Extrusion mouth cutting tool

A cutting tool and blade technology, applied in the field of extrusion cutting tools, can solve problems such as unfavorable production efficiency, increased processing costs, and inability to perform secondary utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

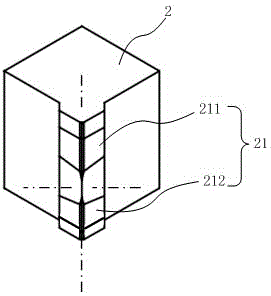

[0009] Embodiment 1, with reference to appended Figure 1-2 .

[0010] An extruding tool, including four identical, uniformly radially distributed relative to the workpiece 1 to be processed, flap-type opening and closing tool units 2, each of the tool units 2 includes a blade portion 21, and the The blade 21 includes a first blade 211 above the blade and a second blade 212 below the blade. The first blade 211 and the second blade 212 are symmetrical about the center of the blade 21 . The tool is made of high-quality hard alloy material with high hardness. After rough machining, it is quenched and then precision ground. Because it is processed into a double-edged part, the service life of the tool has been improved qualitatively, because there is no batch problem. Therefore, the replacement of the tool has almost no impact on production, and the problem of complex tool replacement has been further improved.

Embodiment 2

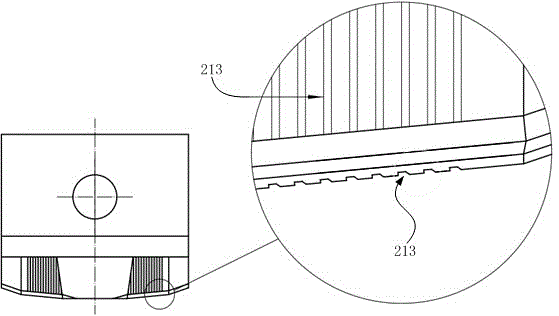

[0011] Embodiment 2, with reference to appended Figure 1-3 .

[0012] Others are similar to Embodiment 1, except that a part of the first blade portion 211 and the second blade portion 212 is provided with a texture 213 by electric discharge machining. It can increase the friction between the workpiece and the tool, and improve the added value and use effect of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com