Food release agent and preparation method thereof

A release agent, food technology, applied in the direction of dough anti-sticking, etc., can solve the problems of unsatisfactory stability and release effect, bad smell, bottom coking, etc., to achieve good smell and safety, good stability and release Modular effect, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

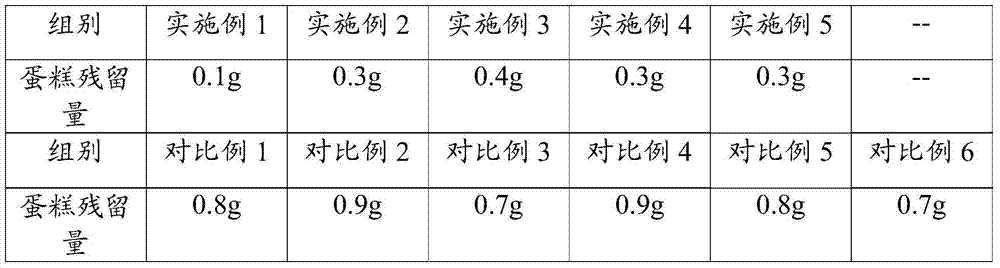

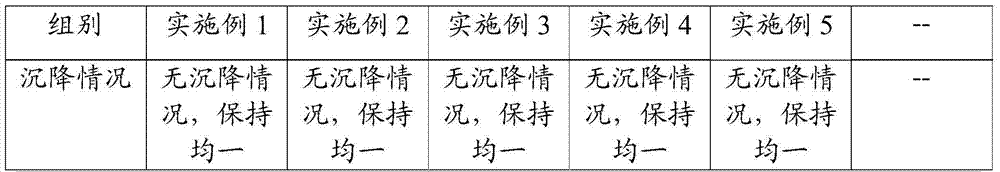

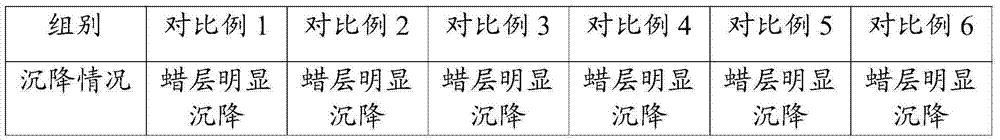

Examples

Embodiment 1

[0021] A food release agent, which is made of the following components in terms of mass percentage: 93% of first grade soybean oil, 2% of soybean lecithin, 3% of carnauba wax and 2% of polyglyceryl myristate.

[0022] This food release agent is made through the following steps:

[0023] a. Mix the first-grade soybean oil, soybean lecithin, carnauba wax and polyglyceryl myristate in a formula quantity, and then heat at 95° C. for 18 minutes to obtain a reaction material;

[0024] b. Cool the reaction material obtained in step a to 32°C, and pass through a 60-mesh sieve to obtain the product.

Embodiment 2

[0026] A food release agent is prepared from the following components in terms of mass percentage: 90% of first grade soybean oil, 1% of cephalin, 1% of carnauba wax and 8% of polyglycerol stearate.

[0027] This food release agent is made through the following steps:

[0028] a. Mix the first-grade soybean oil, cephalin, carnauba wax and polyglyceryl stearate in a formula quantity, and then heat at 90° C. for 20 minutes to obtain a reaction material;

[0029] b. Cool the reaction material obtained in step a to 35°C, and then pass through a 65-mesh sieve to obtain the product.

Embodiment 3

[0031] A food release agent is prepared from the following components in terms of mass percentage: 97% of first grade soybean oil, 1% of soybean lecithin, 1% of carnauba wax and 1% of polyglyceryl palmitate.

[0032] This food release agent is made through the following steps:

[0033] a. Mix the first-grade soybean oil, soybean lecithin, carnauba wax and polyglycerol palmitate in a formula amount, and then heat at 93° C. for 15 minutes to obtain a reaction material;

[0034] b. Cool the reaction material obtained in step a to 30°C, and then pass through a 55-mesh sieve to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com