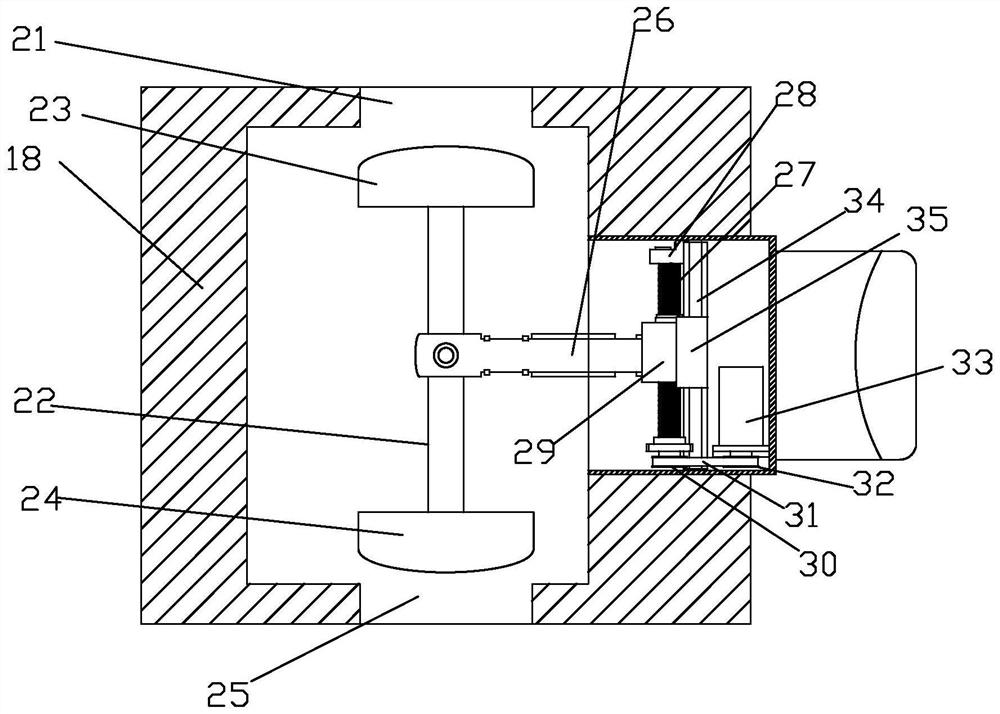

[0036] 1. The low-nitrogen combustion circulating fluidized bed boiler includes a furnace 1, an air inlet system, a separation system and a coal inlet system. The air inlet system is installed at the lower end of the furnace 1. The coal feeding system is installed at the lower end of the furnace 1. The coal feeding system includes a coal dropping pipe 10, a detachable coal feeding hopper 40 and a coal pusher 11. The coal dropping pipe 10 is connected to the furnace 1. Coal feeding hopper 40 is matched with each other, and detachable coal feeding hopper 40 is installed to the mouth of coal falling pipe 10 in the way of putting in; existing coal falling pipe 10 has a small nozzle, and it is easy to leak out when coal is poured in. The problem of waste; the detachable coal hopper 40 is convenient for pouring coal into the coal drop pipe 10, effectively solving th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com