Sesame seed cake making equipment

An equipment and technology for sesame cakes, applied in the field of sesame cake making equipment, can solve the problems of low work efficiency, unfavorable intelligent development, unfavorable integrated automatic production, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

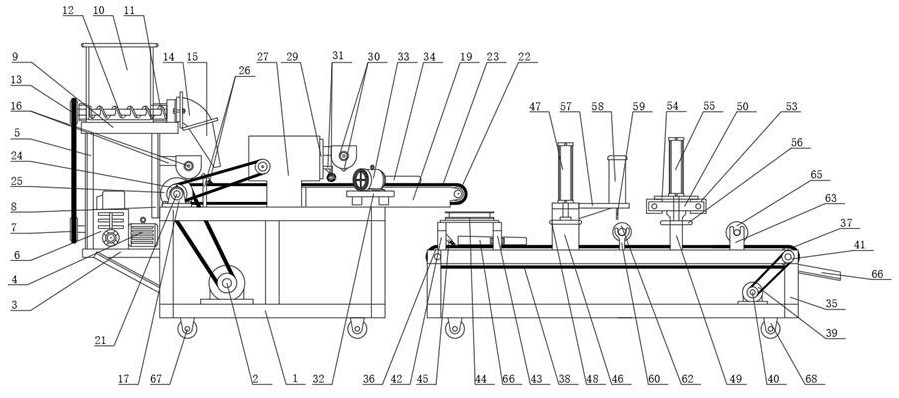

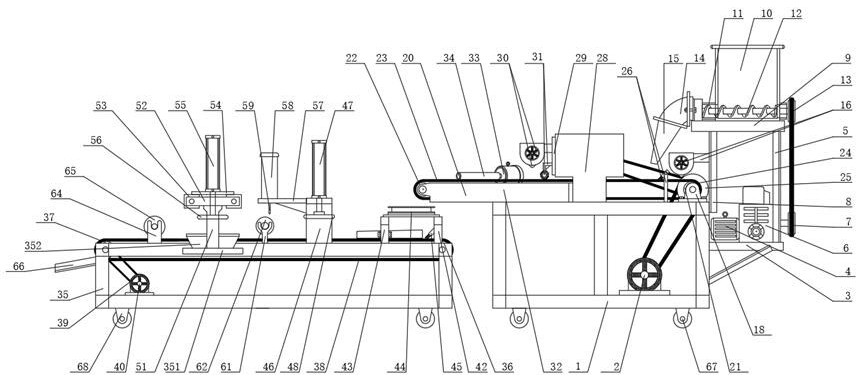

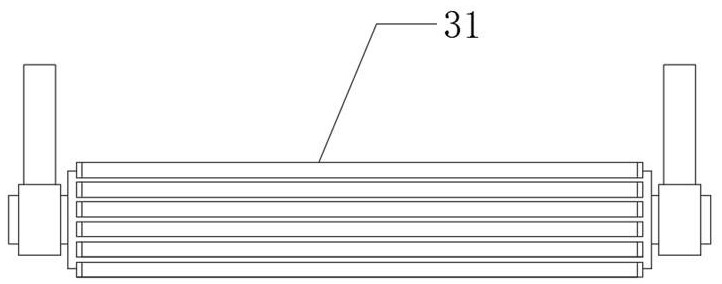

[0040] Such as figure 1 and figure 2 shown;

[0041] A kind of biscuit making equipment, comprising a discharge mechanism, a first conveying and rolling mechanism and a second conveying and rolling mechanism;

[0042] The discharging mechanism is located above the conveying direction of the first conveying and rolling mechanism, and the second conveying and rolling mechanism is located above the conveying direction of the first conveying and rolling mechanism.

[0043] In this embodiment: the sesame seed cake making equipment is composed of a discharge mechanism, a first conveying and rolling mechanism and a second conveying and rolling mechanism. The existing sesame cake making equipment is generally semi-automatic or manual, resulting in low work efficiency, which is not conducive to Integrated automatic production is not conducive to the development of intelligence. In response to this problem, the following structure is added to this plan.

[0044] The discharge mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com