Frequency conversion automatic control device and method of motor of shafting lubricating oil pump

A technology of automatic control device and control method, which is applied in the direction of AC motor control, lubrication pump, control system, etc., can solve the problems of unable to automatically switch control, unable to meet the needs of refined design and use of lubricating oil system, and reduce energy consumption. and noise, reduce the average power, and improve the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

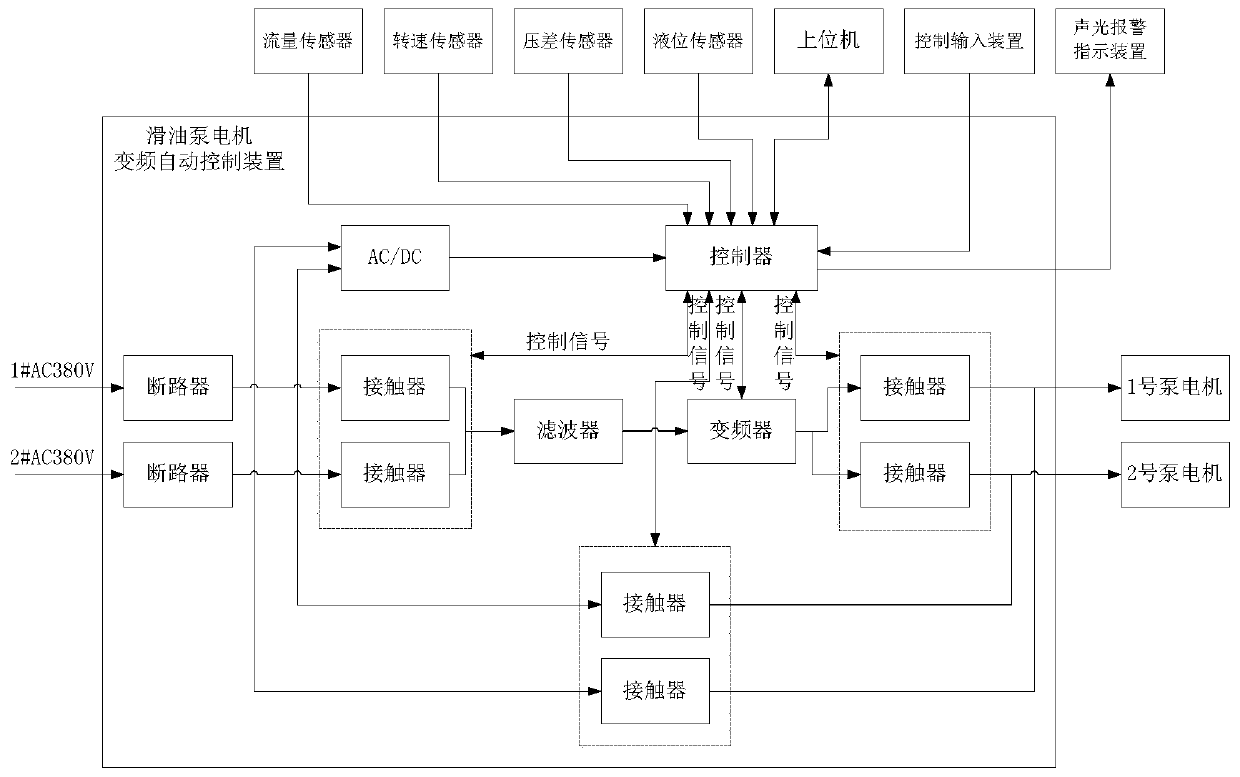

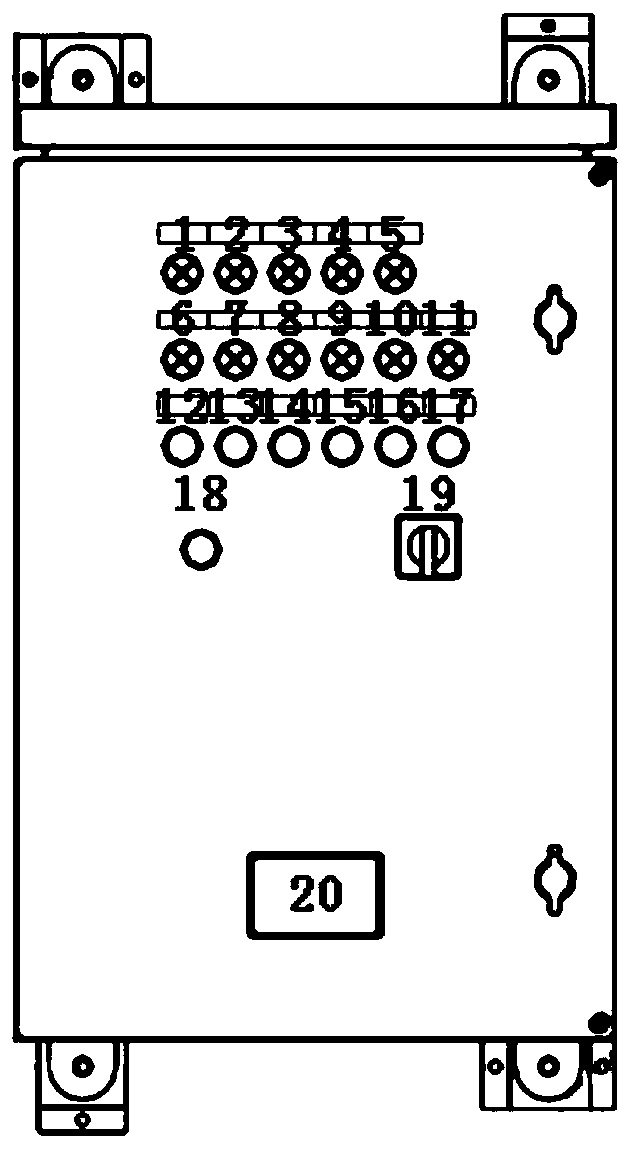

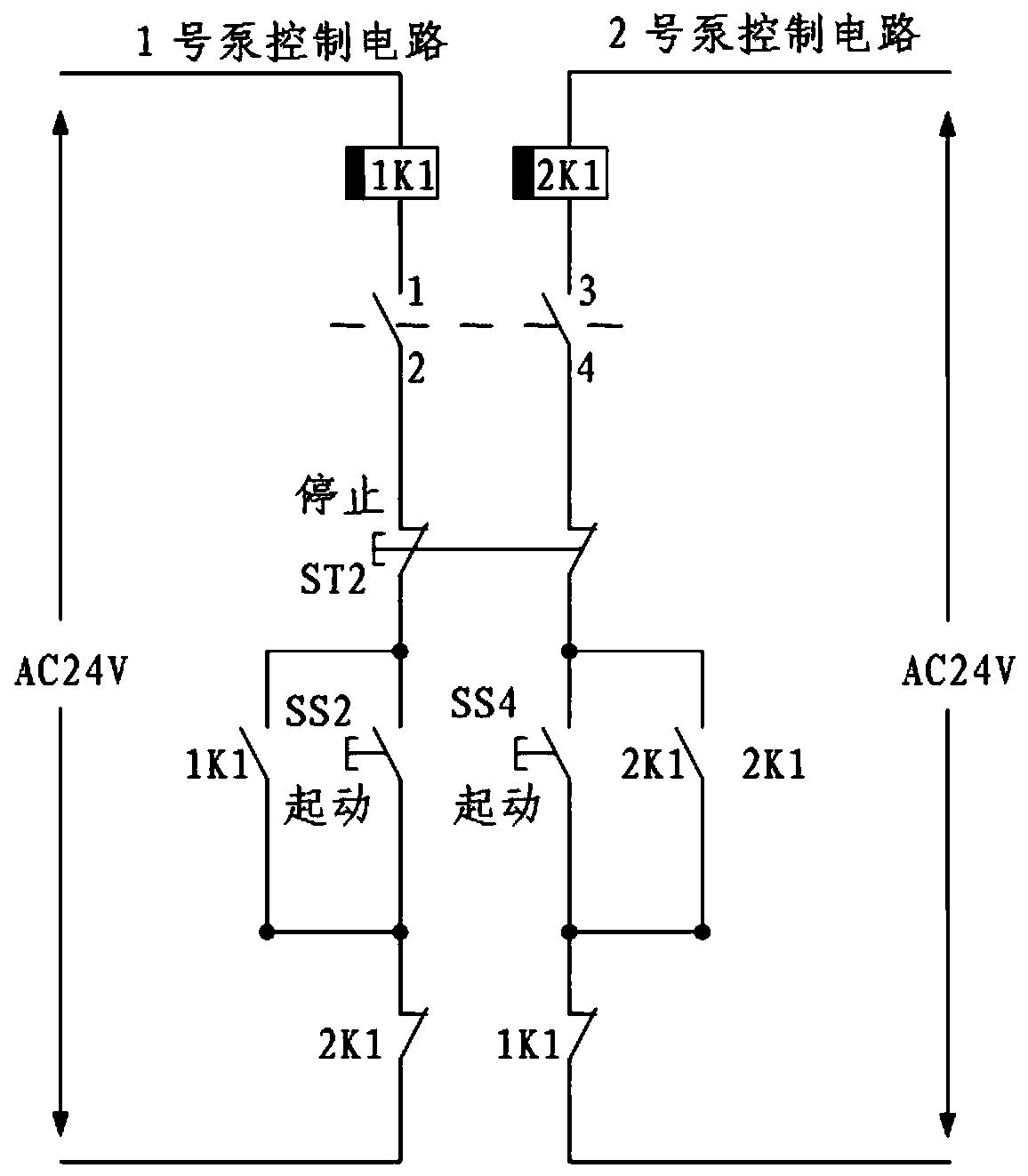

[0038] see Figure 1 to Figure 3 , a shafting lubricating oil pump motor frequency conversion automatic control device of the present invention includes a controller, a sensor, a frequency converter, a contactor, a control input device, an audible and visual alarm indicating device, a filter and a circuit breaker.

[0039] The controller is a PLC programmable controller, and the signal input terminals of the controller are respectively connected with the communication cables of the main control board of the propulsion motor and the signal output terminals of the sensors, and are used to receive the signals sent by the communication cables of the main control board of the propulsion motor and the sensors and calculate and Make logical judgments.

[0040] Sensors include flow sensor, rotational speed sensor, differential pressure senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com