Adjustable gap type oil diverter and lubricating system

A slot type and diverter technology, applied in the field of lubrication system, can solve the problem of oil separator not working, and achieve the effect of high reliability, good stability and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Describe the technical scheme of the present invention in detail below in conjunction with accompanying drawing:

[0046] The invention discloses an adjustable gap type oil shunt and a lubricating system.

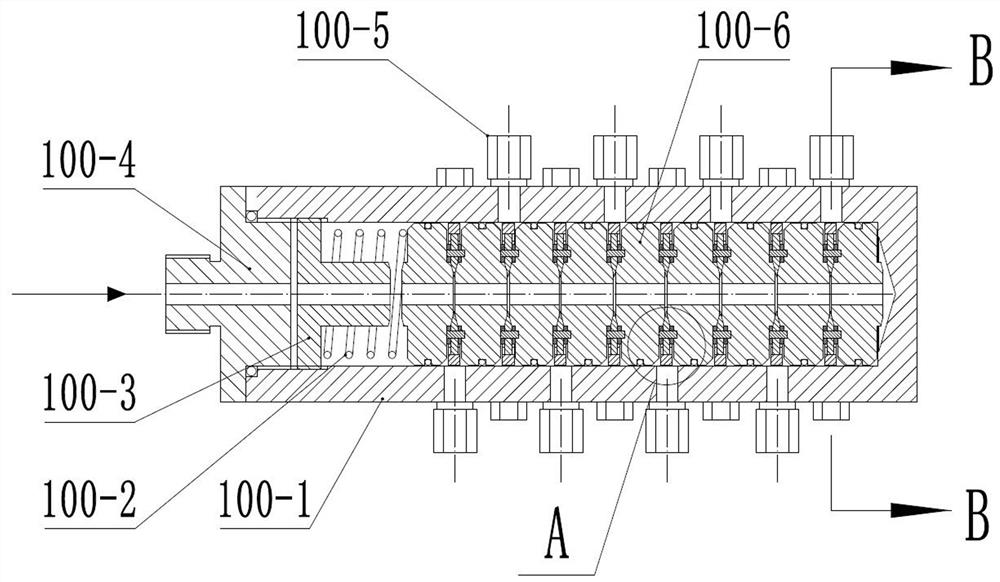

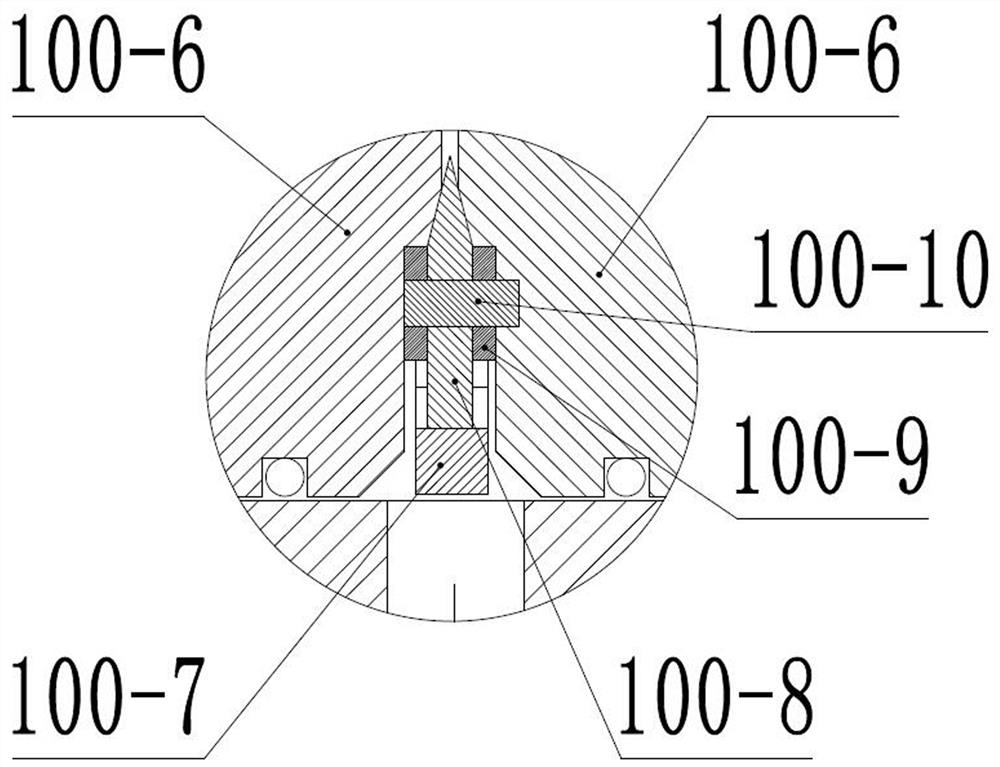

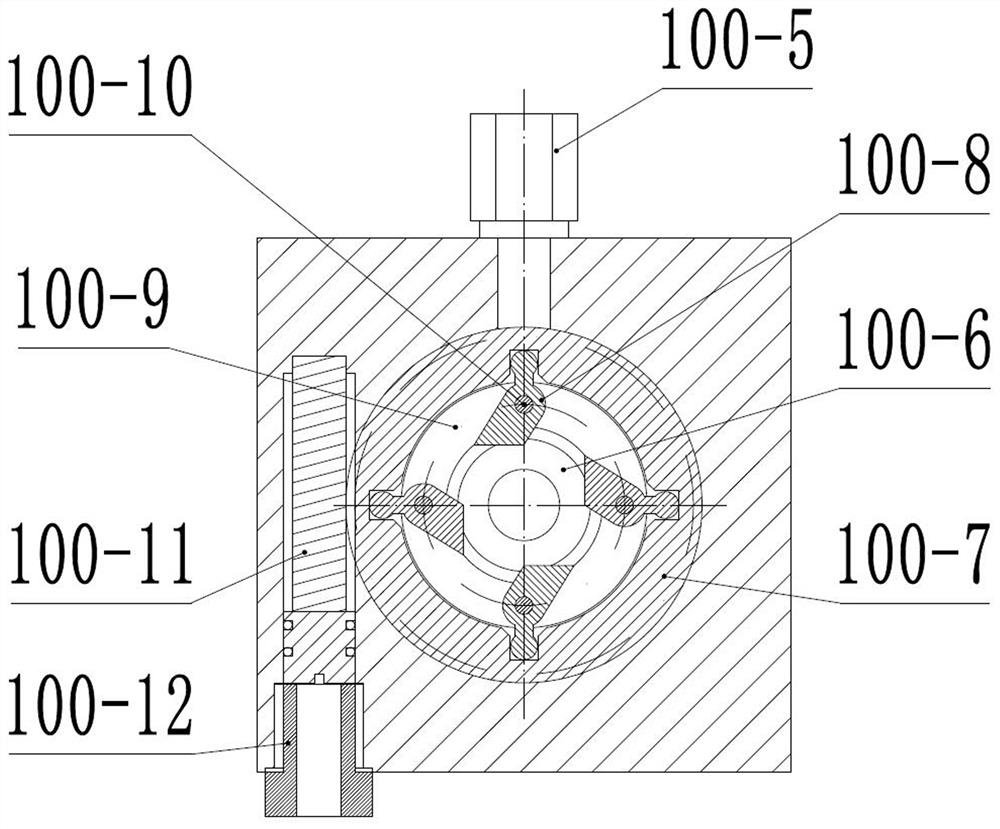

[0047] like figure 1 , an adjustable-slot oil diverter, comprising a casing 100-1 made of pressure-resistant metal material, the casing 100-1 is provided with a core hole, and a number of oil separation outlets 100-1 vertically penetrating through the core hole. 5. The oil separation outlet 100-5 can have single-sided outlet and double-sided outlet, and there is no limit on the number. In practice, 2 to 10 are appropriate.

[0048] A plurality of annular stacked blocks 100-6 are stacked in the core hole along its length direction. The outer circular surface of the stacked block (100-6) is sealed with the core hole. In order to facilitate processing and assembly, all the stacked blocks 100-6 have the same shape and size.

[0049] A compression spring 100-2, a loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com