Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about "Prevention of dough sticking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

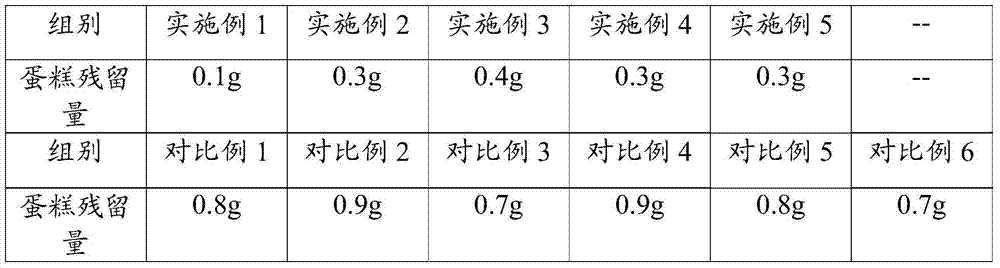

Mold release agent and preparation method thereof

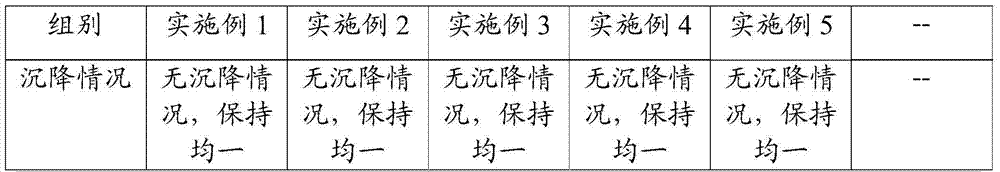

The invention relates to a mold release agent for demolding various bakeware, molds, steel strips and other appliances used in the food industry and a preparation method thereof. The mold release agent contains grease, a wax and an emulsifier, wherein the wax is selected from rice bran wax, soy wax and sunflower seed wax. The method for preparing the mold release agent comprises the process stepsof first rapid cooling and then annealing. The mold release agent is uniform in the storage process, does not settle, and has excellent model release performance. The invention also relates to a method for producing baked food by using the mold release agent.

Owner:嘉里特种油脂(上海)有限公司

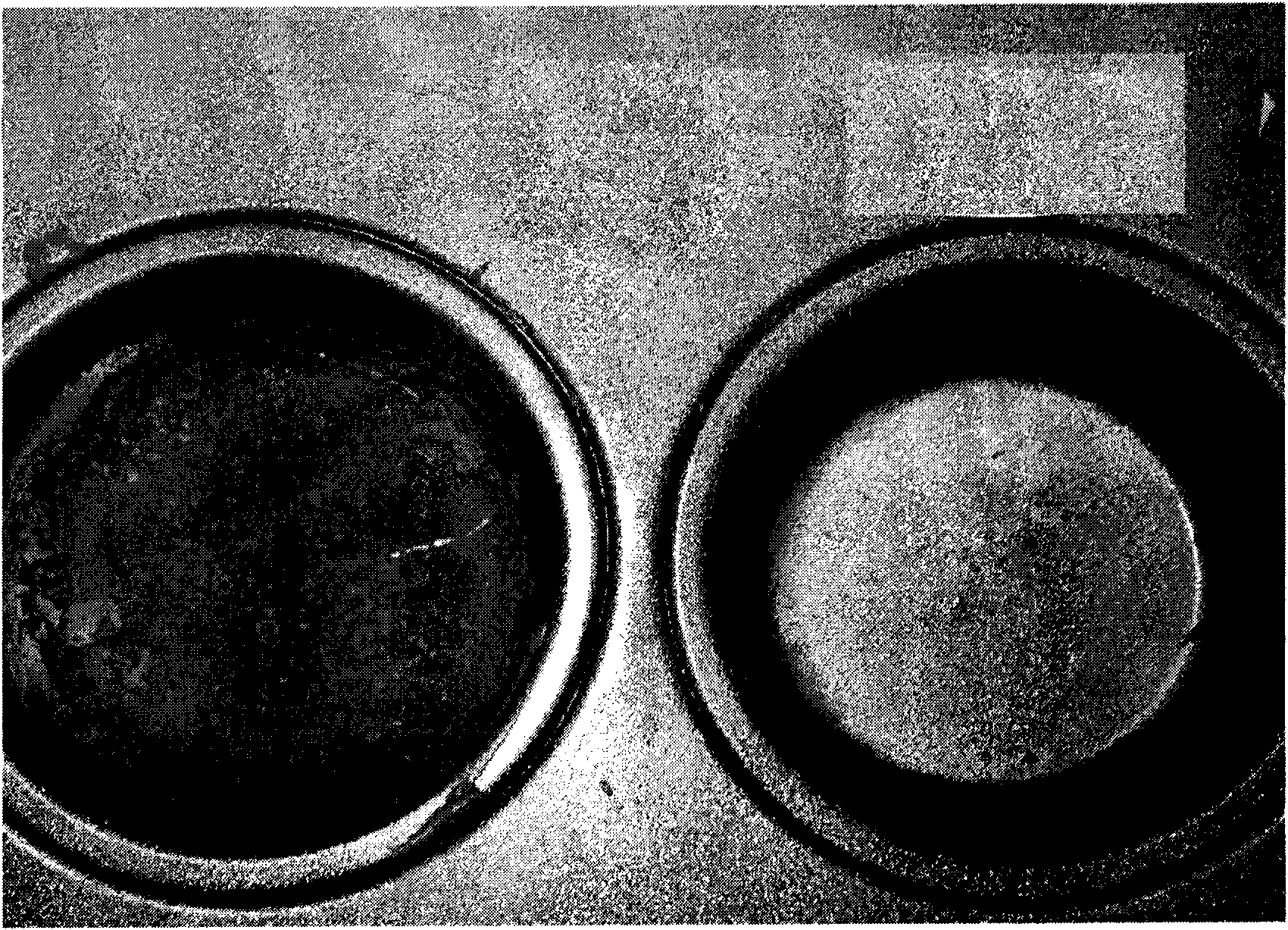

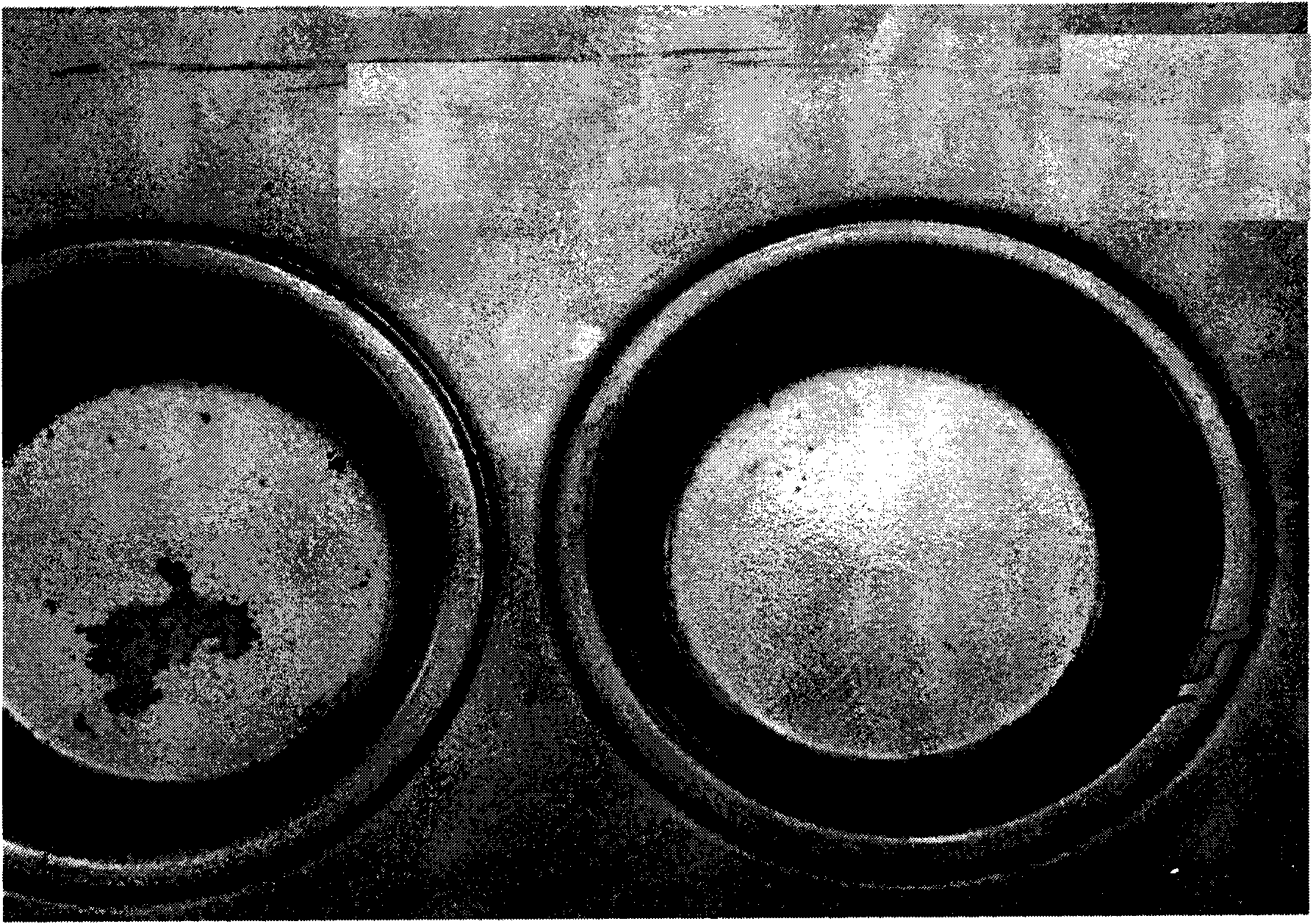

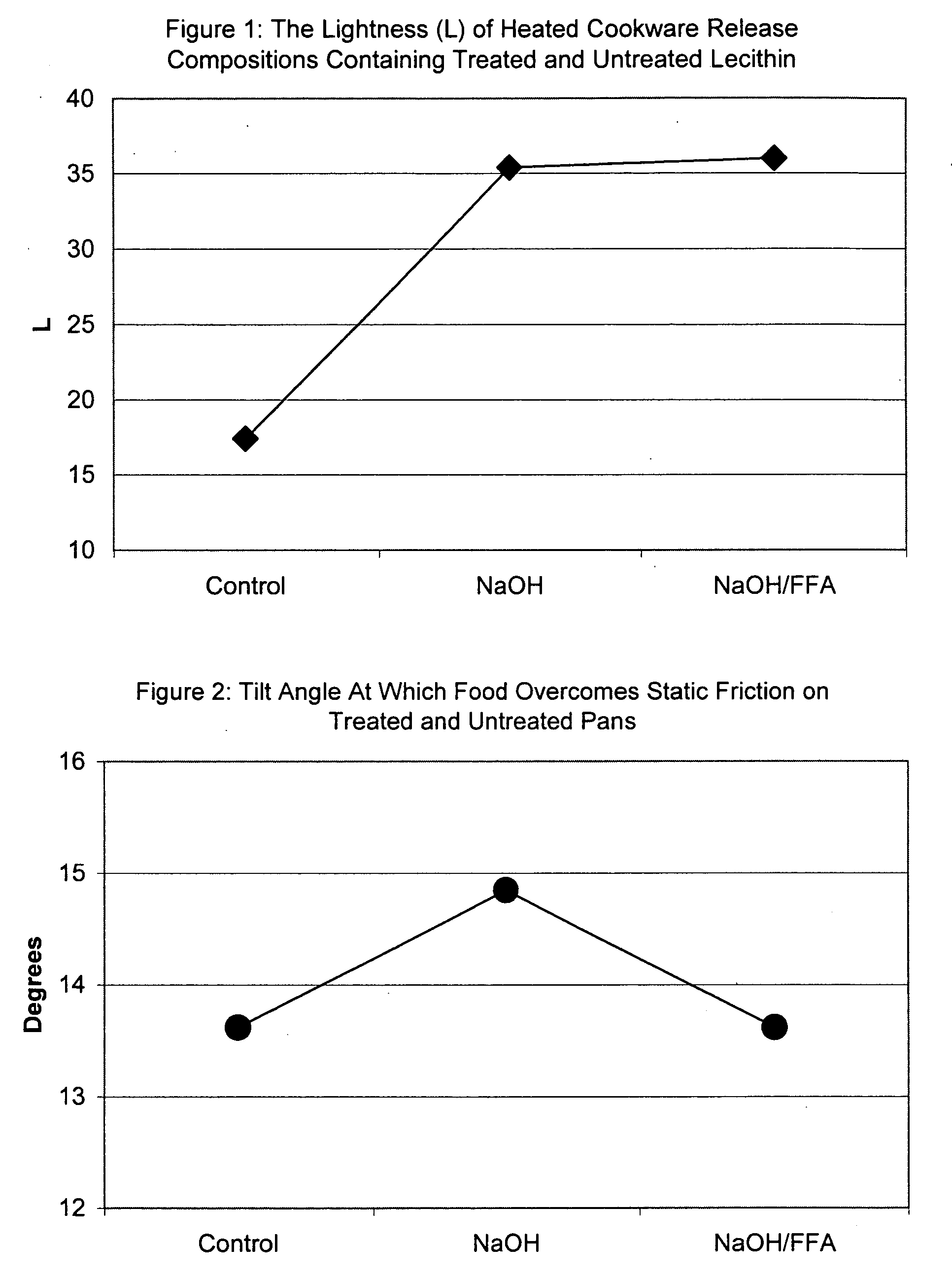

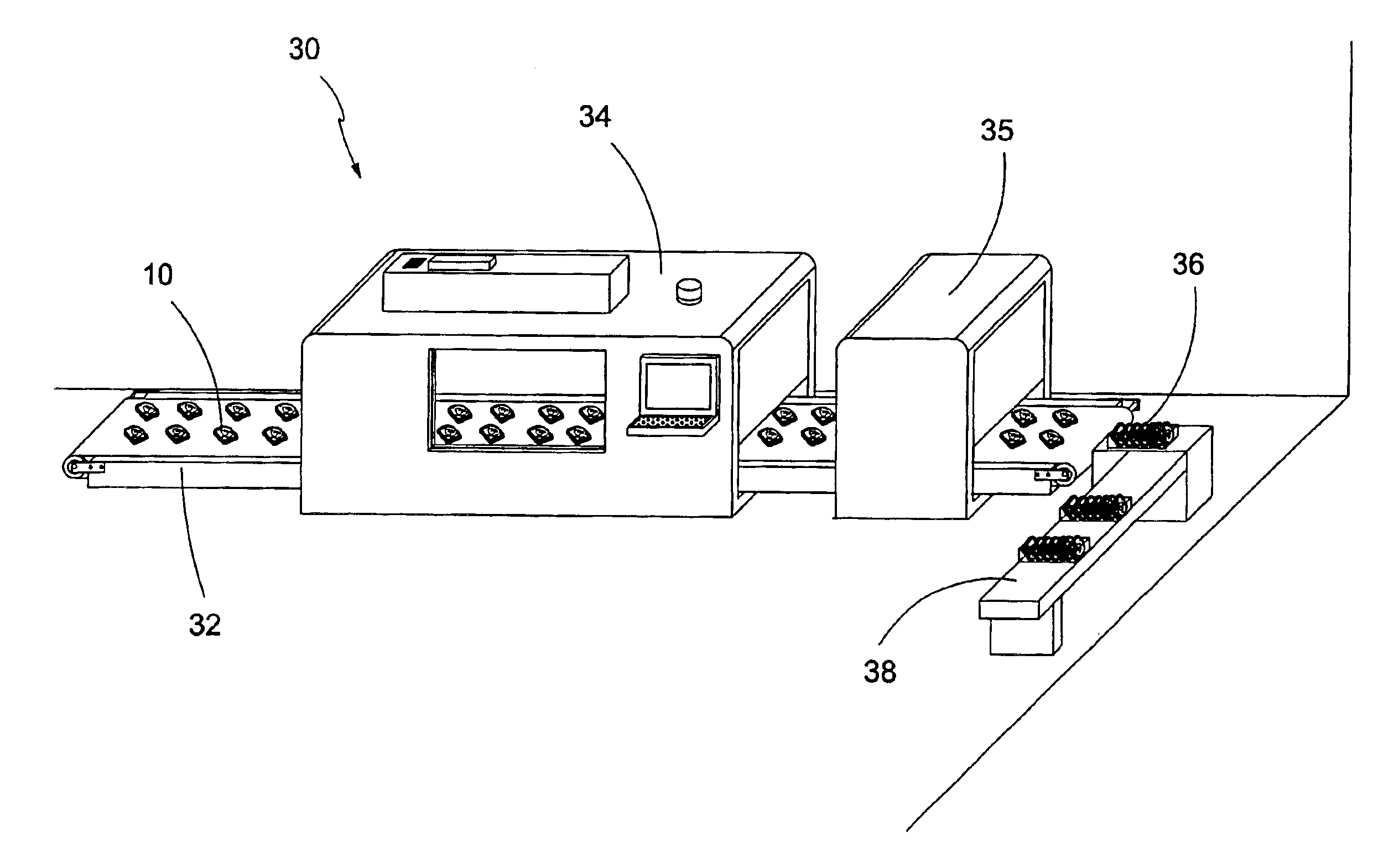

Sprayable cookware release composition with reduced heat induced browning

A sprayable cookware release composition includes an oil, a propellant, and a cookware release agent having lecithin treated with an alkali and a fatty acid at the same time or treated with a mixture of an alkali and a fatty acid. A variety of alkali and fatty acids can be used to treat the lecithin, including more than one alkali and more than one fatty acid. Suitable alkali for treating the lecithin include sodium and potassium sorbate, sodium and potassium carbonate, sodium and potassium bicarbonate, sodium and potassium acetate, sodium and potassium hydroxide, and mixtures thereof. Suitable fatty acids for treating the lecithin include oleic acid, linoleic acid, palmitic acid, stearic acid, and mixtures thereof. The cookware release agent and oil are mixed, and the mixture is dispensed from the aerosol container by the propellant. Suitable cookware release agents include lecithin and variants thereof, such as oil soluble lecithin, water-dispersible lecithin, hydroxylated lecithin, lyso-phopholipid, or a mixture thereof.

Owner:CONAGRA FOODS

Sprayable cookware release composition with reduced heat induced browning

ActiveUS6905722B2CandlesNon-surface-active detergent compositionsWater dispersiblePotassium hydroxide

A sprayable cookware release composition includes an oil, a propellant, and a cookware release agent having lecithin treated with an alkali and a fatty acid at the same time or treated with a mixture of an alkali and a fatty acid. A variety of alkali and fatty acids can be used to treat the lecithin, including more than one alkali and more than one fatty acid. Suitable alkali for treating the lecithin include sodium and potassium sorbate, sodium and potassium carbonate, sodium and potassium bicarbonate, sodium and potassium acetate, sodium and potassium hydroxide, and mixtures thereof. Suitable fatty acids for treating the lecithin include oleic acid, linoleic acid, palmitic acid, stearic acid, and mixtures thereof. The cookware release agent and oil are mixed, and the mixture is dispensed from the aerosol container by the propellant. Suitable cookware release agents include lecithin and variants thereof, such as oil soluble lecithin, water-dispersible lecithin, hydroxylated lecithin, lyso-phopholipid, or a mixture thereof.

Owner:CONAGRA GROCERY PROD CO

Partially thermal treated dough intermediate and method of making

A method of preparing a partially thermal treated dough intermediate which has reduced tendency to adhere to the processing apparatus is disclosed. The dough intermediate is thermal treated to create a temporary impermeable barrier on each of the layers of the intermediate.

Owner:GENERAL MILLS INC

Storage stable pan release coating and cleaner

InactiveUS6852349B2Good storage stabilityEdible oils/fats ingredientsOrganic detergent compounding agentsAcetic acidMonoglyceride

The pan release coating is provided which includes water, mono and diclycerides, polysorbate, and an antimicrobial effective amount of acetic acid, citric acid and sodium benzoate. Desirably, the composition of the present invention is composed of water in an amount of 77% to 95% by weight, acetic acid in the amount of 0.3 to 1% by weight, citric acid in the amount of 0.02 to 1.0% by weight, sodium benzoate in an amount of 0.02 to 0.3% by weight, monoglycerides and diglycerides in the amount of 2 to 8% by weight and polysorbate in the amount of 2 to 7% by weight. Desirably, lecithin is also included. The resulting product has a pH of 4.5 or below, desirably between about 3.5 and 4.5, and most desirably a pH of 3.6 to 3.9. The product has a shelf life of 12 months or longer at room temperature, without refrigeration or a sealed container.

Owner:PETROFERM INC

Bakeware mold oil and method for producing the same

InactiveCN101433224AImprove production environmentThe production environment is smooth and tidyPrevention of dough stickingBaked goodsEngineering

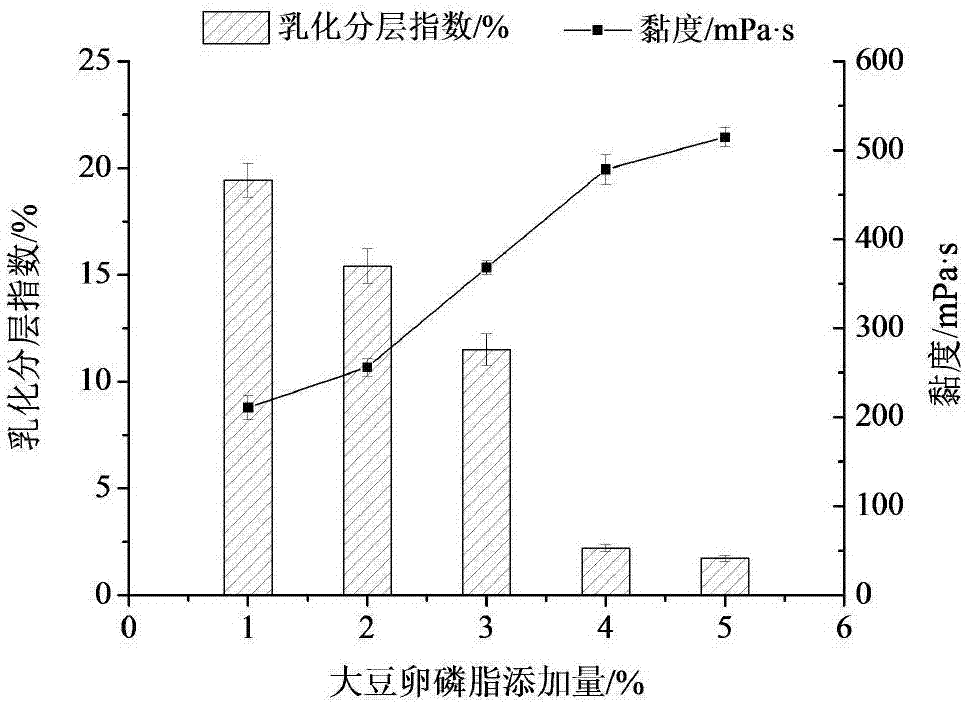

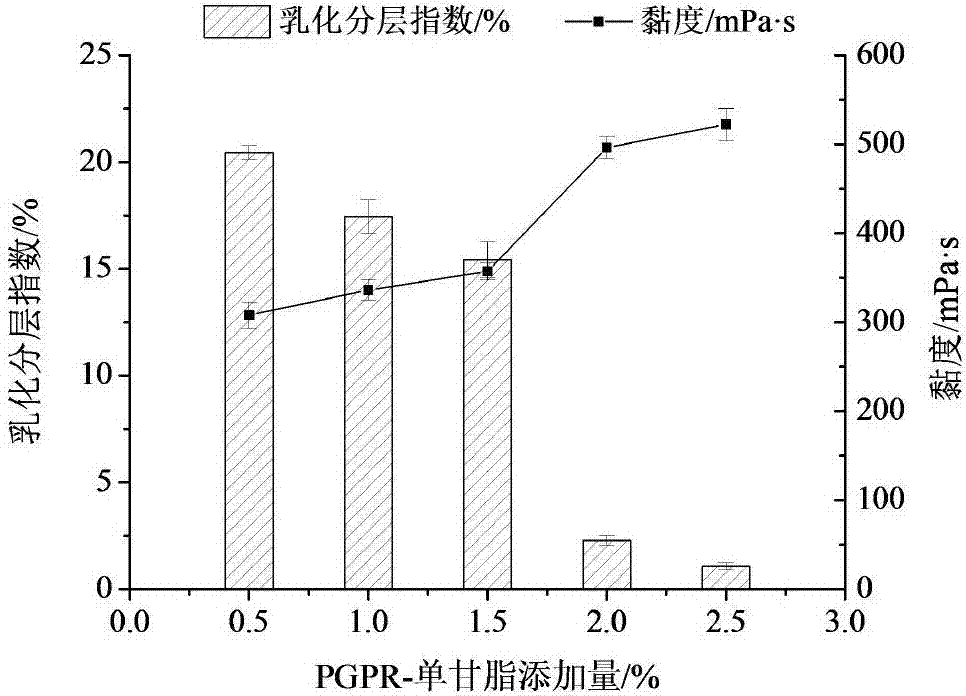

The invention discloses mold oil for a baking pan, which is characterized in that the mold oil for the baking pan comprises the following components in weigh proportion: 193 to 203 portions of rapeseed salad oil, 357 to 363 portions of water, 11.5 to 12.5 portions of polyglycerol polyricinoleate (PGPR), 17 to 19 portions of pharmaceutical grade refined castor oil, and 11 to 13 portions of liquid soybean lecithin. The mold oil for the baking pan has low cost, can improve the production efficiency and finished product rate of baked food, improve the production environment of the baked food, has functions of antisepsis and freshness preservation, can obviously prolong the shelf life of the baked food, and has good market prospect and economical prospect.

Owner:杨东升

Method for preparing oil/water (O/W) type special mould release agent for baking by using palm liquid oil

ActiveCN102326597AGood application effectGood release effectPrevention of dough stickingOil and greaseMonoglyceride

The invention discloses a method for preparing an oil / water (O / W) type special mould release agent for baking by using palm liquid oil. The method comprises the following steps of: (1) preparation of an aqueous phase: adding a stabilizing agent into sterilized water, stirring, mixing, standing, adding hydrophilic emulsifier, citric acid and preservative, stirring and mixing to prepare the aqueousphase; (2) preparation of an oil phase: adding lecithin, distilled monoglyceride, lubricating agent, antioxidant and polydimethylsiloxane, stirring and mixing to prepare the oil phase; and (3) shearing emulsification: pouring the aqueous phase into the oil phase, and cooling the mixture to room temperature. The invention provides the O / W type special mould release agent for baking with stability,uniformity and good coating property and mould release property; the special mould release agent is suitable for mechanical coating and manual brushing, is more convenient and faster in operation, and improves the production efficiency; and the O / W type formula reduces the content of grease, and the heat quantity is lower because the lecithin is added.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Edible releasing agent

The invention relates to an edible releasing agent comprising the following main raw material components according to parts by weight: 100 parts of maize oil, 3 parts of polyacrylate sodium, 1 to 2 parts of lecithin and 3 to 4 parts of rice bran wax. The edible releasing agent has the main characteristics that: (1), the releasing capability is strong, the surfaces of foods are flat and smooth, grease is distributed uniformly, and the taste of the foods can not be influenced; (2), all the raw materials are edible materials or food additives; and (3), no oil fume is generated when the foods are baked, and the ambient environment is not polluted.

Owner:BEIJING BRIDGECOM SE

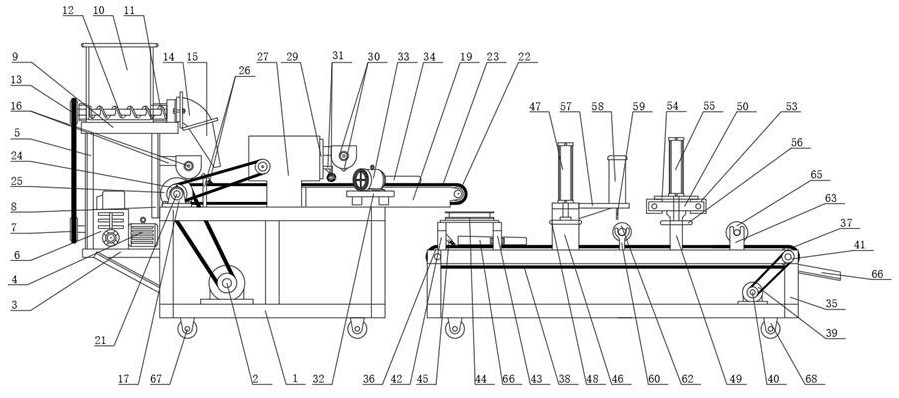

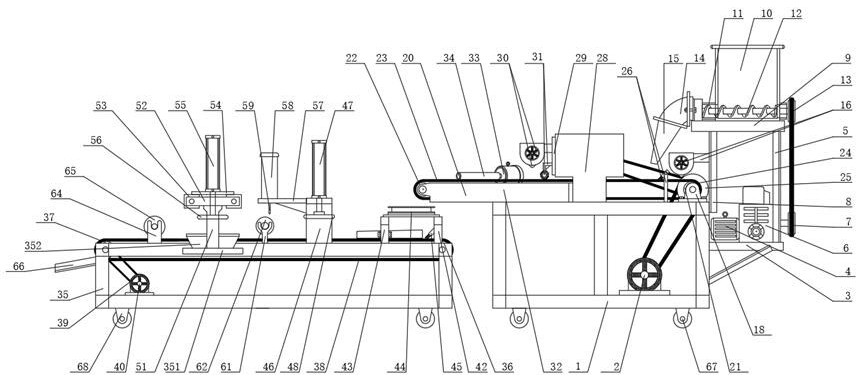

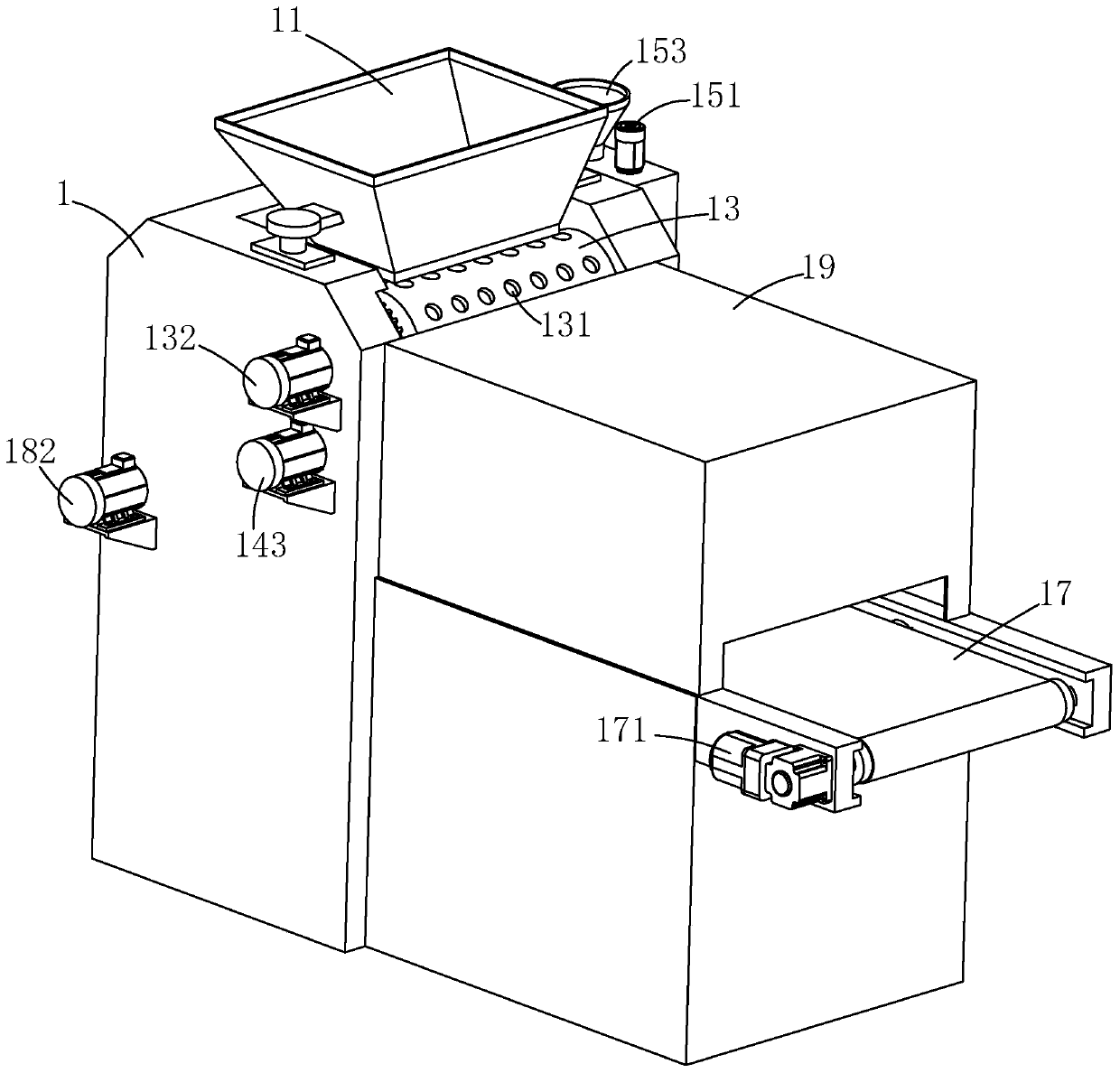

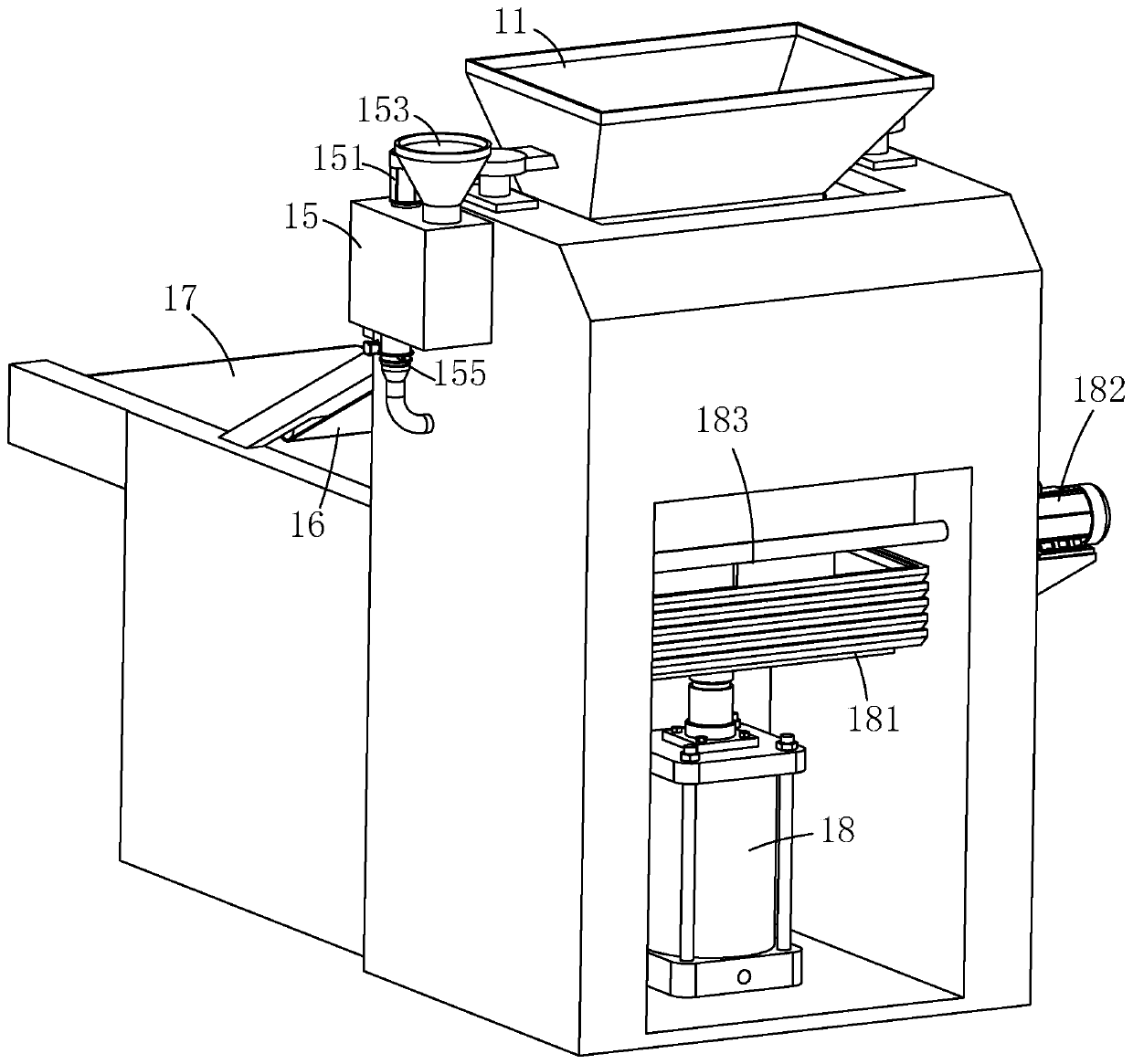

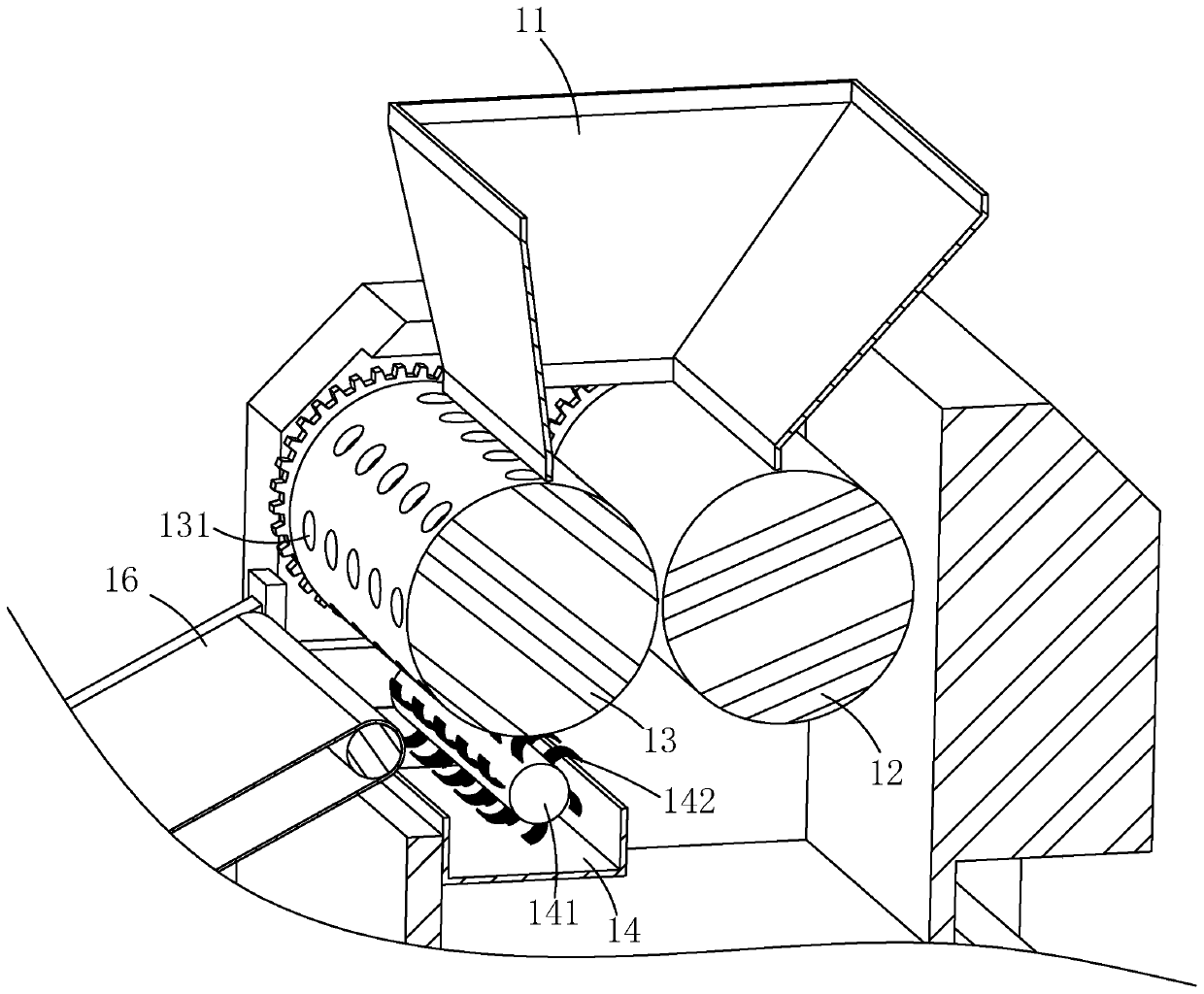

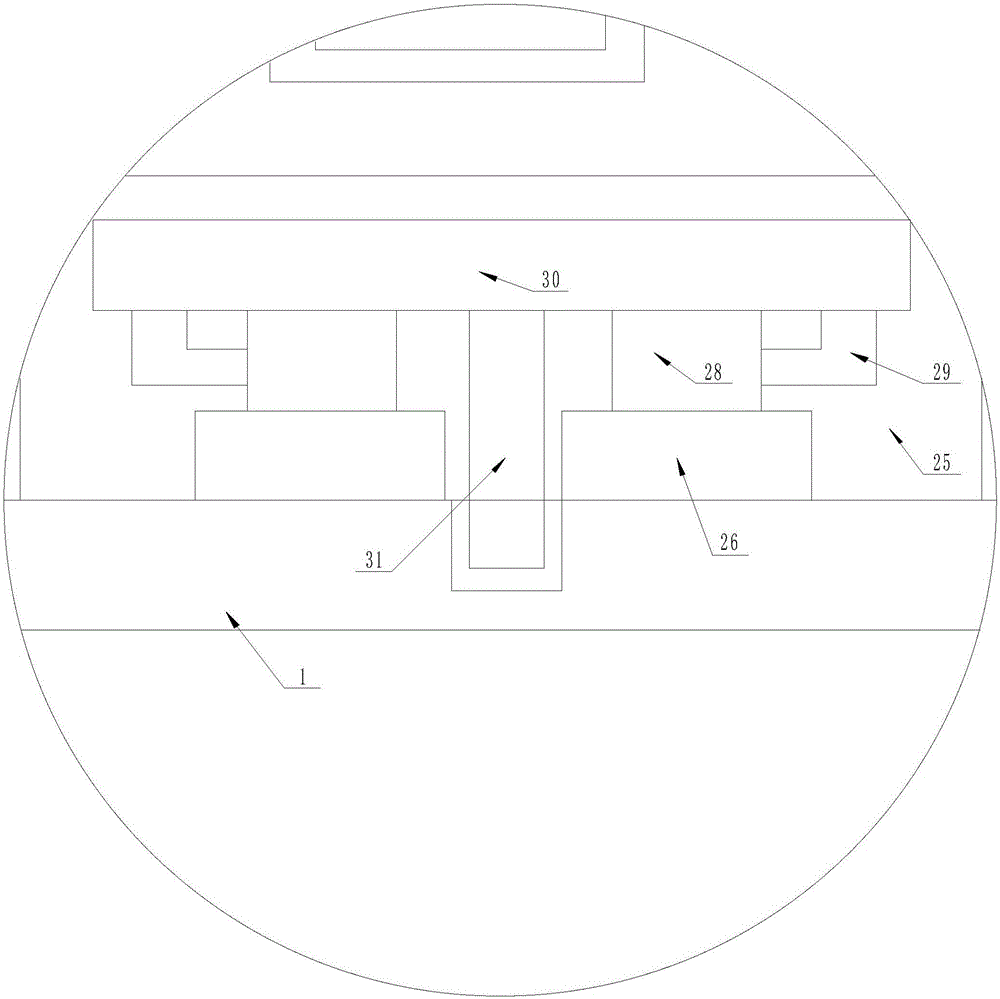

Sesame seed cake making equipment

PendingCN113396949AImprove work efficiencyPrevention of dough stickingDough shaping and cutting apparatusAgricultural engineeringMechanical engineering

The invention belongs to the technical field of sesame seed cake making, and particularly relates to sesame seed cake making equipment. The sesame seed cake making equipment comprises a discharging mechanism, a first conveying and rolling mechanism and a second conveying and rolling mechanism, a first conveying and rolling mechanism, and a second conveying and rolling mechanism; The discharging mechanism is arranged above the conveying direction of the first conveying and rolling mechanism, the second conveying and rolling mechanism is located above the conveying direction of the first conveying and rolling mechanism. The discharging mechanism comprises a first supporting assembly, a first power source conveying assembly and a discharging assembly. A kneaded dough is placed in a material box C of the discharging mechanism, the dough is extruded out of a special-shaped pipe through extrusion, flour spreading and brushing, rolling and material scattering are completed on a conveying belt A, strip-shaped dough sheets are formed, the dough sheets are rolled to be cylindrical in cooperation with a rotating roller, then the dough sheets are conveyed to a conveying belt B, and brushing of redundant flour, section cutting, rolling of dough sections, sesame scattering and the like are completed, dough wrappers used for baking is produced successively; in conclusion, integrated and automatic dough wrapper making is realized, and working efficiency is high.

Owner:刘洪林

Special demolding oil for waffle and preparation method of special demolding oil for waffle

ActiveCN102726480AAvoid breakingImprove protectionPrevention of dough stickingAdditive ingredientCoconut oil

The invention discloses special demolding oil for waffle and a preparation method of the special demolding oil for the waffle and belongs to the field of food processing. The demolding oil provided by the invention is prepared from the following ingredients in parts by weight: 92 to 103 parts of coconut oil, 155 to 170 parts of colza oil, 33 to 50 parts of lard oil, 33 to 50 parts of palm oil, 18to 22 parts of soya bean lecithin, 10 to 15 parts of monostearin and 425 to 510 parts of water. The ingredients of coconut oil, lard oil, monostearin and the like are added. Compared with the prior art, the special demolding oil has the following advantages that the demolding is easily performed during the industrial or manual manufacture of the waffle, so the surface of a mold maintains the smooth state, the mold is favorably protected, the waffle crack is prevented, the finished product rate of products is improved, oil smoke and accumulated scales are reduced, the operation environment is improved, the completeness and the brightness of products are ensured to the maximum degree, and the color is uniform. When being used, the special demolding oil for the waffle and the preparation method provided by the invention have the advantages that the manufactured demolding oil is uniform and consistent, the demolding effect is good, and the quality guarantee period can reach 24 months whenthe special demolding oil is stored in a cool dry place.

Owner:LUOHE LIANTAI FOOD

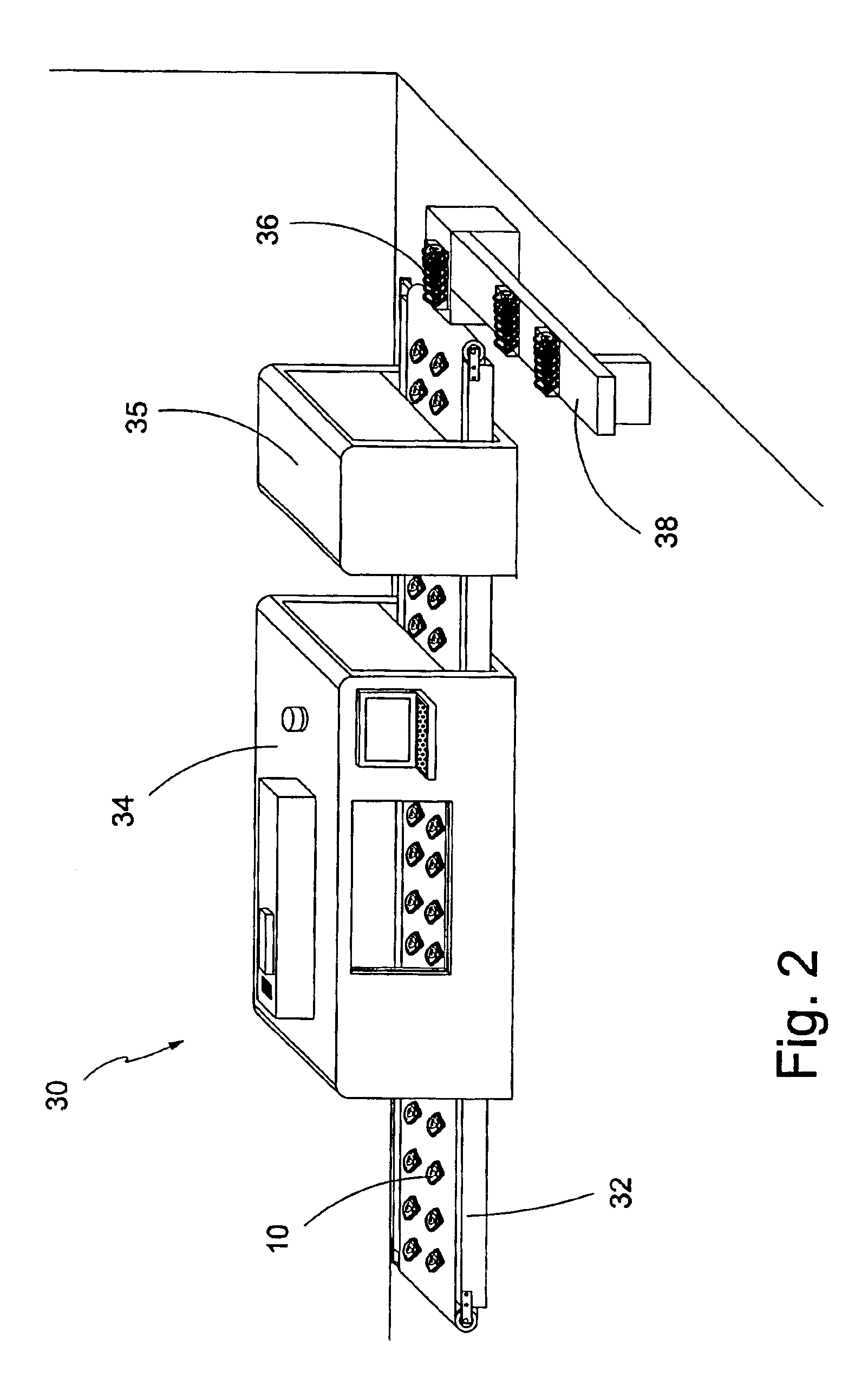

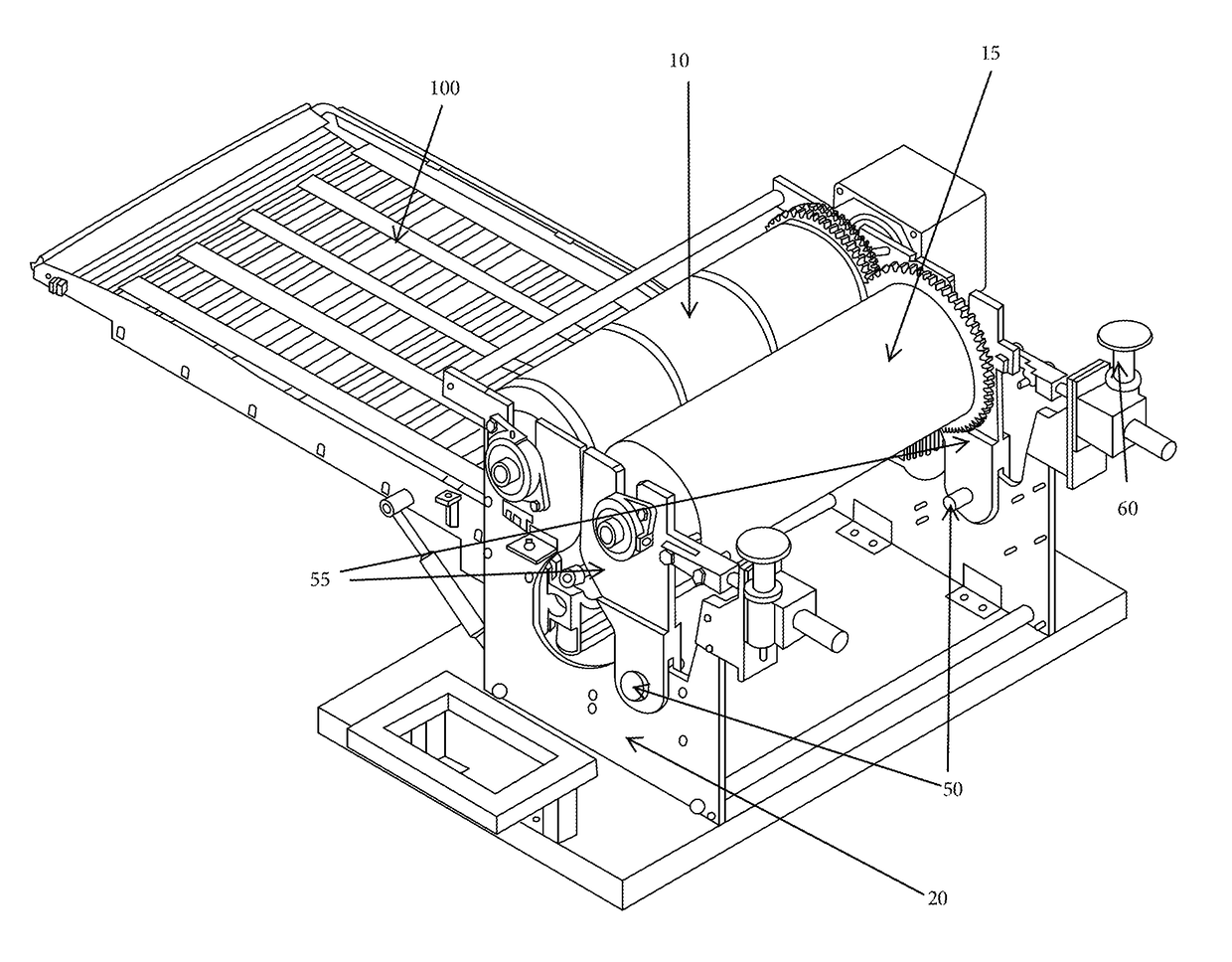

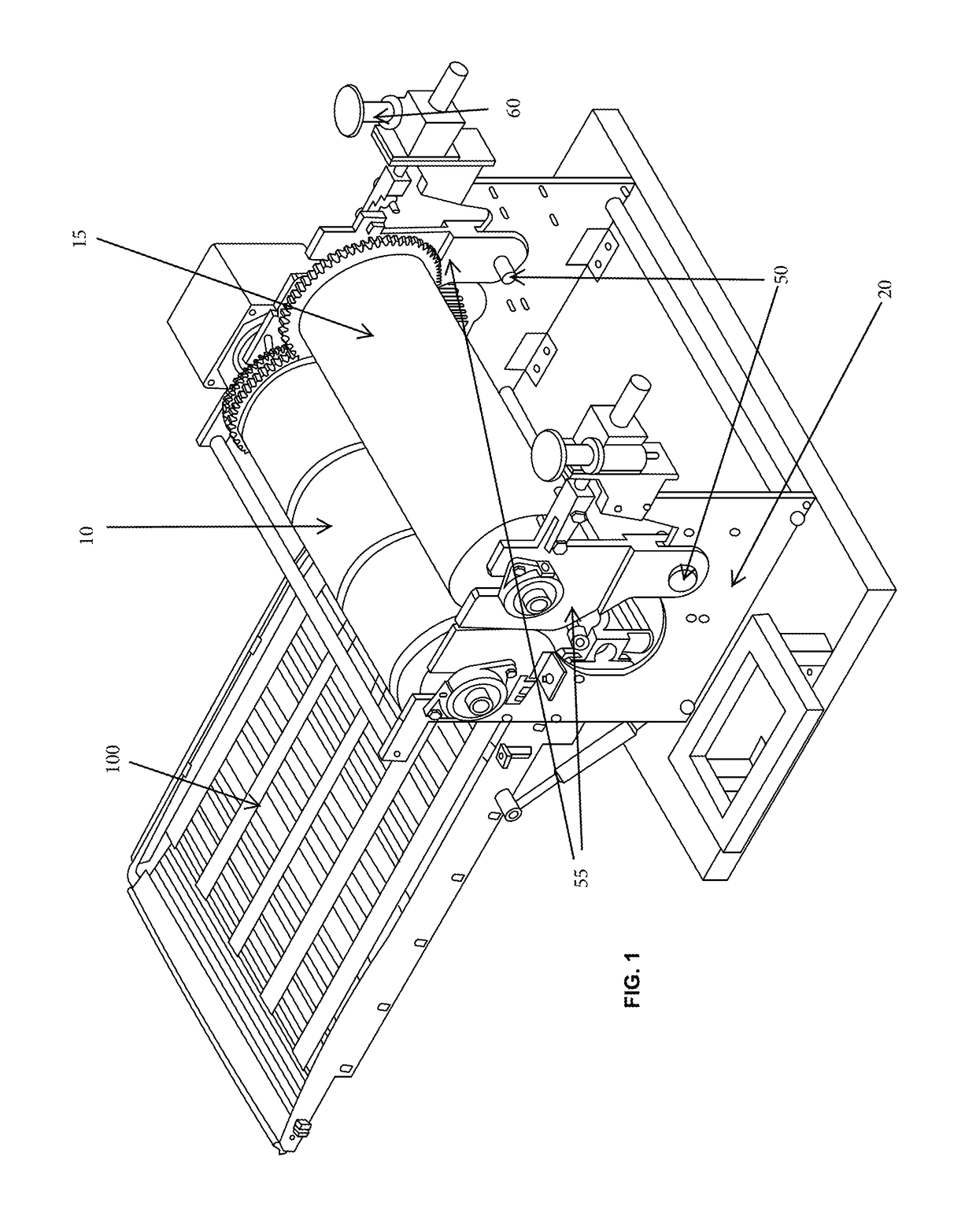

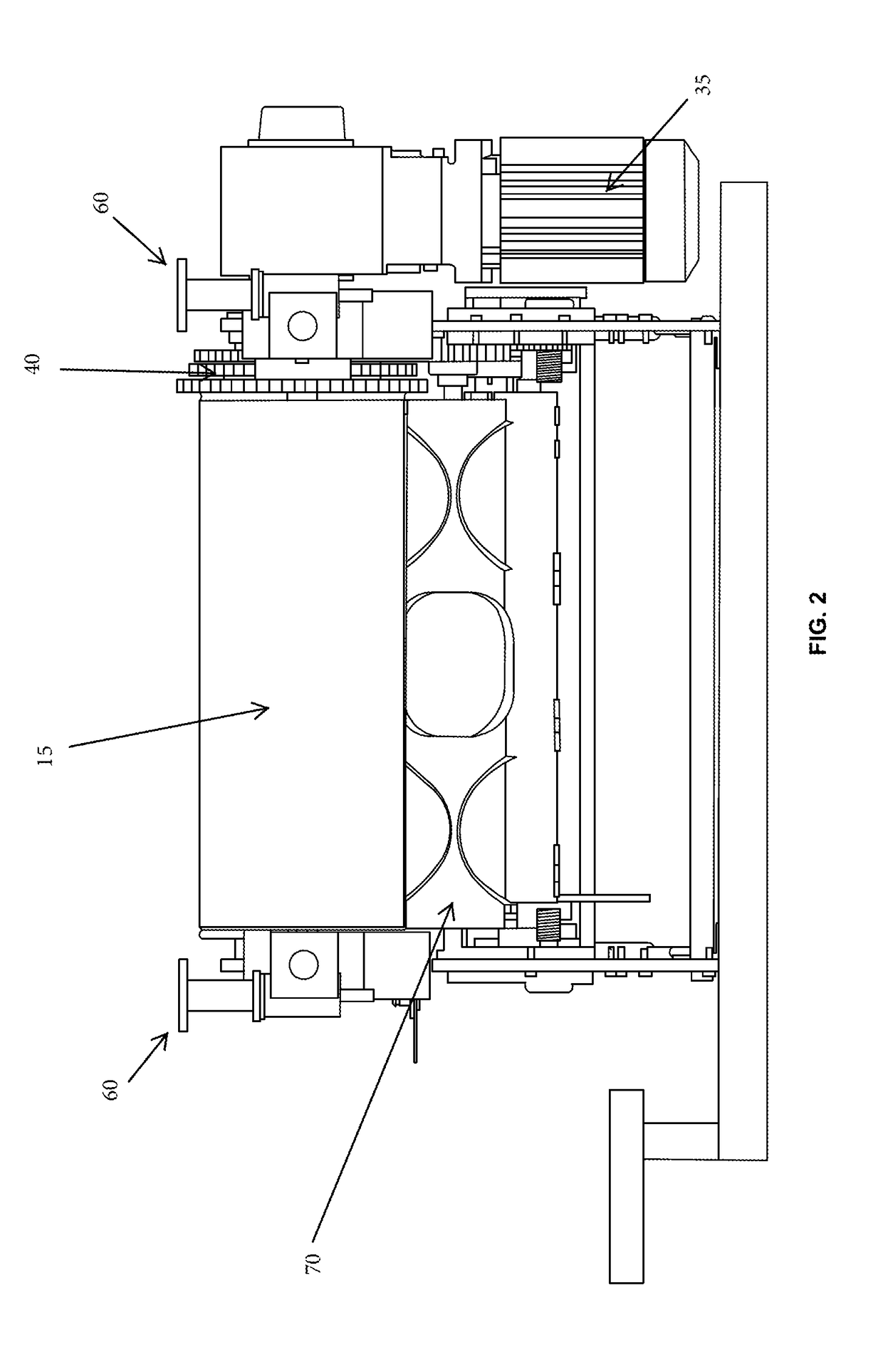

Comestible product sheeter and sheeter roller, and method of using the same

ActiveUS20180132489A1Efficient recyclingIncrease speedDough treatmentDough-sheeters/rolling-machines/rolling-pinsPulp and paper industrySheet material

To address the problems inherent in creating very thin sheets of dough in a sheeting machine at high speed and with efficient recycling and re-sheeting of the re-work cut out from the sheet, a new sheeting machine with a new front roller is provided, wherein the roller includes non-stick and non-release areas and a plurality of grooves in the non-release area.

Owner:GRUMA S A B DE CV

Walnut cookie roller-marking machine

InactiveCN109907086AEasy to demouldReduce viscosityMixing/kneading structural elementsPrevention of dough stickingWalnut NutMotor drive

The invention relates to a walnut cookie roller-marking machine and belongs to the technical field of walnut cookie manufacturing. The walnut cookie roll-marking machine comprises a frame, a feed bucket, a feed roller, a mold roller and a canvas conveyer belt; the outer peripheral wall of the mold roller is provided with a plurality of mold cavities; the frame is provided with a holding trough along the axis of the mold roller; the frame is provided with a dipping roller rotationally right above the holding trough; the outer peripheral wall of the dipping roller is provided with an applicatorbrush partially within the holding trough; the applicator brush is abutted to the walls of the mold cavities; the frame is provided with a motor driving the dipping roller to rotate. With the rotationof the dipping roller, the applicator brush applies edible oil or beaten egg in the holding trough to the die cavities; with the rotation of the feed roller and the mold roller, a raw material fallsbetween the feed roller and a mold and fills the mold cavities of the mold roller to form cookie bases; a layer of beaten egg or edible oil can be applied between the cookie bases and the mold cavities. The walnut cookie roller-marking machine allows the cookie bases to be released more easily and allows chances for sticking to be lessened.

Owner:西安大业食品有限公司

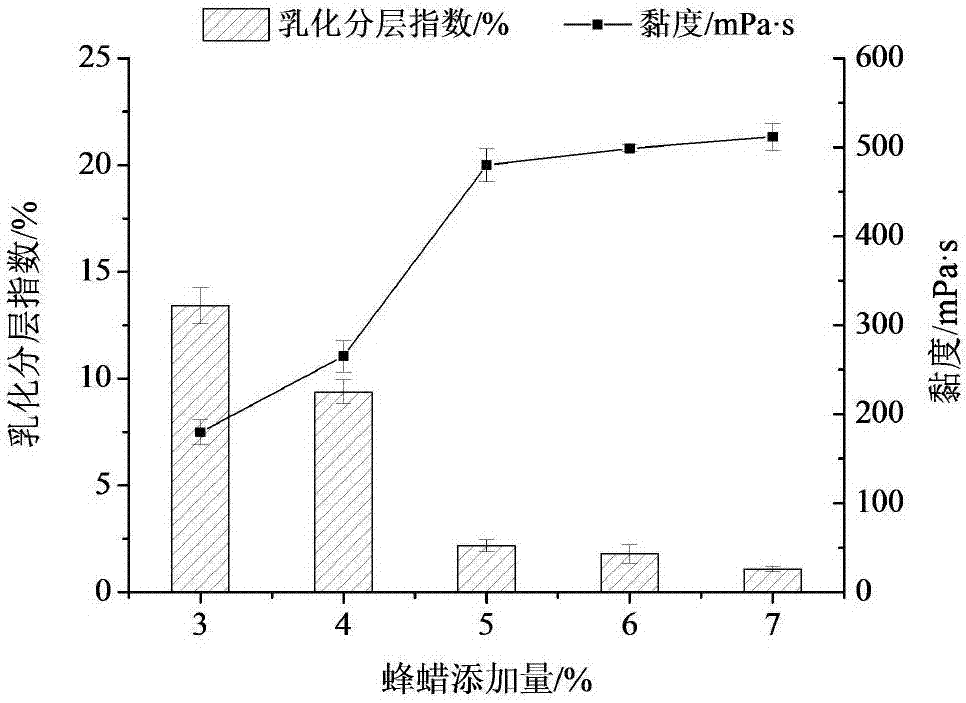

O/W type palm oil based special mold release agent for baking and preparation method thereof

InactiveCN107212044AImprove system stabilityMaintain system stabilityPrevention of dough stickingChemistryOil in water

The invention provides an O / W (oil in water, which is referred to as O / W) type palm oil based special mold release agent for baking and a preparation method thereof. The preparation method comprises the following steps of (1) stirring palm fluid oil and beeswax, performing heating until the beeswax completely dissolves, then adding soybean lecithin, polyglycerol esters of interesterified ricinoleic acid-glyceryl monoaliphatic ester, performing heating, and performing sufficient stirring so as to obtain an oil phase A of the mold release agent; (2) adding a composite stabilizer to purified water, performing heating, performing sufficient stirring, and performing uniform blending so as to obtain an aqueous phase B; (3) slowly pouring the aqueous phase B into the oil phase A under the high-speed shearing condition at 65-95 DEG C, performing emulsification for the emulsification time being 0.5-2.5min, and then performing ice bath cooling to room temperature; and (4) adding potassium sorbate to products obtained in the step (3) so as to obtain the O / W type palm oil based special mold release agent. The mold release agent is convenient to apply, high in concentration, high in efficiency and nuisance-free, fills the blank of the research of the O / W type special mold release agent for baking in China, and meets the requirements of the market for the special mold release agent for baking, so that the application range of the palm oil in the food industry is extended.

Owner:大马棕榈油技术研发(上海)有限公司 +1

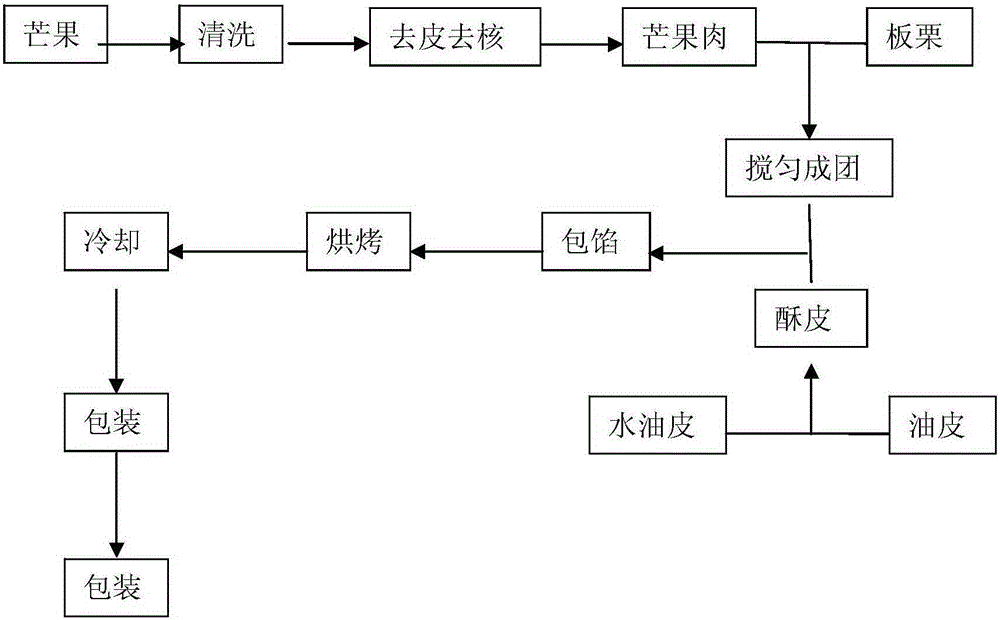

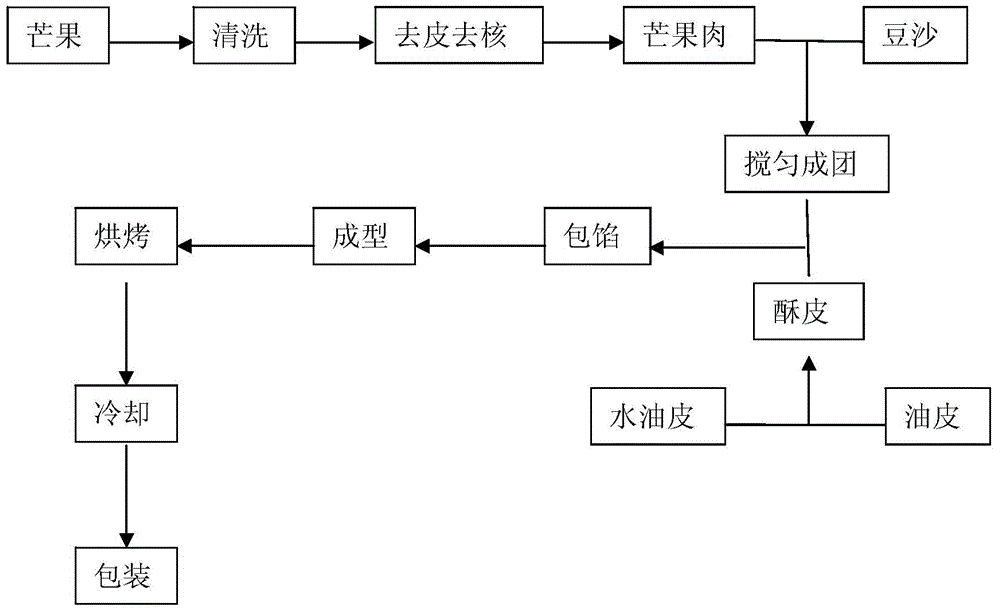

Making method of mango and chestnut pastry mooncake

InactiveCN105211155AUniform colorBeautiful surface patternPrevention of dough stickingBakery productsEngineeringNutrient

The invention provides a making method of a mango and chestnut pastry mooncake. The method includes the steps of firstly, making mooncake filling; secondly, making mooncake peel; thirdly, making the mooncake, wherein the mooncake filling is made from mango pulp and chestnut meat, and the mooncake peel is made from water-oil peel and oil peel. The mooncake is made through processes of filling wrapping, forming, baking, twice egg liquid brushing, cooling, packaging and the like. The making method has the advantages that a new member is added to the mooncake family, the variety of the mooncake is enriched, the mooncake can be used for being eaten as food rich in nutrient in ordinary times beside being tasted in the Mid-Autumn Festival during moon enjoying, cholesterol can be reduced, cardiovascular diseases, hypertension, atherosclerosis, breast cancer and other diseases are prevented and treated, and the mooncake has multiple pastry layers, is delicious, fragrant and sweet in taste, is just melt in the mouth like snowflakes, and is delicious food necessary in the Mid-Autumn Festival.

Owner:BAISE UNIV

Release oil for food industry

InactiveCN107343514AAppropriate application statusImprove stabilityPrevention of dough stickingTemperature resistanceRice Bran Extract

The invention relates to release oil for the food industry and particularly to oil composition for release. The oil composition is prepared, in percentage by weight, 40%-100% of base oil, 0-7% of an emulsifier, 0-1,000 ppm of an antioxidant and 0-60% of water, wherein the base oil contains rice bran oil accounting for 50%-100% of the total weight of the base oil under the condition that the oil composition is not prepared from 100% rice bran oil (in terms of the total mass of the oil composition). The invention further relates to a preparation method of the oil composition as well as an application of the rice bran oil in preparation of the oil composition for release or in improving the release effect of baked products or in improving the wall mounting performance of the oil composition for release. The oil composition has proper viscosity, application performance, wall mounting performance, stable quality, high-temperature resistance and excellent release effect when used as release oil.

Owner:GOLDEN SEA SPECILTY FATS

Preparation of an edible product from dough

The present invention is directed to mold control and extended shelf life methods and compositions for preparing edible dough-based products, such as, for example, breads, by treating the surface of the dough used to prepare the edible product with at least one preservative and at least one pH adjusting agent prior to or during baking. The present invention is also directed to methods and compositions for preparing edible dough-based products, such as, for example, breads, by treating the surface of the dough used to prepare the edible product with a at least one pH adjusting agent prior to or during baking. The present invention is further directed to improved pan oil compositions for preparing edible dough based products which comprise at least one preservative in an amount effective to inhibit mold growth on the surface of the bread prepared from the dough and at least one pH adjusting agent in an amount effective to improve the activity of the at least one preservative and / or inhibit microbial growth on the surface of the bread prepared from the dough.

Owner:INNOVATIVE CEREAL SYST +3

Low-residue, easy-cleaning and low-viscosity structured lipid pan release compositions and methods

InactiveUS7247334B2Low viscosityHigh smoke pointFatty acid esterificationFatty-oils/fats refiningSmoke pointMedium chain triglycerides oil

Medium chain triglyceride oils are interesterified with long chain edible oils in order to form interesterified structured lipids. These structured lipids find special application in food service pan release cooking compositions and methods. The products have a relatively low viscosity of between about 20 and about 52 centipoise while having a smoke point which is especially suitable for cooking applications. They provide enhanced release properties, reduced darkening effects, less residue build-up, and enhanced cleaning of griddling, cooking and baking pans, containers and utensils.

Owner:BUNGE OILS INC

Demoulding oil for bread

The invention discloses demoulding oil for bread. A preparation method for the demoulding oil comprises the steps as follows: (1) mixing soybean salad oil, polyglycerol polyricinoleate, hydrogenated oil fat and sucrose fatty acid ester, and uniformly stirring to prepare an oil phase; (2) driving the oil phase prepared in the step (1) into an emulsifying tank, starting a stirring and circulating pump, and adjusting the pressure of a circulating pipeline of the emulsifying tank to be 7-9 bar; and while starting the stirring and circulating pump, adding drinking water into the emulsifying tank, and controlling the flow of the added water to be 15-20 L / min; (3) after adding the drinking water, keeping the pressure of the circulating pipeline to be 7-9 bar, and circularly mixing for 15-20 min;and (5) filling under the condition of keeping the stirring state of the emulsifying tank and the circulating state of the pump, wherein the raw materials by mass percent used in the preparation method comprise 32-37% of soybean salad oil, 1-4% of polyglycerol polyricinoleate, 1-6% of hydrogenated oil fat, 0.1-1% of sucrose fatty acid ester and 58-60% of drinking water. The demoulding rate of thedemoulding oil can reach 100%, and the demoulding oil is suitable for demoulding of bread, in particular for the bread with sugar content of less than 15%.

Owner:ZEELANDIA BAKERY INGREDIENTS WUXI CO LTD

Efficient production method of freeze-dried vegetable noodles

ActiveCN110583996AEasy to brewSmooth tasteFood preservationPreservation by coolingFreeze-dryingDrying time

The invention discloses an efficient production method of freeze-dried vegetable noodles, and belongs to the field of food processing. The method comprises: taking high-gluten wheat flour and vegetable flour as main raw materials, adding modified starch, edible salt, emulsifier, edible colloid, water-retaining agent, edible oil, flavor enhancer, coloring agent, maltodextrin, gluten flour, etc., and performing proofing, dough-pressing, cooking, high-temperature steam gelatinization, water-rinsing, ultrasonic treatment and infrared freeze drying to obtain instant freeze-dried vegetable noodles.The freeze-dried noodles produced by the method have a moisture content between 5% and 8%; a drying time shortened by more than 10 hours compared with ordinary freeze-drying; a high quality rate of more than 90%; easy brewing; smooth, tough and chewy mouthfeel; strong fragrance, pale yellow color, long shelf life, and low production power consumption. The method is an efficient production method of high-quality freeze-dried vegetable noodles with high product yield, long product shelf life, simple process flow, and low energy consumption, and is suitable for industrial production.

Owner:JIANGNAN UNIV

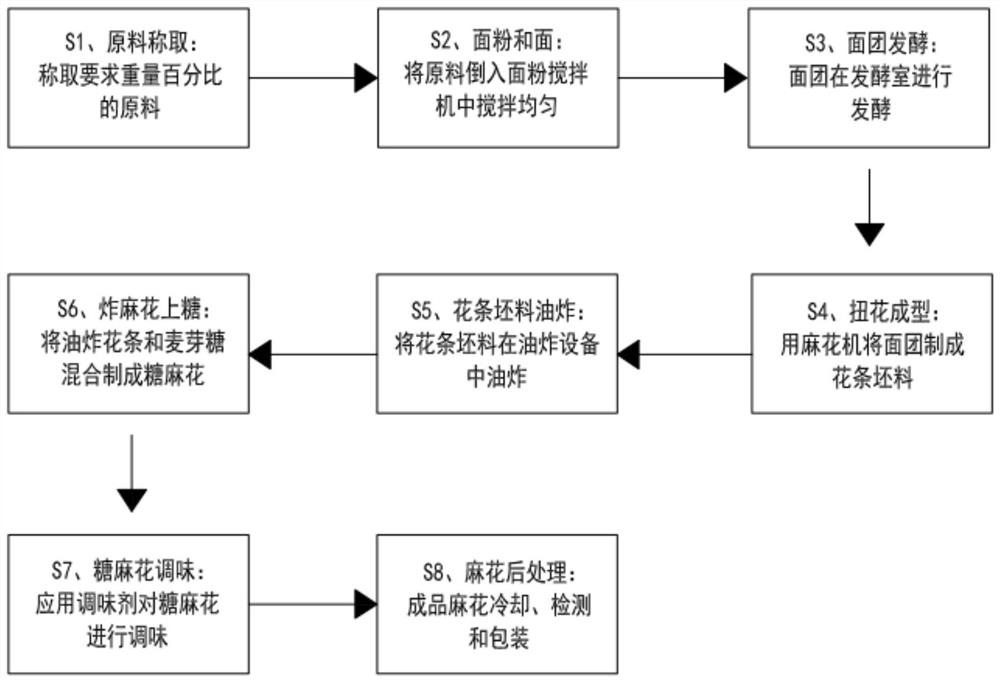

Black tartary buckwheat fried dough twist and preparation method thereof

PendingCN111771938ANutritious and healthierPromote peristalsisDough treatmentPre-baking dough treatmentBiotechnologyPolygonum fagopyrum

The invention discloses a black tartary buckwheat fried dough twist and a preparation method thereof. The black tartary buckwheat fried dough twist is prepared by taking black tartary buckwheat flour,corn flour and wheat flour as main raw materials, adding one or more of corn starch, vital gluten, a leavening agent, a seasoning, syrup and whole egg liquid in a certain proportion as a modified auxiliary material, and performing a specific forming and frying preparation method. The black tartary buckwheat fried dough twist prepared by the preparation method is crisp in mouthfeel, is crispy butnot greasy, has the faint scent of buckwheat, is rich and diversified in nutrition, and has a certain health-care function; the corn starch is added into the fried dough twist, and sugar and the auxiliary material are added for seasoning after frying, so that the fried dough twist is golden and bright in appearance, and the taste can be customized.

Owner:贵州问候自然荞麦健康食品有限公司

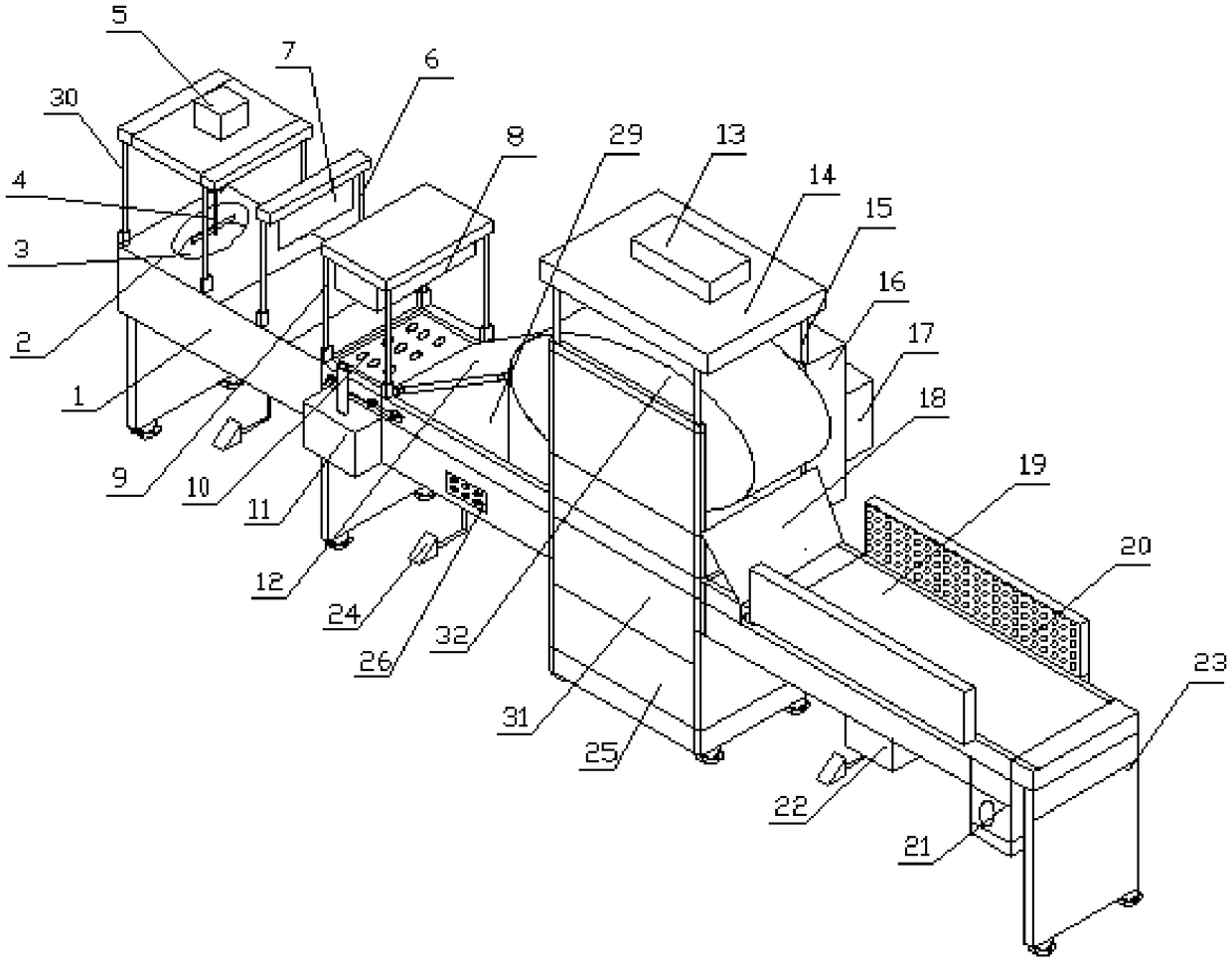

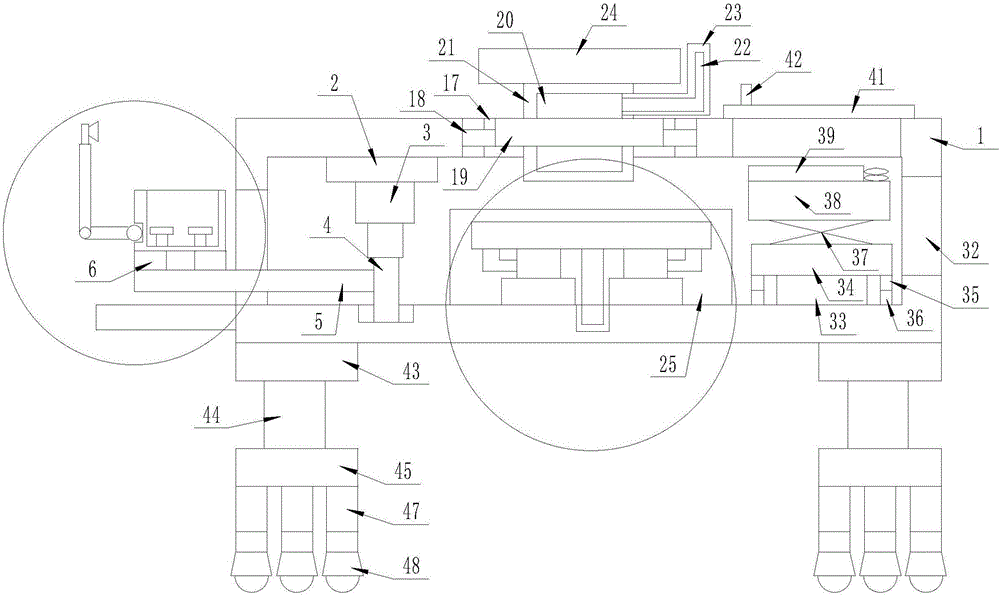

Full-automatic production line of moon cakes

InactiveCN107668112AAvoid stickingReduce workloadPrevention of dough stickingDough embossing machinesProduction lineMolding machine

The invention discloses a fully automatic production line for moon cakes, which comprises a filling forming machine, a moon cake molding machine, a plate arrangement device, and a baking device. The filling forming machine and the moon cake pressing machine are respectively provided with a conveyor belt and an intermediate conveyor belt. Two conveyor belts The moon cake molding machine on both sides of the middle conveyor belt is equipped with a dough shaping conveyor belt and a dough shaping plate that are used in conjunction with each other. There is a manual placement area for moon cake trays on the rack, a rack for placing oil paper on the side of the transmission rack, a walking rack above the placement rack and the transfer rack, and an oil paper placement rack for automatically placing oil paper into the moon cake tray on the walking rack device, the transmission frame is in contact with the transmission roller on the baking device, and an automatic oiling device is installed on the baking device. The invention has simple structure and reasonable design, can improve work efficiency, reduce work burden of workers and improve the quality of moon cakes.

Owner:陈荷芬

Food release agent and preparation method thereof

InactiveCN104719363AImprove stabilityGood release effectPrevention of dough stickingSOYBEAN SEED OILSoybean oil

The invention relates to a food release agent. The food release agent is composed of, by mass, 90% to 97% of first-grade soybean oil, 1% to 5% of phosphatide, 1% to 5% of carnauba wax and 0 to 8% of polyglycerol fatty acid ester. The invention further provides a preparation method of the food release agent. The food release agent is good in stability and release performance and the preparation method is simply and easy to operate.

Owner:GUANGZHOU TIANHUI FOOD

Release agent for food

InactiveCN104472614ANo harmExcellent mold releasePrevention of dough stickingMedicineSurface-active agents

The invention discloses a release agent for food. The release agent for the food comprises, by weight, 40-60 parts of edible peanut oil, 20-40 parts of soybean phosphatide oil, 5-10 parts of thickening agents, 3-5 parts of surface active agents, 1-5 parts of lecithin and 0.1-0.8 part of essence. The release agent for the food has an excellent mold release effect, cannot have any influence on the food, is healthy and safe, cannot generate oil smoke in the process of food processing, and cannot cause damage to the environment and human bodies, a preparation method is simple, and the production cost is low.

Owner:昆山瑞昱化工有限公司

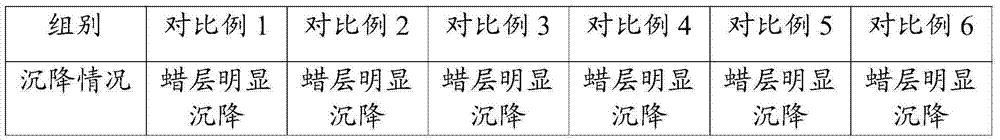

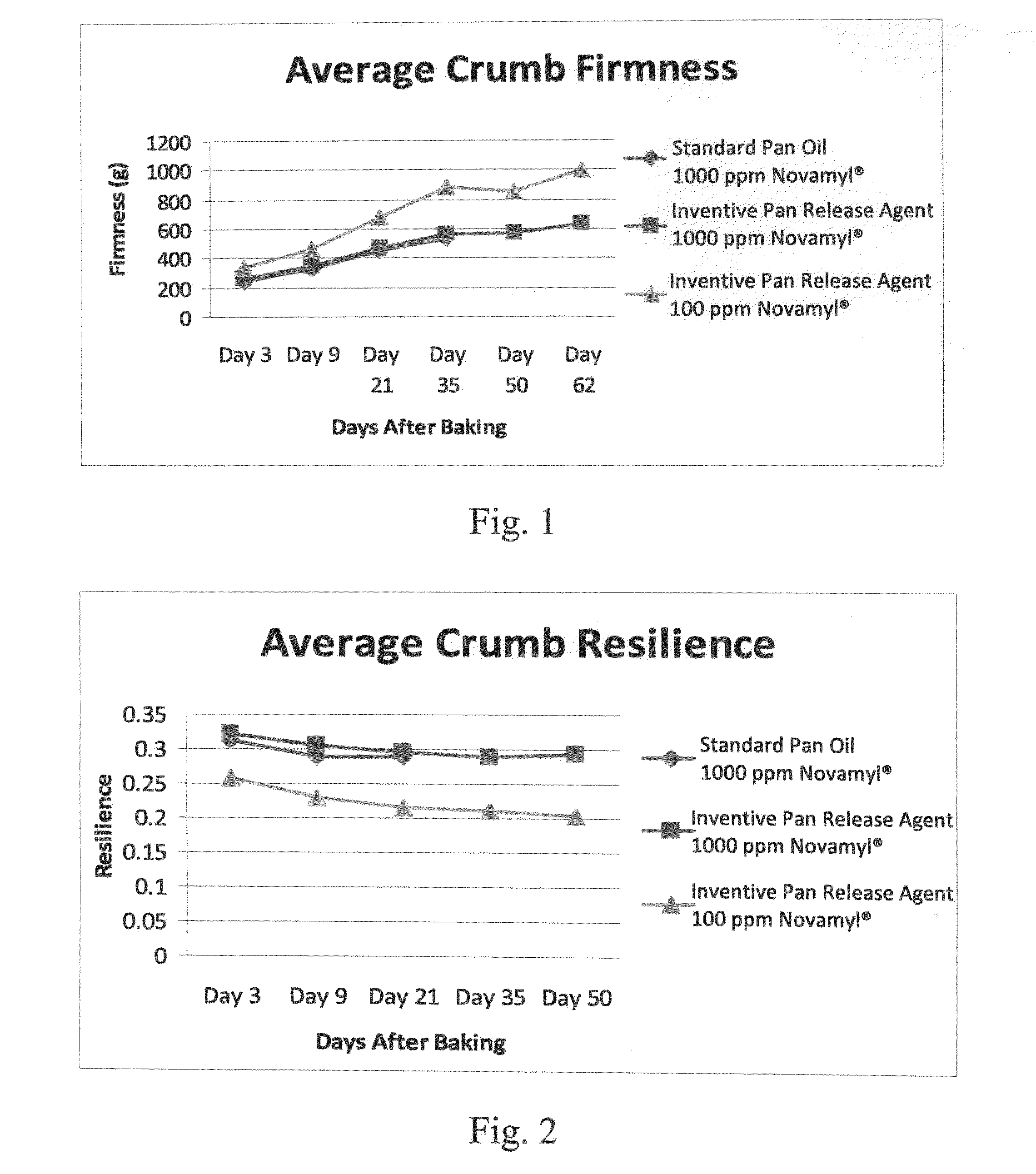

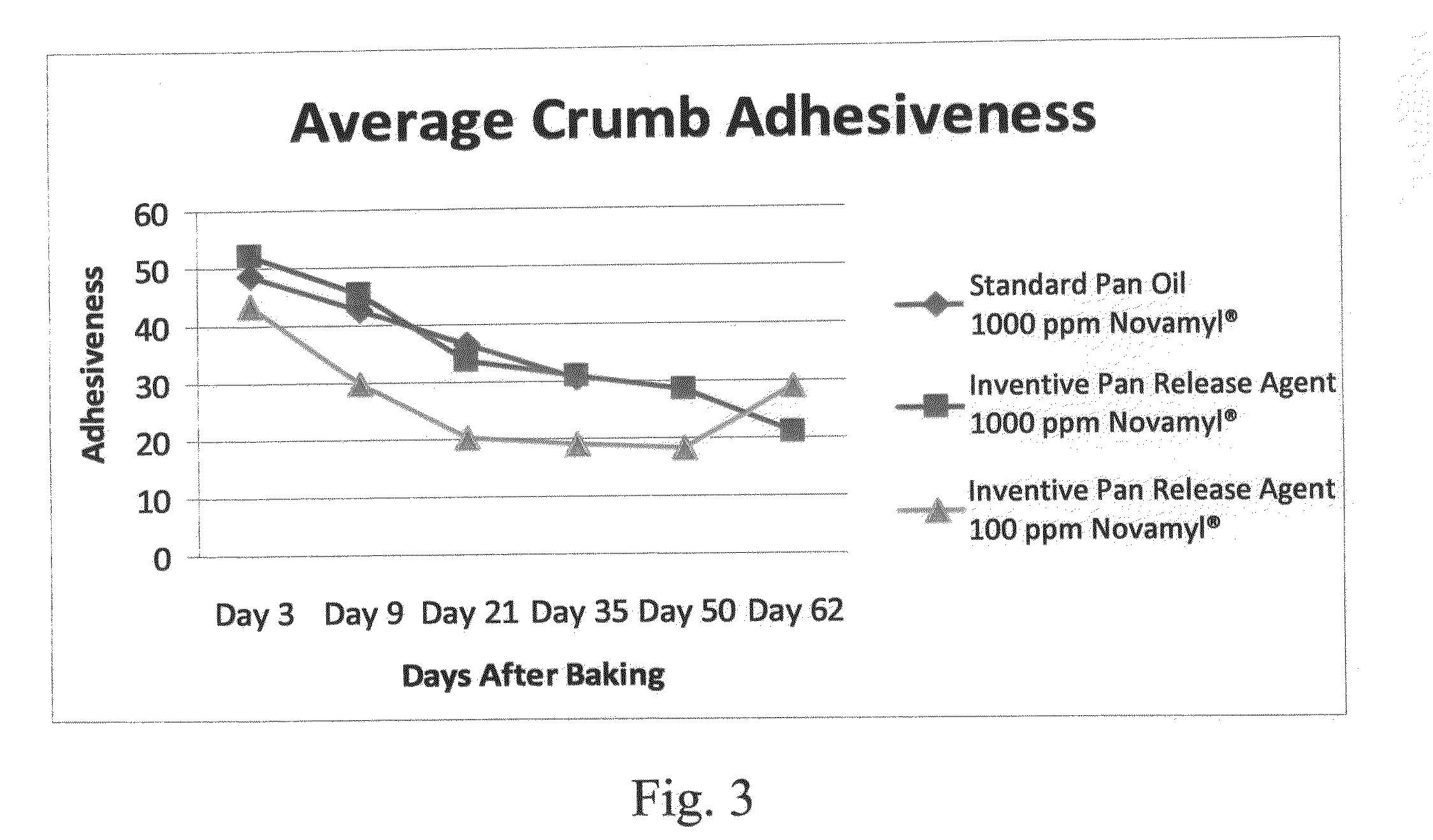

Pan release compositions for preparation of long shelf life, bakery products

InactiveUS20110300265A1Extended shelf lifeLong mold-free shelf lifeDough treatmentConfectioneryBaked goodsChemical preservatives

The present invention is directed to methods and compositions for making dough- and batter-based bakery foods, such as bread and cake having extremely long, mold-free and freshness shelf lives, by using a novel antimicrobial pan release agent comprising an essential oil dispersed or dissolved in a fat- or oil-based carrier, along with other natural or chemical antimicrobial agents, anti-staling enzymes, and / or flavor enhancement systems. The invention is also directed to the methods and compositions for preparing all-natural dough- and batter-based bakery products, such as bread and cake having long mold-free shelf lives, by treating the surface of the dough, batter, or baked product with the antimicrobial pan release agent, in conjunction with anti-staling enzymes and natural preservatives in the dough or batter formulations. Further, the invention is concerned with all-natural bakery products having extremely long, mold-free shelf lives which are substantially free (both internally and on the exterior surface) of chemical preservatives and antimicrobial agents other than the all-natural antimicrobial pan release agent and optional natural antimicrobial agents inside the dough.

Owner:CARAVAN INGREDIENTS

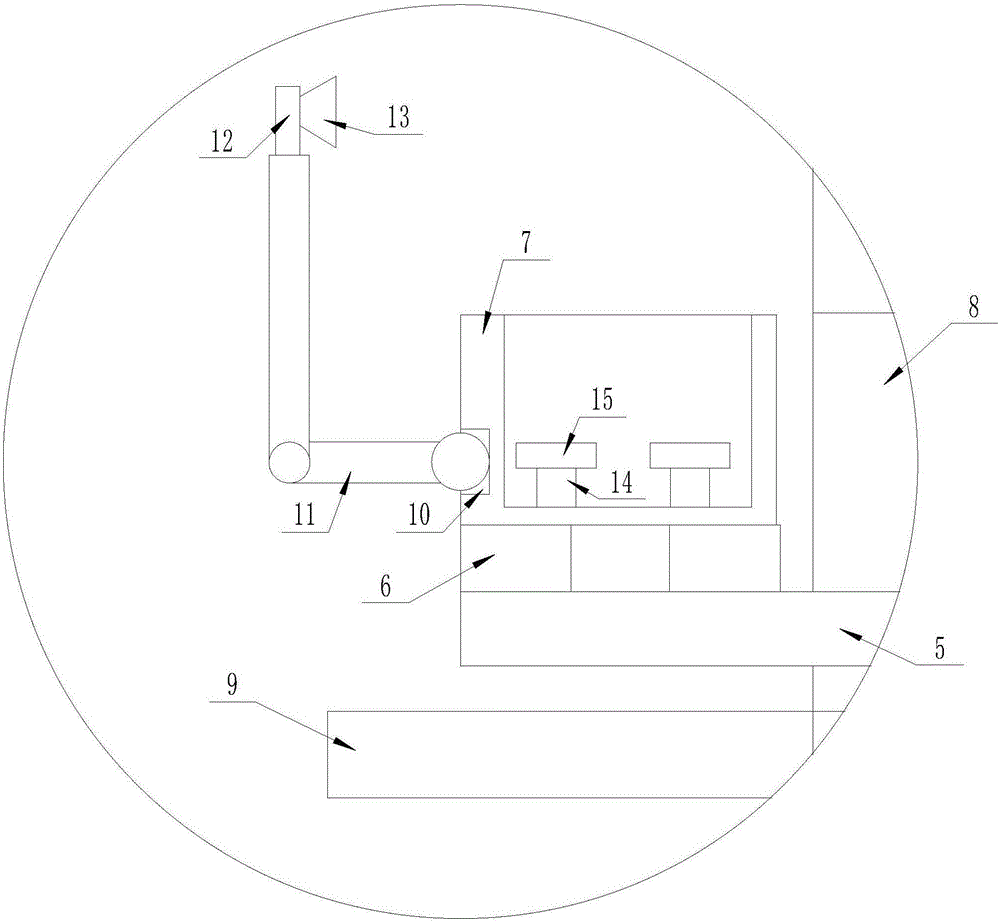

Sesame seed cake baking machine capable of automatically loading and unloading materials

InactiveCN108739904ARapid coolingReduce dosageBaking ovenPrevention of dough stickingCooking & bakingFuel tank

The present invention discloses a sesame seed cake baking machine capable of automatically loading and unloading materials. The sesame seed cake baking machine comprises a sesame seed cake baking machine main body, a worktable, a dough kneading bucket, a stirring rod, a stirring motor, dough cutting electric telescopic rods, a cutter, a mold, mold electric telescopic rods, a mold conveyor belt, anoil tank, a material feeding conveyor belt, a first heating box, a heat dissipation plate, heat dissipation plate electric telescopic rods, a gear box, a motor, a sesame seed cake shovel plate, a material discharging conveyor belt, two baffle plates, a material discharging conveyor belt motor box, a fan box, a support plate, a foot switch, an electrical box, a power control board, an oil tank spraying nozzle and a suction pump. The sesame seed cake baking machine can automatically knead dough, automatically cut dough and automatically press dough cake raw materials; besides, oil-spraying canalso be used to solve an adhesion problem of the dough cake, and saves amount of edible oil; the machine can also conduct the automatic material loading and automatic material unloading, heat the surface of the dough cake, improve efficiency of baking and also quickly cool the temperature of the baked dough cake, is convenient for people to take the sesame seed cake, brings convenience for people,and is simple in structures and convenient for promotion.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

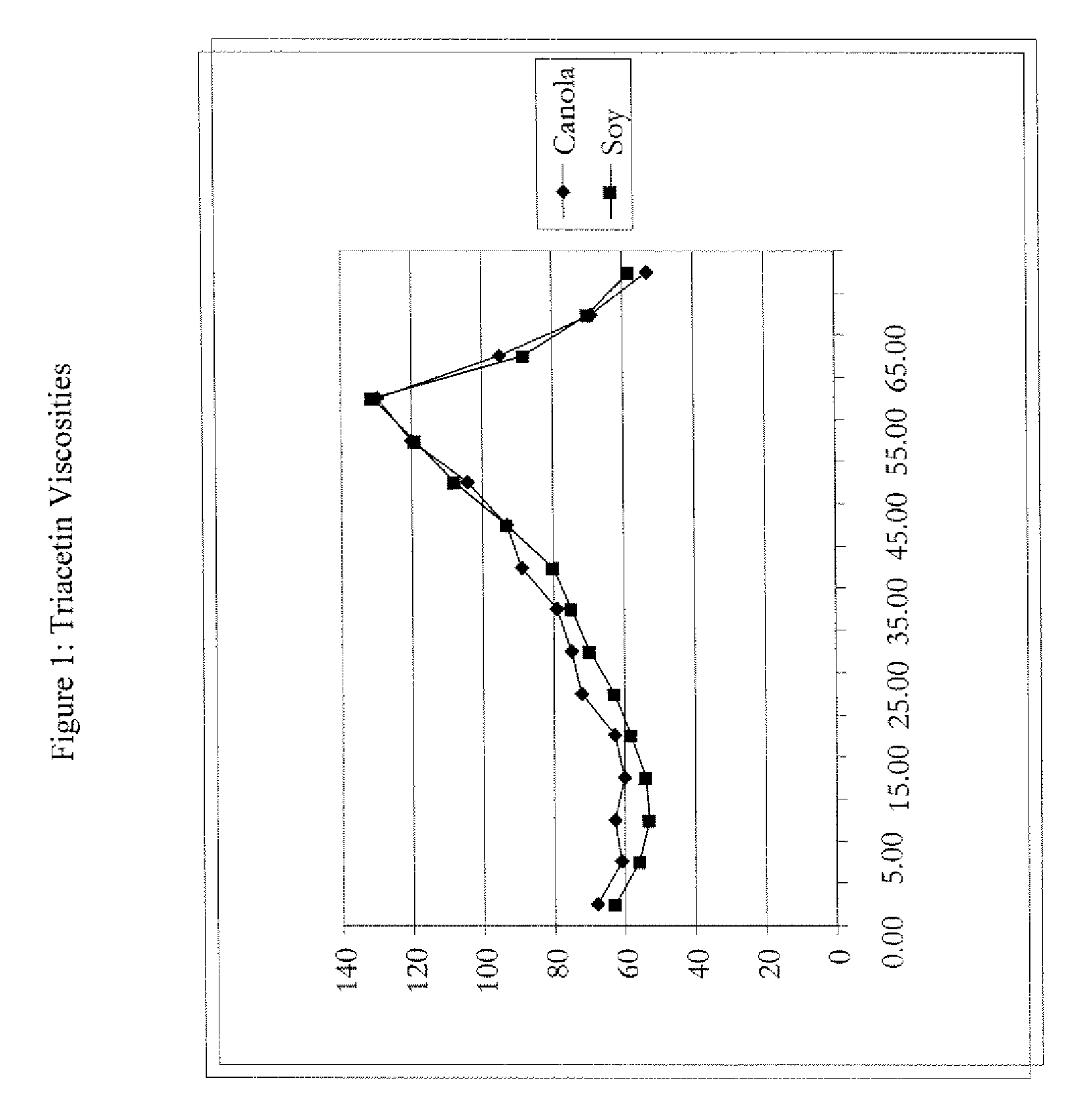

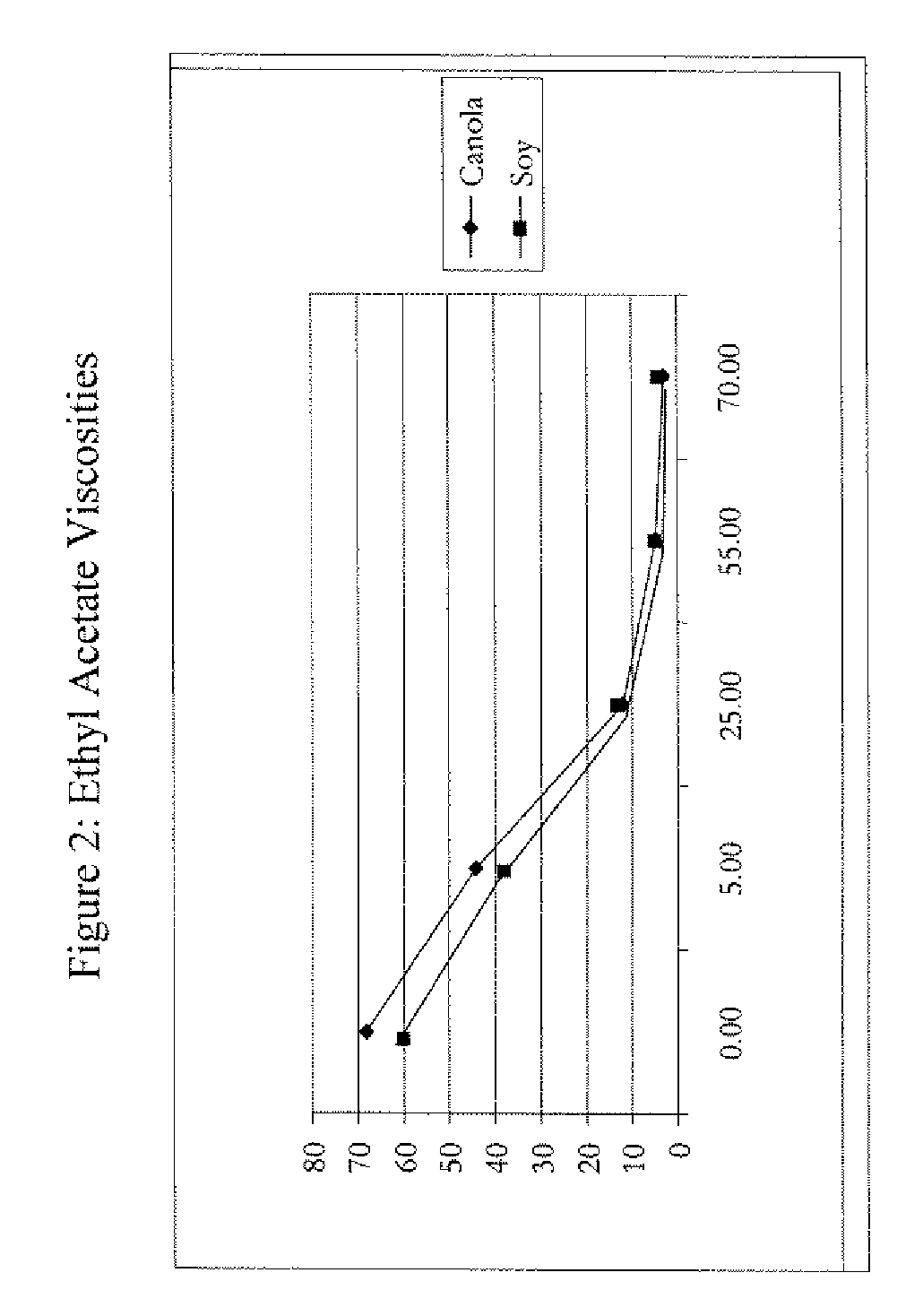

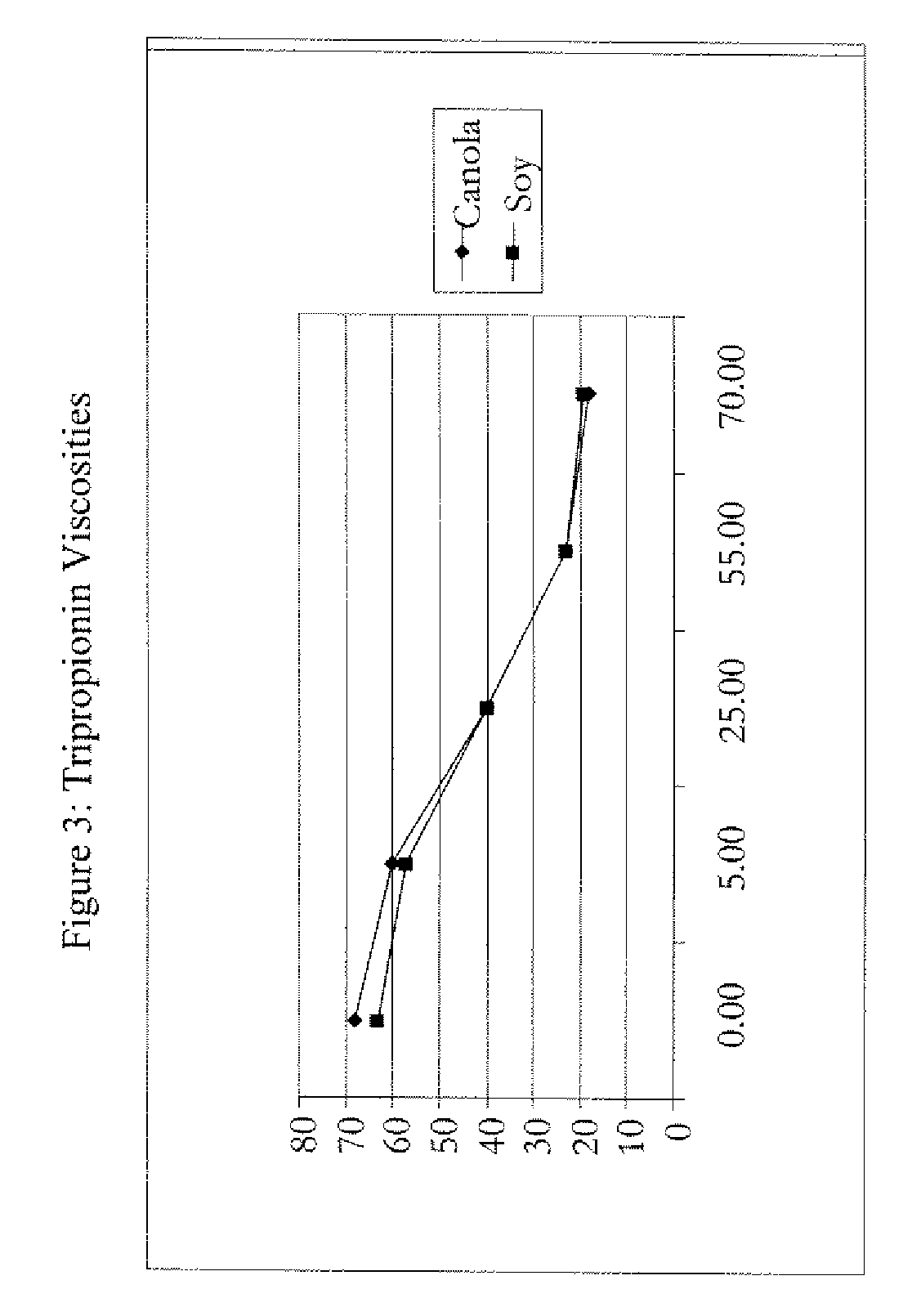

Controlled viscosity oil composition and method of making

InactiveUS8158185B2Desired viscosityLow viscosityGroup 5/15 element organic compoundsPrevention of dough stickingAcetic acidAlcohol

The present invention relates to a sprayable oil composition comprising a blend of an oil, an edible solvent selected from the group consisting of triacetin, tripropionin, tributyrin, and ethyl acetate; and a preferably an emulsifier such as a lecithin. Advantageously, the viscosity of the blend can be controlled without interesterification of the solvent with the oil. Furthermore, such oil compositions can be effective sprayable oils such as for pan release applications while being substantially free of alcohols.

Owner:BUNGE OILS INC

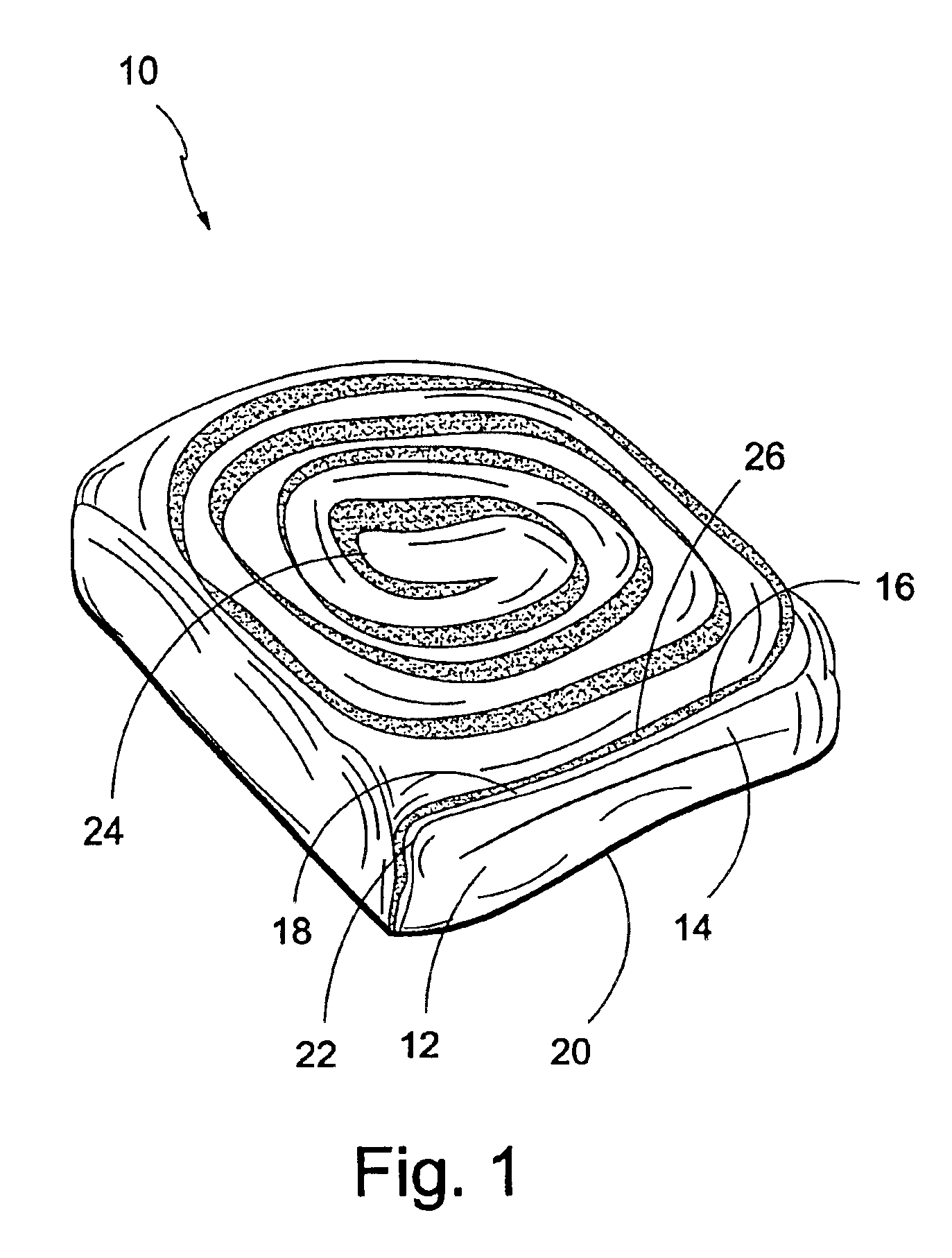

Rolled sheet of cookie dough

ActiveUS20060263504A1Easy to optimizeEase and convenienceBaking mixturesPrevention of dough stickingBiomedical engineering

Methods and formulations for forming a rolled cookie dough configuration for shipment, display and storage. The rolled configuration can be frozen and / or refrigerated and be subsequently unrolled prior to use. The cookie dough can be formulated so as to unroll into a flat sheet configuration without cracking, breaking and / or sticking together. When unrolled, the flat sheet configuration can be sliced / cut with cookie cutters to create specially shaped cookie units for baking. Excess dough can be trimmed and rerolled for further cutting with a cookie cutter.

Owner:GENERAL MILLS INC

Barbecue carrying device with auto-changing paper function

ActiveCN106614845AReduce labor intensityEconomically beneficialPrevention of dough stickingBaking-tinsEngineeringPaper sheet

Owner:山东上禾中创科技成果转化有限公司

Making method of mango and sweetened bean paste pastry mooncake

InactiveCN105211218AUniform colorBeautiful surface patternPrevention of dough stickingBakery productsNutrientCooking & baking

Owner:BAISE UNIV

Ready-to-eat farinaceous product and a method for the preparation thereof

InactiveUS20150250191A1Low in fatMinimize resultMilk preparationDough treatmentReady to eatReduced fat

The invention provides a method of preparing a ready-to-eat farinaceous food product, said method comprising the successive steps of:a) preparing a farinaceous dough by mixing flour, water and optionally one or more other bakery ingredients;b) dividing the dough into one or more dough portions;c) shaping the one or more dough portions into one or more shaped dough pieces;d) proving the dough pieces;e) contacting 30-60% of the total surface area of the one or more shaped dough pieces with hot oil during a period of at least 10 seconds to produce one or more partially fried dough pieces comprising a fried surface area and a non-fried surface area; andf) baking said one or more partially fried dough pieces to produce one or more baked dough pieces;wherein a layer of edible material is applied to 40-70% of the surface area of the shaped dough pieces, the partially fried dough pieces or the baked dough pieces and wherein the surface area of the final ready-to-eat product that is not covered by the layer of edible material is fried surface area.This method achieves a significant reduction in fat uptake during preparation of the ready-to-eat farinaceous product without introducing a perceptible adverse effect on product quality.Another aspect of the invention relates to ready-to-eat food product comprising a body of baked farinaceous dough, 40-70% of the surface area of said body of baked dough being coated with a layer of edible material, wherein the surface of the baked dough body that is not coated with the layer of edible material is fried surface area and wherein at least 70 wt. % of the surface of the baked dough body that is covered with the layer of edible material is non-fried.

Owner:CSM NEDERLAND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com