Device and method for replacing lubricating grease of bearing of rotating equipment

A technology for lubricating rotating equipment and bearings. It is used in lubricating oil containers, lubricating oil input, engine lubrication, etc. to achieve smooth wear and heat transfer, avoid excessive temperature rise, and reduce impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

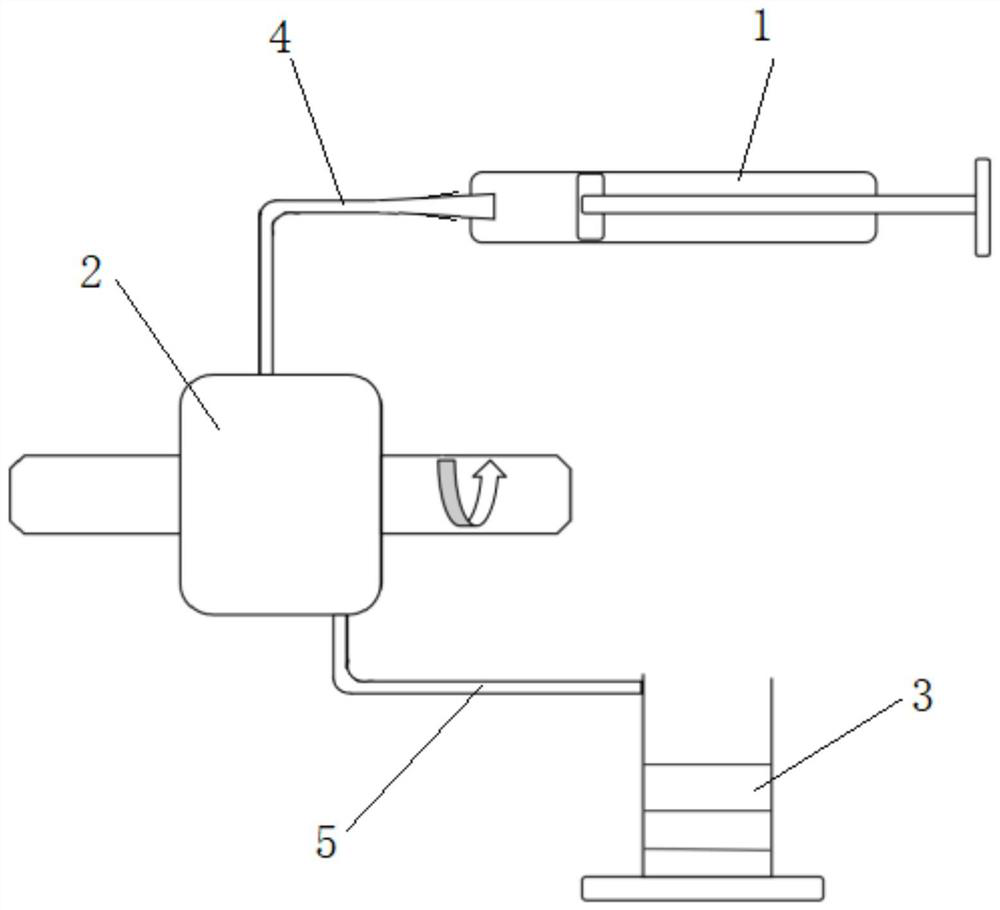

[0035] like figure 1 As shown, Embodiment 1 of the present invention provides a device for replacing the bearing lubricating oil of a rotating equipment, including:

[0036] The new lubricating grease filling device 1 is used to be arranged above the bearing 2 of the rotating equipment, and is connected to the bearing 2 of the rotating equipment through an oil filling pipeline 4, so as to fill the bearing 2 of the rotating equipment with lubricating grease.

[0037] The measuring tool 3 is used to be arranged under the bearing 2 of the rotating equipment, and is connected to the waste oil outlet of the bearing 2 of the rotating equipment through the grease collection pipeline 5, and is used to measure the volume of the old lubricating grease discharged from the bearing 2 of the rotating equipment.

[0038] Through the above arrangement, the old lubricating grease can be discharged while adding the lubricating grease, and the old lubricating grease can be collected, and the vol...

Embodiment 2

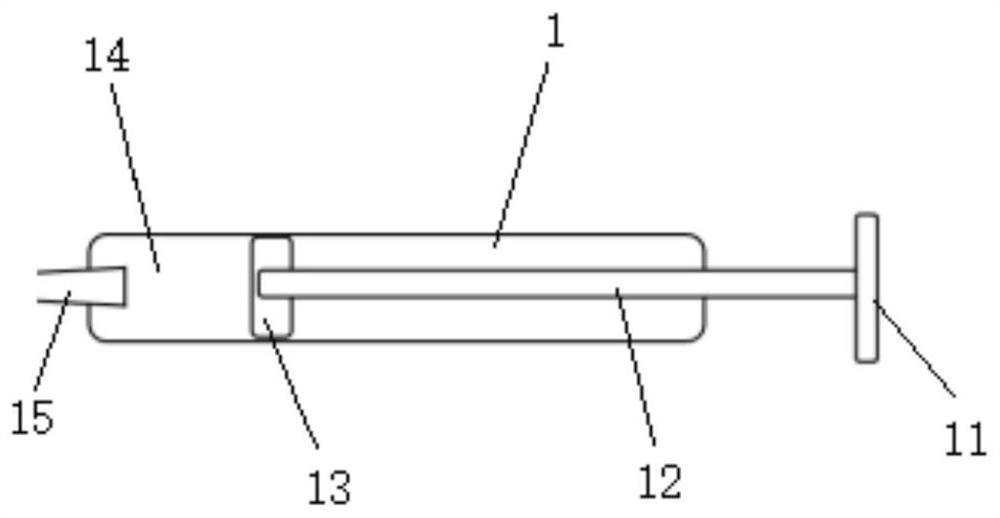

[0046] Embodiment 2 of the present invention is different from Embodiment 1 in that the second end of the push rod 12 is fixedly connected with the output shaft of a cylinder or a hydraulic cylinder. The push rod 12 is pushed by an air cylinder or a hydraulic cylinder.

Embodiment 3

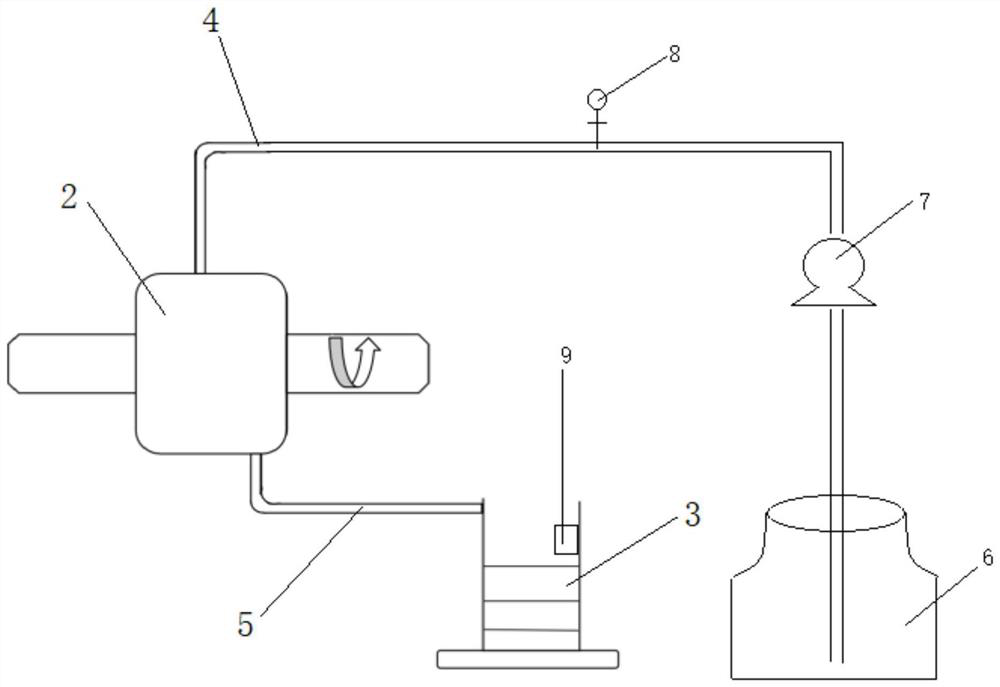

[0048]Embodiment 3 of the present invention is different from Embodiment 1 in that a new example is given for the new lubricating grease filling device 1. In the embodiment of the present invention, the new lubricating grease filling device 1 includes a grease tank 6 And the oil pump 7 , the grease tank 6 is connected to the bearing 2 of the rotating equipment through the oil filling pipeline 4 , and the oil pump 7 is arranged on the oil filling pipeline 4 .

[0049] Through the above settings, the oil pump is directly used to suck lubricating grease for grease filling, so as to realize the automation of grease filling.

[0050] As a preference of this embodiment, a flow meter 8 is provided on the oil filling pipeline 4 , and through this arrangement, the volume of lubricating grease filling can be monitored.

[0051] As a preference of this embodiment, a liquid level gauge 9 is provided on the top of the inner wall of the waste oil collection barrel, and an alarm device is el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com