Lubrication system with a signal transmission element

A lubrication system and signal transmission technology, applied in the field of lubrication systems, can solve problems such as destructive, complicated and impossible wiring of the lubrication system, and achieve the effect of fast signal transmission and simple signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, identical or functionally equivalent elements are denoted by the same reference numerals.

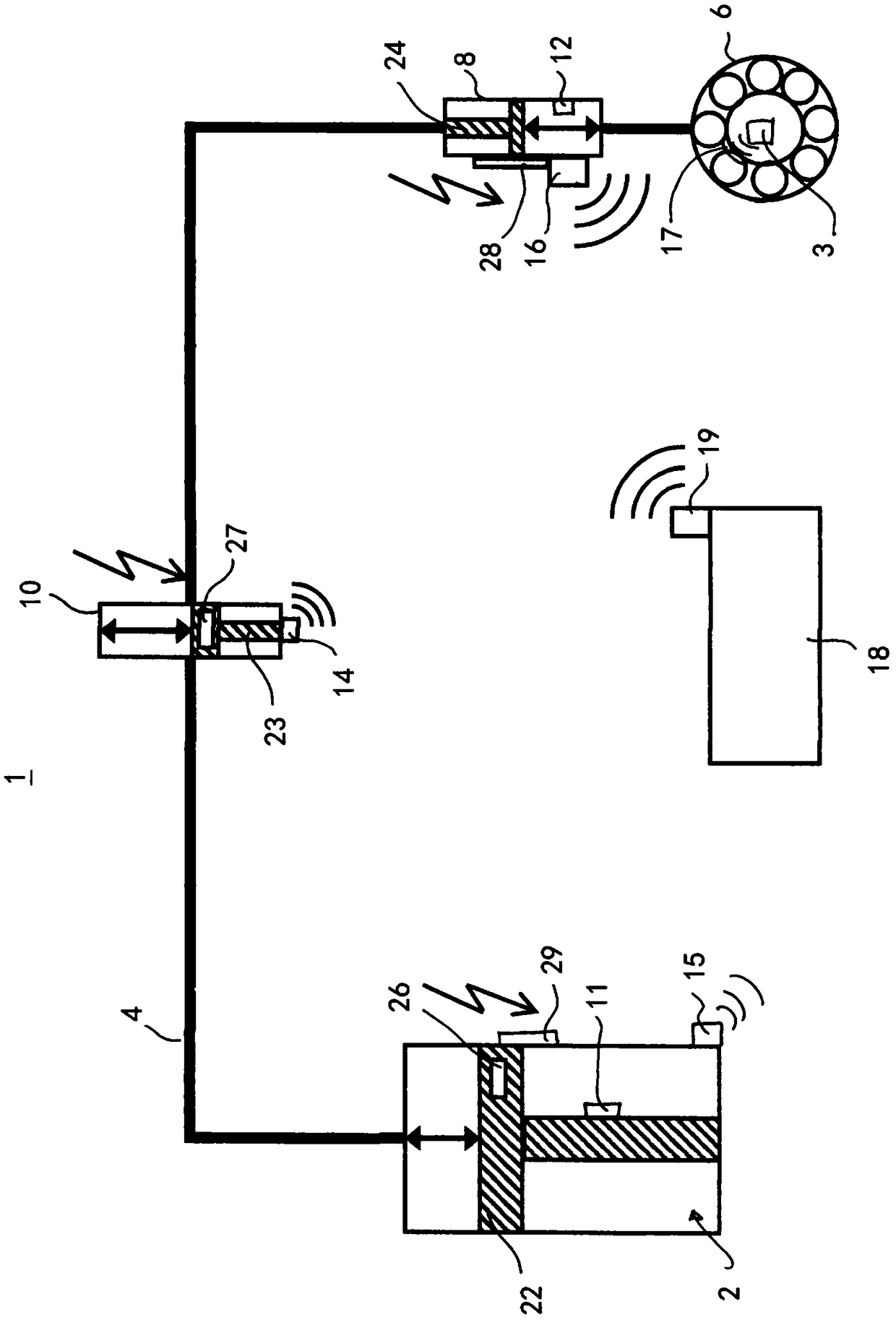

[0023] figure 1 A lubrication system 1 is schematically shown comprising a lubricant pumping arrangement 2 connected to a lubricant line 4 for pumping lubricant to points to be lubricated here described as bearings 6. In order to deliver precisely metered lubricant or to generally distribute lubricant to the bearing, a lubricant distribution device 8 arranged upstream of the bearing 6 is also provided. For example, the lubricant distribution device may be a single line dispenser or a progressive dispenser. like figure 1 As shown, the lubrication system monitoring device is also arranged on the lubricant pipeline 4 in the form of a sensor 10 , for example, the sensor 10 monitors the flow rate of the lubricant flowing through the pipeline 4 or its temperature or viscosity. exist figure 1 In the exemplary embodiment shown, the lubrication system monitoring dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com