Heavy type gearbox oil flow test lubrication testing system

A test system and gearbox technology, applied in the direction of lubricating parts, engine lubrication, engine flow, etc., can solve problems such as single function, large error, and inability to simulate gearboxes, etc., to achieve high integration, small volume, and space volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

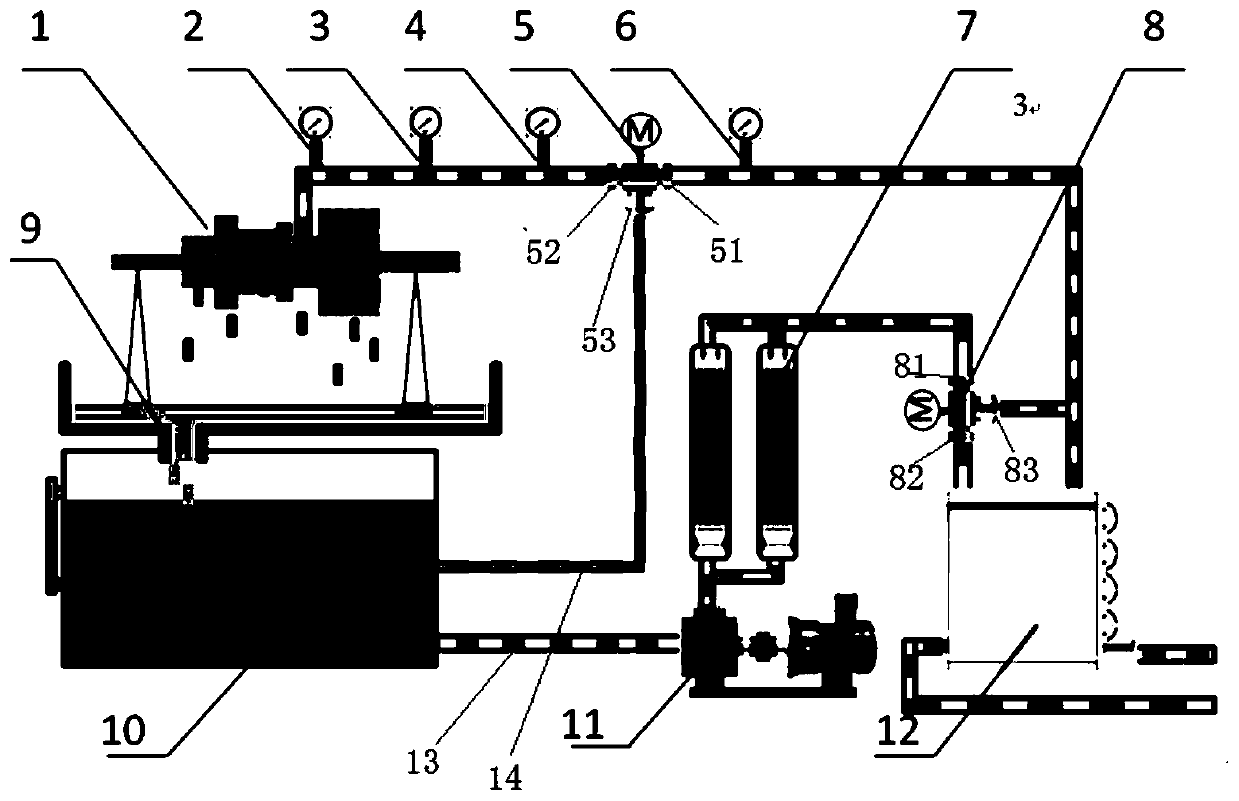

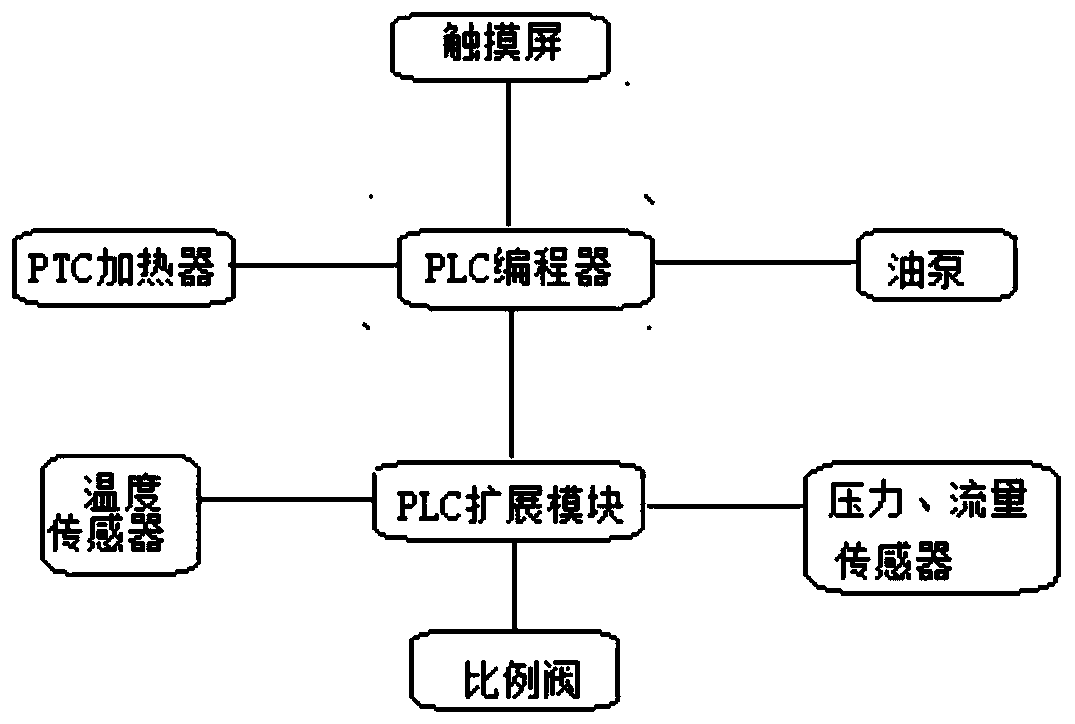

[0019] Such as figure 1 As shown, the present invention provides a kind of lubrication testing system for heavy-duty gearbox oil flow test, comprising: oil receiving pan 9 and oil tank 10, the support for placing test samples is arranged above the oil receiving pan 9; the oil receiving pan 9 is provided with outlet The oil channel is also connected with the fuel tank 10; it also includes an oil outlet pipeline 13, the input end of the oil outlet pipeline 13 is connected with the oil tank 10, and the output end of the oil outlet pipeline 13 is positioned directly above the place where the test sample is placed; on the oil outlet pipeline 13 A gear pump 11 , a heater 7 , a heat exchanger 12 , a proportional valve, a pressure sensor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com