Black tartary buckwheat fried dough twist and preparation method thereof

A technology of black tartary buckwheat twists and twists, applied in the field of black tartary buckwheat twists and its preparation, can solve the problems of single taste, rough processing technology, and difficult fermentation, etc., achieve rich nutrition and healthier, facilitate digestion and absorption, and ensure a balanced diet Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

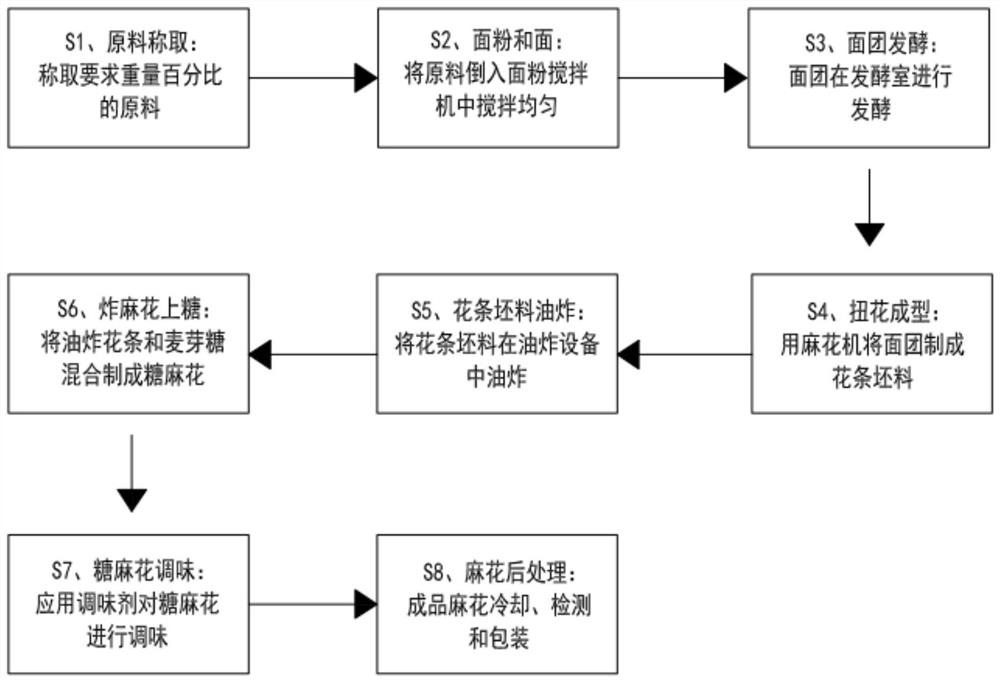

[0036] The preparation method of black tartary buckwheat fried dough twist of the present invention (preparation method one):

[0037] S1 Raw materials are weighed, and the raw materials of the following weight percentages are weighed: 5% to 20% of tartary buckwheat flour, 40% to 70% of wheat flour, 5% to 20% of corn flour, 8% to 20% of gluten powder, and 8% of whole egg liquid %~20%; the corn flour is a mixture of waxy corn flour, yellow corn flour and white corn flour, and the weight ratio of corn flour is 1:0.2~0.5:1;

[0038] S2 Flour kneading, pour the raw materials weighed in step S1 into the flour mixer, and add 0.05% to 0.2% of the total weight of the raw materials weighed in step S1. After mixing evenly, add whole egg liquid and water in the flour mixer Stir and knead the noodles in the middle to make a dough; the leavening agent is yeast powder; the mixing of the noodles means that the tartary buckwheat flour, wheat flour, corn flour and starter are mixed evenly for ...

Embodiment 1

[0058] Embodiment 1: according to preparation method one of the present invention

[0059] Step S1 raw material is weighed, and the raw material of following weight percentage is taken: tartary buckwheat flour 10kg, wheat flour 55kg, corn flour 12kg (wherein, waxy corn flour 5kg, yellow corn flour 2kg, white corn flour 5kg), gluten powder 15kg, whole Egg liquid 8kg;

[0060] Step S2 Flour and flour, pour the raw materials weighed in step S1 into a flour mixer, and add yeast powder with a total weight of 0.15% of the raw materials weighed in step S1, mix evenly, then add whole egg liquid and water and stir in a flour mixer Knead dough and make dough; dough fermentation time 2.5H; then twist flower forming, frying and sugaring steps;

[0061] Step S7 seasoning, adding pre-prepared seasoning to make seaweed flavor, the seasoning is seaweed, honey, monosodium glutamate, edible salt and amino acid hydrolyzed vegetable protein seasoning liquid;

[0062] The seaweed-flavored black ...

Embodiment 2

[0064] The difference with Example 1 is that the raw materials of step S1 are weighed, and the raw materials of the following weight percentages are weighed: 15kg of tartary buckwheat flour, 50kg of wheat flour, 15kg of corn flour (wherein, 6.5kg of waxy corn flour, 2kg of yellow corn flour, 2kg of white corn flour 6.5kg), gluten powder 10kg, whole egg liquid 10kg;

[0065] Step S2 Flour and flour, pour the raw materials weighed in step S1 into a flour mixer, and add 0.2% yeast powder of the total weight of raw materials weighed in step S1, mix evenly, then add whole egg liquid and water and stir in a flour mixer Knead the dough and make it into dough; the dough fermentation time is 1H; followed by the steps of twisting flower forming, frying and sugaring;

[0066] Step S7 seasoning, adding pre-prepared seasoning to make salt and pepper flavor, the seasoning is monosodium glutamate, edible salt and amino acid hydrolyzed vegetable protein seasoning liquid;

[0067] The salt-an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com