Method for building load-bearing H-steel

A construction method, H-shaped steel technology, applied in the direction of manufacturing tools, workpiece edge parts, arc welding equipment, etc., can solve the problems of bending deformation, twisting deformation, corner deformation, etc., and achieve the effect of low manufacturing cost, convenient manufacturing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] A kind of construction method of load-bearing H section steel, its content comprises the following steps:

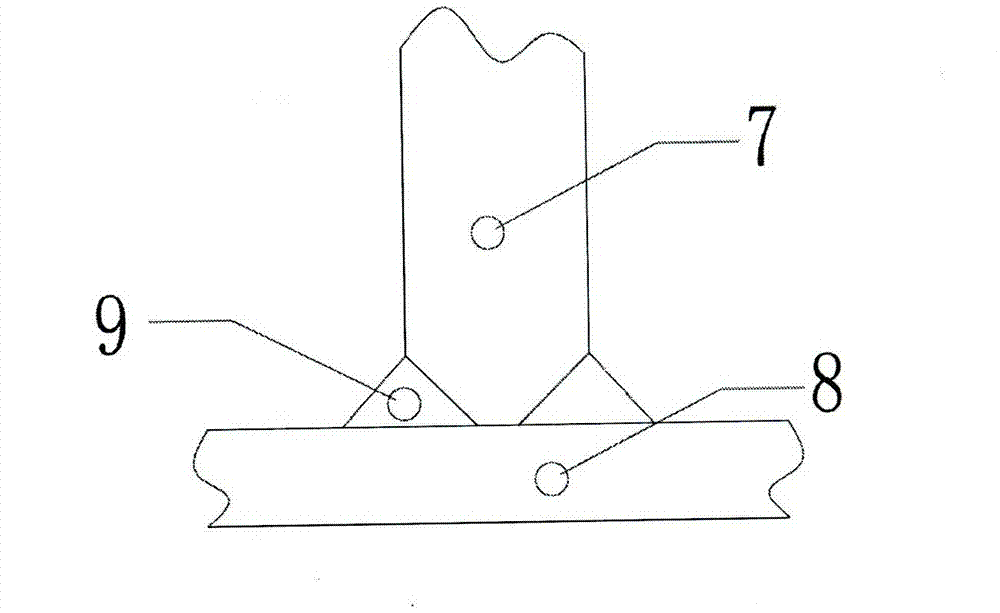

[0021] The first step, cutting and edge preparation: to ensure the initial blanking size, plate cutting adopts gantry flame multi-nozzle cutting. H-shaped steel is welded by 7 webs and 8 flanges, and the groove is semi-penetrated, such as figure 1 shown. It can not only satisfy the load bearing, but also prevent deformation and improve the quality.

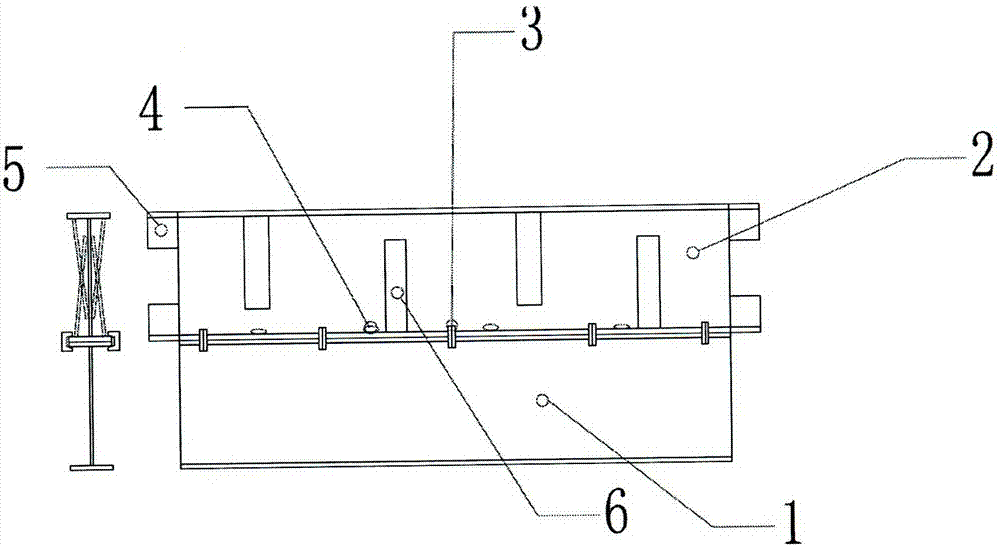

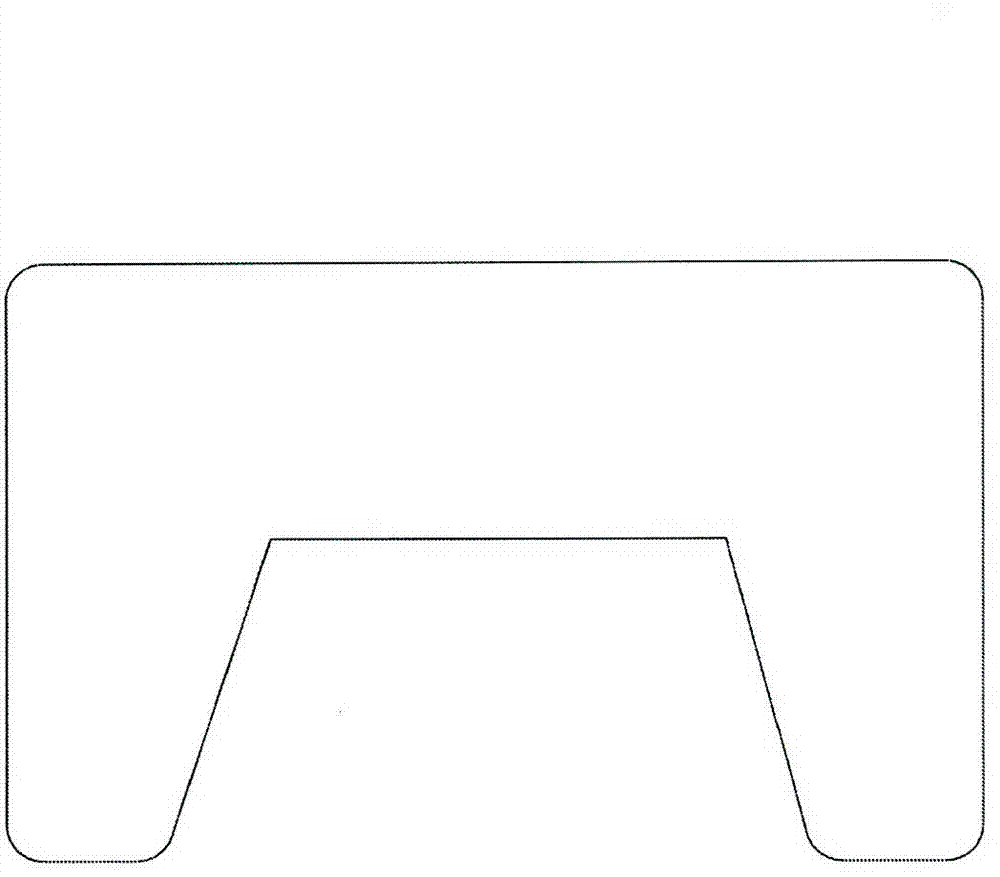

[0022] The second step, installation, positioning: such as figure 2 As shown, place the H-shaped steel tire frame on a flat field. Nail welding H-shaped steel 2 to be welded (the distance between the welding meat 4 is 300mm), the arc starting plate and the arc receiving plate 5, and the self-made fixture 3, such as image 3 As shown, clamp the upper and lower H-shaped stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com