Intelligent lubricating oil pump station

A technology for lubricating oil and pumping stations, which is applied in the direction of lubricating pumps, lubricating oil containers, lubricating oil control valves, etc., which can solve the problems of piston rod stuck, lubricating oil can not be dried and hardened, etc., so as to increase fluidity and improve The effect of long service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

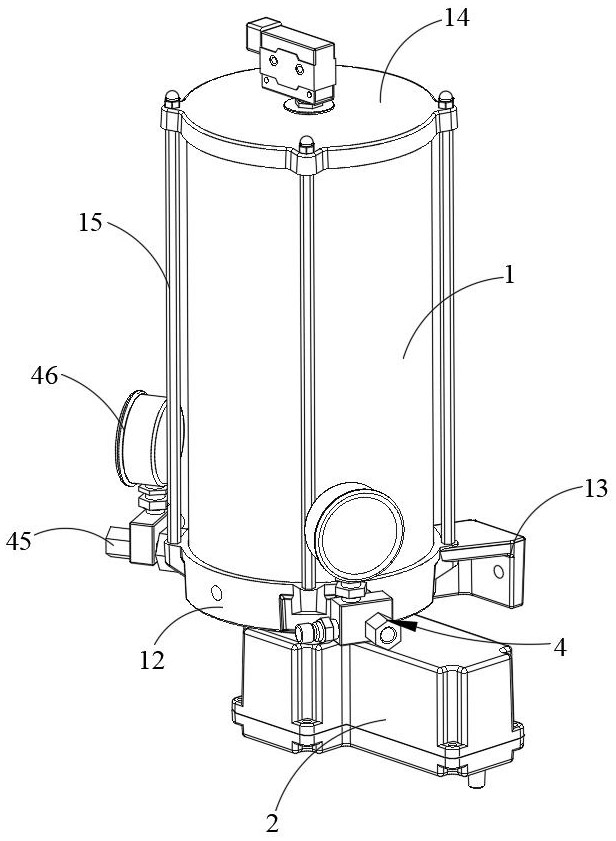

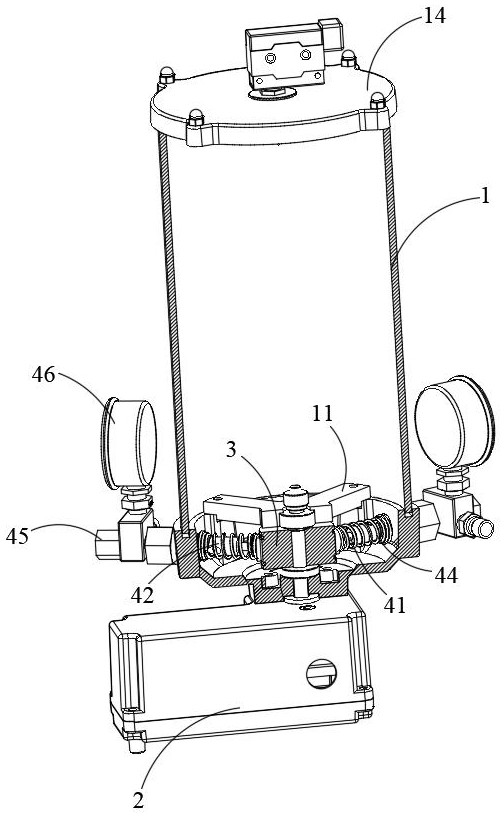

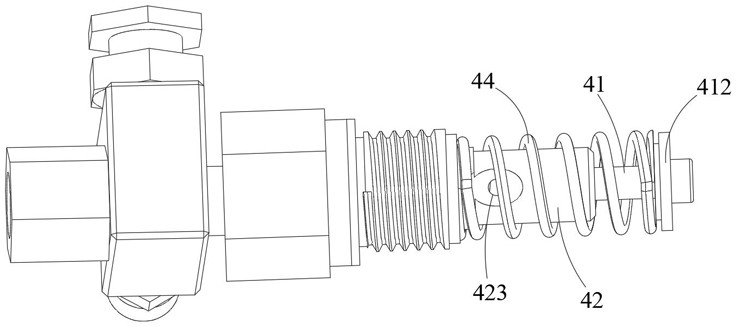

[0038] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0039] Such as Figure 1 to Figure 5 As shown, an intelligent lubricating oil pumping station of the present invention includes: an oil storage barrel 1, a rotating motor 2, an eccentric disc 3 and a number of pump elements 4, the oil storage barrel 1 is a hollow column, and the oil storage barrel 1 is The main container for storing lubricating oil, the rotating motor 2 is arranged at the bottom of the oil storage barrel 1, the rotating motor 2 is arranged under the outer wall of the oil storage barrel 1, and the rotating shaft of the rotating motor 2 is arranged at Inside the oil storage barrel 1, the eccentric disc 3 is arranged at the inner bottom of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com