Rotating-shaft-type main engine intelligent lubricating system and control method thereof

A technology of a lubrication system and a control method, which is applied in the field of lubrication systems, and can solve the problems of inconvenient intelligent operation of the lubrication system and manual start-up of the backup pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

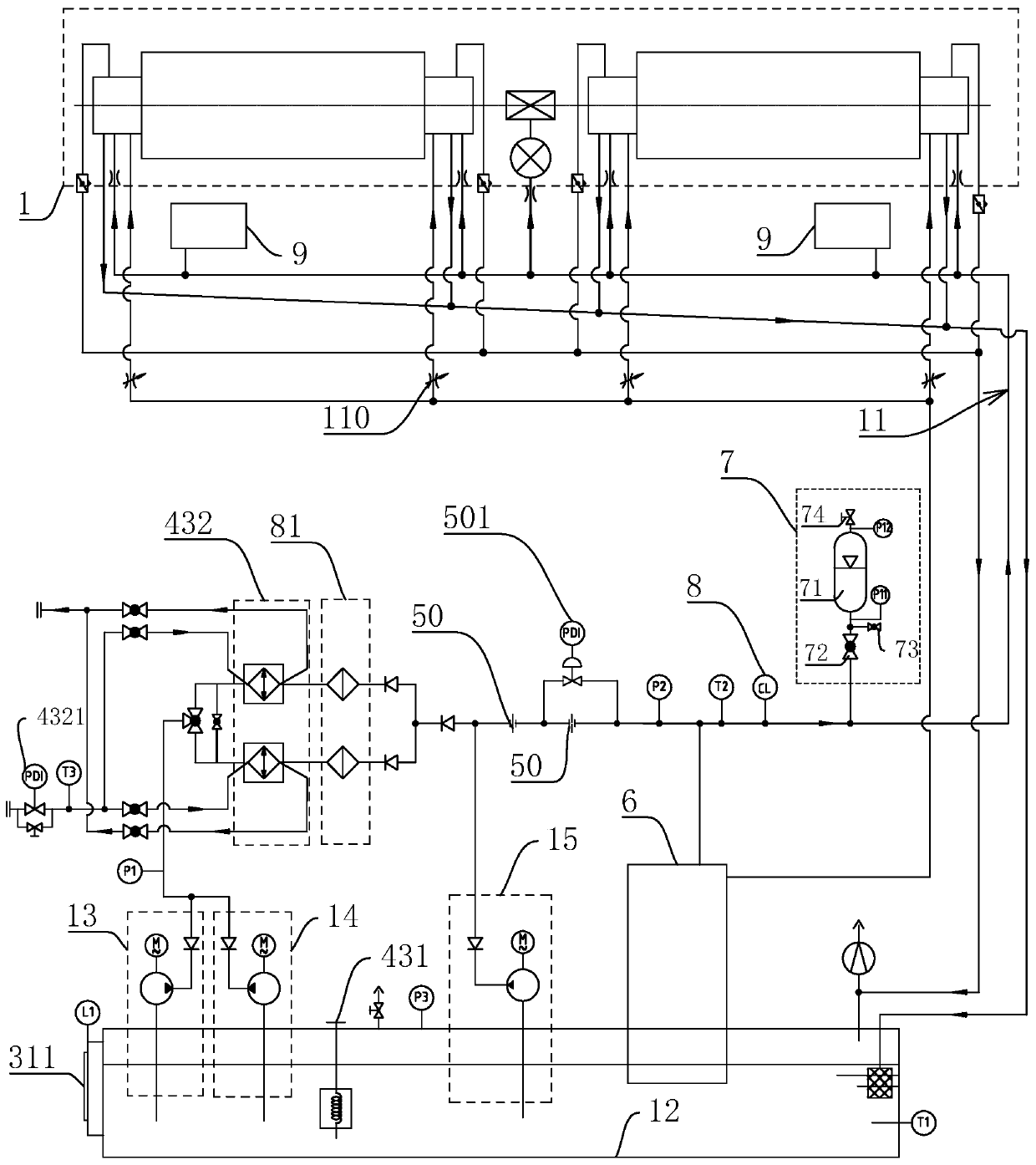

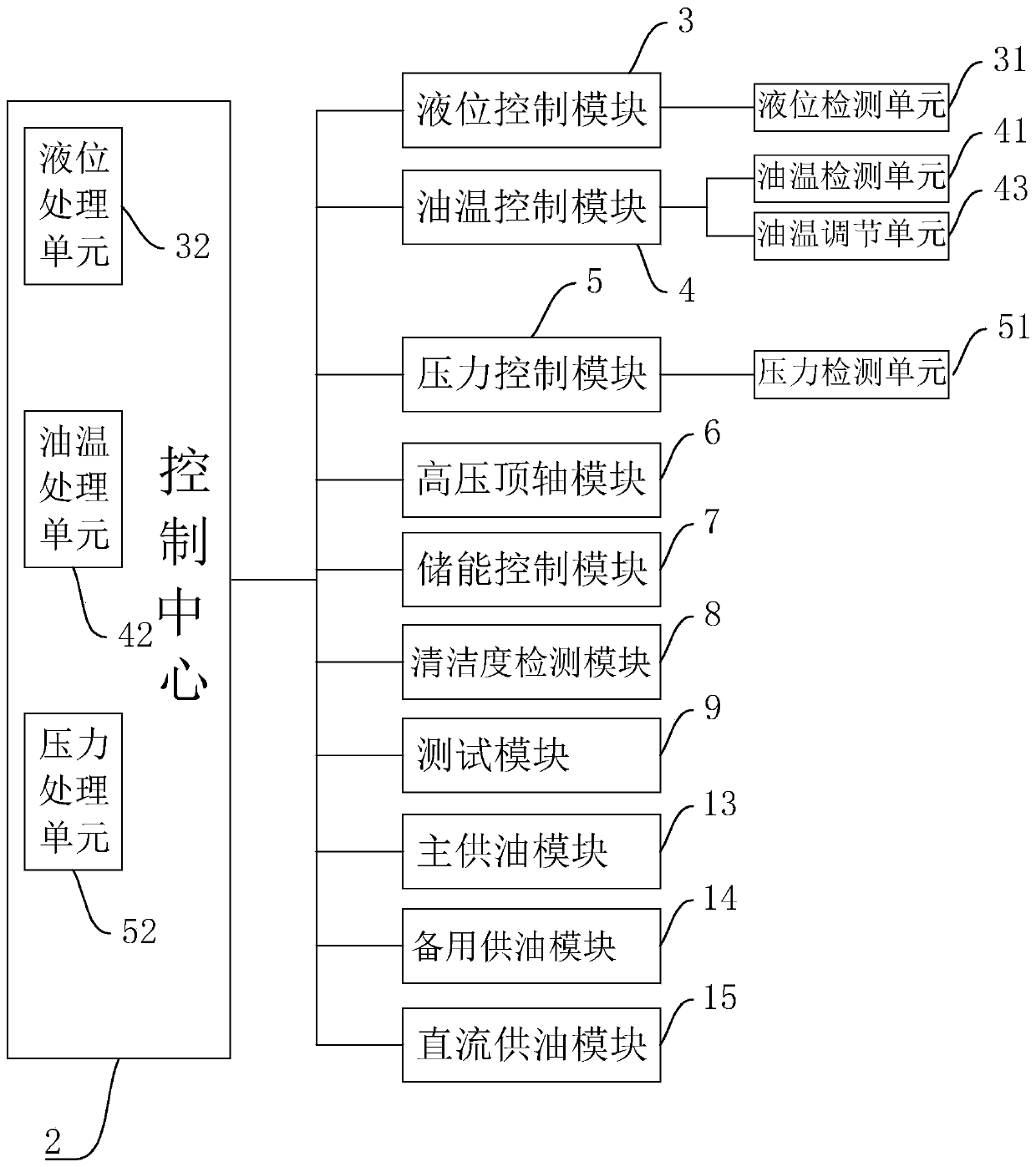

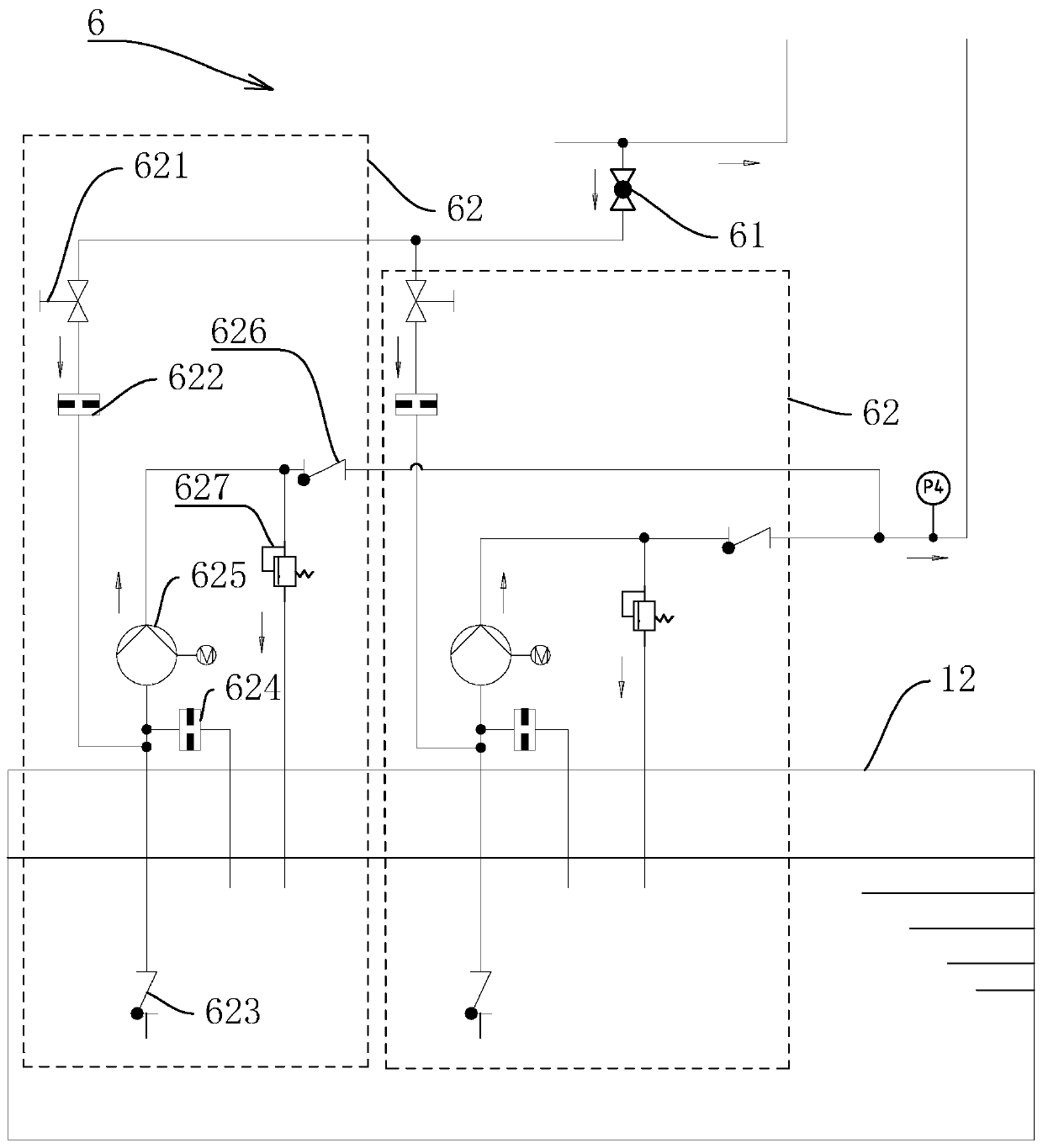

[0062] An intelligent lubrication system for a rotating shaft host, refer to figure 1 and figure 2 , which includes a unit 1, an oil supply pipeline 11, an oil tank 12, a main oil supply module 13, a backup oil supply module 14 and a DC oil supply module 15, the unit 1 includes a generator and a steam turbine connected to the generator through a coupling, Steam turbines and generators have multiple bearings on their rotors. The main oil supply module 13, the backup oil supply module 14 and the DC oil supply module 15 are all arranged on the fuel tank 12, the main oil supply module 13 and the backup oil supply module 14 are mutually backup, the main oil supply module 13 and the backup oil supply module 14 All adopt AC oil pumps; the DC oil supply module 15 includes a DC power supply, an inverter and an AC oil pump, so that the three oil supply modules adopt the same control method. The main oil supply module 13 , the standby oil supply module 14 and the direct current oil su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com