Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about "Engine flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

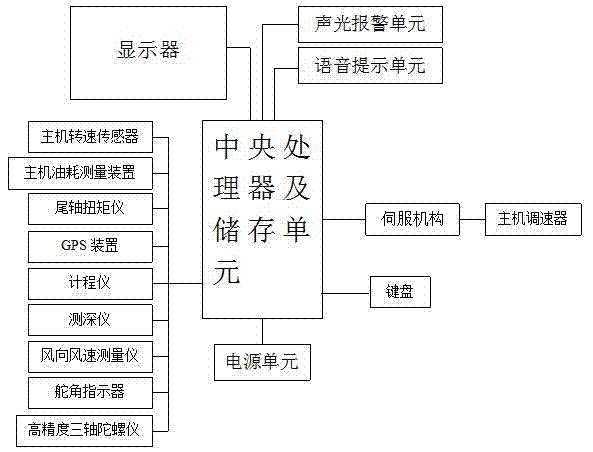

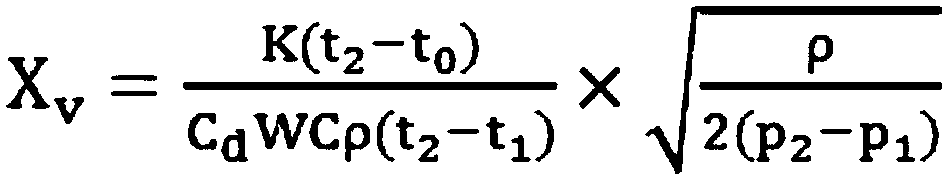

System optimization method and device of ship operation energy efficiency

ActiveCN102768524AStrong targetingVersatileElectrical controlWatercraft hull designMathematical modelData acquisition

Owner:CHANGSHA LVHANG ENERGY SAVING SCI & TECH

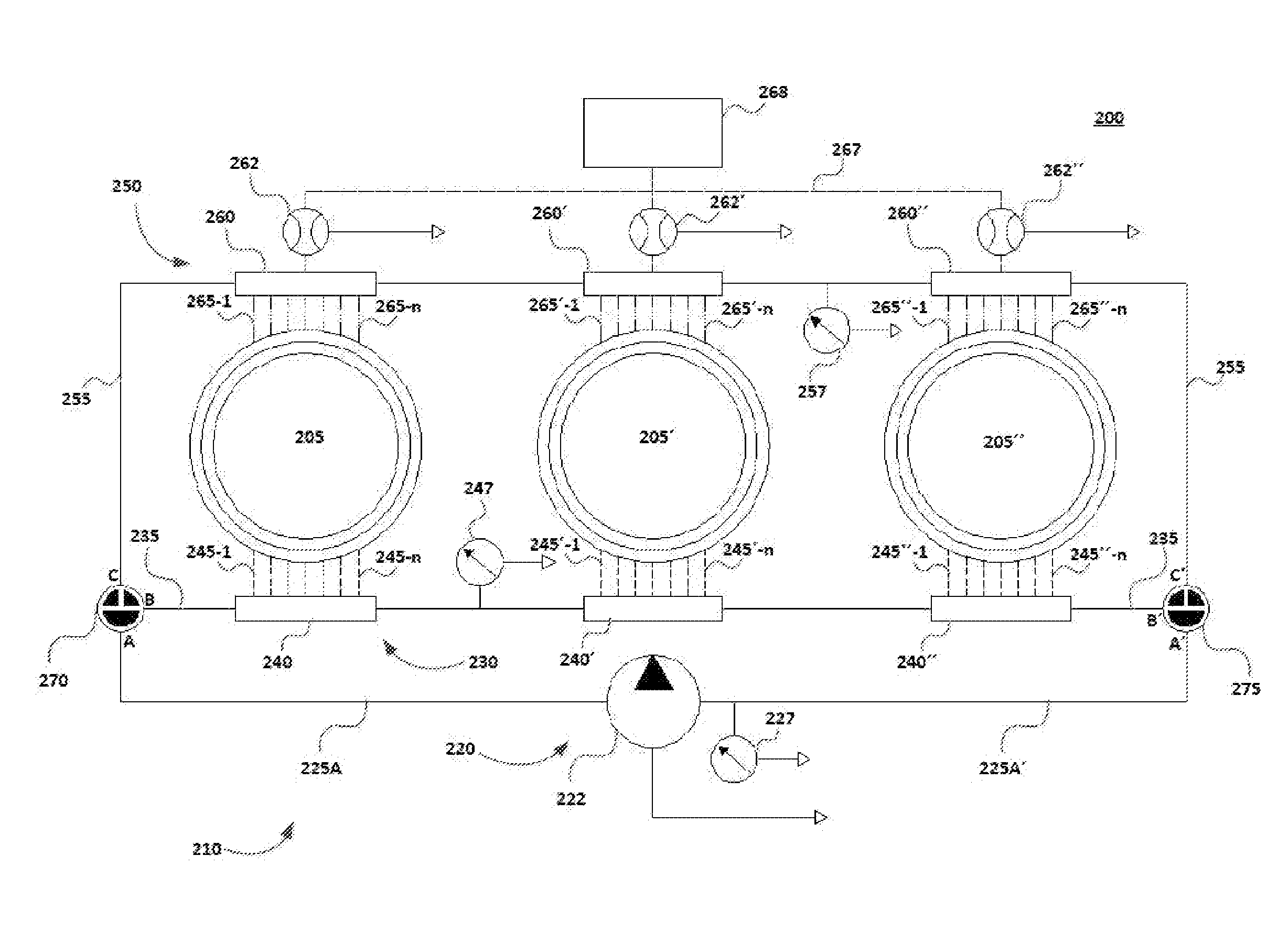

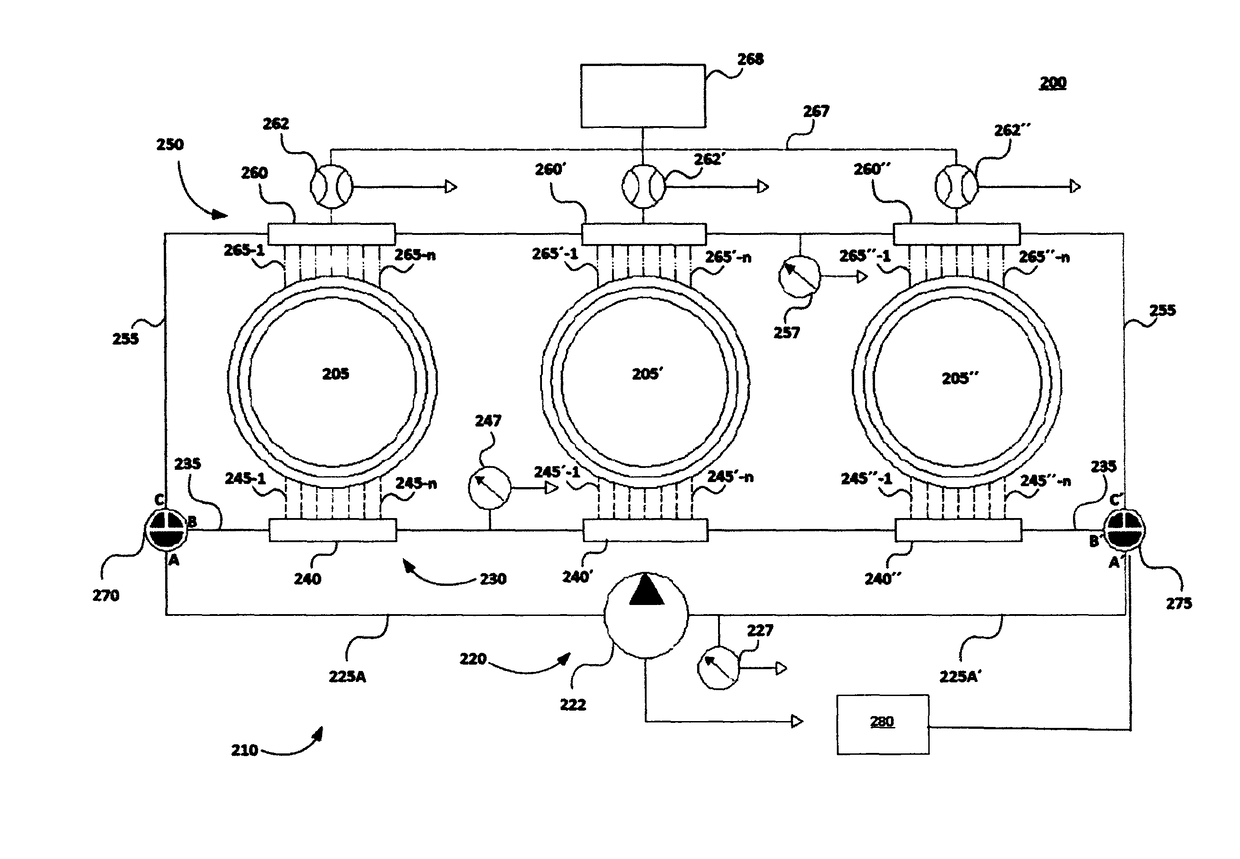

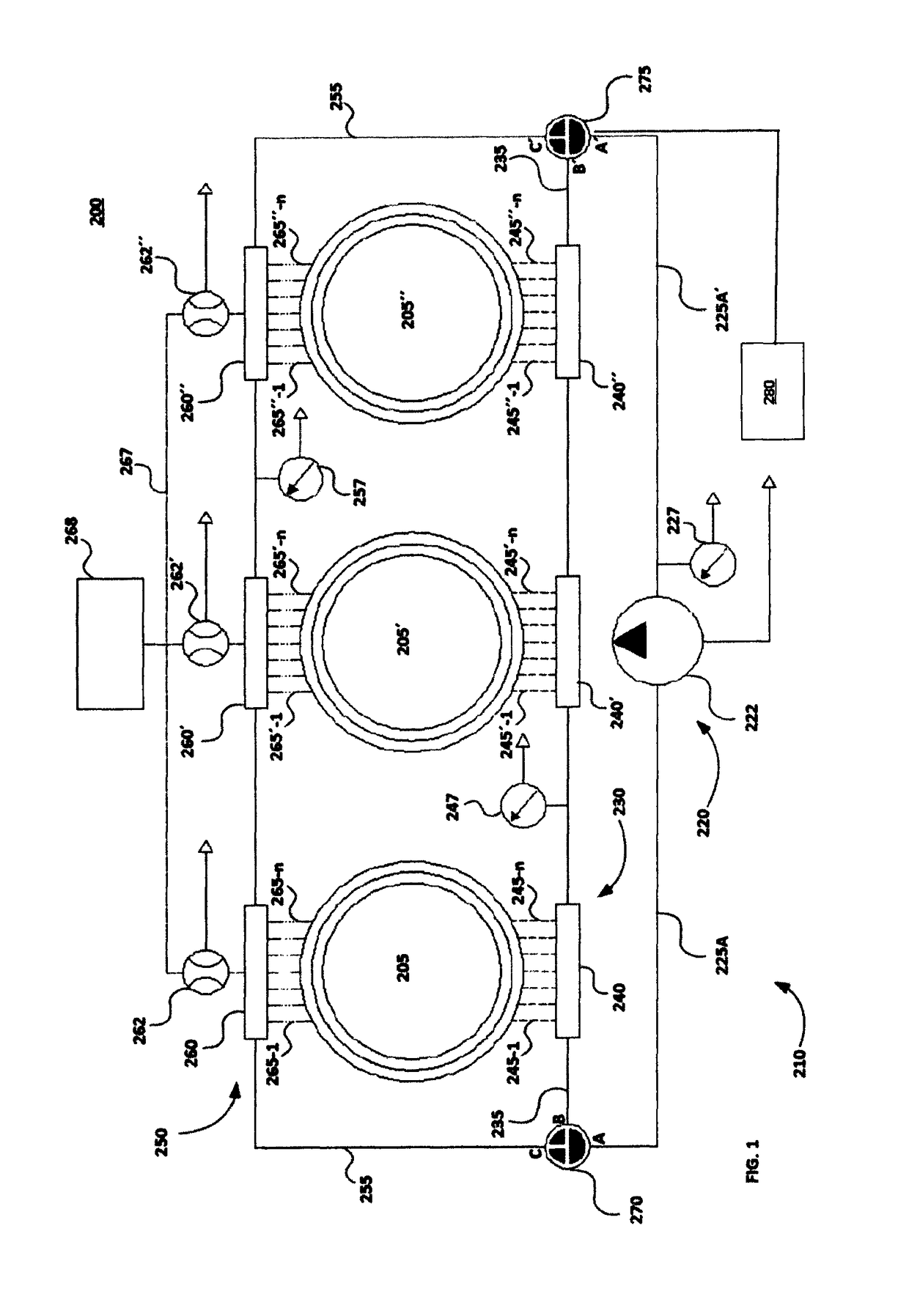

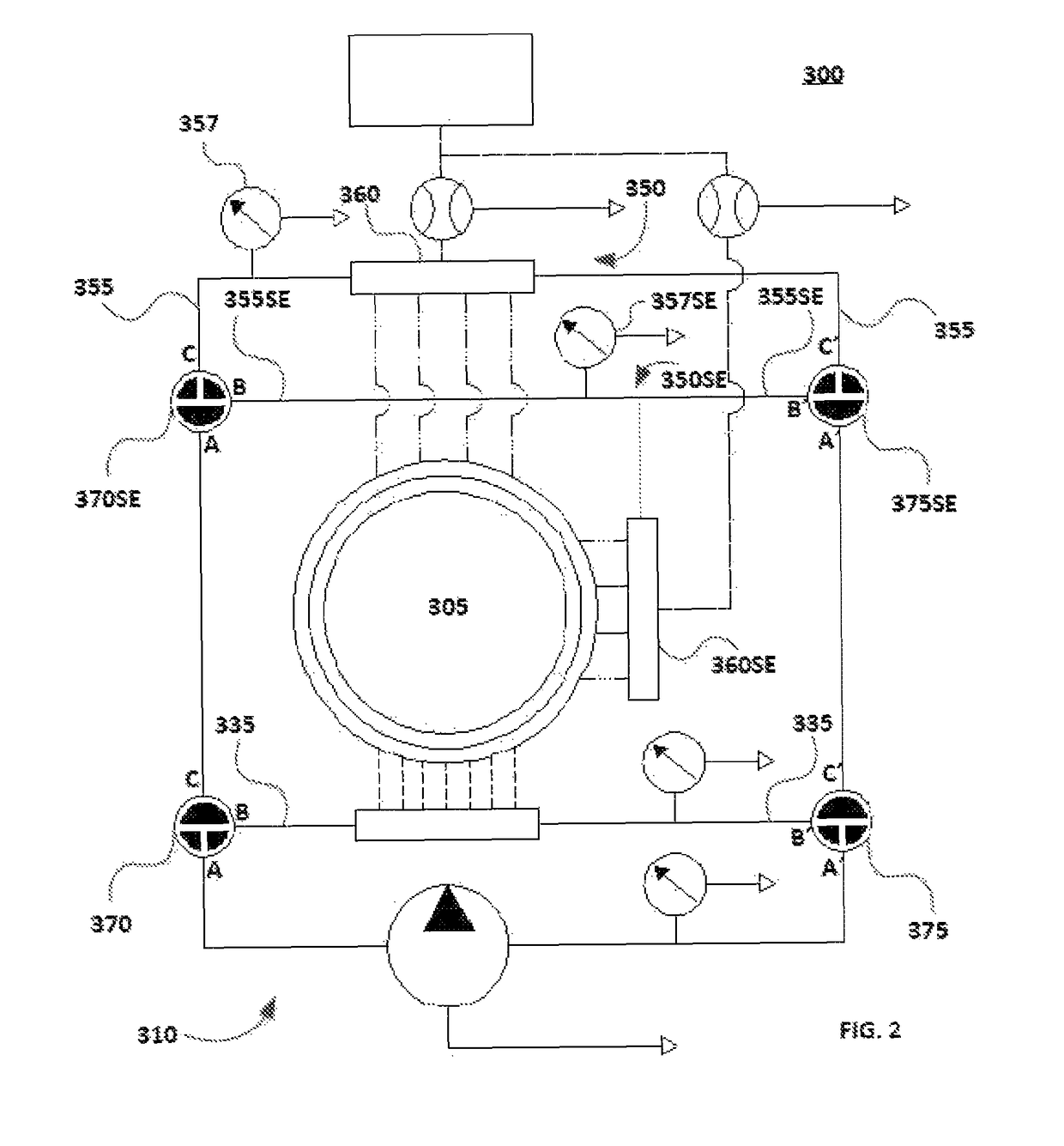

Lubrication systems for bearing assemblies

ActiveUS20140193263A1Maintain balanceRestricts distributionPropellersPump componentsLubricationLubricant

A lubrication system is disclosed for a bearing assembly, the bearing assembly having at least one bearing. The lubrication system may comprise a pump circuit, an injection circuit, an extraction circuit and at least one three-way valve. The pump circuit may comprise at least a pump. The injection circuit may provide lubricant to the bearing during an injection mode of operation. The extraction circuit may extract lubricant from the bearing during an extraction mode of operation. A flow combination topology of the first three-way valve may allow operation of the lubrication system in the injection mode or in the extraction mode or in both modes simultaneously.

Owner:GE RENEWABLE TECH WIND BV

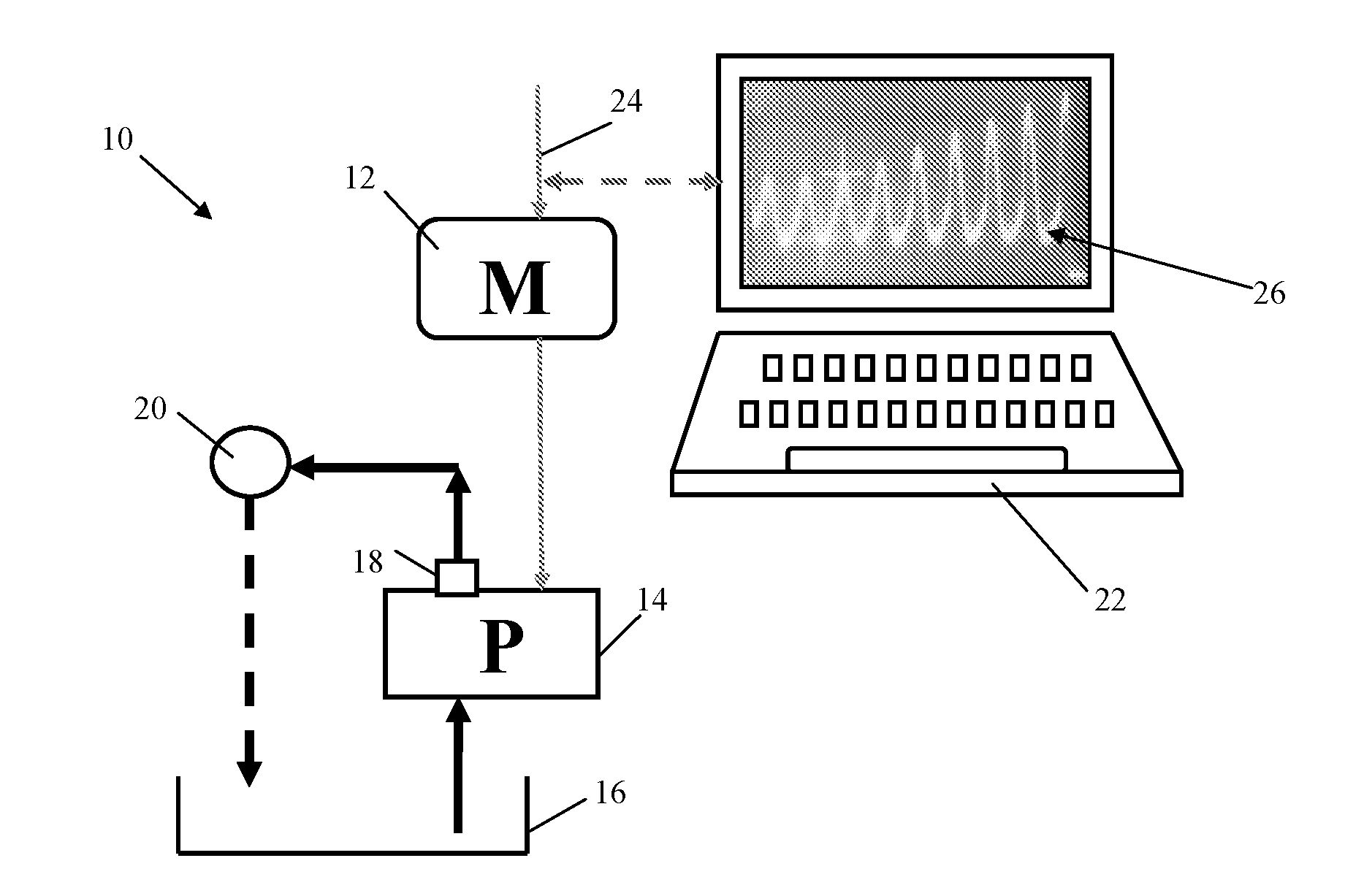

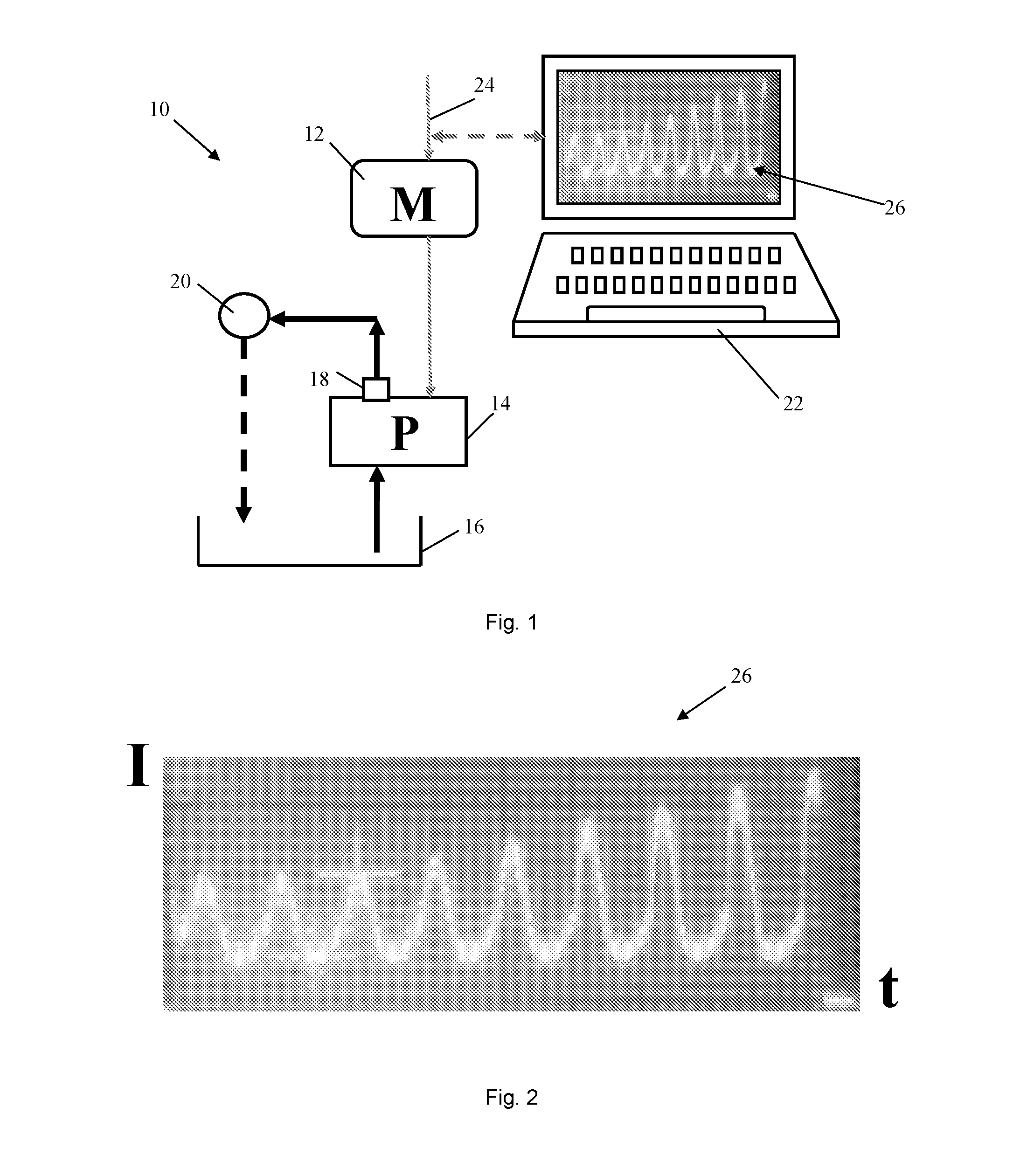

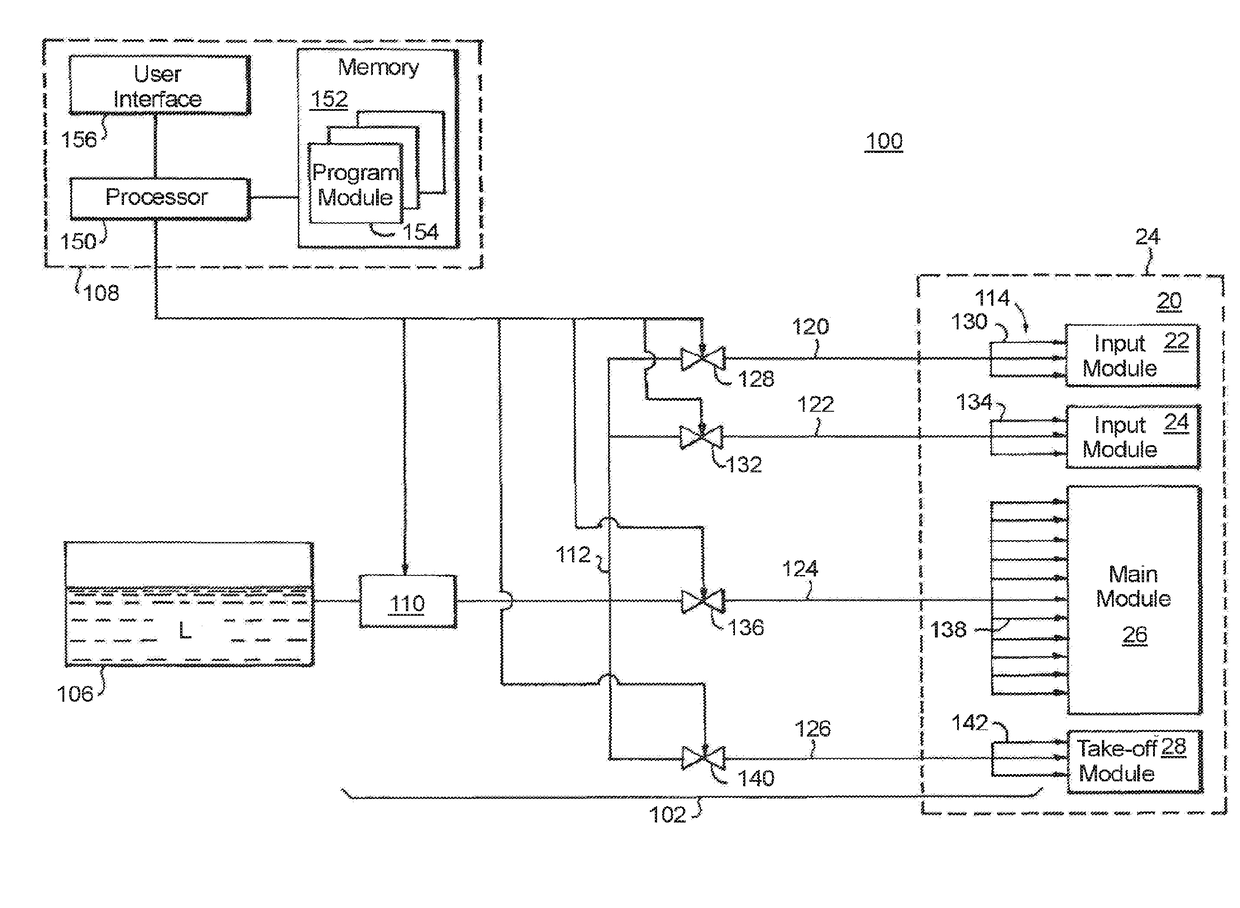

System, method & computer program product

ActiveUS20160208983A1Low costReduce complexityDC motor speed/torque controlLubricating pumpsPower flowEngineering

A lubrication system comprising a motor, a positive displacement pump driven by the motor, a lubricant container in fluid communication with the positive displacement pump and at least one lubricant outlet in fluid communication with the lubricant container. The positive displacement pump is arranged to carry out at least one discharge stroke to dispense lubricant from the at least one lubricant outlet when the lubrication system is in use. The lubrication system also comprises a control unit that is arranged to determine an amount of lubricant that is dispensed from the lubricant container via the at least one lubricant outlet when the lubrication system is in use. The control unit is arranged to monitor current supplied to the motor to obtain a motor current signal, and to determine a number of the discharge strokes from the motor current signal.

Owner:OSAKEYHTIO SKF

Gearbox lubricating system and lubricating oil flow control method of gearbox lubricating system

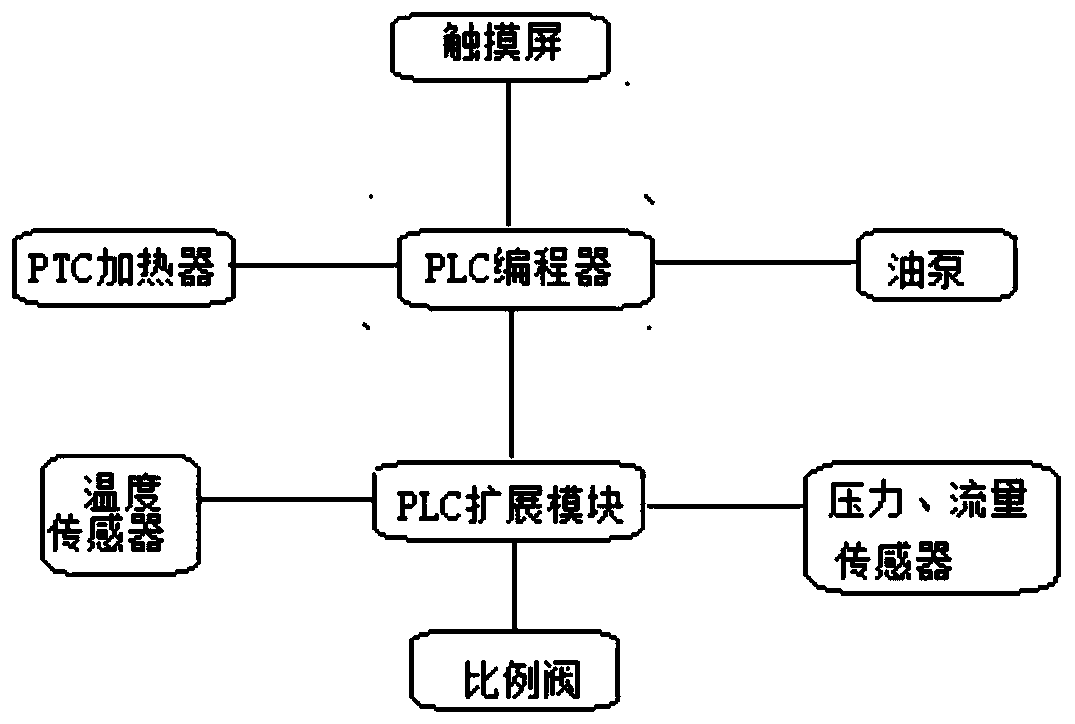

PendingCN108302188AEasy to operateEasy to controlTurbinesEngine temperatureElectric controlControl valves

The invention discloses a gearbox lubricating system. The system comprises an annular loop which is sequentially connected with a lubricating oil tank, an oil pump, a radiator and an electric controlreversing valve, wherein a through passage is further arranged between the oil pump and the control valve, and the through passage is arranged in parallel with the radiator; the system further comprises a PLC main controller, a first temperature sensor, a second temperature sensor, a first temperature sensor and a second temperature sensor, wherein the first temperature sensor, the second temperature sensor, the first temperature sensor and the second temperature sensor are connected with the PLC main controller; the electric control reversing valve is connected with the PLC main controller, the control of an open precision of the electric control reversing valve is realized through the PLC main controller according to the monitoring data of the first temperature sensor, the second temperature sensor, the first temperature sensor and the second temperature sensor. The invention further discloses a lubricating oil flow control method of the gearbox lubricating system. According to the system and method, the PLC main controller is additionally arranged, the electric control reversing valve, the temperature sensors and pressure sensors are connected with the PLC main controller, wherein the service life and the precision control of the electric control reversing valve are relatively high, so that the service life and the intelligent control degree of the gear box lubricating system can be greatly improved.

Owner:GUODIAN UNITED POWER TECH

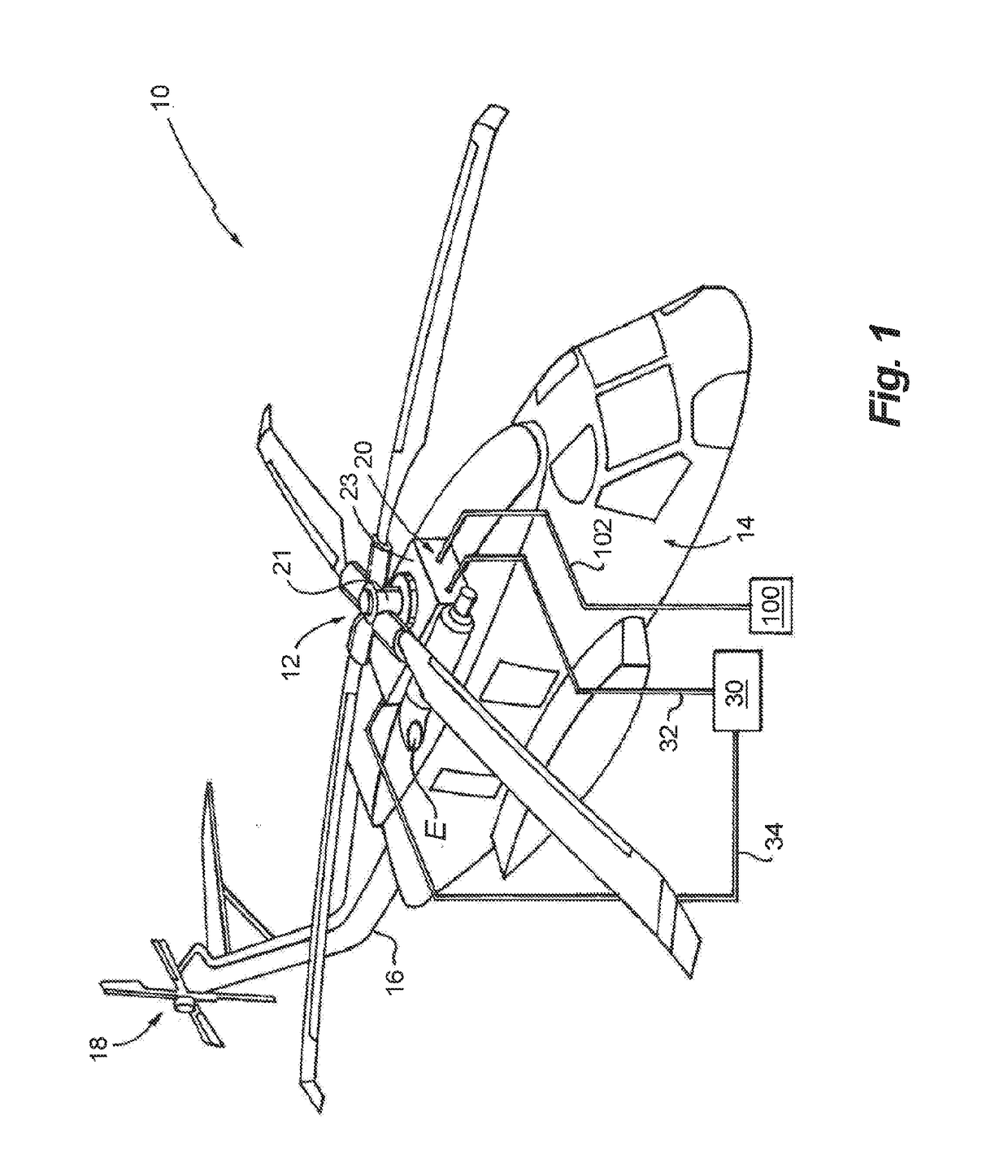

Lubrication systems for transmissions

A lubrication system for a transmission includes a flow-metering device and a controller. The controller is operatively associated with the flow-metering device to cause the flow-metering device to intermittently issue lubricant from the flow-metering device into a transmission based on an operating parameter of the transmission.

Owner:SIKORSKY AIRCRAFT CORP

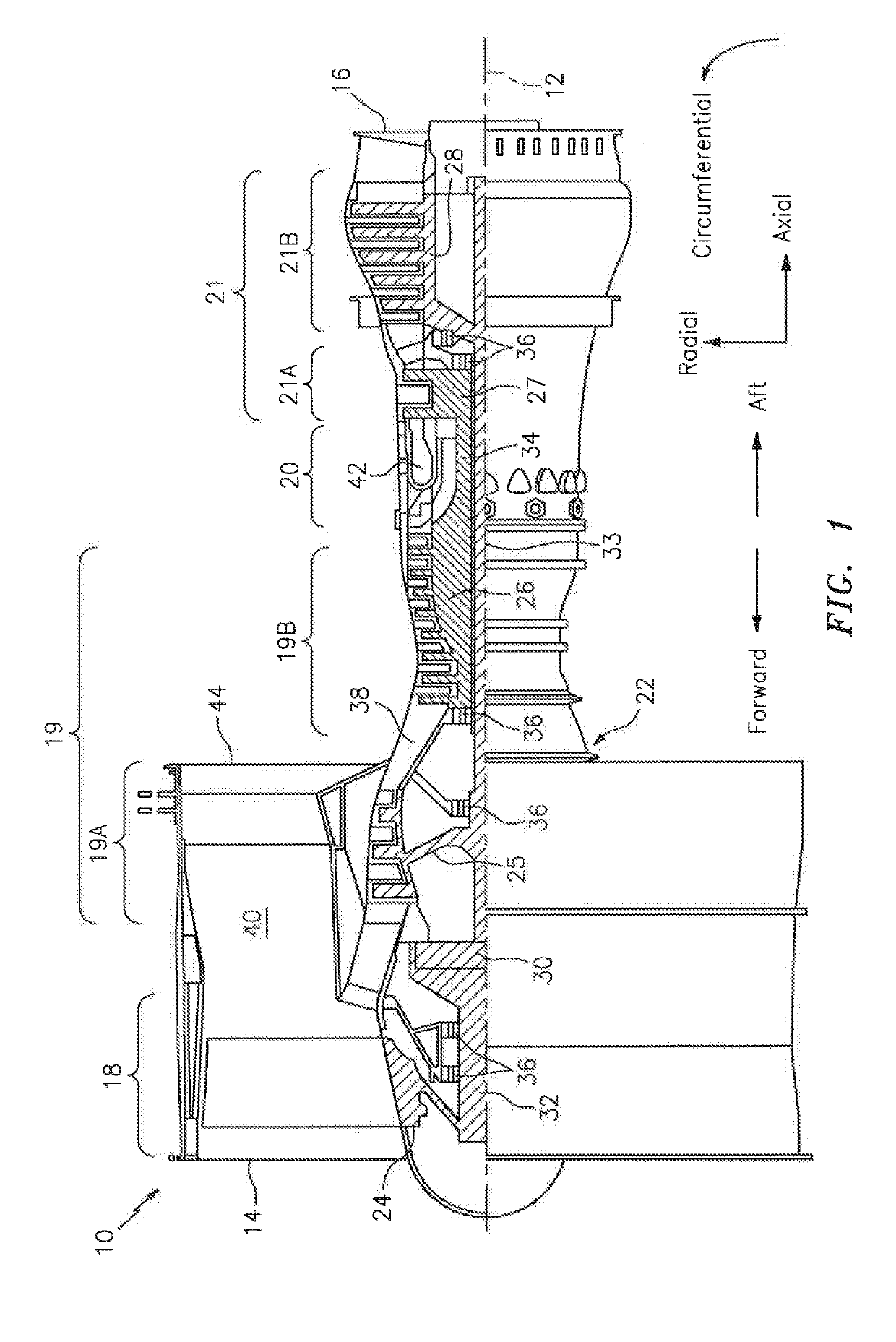

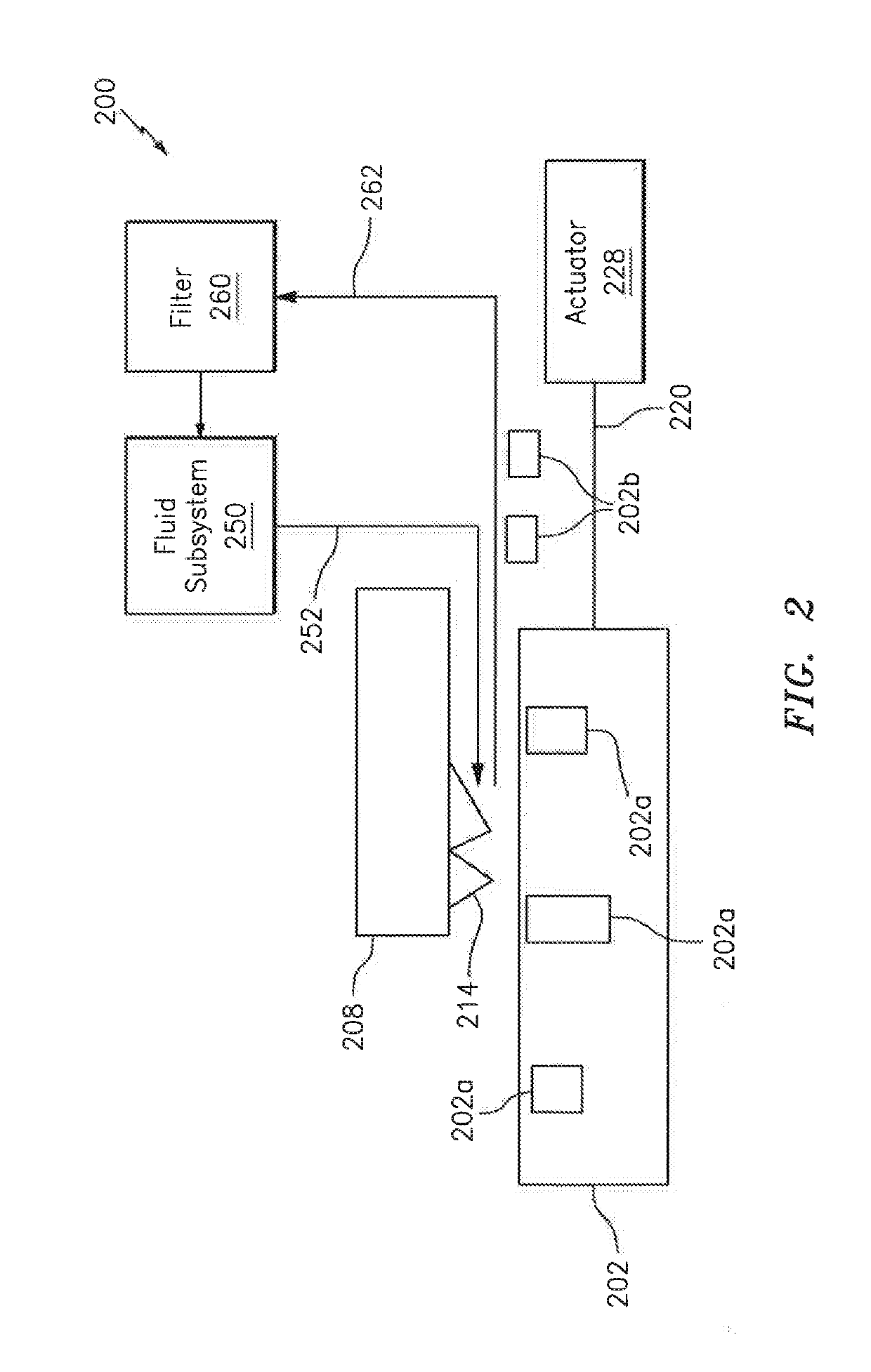

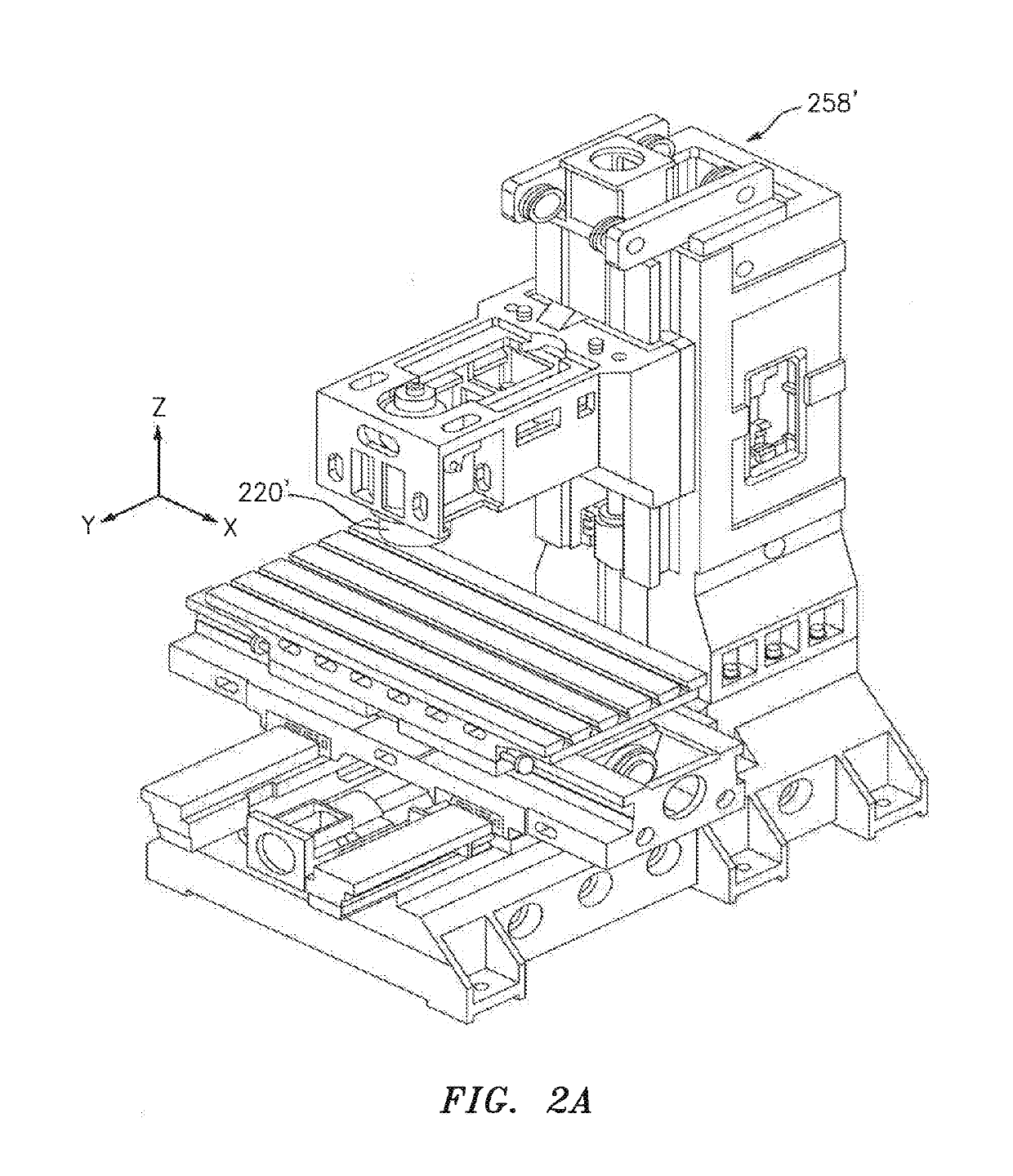

Closed-loop fluid control to obtain efficient machining

A system includes a machine tool that includes a cutting tool, a fluid subsystem that provides fluid to the cutting tool, and at least one processor that executes instructions that cause the at least one processor to: obtain a signal indicative of a load on the cutting tool, establish a first value of at least one parameter of the fluid based on the signal, obtain a second value of the at least one parameter that is based on a simulation, determine a difference between the first value and the second value, and adjust a state of a device of the fluid subsystem based on the determined difference.

Owner:RAYTHEON TECH CORP

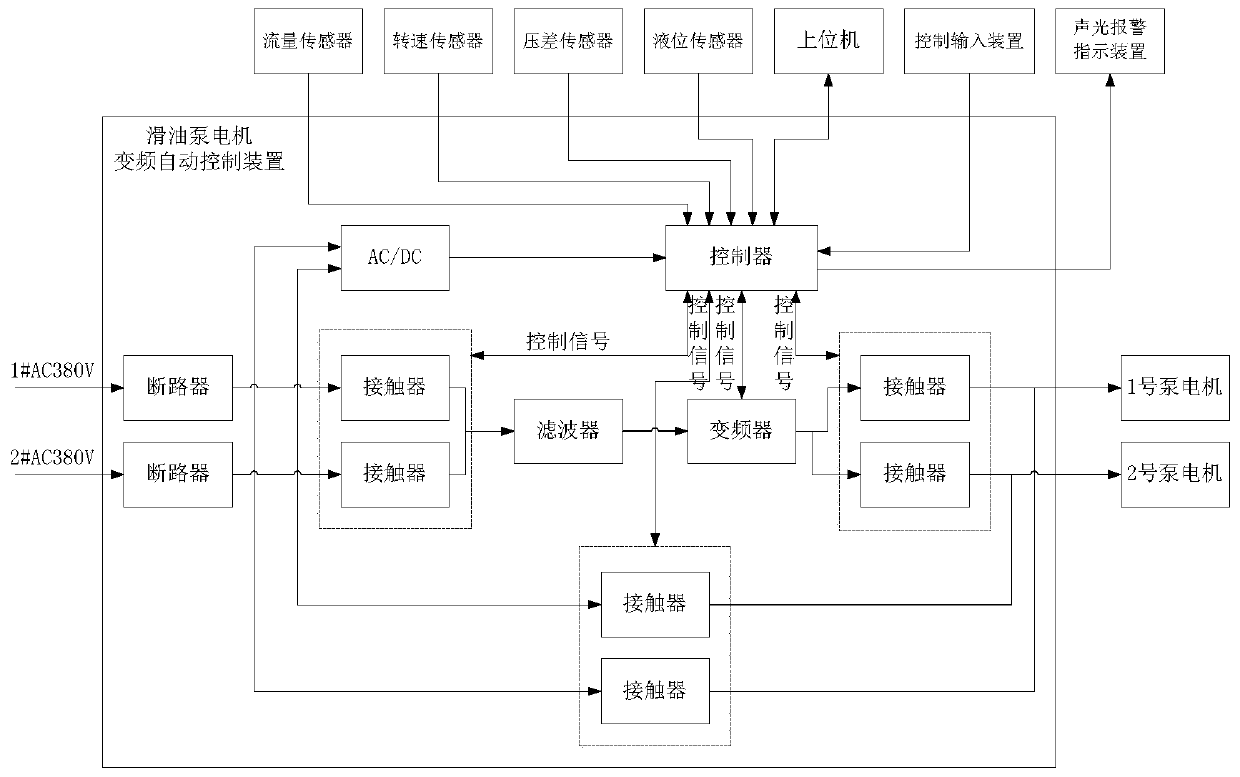

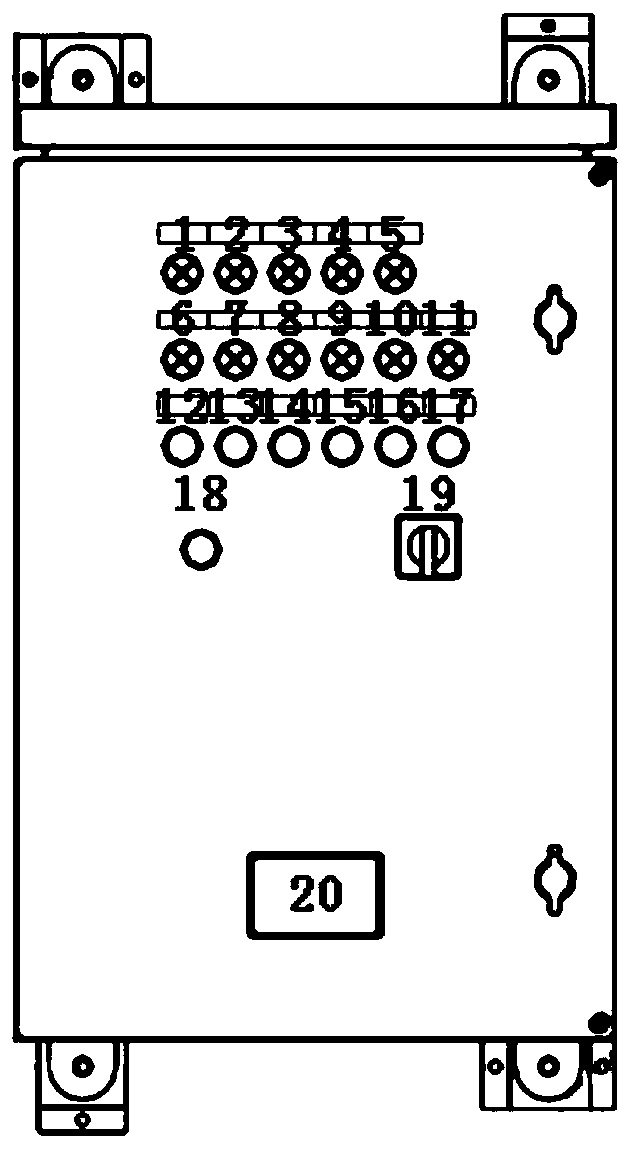

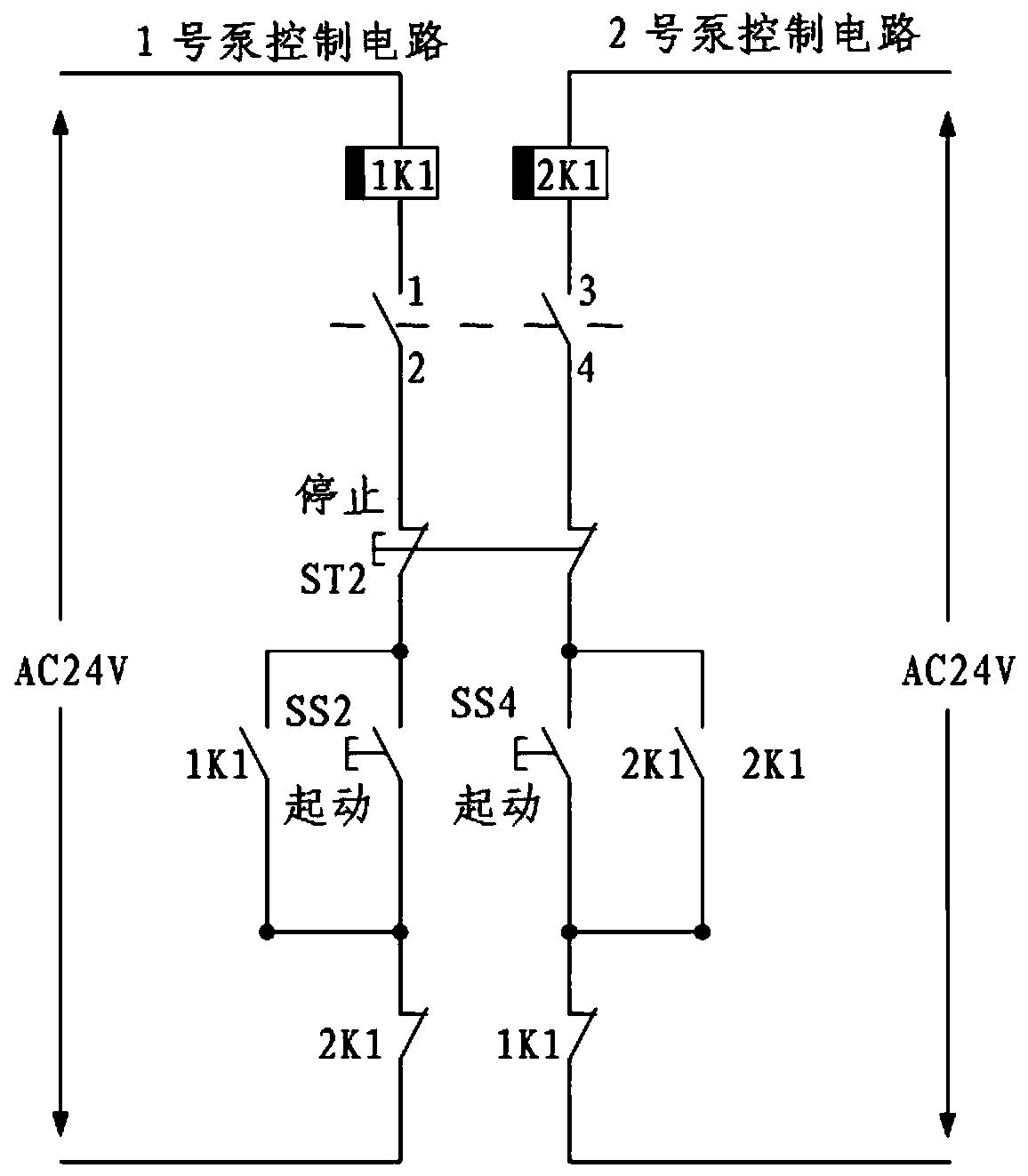

Frequency conversion automatic control device and method of motor of shafting lubricating oil pump

InactiveCN110486609AAvoid getting out of controlLow powerEngine pressureAC motor controlFrequency changerAutomatic control

The invention provides a frequency conversion automatic control device and method of a motor of a shafting lubricating oil pump. The device comprises a sensor, a controller, a frequency converter anda contactor; the function of adjusting the flow and controlling frequency conversion output by using the shafting rotating speed is realized on the basis of automatically controlling the operation oftwo motors of the lubricating oil pump, and the device is used for providing the fine control requirements of lubricating oil according to the user requirements of a lubricating oil system under different operating working condition; the device has lubricating oil flow monitoring, fault alarming and manual emergency operation functions; and when the frequency converter breaks down, an input powersupply of a power grid is directly used as the power supply of the lubricating oil pump motors, so that the flow of a lubricating oil pipe is prevented from being out of control due to the failure ofthe lubricating oil system, maintenance personnel can be timely reminded to repair the frequency converter, and the equipment use reliability is further improved.

Owner:CHINA SHIP DEV & DESIGN CENT

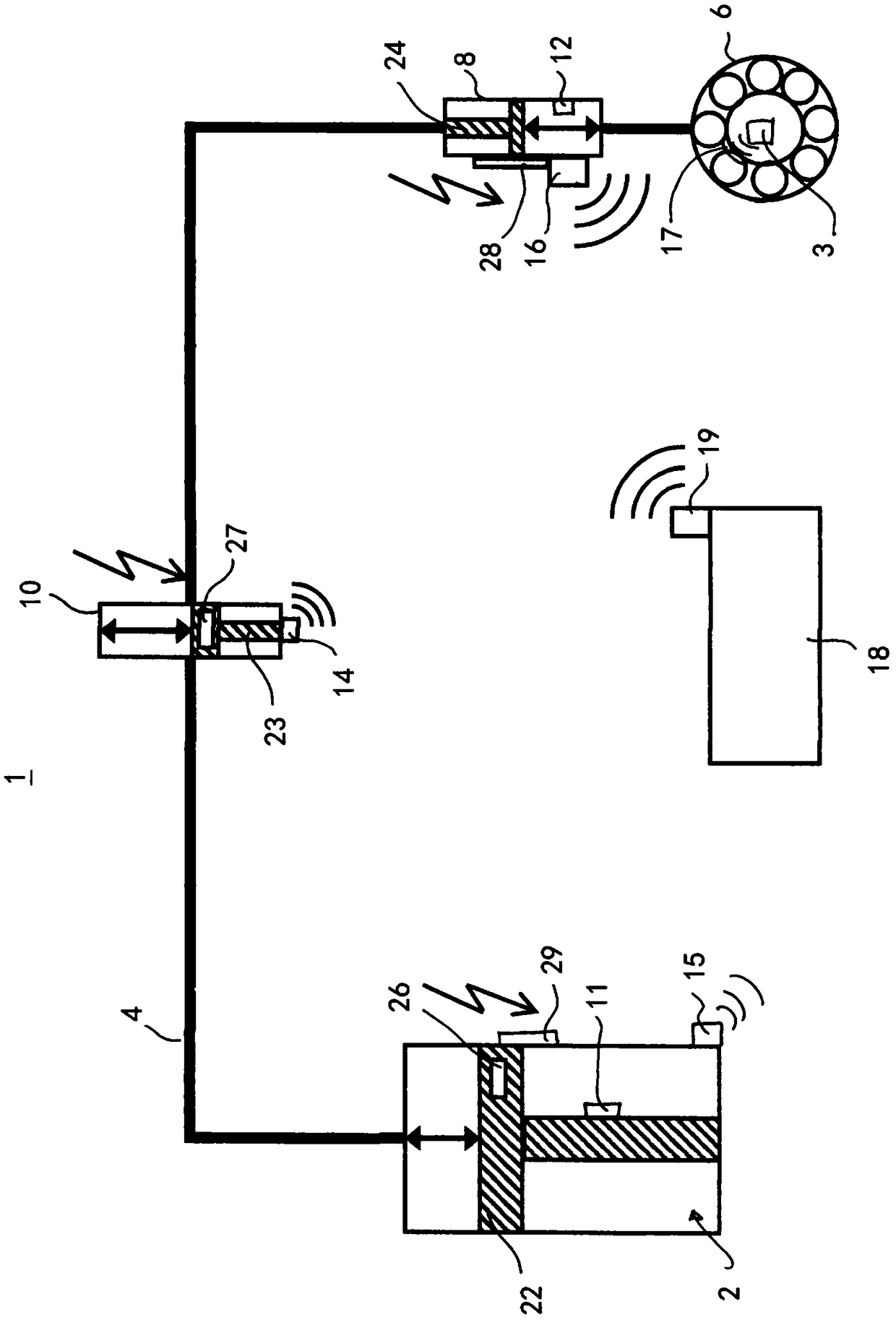

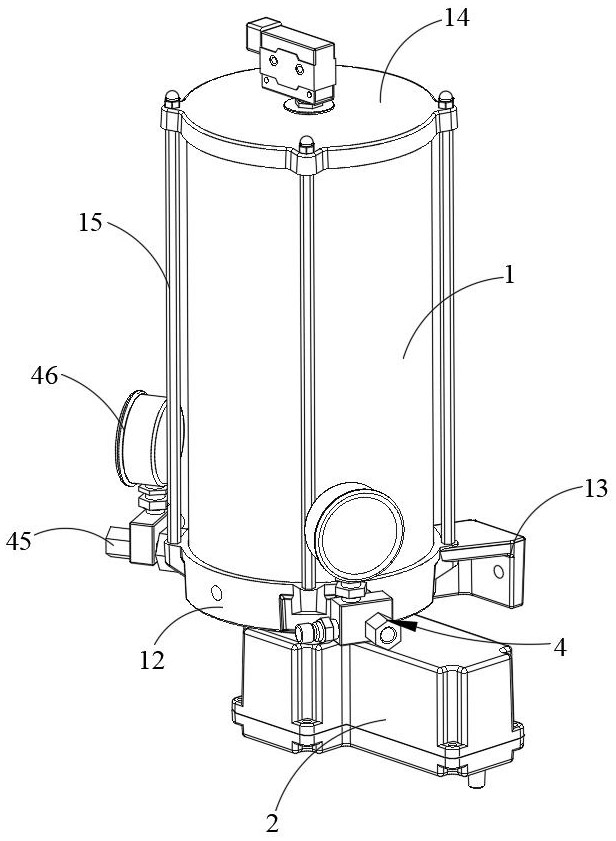

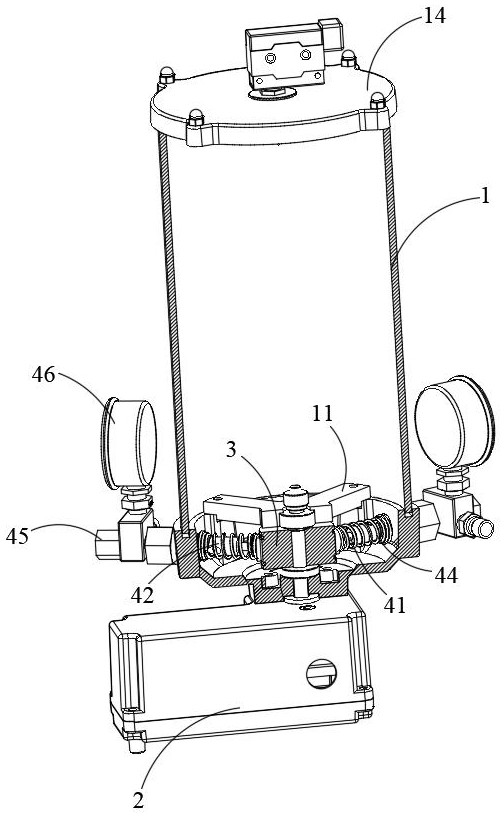

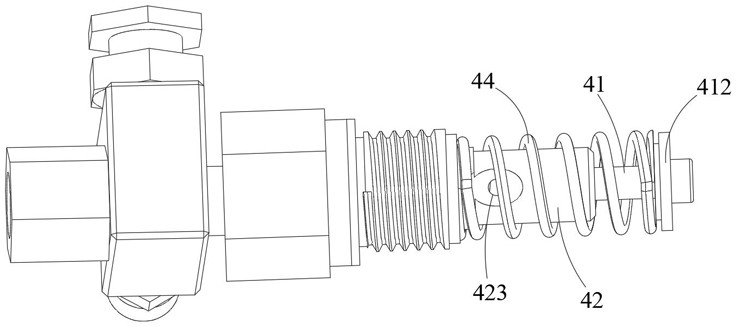

Lubrication system with a signal transmission element

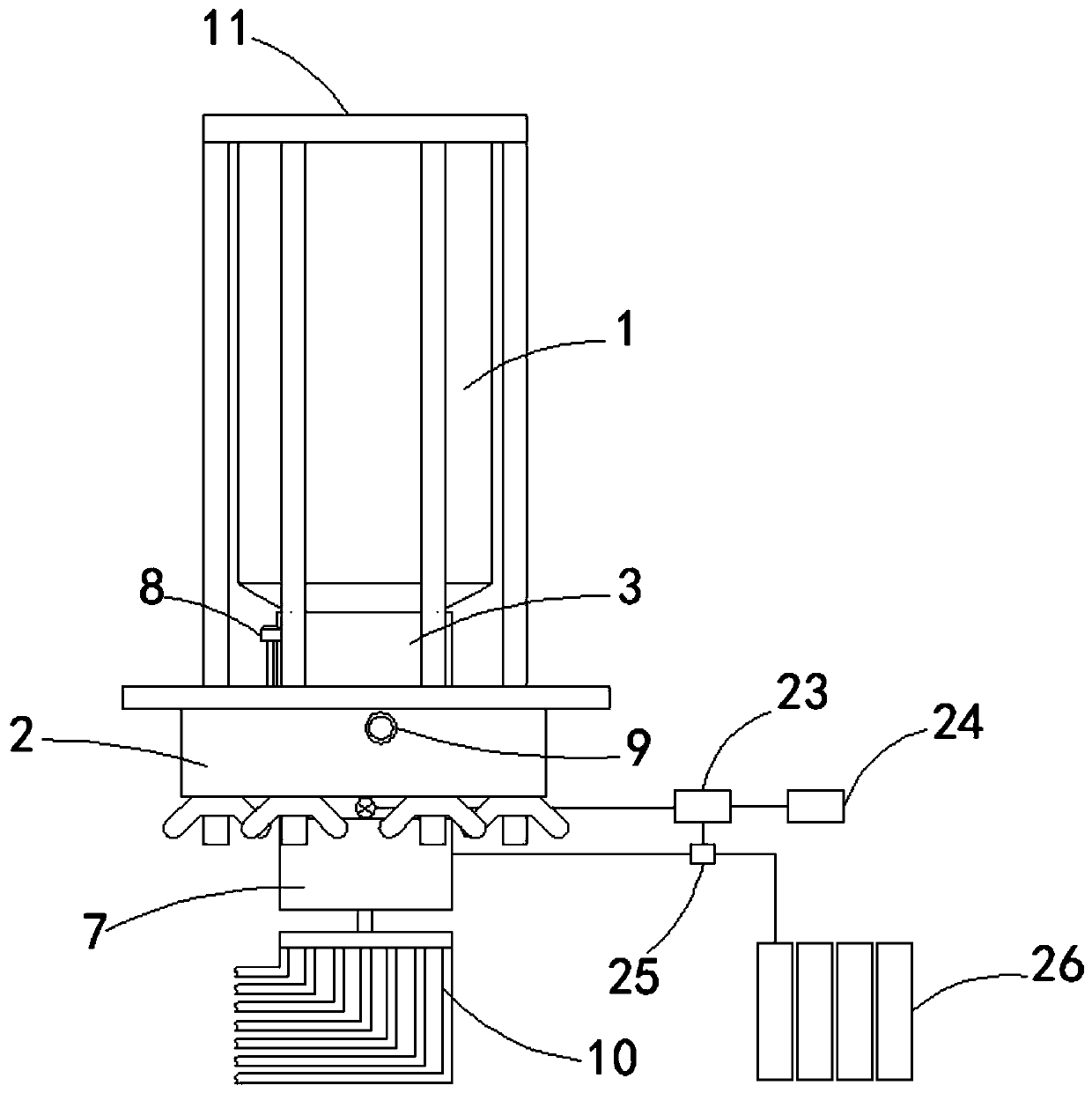

PendingCN109386717ARealize automatic monitoringSignal transmission is simple and fastEngine pressureBatteries circuit arrangementsEngineeringDistributor

The invention discloses a lubrication system configured to supply a lubricant to at least one lubrication point. The lubrication system includes at least one lubricant pump configured to pump the lubricant to the at least one lubrication point, a lubricant distributor configured to distribute the lubricant at the at least one lubrication point, a control unit configured to control at least the lubricant pump and / or the lubricant distributor, at least one lubrication system monitor configured to monitor a monitoring variable of the lubrication system, and at least one signal transmission deviceconfigured to wirelessly transmit a signal indicative of the monitoring variable provided by the lubrication system monitor to the control device or to receive signals therefrom.

Owner:德国斯凯孚润滑油系统有限责任公司

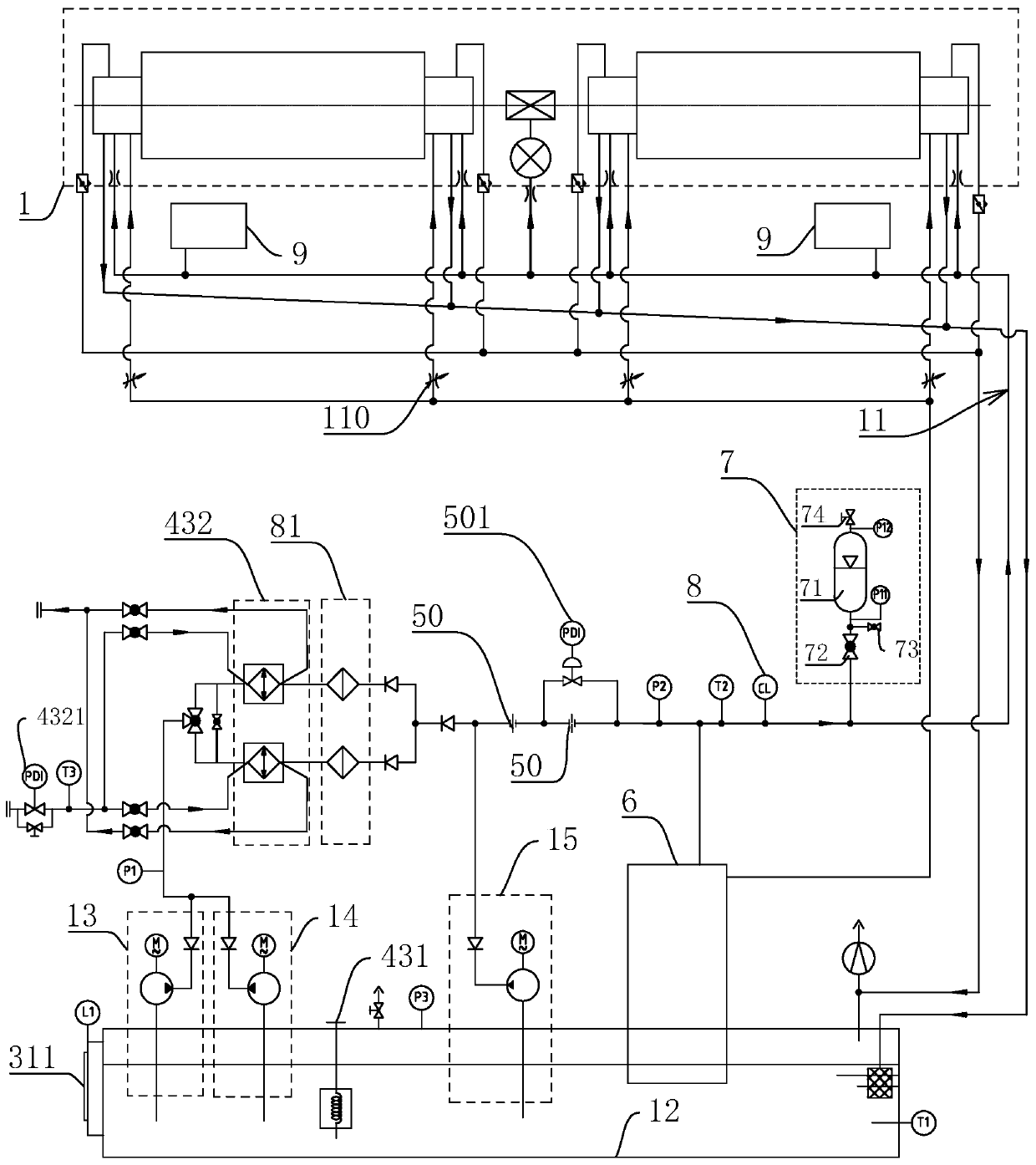

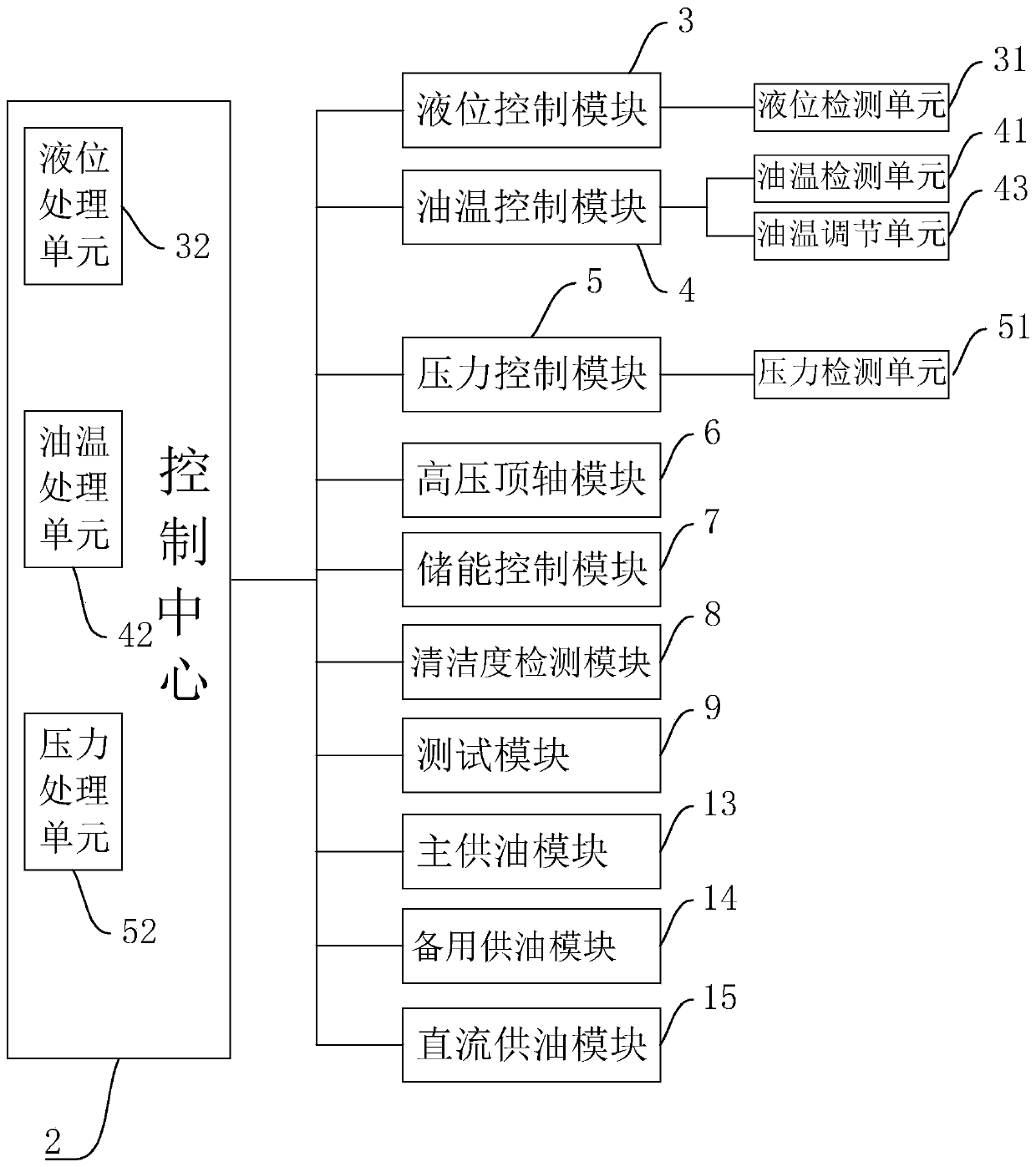

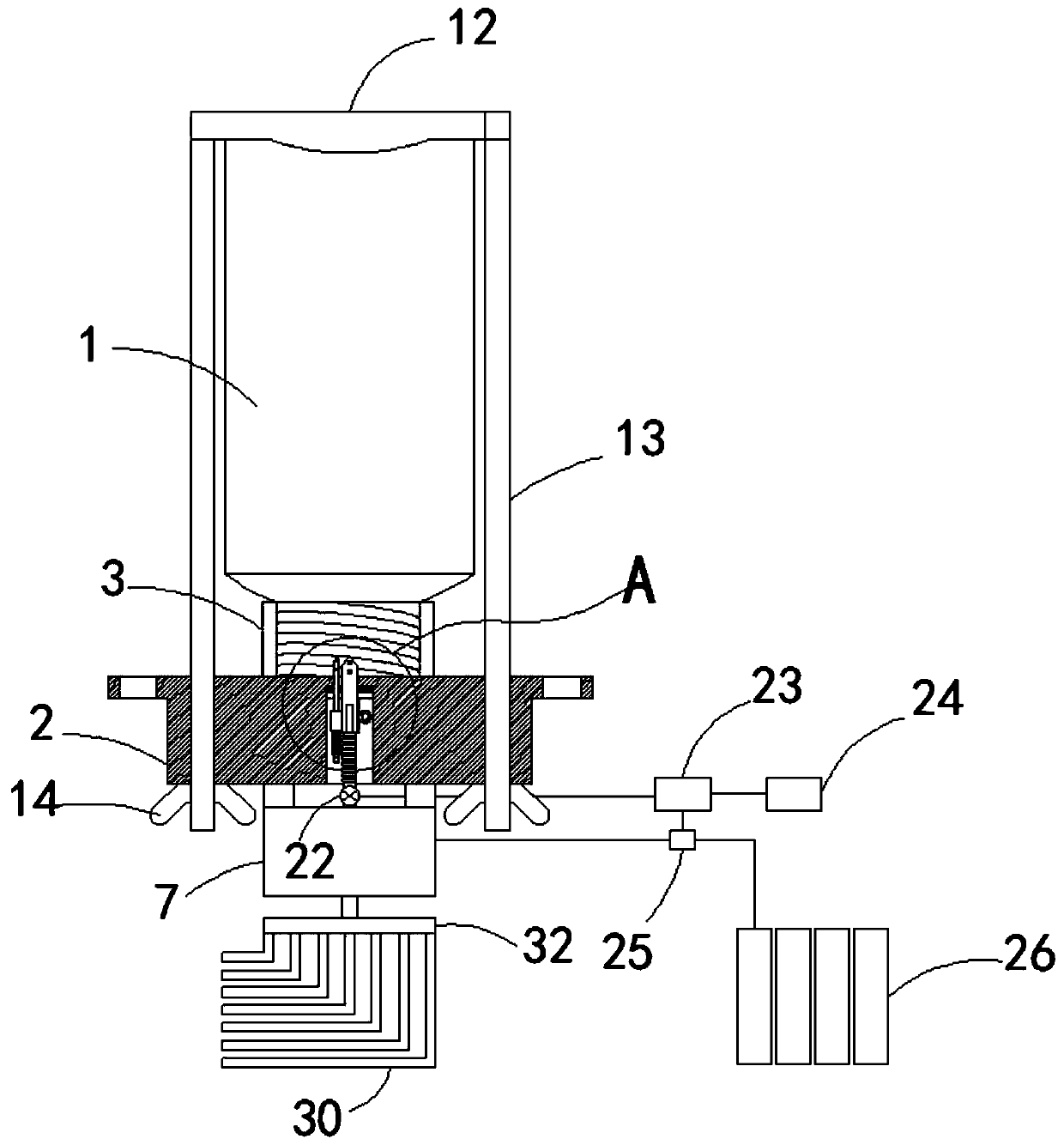

Rotating-shaft-type main engine intelligent lubricating system and control method thereof

PendingCN111336397AProduces the effect of a secure bootEnsure safetyEngine temperatureEngine pressureControl engineeringProcess engineering

The invention discloses a rotating-shaft-type main engine intelligent lubricating system and a control method thereof, and relates to the technical field of lubricating systems. The rotating-shaft-type main engine intelligent lubricating system and the control method thereof aim to solve the technical problem that a standby pump needs to be started manually in an existing lubricating oil system, and consequentially, intelligent operation of the whole lubricating system is inconvenient to realize. According to the key points of the technical scheme, the rotating-shaft-type main engine intelligent lubricating system comprises a unit, an oil supply pipeline, an oil tank, a main oil supply module, a standby oil supply module and a direct-current oil supply module, the main oil supply module, the standby oil supply module and the direct-current oil supply module are all arranged on the oil tank and connected to the oil supply pipeline, and the oil supply pipeline is connected to a to-be-lubricated position of the unit; and a control center, a liquid level control module, an oil temperature control module, a pressure control module, a high-pressure shaft jacking module, an energy-storagecontrol module, a cleanliness detecting module and a testing module which are matched and the corresponding control method are further included. The automation and intelligence effects of the lubricating system are improved.

Owner:JIANGSU JIANGHAI LUBRICANTS HYDRAULIC EQUIP

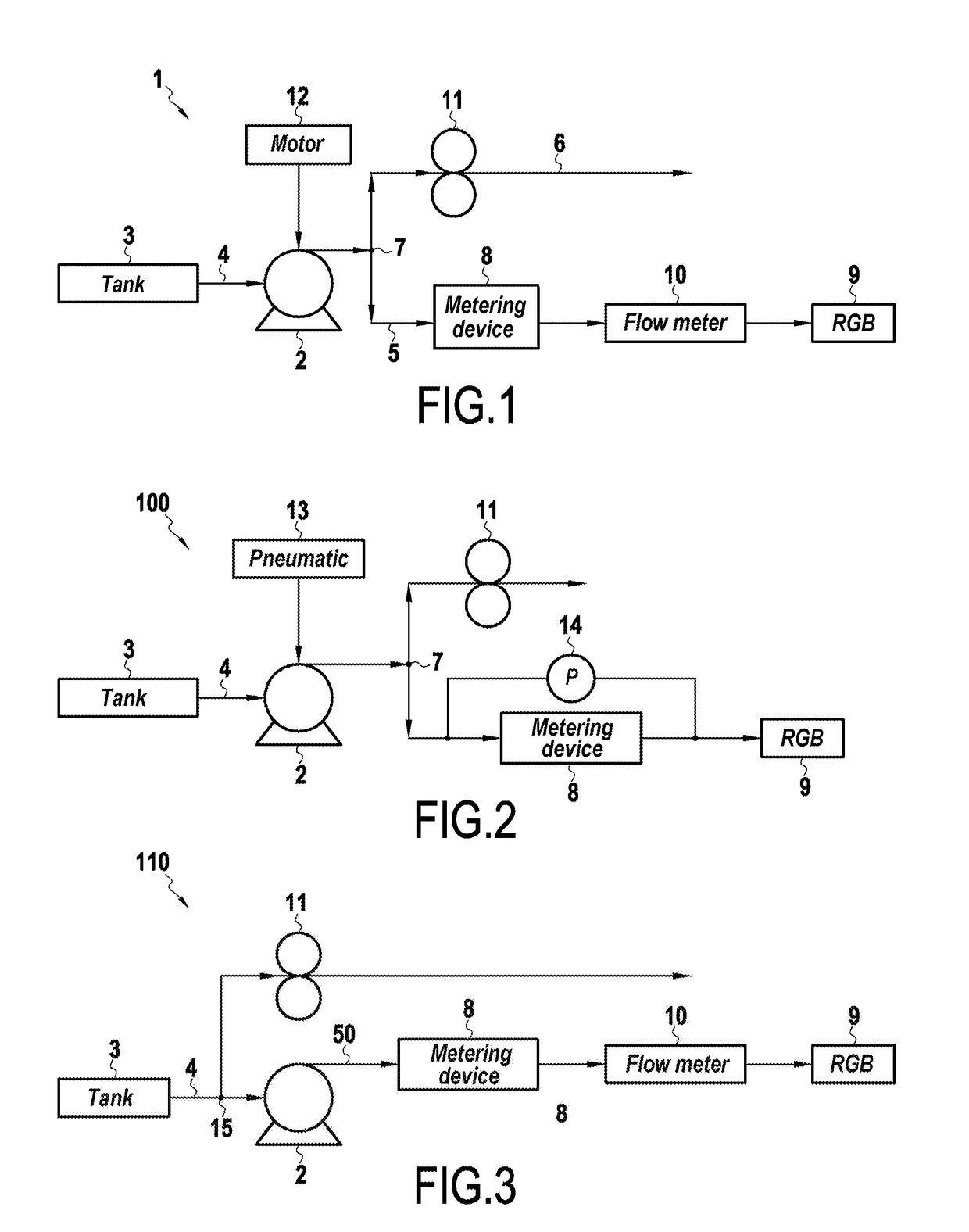

System and method for supplying lubrication fluid to at least one member of an aircraft propulsion assembly

A feed system for feeding lubricating oil to members of a turbine engine including a reduction gearbox, the feed system including a nonpositive-displacement pump device for connecting upstream to an oil tank and driven in rotation at a speed that is not correlated with an operating speed of the turbine engine; a separator node connected to the outlet of the nonpositive-displacement pump device; a first delivery branch for lubricating the RGB connected to the nonpositive-displacement pump device via the separator node; a second delivery branch for lubricating other members connected to the nonpositive-displacement pump device via the separator node, the second delivery branch including a positive-displacement pump; and at least one fluid metering device having a metering slot fed by the nonpositive-displacement pump device via the separator node for the purpose of feeding the RGB.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Lubrication systems for bearing assemblies

A lubrication system is disclosed for a bearing assembly, the bearing assembly having at least one bearing. The lubrication system may comprise a pump circuit, an injection circuit, an extraction circuit and at least one three-way valve. The pump circuit may comprise at least a pump. The injection circuit may provide lubricant to the bearing during an injection mode of operation. The extraction circuit may extract lubricant from the bearing during an extraction mode of operation. A flow combination topology of the first three-way valve may allow operation of the lubrication system in the injection mode or in the extraction mode or in both modes simultaneously.

Owner:GE RENEWABLE TECH WIND BV

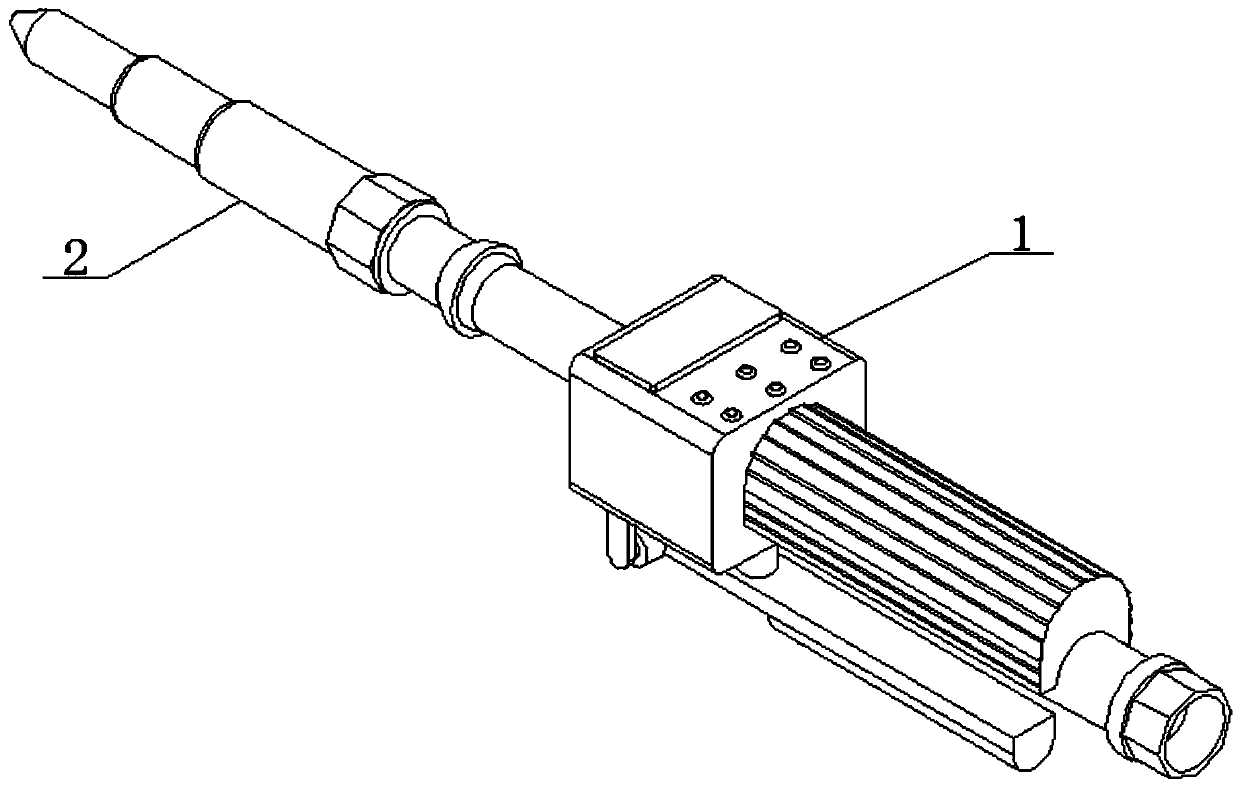

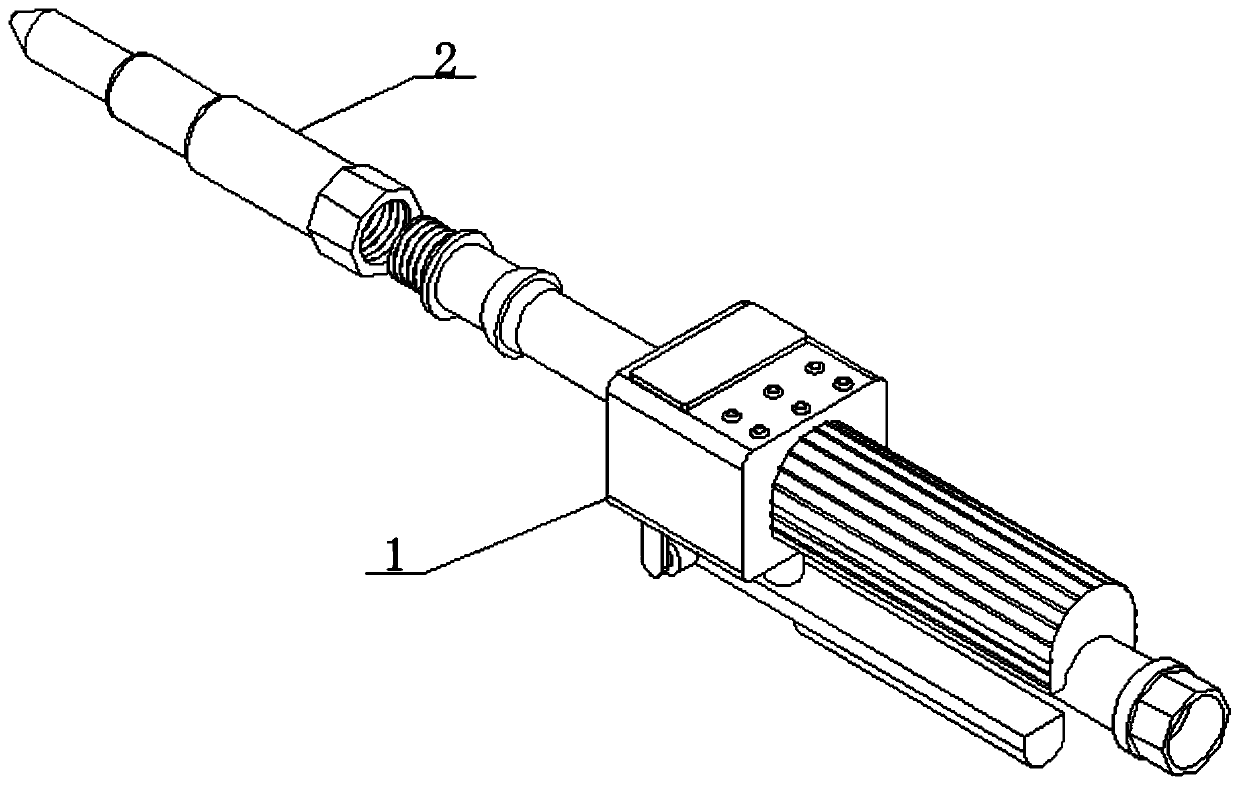

Lubricating grease filling equipment

InactiveCN110848547AEasy to useFor later observationProportioning devicesManual lubricationThermodynamicsMechanical engineering

The invention discloses lubricating grease filling equipment. According to the technical scheme, the lubricating grease filling equipment is characterized by comprising a control structure and an extension structure, wherein the control structure comprises an electronic flowmeter, an oil inlet metal cylinder and an oil outlet metal cylinder, a liquid inlet of the electronic flowmeter is connectedwith the oil inlet metal cylinder in a penetrating manner, a liquid outlet of the electronic flowmeter is connected with the oil outlet metal cylinder in a penetrating manner, a port of the oil outletmetal cylinder is connected with the extension structure, one side of the bottom end of the electronic flowmeter is rotatably connected with a pressing handle, and the upper end face of the pressinghandle is fixedly connected with a flow stopping key of the electronic flowmeter. The problems that structure of adding an auxiliary part is not arranged at the mouth of an oil gun when existing lubricating grease filling equipment is in use, use is inconvenient when different devices are filled with oil, meanwhile, the filling equipment does not have a flow control function on the oil gun, the lubricating grease filling equipment is inconvenient to use, the use flexibility and the convenience are low, and the lubricating grease filling equipment is not convenient to use in the later period are solved.

Owner:常州欣灏电子商务有限公司

Lubricating device for crane maintenance

The invention discloses a lubricating device for crane maintenance. The lubricating device comprises a machine shell and a lubricating oil box; two component openings are formed in the surface of themachine shell, positioning rods are inserted into the two component openings correspondingly, the tail ends of the positioning rods are of threaded pipe structures, fastening bolts are rotationally installed on the surfaces of the positioning rods, the side faces of the positioning rods are of sliding rail structures, and the positioning rods and the machine shell are installed in a sliding mode;a driven shaft is rotationally connected with each positioning rod, bearing boxes are symmetrically installed on the positioning rods through adjusting bolts, and rollers are rotationally connected with the bearing boxes; the machine shell is of a hollow structure, a controller is arranged in the machine shell, an infrared receiver is arranged on the controller, a motor is connected with the controller, and the driving end of the motor is connected with a transmission shaft; and an L-shaped fastening strip is fixedly connected with the machine shell, and a limiting round rod is arranged on thefastening strip in a penetrating mode. According to the lubricating device for crane maintenance, the lubricating device can conveniently adapt to ropes with different diameter sizes, and when the lubricating device has the problems of oil shortage and blockage, a user can replace the lubricating device at the first time.

Owner:安徽省雄峰起重机械有限公司

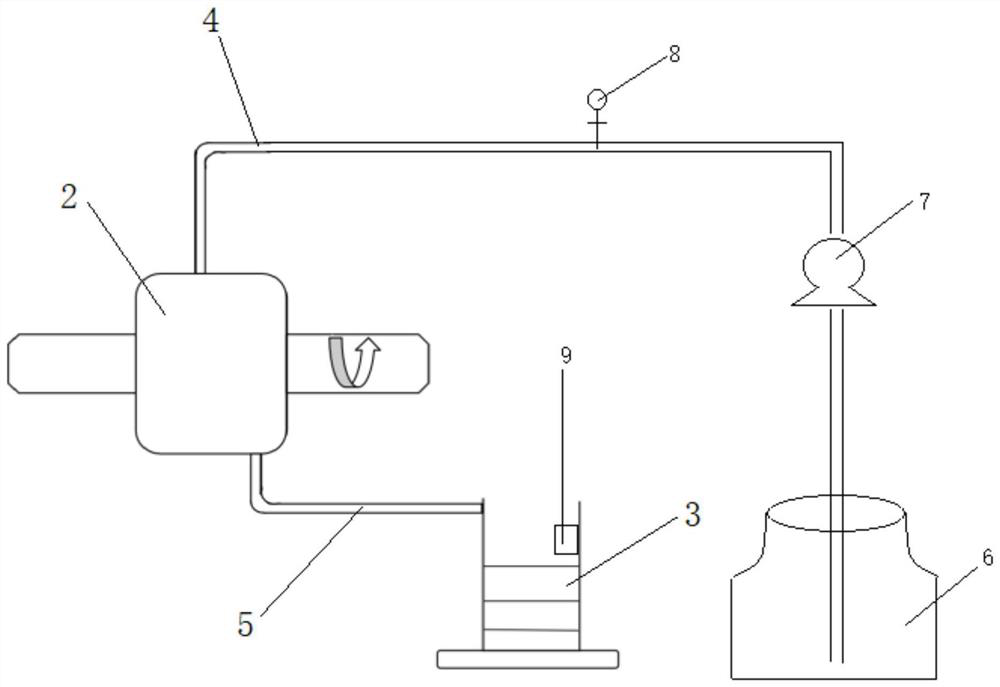

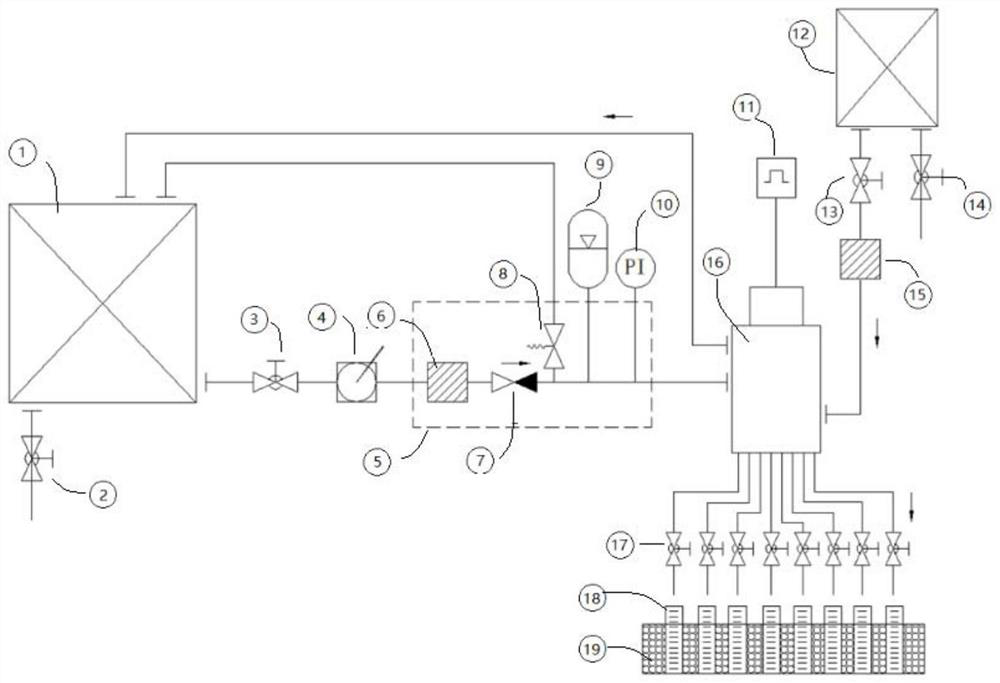

Heavy type gearbox oil flow test lubrication testing system

PendingCN110762377ARegulating pressureAdjustable temperatureEngine temperatureEngine pressureFlow transducerGear pump

The invention provides a heavy type gearbox oil flow test lubrication testing system. The heavy type gearbox oil flow test lubrication testing system is characterized by comprising an oil drip pan andan oil tank; a support for containing a test sample is arranged above the oil drip pan; the oil drip pan is provided with an oil outflow passageway and communicates with the oil tank; the system further comprises an oil outflow pipeline, the input end of the oil outflow pipeline communicates with the oil tank, and the output end of the oil outflow pipeline is located over the position where the test sample is put; and a gear pump, a heater, a heat exchanger, proportional valves, pressure sensors, a temperature sensor and a flow sensor are arranged on the oil outflow pipeline. The system aimsat the defects in the prior art, and the heavy type gearbox oil flow test lubrication testing system is provided to provide the strong data support for development, design and shaping of new products.

Owner:DONGFENG COMML VEHICLE CO LTD

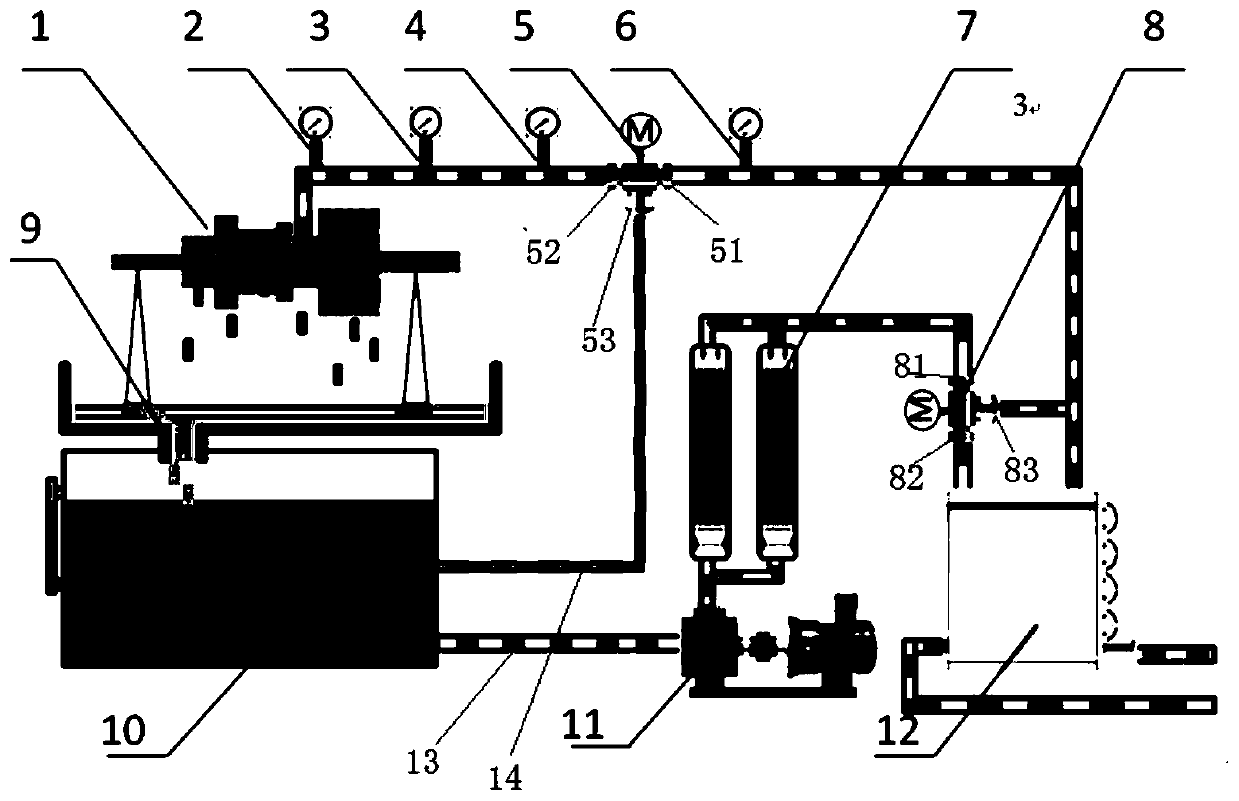

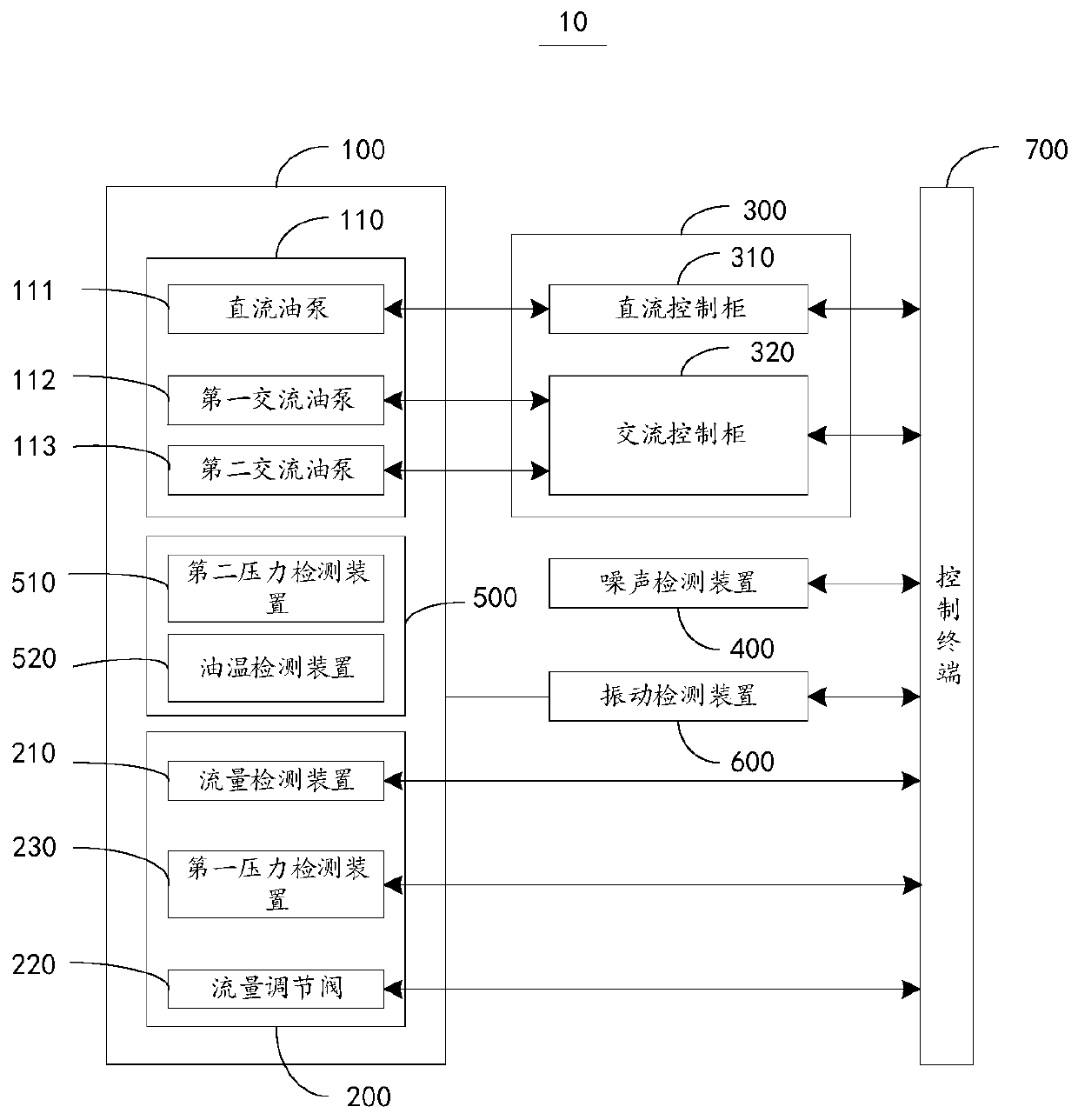

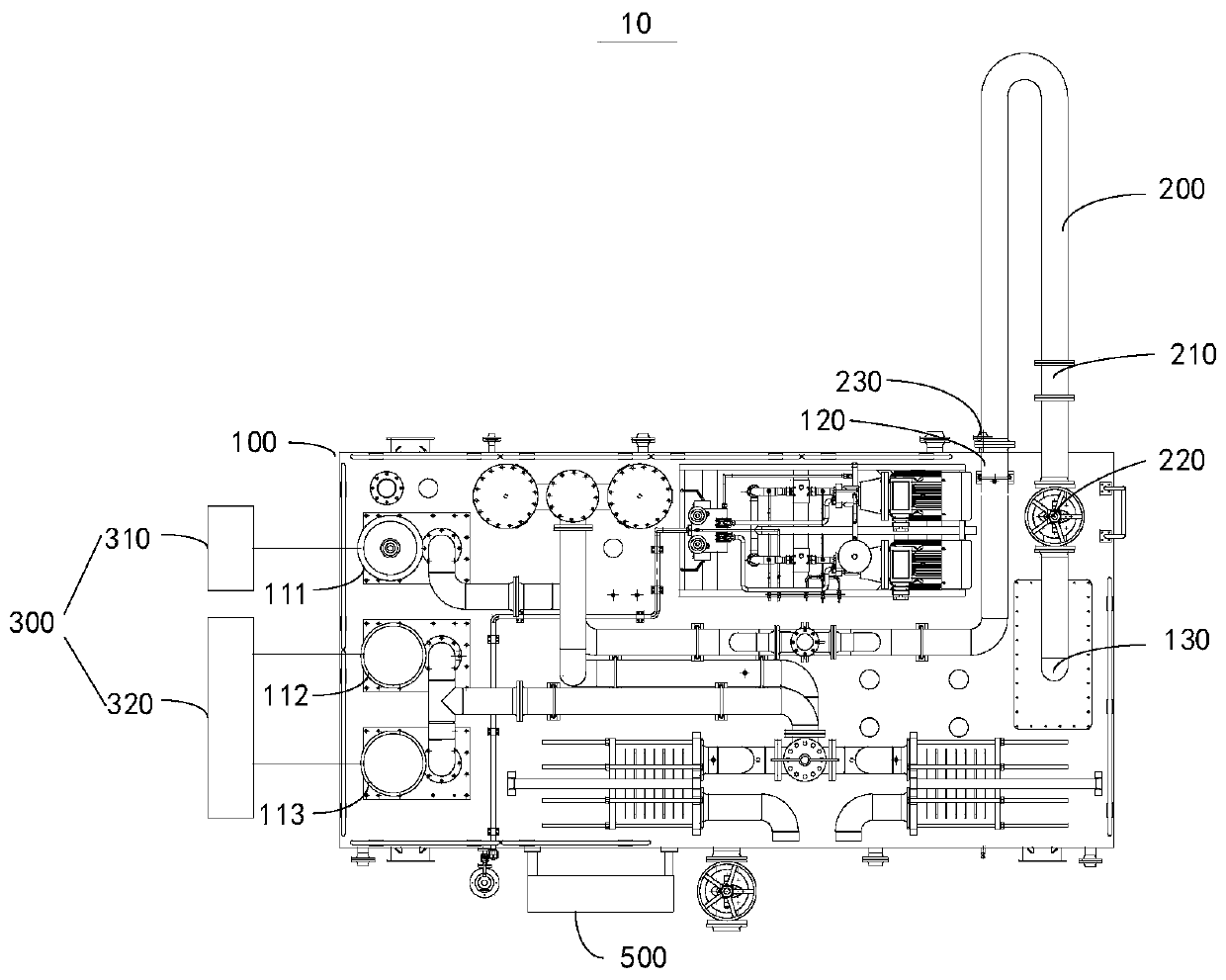

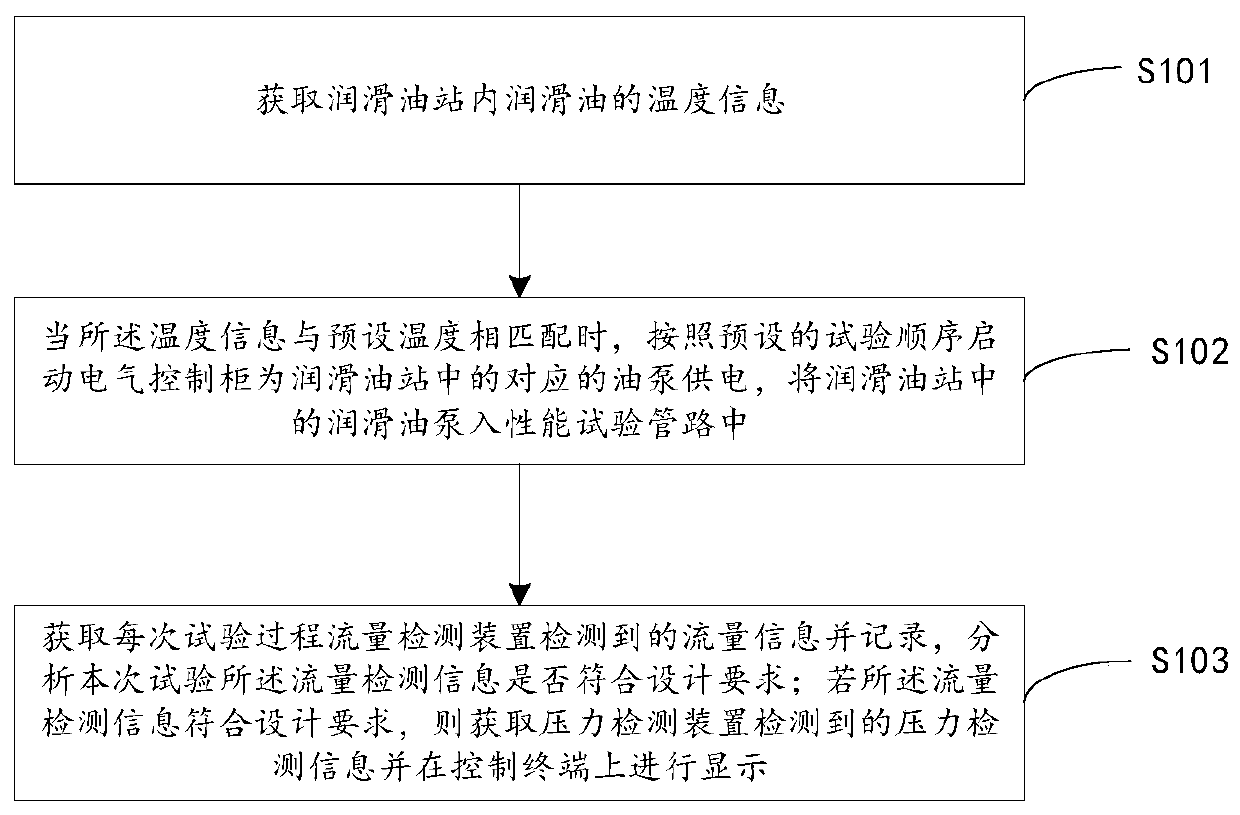

Lubricating oil station performance testing system and method

PendingCN110566797AFind design problems in timeTimely detection of manufacturing problemsEngine pressureLubrication elementsElectrical controlComputer terminal

The embodiment of the invention provides a lubricating oil station performance testing system and method. The lubricating oil station performance testing system comprises a lubricating oil station, aperformance testing pipeline, an electrical control cabinet and an electrical control cabinet connecting control terminal, wherein the electrical control cabinet is connected with an oil pump of the lubricating oil station, one end of the performance testing pipeline is connected with the output pipe port of the lubricating oil station, the other end of the performance testing pipeline is connected with the return pipe port of the lubricating oil station, the performance testing pipeline is provided with a flow detection device and a first pressure detection device which are connected with thecontrol terminal, the control terminal is used for controlling the electrical control cabinet to supply power to the oil pump, receiving flow detection information of the flow detection device and pressure detection information of the first pressure detection device, and displaying, parameters of outlet flow, outlet pressure and the like of the lubricating oil station are detected through the arranged performance testing pipeline, and various performance parameters of the lubricating oil station are acquired in advance, so that the design problem or the manufacturing problem of the lubricating oil station is conveniently found in time.

Owner:DEYANG DONGQI POWER STATION EQUIP

Intelligent lubricating oil pump station

PendingCN114508686AImprove liquidityEasy to operateLubricating pumpsLubrication containersPiston rodOil pump

The intelligent lubricating oil pump station comprises a piston rod, a piston sleeve and a sealing ring, and the piston rod is arranged in the piston sleeve in a sliding mode; a first containing bin and a second containing bin are formed in the piston sleeve, the inner diameter of the second containing bin is larger than that of the first containing bin, and the first containing bin is arranged at the end, close to the eccentric disc, of the piston sleeve. The outer wall of the end of the piston rod is sleeved with the sealing ring, and after the piston rod slides inwards and passes through the oil inlet hole, lubricating oil is injected into the second containing bin through the oil inlet hole; when the piston rod continues to move inwards until the sealing ring penetrates through the second containing bin and slides into the inner wall of the first containing bin, the sealing ring can push the lubricating oil to flow from the second containing bin to the inner wall of the first containing bin. The piston rod is convenient to operate, the sealing ring arranged on the outer wall of the piston rod in a sleeving mode pushes lubricating oil to flow into the first containing bin from the second containing bin so as to increase the flowability of the lubricating oil between the piston rod and the piston sleeve, and the service life of equipment is prolonged.

Owner:南通市华东润滑设备有限公司

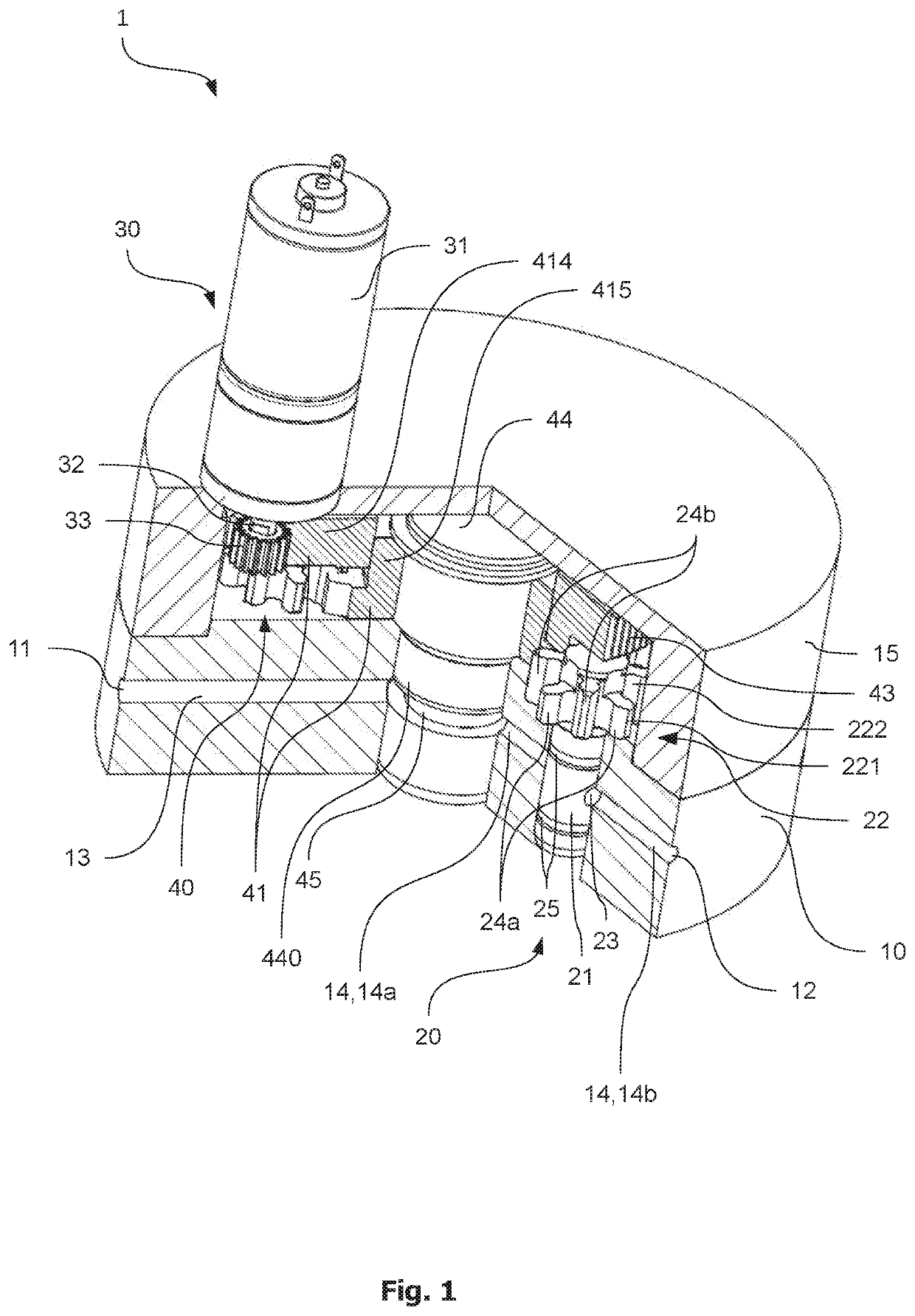

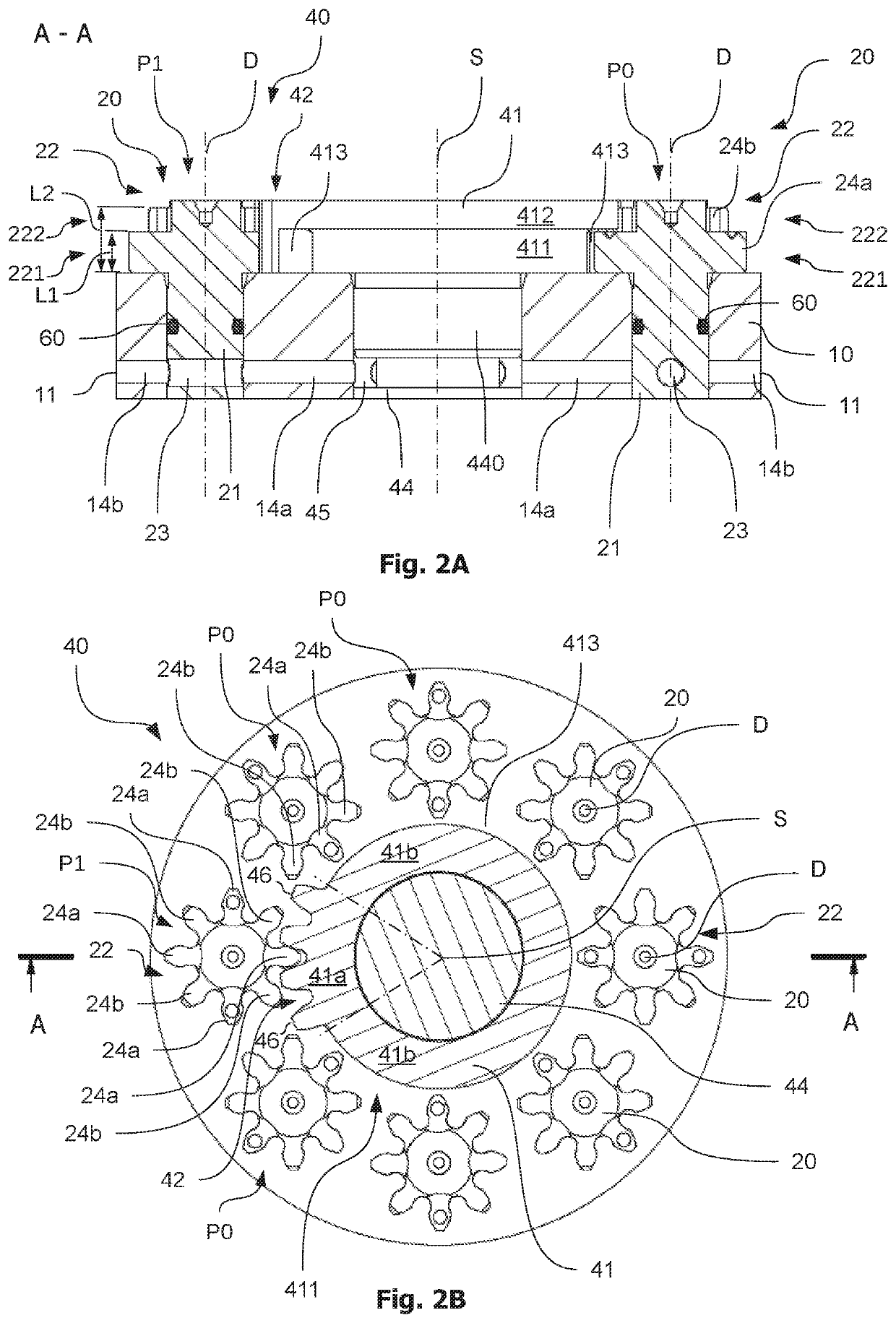

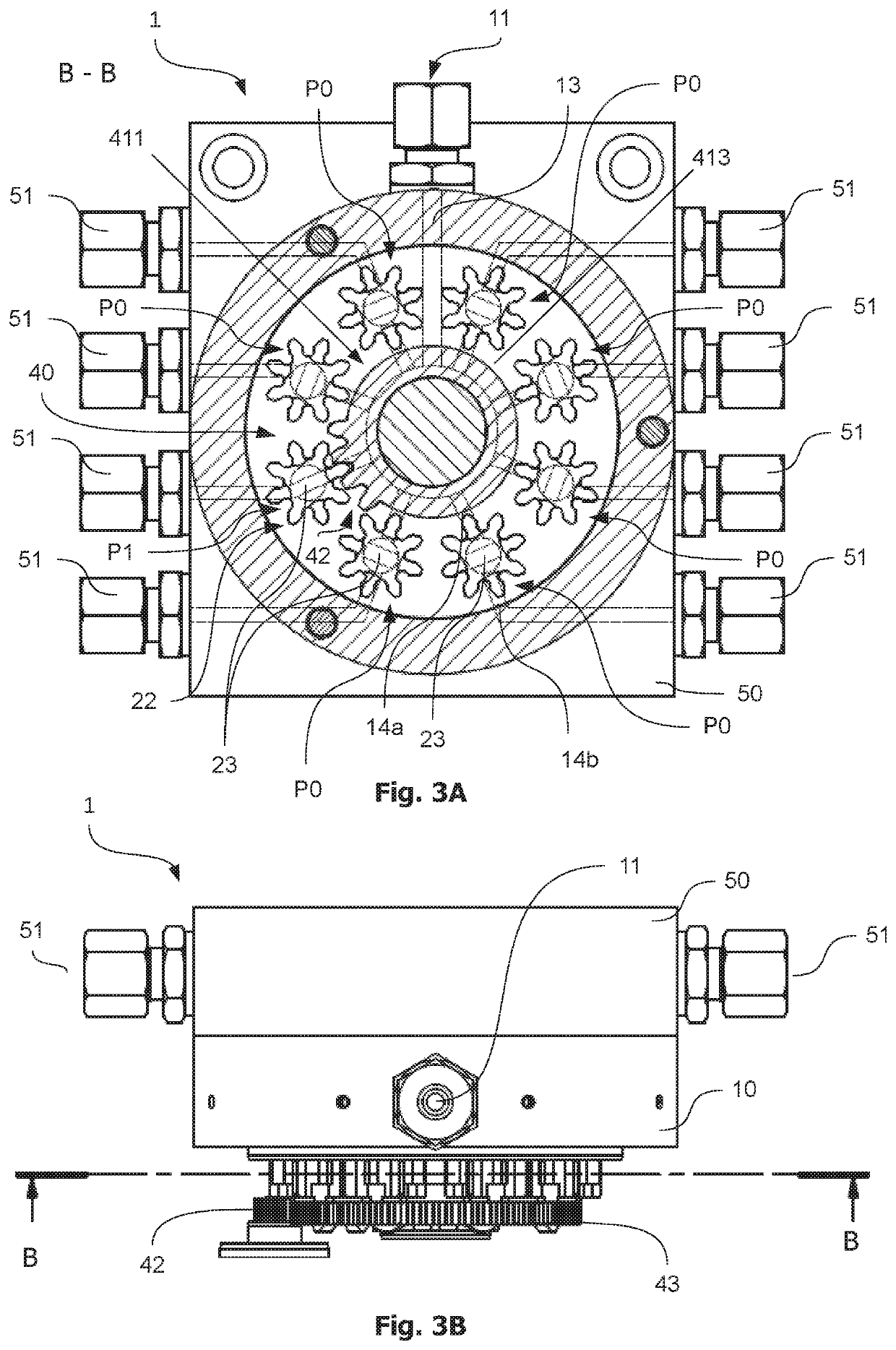

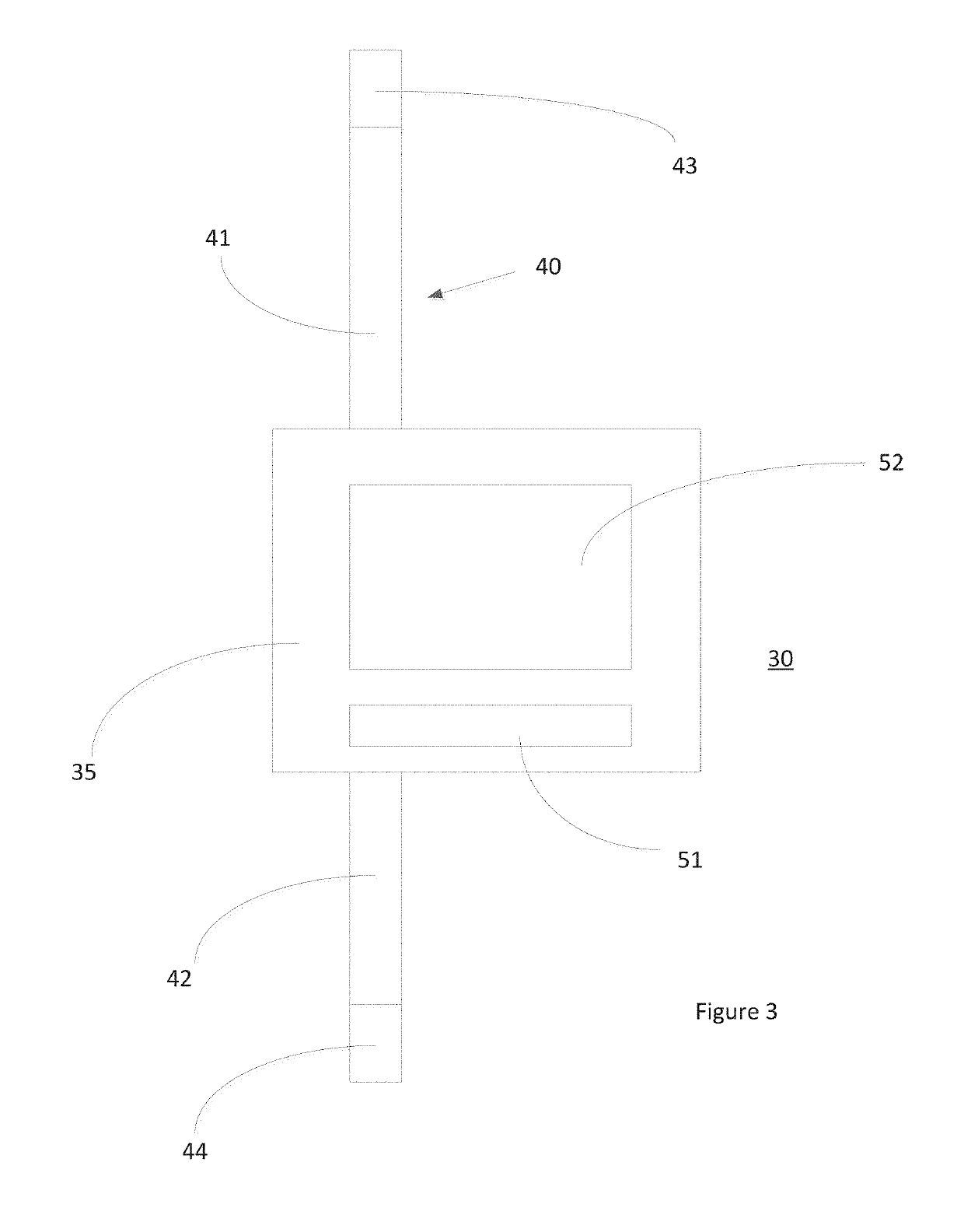

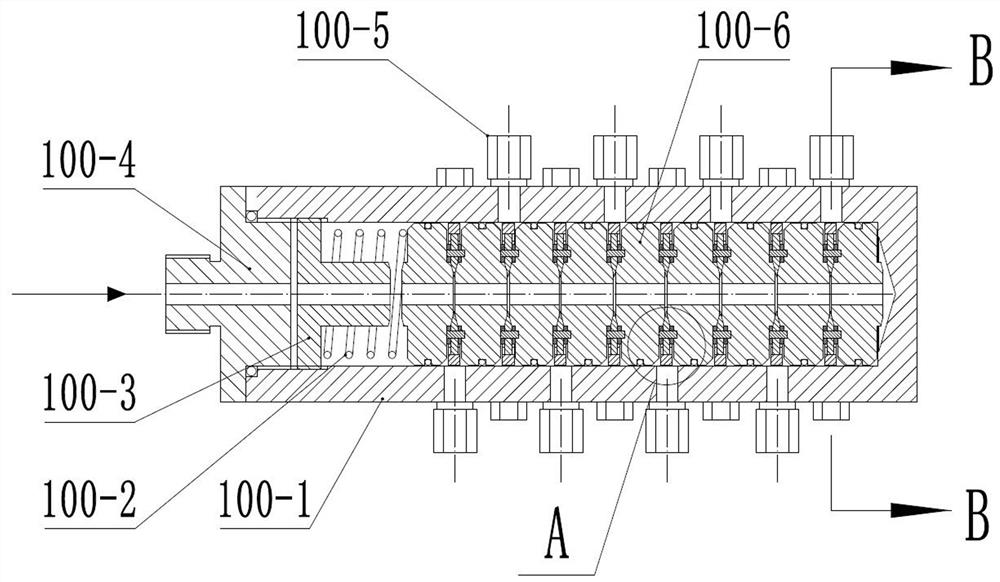

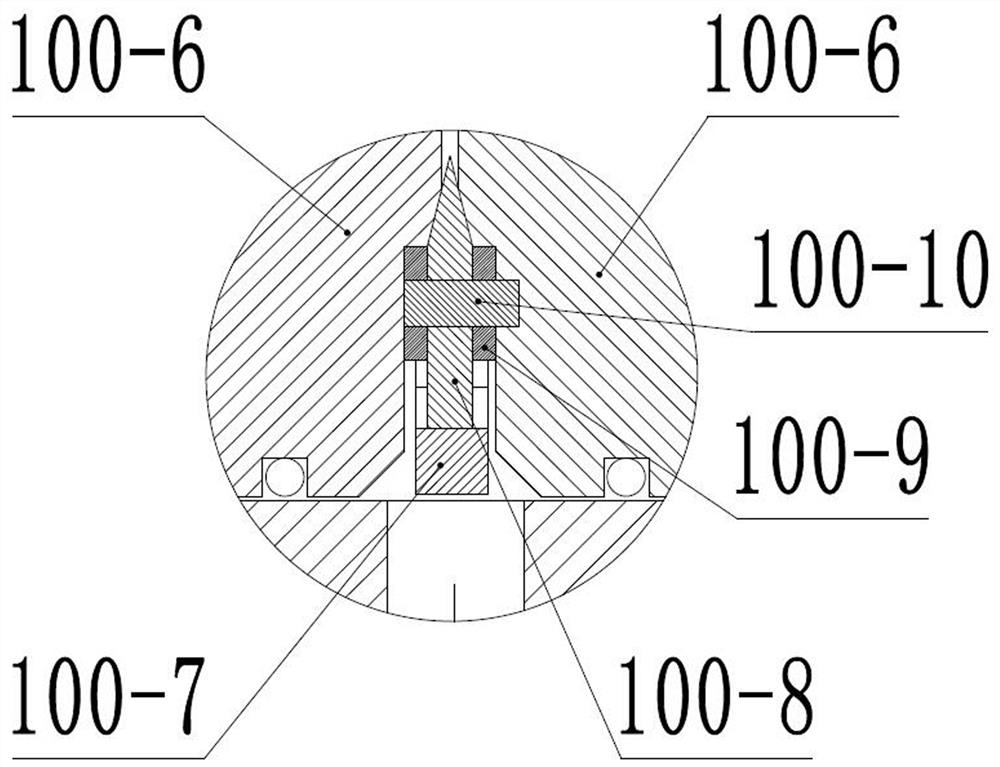

Lubricant Distributor, Especially Sectional Distributor

ActiveUS20200003363A1Reliable controlEasy to implementOperating means/releasing devices for valvesMultiple way valvesGear wheelControl engineering

The invention relates to a lubricant distributor, in particular a sectional distributor, for distributing lubricant to at least one lubrication point, comprising a distributor body having an inlet opening for lubricant which is fluidically connected to at least one outlet passage, which opens into an outlet opening of the distributor body, a rotary valve which is rotatably mounted in the distributor body and which is adjustable between an open position of the rotary valve, in which the outlet passage is open in order to allow lubricant to pass through to the outlet opening, and a closed position of the rotary valve, in which the outlet passage is closed, a drive, in particular an electromotive drive, which is coupled to a control gear, comprising a control gearwheel having at least one control toothing section engageable with a toothing of the rotary valve to move the rotary valve between the open position and the closed position. In addition, the invention relates to a method for distributing lubricant to at least one lubrication point.

Owner:GROENEVELD BEKA GMBH

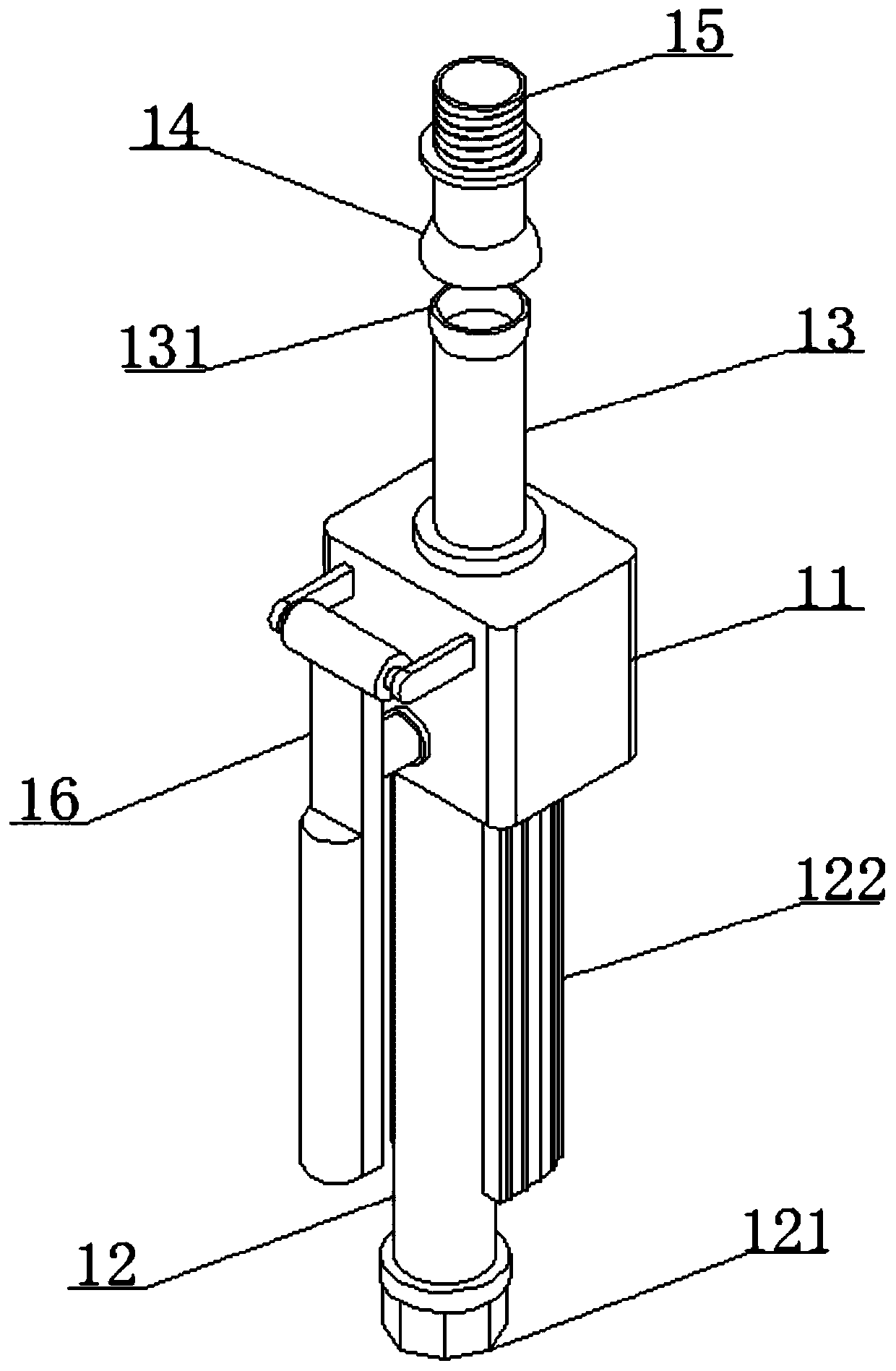

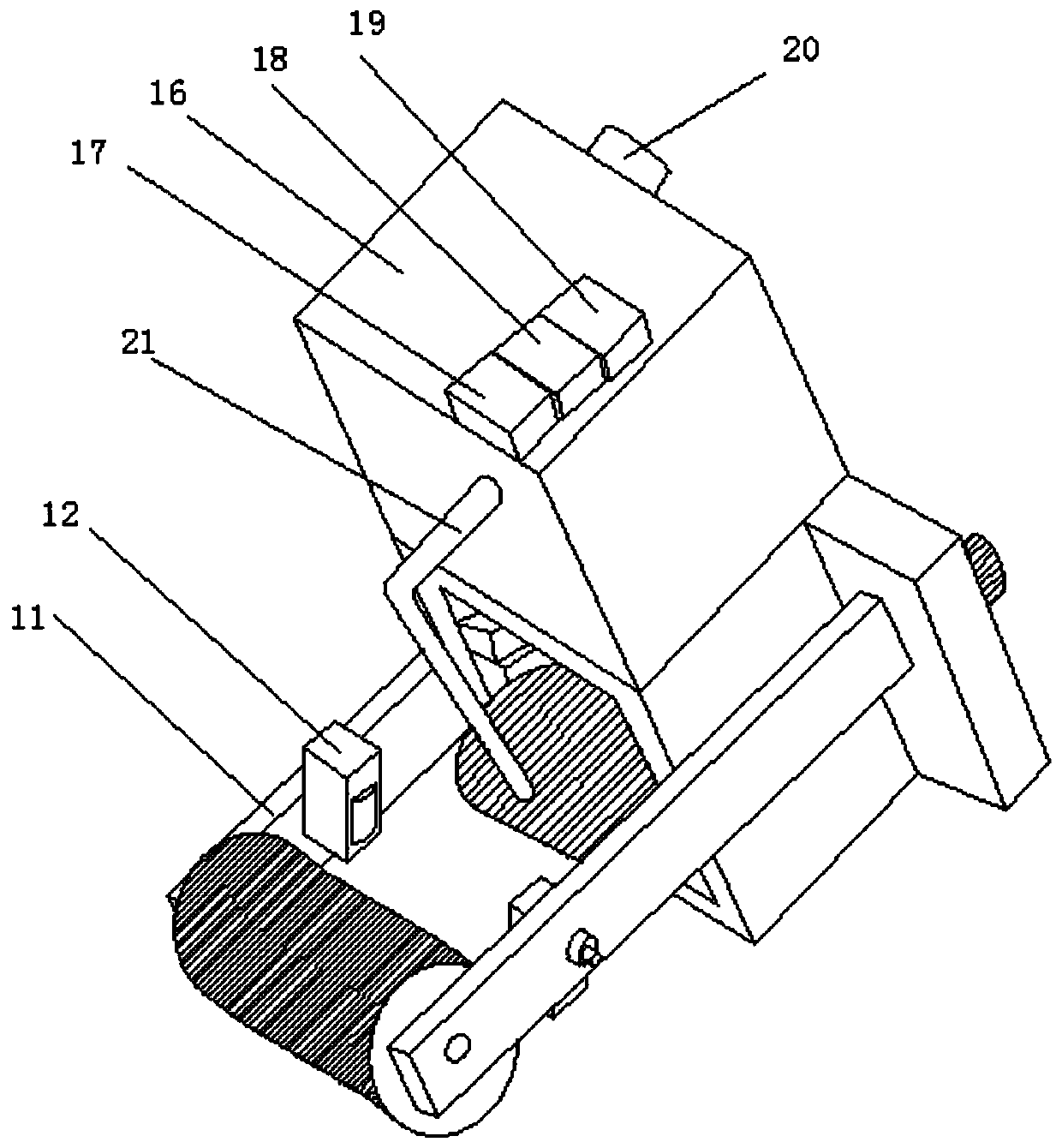

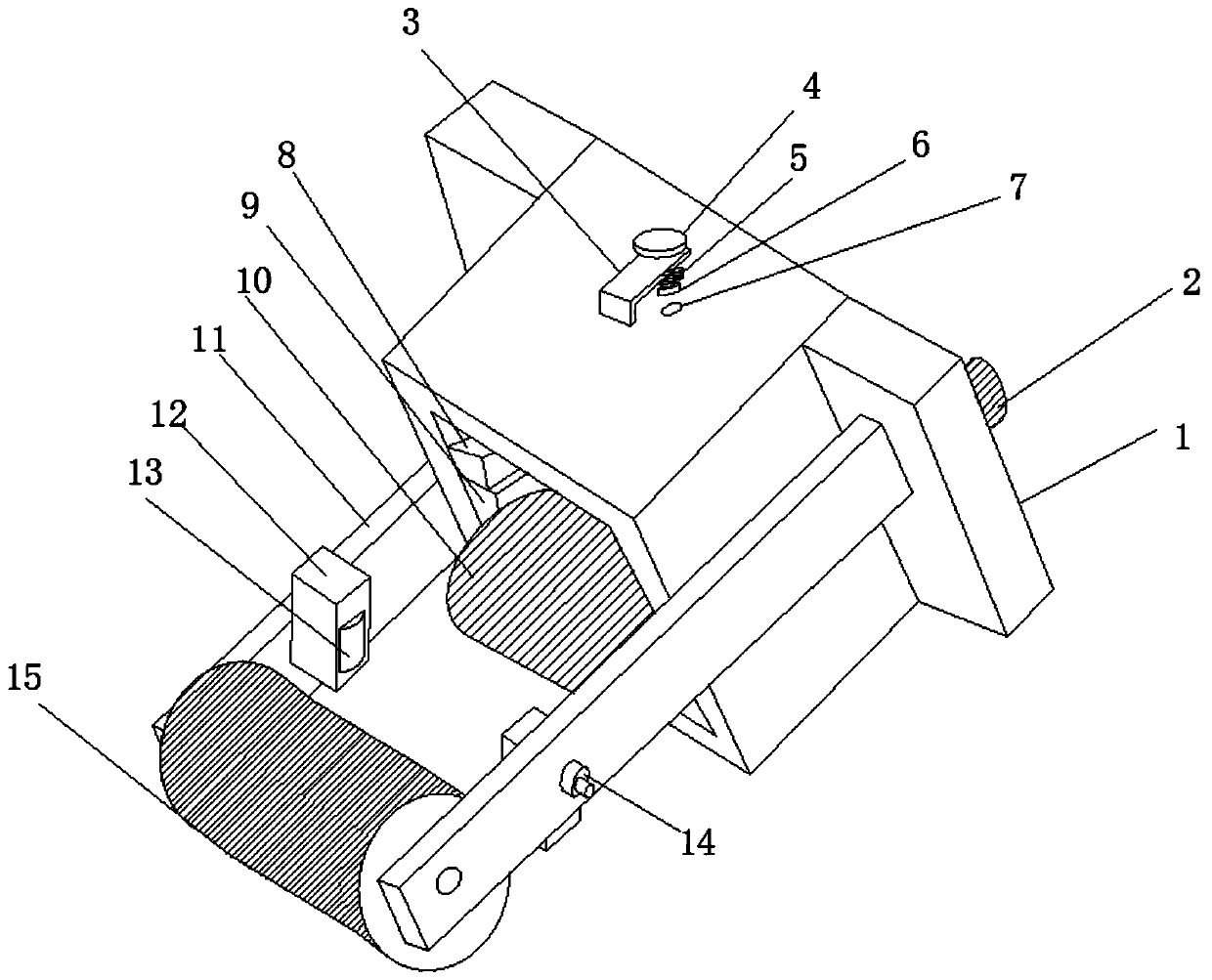

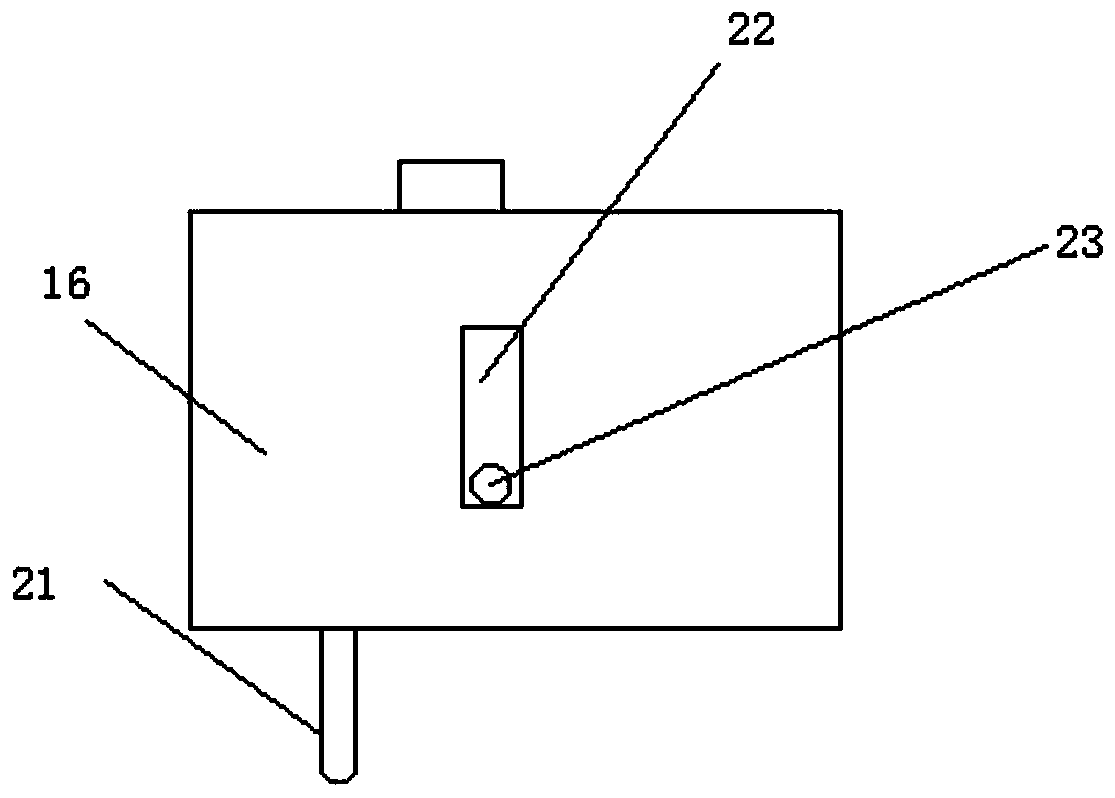

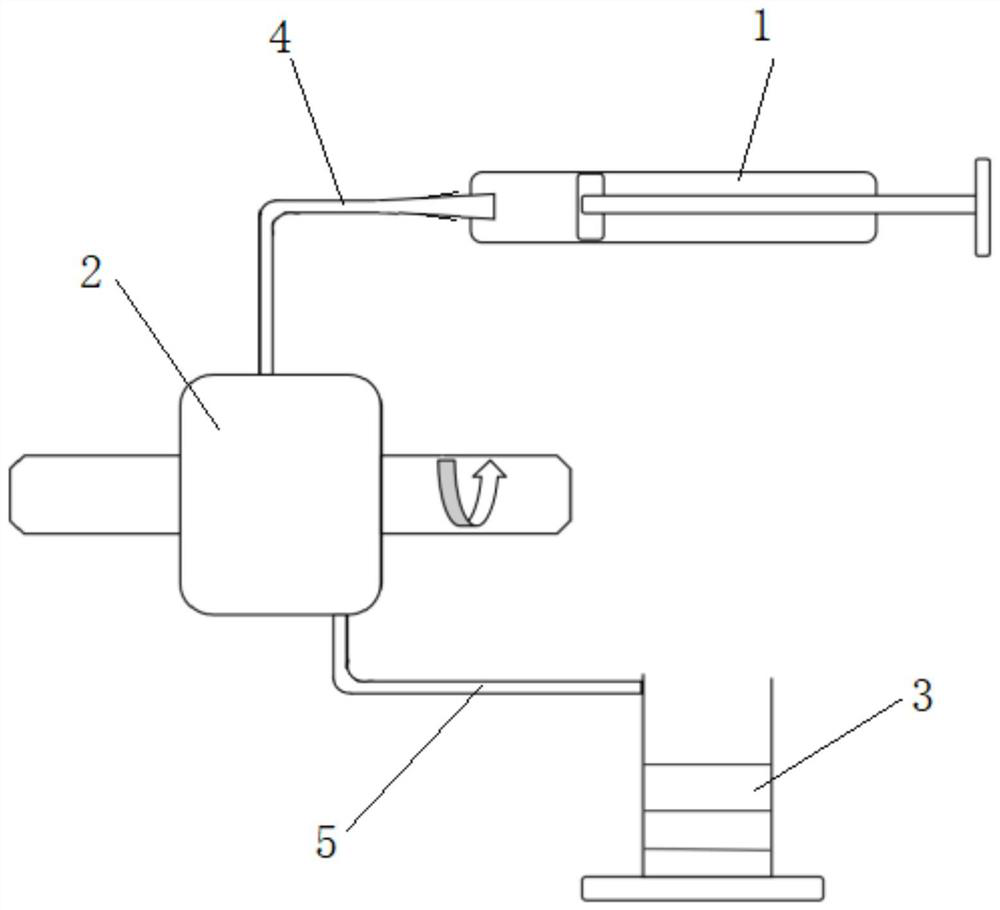

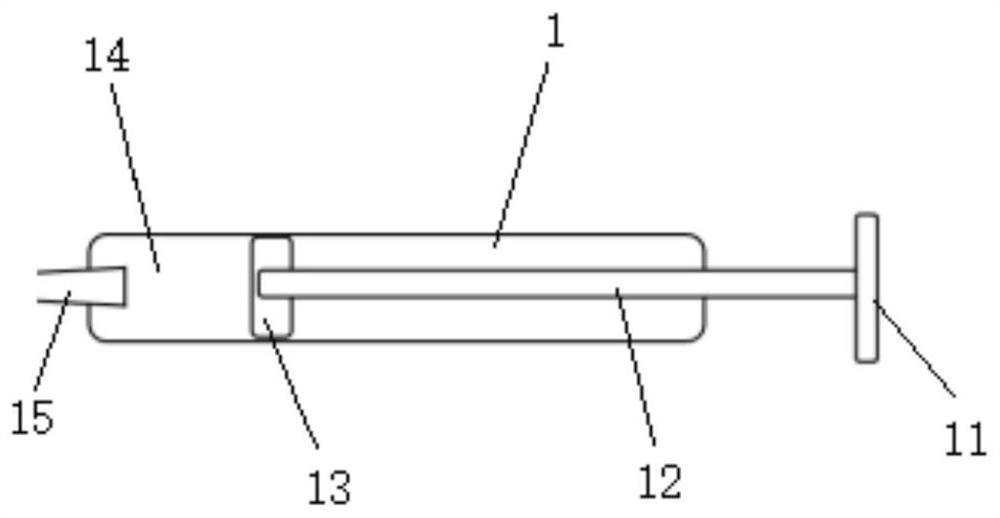

Device and method for replacing lubricating grease of bearing of rotating equipment

PendingCN114738652AShorten transition timeWell formedEngine levelsLubricant transferOil and greaseWaste oil

The invention discloses a rotating equipment bearing lubricating grease replacement device and method, and the device comprises a new lubricating grease filling device which is arranged above a rotating equipment bearing, is connected to the rotating equipment bearing through an oil injection pipeline, and is used for filling the rotating equipment bearing with lubricating grease; and the measuring tool is arranged below the rotating equipment bearing, is connected to a waste oil outlet of the rotating equipment bearing through a grease collecting pipeline, and is used for measuring the volume of grease discharged by the rotating equipment bearing. The lubricating grease is added in the speed reduction and idle running process of equipment, old lubricating grease is still in a moving state, the temperature is not prone to being reduced, and flowing and discharging of the lubricating grease are easily guaranteed; and the filled new lubricating grease can easily absorb heat, so that the conversion time of the lubricating grease from a semi-solidified state to a flowable state is shortened, and a protective oil film is easily formed.

Owner:HUANENG CLEAN ENERGY RES INST

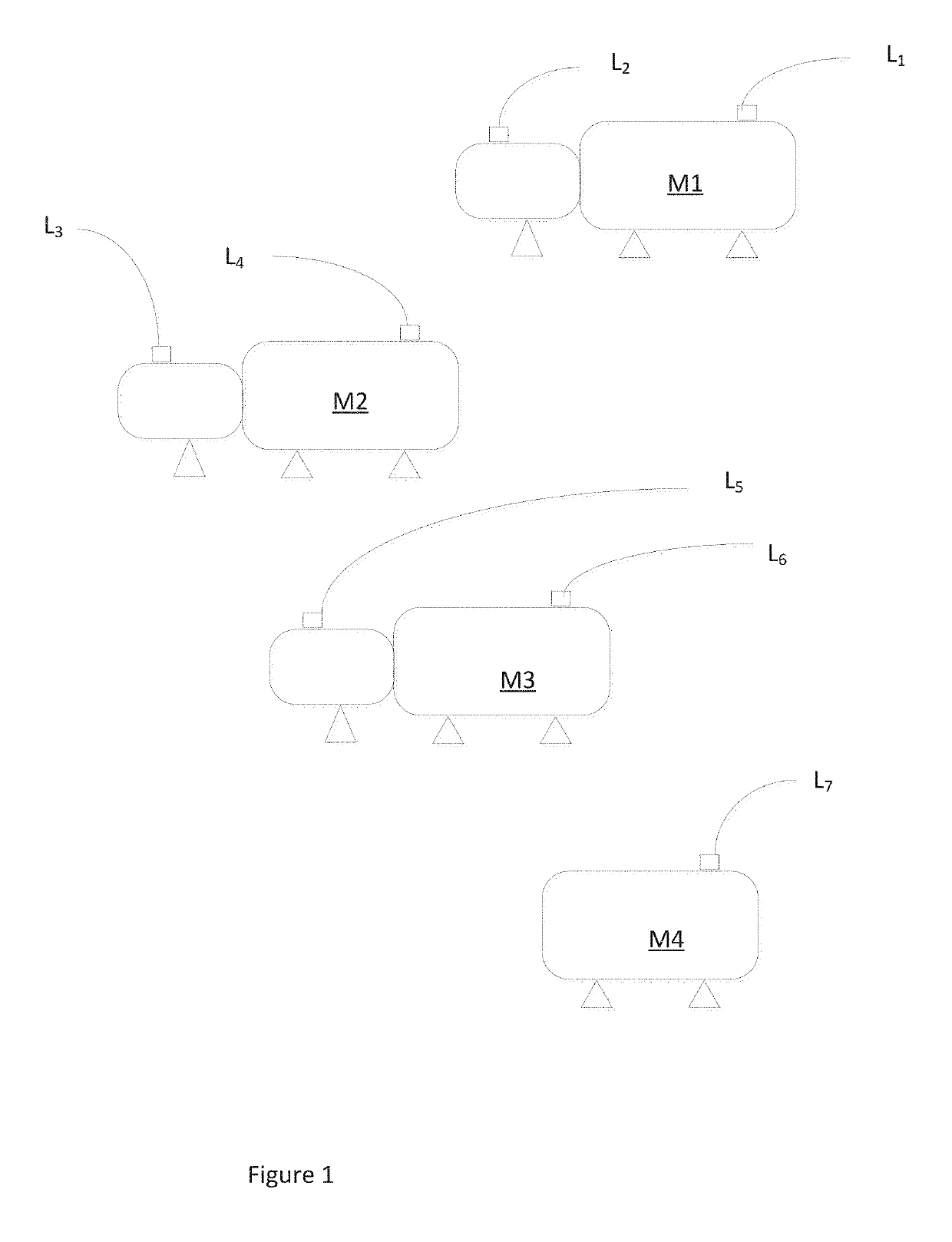

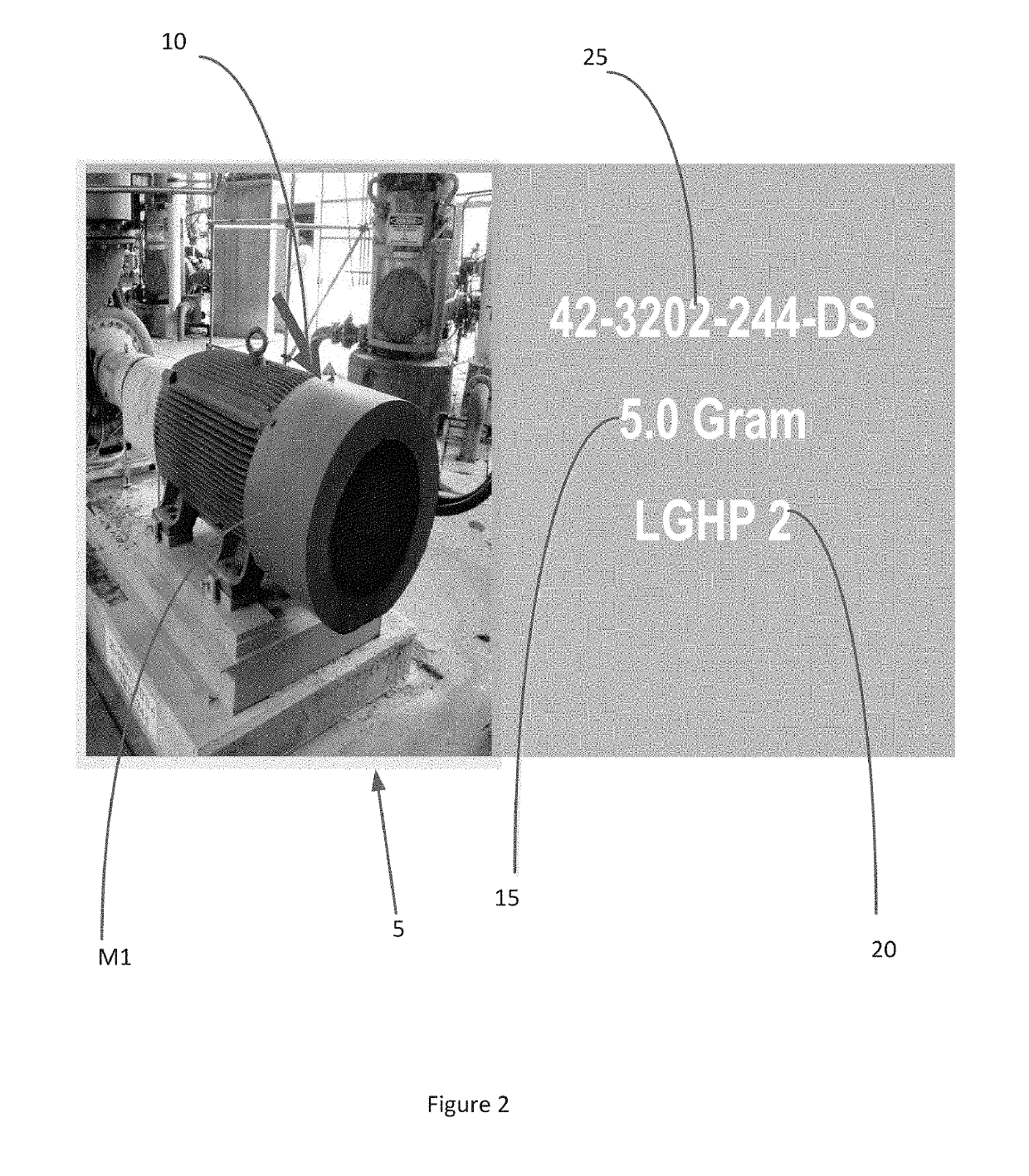

System and method for executing a lubrication plan

ActiveUS10422475B2Reduce in quantityReduce the possibilitySignal processingFlow propertiesComputer graphics (images)Display device

A method of executing a lubrication plan for lubricating a plurality of machines with grease is provided. Each machine includes one or more lubrication points where grease is delivered. The method defines a set of instructions for the lubrication plan, including at least a series of prescribed grease volumes to be delivered at a corresponding series of lubrication points; generating an image of each lubrication point in the series, including a visual indication of the location of that lubrication point on the machine; storing the set of instructions and each generated image in a system including a grease meter and a display device; displaying a generated image of a lubrication point on the display device, including the prescribed grease volume be delivered there; delivering grease at that lubrication point via the grease meter, displaying a generated image of a further lubrication point, including the prescribed grease volume be delivered there.

Owner:AB SKF

Multi-point oil outlet lubrication pumping system

PendingCN114704758AFlow adjustableSignal processingSafety/regulatory devicesOil separationLubrication

The invention relates to the technical field of lubricating systems, and particularly discloses a multi-point oil outlet lubricating pumping system which comprises a machine shell and an oil tank arranged on the machine shell, an oil inlet device used for adding oil into the oil tank is arranged on the machine shell, and an oil way distribution device and a conveying device are arranged on the machine shell; the oil way distribution device comprises an oil storage block connected to the machine shell, an oil storage cavity is formed in the oil storage block, the oil outlet end of the conveying device communicates with the oil storage cavity, and a plurality of oil outlet assemblies are arranged on the oil storage block. The oil outlet assembly comprises an oil separation cover connected to the cavity wall of the oil storage cavity, a first through hole is formed in the oil separation cover, an oil separation barrel is rotationally connected to the oil storage block, the oil separation barrel extends into the oil storage cavity and is attached to the oil separation cover, a first through hole is formed in the oil separation barrel, an adjusting piece is arranged on the oil storage block, and the first through hole is formed in the adjusting piece. And the adjusting piece is used for driving the oil separation barrel to rotate.

Owner:丽睿声科技(南京)有限公司

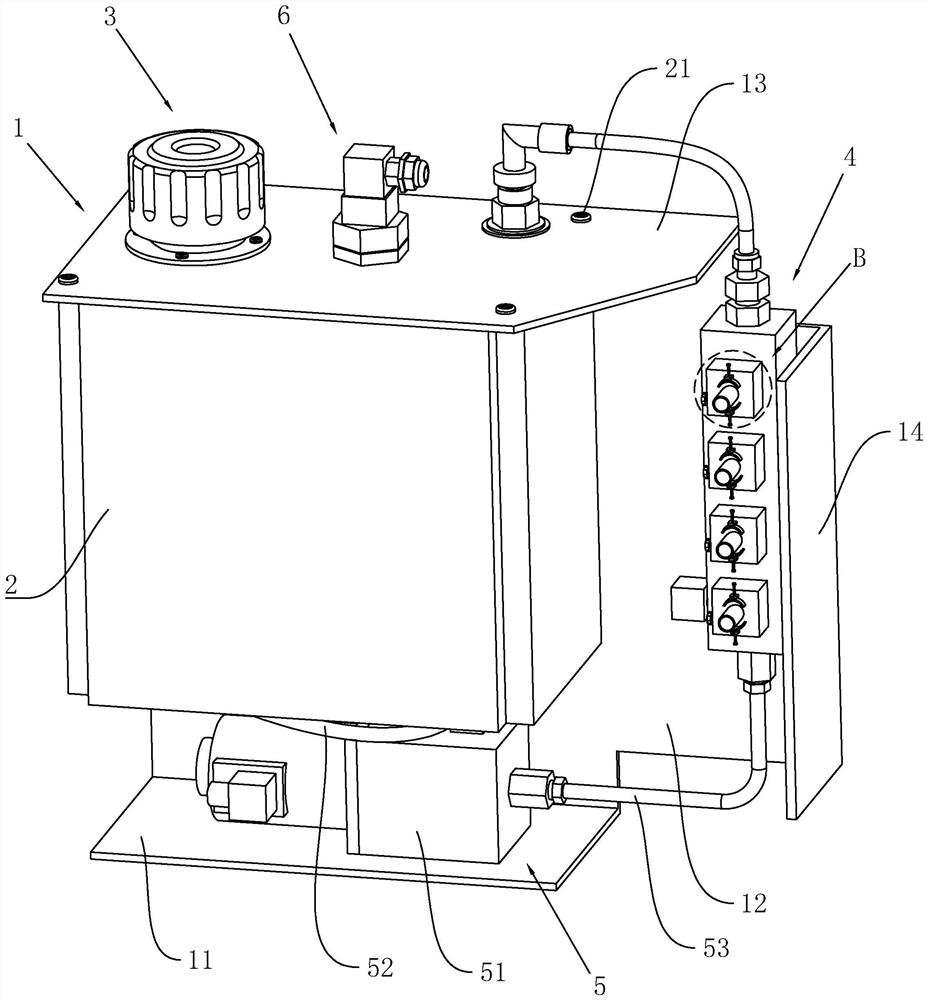

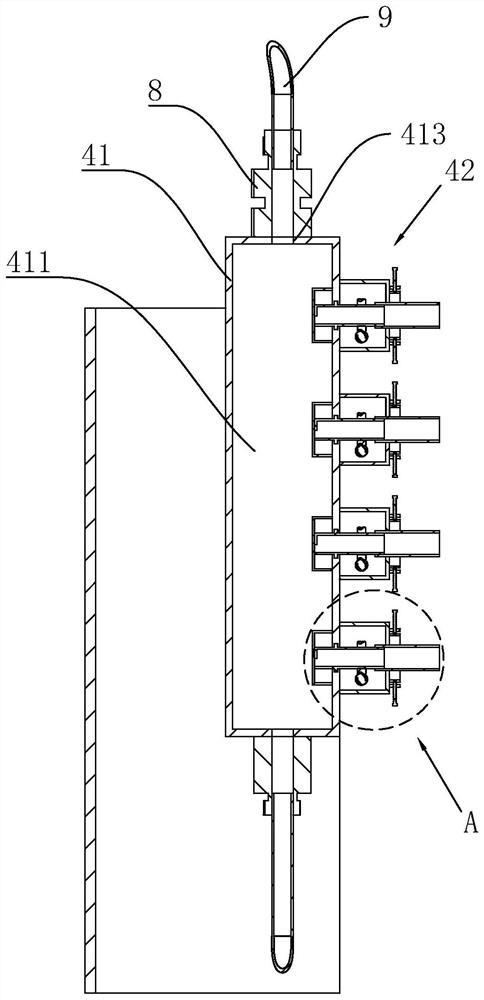

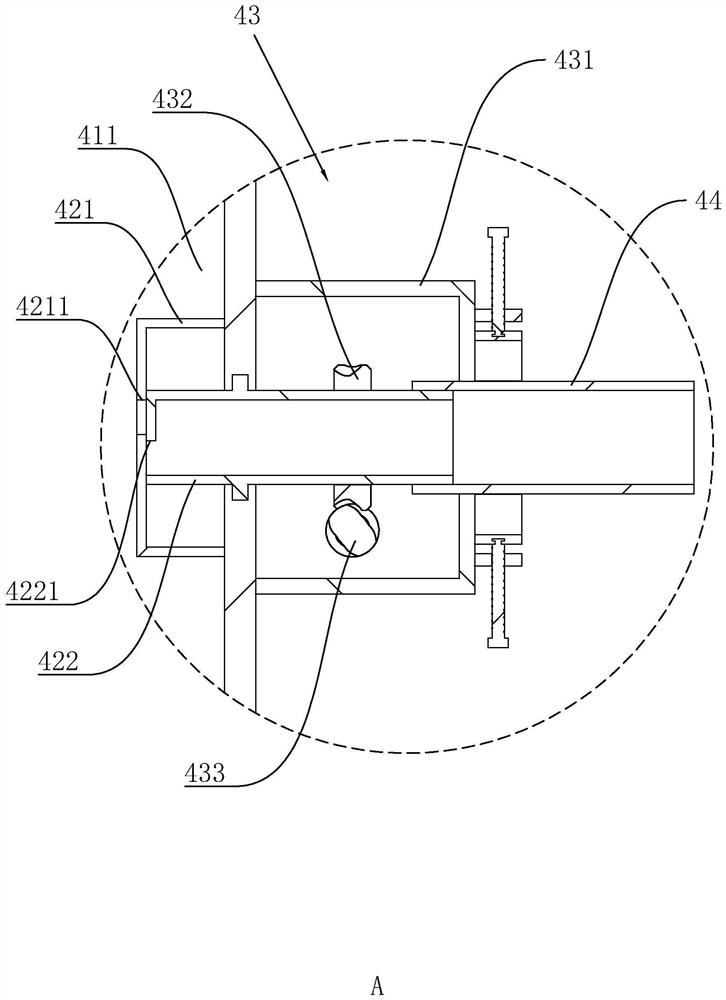

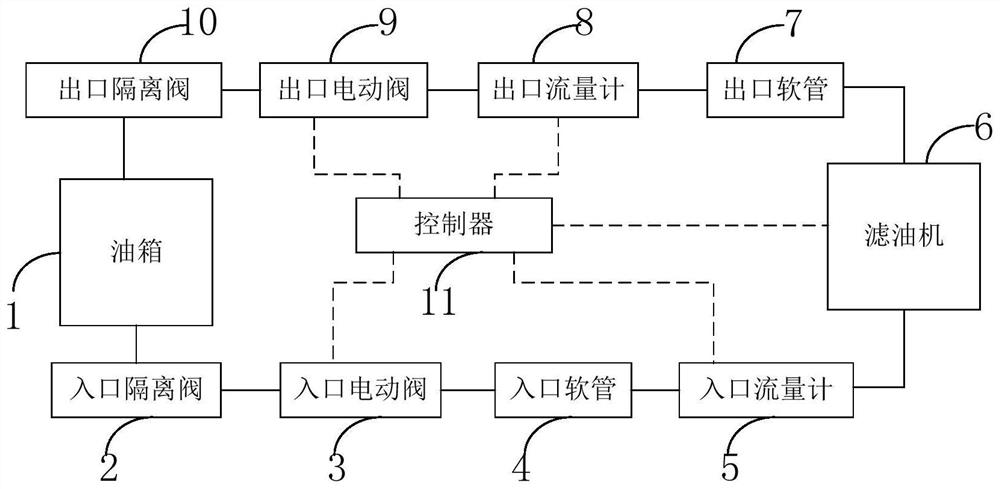

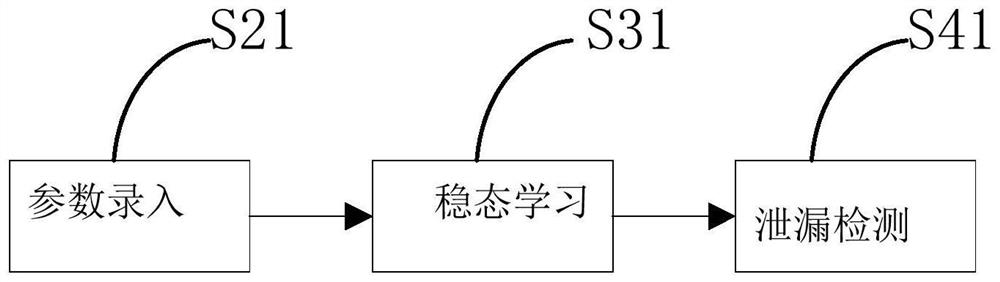

Threshold self-learning oil filter pipeline leakage detection and protection device and method

PendingCN114576542AReduce leakageRealize automatic protection controlSignal processingPipeline systemsProcess engineeringControl theory

The invention discloses a threshold self-learning oil filter pipeline leakage detection and protection device and method. A first flow meter, a second flow meter, a first electric valve and a second electric valve are arranged on an inlet pipeline and an outlet pipeline of an oil filter; the first electric valve and the second electric valve are used for collecting the flow in the inlet pipeline and the outlet pipeline, the controller is used for comparing the flow with corresponding reference flow data to judge whether pipeline leakage exists or not, and if the pipeline leakage exists, the controller immediately gives an alarm, the oil filter is shut down, and the inlet electric valve and the outlet electric valve are closed at the same time. When leakage occurs, inlet and outlet electric valves of an oil filter and oil using equipment can be rapidly closed, the leakage amount of lubricating oil is reduced to the maximum extent, automatic protection control over leakage in the lubricating oil filtering process is achieved, manual closing is not needed, the safety of oil treatment work is improved, and the working intensity of field operators is reduced. The device can effectively prevent oil leakage, realizes unattended operation in the oil treatment process, and saves manpower.

Owner:XIAN THERMAL POWER RES INST CO LTD

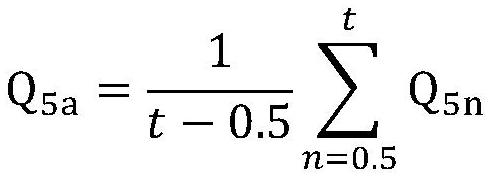

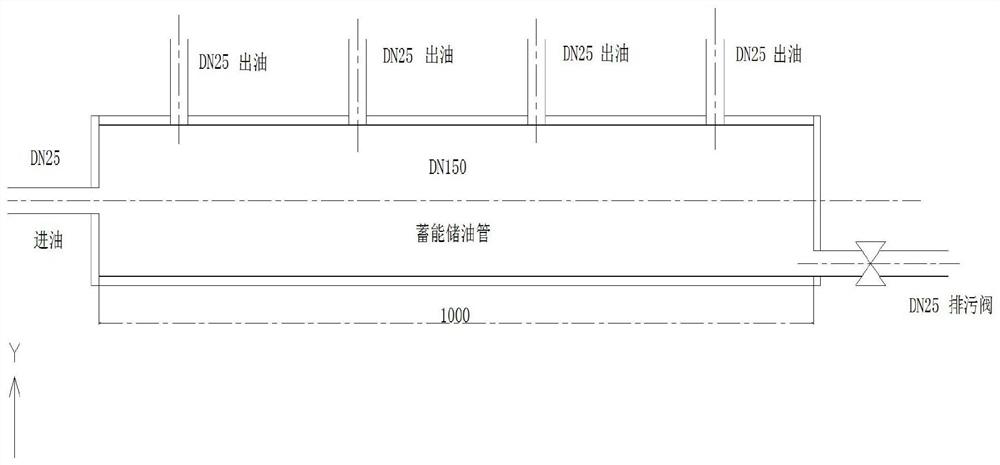

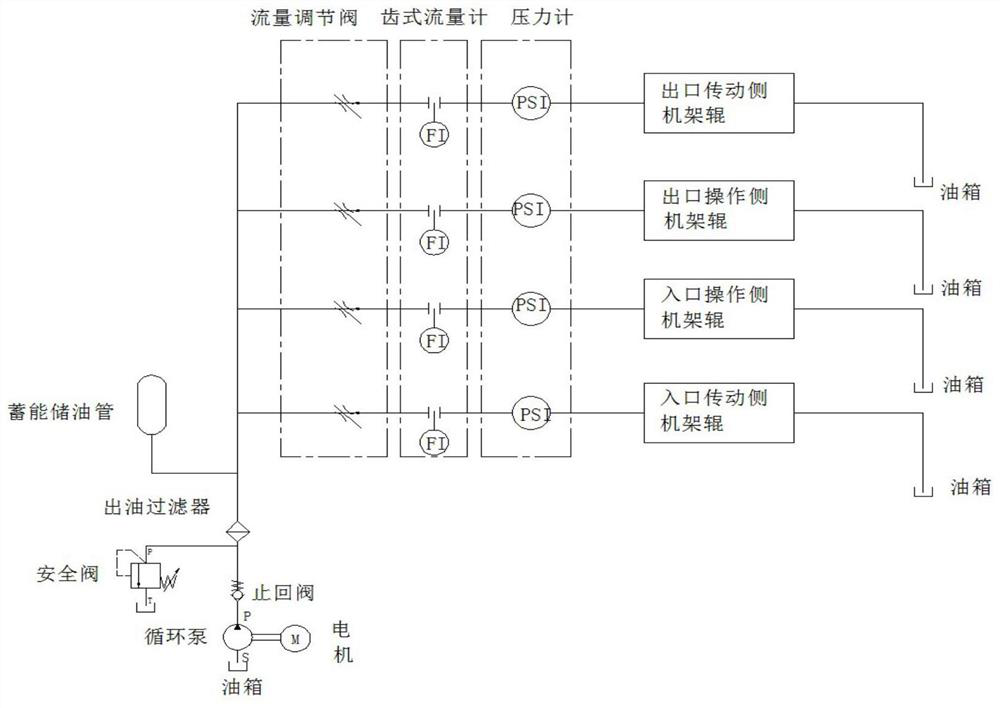

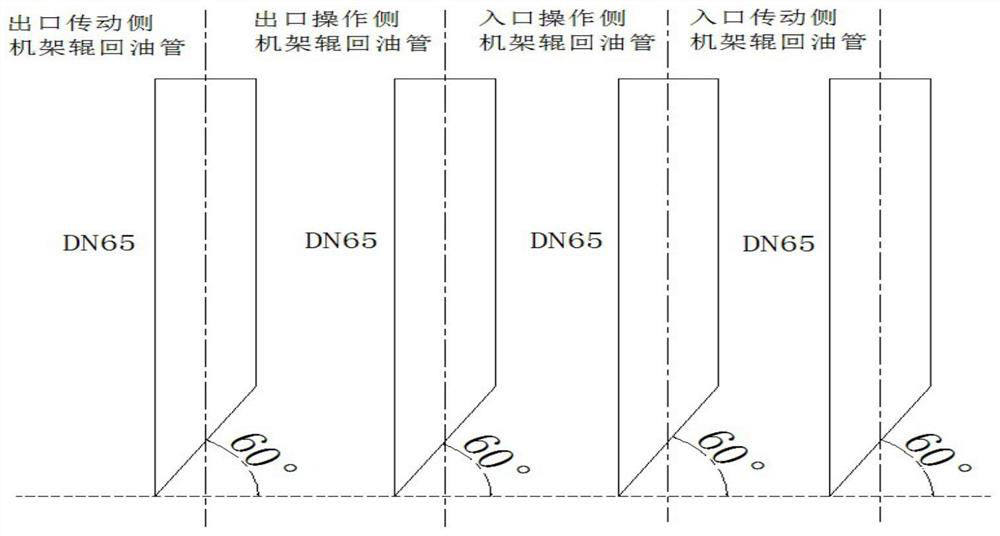

Method for improving use reliability of lubricating system for 5M rolling mill stand roll

PendingCN113653931AExtended service lifeImprove lubricationEngine pressureRolling safety devicesThermodynamicsLubrication

The invention discloses a method for improving the use reliability of a lubricating system for a 5M rolling mill stand roll. The method for improving the use reliability of the lubricating system for the 5M rolling mill stand roll is characterized in that a pipeline of the lubricating system for the rolling mill stand roll is transformed, the design that one main pipe of the original pipeline is divided into four branch pipes to lubricate four stand roll user points separately, finally, the four branch pipes are gathered to the main pipe and return to an oil tank, and only the main pipe is provided with a pressure monitor is changed into the design that the four stand roll user points are provided with an independent loop for lubrication separately, the loops do not influence one another, each loop is independently provided with a flow meter and a pressure sensor, and real-time monitoring for lubrication pressure and flow of the four stand roll user points is realized. According to the invention, poor lubrication and uneven lubrication of a stand roll bearing are effectively avoided, and the service life of the stand roll is prolonged.

Owner:NANJING IRON & STEEL CO LTD

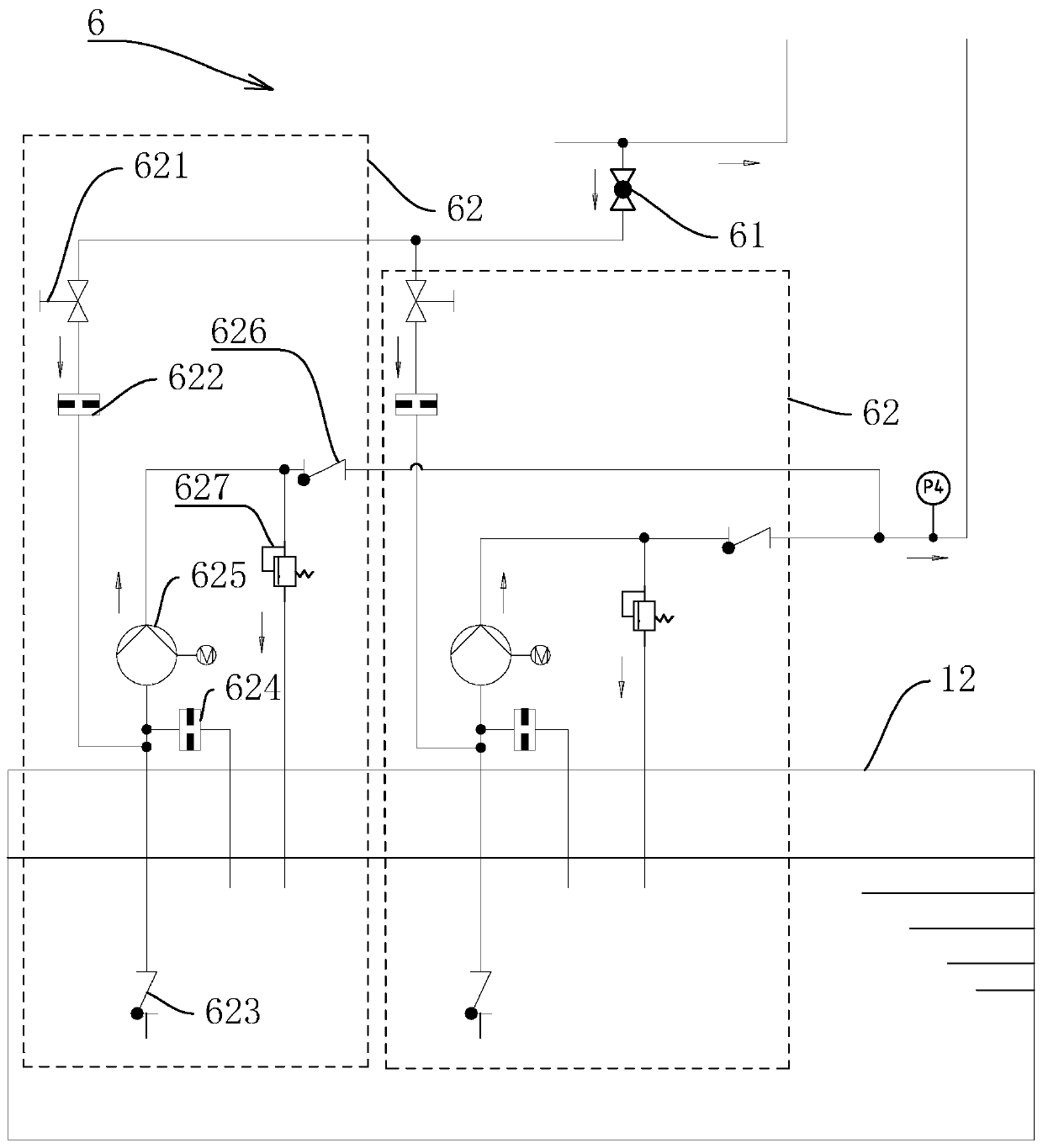

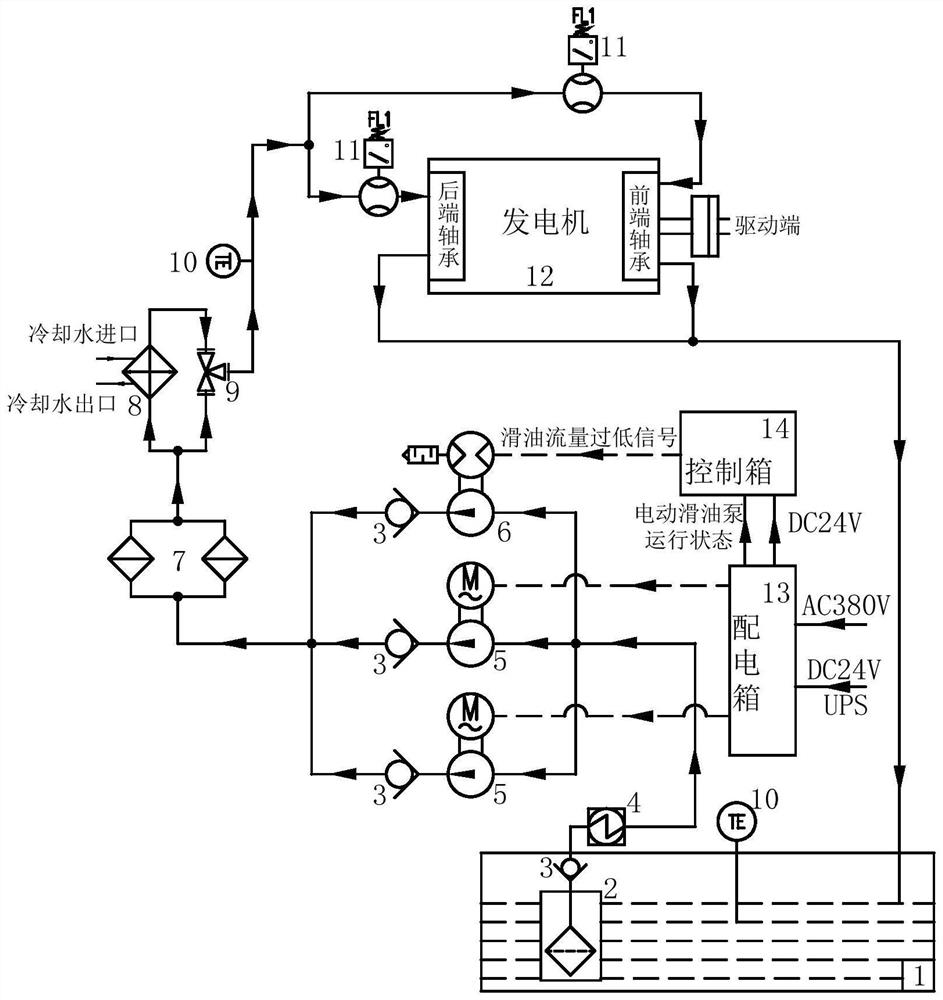

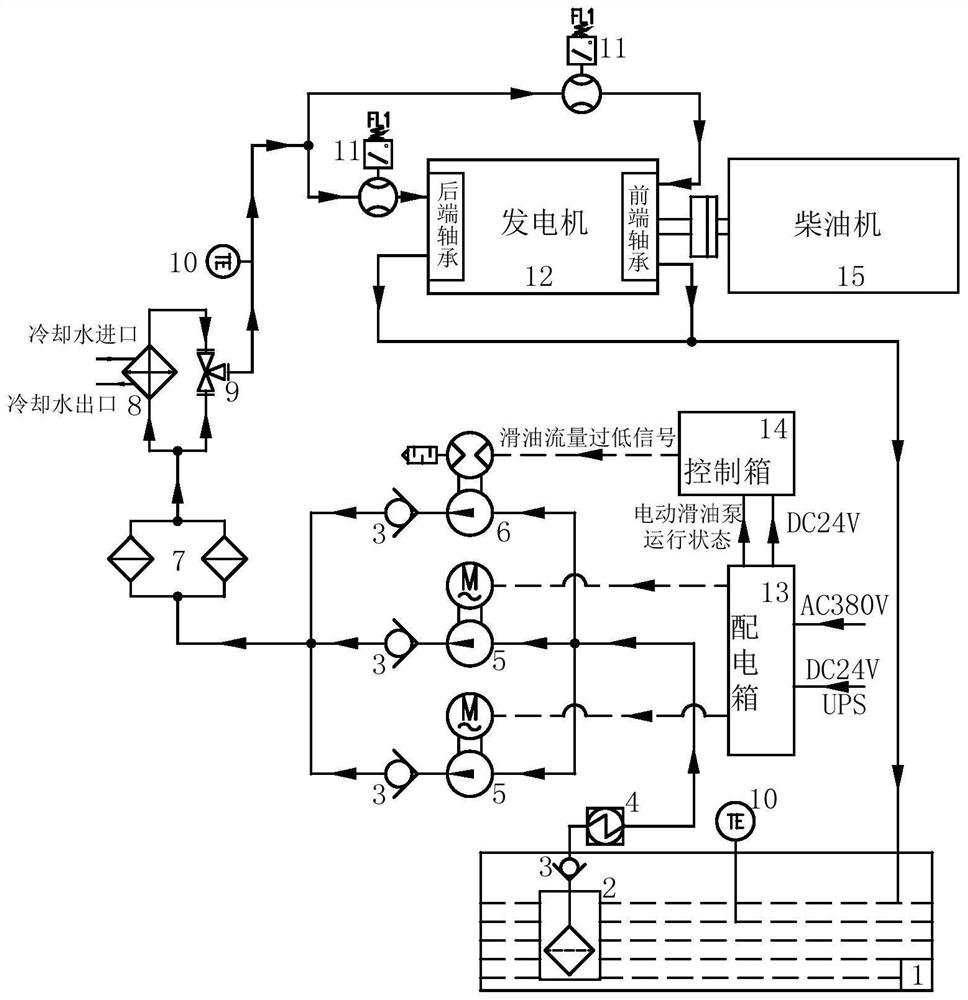

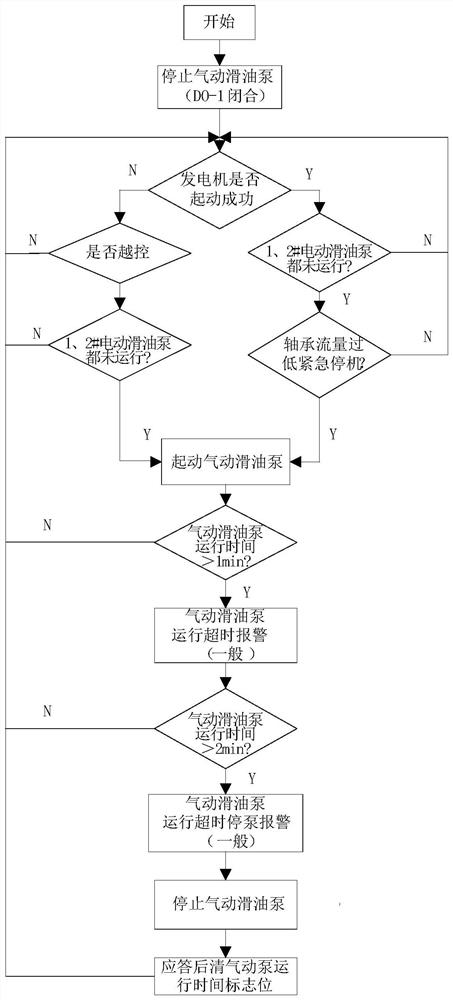

Generator lubricating oil system based on pneumatic pump and electric pumps and safety protection method

PendingCN113566103AGuaranteed uptimeAvoid security issuesWaterborne vesselsBearing componentsControl theoryMotronic

The invention relates to a generator lubricating oil system based on a pneumatic pump and electric pumps and a safety protection method. The system comprises a generator lubricating oil tank, the electric lubricating oil pumps, the pneumatic lubricating oil pump, a distribution box and a control box; the input ends of the two electric lubricating oil pump and the pneumatic lubricating oil pump are connected with the generator lubricating oil tank, and the output ends of the two electric lubricating oil pump and the pneumatic lubricating oil pump are connected with a generator, and lubricating oil is provided for bearings at the front end and the rear end of the generator; and the two electric lubricating oil pumps and one pneumatic lubricating oil pump are used as backups for each other, so that the long-term reliable operation of the generator lubricating oil system is ensured. The generator lubricating oil system adopts a pneumatic mode and an electric mode to realize the supply of the lubricating oil of the generator; the two electric pumps and the pneumatic pump are used as backups for each other, so that long-term reliable operation of the lubricating oil system can be guaranteed; and the problem that the generator cannot be safely shut down or started due to interruption of peripheral power supply and the problem that the generator is forced to shut down due to interruption of peripheral power supply can be avoided.

Owner:SHANGHAI MARINE EQUIP RES INST

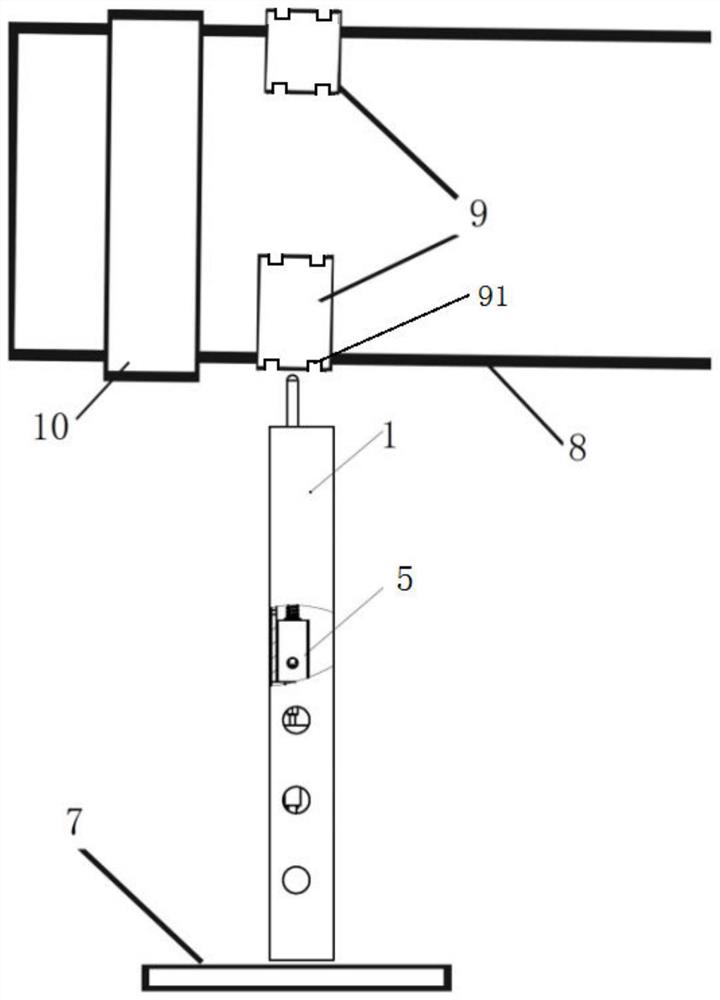

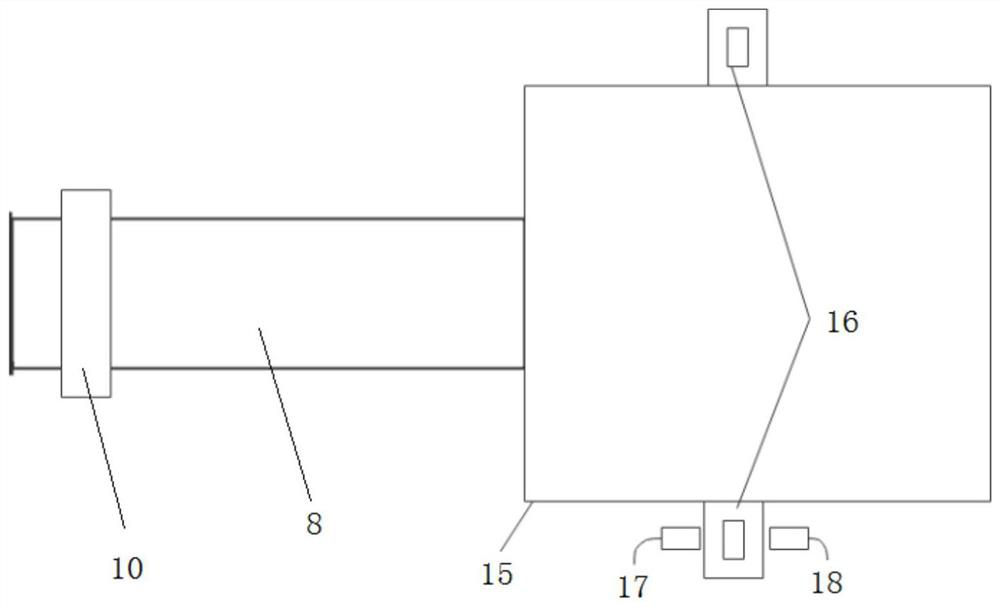

A multi-point grease automatic lubrication micro-control system for automobile chassis

ActiveCN109140217BNormal supplyAvoid damageSignal processingSafety/regulatory devicesOil and greaseControl system

The invention belongs to the technical field of oil fluid lubricating equipment, and particularly relates to a multipoint automatic grease lubricating micro-control system for an automotive chassis. The multipoint automatic grease lubricating micro-control system comprises a lubricating oil cylinder and a mounting base used for fixing and mounting the lubricating oil cylinder. The mounting base comprises a threaded sleeve tube placed at the upper end of the mounting base, and the lubricating oil cylinder is connected with the threaded sleeve tube. A groove is formed in the bottom face of the mounting base, and an oil guide inserting pin and an air inlet inserting pin are arranged in the groove. The oil guide inserting pin and the air inlet inserting pin are fixedly connected, and openingscorresponding to the upper ends of the oil guide inserting pin and the air inlet inserting pin are formed in the top face of the groove. The oil guide inserting pin is connected with the input end ofan lubricating oil pump fixedly mounted on the lower side of the mounting base, the air inlet inserting pin is connected with an air inlet cap arranged on the outer side of the groove, and the oil guide inserting pin is further connected with a rotating rotary knob through a transmission mechanism. The output end of the lubricating oil pump is connected with an oil supply pipeline. The multipointautomatic grease lubricating micro-control system can reduce the occupied space of equipment, cleaning and maintenance of the equipment are facilitated, and meanwhile oil leakage accidents occurring when the lubricating oil cylinder is replaced can be avoided.

Owner:JILIN INST OF CHEM TECH

Adjustable gap type oil diverter and lubricating system

ActiveCN114811393AAchieve independent controlRealize closed-loop controlEngine pressureOperating means/releasing devices for valvesEngineeringOil distribution

The invention discloses an adjustable gap type oil diverter and a lubricating system. The adjustable gap type oil divider comprises a shell, and a core hole and an oil dividing outlet are formed in the shell. A plurality of annular stacking blocks are stacked in the core hole; a compression spring, a locking pressing plate and a gland are sequentially arranged at the orifice of the core hole from inside to outside; through holes are formed in the gland and the locking pressing plate, and the through holes of the gland and the locking pressing plate correspond to the center holes of the stacked blocks in position to form an oil inlet channel; the adjustable gap type oil diverter further comprises a plurality of adjusting plates and an adjusting driving mechanism. The adjusting plates are located in gaps between the adjacent stacking blocks, and the gaps correspond to the oil distribution outlets in position one to one. The lubricating system comprises an air compressor, an oil supply station, an oil-gas mixer and the like. According to the flow divider, independent adjustment of the branch flow can be achieved, the problem that after a certain branch is blocked, other branches cannot work is solved, independent control over the oil supply amount and the oil gas flow can be achieved through a lubricating system, and the lubricating effect is improved.

Owner:YANTAI HUASHUN MACHINERY ENG EQUIP

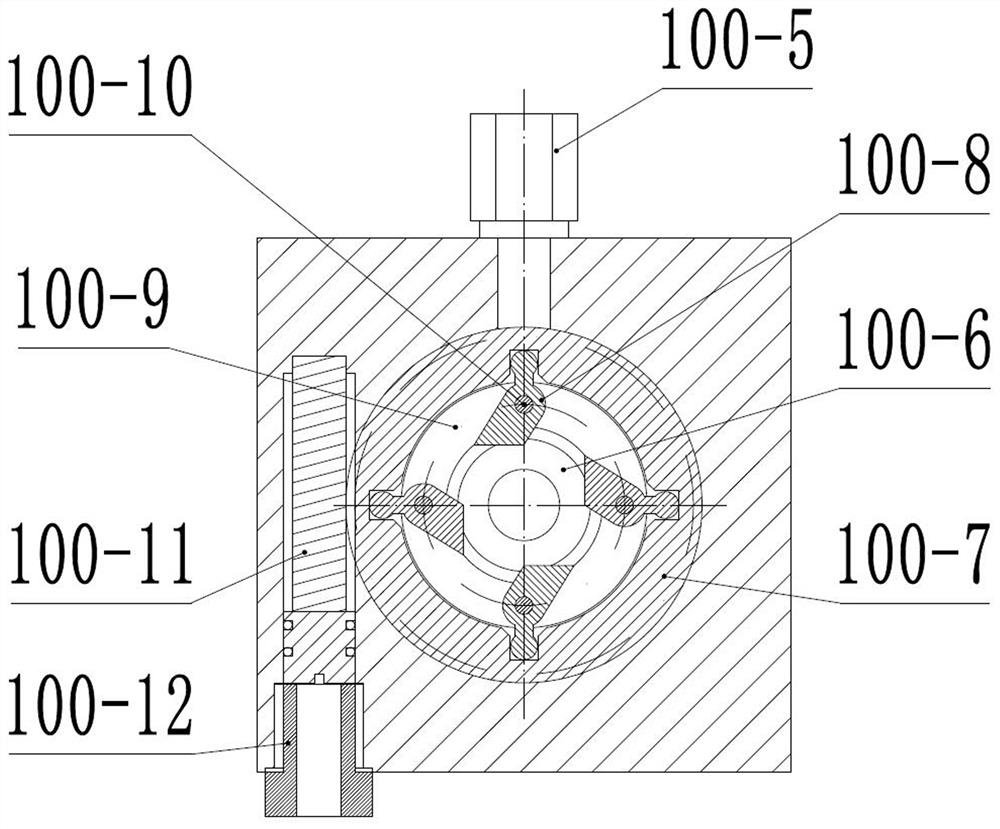

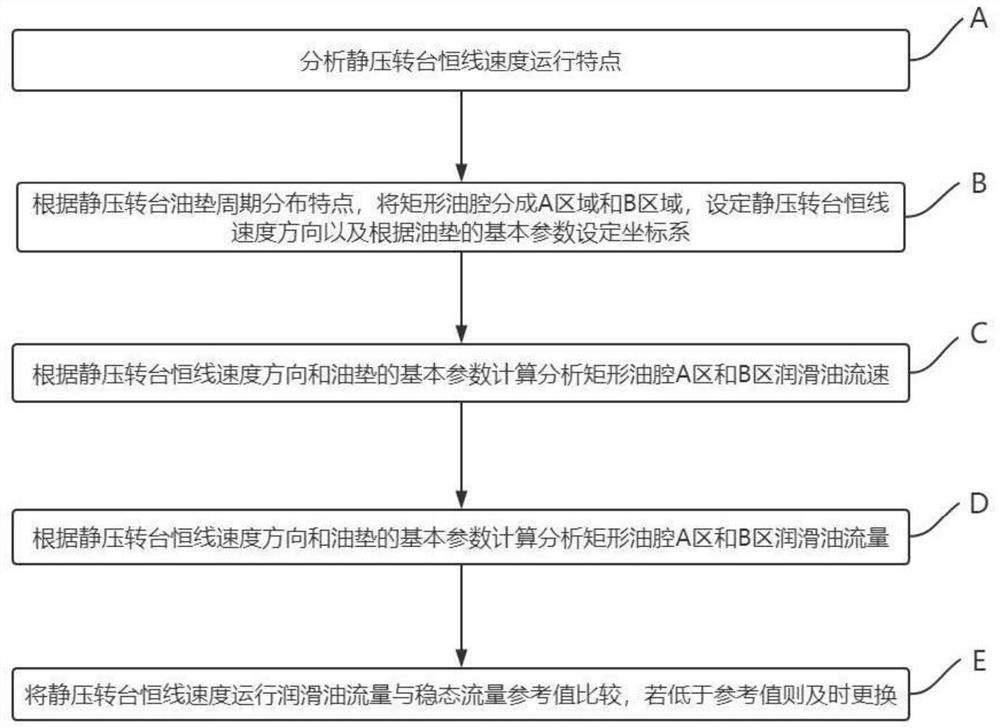

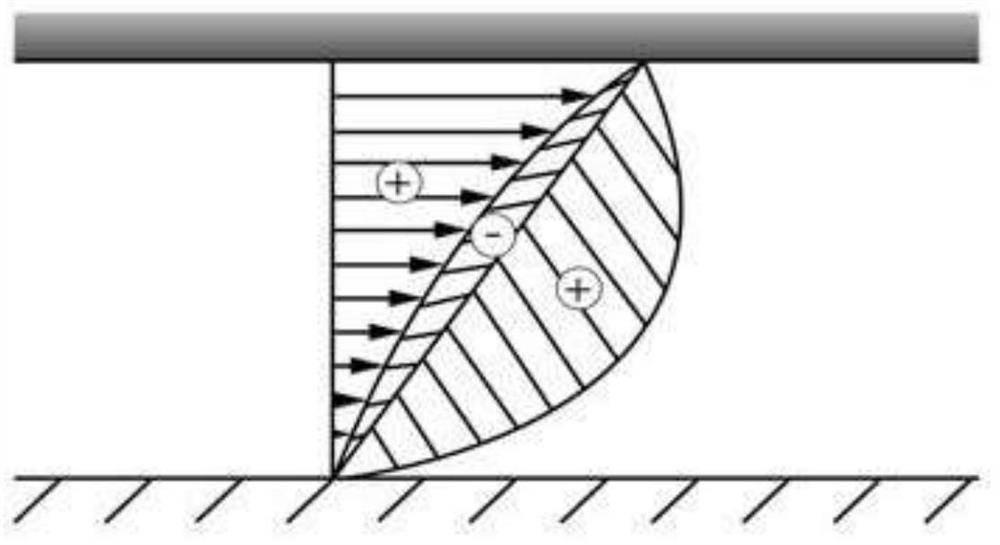

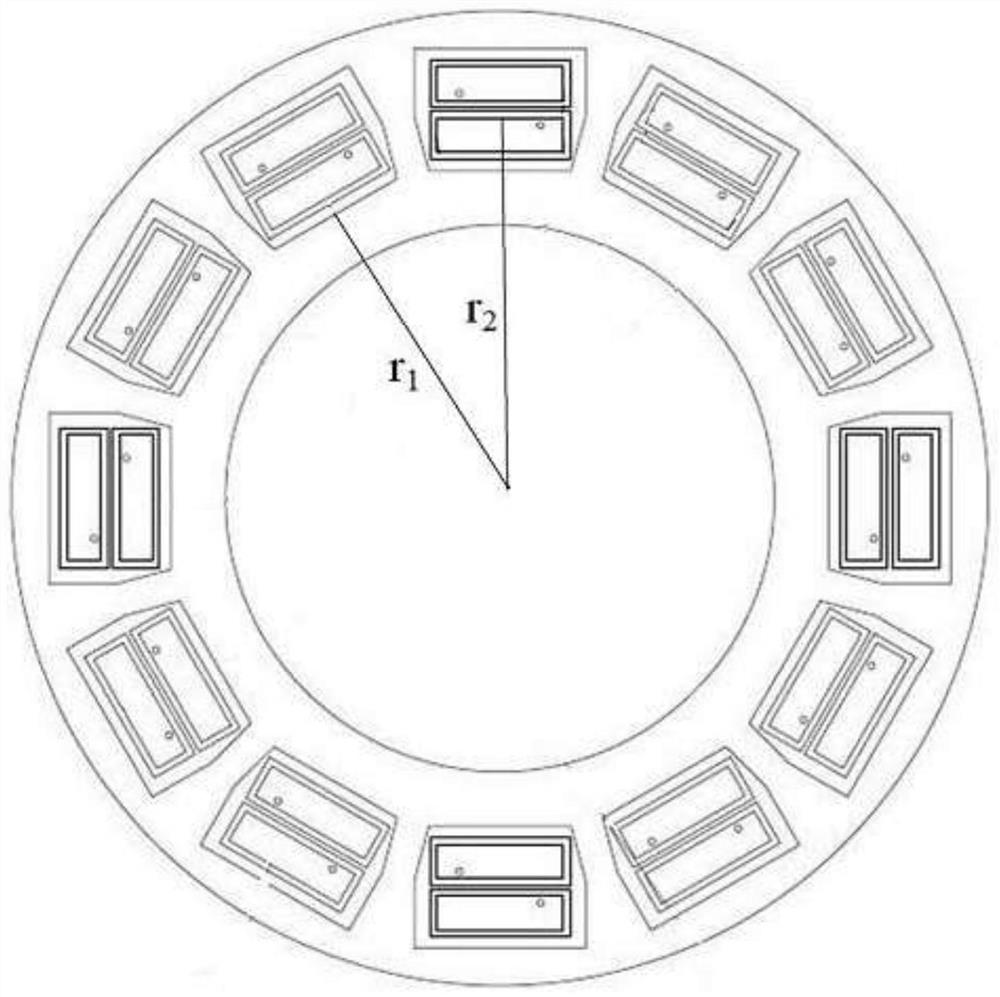

A test method for oil film lubrication performance of static pressure turntable running at constant linear velocity

ActiveCN111322511BEffective prediction of lubricityImprove surface qualityFlow propertiesDesign optimisation/simulationConstant linear velocityEngineering

The invention discloses a method for detecting the lubricating performance of an oil film running at a constant linear velocity on a static pressure turntable, comprising the following steps: analyzing the characteristics of the constant linear velocity operation of the static pressure turntable; according to the periodic distribution characteristics of the oil pad of the static pressure turntable, taking a single rectangular oil chamber for analysis, Divide the rectangular oil chamber into A area and B area, set the direction of the constant linear velocity of the static pressure turntable and set the coordinate system according to the basic parameters of the oil pad; calculate and analyze the rectangular oil according to the direction of the constant linear velocity of the static pressure turntable and the basic parameters of the oil pad lubricating oil flow rate in area A and B of the cavity; calculate and analyze the lubricating oil flow rate in area A and B of the rectangular oil chamber according to the constant linear velocity direction of the static pressure turntable and the basic parameters of the oil pad; The steady-state flow reference value is compared, and if it is lower than the reference value, it will be replaced in time. The invention has important significance for effectively predicting the oil film lubrication performance of the static pressure turntable running at constant linear speed and improving the surface quality of the processed workpiece on the static pressure turntable.

Owner:NANJING INST OF TECH

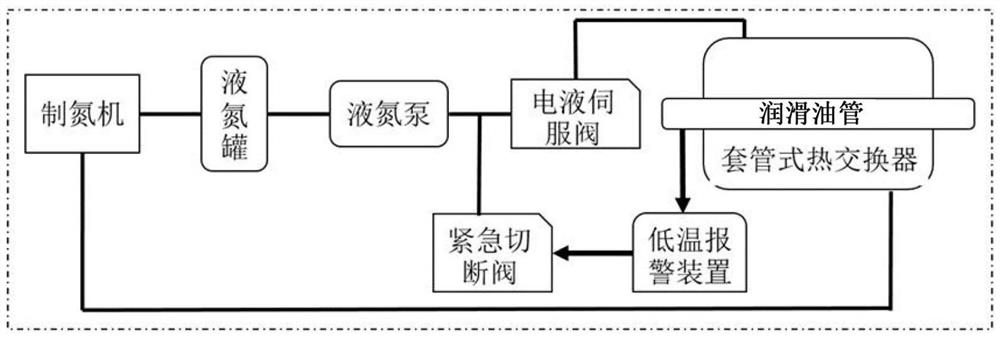

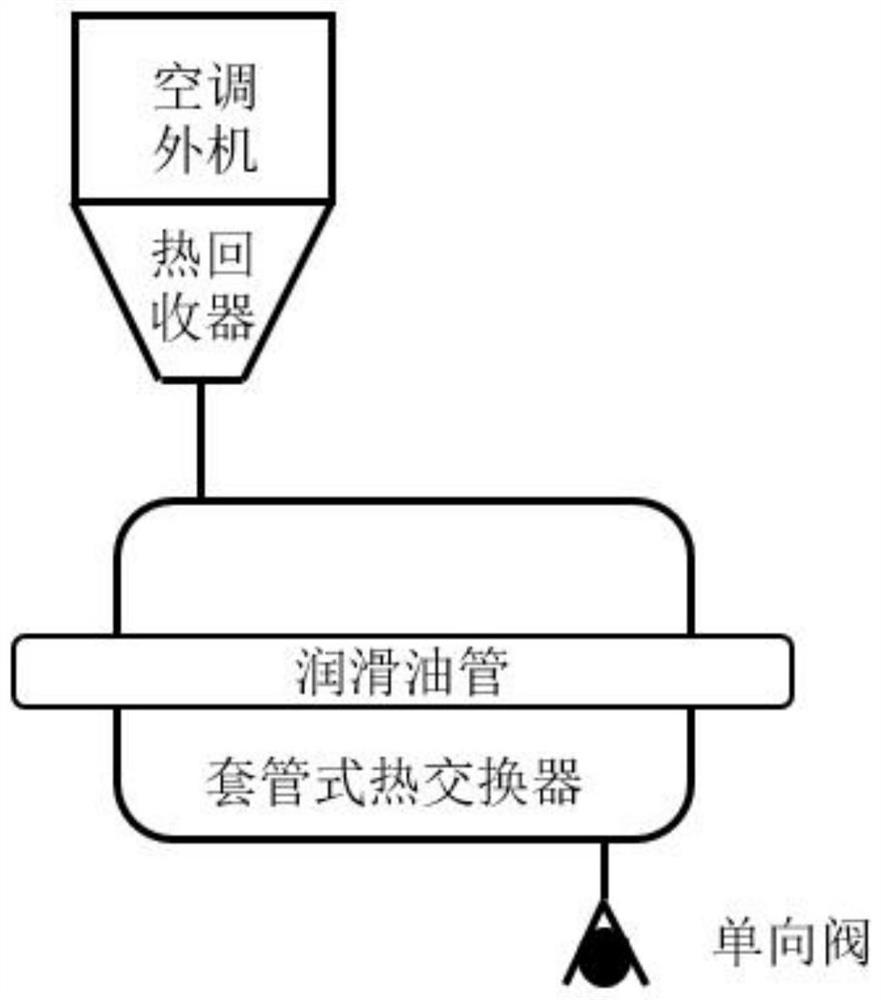

Lubricating system of road surface acceleration loading equipment

ActiveCN113958850AAvoid stickingExtended service lifeEngine temperatureEngine pressureOil canLiquid nitrogen cooling

The invention discloses a lubricating system of road surface acceleration loading equipment. The lubricating system comprises a control system and an oil supply system. The oil supply system provides lubricating oil for the acceleration loading equipment through a main oil supply pipeline, and a liquid nitrogen cooling system, an air conditioner heat recovery heating system and a lubricating parameter compensation system are arranged between the oil supply system and the acceleration loading equipment. The liquid nitrogen cooling system and the air conditioner heat recovery heating system conduct temperature regulation and control on the lubricating oil of the main oil supply pipeline, the lubricating parameter compensation system conducts secondary compensation on temperatures and flow parameters of the oil supply system, and the liquid nitrogen cooling system, the air conditioner heat recovery heating system and the lubricating parameter compensation system are electrically connected with the control system. According to the lubricating system, the lubricating oil can be kept at the optimal lubricating oil temperature under the extreme environment temperature condition of a wide temperature range and a large gradient temperature field, so that the acceleration loading equipment can be well lubricated under the simulated extreme environment condition, a guide wheel is prevented from being stuck, the service life of the guide wheel and a rail is prolonged, and the lubricating system is applicable to the technical field of equipment lubrication.

Owner:益路恒丰衡水沥青科技有限公司

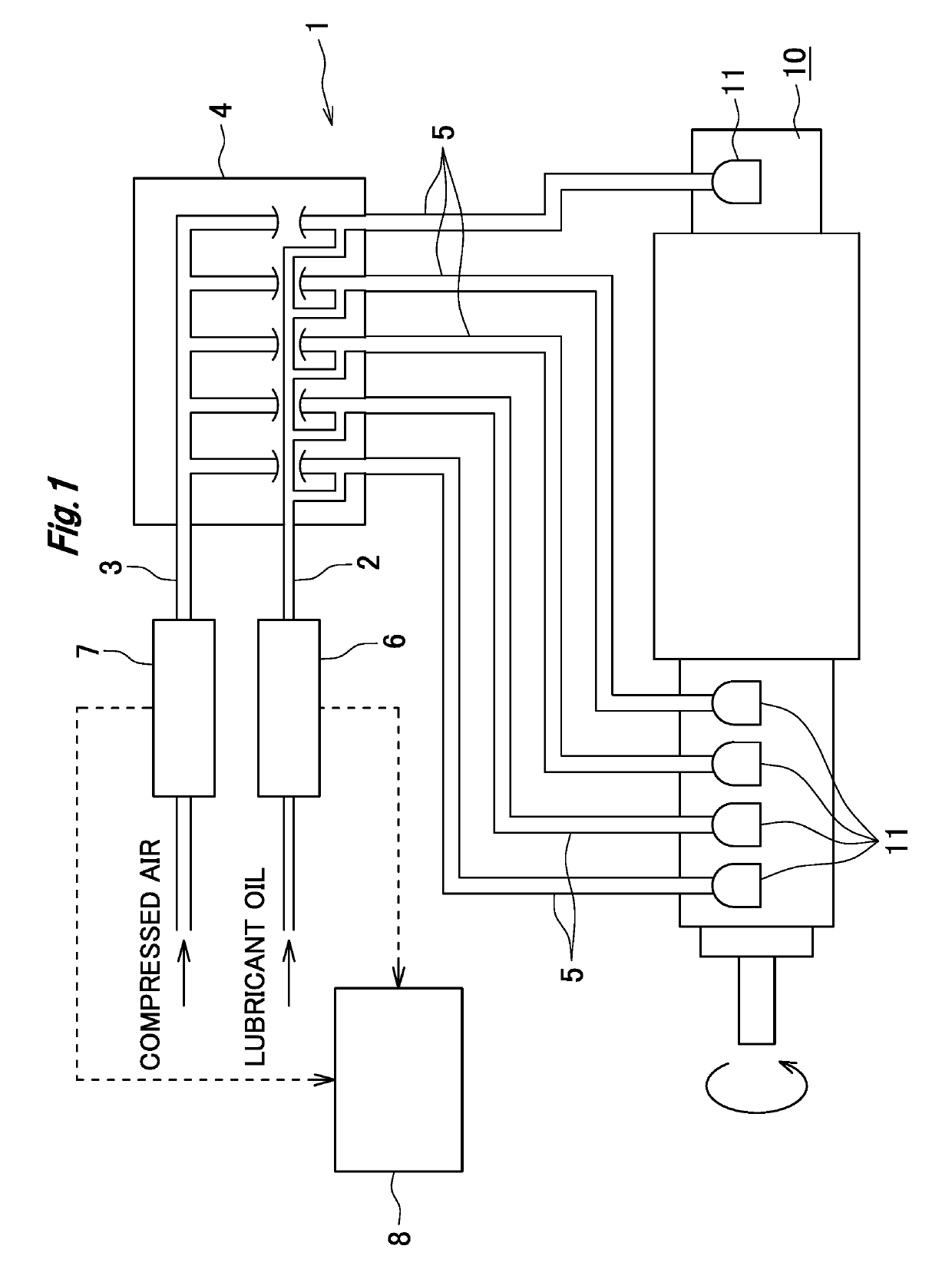

Oil air supply system

InactiveUS20190195425A1Accurate measurementSurely detectedEngine pressureBearing componentsProcess engineeringStreamflow

The oil air supply system includes a lubricant oil supply pipeline, a compressed air supply pipeline, a mixing device which distributes lubricant oil supplied from the lubricant oil supply pipeline in a fixed amount and mixes the lubricant oil with compressed air to generate oil air, a plurality of oil air supply pipelines which supply the oil air to a plurality of bearings of a main spindle device respectively, a flow rate sensor provided in the lubricant oil supply pipeline and detects the flow rate of the lubricant oil, a pressure sensor provided in the compressed air supply pipeline and detects the pressure of the compressed air, and an abnormality detection device which detects supply abnormality of lubricant oil based on a detection signal output from the flow rate sensor and detects supply abnormality of compressed air based on a detection signal output from the pressure sensor.

Owner:OKUMA CORP

Intelligent lubrication system for heavy-duty bearings of wind turbines

An intelligent lubricating system for a heavy-duty bearing of a wind power generating set belongs to the technical field of wind turbines. Installed on the base of the engine room, it includes a trigger device and an oil suction and injection pipeline connected to the main bearing. The trigger device includes an action connecting rod and a trigger block. The trigger block is arranged on the outer periphery of the main shaft. One end of the action link is a free end for It is triggered by contact with the trigger block, and the other end is connected to the oil injector. The oil suction and oil injection pipeline includes an oil suction pump, an oil suction filter, a grease storage tank, an oil injector and an oil injection filter connected in sequence. The oil suction pump is connected to the main bearing on the main shaft Oil outlet, the oil outlet pipe of the oil injection filter is connected to the oil injection port of the main bearing to form a lubricating oil circulation; through the rotation of the main shaft, the action connecting rod contacts the trigger block, driving the action connecting rod to reciprocate, and the oil suction pump sucks the lubricating oil flowing out of the main bearing , After being filtered by the oil suction filter, it is stored in the grease storage tank, and then filtered by the oil injector and the oil injection filter, and then returned to the oil injection port of the main bearing for supplementary lubrication. The invention can realize the circulation lubrication of the bearing and improve the service life of the main bearing.

Owner:沈阳依纳科技有限公司

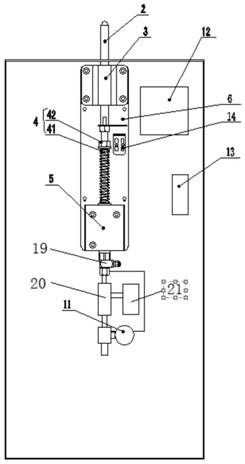

Simple testing device for electric control oil injector

ActiveCN112747246AStable pressureSimple structureLubricant filling/drainingEngine flowPressure stabilizationHydraulic pump

The invention discloses a simple testing device for an electric control oil injector. The simple testing device comprises a hydraulic oil tank, a hydraulic oil supply valve, a hydraulic pump, a pressure accumulation block assembly, a pulse signal generator, a lubricating oil gravity oil tank, a lubricating oil supply valve, a lubricating oil filter, an oil discharge valve and measuring cylinders, wherein the hydraulic oil tank, the hydraulic oil supply valve, the hydraulic pump and the pressure accumulation block assembly sequentially communicate through a hydraulic oil supply pipeline and supply hydraulic oil for testing to the oil injector, and the lubricating oil gravity oil tank, the lubricating oil supply valve and the lubricating oil filter sequentially communicate to the oil injector through a lubricating oil pipeline to supply lubricating oil for operation; and a first oil return pipeline is arranged between the oil injector and the hydraulic oil tank, a second oil return pipeline is arranged between the pressure accumulation block assembly and the hydraulic oil tank, and the pulse signal generator is in telecommunication connection with the electric control end of the oil injector. The device is simple in structure, the system pressure is stable and adjustable, an electric motor is not needed, pressure control and all testing work of the hydraulic system can be achieved only through manual operation, and operation is easy and convenient.

Owner:SHANGHAI HULIN HEAVY IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com