Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Mouth cuts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

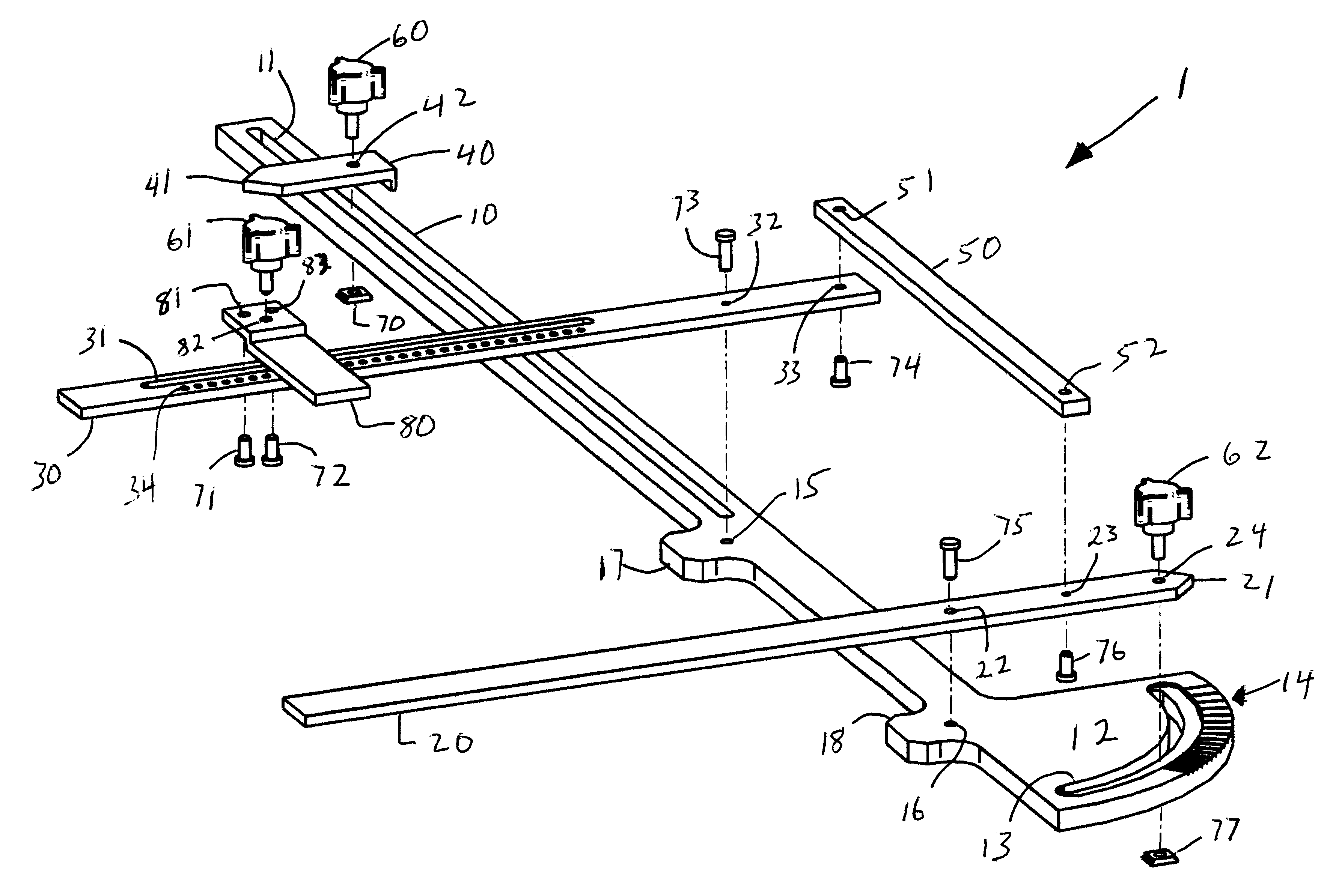

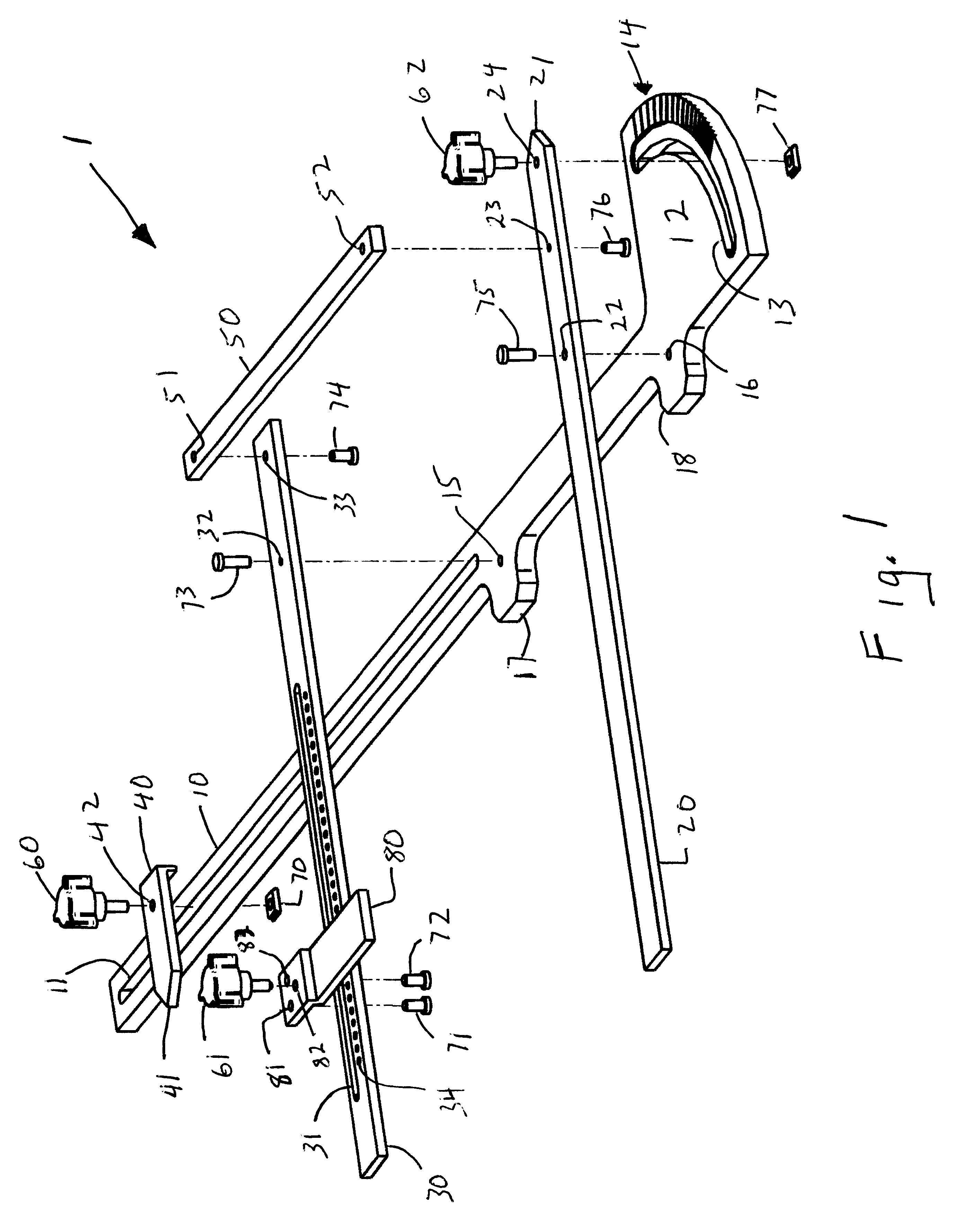

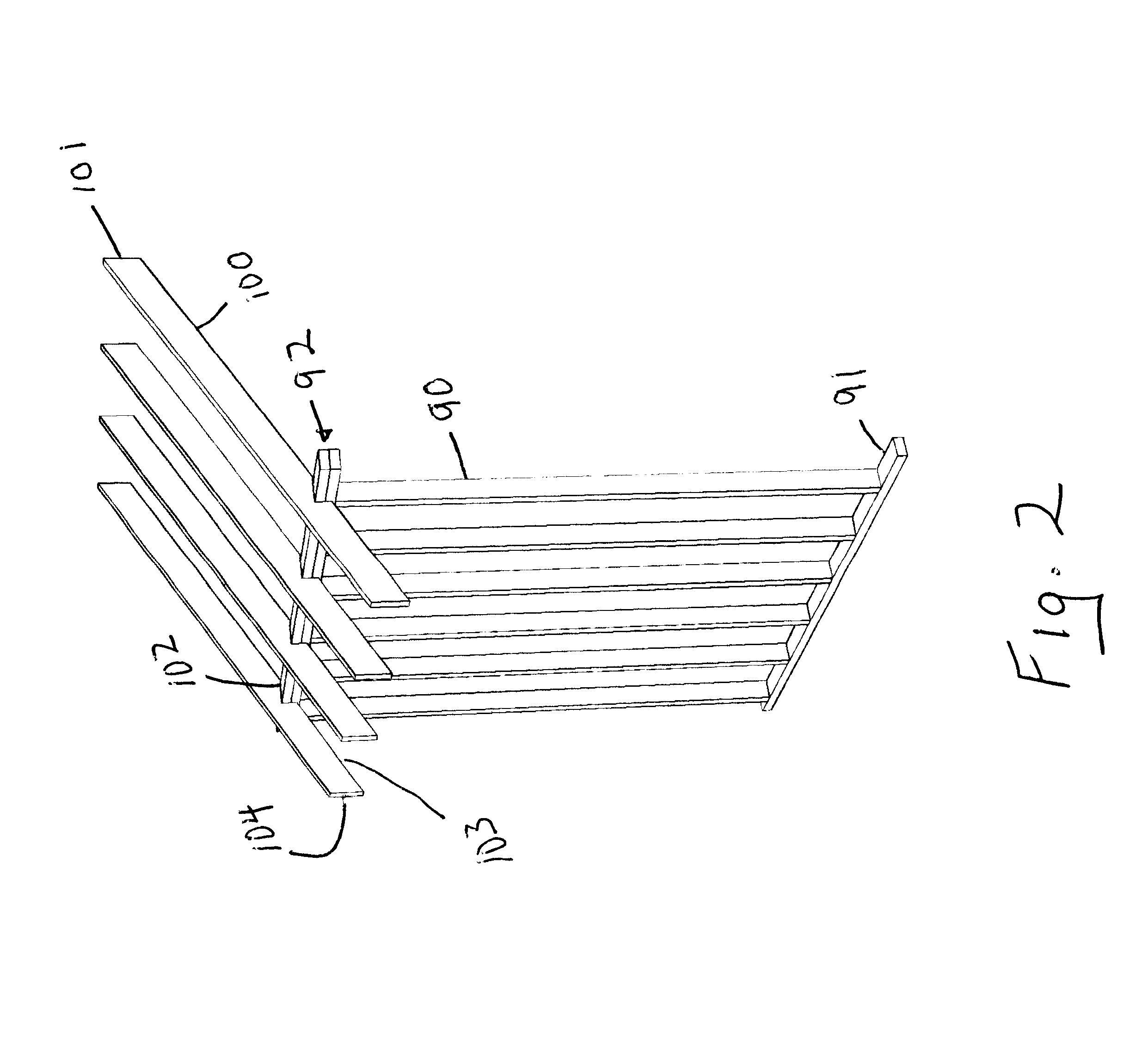

Common rafter and hip layout tool

A common rafter and hip layout tool which provides a protractor portion, a common cut marking edge, a common cut marking edge pantograph arm to which is connected a bird's mouth marking arm, a seat cut marking arm connected at a right angle to the bird's mouth marking arm and a tail length marking arm. The pantograph arm and connected bird's mouth marking arm facilitates the marking of the bird's mouth cut and the seat cut. Movement of the common cut marking edge to the location indicated by the tail length marking arm facilitates the making of parallel cuts for the common rafter ridge cut and the tail cut.

Owner:NYQUIST SHELBY M

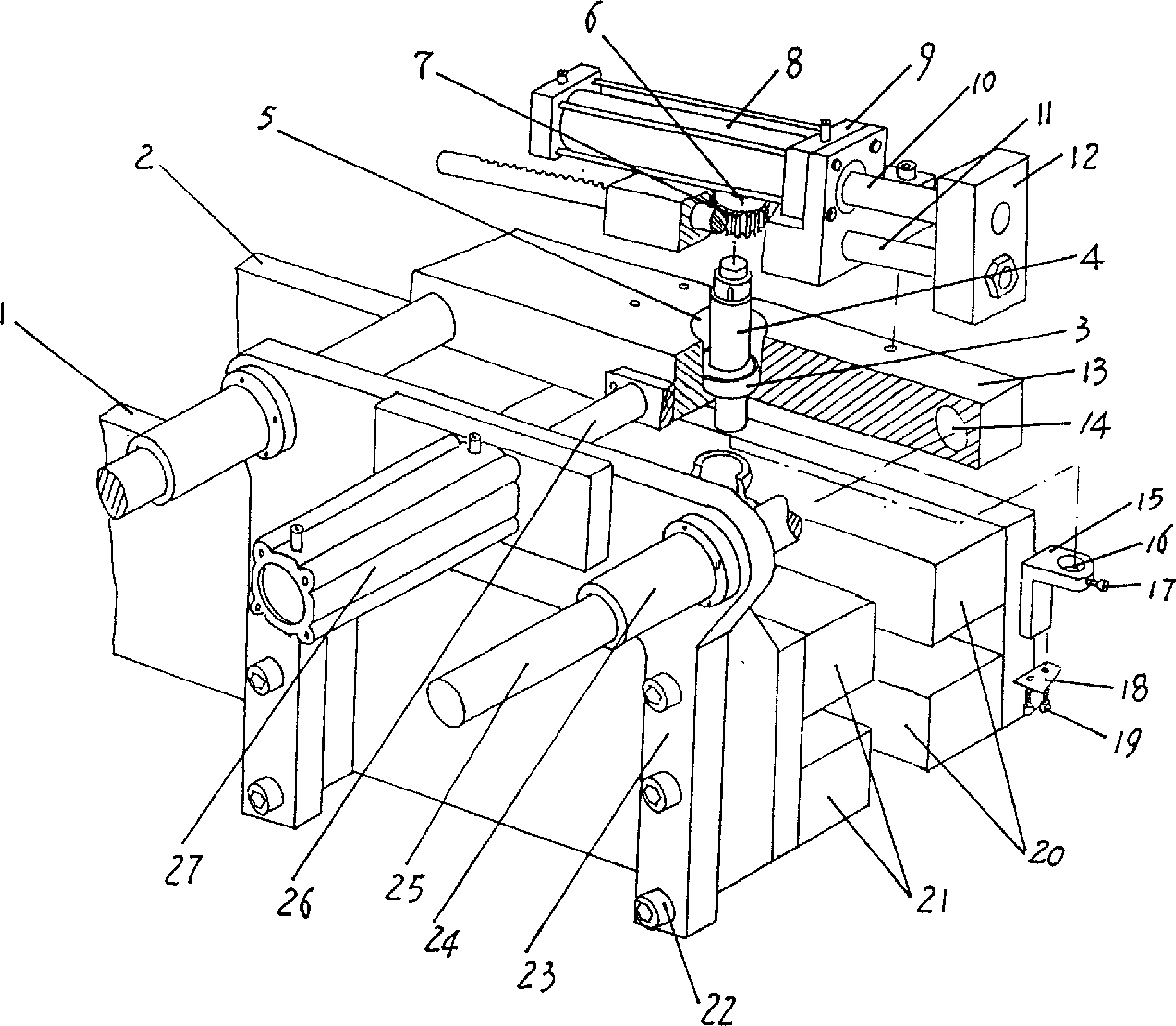

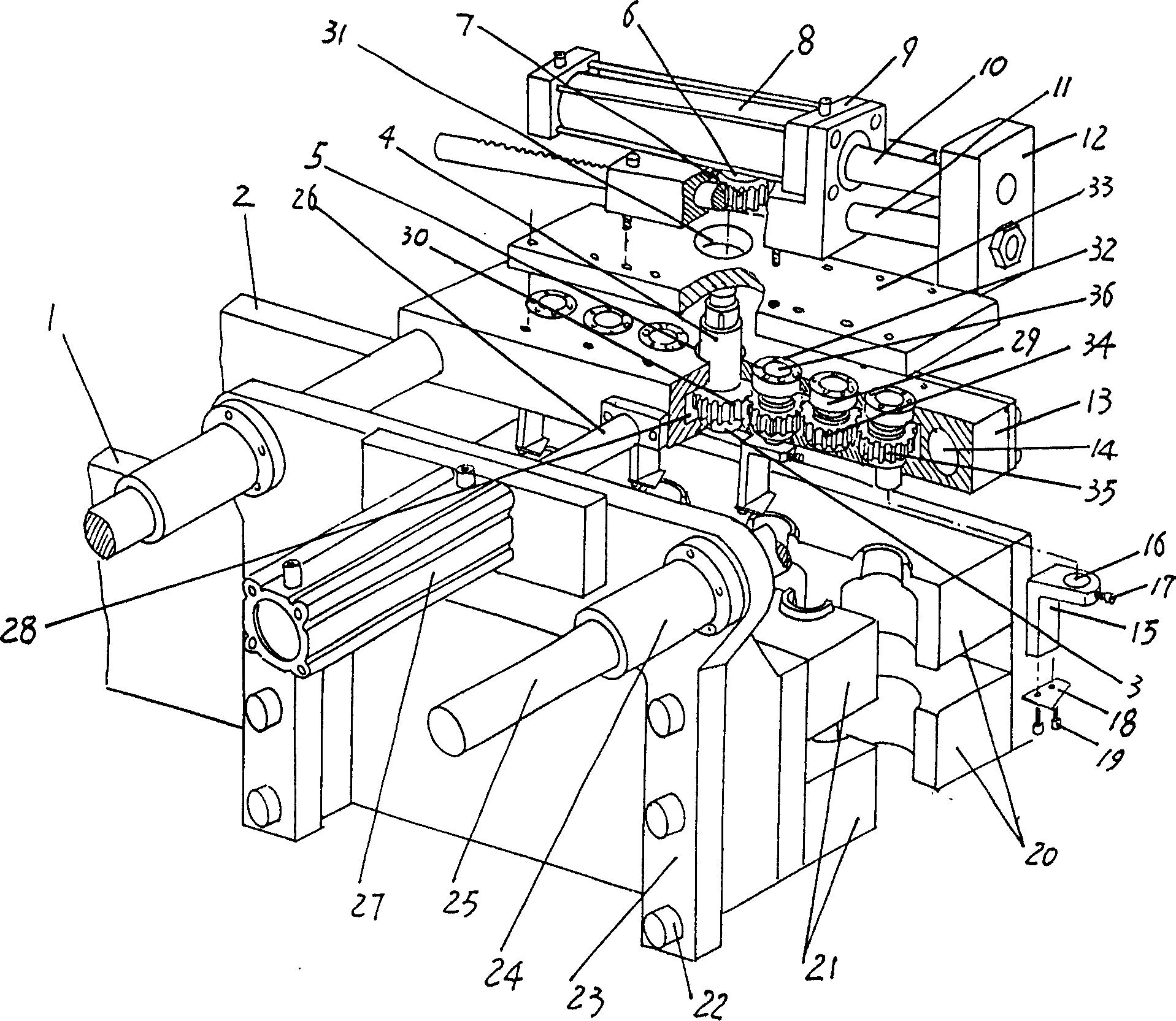

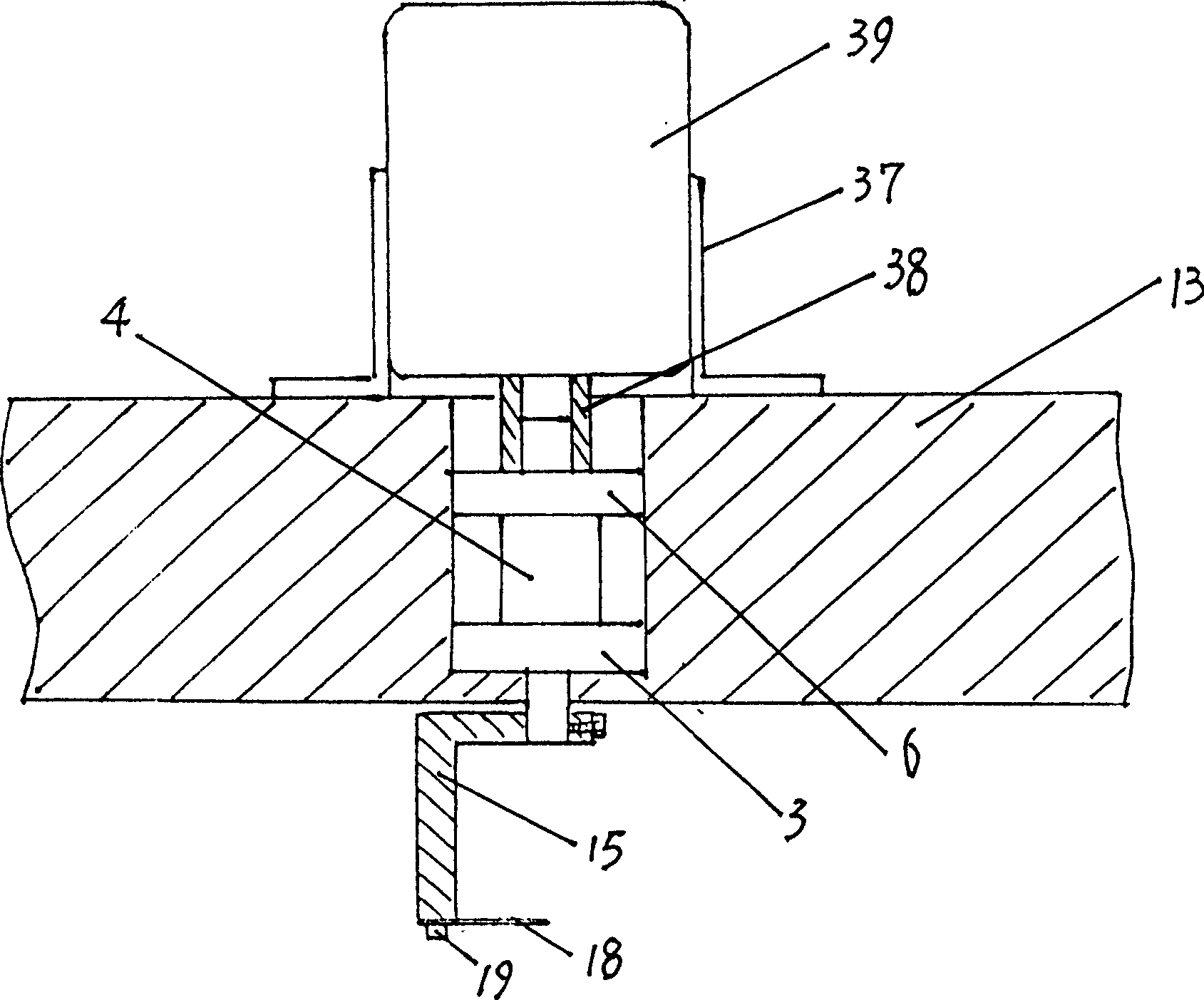

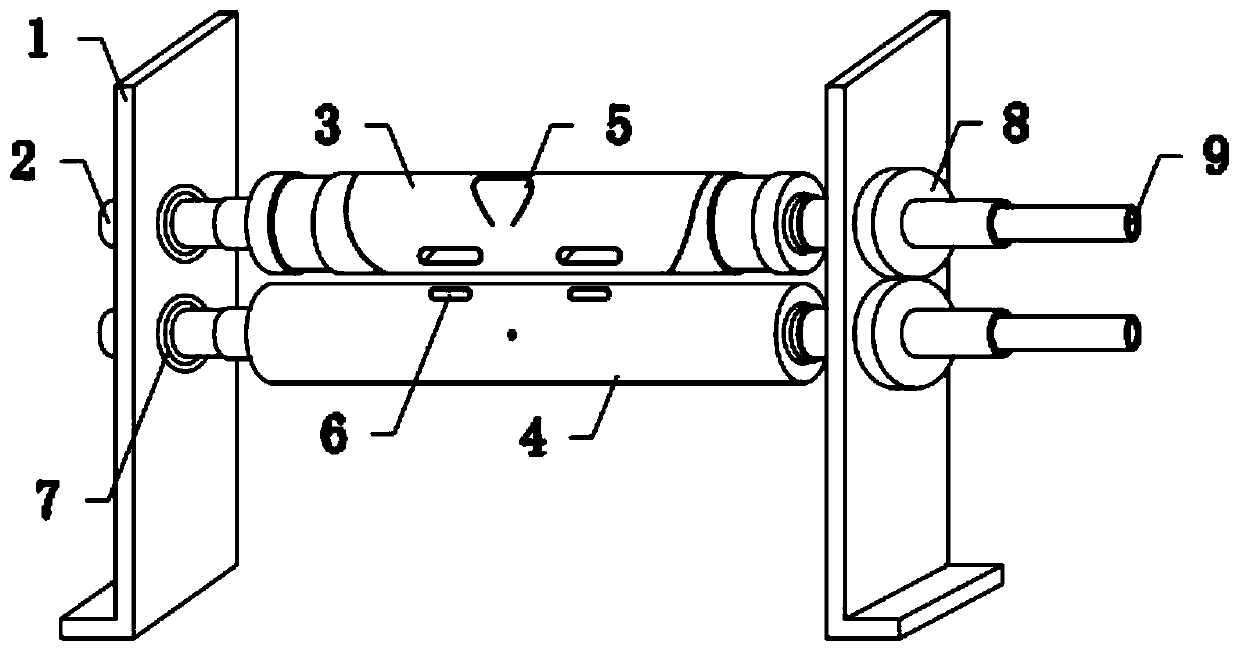

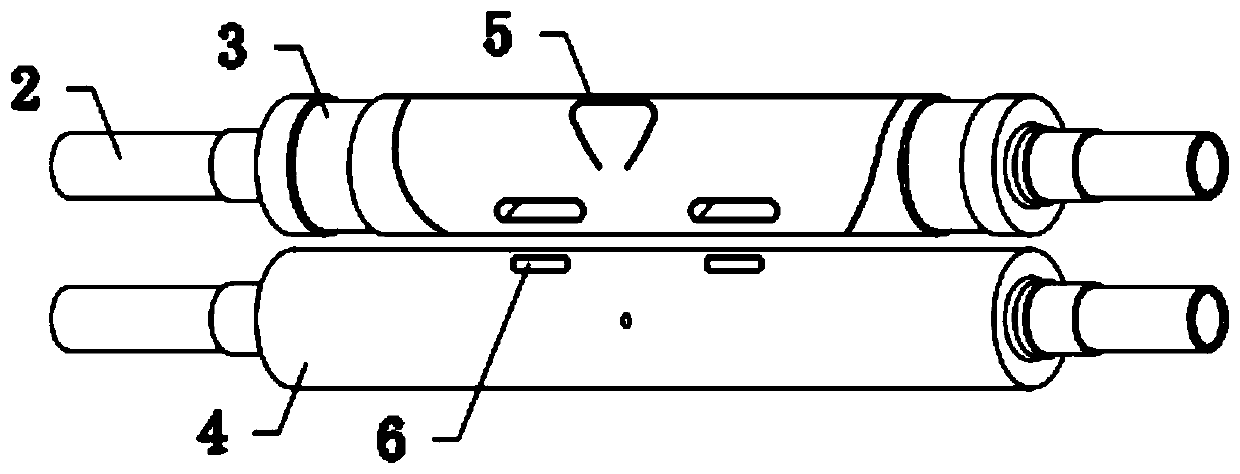

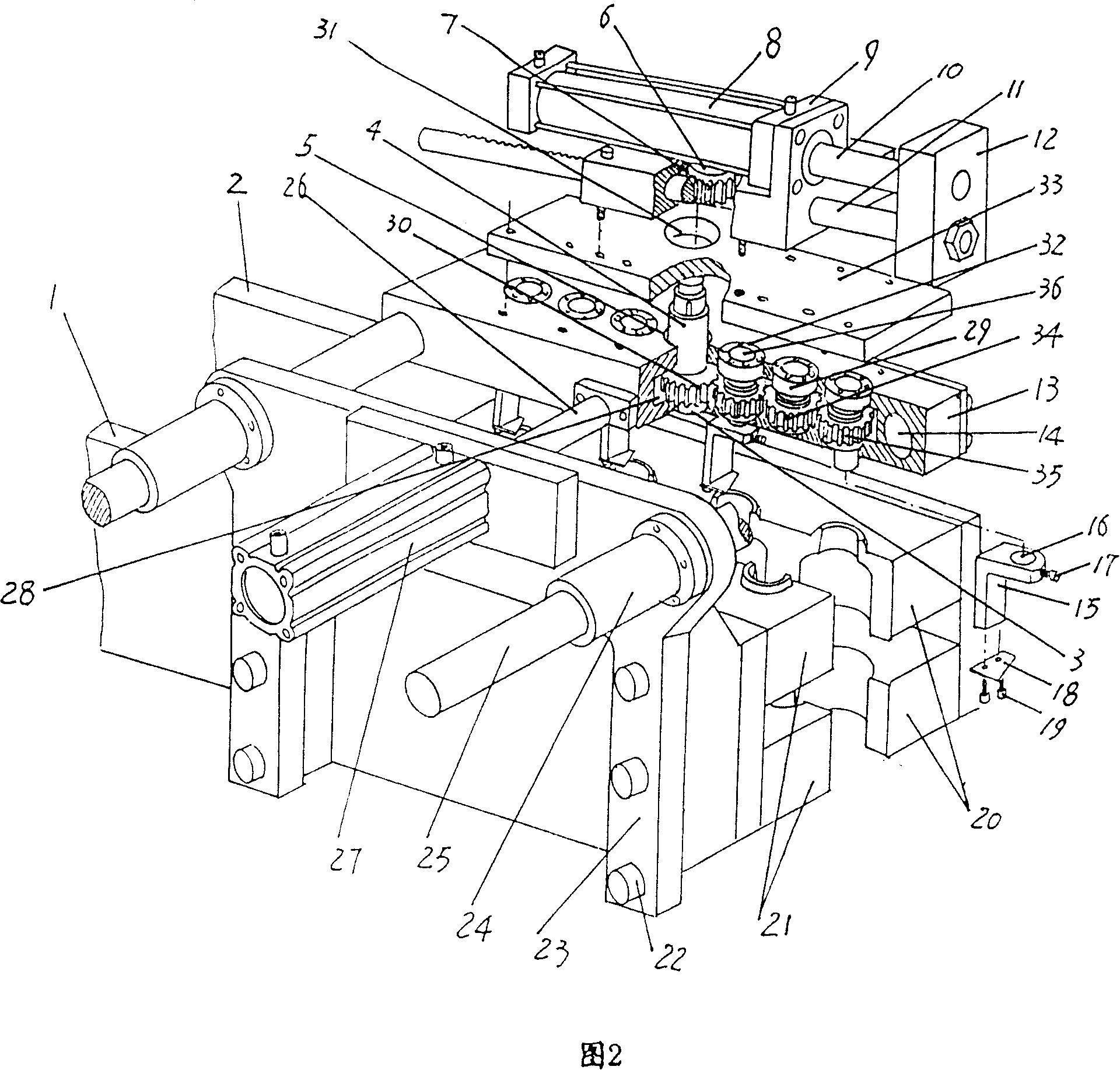

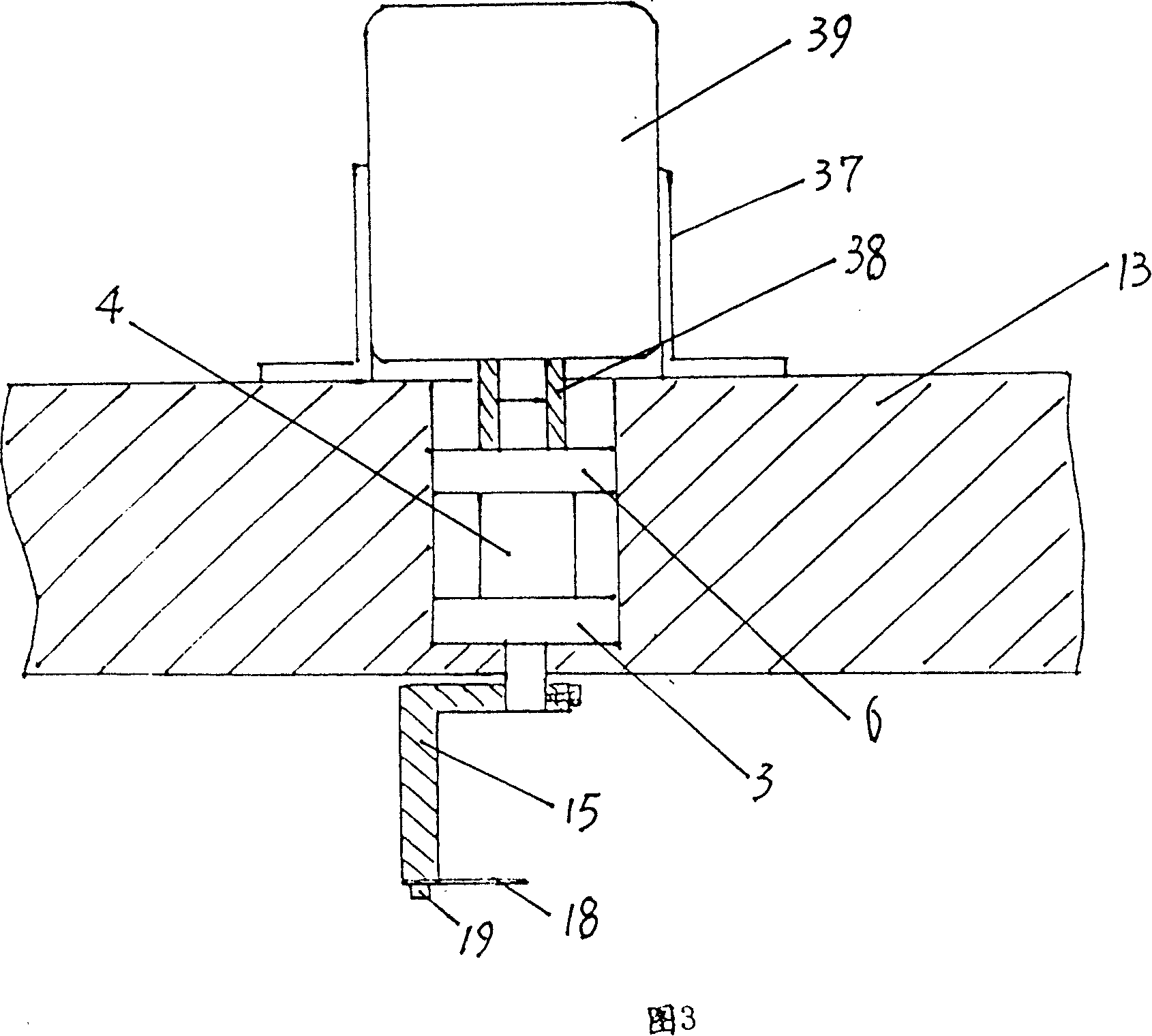

Bottle mouth cutting mechanism of automatic bottle blow molding machine

ActiveCN1654189AEliminate movement errorsGuaranteed cutting qualityDomestic articlesMetal working apparatusBlow moldingMolding machine

The bottle mouth cutting mechanism as one auxiliary mechanism for automatic bottle blowing and molding machine includes one bottle holding device, one moving device and one bottle mouth flash edge cutting device. The bottle holding device is connected to one inner and outer mold plate pair capable of being opened and closed in the automatic bottle blowing and molding machine; the moving device is set on the bottle holding device; and the bottle mouth flash edge cutting device is set on the moving device and over the bottle holding device. The said structure makes the three parts of the bottle holding device, the moving device and the bottle mouth flash edge cutting device connected into one integral and this results in high cutting quality, simple integral structure and high cutting efficiency.

Owner:ZHANGJIAGANG TONGDA MACHINERY

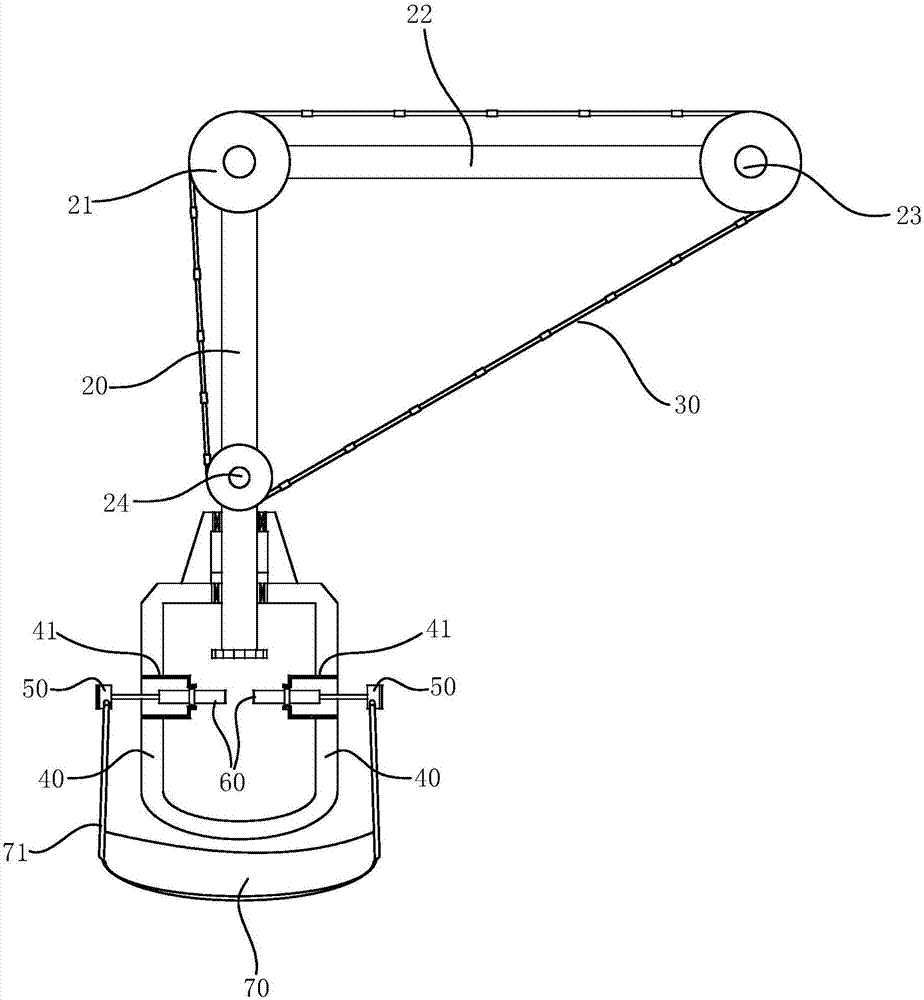

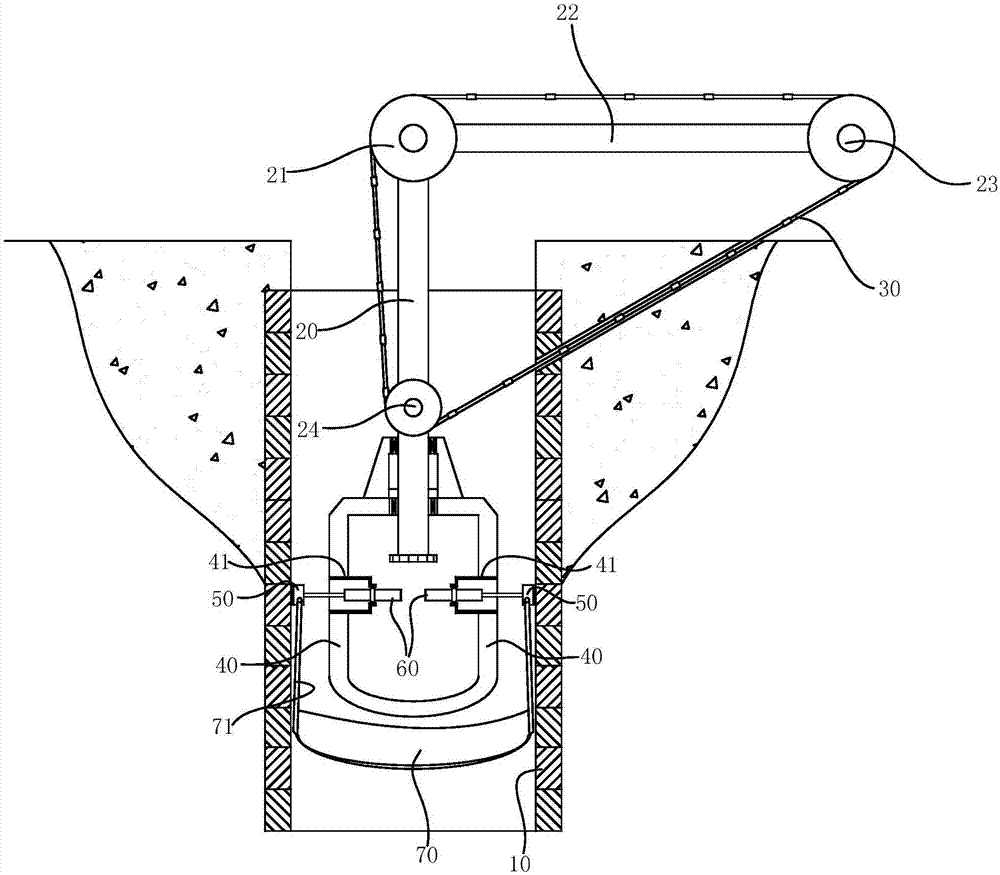

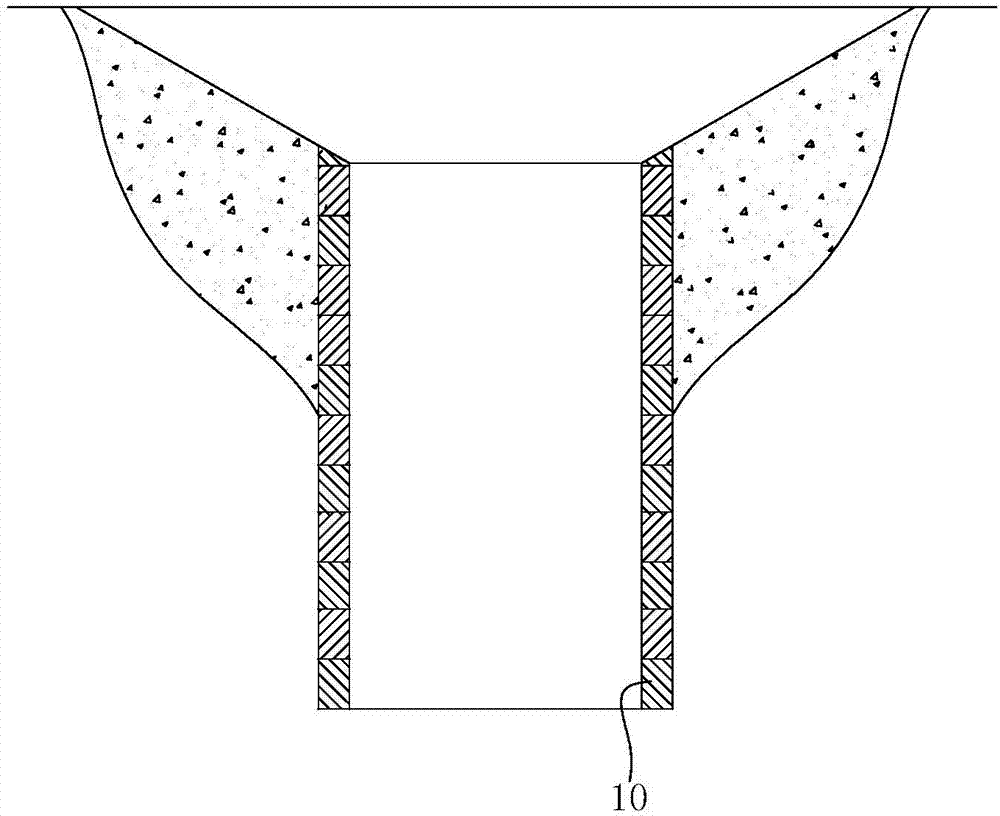

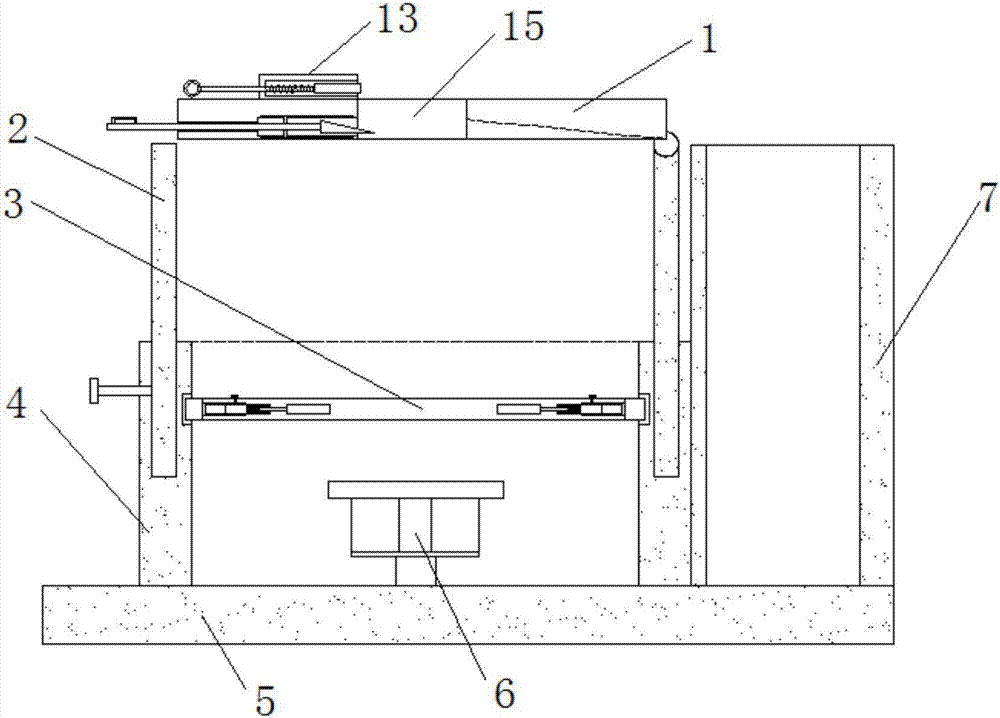

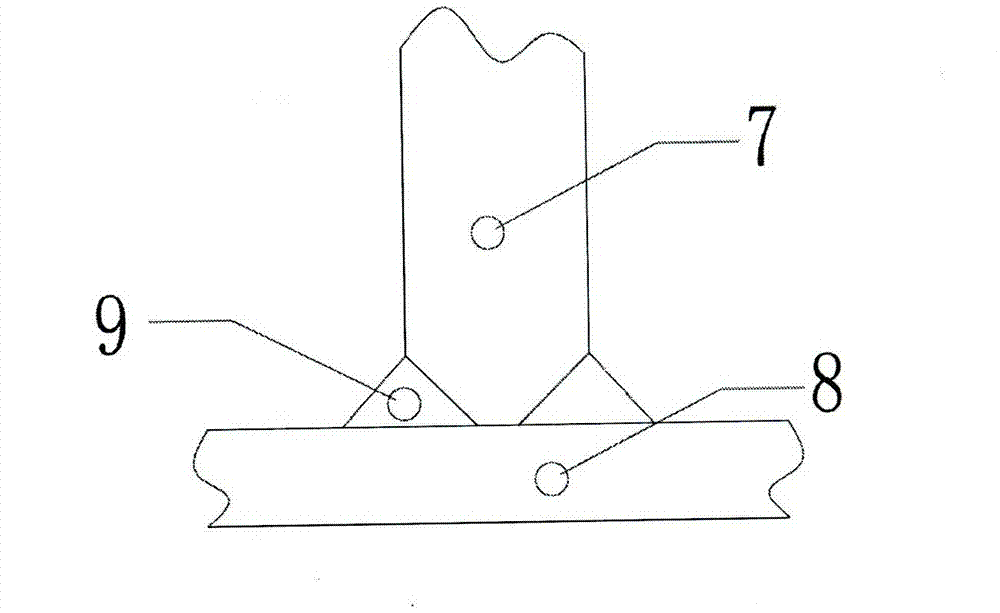

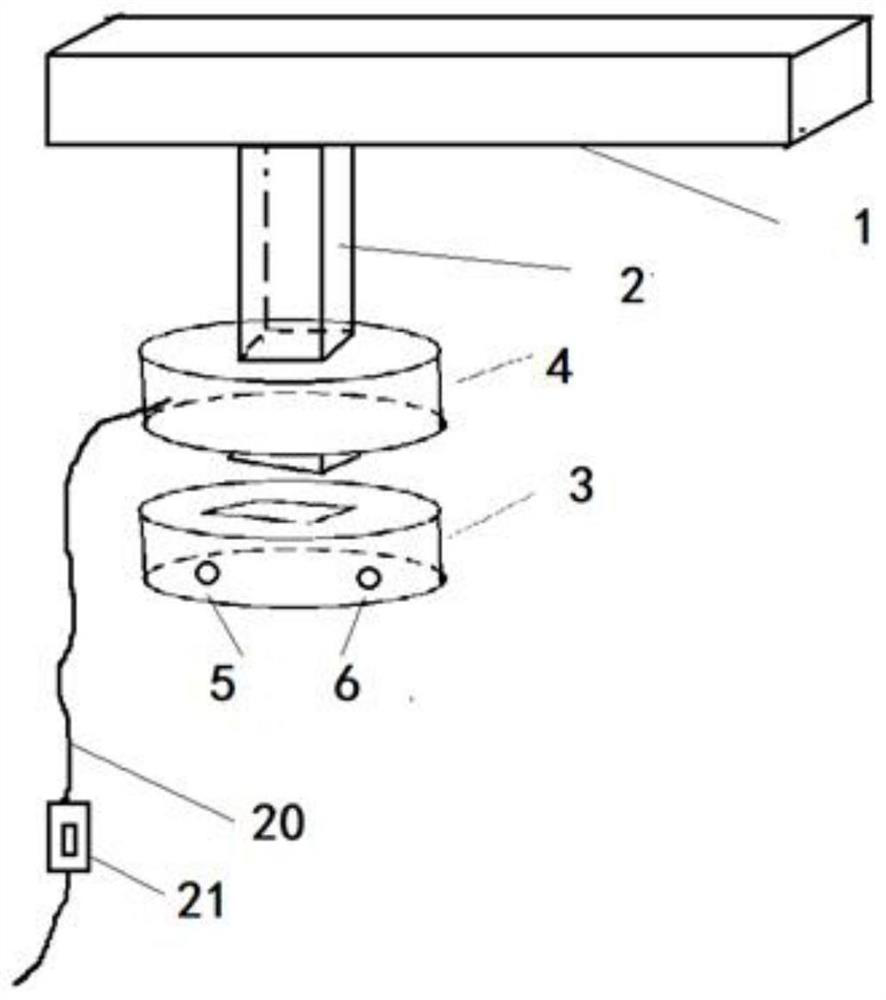

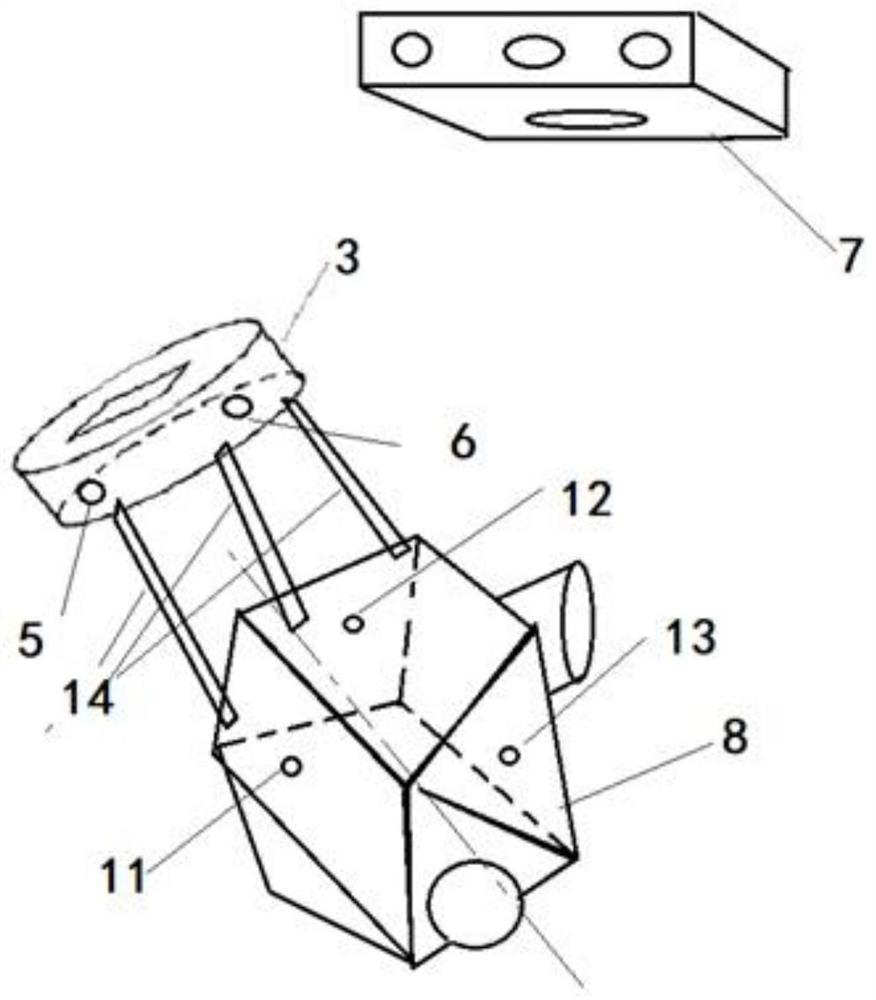

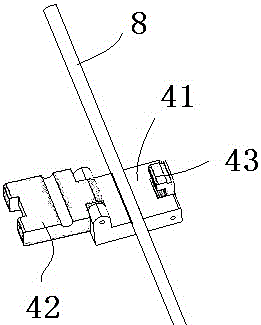

Inspection well mouth cutting device and inspection well mouth construction method

ActiveCN107310050ANo need to manually breakImprove cutting efficiencyWorking accessoriesUnderwater structuresMouth cutsEngineering

The invention relates to an inspection well mouth cutting device. The inspection well mouth cutting device comprises a positioning mechanism extending into an inspection well mouth. A supporting rod is vertically arranged on the positioning mechanism. The rod core of the supporting rod is the same as an inspection well. A driving mechanism drives the supporting rod to rotate. The upper end of the supporting rod is provided with a rope saw. The rope saw penetrates through the well wall of the inspection well and obliquely extends upwards. By means of the obliquely arranged rope saw, the inspection well mouth can be constructed conveniently. The driving mechanism is started to make the supporting rod rotate in a wellhole of the inspection well so as to realize cutting operation on the inspection well mouth. Through the obliquely arranged rope saw, the cut well mouth is made in a cone-frustum shape. Thus, an inspection well lid module matched with the wellhole of the inspection well is also in a cone-frustum shape and just needs to be prefabricated in advance.

Owner:袁奥

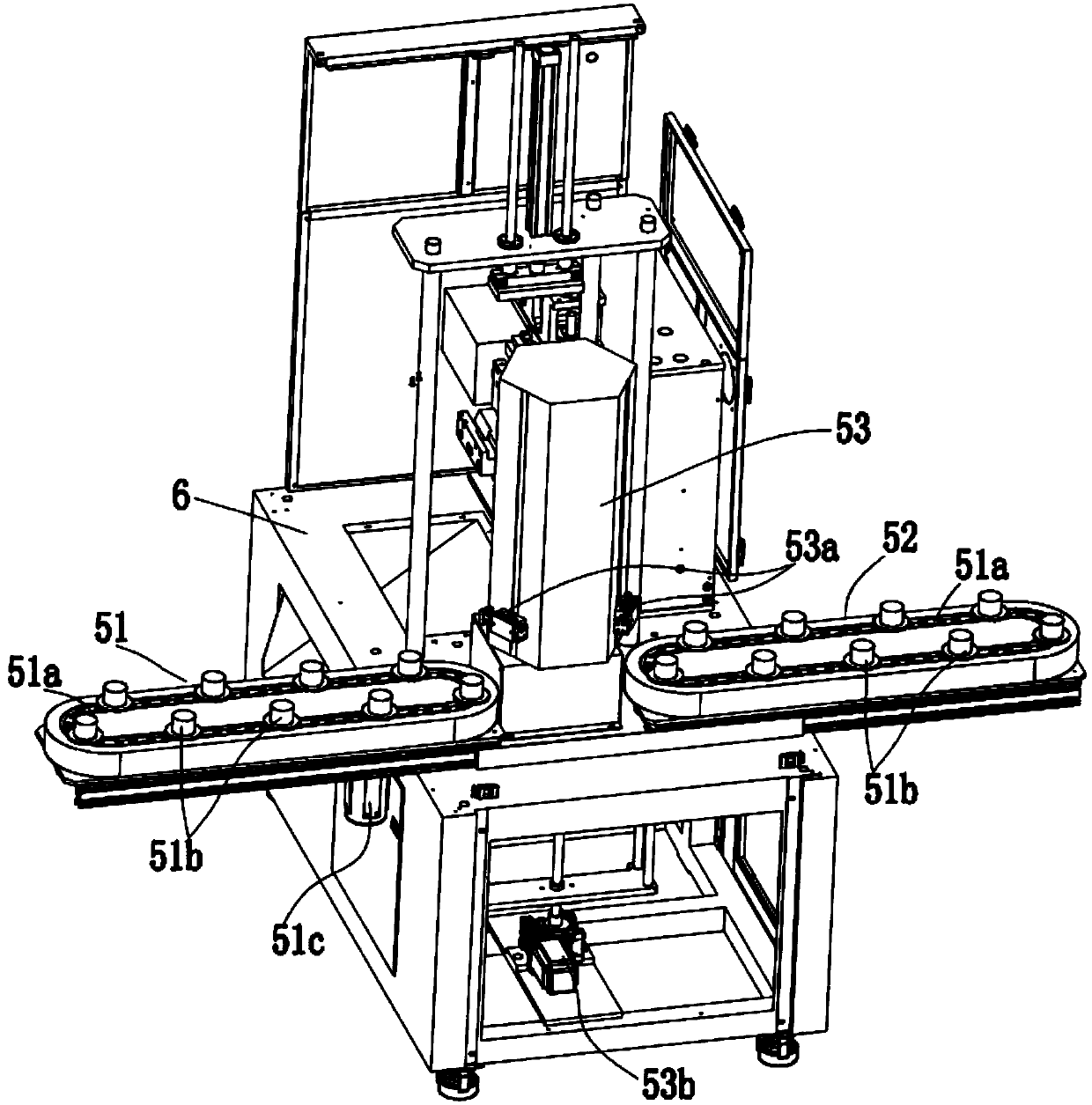

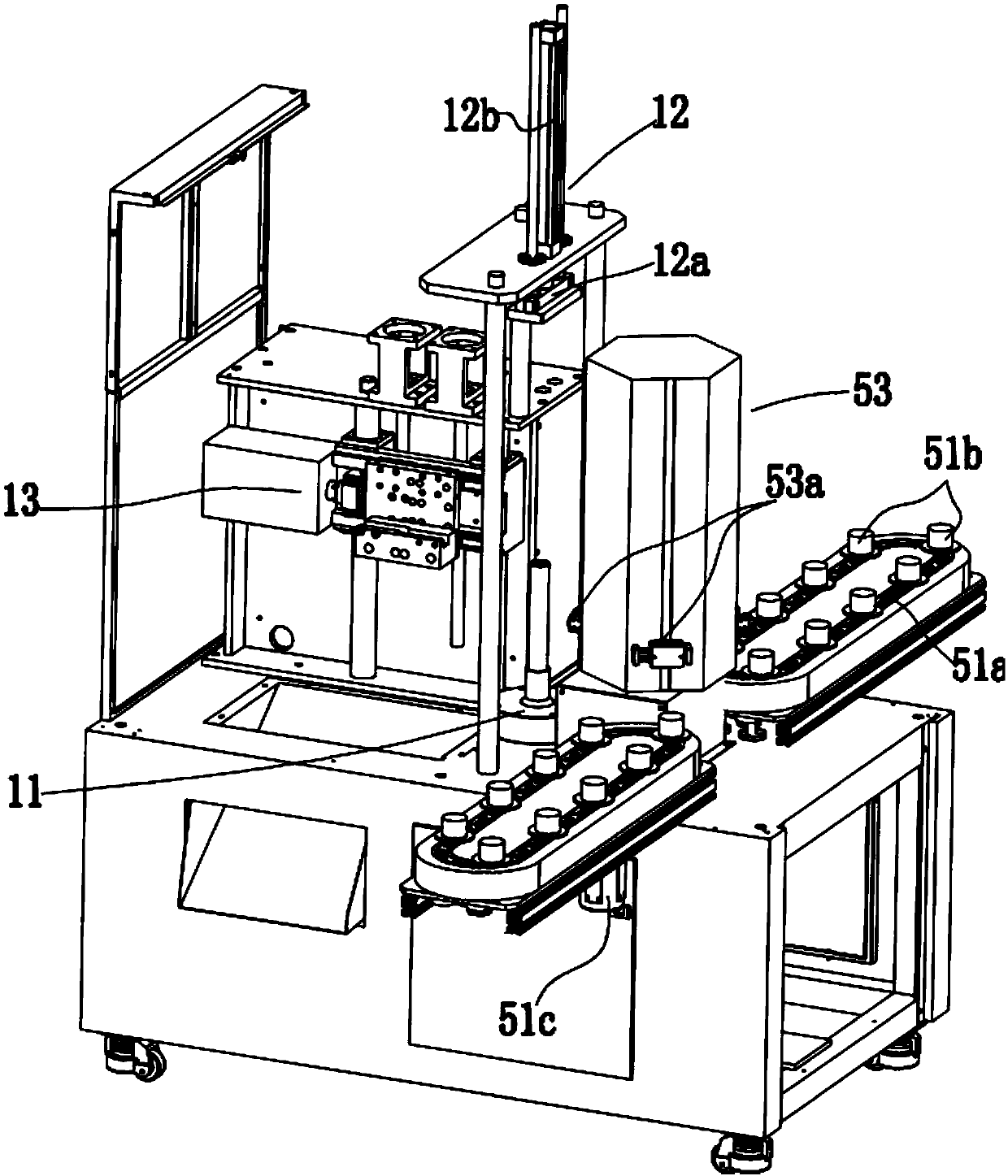

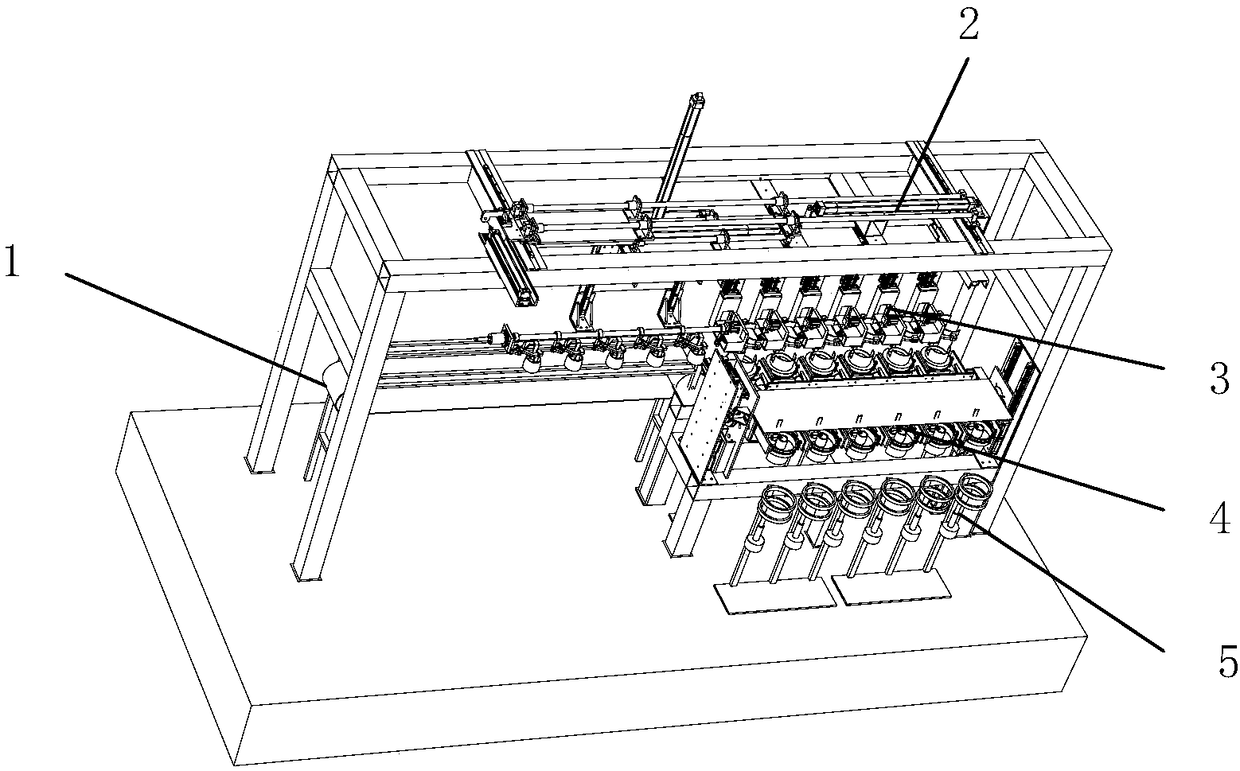

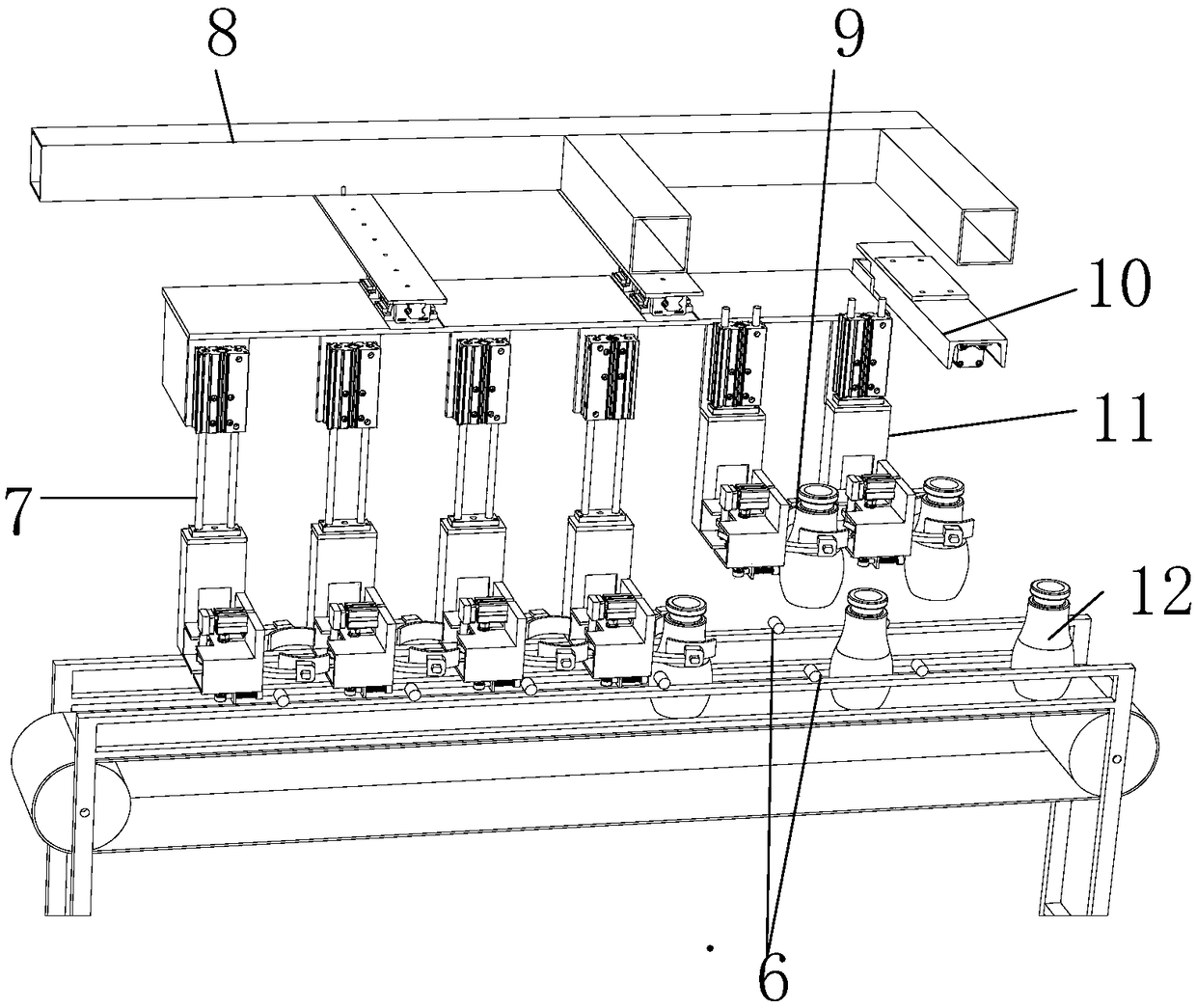

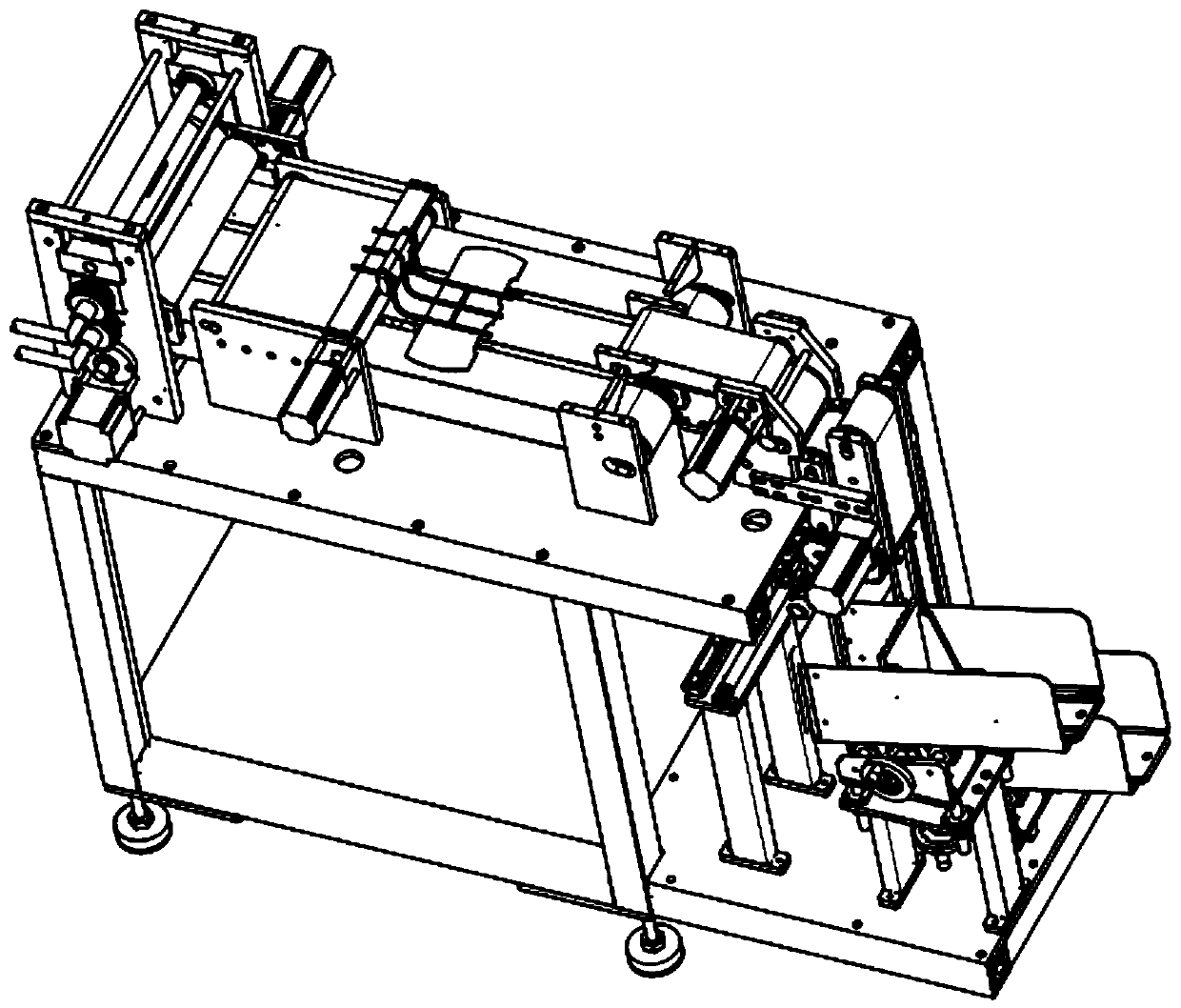

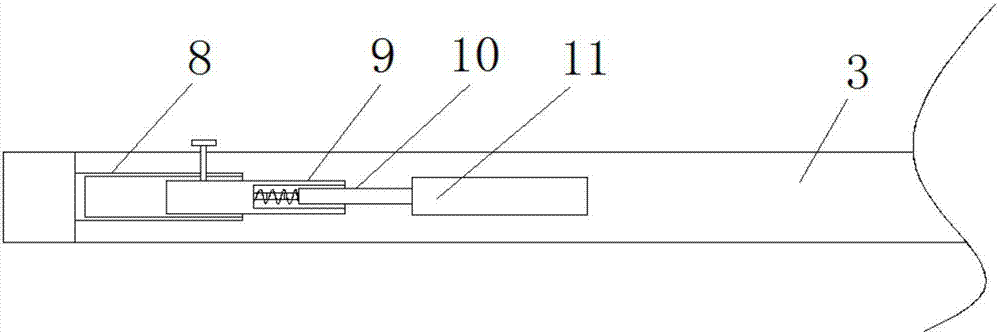

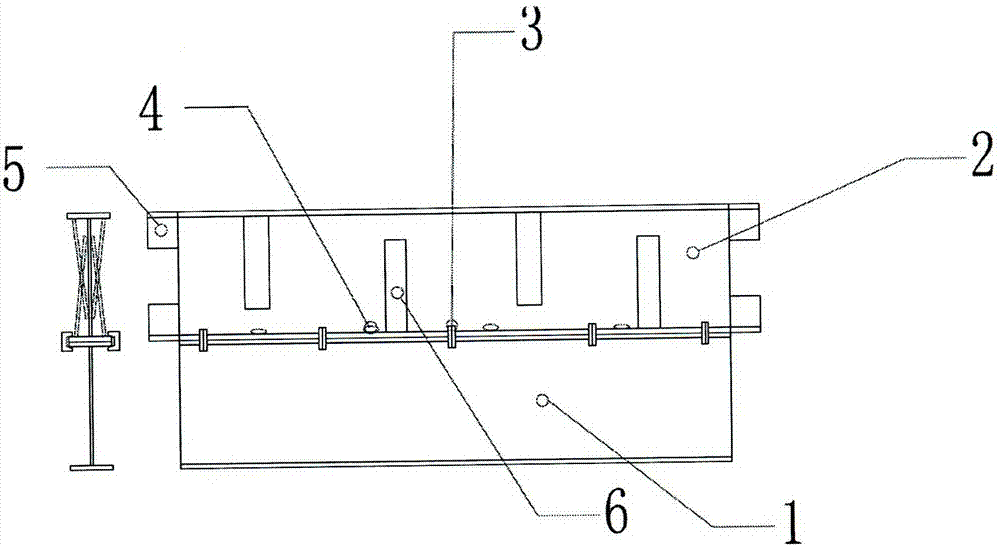

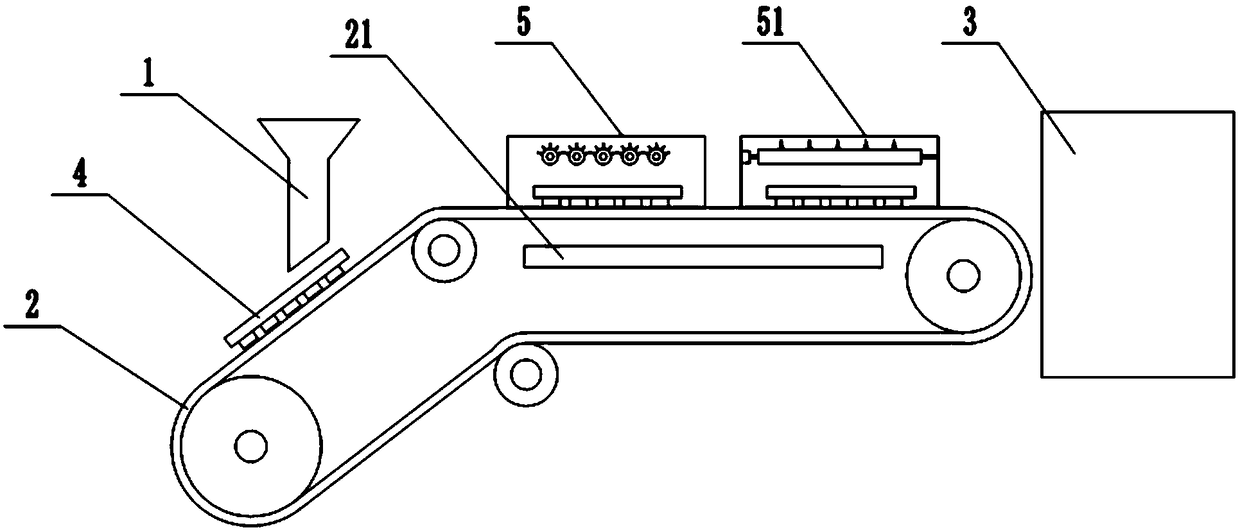

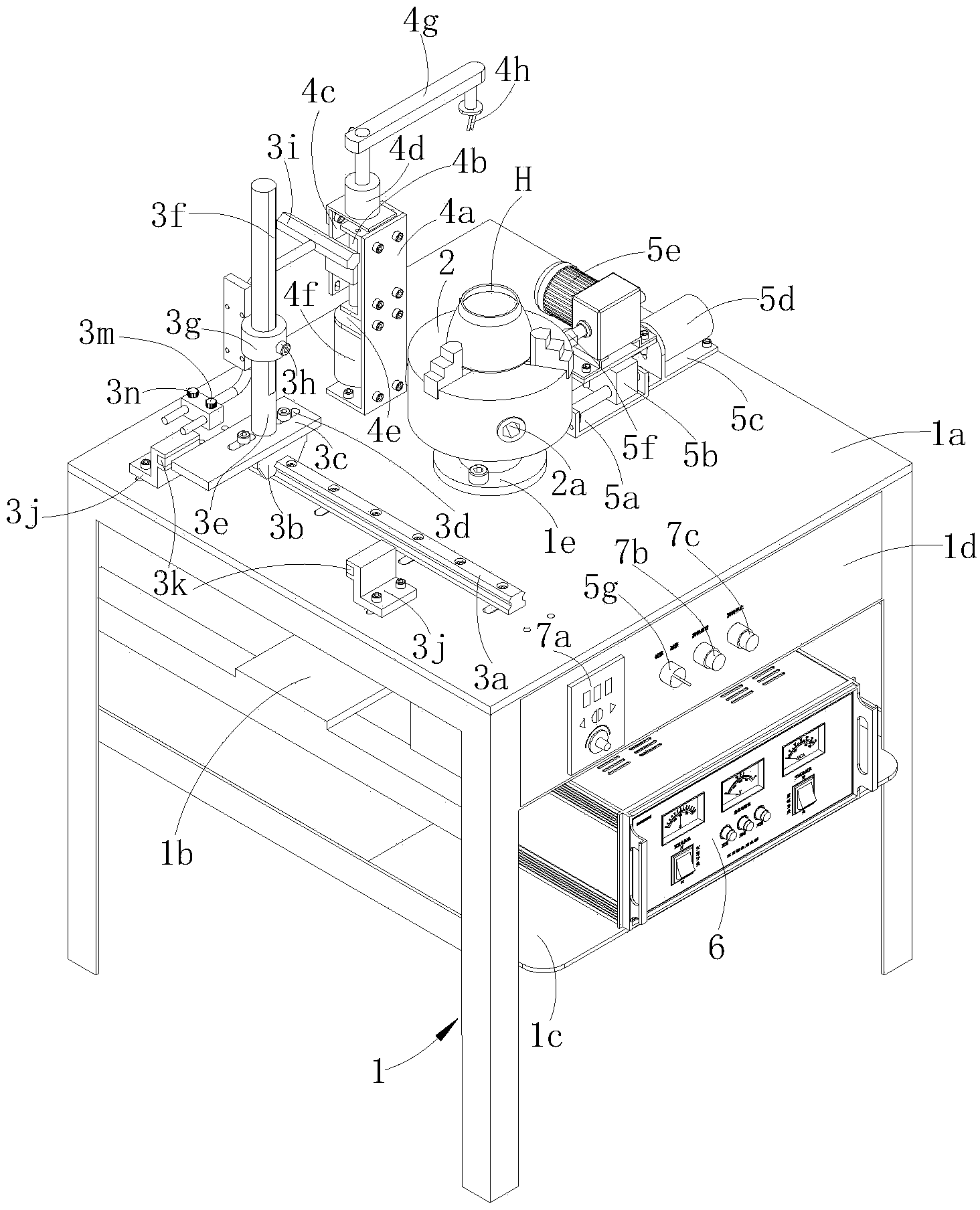

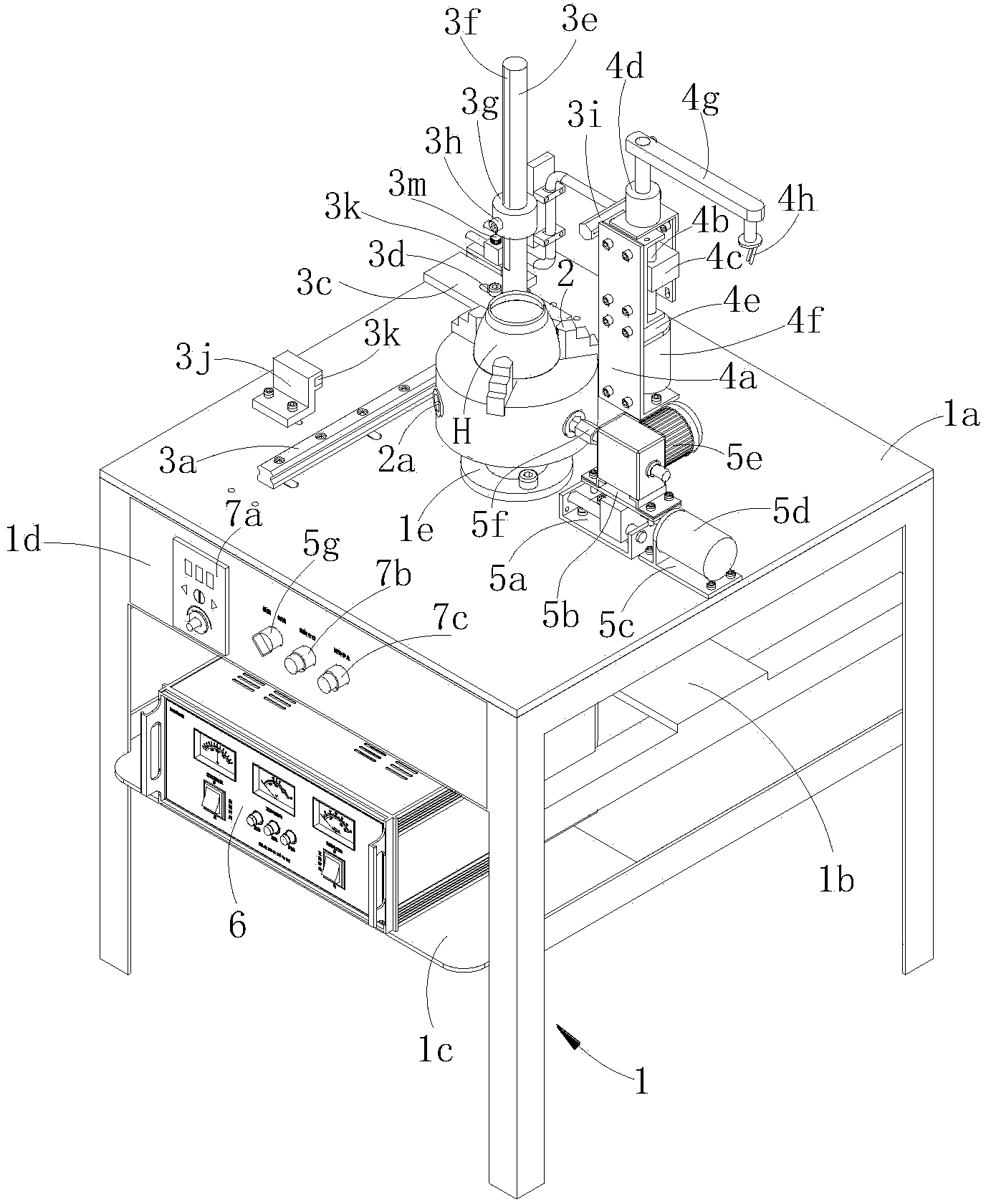

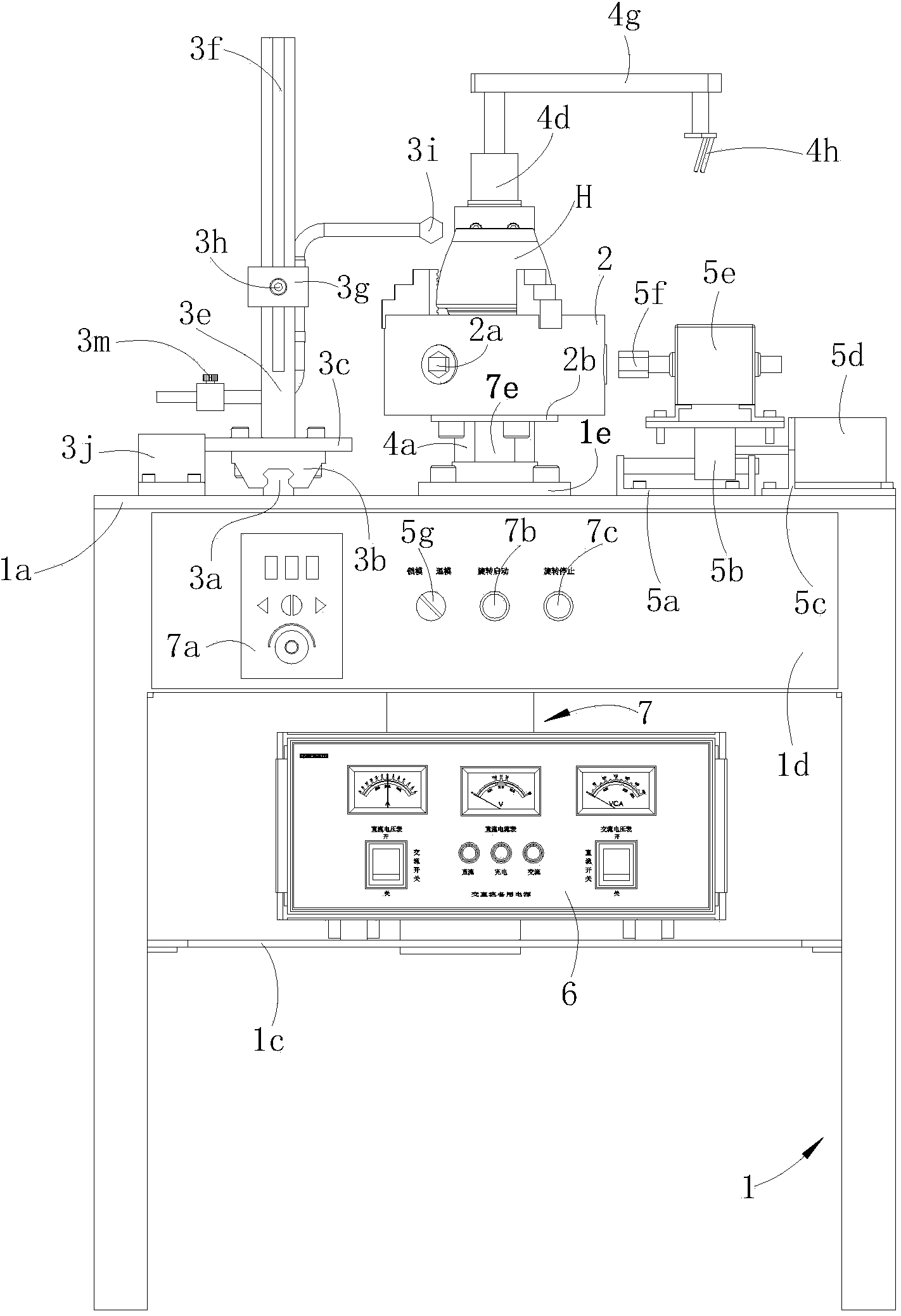

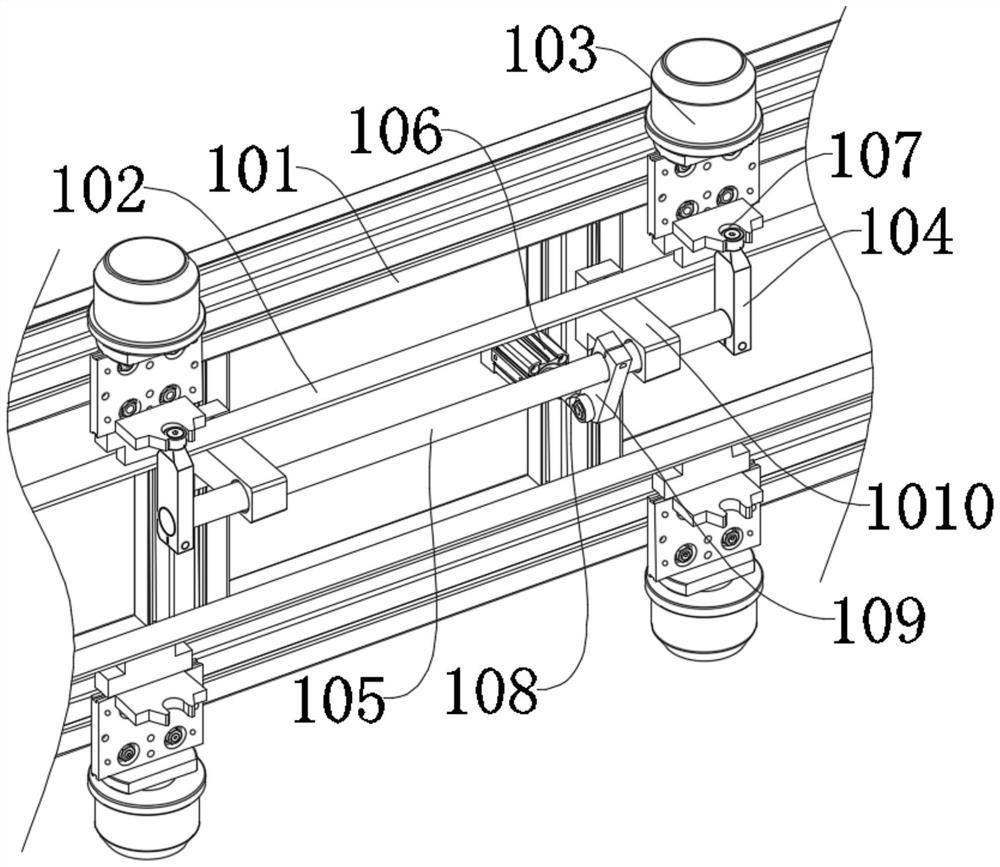

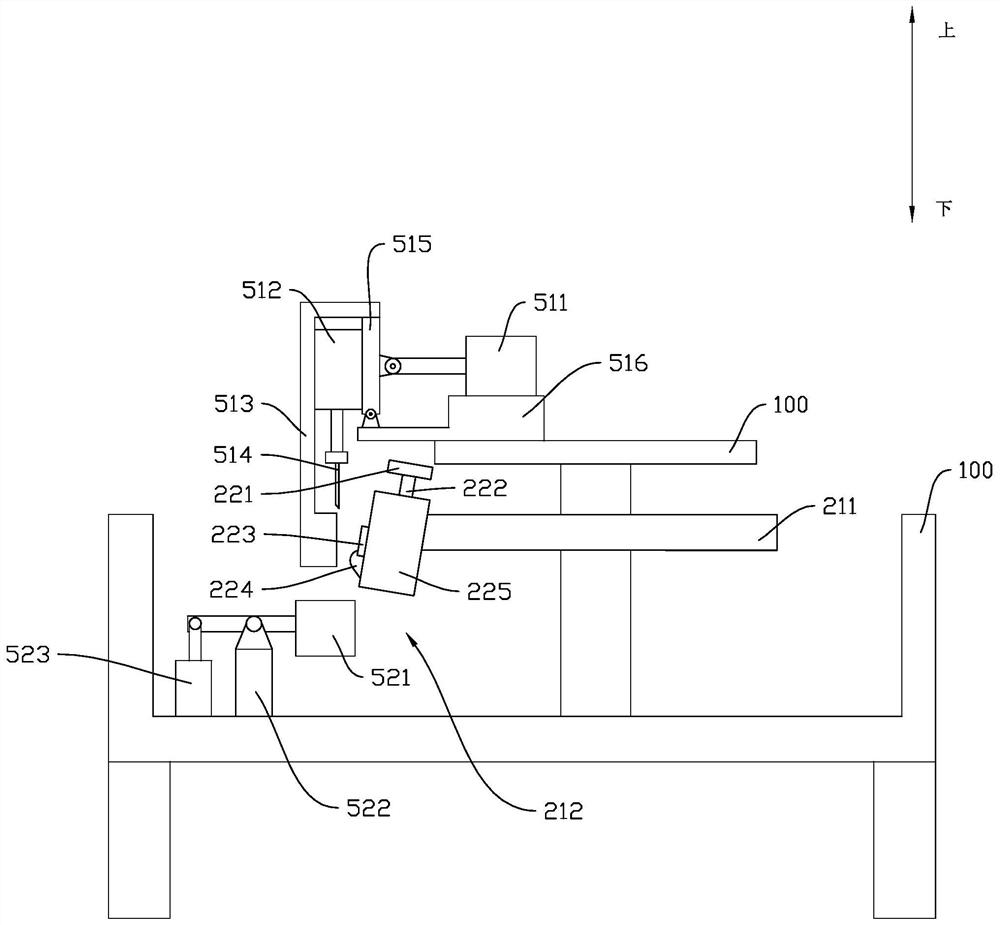

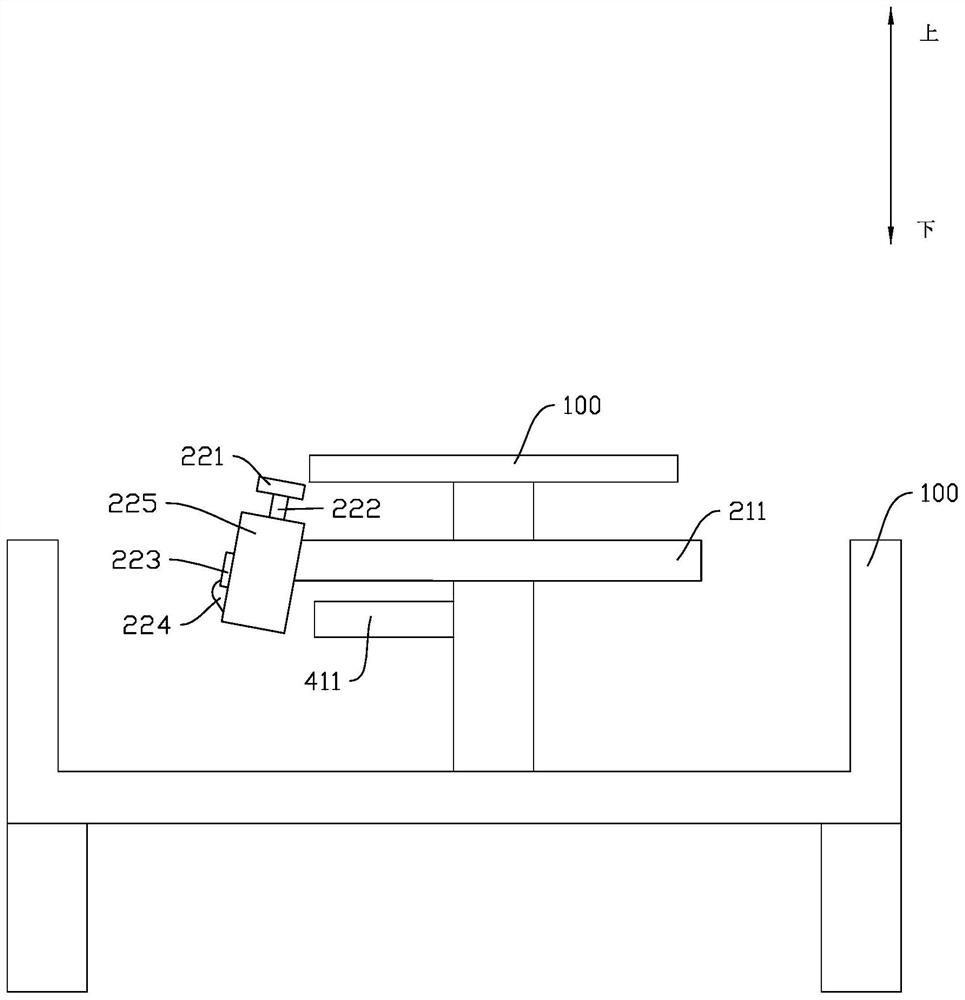

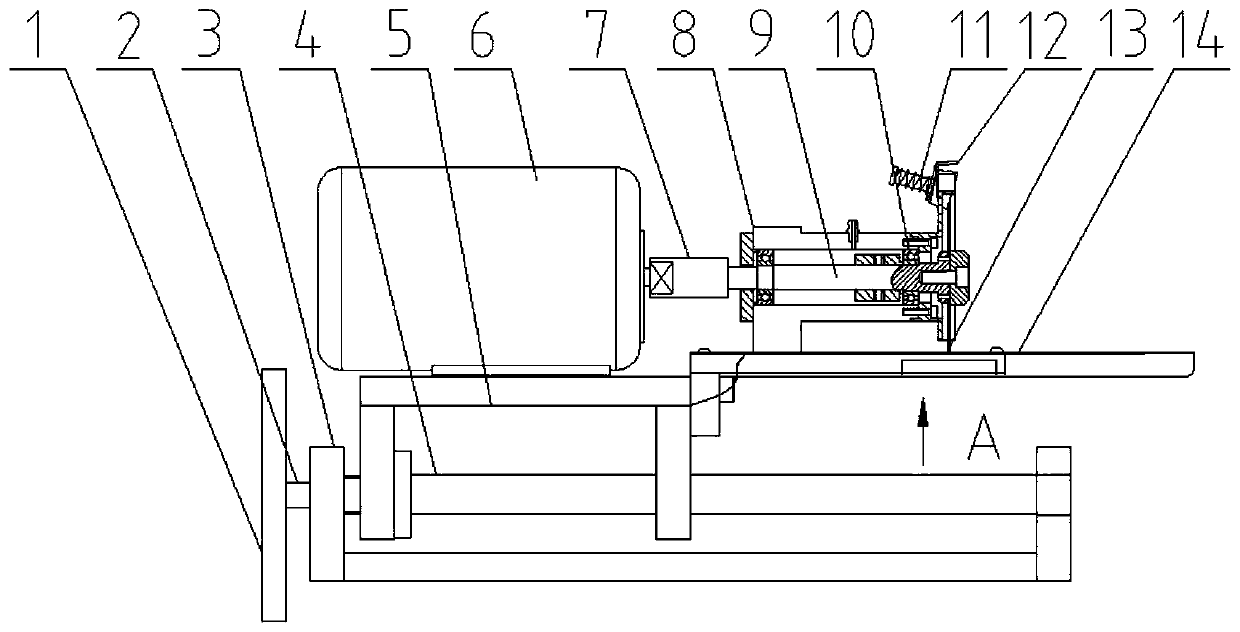

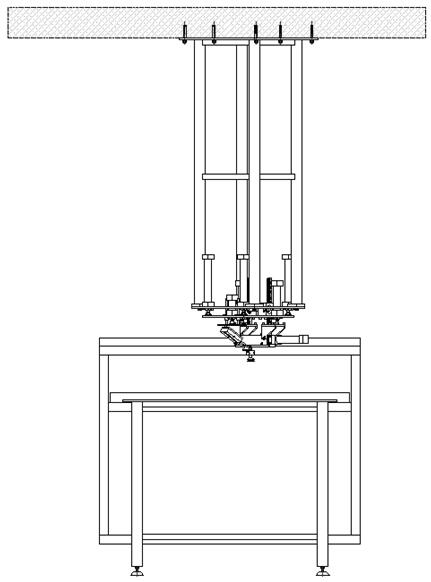

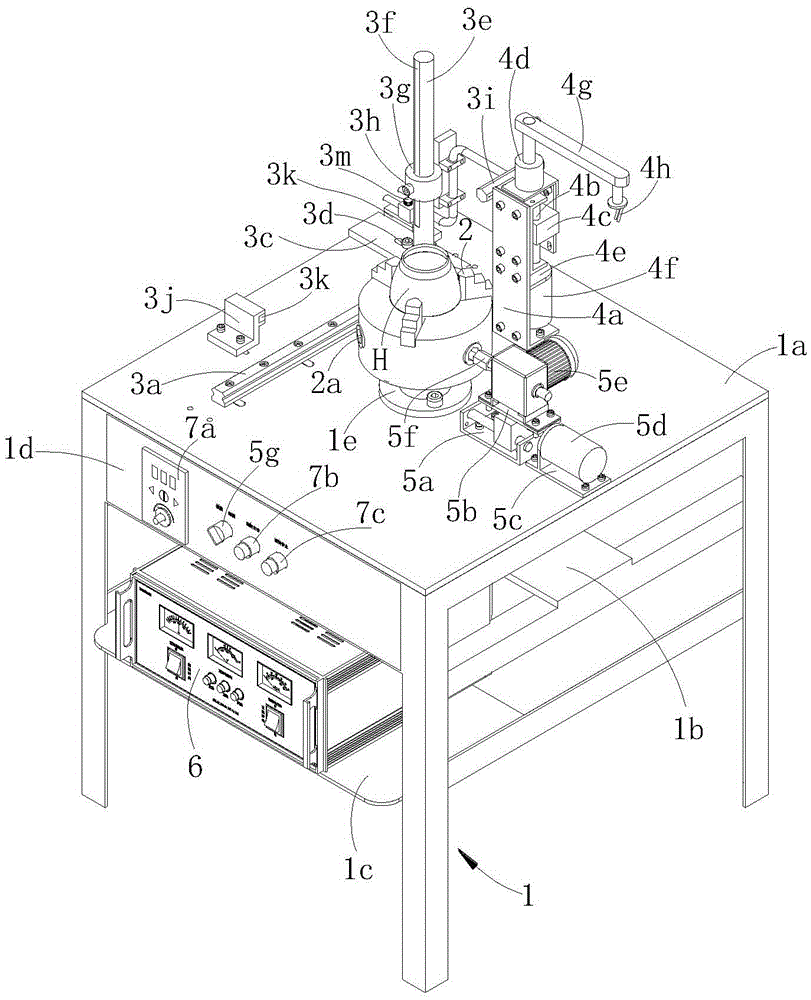

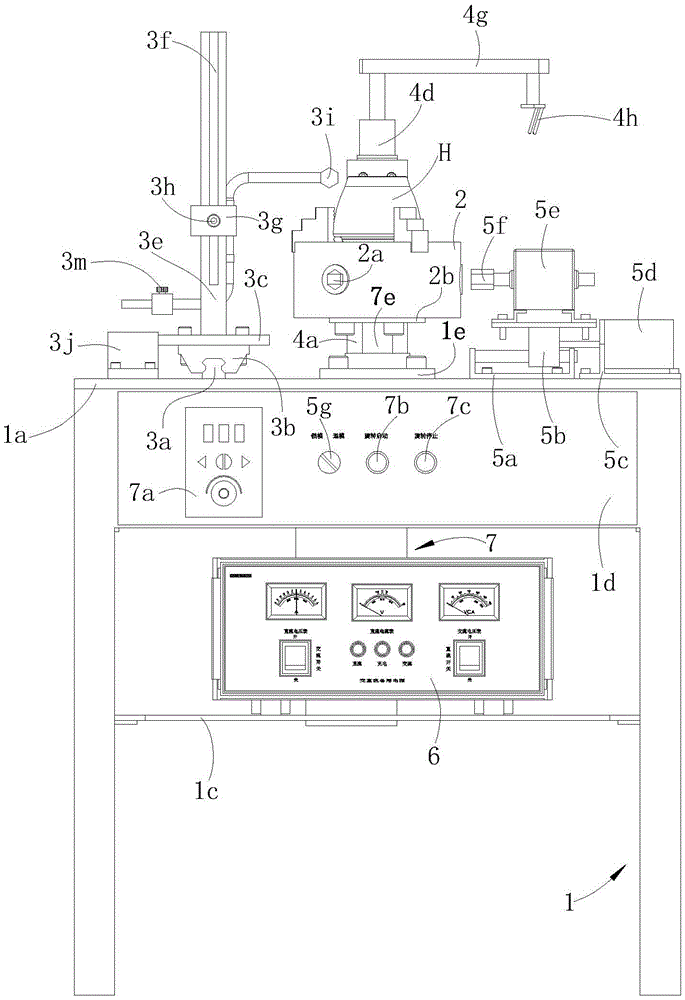

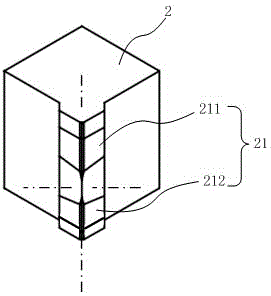

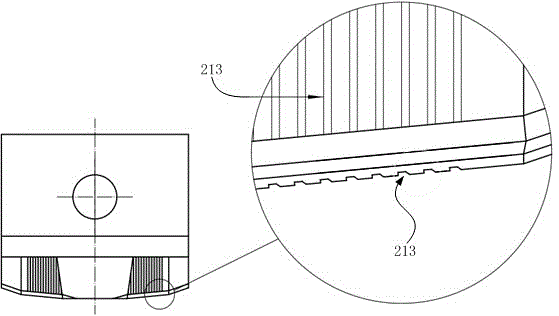

Automatic production line for cup bodies of vacuum cups (kettles)

InactiveCN110270837AReduce management costsReduce handling and passingOther manufacturing equipments/toolsProduction lineMouth cuts

The invention discloses an automatic production line for cup bodies of vacuum cups (kettles). The automatic production line comprises a mouth cutting device, a mouth finishing and bottom finishing device, an upper angle and lower angle rolling device, a control device, a conveying device and a machine frame, wherein the mouth cutting device, the mouth finishing and bottom finishing device, the upper angle and lower angle rolling device, the control device and the conveying device are arranged on the machine frame, the mouth cutting device, the mouth finishing and bottom finishing device, the upper angle and lower angle rolling device and the conveying device are electrically connected with the control device, and the mouth cutting device, the mouth finishing and bottom finishing device and the upper angle and lower angle rolling device are connected through the conveying device. Compared with the prior art, the mouth cutting device, the mouth finishing and bottom finishing device and the upper angle and lower angle rolling device in the machining process of the cup bodies of the vacuum cups (kettles) are effectively integrated through the conveying device, moreover, the control device controls and coordinates the work, all the machining devices also can work independently, the whole production line can be controlled by a few personnel, so that labor resources and material management cost are greatly saved, a workpiece conveying and transferring process performed after machining of the traditional working procedure is omitted, the production efficiency is also remarkably improved, and meanwhile, the occupied space is also reduced.

Owner:永康市创益者工贸有限公司

Full-automatic glass cup cap mouth cutting machine and method

PendingCN108863030AReduce manufacturing costAchieve high efficiencyGlass severing apparatusGlass productionMouth cutsEngineering

The invention discloses a full-automatic glass cup cap mouth cutting machine and method. A glass cup translation mechanism is utilized to grasp a glass cup on a conveyor belt and translate the glass cup to the upper side of a die overturning mechanism; the die overturning mechanism inverts the glass cup onto a heating device in a rotating manner, and a cap mouth is removed through heating; and thedie overturning mechanism drives a processed finished cup product in the rotating manner to move to a set position, and a finished cup product translation mechanism grasps the processed finished cupproduct and put the processed finished cup product on the conveyor belt. The full-automatic glass cup cap mouth cutting machine and method provided by the invention are high in production efficiency,reduces the manual cost, avoids the problems of harsh environments, high risk and the like during manpower work, realizes automation of glass cup cap mouth cutting and is simple in mechanism and highin reliability.

Owner:UNIV OF JINAN

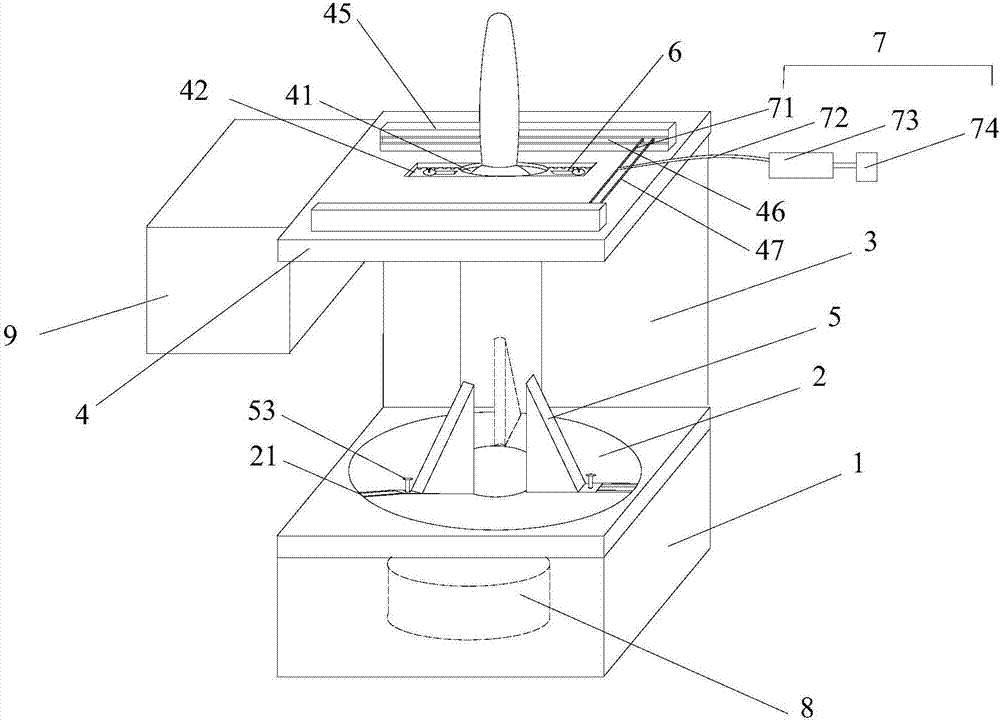

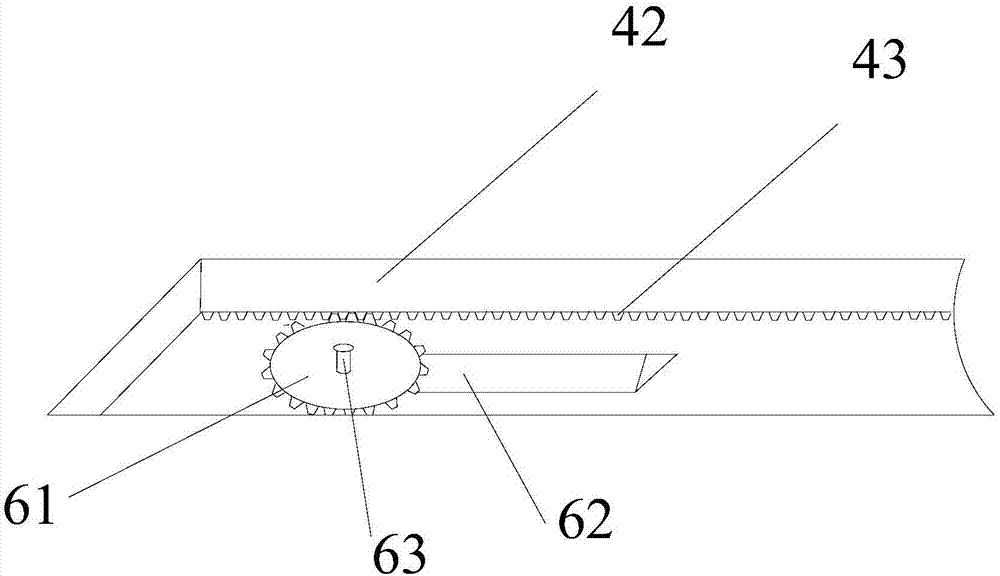

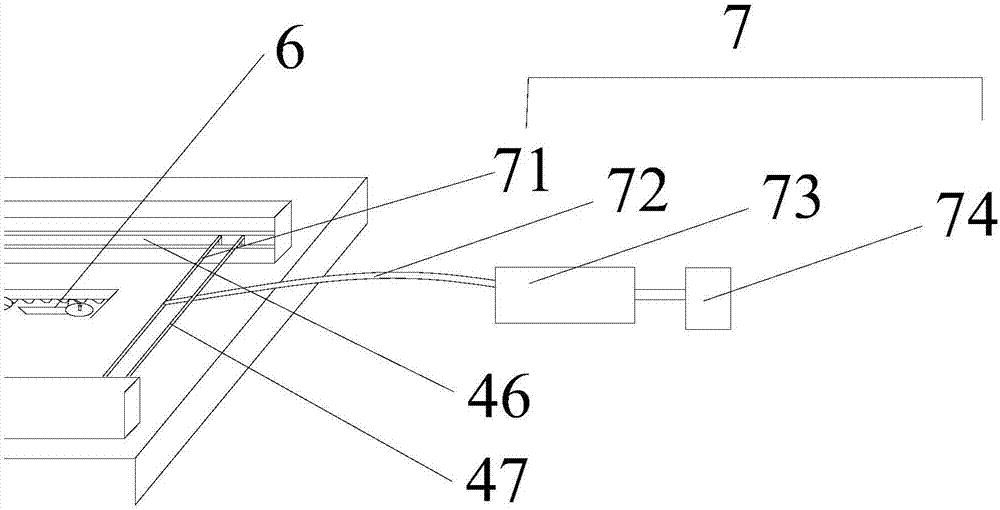

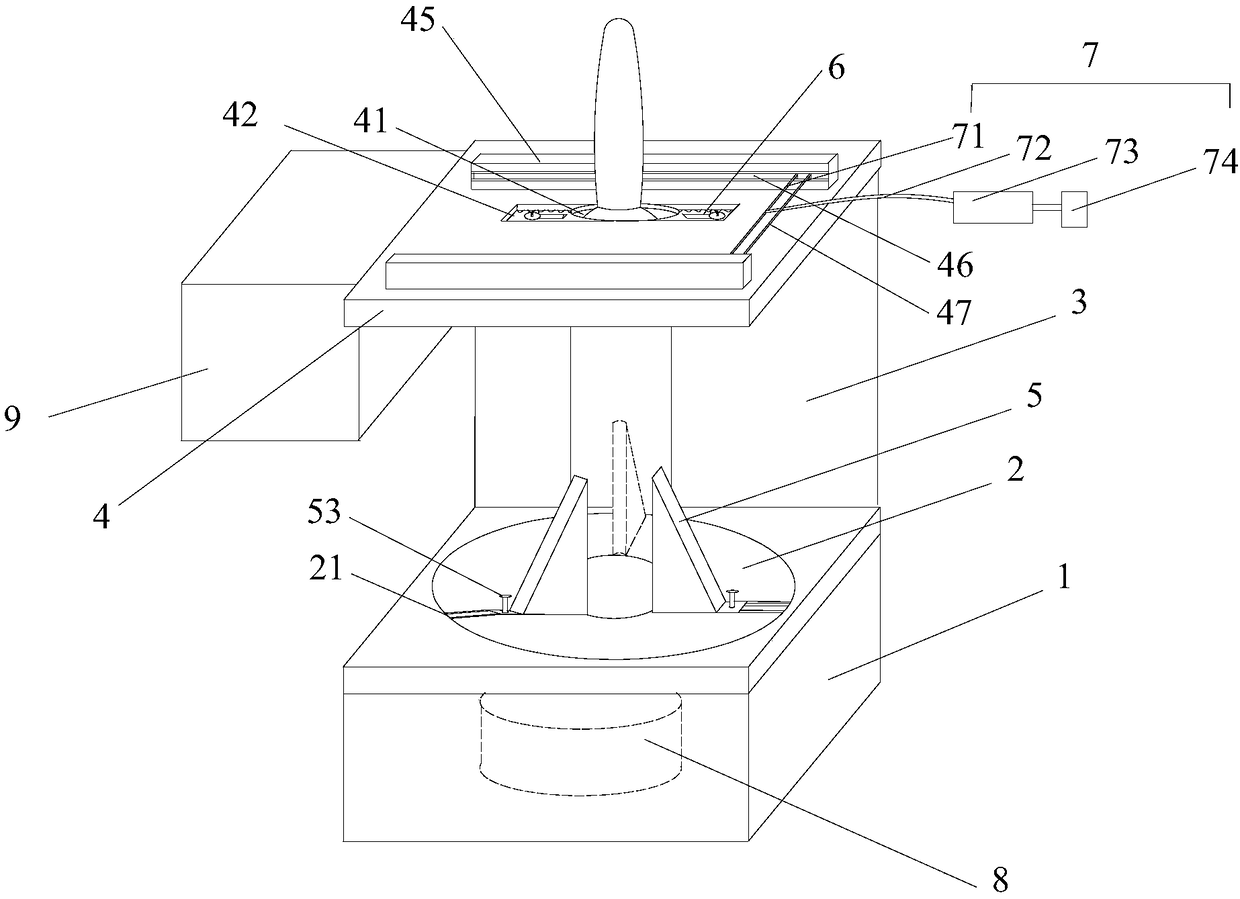

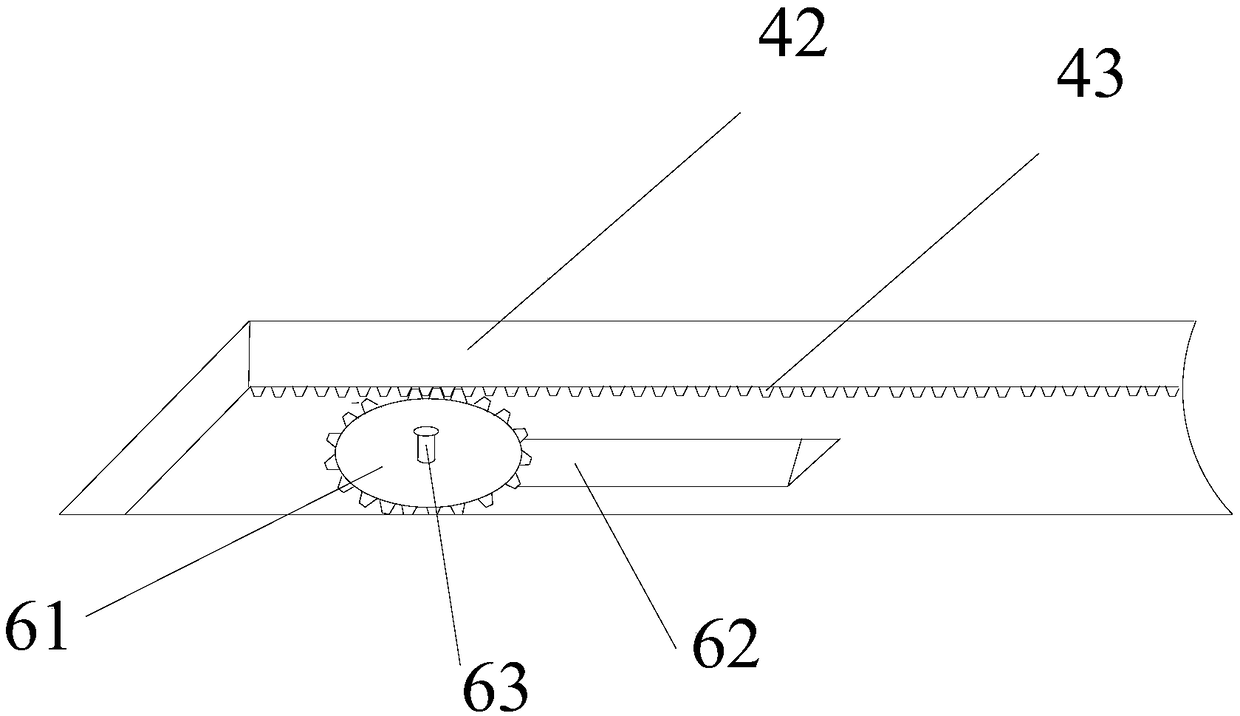

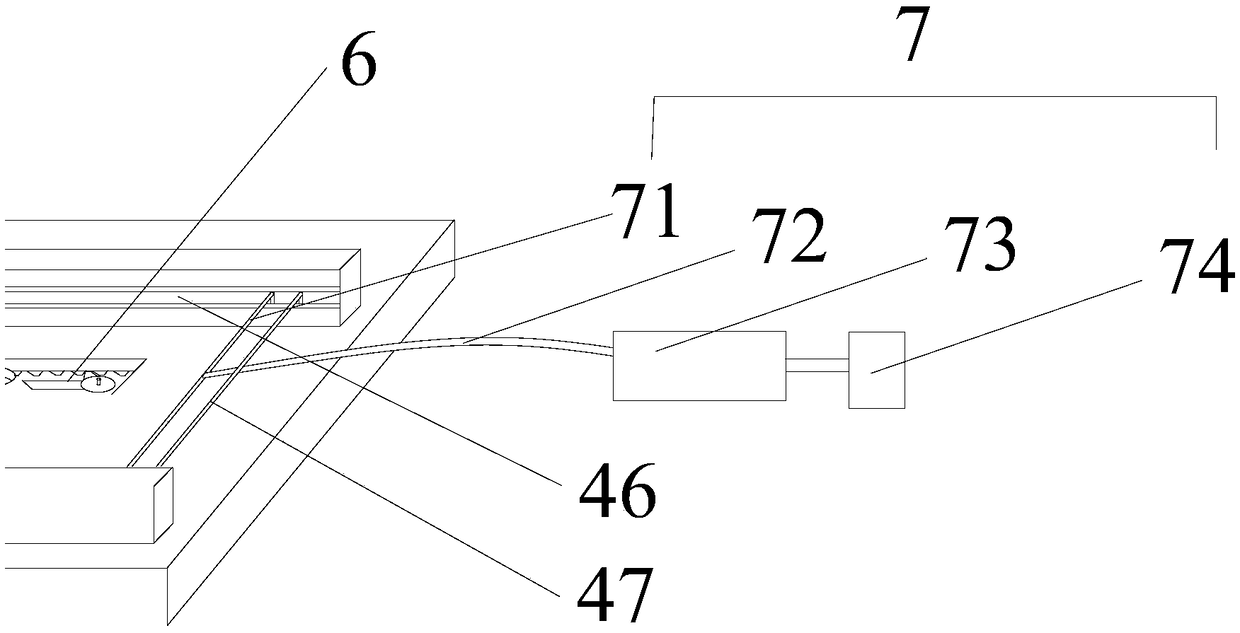

Medicinal liquid injection bottle mouth cutting device

InactiveCN107473156AQuick tapTap quickly to makeBottle/container closurePower operated devicesEngineeringMouth cuts

The invention discloses a medicinal liquid injection bottle mouth cutting device, and belongs to the technical field of medical instruments. The cutting device comprises a base box, a rotating platform, supporting plates, a cutting platform, multiple fastening blocks, a cutting device body and a pushing rod device; the rotating platform is connected with a rotating motor; the base box and the cutting platform are connected through the supporting plates; the fastening blocks are movably arranged on the rotating platform; a cover plate is arranged on a rectangular groove, the cutting device body is arranged in the rectangular groove, and saw teeth are arranged at the bottom of the rectangular groove; the cutting device comprises a gear, a cutter and a handle, the lower end of the handle penetrates out of the bottom of the gear and is connected with the inner end of the cutter through a bearing, and the gear is meshed with the saw teeth; the pushing rod device comprises a pushing rod, a high-pressure air pipe, an air storage tank and an air pump, the two ends of the pushing rod are fixed in second dovetail grooves, the air storage tank and the pushing rod are connected through the high-pressure air pipe, and the air storage tank is connected with the air pump. According to the cutting device, operation is convenient, the cutting face is level, the cutting device is suitable for injection bottles with different specifications, and the cutting efficiency is high.

Owner:PINGDINGSHAN UNIVERSITY

Press blade device of gel mask machine

PendingCN110355820AQuick collectionImprove collection efficiencyMetal working apparatusMouth cutsEngineering

The invention belongs to the technical field of gel mask processing, and particularly relates to a press blade device of a gel mask machine. The press blade device comprises two rotating rollers withparallel axes; the two rotating rollers are the cutting rotating roller and the supporting rotating roller and are both hollow; the supporting rotating roller is closed at one end and open at the other end or open at both ends; the cutting rotating roller are open at both ends; a cutting part is arranged on the outer wall of the cutting rotating roller; the cutting part comprises a mask contour cutting part, a mask eye cutting part, a mask nose cutting part and a mask mouth cutting part; the mask eye cutting part and the mask mouth cutting part are hollow; and the mask eye cutting part and themask mouth cutting part communicate with an inner cavity of the cutting rotating roller. According to the press blade device, the generated waste can be quickly collected, and the collection efficiency is improved; and the use of energy can be reduced by outputting high-pressure gas at regular time, and the collection efficiency is guaranteed.

Owner:广州科瑞达自动化设备有限公司

Mouth cutting machine for ceramic wine bottle production

InactiveCN107214829AQuality improvementConsistent cuttingCeramic shaping apparatusWine bottleAgricultural engineering

The invention discloses a chipping machine for ceramic wine bottle production, which comprises a base, and the base is provided with a holding mechanism, and the holding mechanism includes an outer sleeve, and the outer sleeve is provided with a notch An upward groove, the groove is interspersed with an inner sleeve, the side of the outer sleeve is provided with a first locking screw for locking the inner sleeve, and the upper end of the inner sleeve is hinged with a cover The cover plate is provided with an opening and a cutting mechanism. The cutting mechanism includes a first pull rod, a fixed block, a push block, a second pull rod, and a cutting blade. The side wall of the opening is provided with a second A storage slot, a sliding slot is provided on the side wall of the first storage slot, and the second pull rod is located in the first storage slot. The invention is easy to operate. The user fixes the ceramic wine bottle through the fixing device, starts the pottery wheel and uses the shaving blade to shave, and after shaving, the waste is pushed into the waste recycling frame by the push block. Improve the cutting quality.

Owner:CHONGQING YONGHENG BOTAO TECH

Method for building load-bearing H-steel

InactiveCN102962558AReduce manufacturing costSimple structureWelding/soldering/cutting articlesWorkpiece edge portionsMouth cutsEngineering

The invention discloses a method for building load-bearing H-steel. The method comprises the following steps of: providing a joint way and a welding sequence, cutting a flange plate and a web plate, making edge preparation, and ensuring an initial blanking size, wherein gantry flame multi-mouth cutting is adopted in plate cutting, a half through welding form is adopted in the joint way, the H-steel is made by welding and splicing the web plate with the flange plate, and a half through welding groove form is adopted; preparing, making and positioning a required hard support, which comprises an H-steel jig, a self-made clamp and a brace to prevent deformation; and welding symmetrically and synchronously from a central position to two ends along the length direction of the H-steel. The load-bearing H-steel has the advantages of low production and manufacturing cost, simple structure, high place flexibility, convenience in manufacturing, effective guarantee of strength quality, and great reduction in cost and construction period consumption on correction after deformation.

Owner:大连船舶重工船业有限公司

Muscovy duck under-forest breeding method

The invention relates to a muscovy duck under-forest breeding method. The method specifically comprises the steps that the bladder tip of each hatched muscovy duck is reduced by one centimeter in 24 hours; after the muscovy ducks are bred for three weeks, the mouth tip of each muscovy duck is cut by two centimeters through a mouth cutting device; the breeding tree farm of the muscovy ducks is a tree farm with a slope; cichorium endivia and alfalfa are planted in the tree farm in spring and summer, and radish and ryegrass are planted in autumn and winter; when the muscovy ducks grow for 5-6 weeks, the duck is fed in the way that pellet feed for ducks and greengrass feed both account for 50%; when the muscovy ducks grow for 6-10 weeks, 25% of the pellet feed for ducks, 25% of wheat and 50% of the greengrass feed are fed; when the muscovy ducks grow for 10-20 weeks, 50% of the wheat and 50% of the greengrass feed are fed. By the adoption of the method, the mode that the muscovy ducks are bred through the water surface is changed, management is simpler in the breeding process of the muscovy ducks, feed can be reduced, the morbidity of the muscovy ducks is lowered, and the breeding benefits are increased.

Owner:无为县凤鸣草岗生态农业有限公司

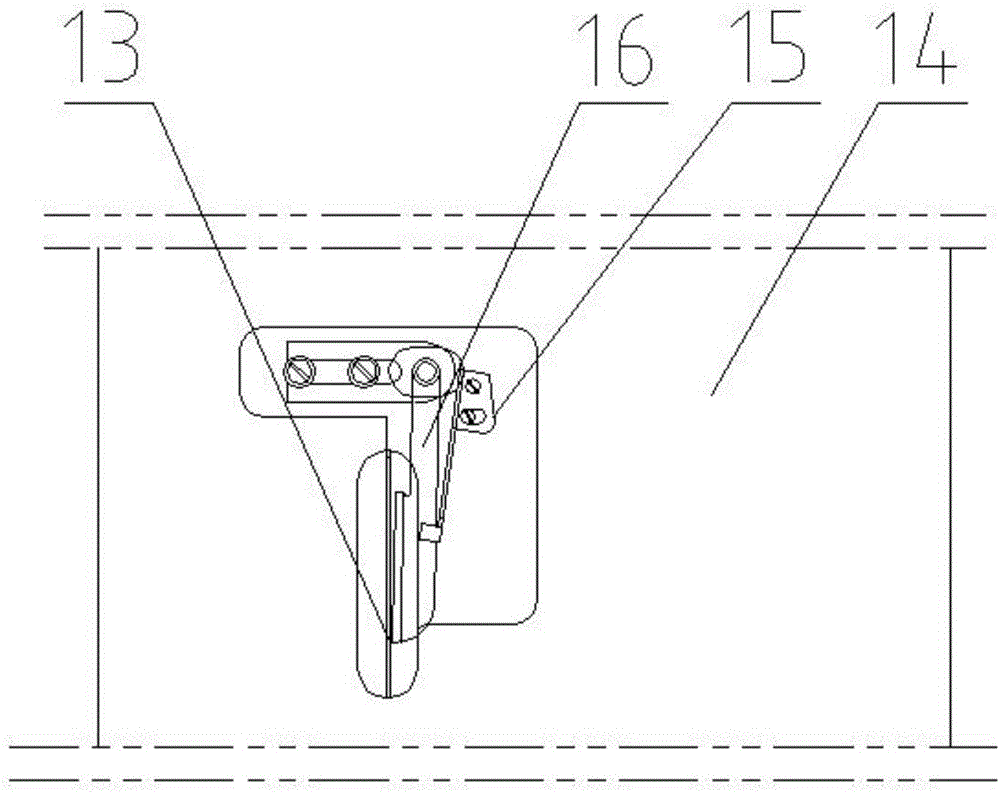

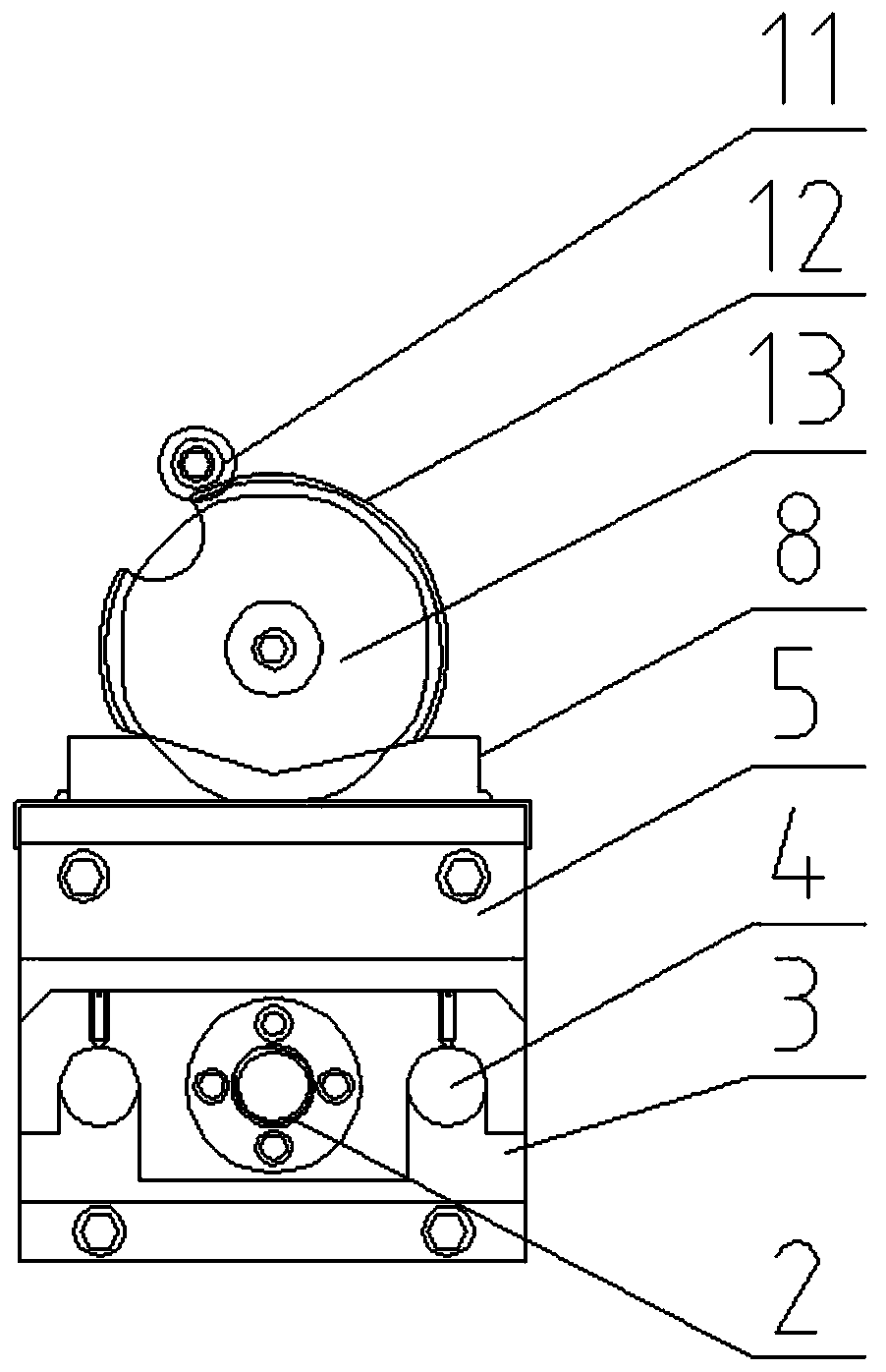

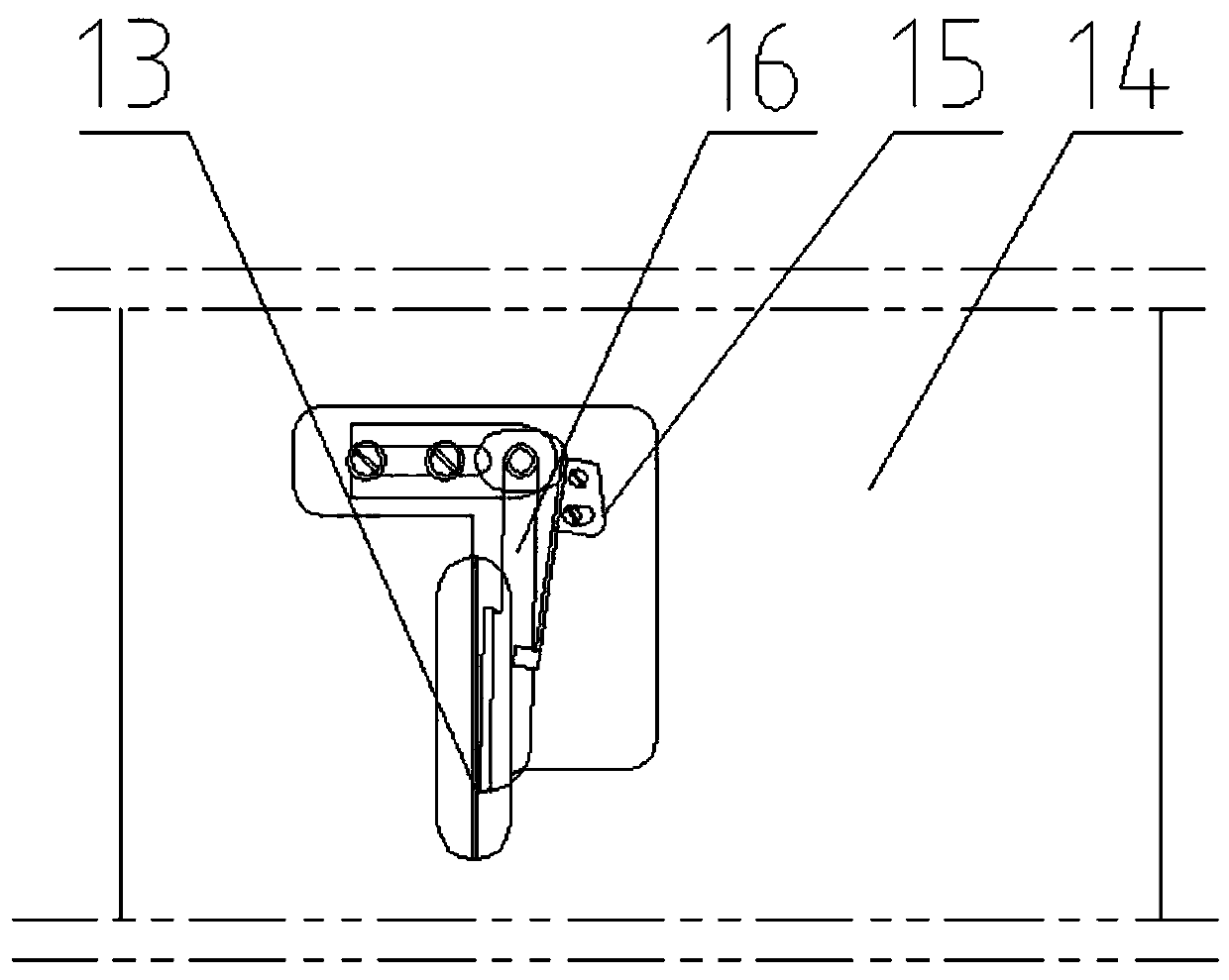

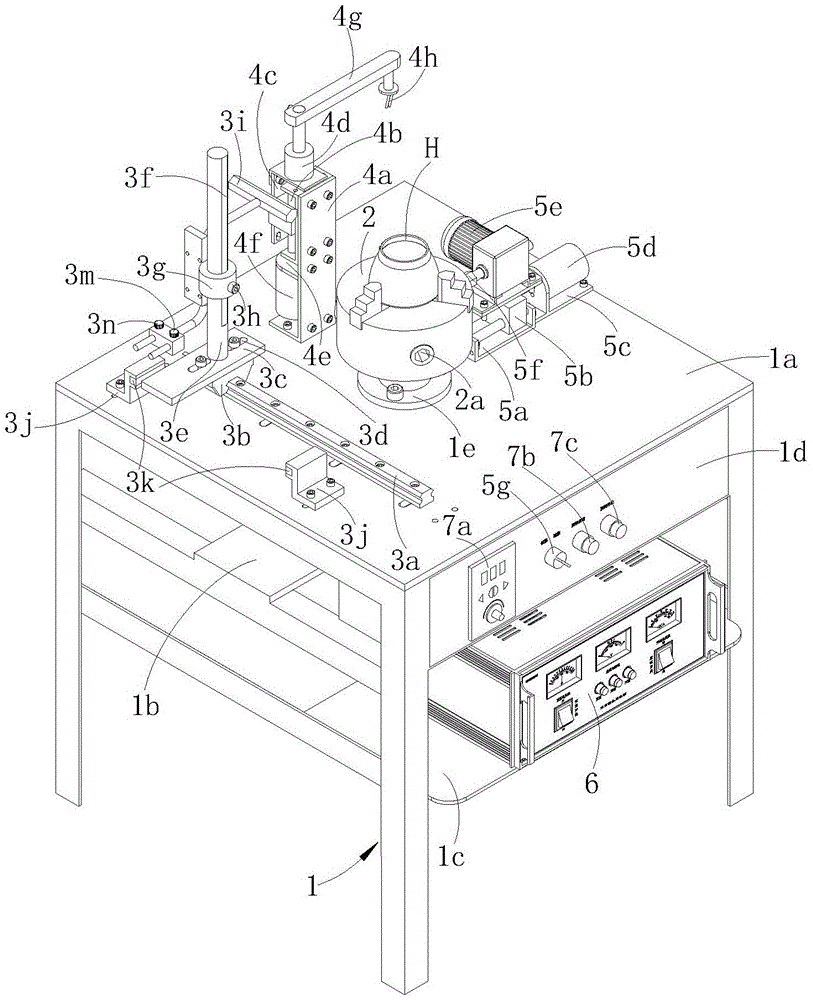

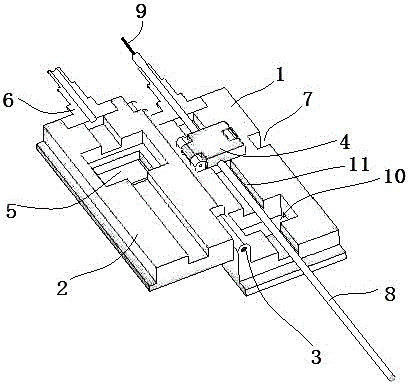

Sealant mouth cutting device and sealant dispenser robot

ActiveCN111098315APrecisely limited widthGuaranteed smoothShearing machinesFeeding apparatusElectric machineryStructural engineering

The invention relates to the technical field of building equipment, and provides a sealant mouth cutting device and a sealant dispenser robot. The sealant mouth cutting device is used for cutting a sealant mouth before a sealant rubber discharges a sealant, and comprises a base plate, a cutting mechanism and an aligning mechanism, wherein the cutting mechanism is installed at one end of the base plate and comprise a motor body fixed to the base plate, a motor shaft stretching out of the motor body, and a cutting disc installed at the end of the motor shaft; the aligning mechanism is installedat the other end of the base plate and comprises a guide piece vertically installed on the base plate, an aligning table slidably arranged on the guide piece, and an aligning block fixedly connected to the side, close to the base plate, of the aligning table; the aligning block is located at the end, away from the cutting mechanism, of the aligning table; the cutting disc is located on the lower portion of the end, close to the cutting mechanism, of the aligning table; and the aligning block is provided with an aligning hole in a penetrating mode, and the aligning hole is used for allowing thesealant mouth to stretches out to the position above the cutting disc. According to the sealant mouth cutting device provided by the invention, the cutting width of the sealant mouth can be accurately controlled, and the situation that the sealant dispensing quality is influenced is avoided.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

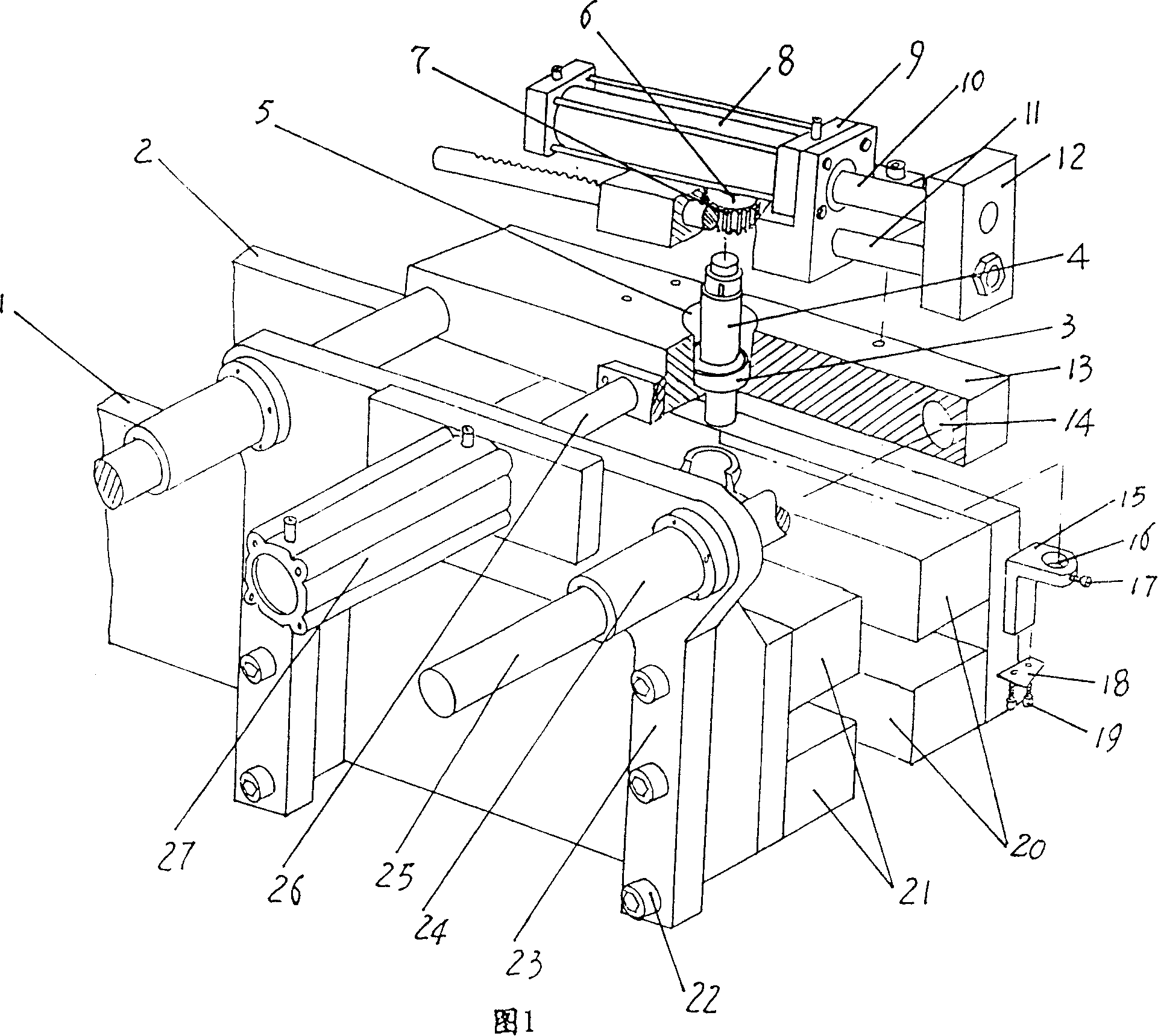

Bottle mouth cutting mechanism of automatic bottle blow molding machine

ActiveCN100376378CEliminate movement errorsGuaranteed cutting qualityDomestic articlesMetal working apparatusBlow moldingMolding machine

The bottle mouth cutting mechanism as one auxiliary mechanism for automatic bottle blowing and molding machine includes one bottle holding device, one moving device and one bottle mouth flash edge cutting device. The bottle holding device is connected to one inner and outer mold plate pair capable of being opened and closed in the automatic bottle blowing and molding machine; the moving device is set on the bottle holding device; and the bottle mouth flash edge cutting device is set on the moving device and over the bottle holding device. The said structure makes the three parts of the bottle holding device, the moving device and the bottle mouth flash edge cutting device connected into one integral and this results in high cutting quality, simple integral structure and high cutting efficiency.

Owner:ZHANGJIAGANG TONGDA MACHINERY

Chestnut shelling device

The present invention relates to the technical field of food processing equipment and discloses a chestnut shelling device. The chestnut shelling device comprises a machine frame, the machine frame isinternally provided with a material guiding hopper, a conveyor belt and a separating mechanism, the conveyor belt is composed of an inclined portion and a horizontal portion, the inclined portion islocated under the material guiding hopper, and the separating mechanism comprises a heating table and a plurality of material taking devices; the conveyor belt is provided with a material receiving tray, the material receiving tray is provided with a plurality of receiving boxes, the receiving box can and only can accommodate one chestnut; and the machine frame is internally fixedly provided witha horizontal mouth-cutting mechanism and a longitudinal mouth-cutting mechanism adjacent to each other, and besides, the horizontal mouth-cutting mechanism and the longitudinal mouth-cutting mechanismare located on the horizontal portion of the conveyor belt. The chestnuts to be processed fill fully in the receiving boxes on the material receiving tray, the conveyor belt is used to drive the material receiving tray to successively pass through the horizontal mouth-cutting mechanism and the longitudinal mouth-cutting mechanism, finally cross-shaped cutting mouths on the chestnuts are realized,after the mouth cutting, the chestnuts are heated on the heating table to enable the cutting mouths of the chestnuts to open, and the material taking devices are cooperated to take out fruit fleshesof the chestnuts.

Owner:象山锦绣升平食品有限公司

Detection method used for cylinder lithium ion battery seal slice test

PendingCN107884409AAccurate detectionLow costPreparing sample for investigationMaterial analysis by optical meansElectrical batteryObservation unit

The invention discloses a detection method used for a cylinder lithium ion battery seal slice test, comprising the following steps: step 1, cutting off the mouth part of a cylinder lithium ion battery; step 2, wrapping the cut mouth part with a die making material, so that the mouth part is fixedly sealed in the die making material to form a fixedly sealed sample; step 3, cutting the fixedly sealed sample to show up the section of the mouth part; and step 4, observing and detecting the shown-up dimension of the section of the mouth part, and calculating the compressed ratio of a sealing ring of the cylinder lithium ion battery according to the dimension. The detection method has the advantages of being capable of rapidly and accurately obtaining the compressed ratio to calculate the required dimension, for example, the thickness of the sealing ring, then calculating the compressed ratio according to the obtained dimension, and then judging the feasibility of a sealing process accordingto the compressed ratio subsequently, and being rapid and accurate in detection and low in cost.

Owner:DYNABAT NEW ENERGY SCI & TECH CO CLD FUJIAN

Insulation bag processing process and insulation bag processed through process

InactiveCN110606283AReduce manufacturing costGuaranteed tightnessDomestic cooling apparatusLighting and heating apparatusInsulation layerMouth cuts

The invention relates to an insulation bag processing process and an insulation bag processed through the process. The process includes the steps of cutting a raw material into all parts of the insulation bag, welding an external bag zipper and an internal bag zipper to the long side of an external bag large body face cut part and the long side of an internal bag large body face cut part correspondingly, welding the two short sides of the external bag large body face cut part together, welding a back carrying unit to the back side of an outer frame, welding the two short sides of the internalbag large body face cut part together, welding a lining bottom cut part to the bottom of an inner frame, welding a lining mouth cut part to the bottom side of the internal bag zipper on the top of aninner bucket body, seamlessly welding an inner bucket structure to an outer bucket structure so that an insulation layer can be clamped in a sealed cavity formed between the inner bucket structure andthe outer bucket structure, and welding a bag cover cut part to the external bag zipper on the outer bucket structure to form a complete bag body. The insulation bag is high in airtightness, and theinsulation effect is effectively improved.

Owner:惠州宏丰科技发展有限公司

Semiautomatic mouth cutting and rounding device of glass teapot bodies

Disclosed is a semiautomatic mouth cutting and rounding device of glass teapot bodies. The semiautomatic mouth cutting and rounding device of the glass teapot bodies is characterized in that a fire gun is pointed at a chuck, the axis of the chuck is vertical to a bottom plate of a support, the chuck is located on the middle area of the bottom plate, a chuck motor is installed in the support and pressed against a chuck motor installation plate, the chuck motor installation plate is provided with a sensor, a chuck motor shaft with a sensor permanent magnet is connected with the chuck, a linear motor static bottom seat and a first telescopic electromagnet are arranged on the upper side of the bottom plate, a linear motor slide bottom seat with a linear motor is arranged on the linear motor static bottom seat, a chuck key is arranged on a linear motor shaft, the first telescopic electromagnet is connected with the linear motor slide bottom seat, a rotary electromagnet slide bottom seat with a rotary electromagnet is arranged on the upper portion of a crank arm support on the upper side of the bottom plate, the rotary electromagnet is connected with the inner end of a mouth rounding crank arm, a mouth rounding rod is arranged at the outer end of the mouth rounding crank arm, and a second telescopic electromagnet on the lower portion of the crank arm support is connected with the rotary electromagnet slide bottom seat. The semiautomatic mouth cutting and rounding device of the glass teapot bodies reduces breakage rate of the glass teapot bodies, and labor intensity and industrial injury accident rate of operators, and improves processing quality, qualified rate and processing efficiency of the glass teapot bodies.

Owner:安徽凤阳亚欧玻璃工艺品有限公司

Cup rim processing technology and assembly line

PendingCN114227160AIncrease daily outputImprove work efficiencyPositioning apparatusMetal-working holdersWater flowEngineering

The invention relates to the field of cup automation, and discloses a cup rim processing technology which comprises the following steps: a, assembly line feeding: putting cup bodies on an assembly line capable of conveying the cup bodies in a stepping manner; b, cup body opening necking is conducted, specifically, to-be-machined cup bodies on an assembly line are placed on a cup opening necking device through a feeding and discharging device, and threads are driven to be formed on cup body openings; c, material changing is conducted through the necking device, and through the feeding and discharging device, the positions of the cup bodies to be machined on the assembly line and the positions of the cups with the necked inner cup openings in the necking device are exchanged; d, assembly line conveying is conducted, specifically, the assembly line conveys the cup with the necked cup opening to the next procedure, and the cup body to be machined is aligned with cup opening necking equipment; and e, cup mouth cutting is conducted, specifically, the water flow line is conveyed to the cup mouth cutting device, and the cup mouth of the cup subjected to cup mouth necking is cut through the cup mouth cutting device. The cups on the assembly line and the machining equipment are exchanged through the feeding and discharging device, and the working efficiency is improved.

Owner:浙江明科自动化科技有限公司

Multangular cutter mechanism

The invention discloses a multangular cutter mechanism, which comprises a hand wheel, an adjusting screw, a permanent seat, a guide rod, a shifting-seat, a motor, a coupling, a cutter shaft base, a cutter shaft, a cutter shaft bearing, a blade grinder, a blade housing, a multangular blade, a workbench, a leaf spring and a blade tableting. The motor, the cutter shaft and the multangular blade are linked as a whole through the coupling. The motor turning at high speed drives the multangular blade to rotate. The edge of the multangular blade is designed under the workbench. The blade tableting and the elastic leaf spring capable of forming a mouth-cutting shape are arranged under the side of the workbench so as to guarantee the blade tableting cling to the multangular blade when the multangular blade is rotatable cutting and at the same time the multangular blade rotates freely. Adjusting the hand wheel and the adjusting screw make the multangular blade moves left and right so that different widths of materials can be obtained. The multangular cutter mechanism has the advantages of making maximal use of the blade, saving the cost, lower noise, high production efficiency and elegant appearance.

Owner:JIANGSU HONGYE MACHINERY

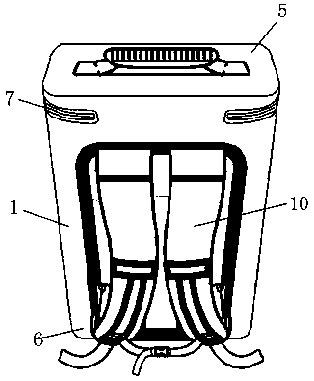

Automatic vaccine injection equipment

PendingCN112057198APrevent tamperingImprove survival rateAutomatic syringesStacking articlesInjection equipmentMouth cuts

The invention discloses automatic vaccine injection equipment. The equipment comprises a bracket, a rotating mechanism, a nozzle cutting mechanism, an injection mechanism, a positioning mechanism, anda releasing mechanism, wherein the rotating mechanism comprises a first disc and a plurality of fixtures, the fixtures are arrayed in the equal spacing manner along the first disc, and the first discis rotatably arranged on the bracket; a chick is placed in the fixtures and positioned through the positioning mechanism, then the mouth of the chick is cut by the mouth cutting mechanism through thefirst disc, then the chick is conveyed to the injection mechanism for automatic vaccine injection, then the chick is released from the fixtures through the releasing mechanism, automatic vaccine injection of the chick is completed, the labor intensity is reduced, and the efficiency is improved.

Owner:开平市旭峰农牧有限公司

A 3D fast positioning tool for casting pouring riser cutting and its operation method

The invention relates to a 3D rapid positioning tool for casting pouring riser cutting, including a beam; a connecting arm, which is vertically connected to the beam; a positive suction cup, which is connected to one end of the connecting arm; And the anti-sucker is provided with a plurality of first positioning points; the valve body is provided with a plurality of second positioning points on its surface; a three-dimensional camera is suitable for capturing the first and second positioning points, and the anti-suction cup, the valve body The relative position is fixed; the steel bar is suitable for connecting the anti-suction cup and the valve body; through the use of a three-dimensional camera, the storage of the positioning points on different valve bodies is realized, so that the valve body and the anti-suction cup are connected through the steel bar; the valve body is accurately positioned After hoisting, cut the sprue riser.

Owner:WUZHONG INSTR

Method for breeding drought ducks under forest

InactiveCN110896918AReduce morbidityEasy to manageAnimal feeding stuffLeaf crop cultivationTree farmCichorium endivia

The invention relates to a method for breeding drought ducks under a forest. The method specifically comprises the following steps: wing tips of hatched drought ducks are sheared by 1 cm within 24 h;after the drought ducks are raised for 3 weeks, mouth tips of the drought ducks are cut by 2 cm with a mouth cutting device; a breeding forest farm for the drought ducks is a forest farm with slopes;cichorium endivia and alfalfa are planted in the forest farm in spring and summer, and radish and ryegrass are planted in autumn and winter; and the drought ducks at the age of 5-6 weeks are fed with50% of pellet feed for ducks and 50% of green grass feed, the drought ducks at the age of 6-10 weeks are fed with 25% of pellet feed for ducks, 25% of wheat and 50% of green grass feed, and the drought ducks at the age of 10-20 weeks are fed with 50% of wheat and 50% of green grass feed. The method changes a water surface breeding manner for breeding drought ducks, so that the drought ducks are simpler to manage during breeding, feed is saved, the incidence of the drought ducks is decreased, and breeding benefits are improved.

Owner:湘潭县金丝凤养殖专业合作社

A multi-angular cutter mechanism

Owner:JIANGSU HONGYE MACHINERY

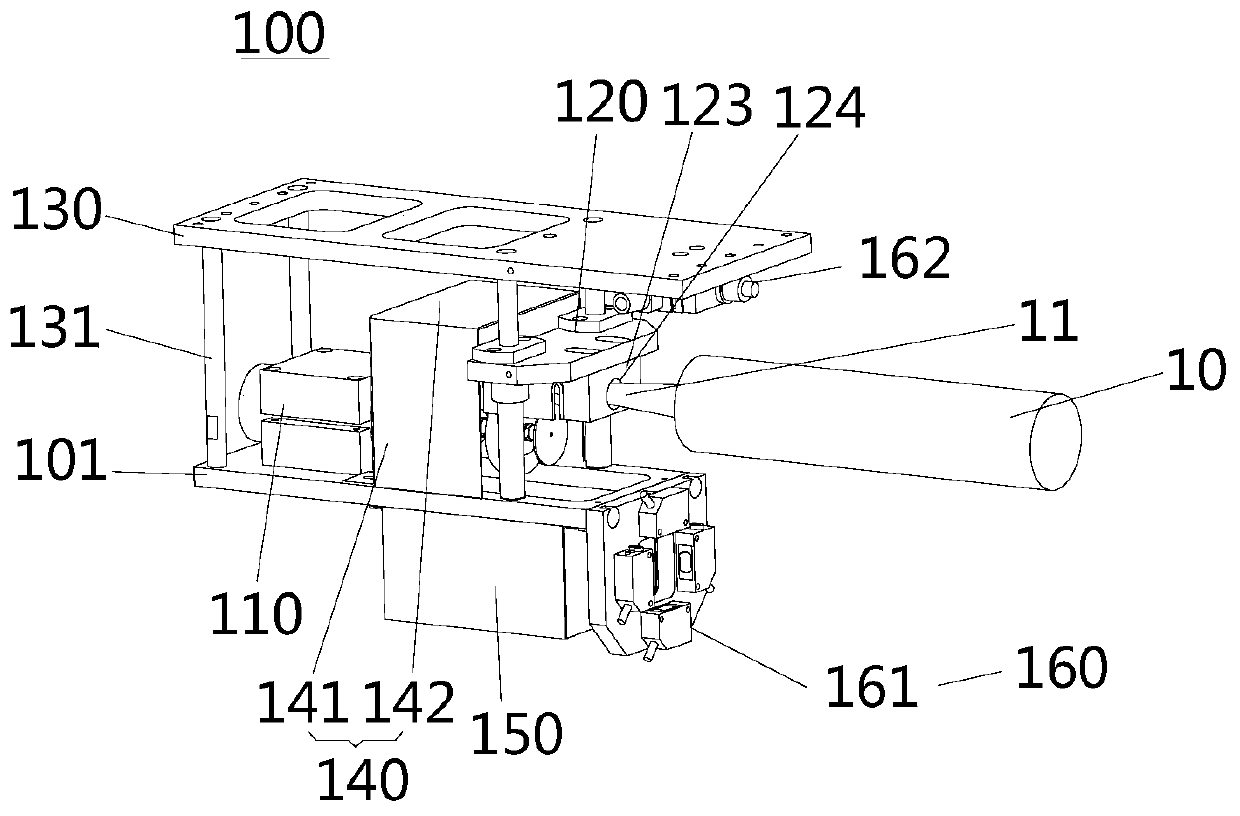

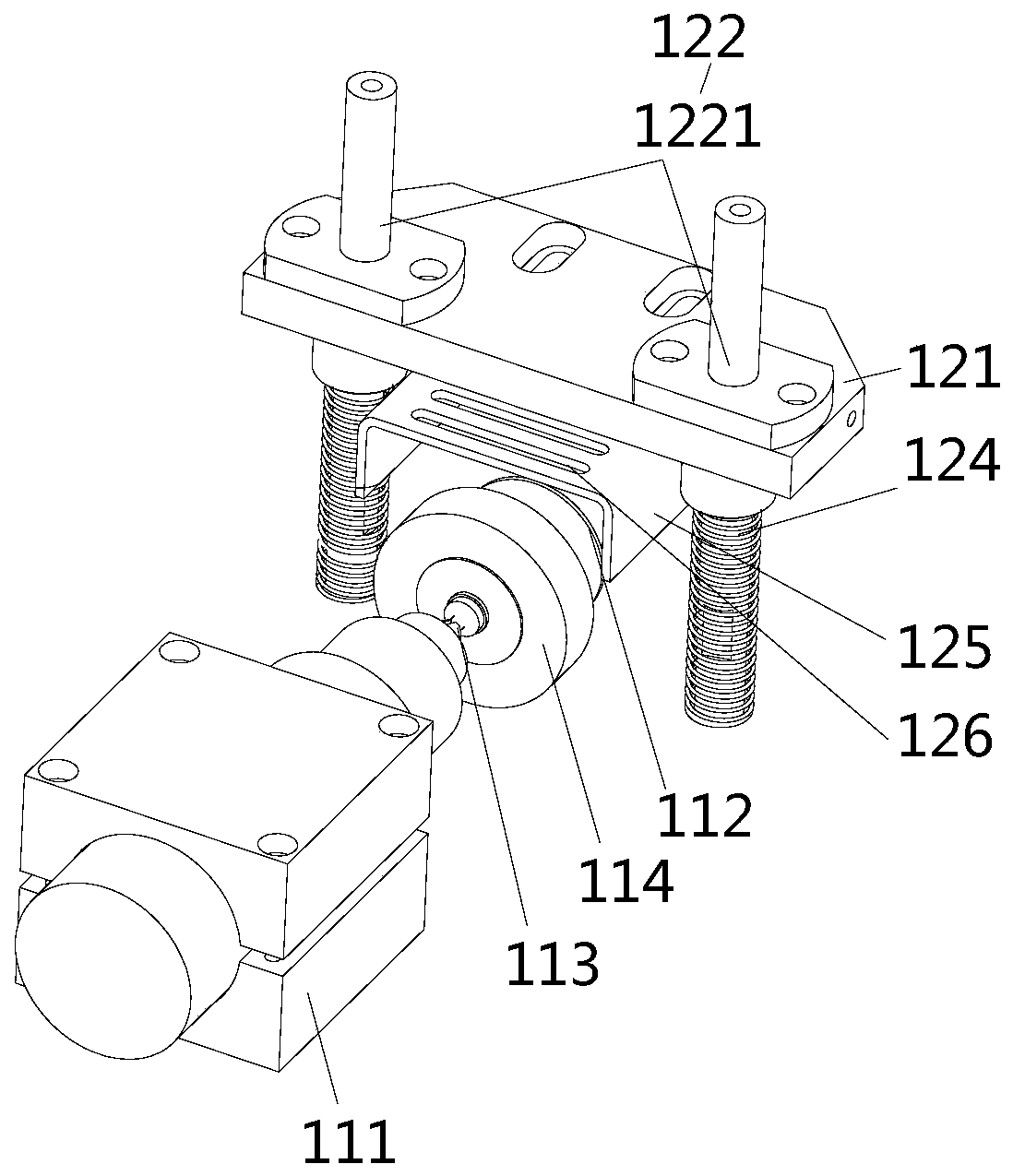

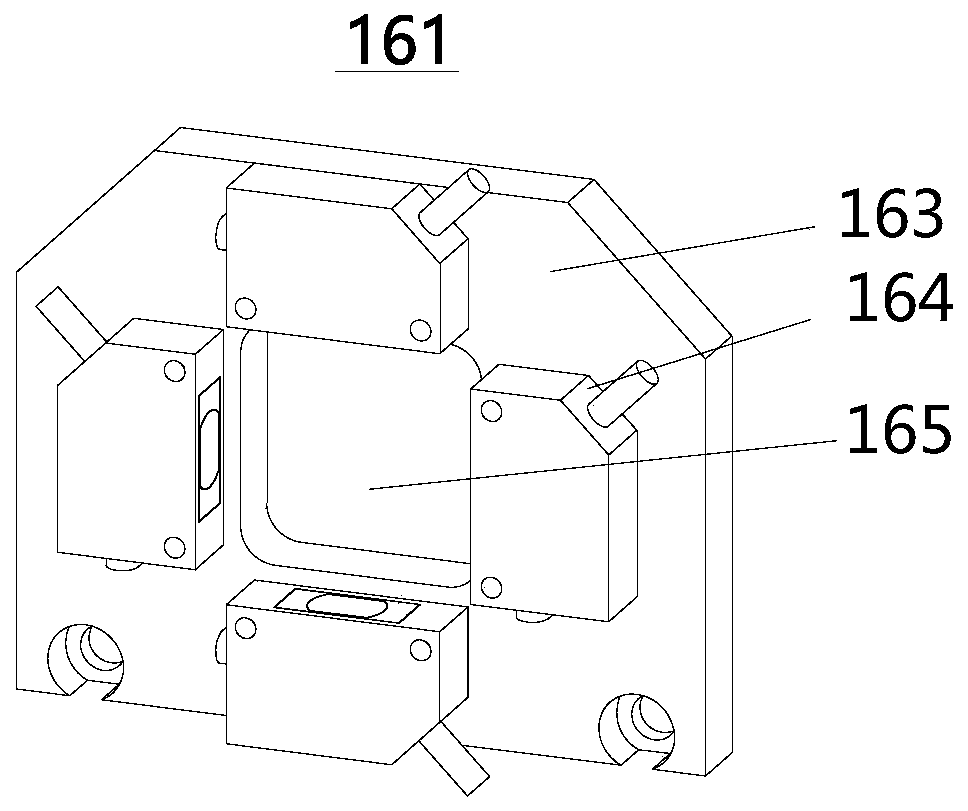

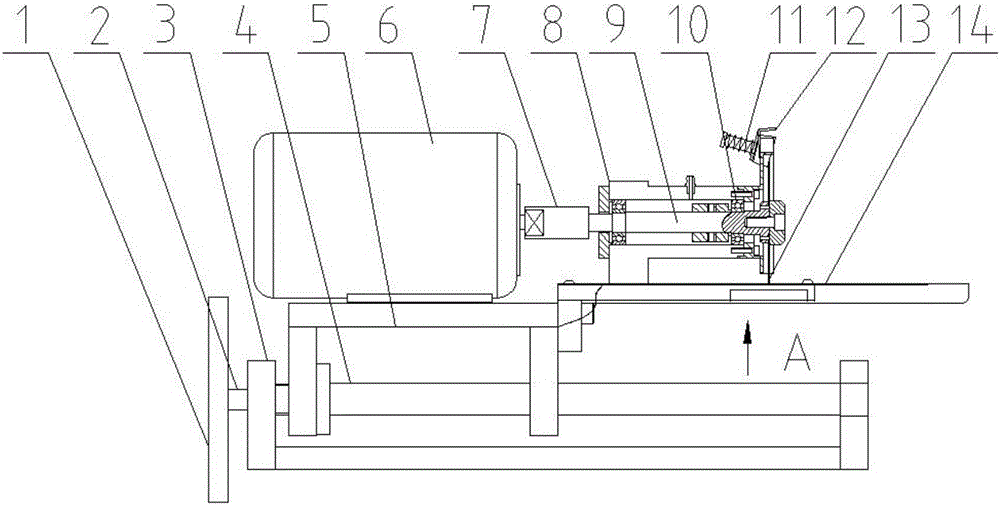

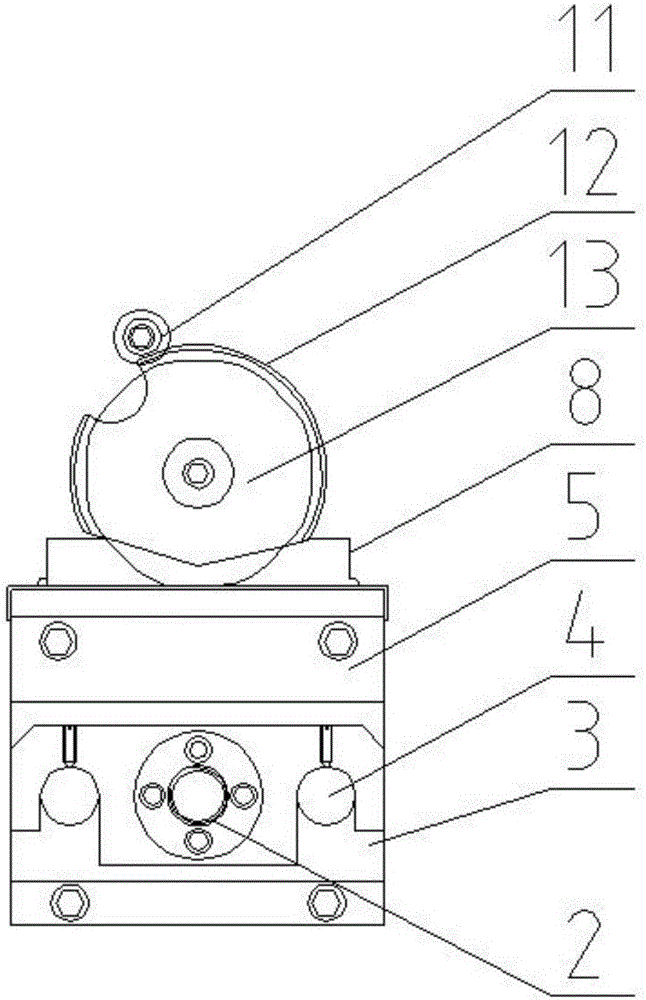

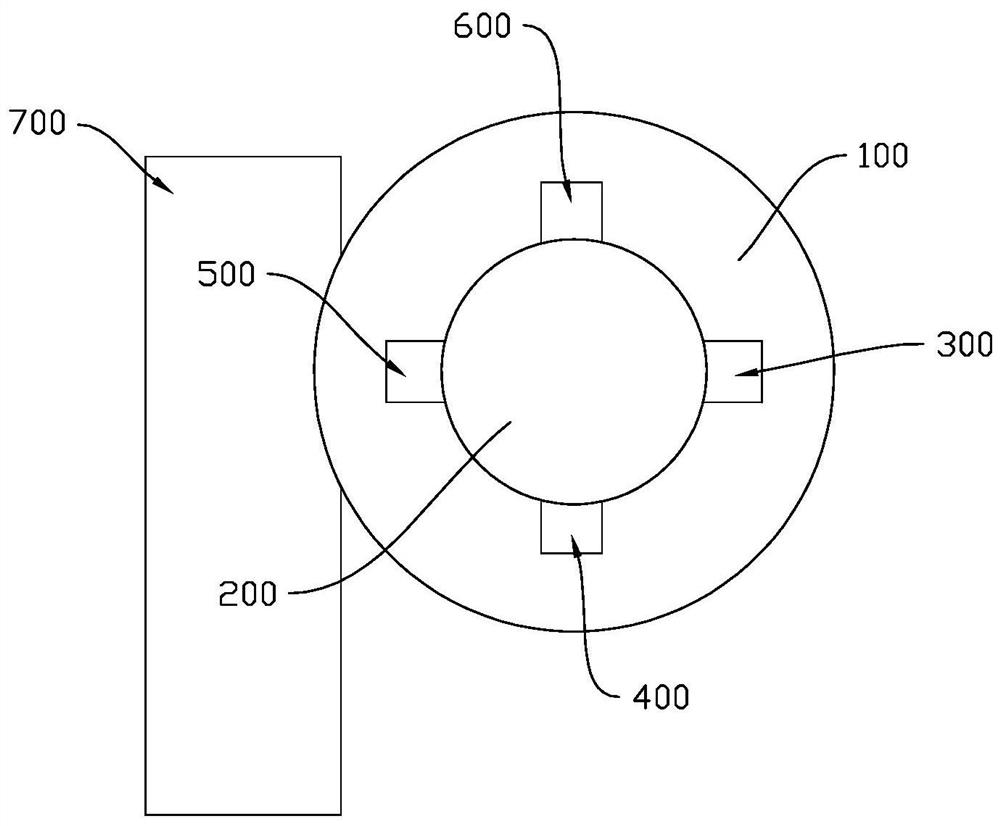

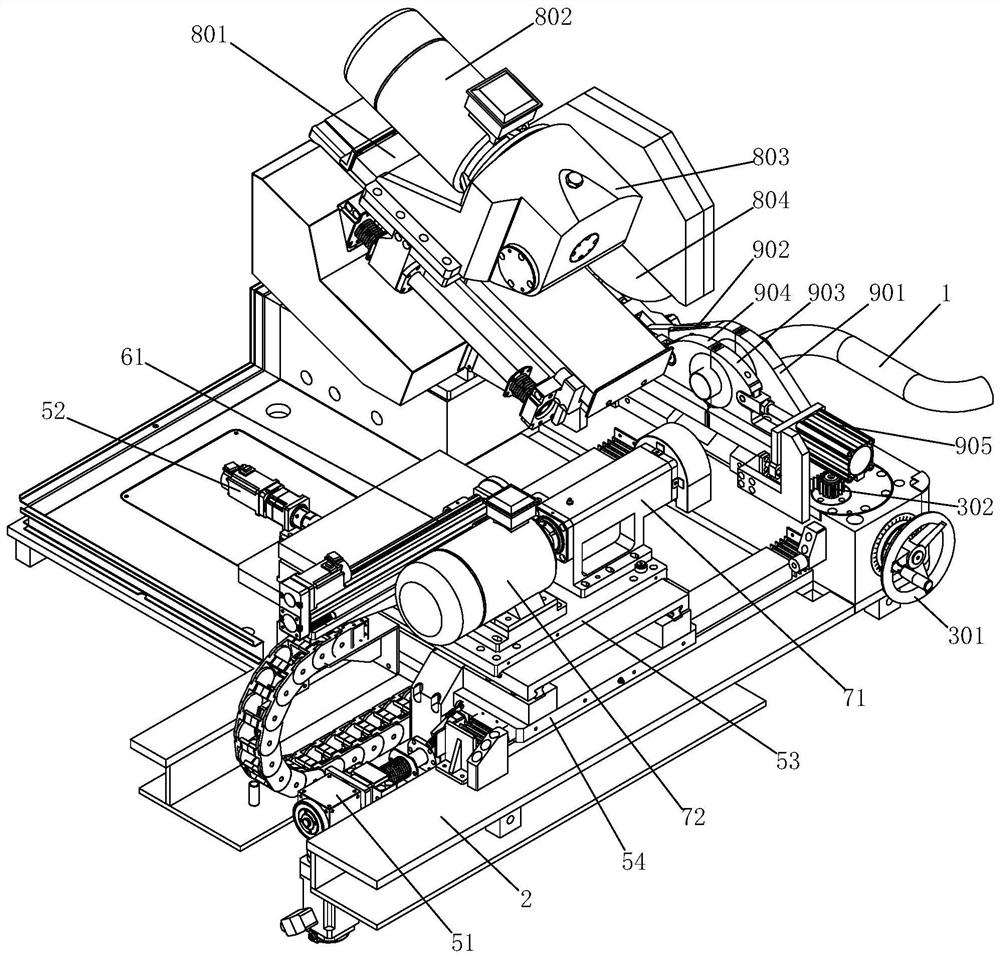

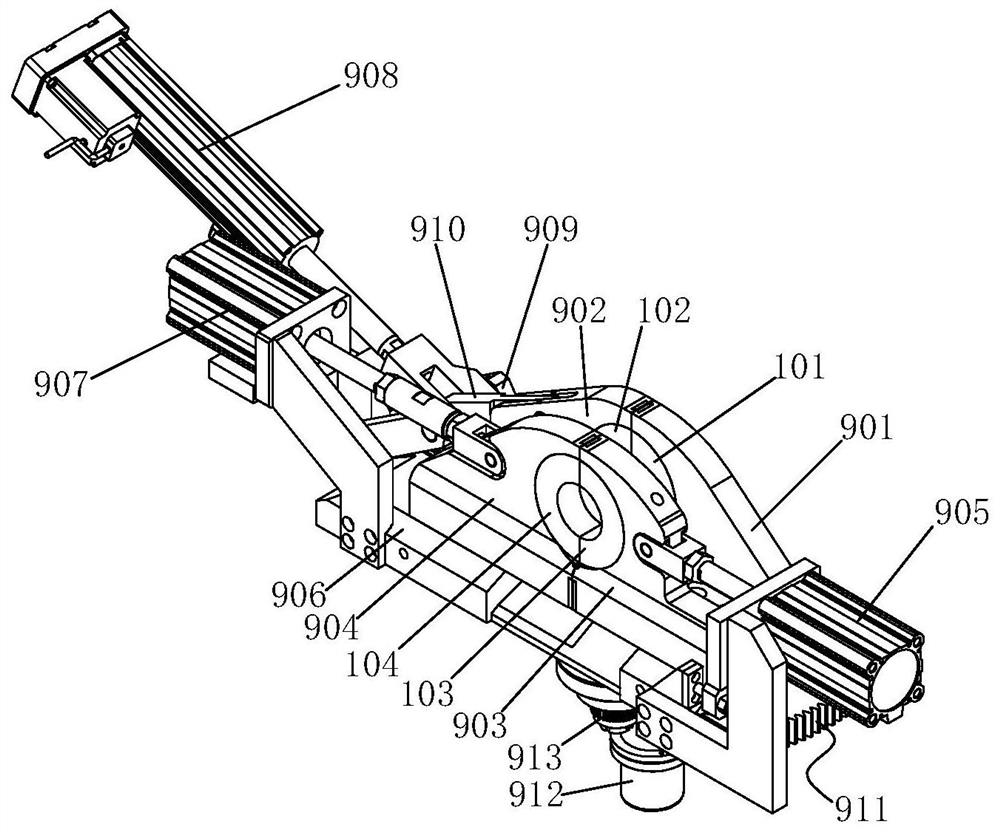

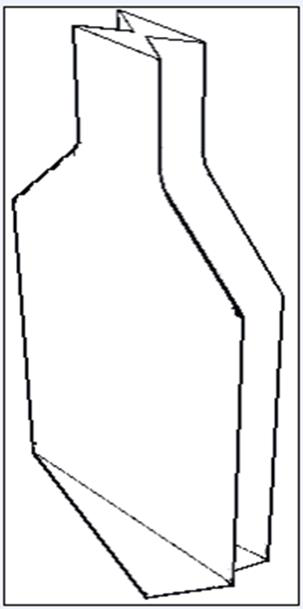

Pipe fitting cutting equipment and horseshoe cutting method thereof

ActiveCN111673466BPrecise positioningEasy to holdOther manufacturing equipments/toolsPositioning apparatusPhysical medicine and rehabilitationPipe fitting

The invention discloses a pipe fitting cutting device and a horseshoe cutting method thereof. The pipe fitting cutting device includes a fuselage on which a cutting device and a conduit clamping device are installed, and the conduit clamping device includes a first clamping seat , the second clamping seat and the clamping device base, the first clamping seat and the second clamping seat are arranged on the clamping device base opposite to each other front and back, and the two cooperate with the clamping conduit front and back, and the first clamping seat is fixed on On the base of the clamping device, the second clamping seat is driven by the clamping motor or the third clamping cylinder to slide back and forth on the base of the clamping device. The base of the clamping device is installed on the body through a rotating shaft and can be driven by rotation The device is driven to rotate, and the cutting device feeds forward and backward. The axis of the rotating shaft is located on the cutting surface of the cutting device. The axes of the shafts intersect. This scheme can quickly and accurately cut and form the horseshoe mouth.

Owner:ZHEJIANG KING MAZON MACHINERY +1

An online ton bag opening angle cutting machine

ActiveCN112265326BReduce labor costsIncrease productivityBag making operationsPaper-makingEngineeringMouth cuts

An online ton bag opening angle cutting machine, comprising a fixed bracket, the bottom end of the fixed bracket is fixed with an upper fixed plate, and the upper fixed plate is vertically provided with a plurality of lifting cylinders, and the piston ends of the lifting cylinders are all Through the upper fixed plate, they are respectively fixedly connected with the upper moving plate, and the upper moving plate is vertically provided with a folding lifting cylinder and a corner cutting lifting cylinder, and the piston end of the folding lifting cylinder passes through the upper moving plate. The plate is fixedly connected with the turning device, and the piston end of the corner-cutting lifting cylinder passes through the upper moving plate and is fixedly connected with the corner-cutting device. The present invention can realize automatic cutting of the single corner of the big bag, which can not only save labor Cost, but also improve production efficiency, suitable for general promotion.

Owner:NANJING HUJIANG COMPOSITE MATERIALS

Semi-automatic cutting and rounding device for glass teapot body

Disclosed is a semiautomatic mouth cutting and rounding device of glass teapot bodies. The semiautomatic mouth cutting and rounding device of the glass teapot bodies is characterized in that a fire gun is pointed at a chuck, the axis of the chuck is vertical to a bottom plate of a support, the chuck is located on the middle area of the bottom plate, a chuck motor is installed in the support and pressed against a chuck motor installation plate, the chuck motor installation plate is provided with a sensor, a chuck motor shaft with a sensor permanent magnet is connected with the chuck, a linear motor static bottom seat and a first telescopic electromagnet are arranged on the upper side of the bottom plate, a linear motor slide bottom seat with a linear motor is arranged on the linear motor static bottom seat, a chuck key is arranged on a linear motor shaft, the first telescopic electromagnet is connected with the linear motor slide bottom seat, a rotary electromagnet slide bottom seat with a rotary electromagnet is arranged on the upper portion of a crank arm support on the upper side of the bottom plate, the rotary electromagnet is connected with the inner end of a mouth rounding crank arm, a mouth rounding rod is arranged at the outer end of the mouth rounding crank arm, and a second telescopic electromagnet on the lower portion of the crank arm support is connected with the rotary electromagnet slide bottom seat. The semiautomatic mouth cutting and rounding device of the glass teapot bodies reduces breakage rate of the glass teapot bodies, and labor intensity and industrial injury accident rate of operators, and improves processing quality, qualified rate and processing efficiency of the glass teapot bodies.

Owner:安徽凤阳亚欧玻璃工艺品有限公司

Extrusion mouth cutting tool

The invention relates to an extrusion mouth cutting tool. The extrusion mouth cutting tool comprises multiple cutting tool individual bodies which are the same, uniformly and radially distributed according to a to-be-processed workpiece and opened and closed in a disc type, wherein each cutting tool individual body comprises a blade part, the blade part comprises a first blade part arranged above the blade part and a second blade part arranged below the blade part, and the first blade part and the second blade part are in central symmetry relative to the central point of the blade part; and each cutting tool individual body adopts a disc type structure and is easy to disassemble, the blade part of each cutting tool individual body can be repaired and processed after each cutting tool individual body is disassembled, and thus the aim of secondary utilization is realized.

Owner:龙口市亨嘉智能装备有限公司

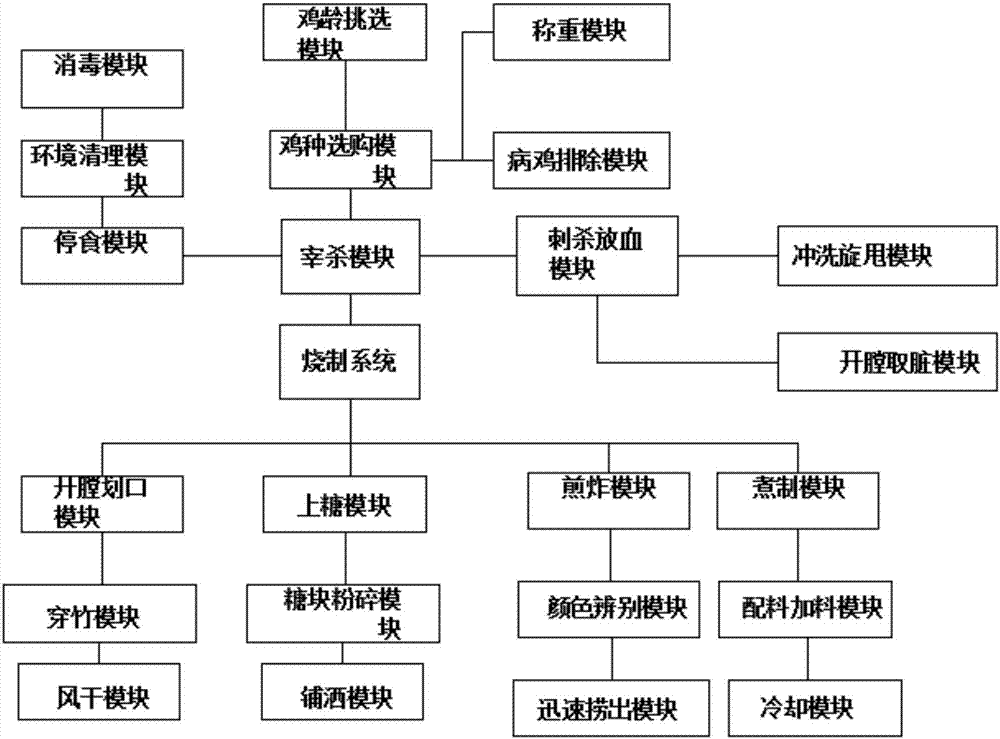

Manufacture method of roasted chickens

The present invention discloses a manufacture method of roasted chickens. The manufacture method of the roasted chickens comprises a chicken breed selection and purchase module, a slaughtering moduleand a roasting system. The chicken breed selection and purchase module, slaughtering module and roasting system are mutually cooperated, so that selected chicken breed edible materials are safer to eat, the roasted chickens are more delicious in taste, the manufacture method enables internal waste of chicken digestive tracts and chicken blood to be discharged more thoroughly and comprehensively, sugar content is evenly dispersed on surfaces of the chickens, and the manufactured roasted chickens are better in taste and fresher and tenderer. An evisceration and mouth cutting module, a sugaring module, a frying module and a cooking module connected by the roasting system are used to conduct the evisceration and mouth cutting of the chicken breeds, wings at both sides are stuffed from openings, only latter halves of the wings are left outside, the stuffed chickens are placed in a cool ventilated place to be dried in shades for 4 hours, a natural air-drying is conducted, after the chickensare slaughtered, and acid dispelled chicken meat is better in mouthfeel. A sugar block crushing module is used to conduct a crushing of sugar blocks and the crushed sugar powder is sprayed on the surfaces of the chickens, so that the sugar powder is more evenly distributed on the surfaces of the chickens.

Owner:JIANGSU JIUSIXIANG FOOD TECH

A rotary knife pelletizer

The invention discloses a rotary cutter type granulator which comprises a pipe feed limiting mechanism, a pipe pressing traction mechanism, an eagle mouth cutting mechanism, a safety cover, a supporting plate rack and an electrical control box, wherein the pipe feed limiting mechanism and the eagle mouth cutting mechanism form an upstream and downstream close docking relationship of the flow direction of the cut pipelines; an upper roller and a lower roller of the pipe pressing traction mechanism are positioned on the middle section of an end-to-end connecting line of the pipe feed limiting mechanism, are perpendicular to the flow direction of the cut pipelines and perform docking clamping and rotating traction on to-be-cut pipeline materials from the pipe feed limiting mechanism; and the pipe feed limiting mechanism, the pipe pressing traction mechanism, the eagle mouth cutting mechanism and the safety cover are integrated on the supporting plate rack, and the eagle mouth cutting mechanism is covered by the safety cover.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

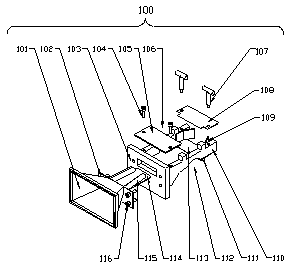

Data line material processing tooling

ActiveCN104242015BPrecise positioningIncrease productivityContact member assembly/disassemblyMouth cutsMaterials processing

The invention discloses a data line material processing tool capable of realizing precise positioning and fully automatic pick-and-place process, which comprises a lower cover and an upper cover which are pivotally installed together, and a shaft extending along the rotation axis direction is formed between the lower cover and the upper cover. Cable channel, at least one end of the cable channel is provided with a cable clamping mouth, when the lower cover and the upper cover are pivotally opened, the cable channel and the cable clamping mouth are longitudinally cut and distributed on both sides so that The cable is installed into the cable channel and exposed from the cable clamping mouth. The cable channel is also provided with an axial fixing clip. The axial fixing clip is located near the cable clamping mouth. The axial fixing clip includes a buckle The lower flap and the upper flap locked together, when the lower cover and the upper cover are pivotally closed, the upper flap and buckle are exposed through the opening in the lower cover or the upper cover.

Owner:江苏双春电子科技有限公司

A device for cutting the mouth of a medical liquid injection bottle

InactiveCN107473156BQuick tapReduce pollutionBottle/container closurePower operated devicesRotary stageGear wheel

The invention discloses a medicinal liquid injection bottle mouth cutting device, and belongs to the technical field of medical instruments. The cutting device comprises a base box, a rotating platform, supporting plates, a cutting platform, multiple fastening blocks, a cutting device body and a pushing rod device; the rotating platform is connected with a rotating motor; the base box and the cutting platform are connected through the supporting plates; the fastening blocks are movably arranged on the rotating platform; a cover plate is arranged on a rectangular groove, the cutting device body is arranged in the rectangular groove, and saw teeth are arranged at the bottom of the rectangular groove; the cutting device comprises a gear, a cutter and a handle, the lower end of the handle penetrates out of the bottom of the gear and is connected with the inner end of the cutter through a bearing, and the gear is meshed with the saw teeth; the pushing rod device comprises a pushing rod, a high-pressure air pipe, an air storage tank and an air pump, the two ends of the pushing rod are fixed in second dovetail grooves, the air storage tank and the pushing rod are connected through the high-pressure air pipe, and the air storage tank is connected with the air pump. According to the cutting device, operation is convenient, the cutting face is level, the cutting device is suitable for injection bottles with different specifications, and the cutting efficiency is high.

Owner:PINGDINGSHAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com