Polymer composite membrane, method for preparing same and lithium ion battery

A polymer and composite membrane technology, applied in the field of lithium-ion batteries, can solve the problems of reduced bonding performance, low safety performance, thermal failure of the diaphragm, etc., to avoid the thermal runaway of the diaphragm, reduce the reaction heat release, and slow down the effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] At the same time, according to the second aspect of the present invention, a method for preparing a polymer composite film is provided, characterized in that the preparation method includes the following steps: S1, providing a polymer base film; S2, using a first resistant The spinning solution of the thermal polymer material and / or the spinning solution of the second heat-resistant polymer material is formed on at least one side surface of the polymer base film by electrospinning to form multiple sub-heat-resistant layers arranged in sequence The precursor is dried to remove the solvent to obtain a heat-resistant layer comprising multiple sub-heat-resistant layers, wherein the melting point of the first heat-resistant polymer material is not less than 200°C; the melting point of the second heat-resistant polymer material is not less than 100°C; the closed cell temperature of each sub-heat-resistant layer increases sequentially along the direction from the inside to the ...

Embodiment 1

[0095] Embodiment 1 (preparation of two-layer polymer composite film of PE base film-heat-resistant layer)

[0096] This example is used to illustrate the polymer composite membrane provided by the present invention and its preparation method.

[0097] (1) Forming a heat-resistant layer (including 6 layers of sub-heat-resistant layers with different materials)

[0098] Add the spinning polymer (see Table 2 for specific raw materials) and optional solubilizers into N,N-dimethylacetamide (DMAc) (commercially purchased from Aladdin Reagent Company, the same below), in a water bath at 70°C Under magnetic stirring, it is fully dissolved to form a spinning solution A-F with a polymer (aforesaid AS) concentration of 15% by weight;

[0099] Table 2

[0100]

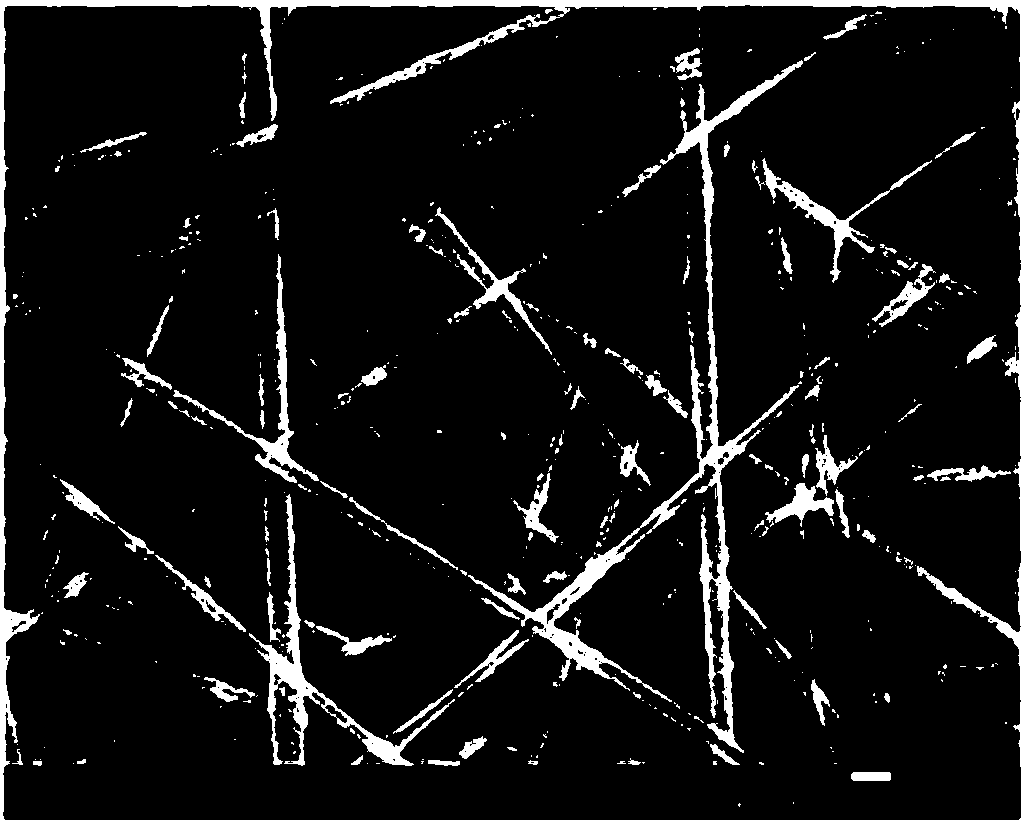

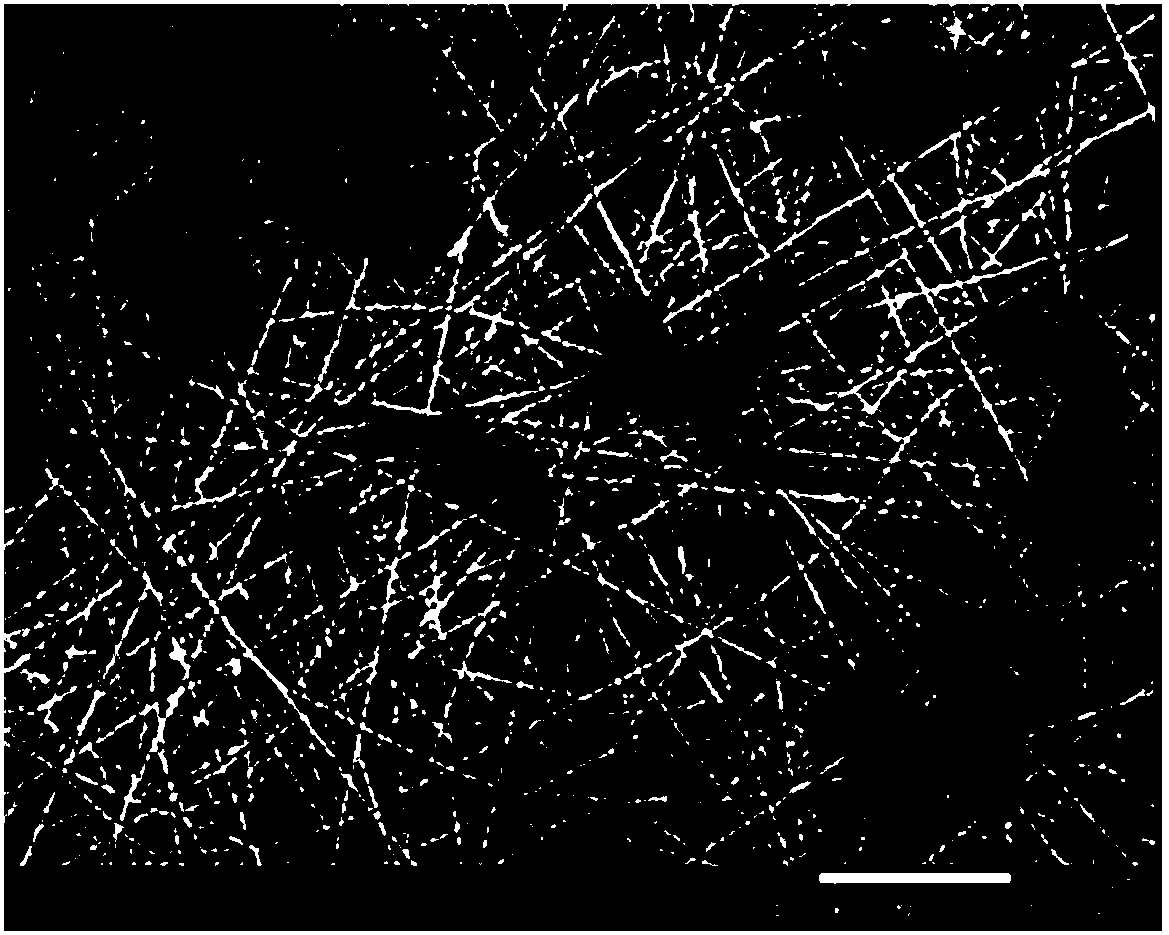

[0101] One side surface of the 11 μm PE base film (purchased from Japan SK Company, the brand is BD1201, the same below) is wrapped on the roller (collecting device), and the other side surface of the PE base film is electro...

Embodiment 2

[0108] Embodiment 2 (preparation of three-layer polymer composite film of heat-resistant layer-PE base film-heat-resistant layer)

[0109] This example is used to illustrate the polymer composite membrane provided by the present invention and its preparation method.

[0110] (1) Form the heat-resistant layer: adopt the method in embodiment 1 to form the first heat-resistant layer (thickness is 3 μ m, porosity 85%) at one side of PE base film earlier (the described first heat-resistant layer comprises PE On the surface of the base film, six sub-heat-resistant layers are sequentially formed, which are sub-heat-resistant layer A (thickness 0.5 μm, closed cell temperature 123 °C), sub-heat-resistant layer B (thickness 0.5 μm, closed cell temperature 132 °C) , sub-heat-resistant layer C (thickness 0.5 μm, closed cell temperature 140 ° C), sub-heat-resistant layer D (thickness 0.5 μm, closed cell temperature 176 ° C), sub-heat-resistant layer E (thickness 0.5 μm, closed cell tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com