Lubricating system of road surface acceleration loading equipment

A technology for accelerating loading and lubricating systems, applied in the field of lubricating systems, which can solve problems such as inability to cope with large gradient changes in extreme temperatures, affect normal operation of equipment, heat and wear of mechanisms, etc., achieve good lubrication, prolong service life, and avoid jamming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

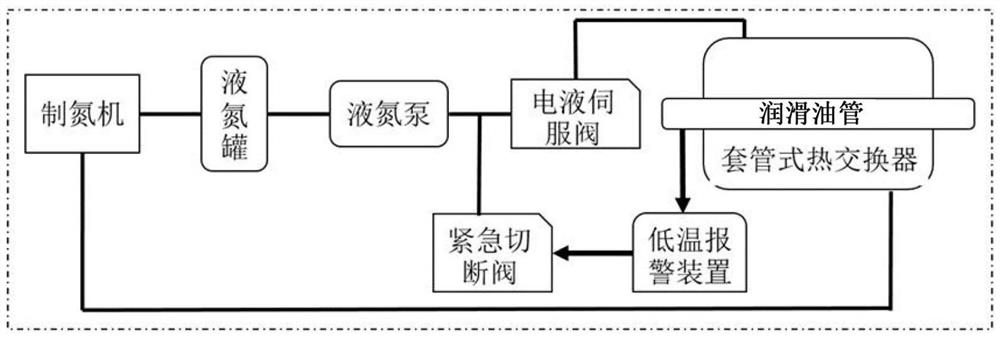

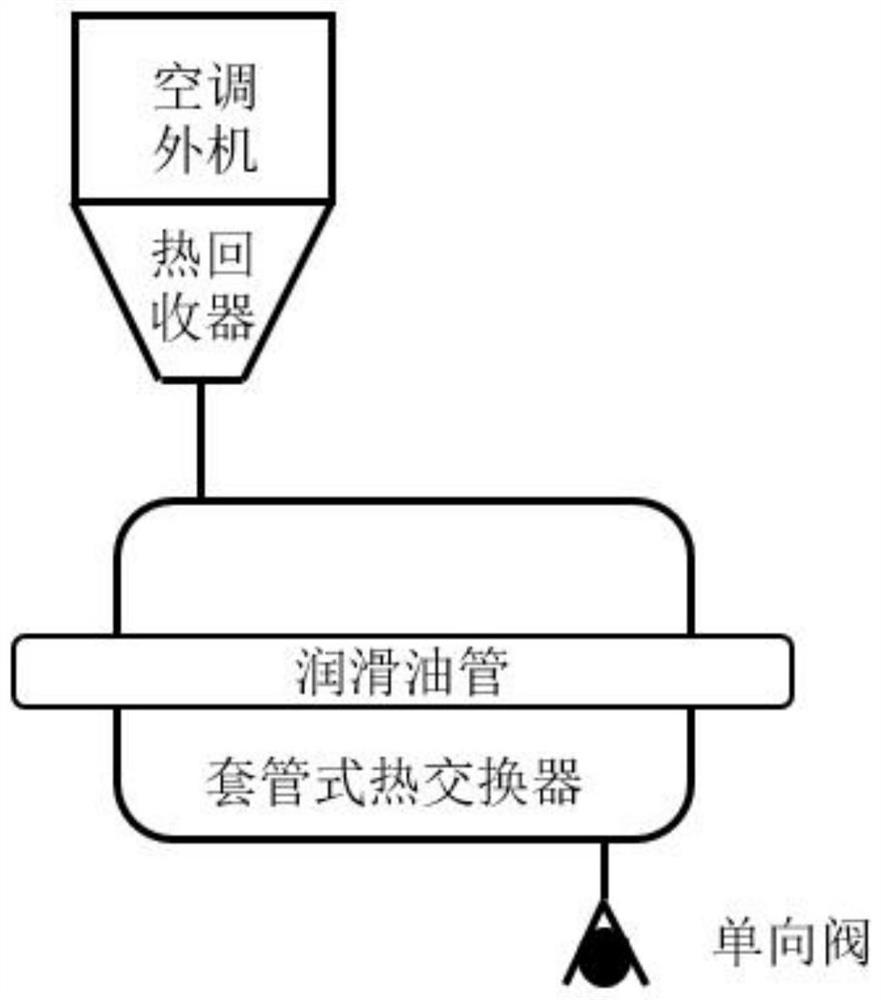

[0023] The invention discloses a lubricating system for road acceleration loading equipment, such as figure 1 As shown, it includes a control system and an oil supply system. The oil supply system provides lubricating oil to the acceleration loading equipment through the main oil supply pipeline. A liquid nitrogen cooling system 5 and air conditioning heat recovery heating are arranged between the oil supply system and the acceleration loading equipment. The system 6 and the lubrication parameter compensation system regulate the temperature of the lubricating oil in the main oil supply pipeline through the liquid nitrogen cooling system 5 and the air-conditioning heat recovery heating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com